A shotcrete containing polymer modified fibers

A technology of shotