Patents

Literature

32results about How to "Effective toughening" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

High adjacent position phenolic resin for toughness reinforcing of elastic body and method for producing the same

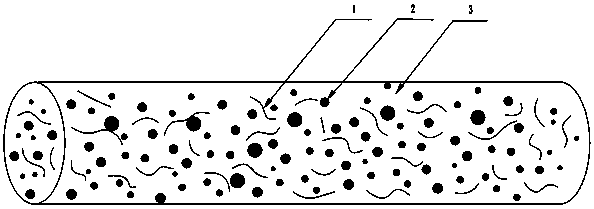

The invention discloses high ortho position formaldehyde phenol resin with elastic toughened, wherein, the elastic body reaches nm-level decentralization in the formaldehyde phenol resin, the content of the elastic body is 3 to 10 percent, and the ortho-para-ratio of the resin is 2.5 to 5. The invention also provides a preparation method of the formaldehyde phenol resin. The invention is characterized in that the high ortho position formaldehyde phenol resin with elastic toughened is prepared by adopting the way of in situ polymerization. Compared with the prior art, the high ortho position formaldehyde phenol resin with elastic toughened of the invention has the advantages of good fluidity, rapid curing and shaping, excellent toughness, simple preparation method, easy practice, etc.

Owner:ZHEJIANG JIAMIN PLASTIC

Ultra-large particle diameter high-fluidity acrylic ester impact-resisting modifier for PVC

The invention relates to super-size and high-flowing type acrylic resin impact modifier used in PVC, which is core-shell structure copolymer. The core layer is obtained through emulsion polymerization among butyl acrylate, crosslinking agent and weak acidic expansion agent; firstly, emulsion polymerization grafting reaction between styrene and methyl methacrylate is carried out continuously on the core layer, then the methyl methacrylate is independently coated into a second shell layer and acrylic impact modifier release agent is added into the emulsion after polymerization is completed and the additive weight portions of the release agent accounts for 2-5 percent of the total amount of the modifier, thus obtaining the shell layer. The particle size of the copolymer grafted of the invention is larger than 450nm; meanwhile the invention also solves the compatibility problem between super-size high glue content impact ACR and PVC to cause the impact ACR to be fast and evenly dispersed in PVC particles, thus the invention can effectively increase the toughness of PVC products and can be widely used in PVC non-transparent products.

Owner:临沂瑞丰高分子材料有限公司

Preparation method for tough epoxy acid anhydride impregnating varnish and impregnating varnish

ActiveCN102618150AOvercome compatibilityOvercoming dispersionEpoxy resin coatingsHydrogen atomRoom temperature

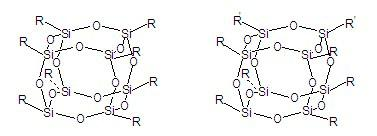

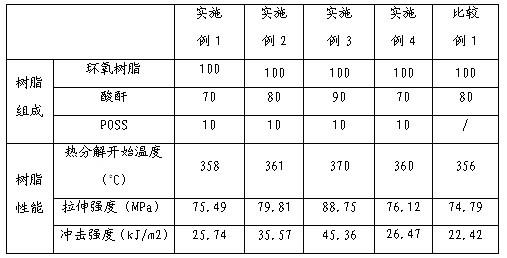

The invention discloses a preparation method for touch epoxy acid anhydride impregnating varnish and impregnating varnish. The method comprises the following steps of: putting 100 parts by weight of epoxy resin into a reaction kettle; heating to 60 DEG C; adding 70-90 parts by weight of acid anhydride, and stirring at the rotating speed of 100-200 revolutions per minute for 30 minutes; adding 1-50 parts by weight of cage-shaped polyhedral oligomeric silsesquioxane (POSS); and continually stirring at the room temperature at the rotating speed of 100-200 revolutions per minute for 1 hour to form the epoxy acid anhydride impregnating varnish. The adopted cage-shaped POSS is cage-shaped POSS containing an active group or an inertial group capable of participating in an epoxy resin reaction, and the general formula can be shown as RXRY(SiO1.5)n, wherein n=8; x+y=8; and R can be one of an active aliphatic epoxy group, an aliphatic epoxy group, amino and hydrogen atom or one of inertial groups selected from phenyl, cyclopentyl, chloropropyl and p-nitrobenzene, and has superior comprehensive performance. Particularly, the toughness is improved remarkably, and the toughness of a material is improved by 10-200 percent.

Owner:ZHUZHOU TIMES ELECTRIC INSULATION

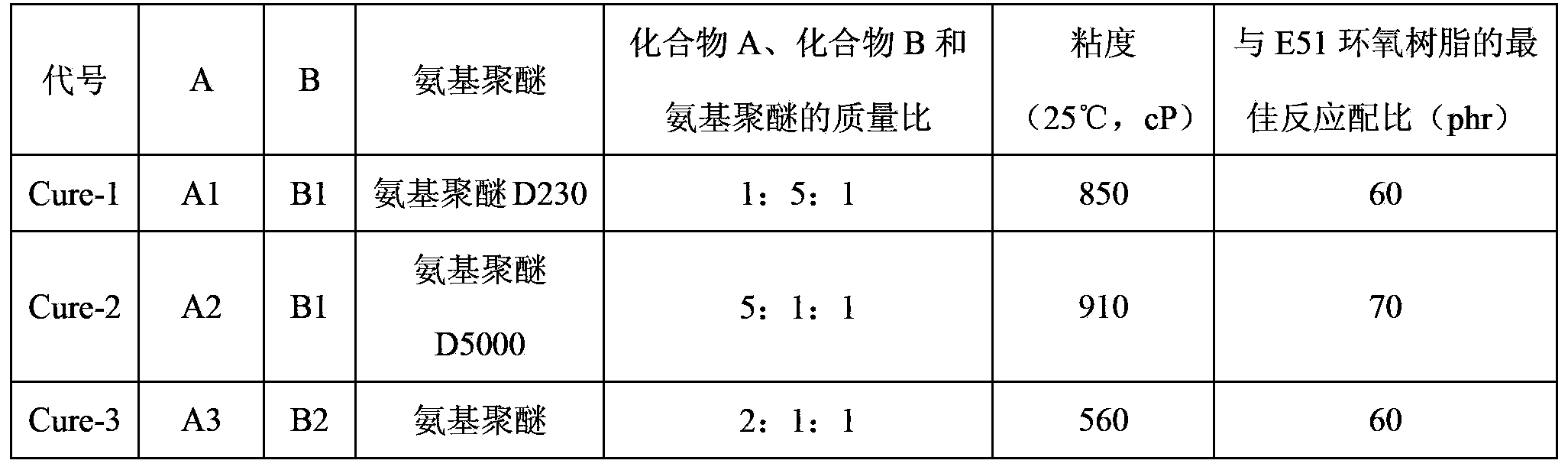

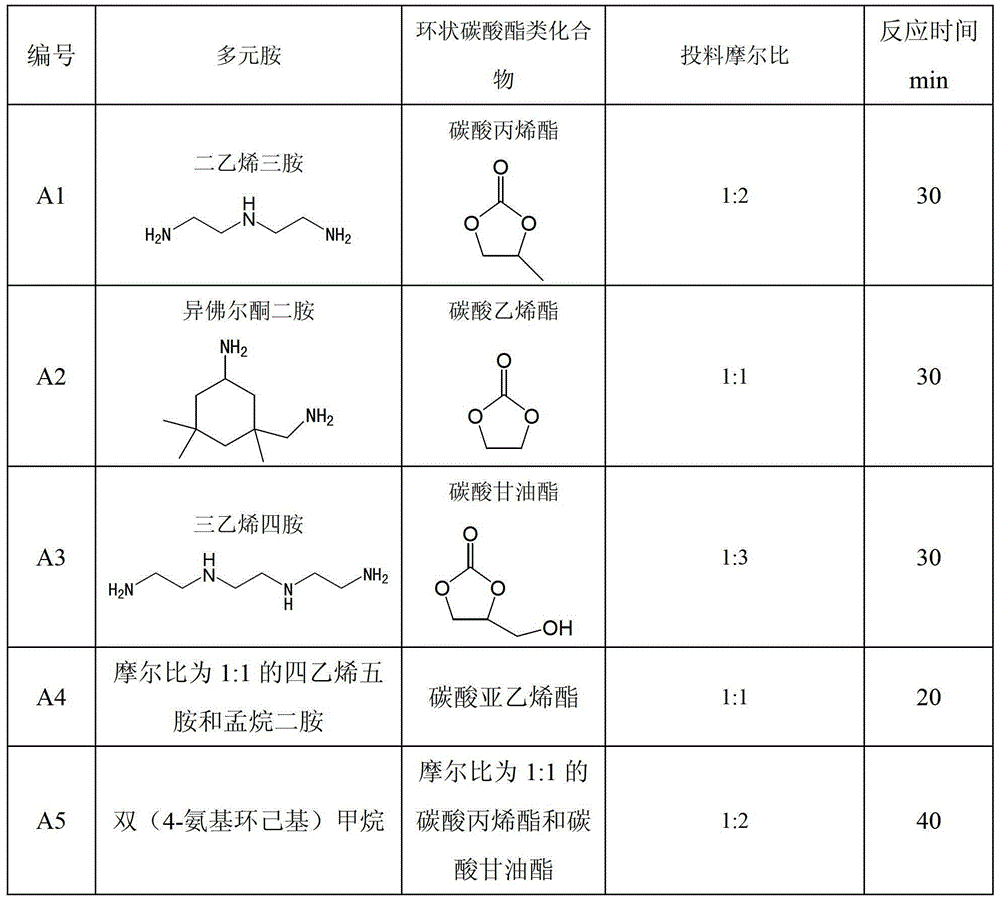

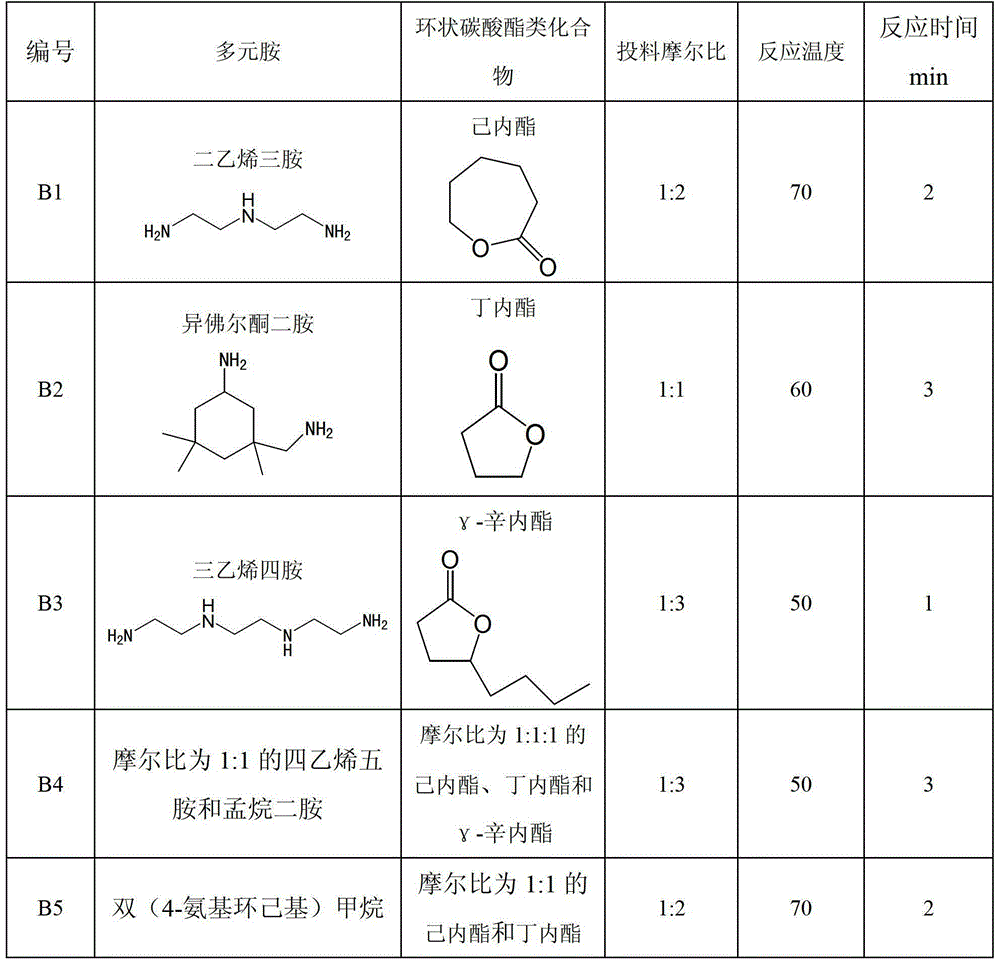

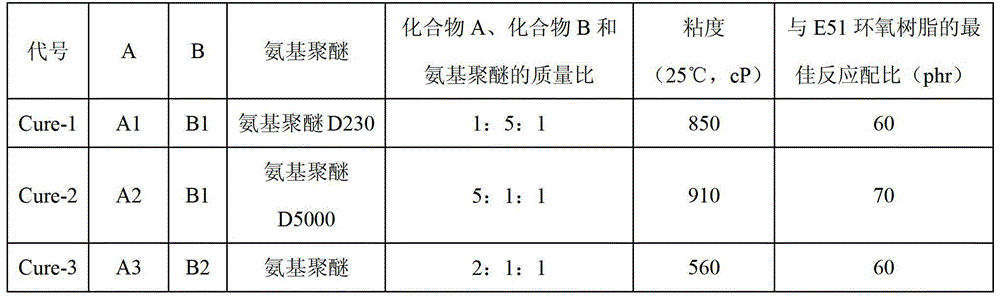

Toughening epoxy resin curing agent and preparation method and application thereof

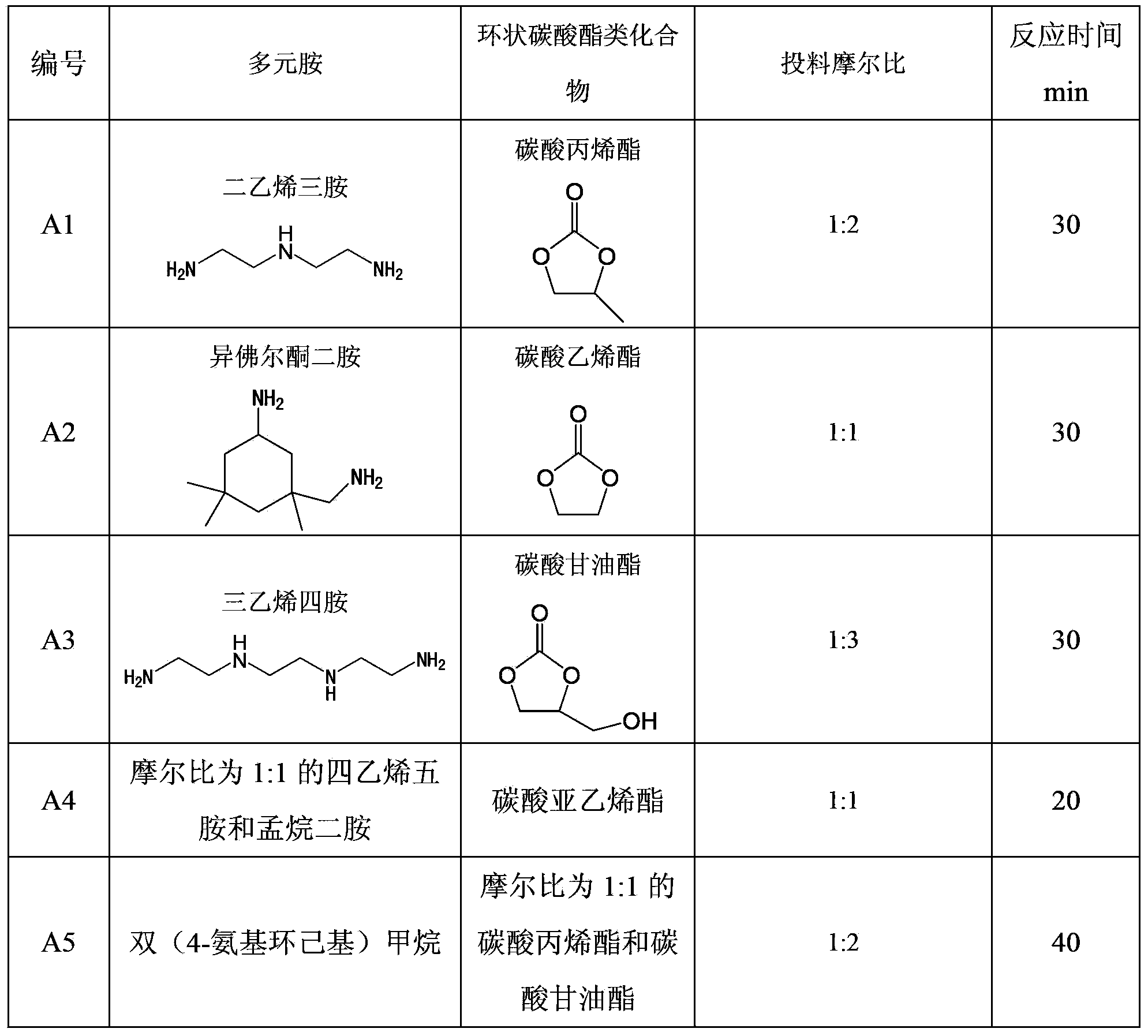

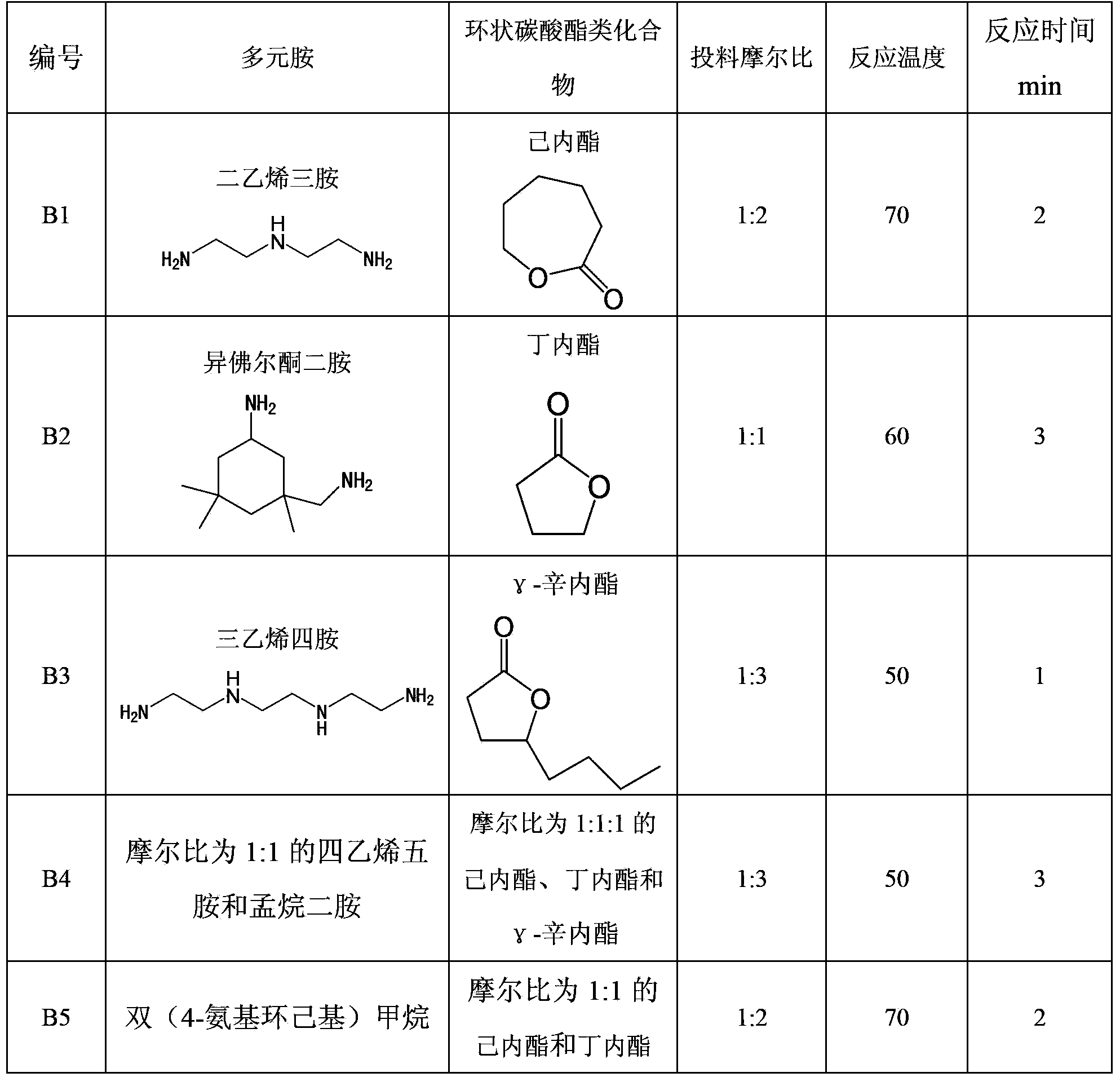

The invention provides a toughening epoxy resin curing agent which is prepared from a compound A, a compound B and amino polyether, wherein polyamine and cyclic carbonate compound are subjected to a cyclic-opening reaction to obtain the compound A, and polyamine and lactone compound are subjected to a cyclic-opening reaction to obtain the compound B. The invention further provides a preparation method and application of the toughening epoxy resin curing agent. The toughening epoxy resin curing agent is simple in preparation method and low in cost, and has the advantages of good toughening effect, low viscosity, solidification at the room temperature, colorlessness, transparency, environment friendliness and the like.

Owner:JIANGSU SOBUTE NEW MATERIALS +1

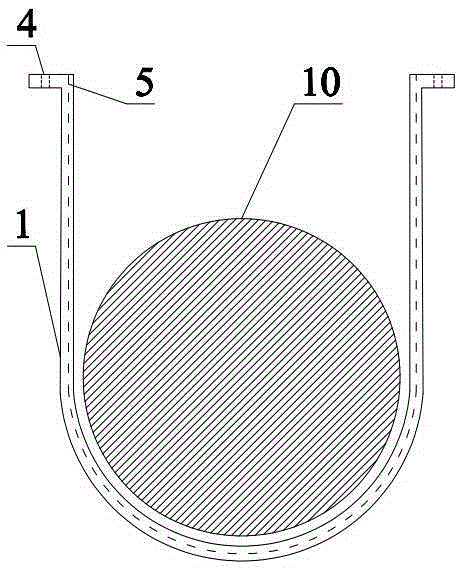

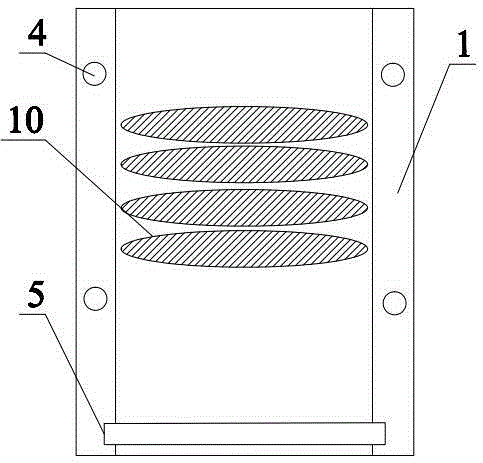

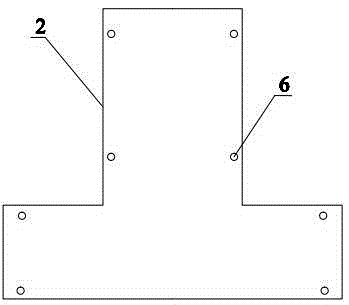

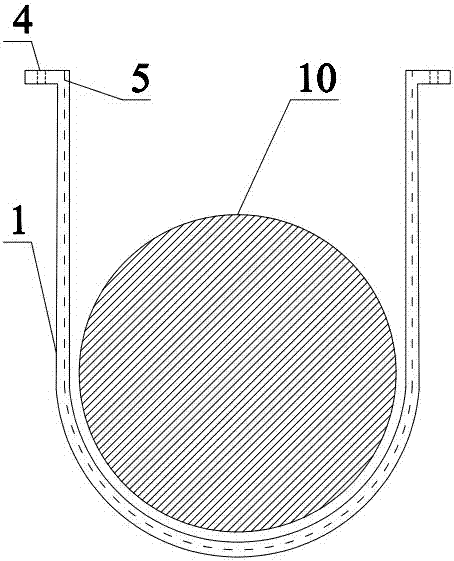

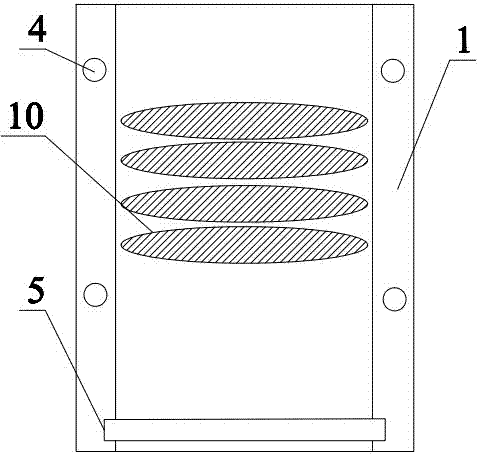

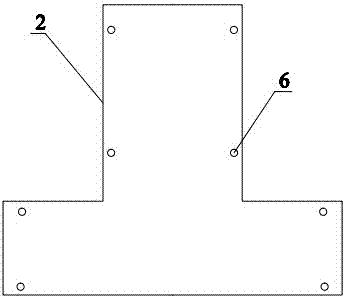

Electric power heat insulation type insulator insulation shielding cover

ActiveCN105356367AGuaranteed insulation effectEasy to installCoatingsApparatus for overhead lines/cablesWear resistantEngineering

The invention discloses an electric power heat insulation type insulator insulation shielding cover. The electric power heat insulation type insulator insulation shielding cover comprises an insulator shielding cover, a shielding cover covering plate, and a suspension clamp shielding cover, the insulator shielding cover is arranged in the U shape, edges of two side surfaces of the insulator shielding cover are provided with first fixing holes, the inner side of the lower part of the insulator shielding cover is provided with a base connecting groove, the insulator shielding cover is movably connected with the suspension clamp shielding cover via the base connecting groove, the shielding cover covering plate is arranged in the T shape, the shielding cover covering plate is provided with second fixing holes corresponding to the first fixing holes, the central part of the suspension clamp shielding cover is provided with a U-shaped metal shielding cover, the external surface of the metal shielding cover is provided with a U-shaped slipway, the inner part of the metal shielding cover is provided with wire clamp fixtures, and surfaces of the insulator shielding cover, the shielding cover covering plate, the suspension clamp shielding cover, and the metal shielding cover are all coated with high-temperature-resistant and wear-resistant insulation paints. According to the electric power heat insulation type insulator insulation shielding cover, the structure is simple, the operation is convenient, the shielding effect is good, and the safety factor is big.

Owner:国网河南省电力公司超高压公司 +1

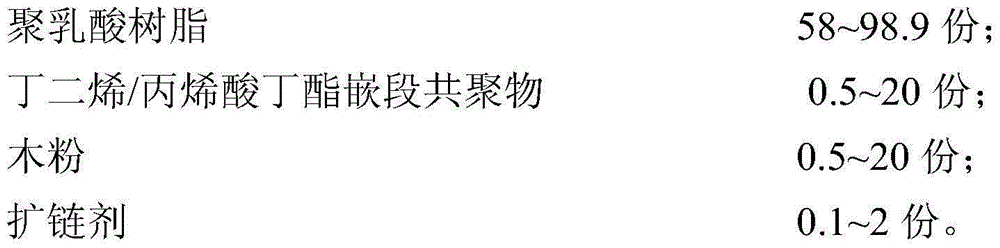

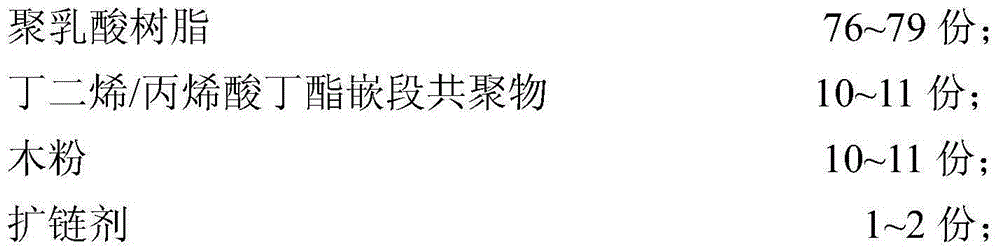

High-toughness polylactic acid composite material and preparation method thereof

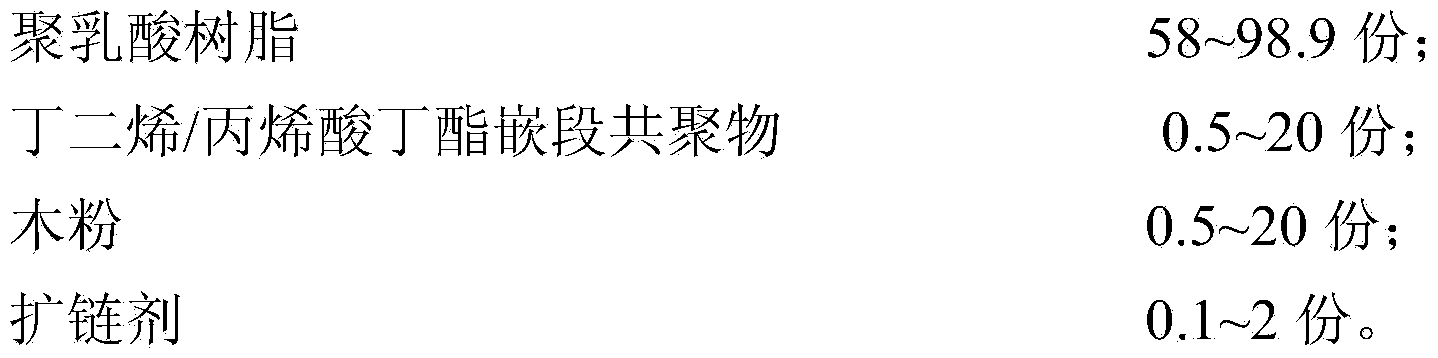

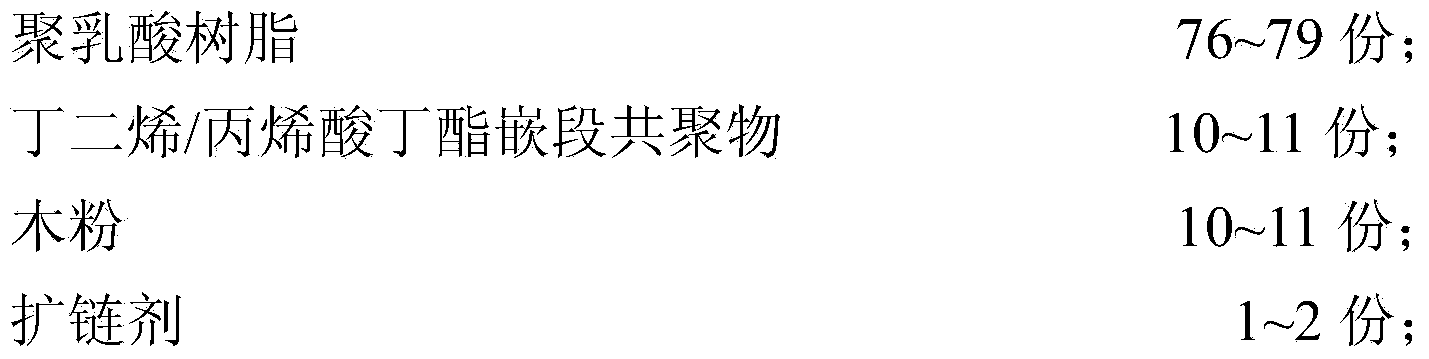

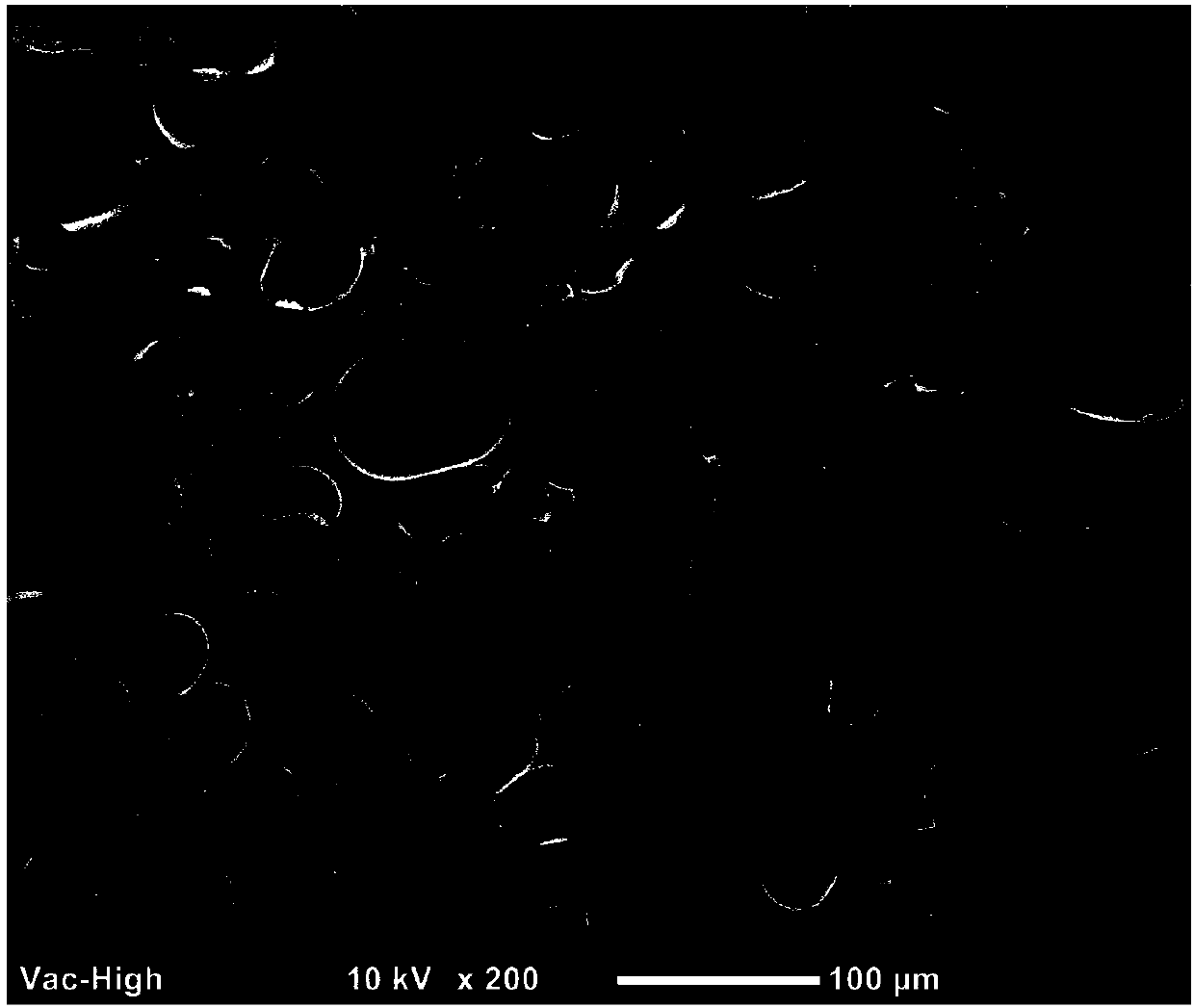

The invention discloses a high-toughness polylactic acid composite material. The high-toughness polylactic acid composite material is composed of the following components in parts by weight: 58-98.9 parts of polylactic acid (PLA) resin, 0.5-20 parts of a butadiene / butyl acrylate segmented copolymer, 0.5-20 parts of wood flour and 0.1-2 parts of a chain extender. The high-toughness polylactic acid composite material adopts the butadiene / butyl acrylate segmented copolymer as a toughening agent so as to realize the aim of effectively toughening PLA resin and overcome the fragile defect of PLA; meanwhile, the wood flour and the chain extender are adopted so that the strength and the rigidity of the material are improved; and the PLA is toughened and the strength and the rigidity of the material are kept as much as possible. The invention further discloses a preparation method for the high-toughness polylactic acid composite material; a double-screw extruder is used for fusing, co-extruding and granulating; and the preparation method is simple in equipment, convenient to operate, easy to control and low in cost and the toughness of the PLA can be improved very well.

Owner:杭州卓普新材料科技有限公司

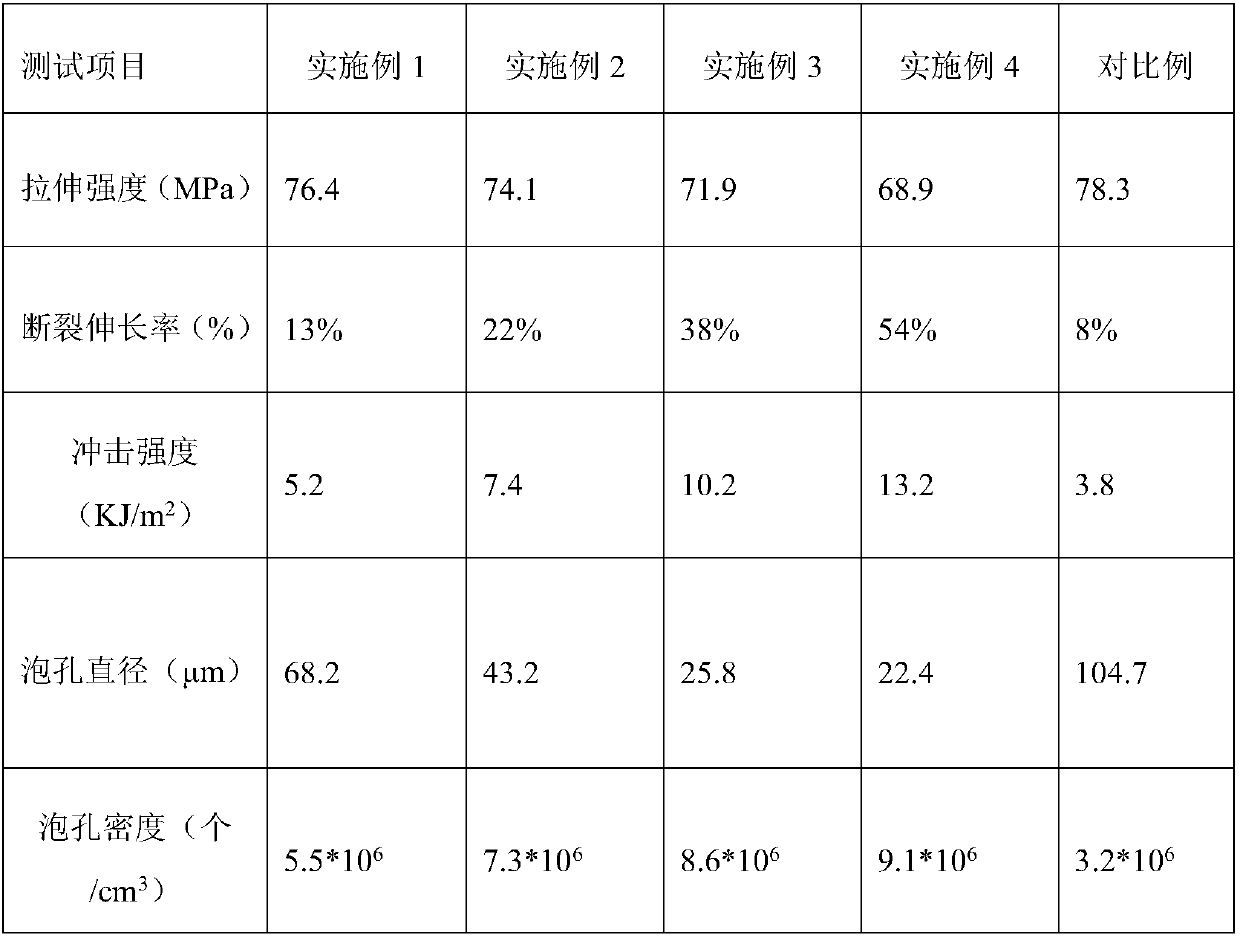

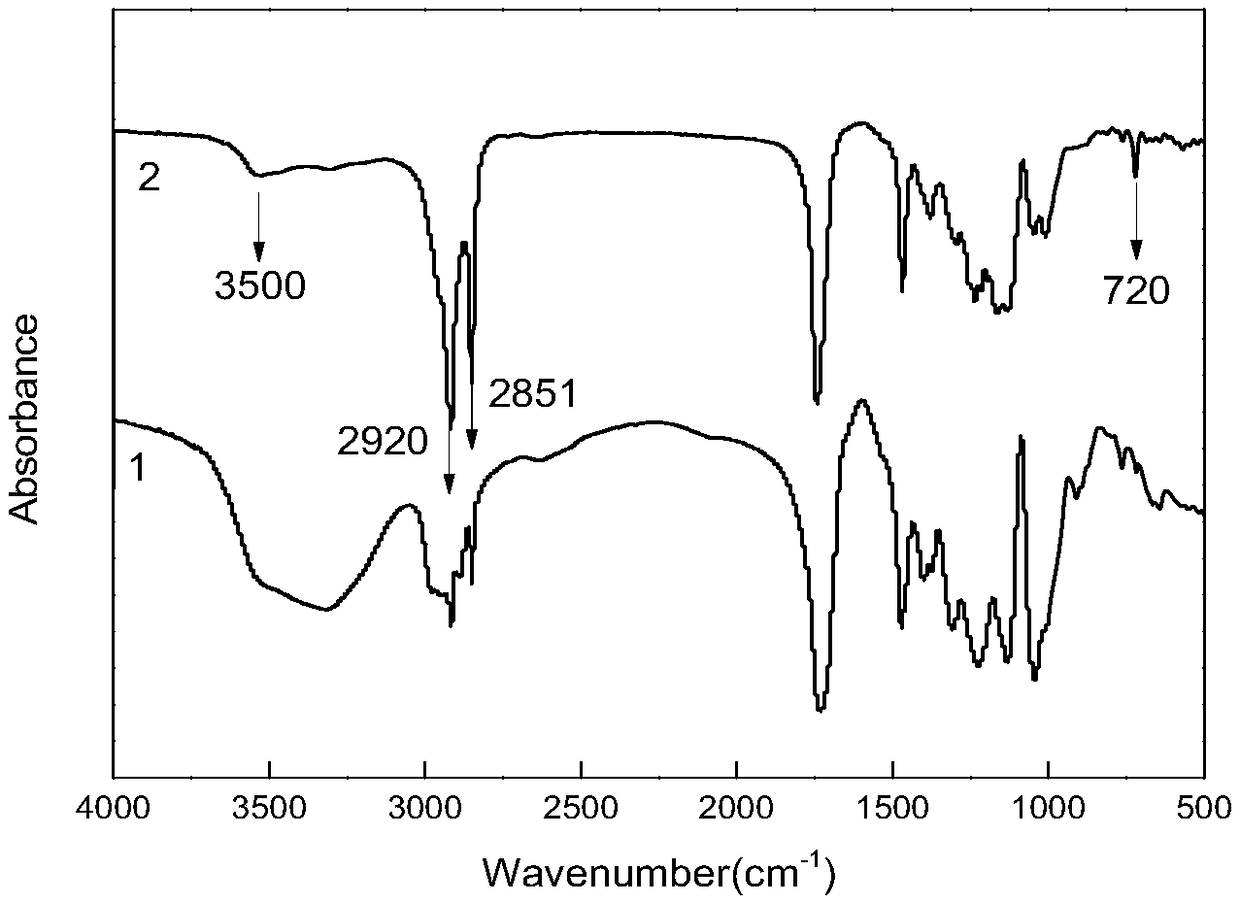

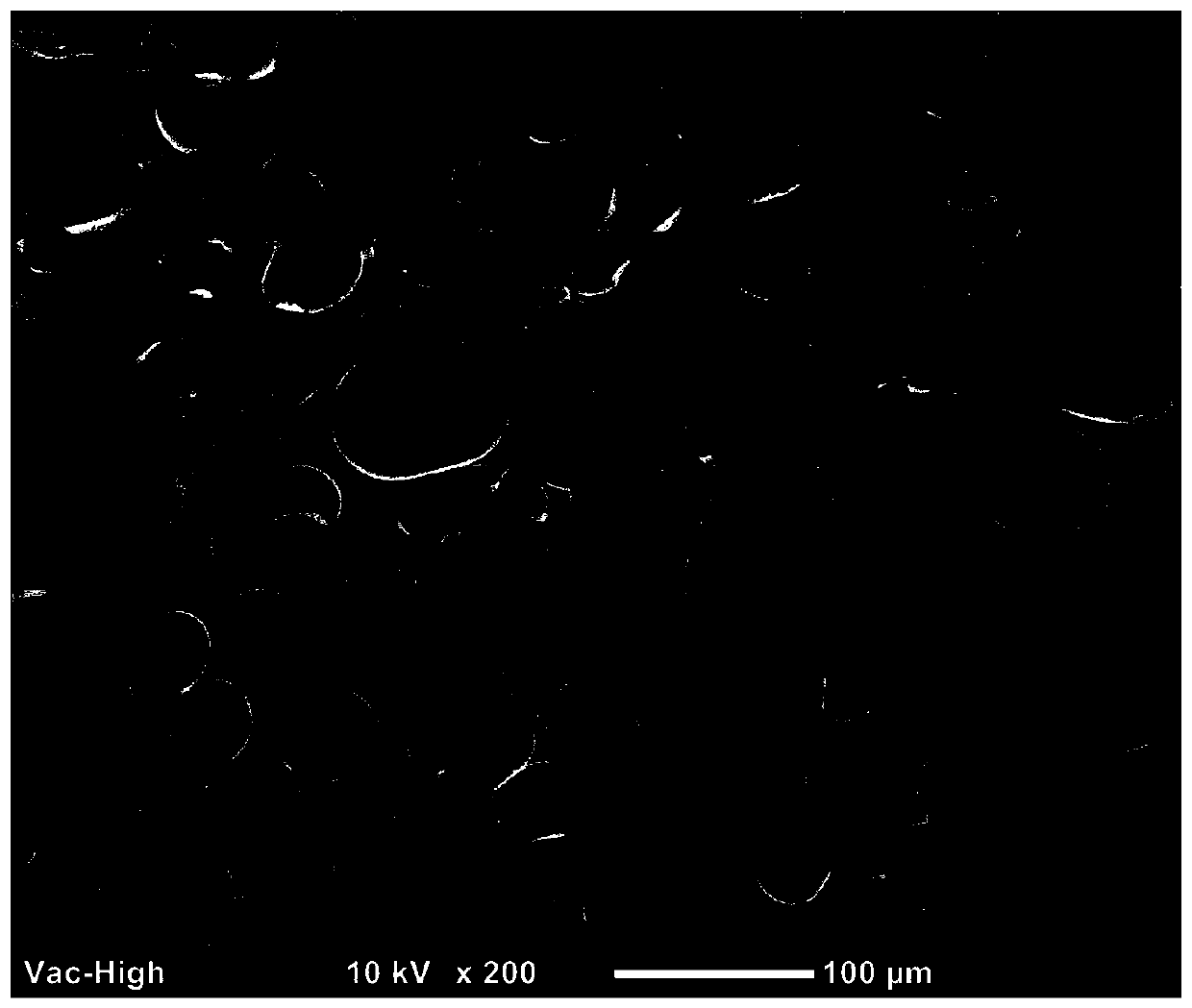

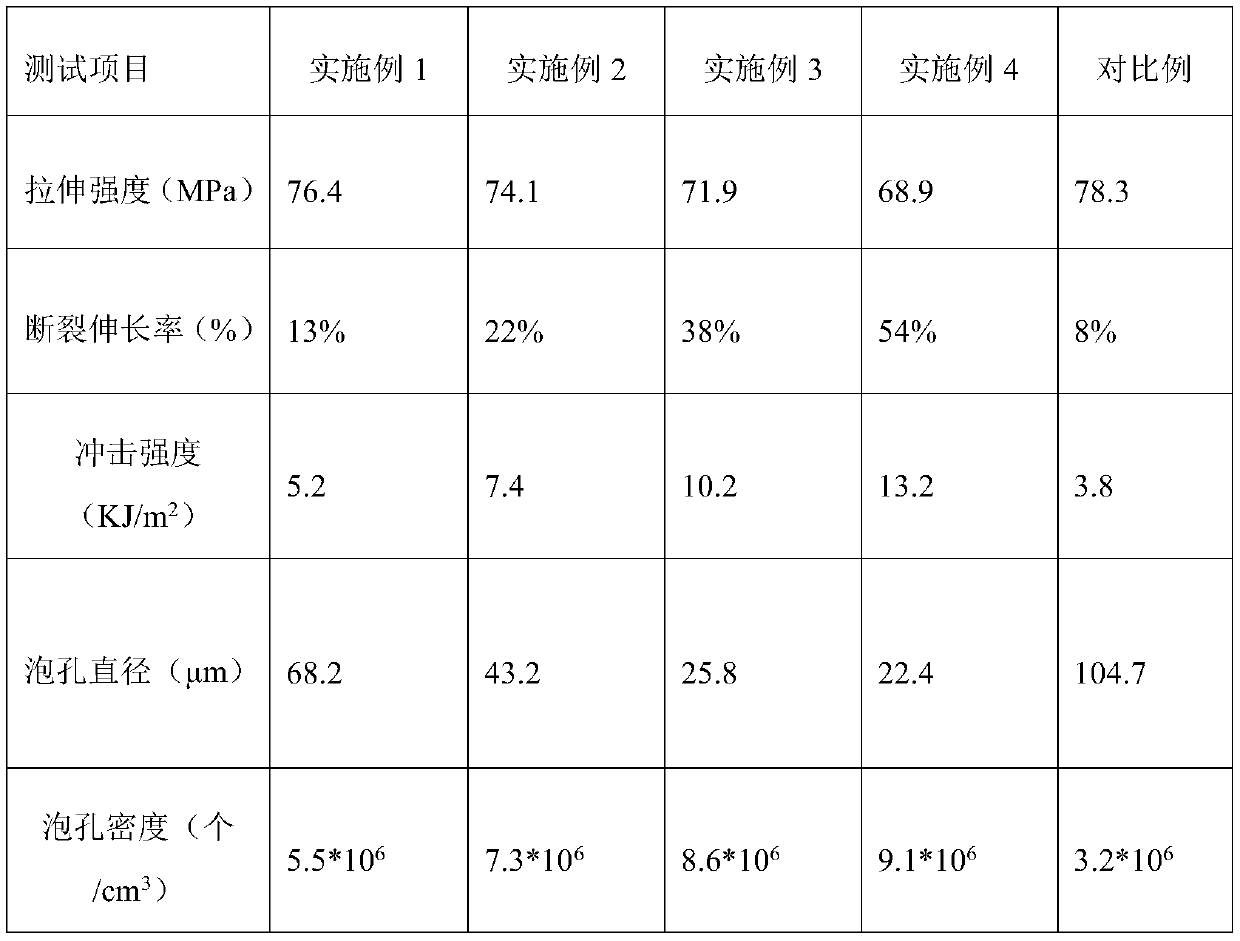

Method and material for preparing polylactic acid-natural rubber porous material by micropore injection molding foaming

The invention belongs to the technical field of micropore injection molding foaming, and discloses a method and a material for preparing a polylactic acid-natural rubber porous material by micropore injection molding foaming. Grafts are prepared through emulsion polymerization; dried polylactic acid particles and glycidyl methacrylate-natural rubber grafts are mixed in proportion, and are molten and mixed by adopting a double-screw extruder for extrusion and granulation; the micropore injection molding foaming is performed on the mixed particles by adopting an injection molding machine with agas compression unit; and with a supercritical CO2 fluid as a foaming agent, a polylactic acid / natural rubber porous material is obtained. Polylactic acid is roughened and modified by adopting naturalrubber; and the method of grafting glycidyl methacrylate on the natural rubber is used for improving polarity of the natural rubber and compatibility with the polylactic acid. The foaming process issimple; the obtained foaming material is more uniform in bubble size and distribution; and meanwhile, the foaming material is better in toughness.

Owner:贵州黔城黔测检测技术有限公司

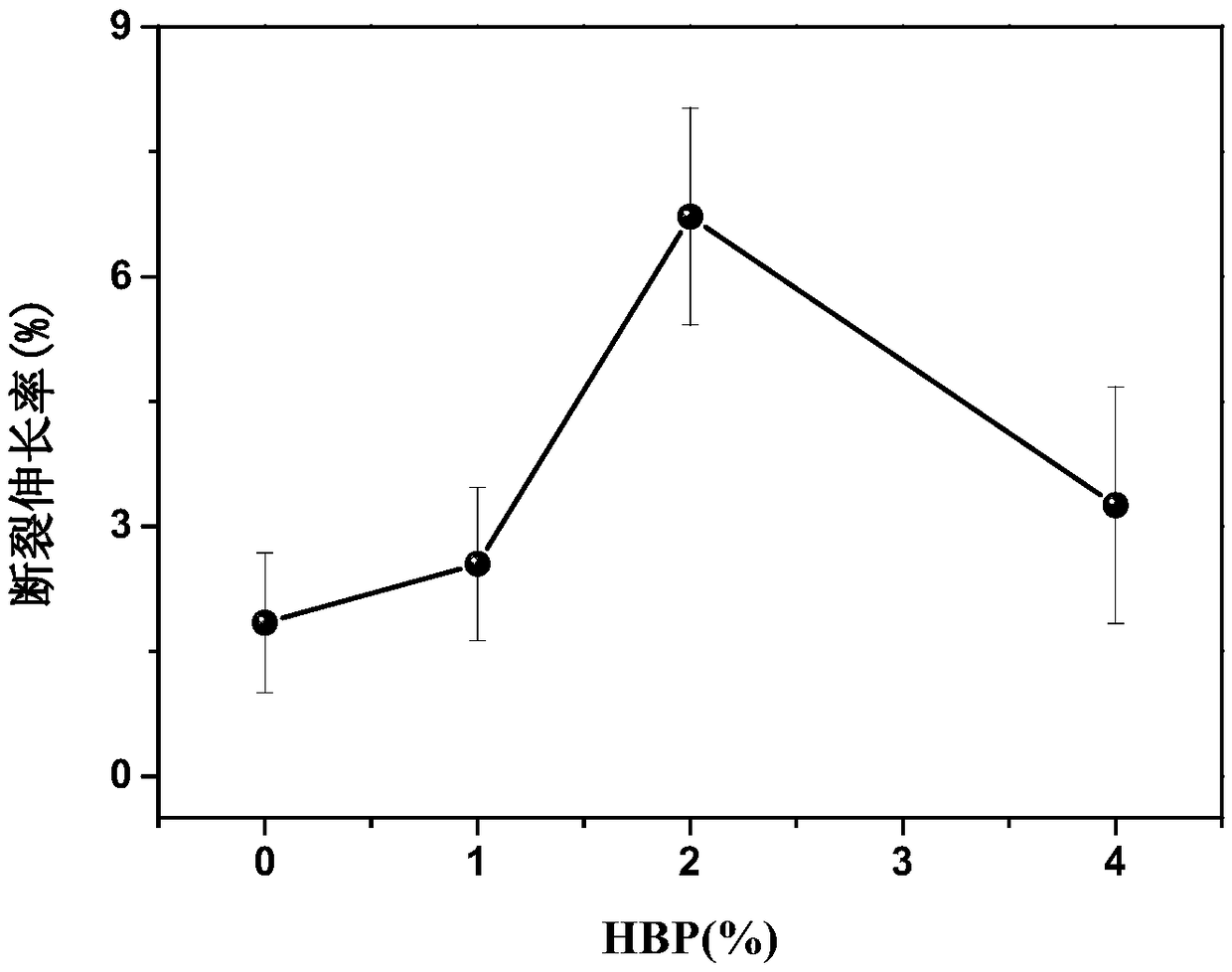

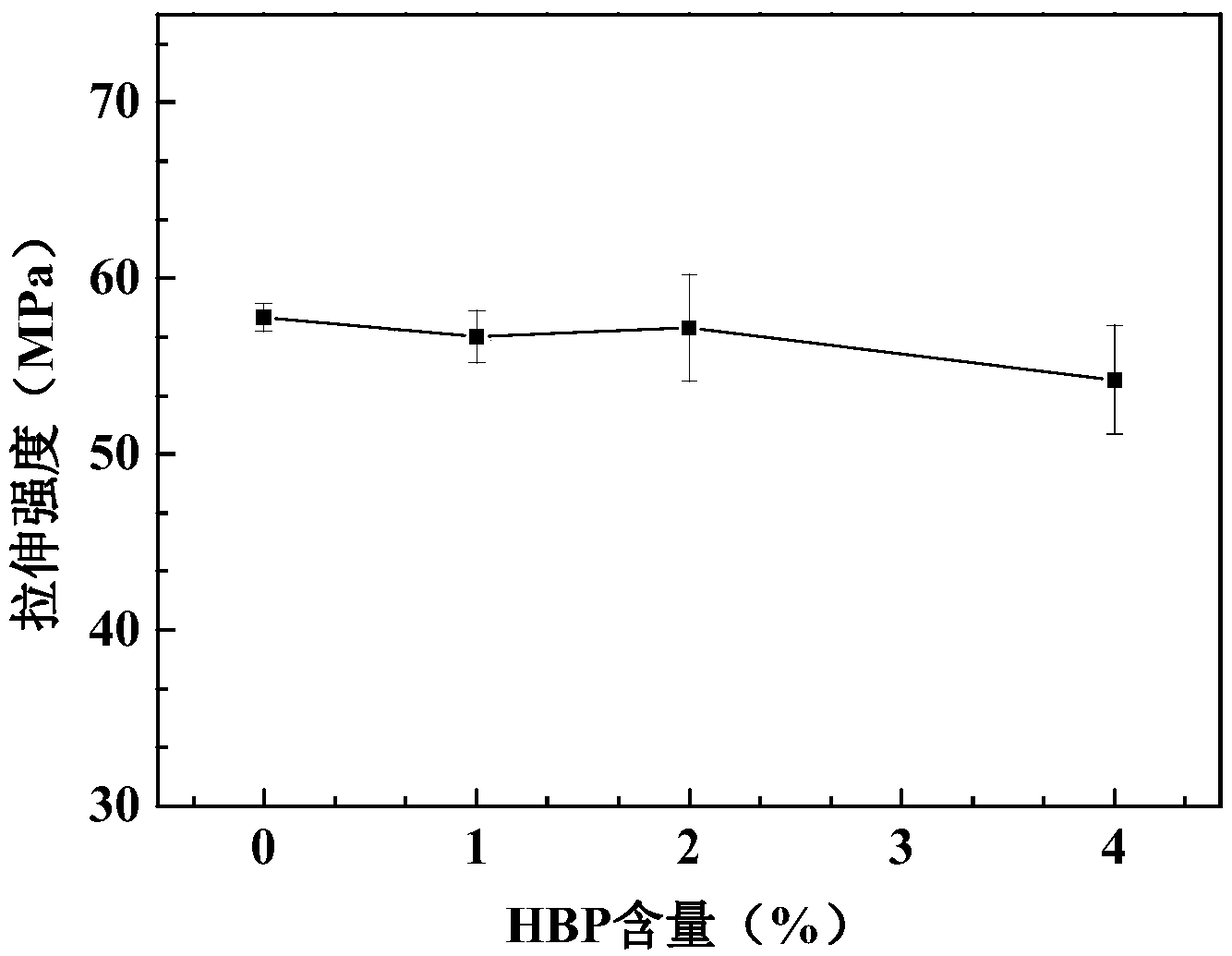

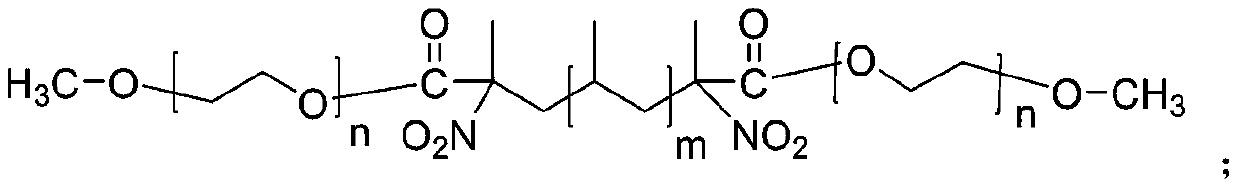

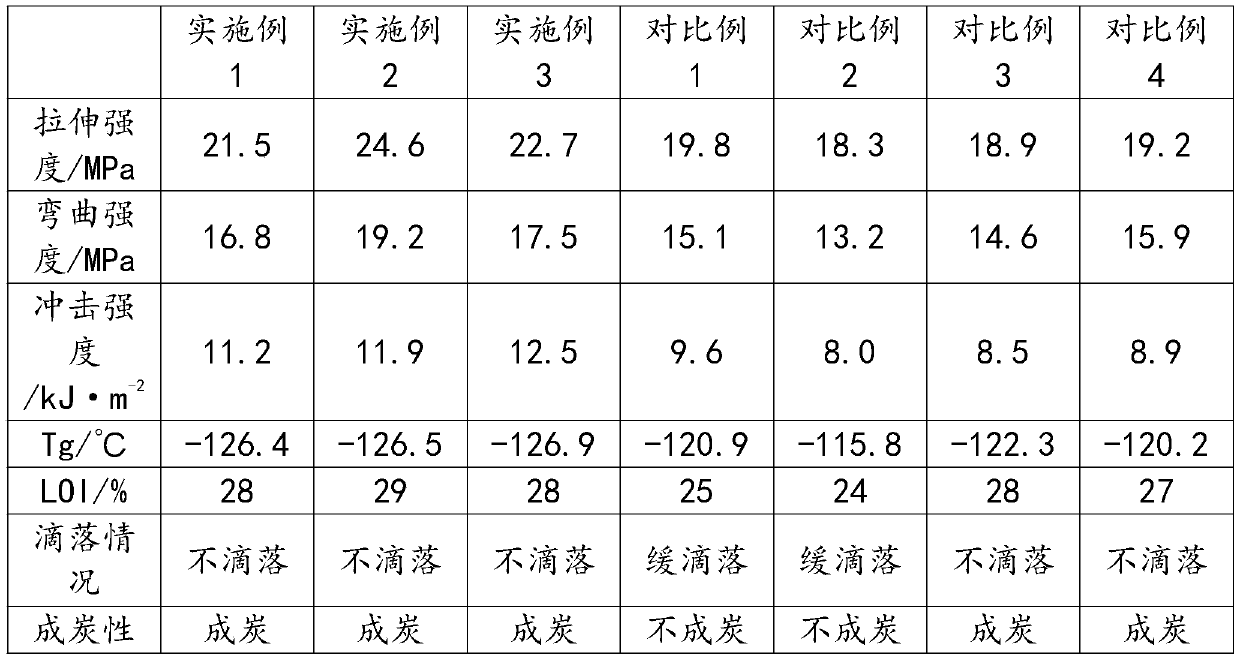

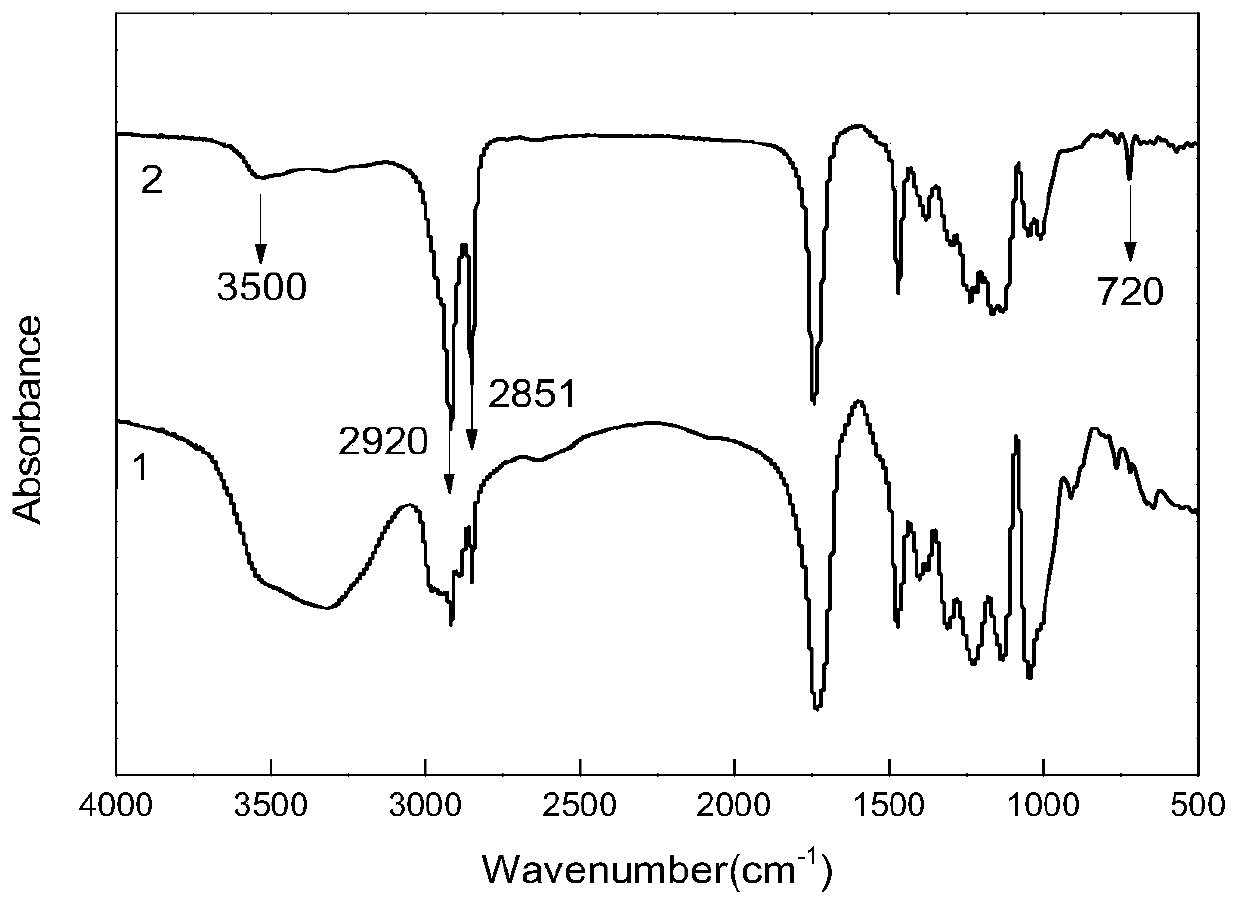

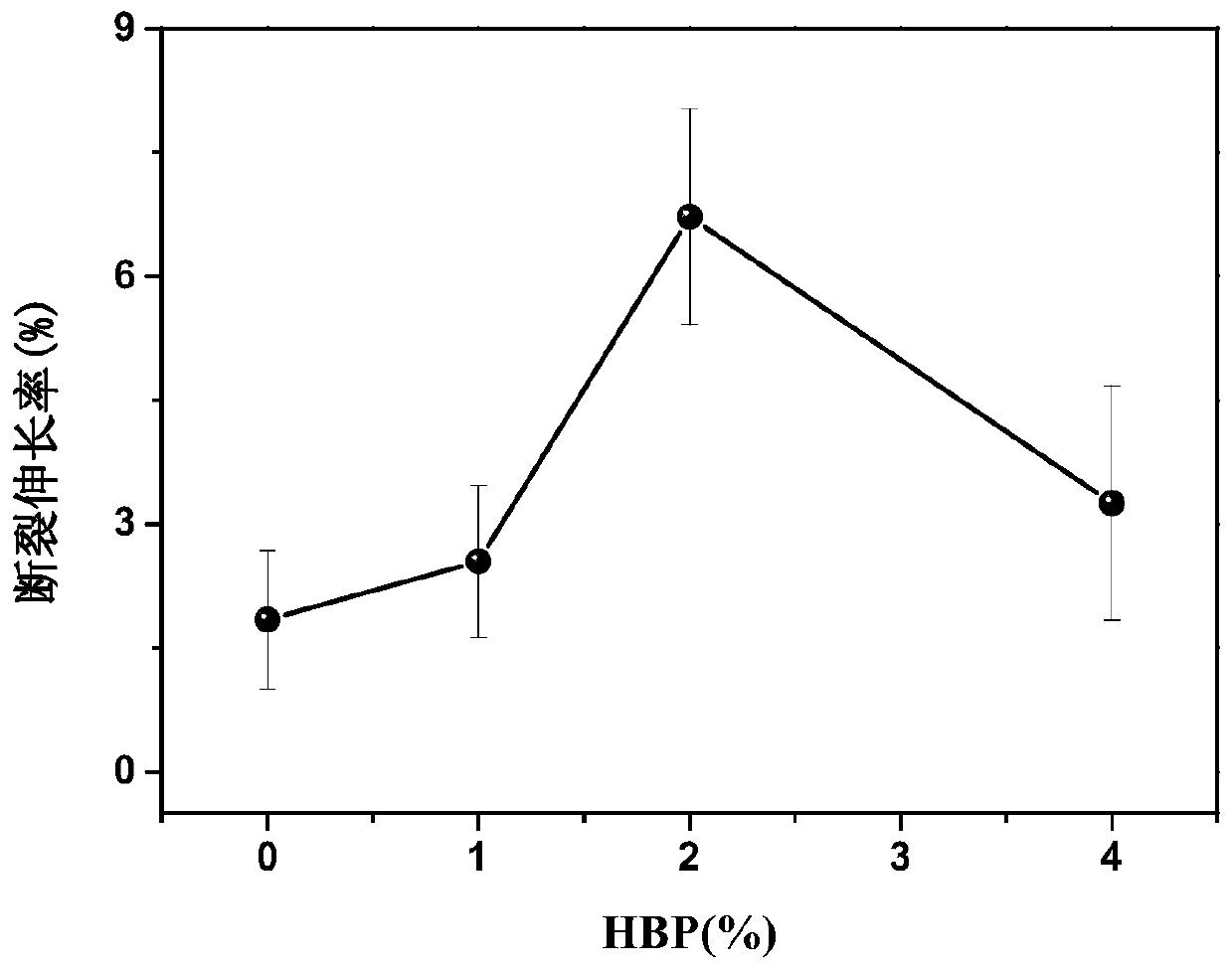

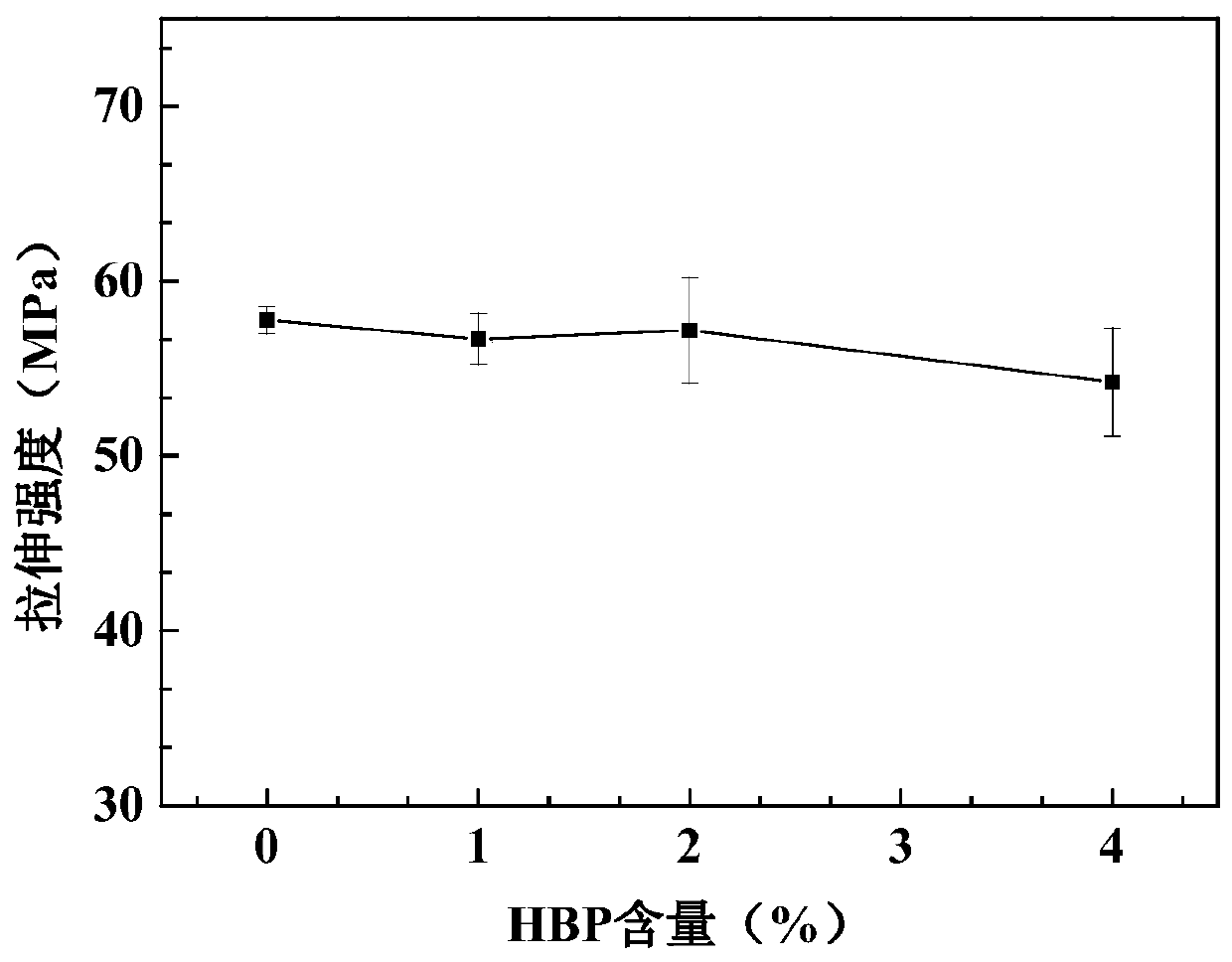

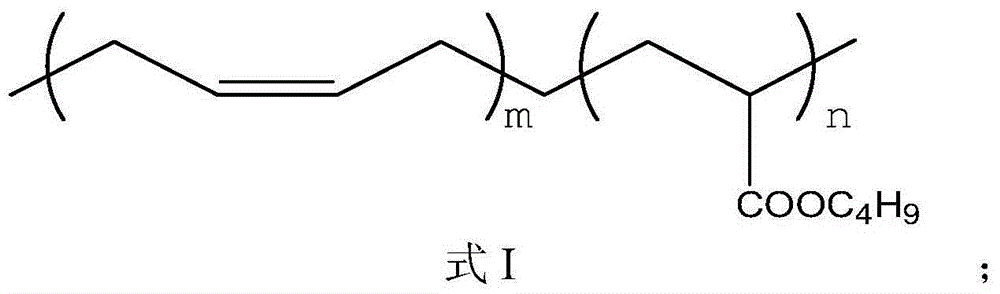

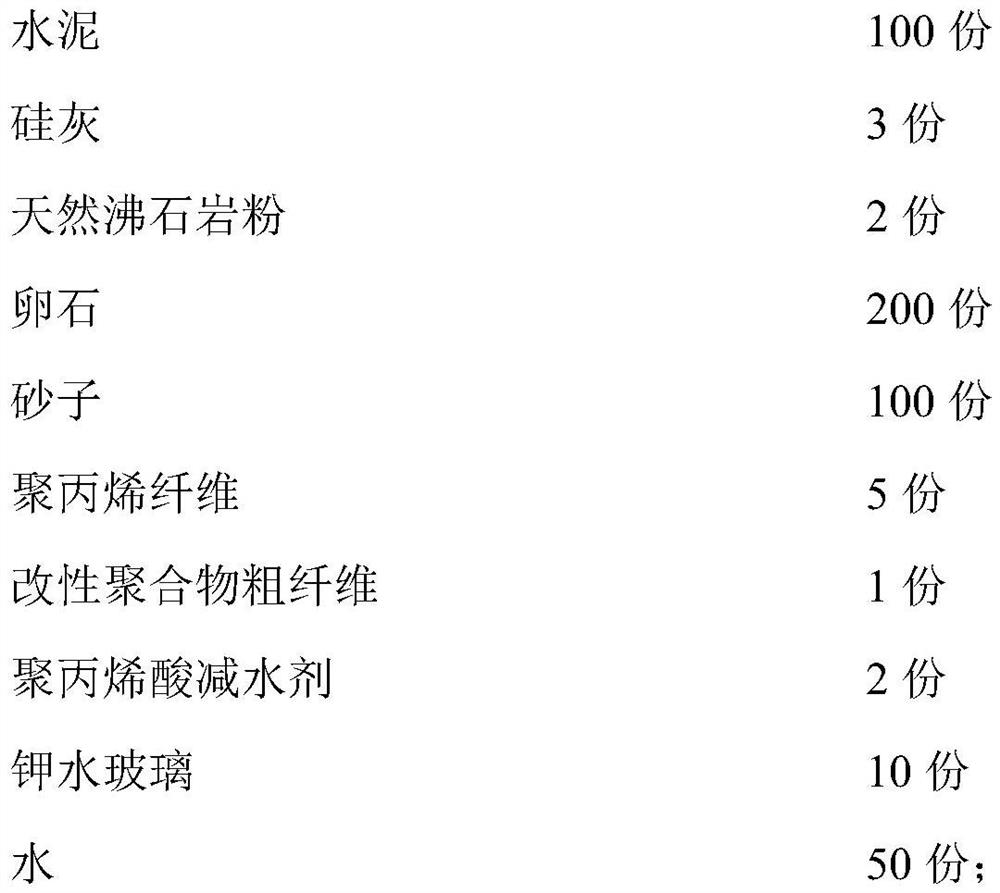

PLA/PPC/HBP (poly lactic acid/propylene oxide copolymer/hyperbranched polymer derivative blend and preparation method thereof

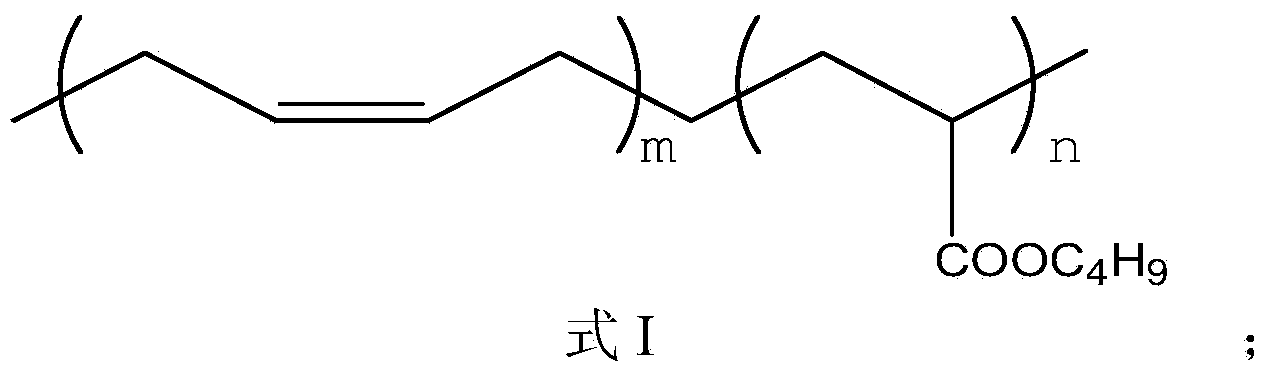

The invention discloses a PLA / PPC / HBP (poly lactic acid / propylene oxide copolymer / hyperbranched polymer derivative blend and a preparation method thereof. The preparation method includes that PLA resin, PPC resin and an HBP derivative are mixed for melt blending prior to cooling to indoor temperature to obtain the PLA / PPC / HBP derivative blend, and the chemical formula of the HBP derivative is as described in the formula I. The PLA / PPC / HBP derivative blend is prepared by adopting a melt-blending method, and breaking elongation of the blend is increased; when the addition amount of the HBP derivative is 2.0wt.%, the breaking elongation of the PLA / PPC / HBP derivative blend is increased by 367% under the condition that the tensile strength is essentially constant as compared with the pure PLA / PPC resin; delta Tg of PLA and PPC is decreased by 18.9DEG C to 15.69DEG C.

Owner:BEIJING TECHNOLOGY AND BUSINESS UNIVERSITY

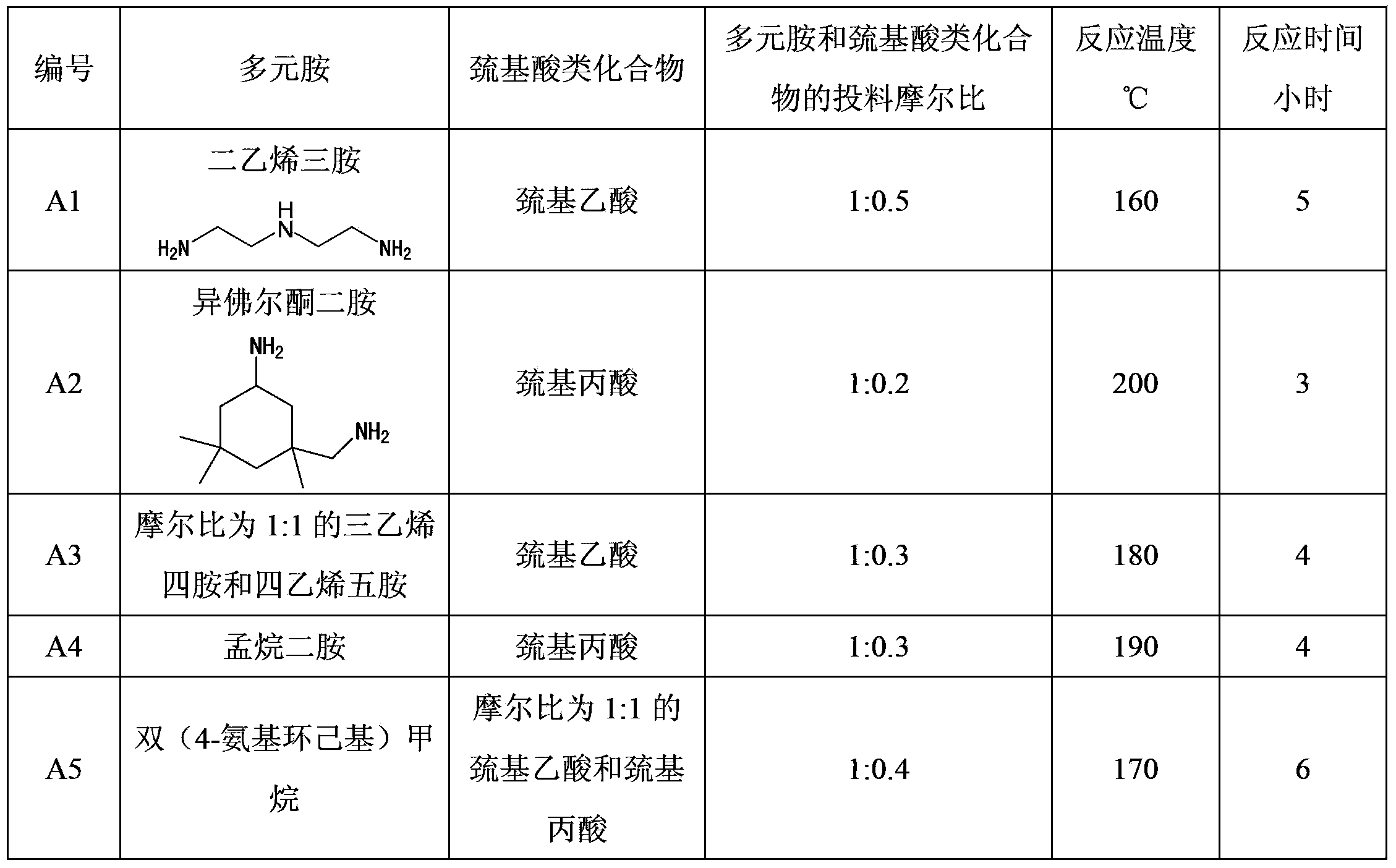

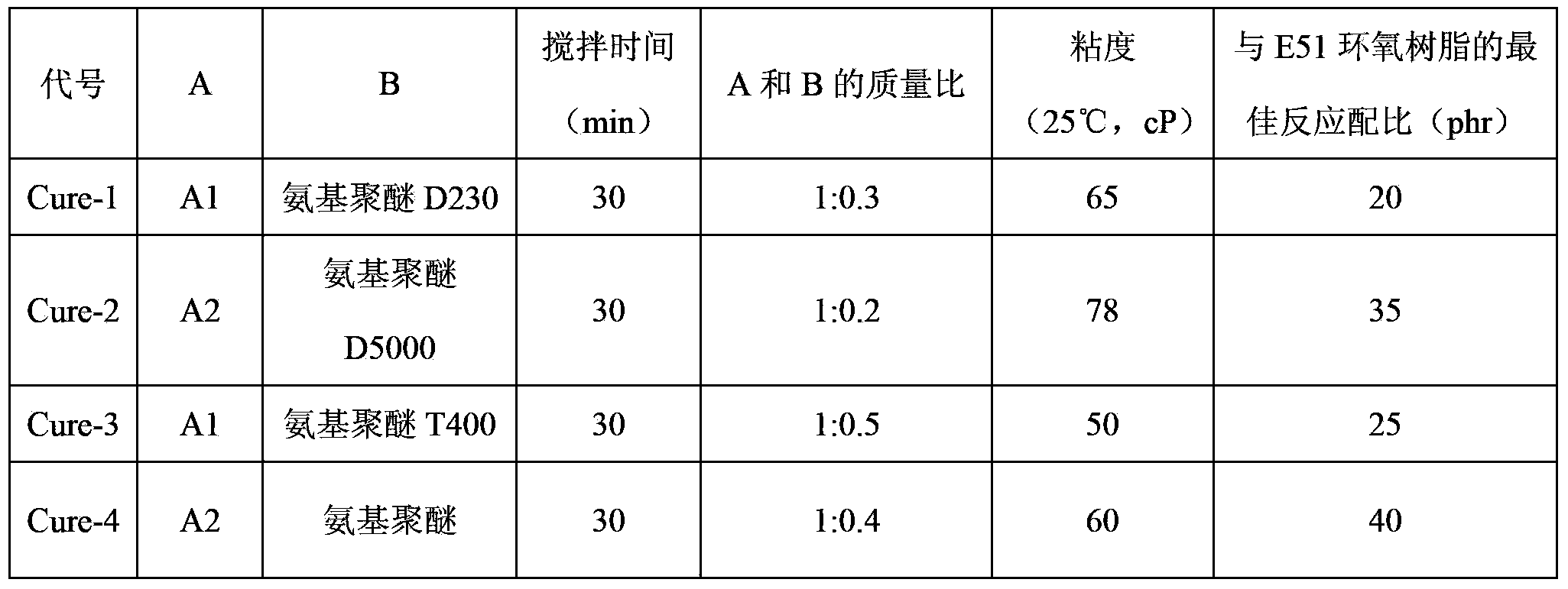

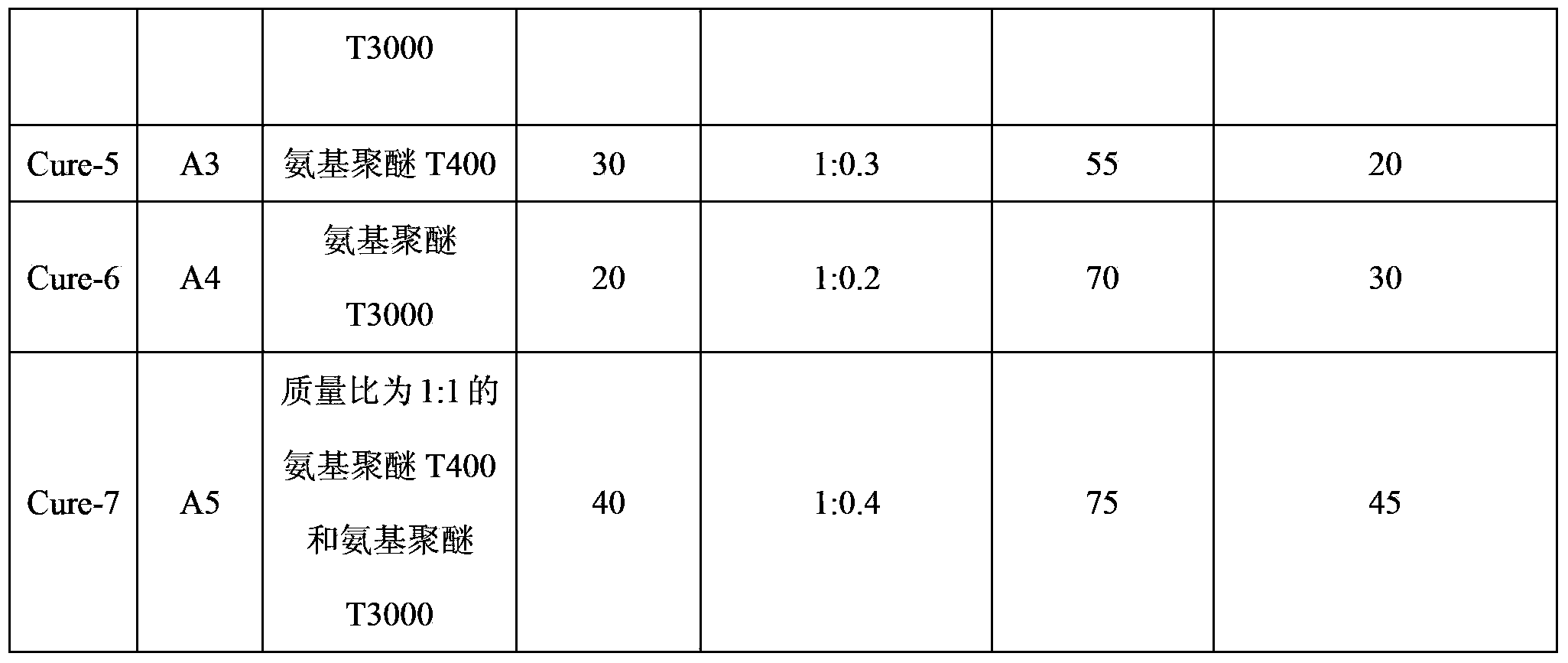

Epoxy resin curing agent, and preparation method and application of epoxy resin curing agent

ActiveCN103435781AEasy to prepareEasy to manufactureNon-macromolecular adhesive additivesCoatingsEpoxyLow temperature curing

The invention provides an epoxy resin curing agent which is prepared by polyamine, a mercaptan acid compound and amino polyether. The invention further provides a preparation method and an application of the epoxy resin curing agent. The epoxy resin curing agent is simple in preparation method and low in cost, and has the advantages of low-temperature curing, good toughening effect, simplicity in preparation, environmental protection and the like.

Owner:JIANGSU SOBUTE NEW MATERIALS +2

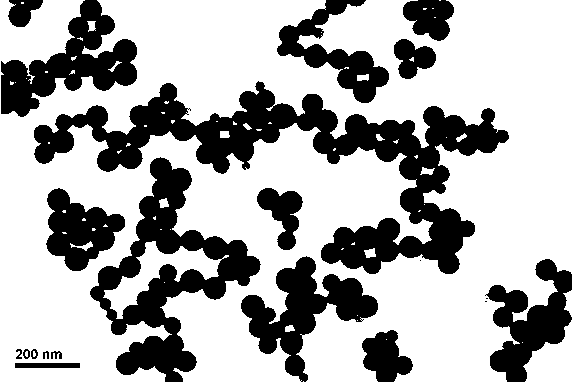

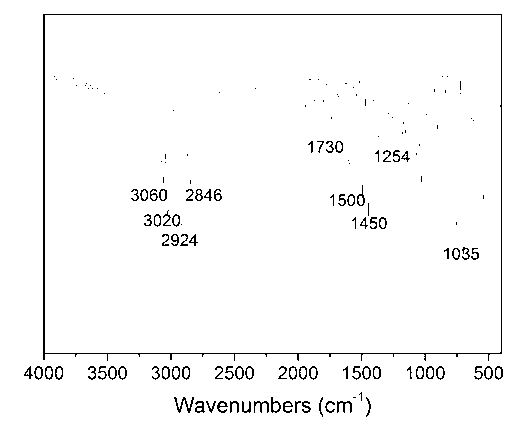

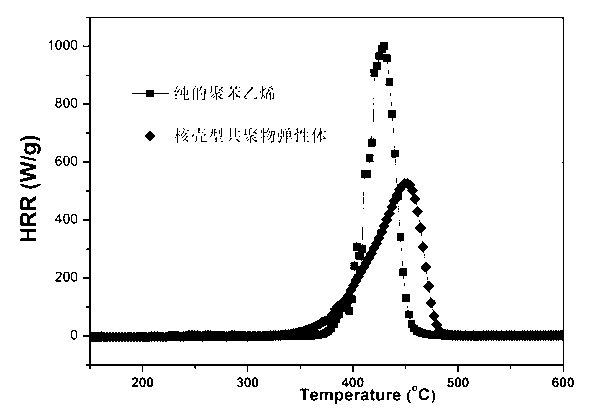

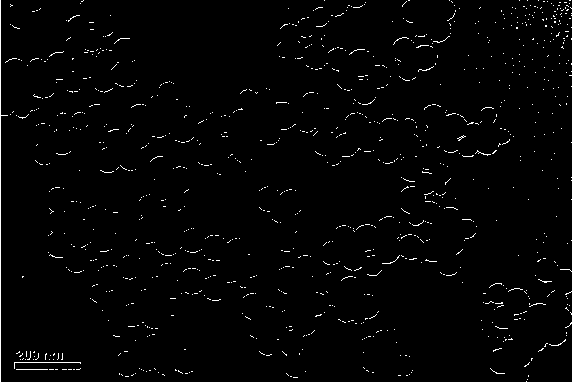

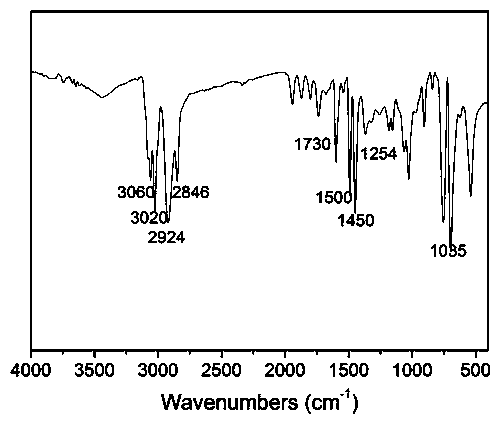

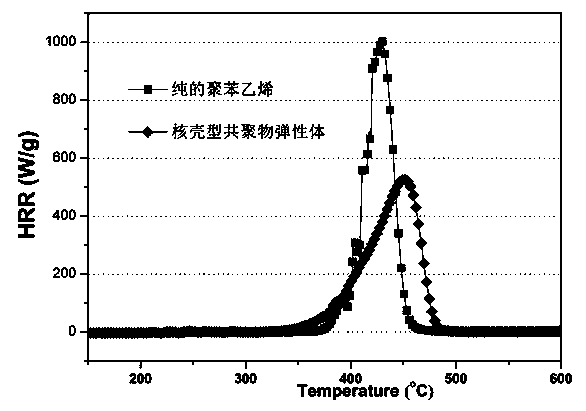

Core-shell type nanostructured polymeric microsphere fire retardant, preparation method and application of core-shell type nanostructured polymeric microsphere fire retardant

ActiveCN103130952AImprove flame retardant performancePromote migrationMicrosphereEmulsion polymerization

The invention discloses core-shell type nanostructured polymeric microsphere fire retardant, a preparation method and application of the core-shell type nanostructured polymeric microsphere fire retardant. Through the method of seeded emulsion polymerization, monomers which include phosphorus and nitrogen elements and polymerizable monomers which include double bond are copolymerized to form macromolecular polymer microspheres with nanoscale and a core-shell structure. The macromolecular polymer microspheres can be used as fire retardant, achieves macromolecule quantization of micromolecule fire retardant, and move and running away of the fire retardant in the process of use can be reduced. Compared with traditional additive fire retardant, the core-shell type nanostructured polymeric microsphere fire retardant has the advantages that compatibility of the fire retardant and macromolecular matrixes are improved, and long flame retardant property of materials can be kept. Through adjustment of the proportion of two monomers in the process of preparation, the core-shell structure of the polymeric microspheres can be changed to meet the scattered need in different macromolecular matrixes. Dispersion and flame retardant properties are improved. In addition, the core-shell type nanostructured polymeric microsphere fire retardant has toughening effects to the macromolecular matrixes.

Owner:苏州安鸿泰新材料有限公司

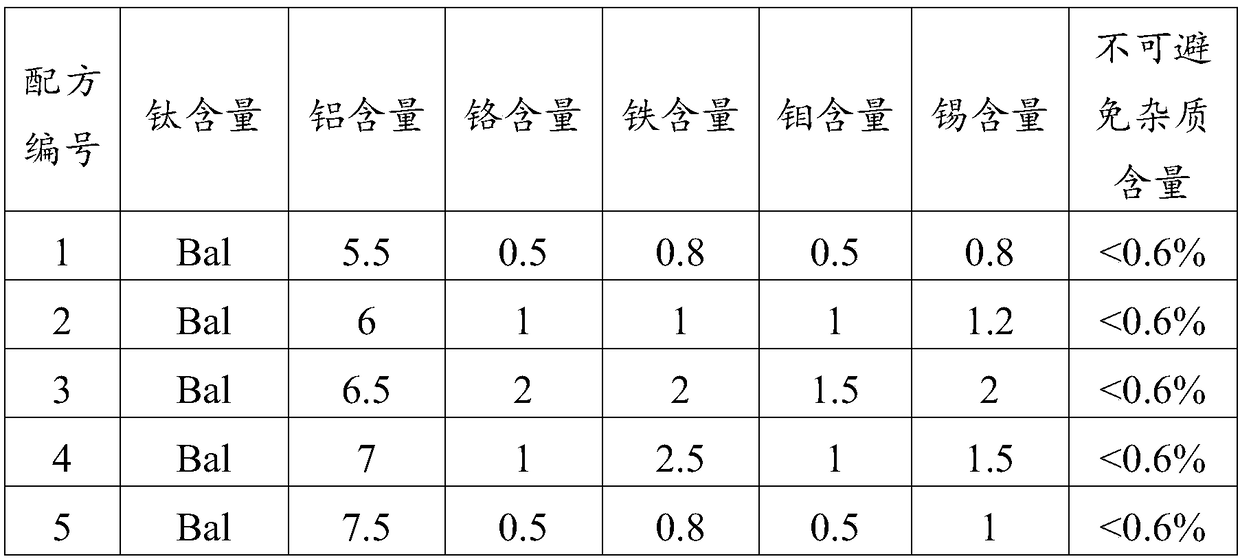

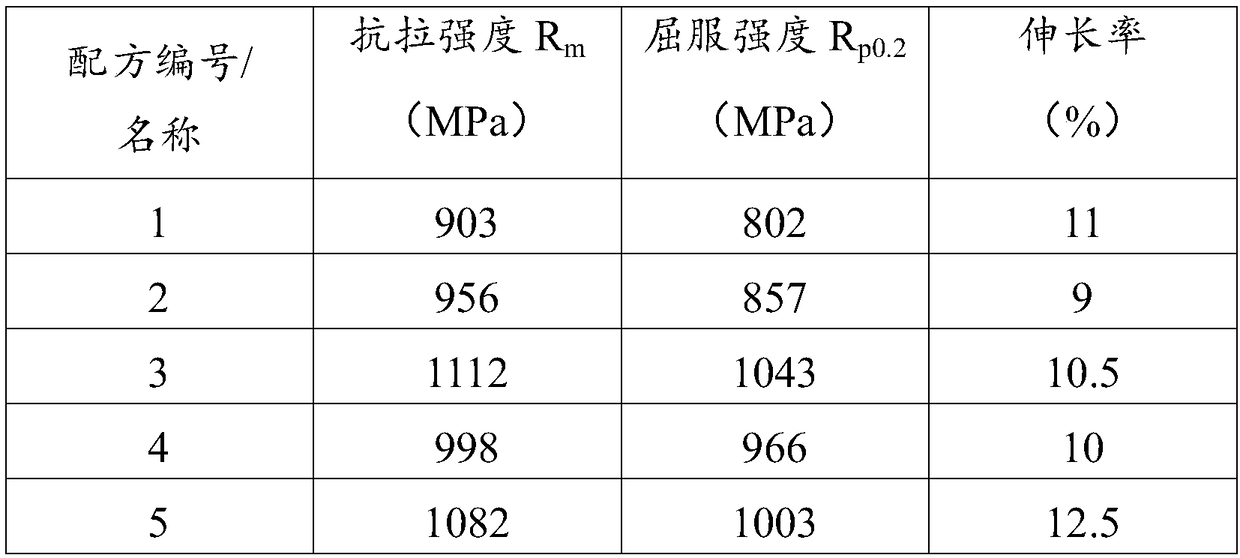

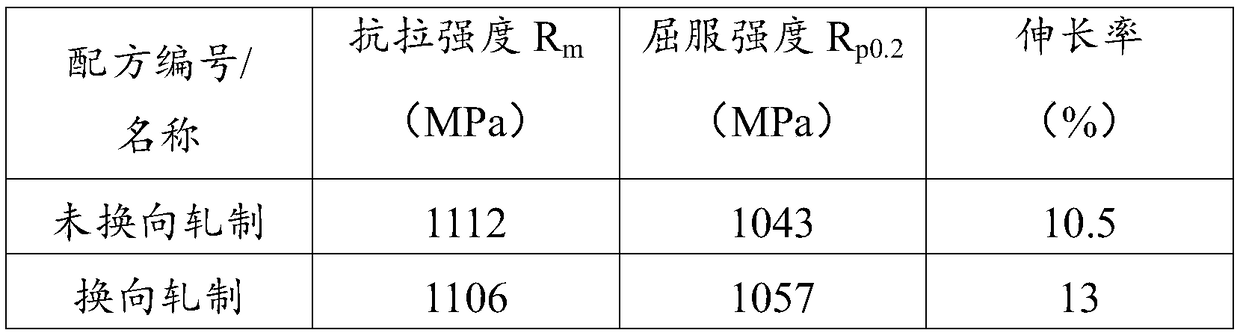

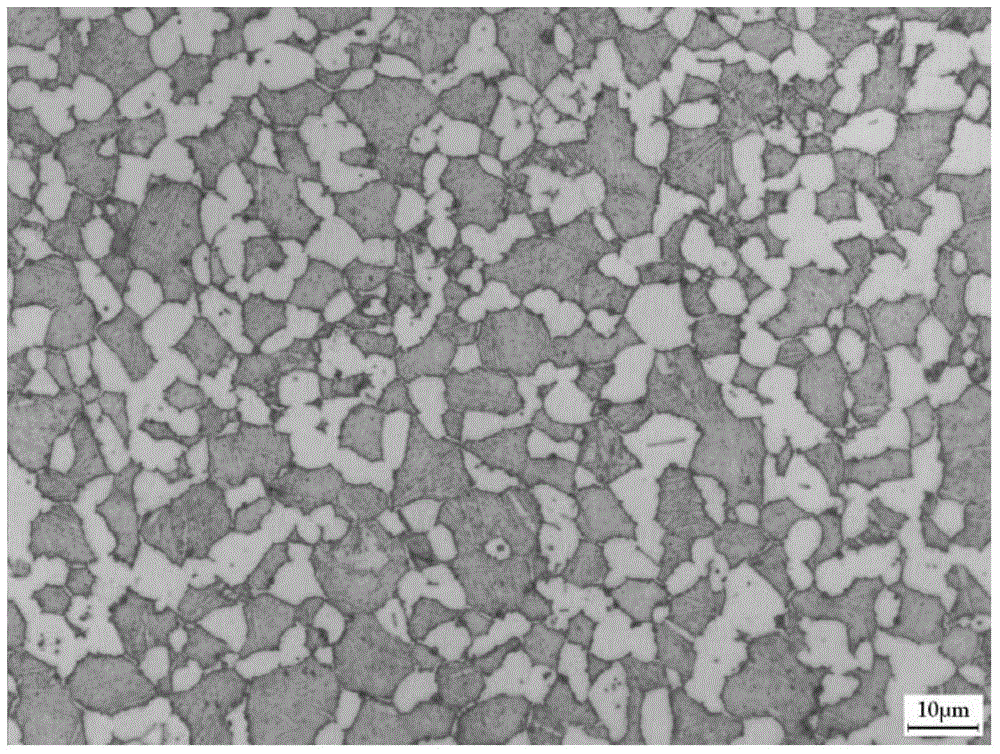

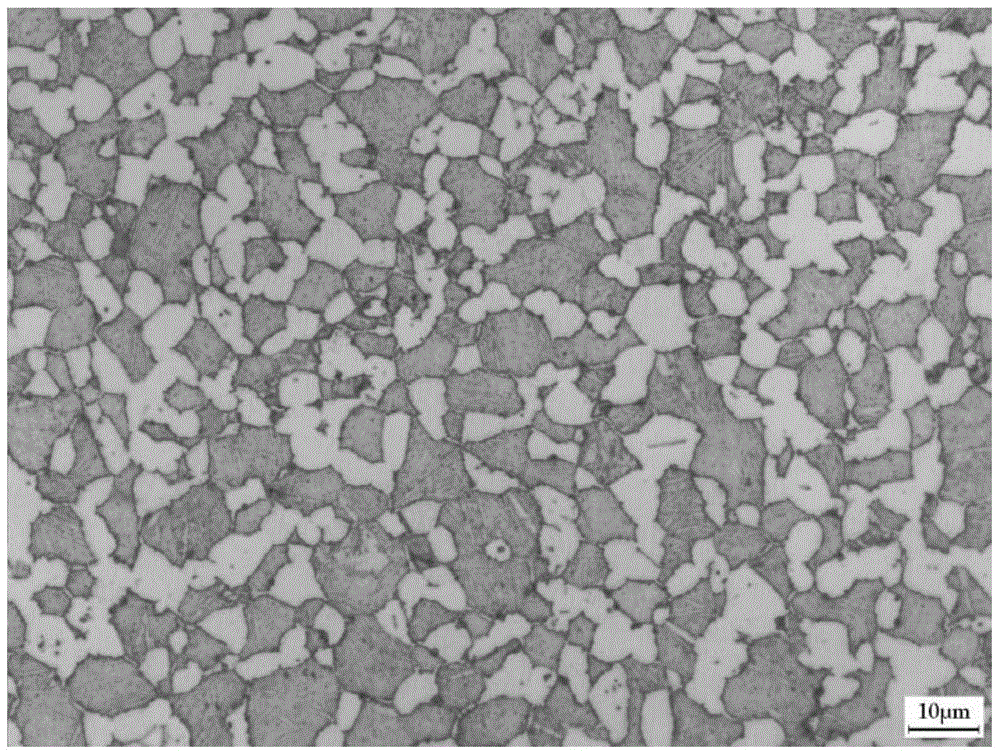

Titanium alloy plate and machining method

The invention relates to the technical field of titanium alloy preparation, in particular to a titanium alloy plate and a machining method. The titanium alloy plate is composed of, by weight, 5.5%-7.5% of Al, 0.5%-2% of Cr, 0.8%-2.8% of Fe, 0.5%-1.5% of Mo, 0.8%-2% of Sn, and the balance Ti and inevitable impurities. The titanium alloy plate provided by the invention has good overall performance,the manufacturing cost is reduced with selection of cheap raw materials each to obtain, and titanium alloys of different toughness levels are obtained through densifying treatment on ingots and control over technical conditions of rolling treatment and heat treatment.

Owner:北京德勤伟业航空投资管理有限公司

Toughened epoxy adhesive capable of being reprocessed and recycled and curing method

ActiveCN110982464AAchieve fixRealize reprocessing recyclingMacromolecular adhesive additivesEpoxy resin adhesivesEndcappingPolymer science

The invention relates to a toughened epoxy adhesive capable of being reprocessed and recycled and a curing method. The toughened epoxy adhesive capable of being reprocessed and recycled comprises thefollowing raw material components in parts by mass: 100 parts of epoxy resin, 15-35 parts of diaminodiphenyl disulfide serving as a curing agent and 20-70 parts of aromatic amino-terminated polysulfide resin serving as a toughening agent, wherein the raw material of the toughening agent aromatic amino terminated polysulfide resin comprises the following components in parts by mass: 100 parts of sulfydryl terminated liquid polysulfide resin, 6-25 parts of diaminodiphenyl disulfide, 0.1 part of tertiary amine, 5 parts of hydrogen peroxide and 150 parts of methane dioxide as a solvent; the curingagent and the toughening agent both contain the same reversible covalent bond, so that the dynamic reversibility of the whole cross-linked structure is realized, the screenwork rearrangement is initiated to enable the epoxy adhesive to have reprocessability and recoverability, and the main performance retention rate after three cycles exceeds 90%; and the problems of environmental pollution and resource waste caused by waste high polymer materials can be effectively relieved.

Owner:NANJING INST OF TECH

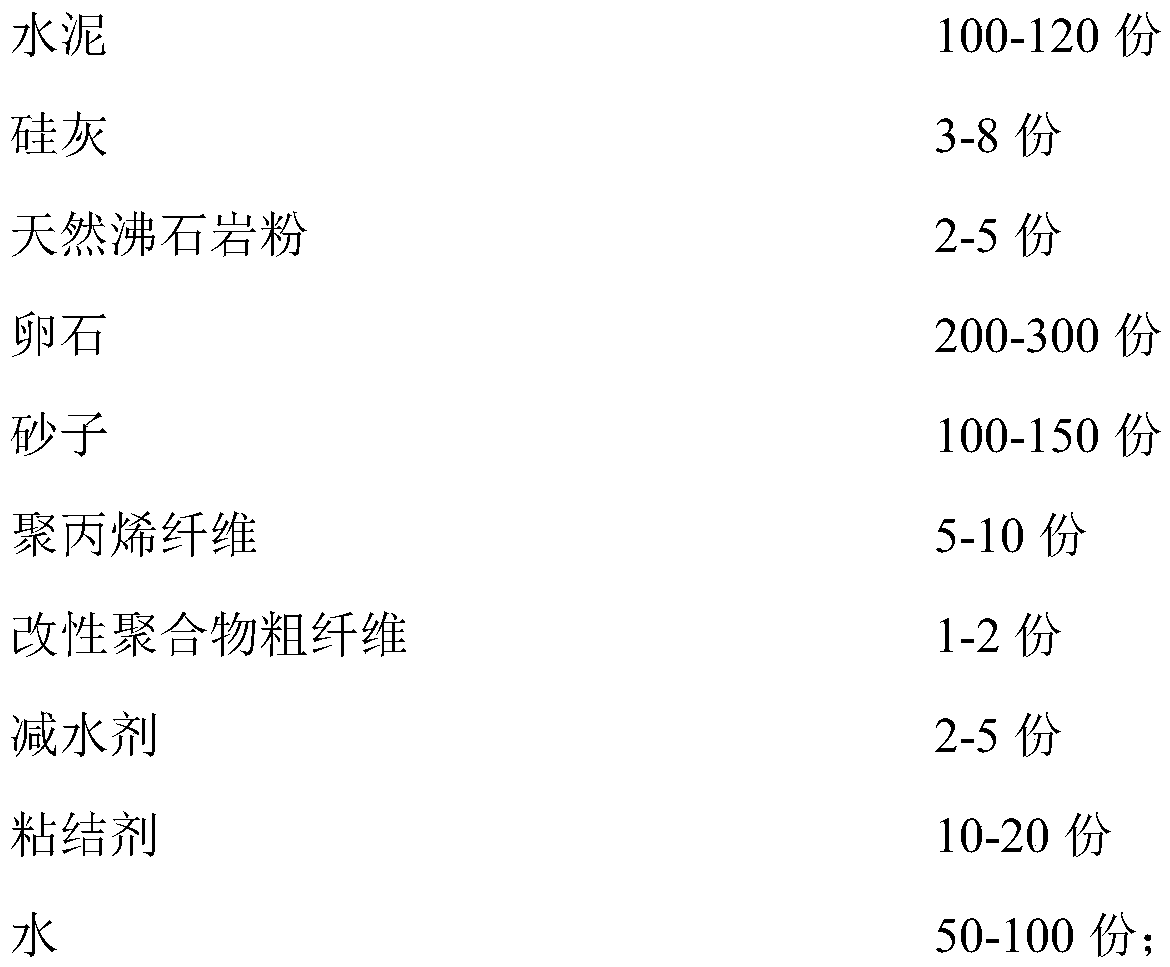

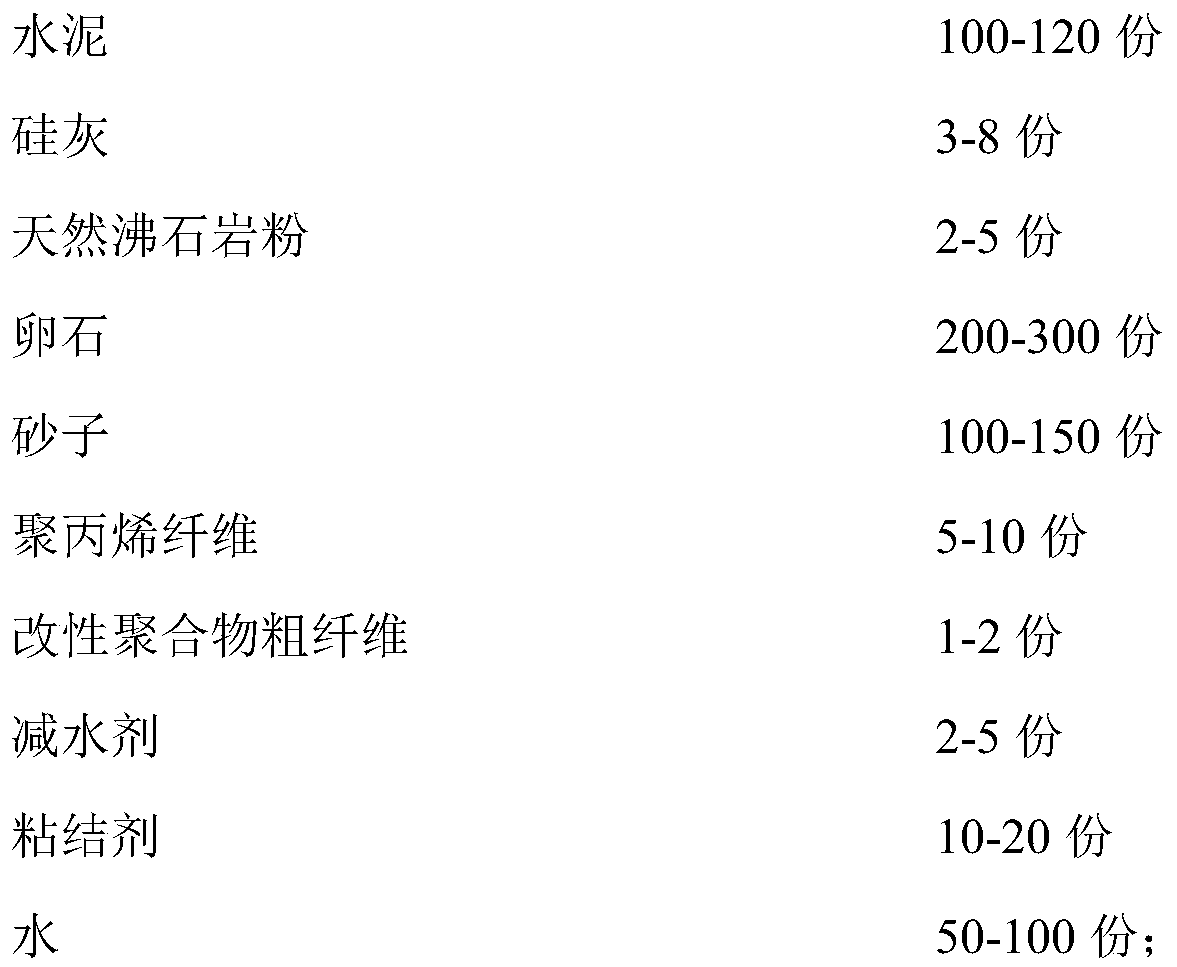

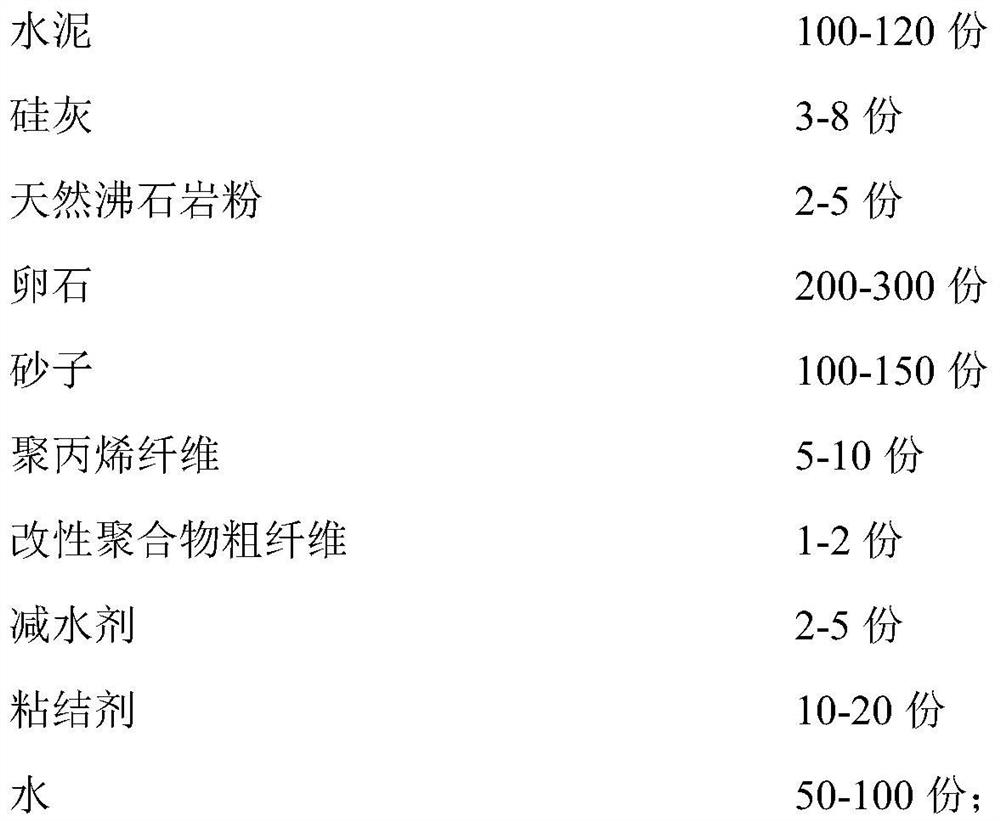

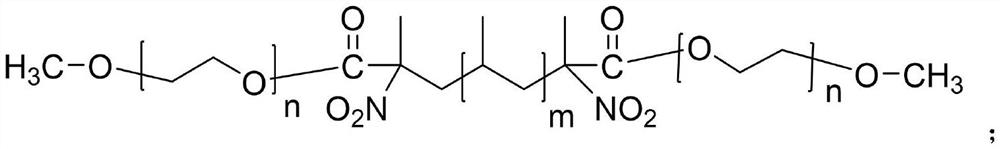

Sprayed concrete containing high polymer modified fibers

ActiveCN111217572AImprove cohesionImprove flexibilityMonocomponent synthetic polymer artificial filamentCrude fibrePolymer science

The invention relates to a sprayed concrete containing high polymer modified fibers. The sprayed concrete is prepared from cement, silica fume, natural zeolite rock powder, pebbles, sands, polypropylene fibers, modified polymer crude fibers, a water reducing agent, a binder and water. The modified polymer crude fibers prepared from a polypropylene-polyethylene glycol block polymer, and has excellent cohesiveness to a cement matrix; and the distribution uniformity of the modified high polymer crude fibers in the cement matrix is also improved, so that the impact strength, wear resistance and slump loss resistance of the sprayed concrete are obviously improved.

Owner:广州天达混凝土有限公司

Toughened modified material for PE pipes and preparation method thereof

InactiveCN110734598AImprove flexibilityImprove flexibility (elongation at breakGroup 5/15 element organic compoundsElastomerOctene

The invention discloses a toughened modified material for PE pipes. The toughened modified material for PE pipes is prepared from the following raw materials in parts by weight: 90-100 parts of polyethylene resin, 5-7 parts of a modified polyethylene octene co-elastomer, 8-10 parts of modified montmorillonite, 3-4 parts of maleic anhydride grafted polyethylene, 0.3-0.5 part of an antioxidant, 1-2parts of a lubricant and 1-2 parts of a plasticizer. The invention also discloses a preparation method of the toughened modified material. According to the invention, PE resin is used as a material matrix; the modified montmorillonite and the modified elastomer material are added into the matrix for reinforcement and toughening, the modified montmorillonite can be uniformly dispersed in the PE matrix to achieve the effects of reinforcement and toughening, oxygen can be blocked, CO can be converted into non-toxic gas, and the modified montmorillonite and a flame retardant have a synergistic effect to achieve the effect of enhancing the flame retardant effect; the prepared composite material has excellent toughness and flame retardant property, is suitable for toughening modification of PE pipes, and can effectively improve the toughness and flame retardant property of the PE pipes.

Owner:界首市奥胜达塑业有限公司

A kind of pla/ppc/hbp derivative blend and preparation method thereof

The invention discloses a PLA / PPC / HBP (poly lactic acid / propylene oxide copolymer / hyperbranched polymer derivative blend and a preparation method thereof. The preparation method includes that PLA resin, PPC resin and an HBP derivative are mixed for melt blending prior to cooling to indoor temperature to obtain the PLA / PPC / HBP derivative blend, and the chemical formula of the HBP derivative is as described in the formula I. The PLA / PPC / HBP derivative blend is prepared by adopting a melt-blending method, and breaking elongation of the blend is increased; when the addition amount of the HBP derivative is 2.0wt.%, the breaking elongation of the PLA / PPC / HBP derivative blend is increased by 367% under the condition that the tensile strength is essentially constant as compared with the pure PLA / PPC resin; delta Tg of PLA and PPC is decreased by 18.9DEG C to 15.69DEG C.

Owner:BEIJING TECHNOLOGY AND BUSINESS UNIVERSITY

Core-shell type nanostructured polymeric microsphere fire retardant, preparation method and application of core-shell type nanostructured polymeric microsphere fire retardant

The invention discloses core-shell type nanostructured polymeric microsphere fire retardant, a preparation method and application of the core-shell type nanostructured polymeric microsphere fire retardant. Through the method of seeded emulsion polymerization, monomers which include phosphorus and nitrogen elements and polymerizable monomers which include double bond are copolymerized to form macromolecular polymer microspheres with nanoscale and a core-shell structure. The macromolecular polymer microspheres can be used as fire retardant, achieves macromolecule quantization of micromolecule fire retardant, and move and running away of the fire retardant in the process of use can be reduced. Compared with traditional additive fire retardant, the core-shell type nanostructured polymeric microsphere fire retardant has the advantages that compatibility of the fire retardant and macromolecular matrixes are improved, and long flame retardant property of materials can be kept. Through adjustment of the proportion of two monomers in the process of preparation, the core-shell structure of the polymeric microspheres can be changed to meet the scattered need in different macromolecular matrixes. Dispersion and flame retardant properties are improved. In addition, the core-shell type nanostructured polymeric microsphere fire retardant has toughening effects to the macromolecular matrixes.

Owner:苏州安鸿泰新材料有限公司

A kind of toughening type epoxy resin curing agent and its preparation method and application

The invention provides a toughening epoxy resin curing agent which is prepared from a compound A, a compound B and amino polyether, wherein polyamine and cyclic carbonate compound are subjected to a cyclic-opening reaction to obtain the compound A, and polyamine and lactone compound are subjected to a cyclic-opening reaction to obtain the compound B. The invention further provides a preparation method and application of the toughening epoxy resin curing agent. The toughening epoxy resin curing agent is simple in preparation method and low in cost, and has the advantages of good toughening effect, low viscosity, solidification at the room temperature, colorlessness, transparency, environment friendliness and the like.

Owner:JIANGSU SOBUTE NEW MATERIALS +1

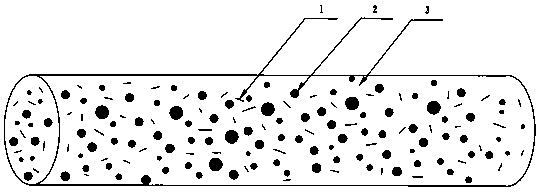

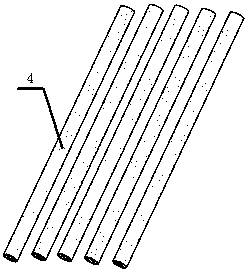

A kind of fiber toughened tungsten carbide welding rod

ActiveCN110666389BEffective tougheningSimple processWelding/cutting media/materialsSoldering mediaCarbide siliconButt welding

The invention discloses a fiber-toughened tungsten carbide electrode. The raw materials for preparing the electrode include the following components in mass percentage: 2-4wt% toughening fiber, 60-70wt% tungsten carbide particles, 24-34wt% nickel-chromium base Alloy powder, 2~4wt% binder, said binder includes the following components in mass percentage: 5~15wt% PMMA, 85~95wt% acetone, and its manufacturing method includes using organic fiber or silicon carbide fiber butt electrode Toughening, so that it is not easy to break and break during use, the toughening fiber is added to the powder composed of tungsten carbide particles and nickel-chromium-based alloy powder used in the electrode matrix, and then the binder is added to mix evenly, and squeezed out by a pressure coating machine After being cut into a single electrode or curled into a disc, a high-strength and high-toughness tungsten carbide electrode can be obtained after drying. The tungsten carbide electrode of the present invention uses toughening fibers to have a good toughening effect on the electrode; less binder is used , low residual carbon content, so that the finished electrode products can be rolled into disks for use, and the process is simple and the cost is low.

Owner:ZHENGZHOU RES INST OF MECHANICAL ENG CO LTD

Preparation method and material of polylactic acid-natural rubber porous material by microporous injection molding

The invention belongs to the technical field of micropore injection molding foaming, and discloses a method and a material for preparing a polylactic acid-natural rubber porous material by micropore injection molding foaming. Grafts are prepared through emulsion polymerization; dried polylactic acid particles and glycidyl methacrylate-natural rubber grafts are mixed in proportion, and are molten and mixed by adopting a double-screw extruder for extrusion and granulation; the micropore injection molding foaming is performed on the mixed particles by adopting an injection molding machine with agas compression unit; and with a supercritical CO2 fluid as a foaming agent, a polylactic acid / natural rubber porous material is obtained. Polylactic acid is roughened and modified by adopting naturalrubber; and the method of grafting glycidyl methacrylate on the natural rubber is used for improving polarity of the natural rubber and compatibility with the polylactic acid. The foaming process issimple; the obtained foaming material is more uniform in bubble size and distribution; and meanwhile, the foaming material is better in toughness.

Owner:贵州黔城黔测检测技术有限公司

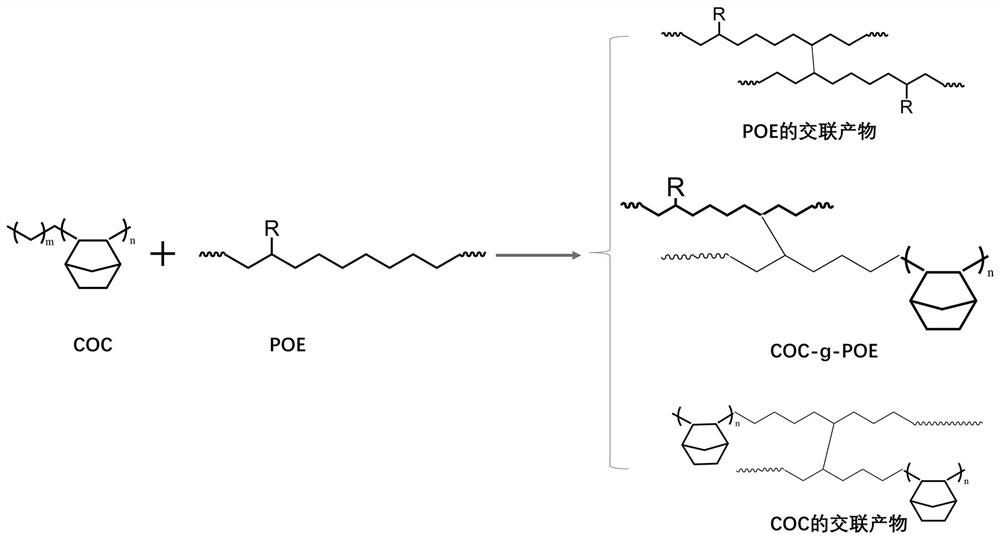

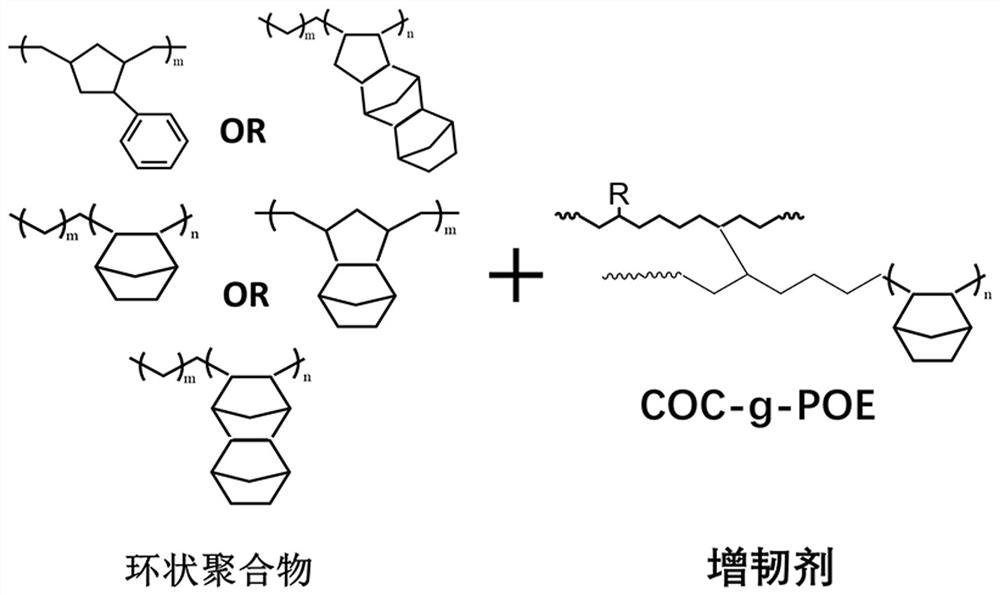

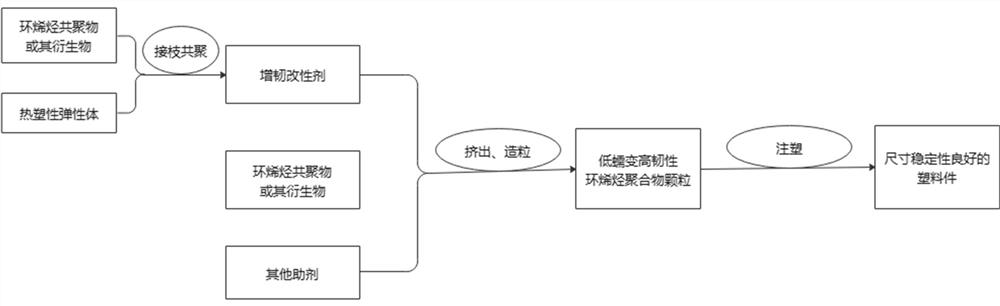

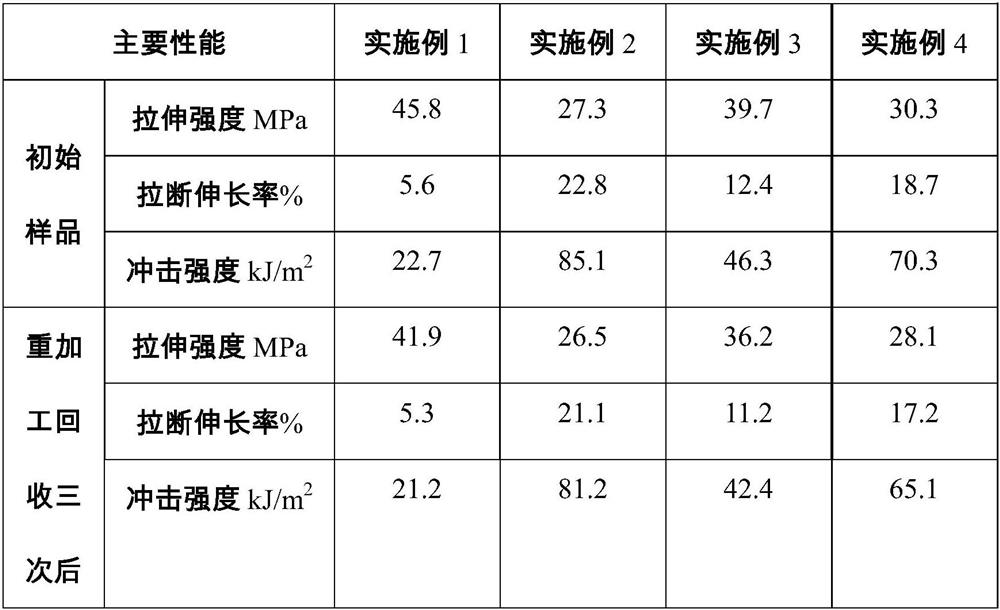

Low-creep high-toughness cycloolefin copolymer composite material and preparation method thereof

ActiveCN114479333AImprove creep resistanceGood dimensional stabilityPlastic recyclingCycloalkenePerylene derivatives

The invention discloses a low-creep high-toughness cycloolefin copolymer composite material which comprises the following components in parts by weight: 100 parts of cycloolefin copolymer resin or derivatives thereof, 5-30 parts of a toughening modifier and 0.1-3 parts of an anti-aging agent. The invention also provides a preparation method of the cycloolefin copolymer. The preparation method comprises the following steps: firstly, preparing the toughening modifier by using a melt grafting method, and then preparing the toughening modifier and cycloolefin copolymer resin or derivatives thereof into the low-creep high-toughness cycloolefin copolymer composite material by using a twin-screw extruder. The recycled cycloolefin copolymer can be used as a main raw material, so that the toughness of the recycled material is improved, the problem of resource shortage is solved, and the environmental problem is also solved.

Owner:XIAMEN MAKE LOCKS MFGR CO LTD +1

A kind of toughened epoxy adhesive that can be reprocessed and recycled and its curing method

ActiveCN110982464BAchieve fixRealize reprocessing recyclingMacromolecular adhesive additivesEpoxy resin adhesivesPolymer scienceFirming agent

This application relates to a toughened epoxy adhesive that can be reprocessed and recycled and its curing method. The raw materials of the toughened epoxy adhesive that can be reprocessed and recycled are proportioned in parts by mass: 100 parts of epoxy resin, 2 parts of curing agent 15-35 parts of aminodiphenyl disulfide and 20-70 parts of the toughening agent aromatic amine-terminated polysulfide resin, wherein the raw materials of the toughening agent aromatic amine-based polysulfide resin are proportioned in parts by mass: 100 parts of mercapto liquid polysulfide resin, 6 to 25 parts of diaminodiphenyl disulfide, 0.1 part of tertiary amine, 5 parts of hydrogen peroxide, and 150 parts of dioxymethane as a solvent; both the curing agent and the toughening agent contain the same The reversible covalent bond realizes the dynamic reversibility of the entire cross-linked structure, which triggers network rearrangement and makes the epoxy adhesive recyclable. After three cycles, the retention rate of the main properties exceeds 90%, which can effectively relieve waste polymers. Environmental pollution and waste of resources caused by materials.

Owner:NANJING INST OF TECH

Fiber toughening tungsten carbide welding rod

ActiveCN110666389AStrong toughnessNot easy to break and breakWelding/cutting media/materialsSoldering mediaCarbide siliconSic fiber

The invention discloses a fiber toughening tungsten carbide welding rod. Raw materials for preparing the welding rod comprise the following components of 2wt%-4wt% of toughening fibers, 60wt%-70wt% oftungsten carbide particles, 24wt%-34wt% of nickel-chromium-based alloy powder, 2wt%-4wt% of binder, and the binder comprises the following components of 5wt%-15wt % PMMA and 85wt%-95wt% of acetone. Amanufacturing method of the fiber toughening tungsten carbide welding rod comprises the steps that organic fibers or silicon carbide fibers are adopted for toughening the welding rod, thus the welding rod is not liable to be broken and fractured in the use process, the toughening fibers are added into powder composed of the tungsten carbide particles and the nickel-chromium-based alloy powder used for a welding rod substrate, then the binder is added, the components are mixed evenly, extrusion molding is conducted through a pressure coating machine, one single welding rod is obtained throughcut-off operation, or a reel is obtained through winding, and the high-strength high-toughness tungsten carbide welding rod is obtained after drying. The toughening fibers are adopted for achieving agood toughening effect on the tungsten carbide welding rod, little binder is used, the carbon residual amount is low, thus the manufactured welding rod product can be wound into the reel to be used, the technology is simple, and cost is low.

Owner:ZHENGZHOU RES INST OF MECHANICAL ENG CO LTD

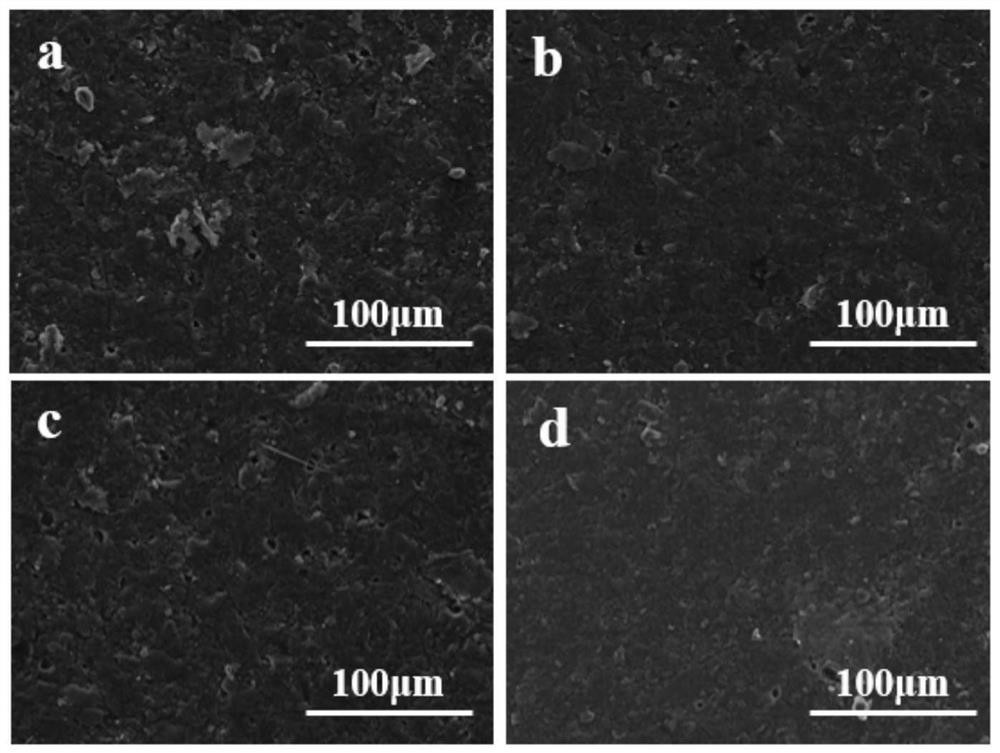

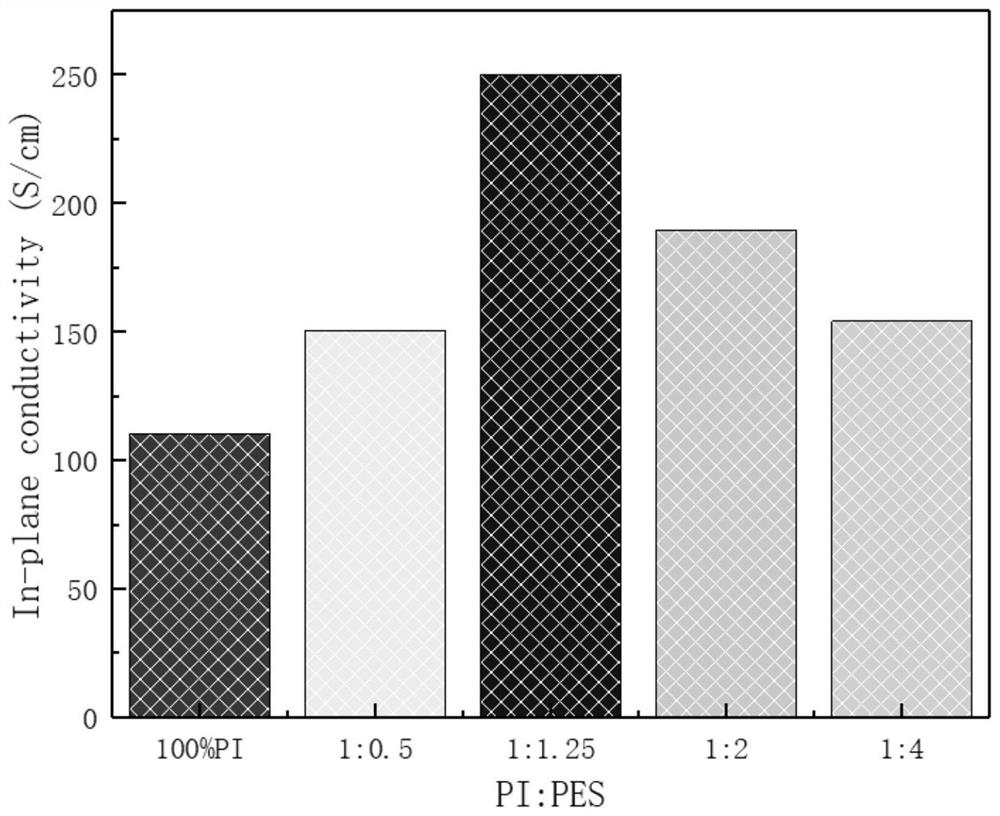

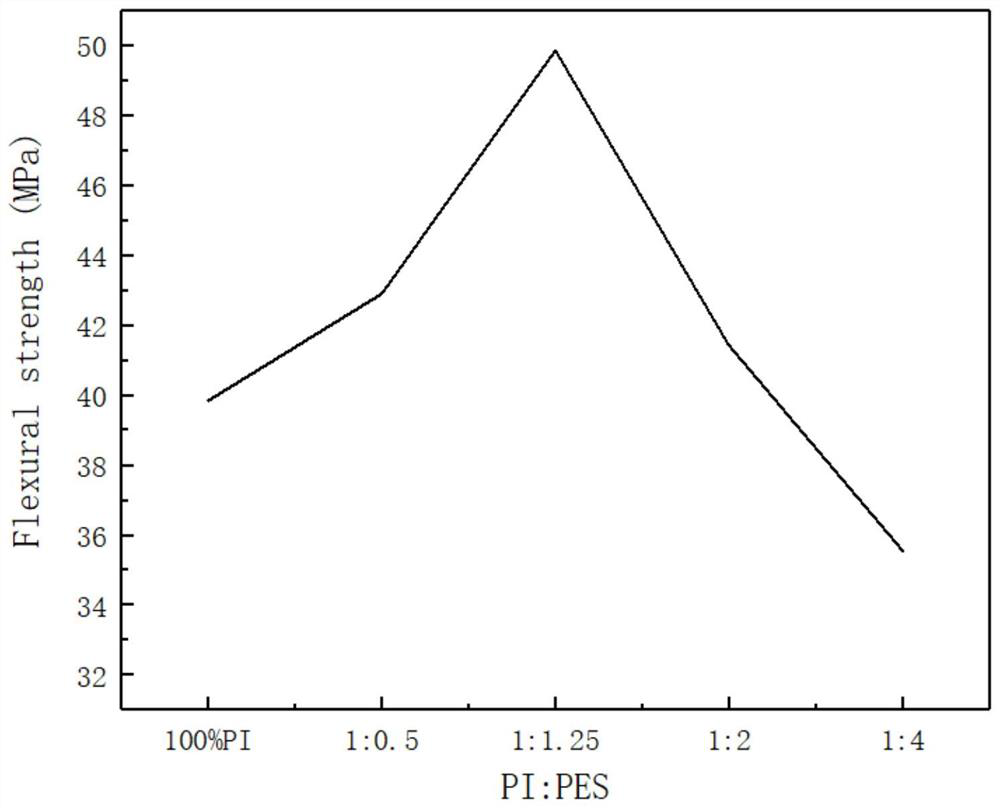

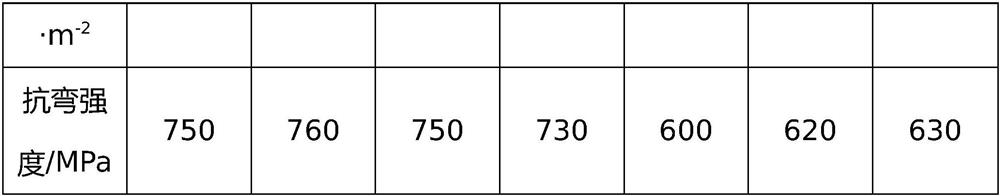

Expanded graphite/polyimide-polyether sulfone composite bipolar plate and preparation method thereof

The invention discloses an expanded graphite / polyimide-polyether sulfone composite bipolar plate and a preparation method thereof. Polyimide, polyether sulfone and expanded graphite are mixed through a wet method, and a mixed material is obtained; the mixed material is sequentially subjected to drying, mold pressing and curing, the expanded graphite / polyimide-polyethersulfone composite bipolar plate with high bending strength and high conductivity is obtained, and the defects that an existing traditional composite graphite bipolar plate is prone to brittle failure, high in hydrogen permeability and the like can be overcome.

Owner:广东氢发新材料科技有限公司

A kind of high tenacity polylactic acid composite material and preparation method thereof

The invention discloses a high-toughness polylactic acid composite material. The high-toughness polylactic acid composite material is composed of the following components in parts by weight: 58-98.9 parts of polylactic acid (PLA) resin, 0.5-20 parts of a butadiene / butyl acrylate segmented copolymer, 0.5-20 parts of wood flour and 0.1-2 parts of a chain extender. The high-toughness polylactic acid composite material adopts the butadiene / butyl acrylate segmented copolymer as a toughening agent so as to realize the aim of effectively toughening PLA resin and overcome the fragile defect of PLA; meanwhile, the wood flour and the chain extender are adopted so that the strength and the rigidity of the material are improved; and the PLA is toughened and the strength and the rigidity of the material are kept as much as possible. The invention further discloses a preparation method for the high-toughness polylactic acid composite material; a double-screw extruder is used for fusing, co-extruding and granulating; and the preparation method is simple in equipment, convenient to operate, easy to control and low in cost and the toughness of the PLA can be improved very well.

Owner:杭州卓普新材料科技有限公司

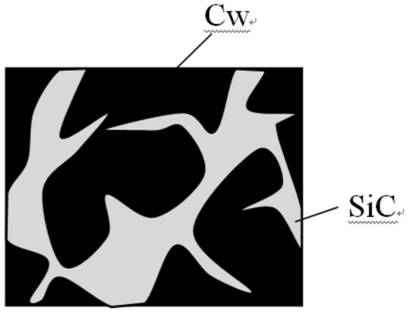

A kind of preparation method of charcoal reinforced silicon carbide matrix composite material

The invention discloses a method for preparing a charcoal-reinforced silicon carbide-based composite material, which comprises the following steps: placing the charcoal in an impregnating agent A for the first impregnation, followed by the first curing to obtain a first-time cured green body, Then put the first cured green body in the impregnating agent B for the second impregnation, and then perform the second curing to obtain the second cured green body, and finally wrap the second cured green body in carbon cloth. The charcoal-reinforced silicon carbide-based composite material can be obtained through sintering treatment, wherein the ceramic precursor in the impregnating agent is polymethylsilane, and the charcoal-reinforced silicon carbide-based composite material is prepared by adopting the precursor transformation method pioneered by the present invention, and the obtained charcoal-reinforced silicon carbide The matrix composite material has high density, and the density is 1.85g / cm 3 Above, it has excellent mechanical strength, high temperature resistance, and wear resistance, and can replace carbon fiber reinforced ceramic materials in a wide range.

Owner:北京信汇碳硅科技有限公司

A heat-insulating insulator insulation shielding cover for electric power

ActiveCN105356367BInsulate the influenceEasy to installCoatingsApparatus for overhead lines/cablesWear resistantThermal insulation

The invention discloses an electric power heat insulation type insulator insulation shielding cover. The electric power heat insulation type insulator insulation shielding cover comprises an insulator shielding cover, a shielding cover covering plate, and a suspension clamp shielding cover, the insulator shielding cover is arranged in the U shape, edges of two side surfaces of the insulator shielding cover are provided with first fixing holes, the inner side of the lower part of the insulator shielding cover is provided with a base connecting groove, the insulator shielding cover is movably connected with the suspension clamp shielding cover via the base connecting groove, the shielding cover covering plate is arranged in the T shape, the shielding cover covering plate is provided with second fixing holes corresponding to the first fixing holes, the central part of the suspension clamp shielding cover is provided with a U-shaped metal shielding cover, the external surface of the metal shielding cover is provided with a U-shaped slipway, the inner part of the metal shielding cover is provided with wire clamp fixtures, and surfaces of the insulator shielding cover, the shielding cover covering plate, the suspension clamp shielding cover, and the metal shielding cover are all coated with high-temperature-resistant and wear-resistant insulation paints. According to the electric power heat insulation type insulator insulation shielding cover, the structure is simple, the operation is convenient, the shielding effect is good, and the safety factor is big.

Owner:国网河南省电力公司超高压公司 +1

A shotcrete containing polymer modified fibers

ActiveCN111217572BImprove cohesionImprove flexibilityMonocomponent synthetic polymer artificial filamentPolymer sciencePolymer modified

The invention relates to a shotcrete containing modified polymer fibers, comprising the following raw materials: cement, silica fume, natural zeolite rock powder, pebbles, sand, polypropylene fibers, modified polymer crude fibers, water reducing agent, viscose A binder and water; wherein, the modified polymer crude fiber is prepared from a block polymer of polypropylene-polyethylene glycol, and has excellent cohesion to a cement matrix; and the modified polymer The uniformity of the distribution of crude fiber in the cement matrix has also been improved, so that the impact strength, wear resistance and slump retention performance of shotcrete are significantly improved.

Owner:广州天达混凝土有限公司

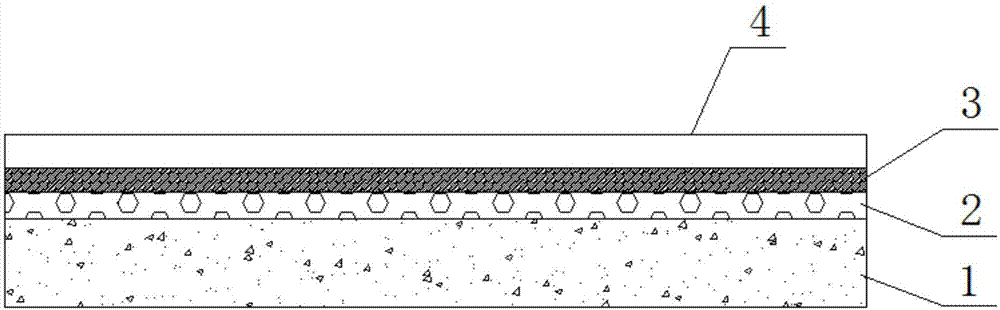

Road with long service life and construction method thereof

InactiveCN107572944AExtended service lifeEffective waterproofIn situ pavingsFiberPulverized fuel ash

The invention discloses a road with a long service life and a construction method thereof. The road comprises a base layer, wherein a waterproof layer is arranged on the upper surface of the base layer; a fireproof layer is arranged on the upper surface of the waterproof layer; a toughening layer is arranged on the upper surface of the fireproof layer. According to the construction method, payingoff leveling is performed; 30 to 40 parts of cement, 15 to 25 parts of stone sand, 10 to 20 parts of pulverized fuel ash and 35 to 55 parts of water are taken; after the uniform stirring, a base layeris flatly laid on the leveling ground; 25 to 45 parts of the cement, 8 to 12 parts of waterproof agents and 20 to 40 parts of the stone sand are taken; after the uniform stirring, one waterproof layer is flatly laid on the upper surface of the base layer; 30 to 50 parts of the cement, 10 to 30 parts of yellow sand, 5 to 15 parts of quartz sand, 5 to 10 parts of fireproofing agents and 30 to 50 parts of water are taken and are mixed; after the uniform stirring, one fireproof layer is flatly laid on the upper surface of the waterproof layer; 25 to 35 parts of the cement, 8 to 12 parts of the yellow sand, 5 to 10 parts of fiber and 25 to 45 parts of the water are taken; after the uniform stirring, one toughening layer is flatly laid onto the upper surface of the fireproof layer. The road hasthe advantages of fireproof performance, waterproof performance, long service life and the like.

Owner:安徽安能建设集团有限公司

A kind of high-performance environment-friendly composite building ceramic material and preparation method thereof

Owner:梅州市溪山陶瓷有限公司

A heat-resistant titanium alloy

The invention discloses a heat-resistant Ti alloy. The heat-resistant Ti alloy comprises components in percentage by mass as follows: 10.0%-12.0% of Al, 5.0%-6.0% of Nb, 3.0%-4.0% of Zr, 1.5%-2.5% of Mo, 1.5%-2.5% of Sn, 0.5%-1% of Ta, 0.2%-0.4% of Si, 0.04%-0.08% of C and the balance of Ti and inevitable impurities. The content of Al in the heat-resistant Ti alloy is between the content of Al in a traditional heat-resistant Ti alloy and the content of Al in a Ti-Al intermediate compound alloy, the usage temperature of the Ti alloy is increased by appropriately sacrificing plasticity of the traditional heat-resistant Ti alloy, and the heat-resistant Ti alloy has the good comprehensive performance and can meet requirements for long-term usage at the temperature of 650 DEG C.

Owner:NORTHWEST INSTITUTE FOR NON-FERROUS METAL RESEARCH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com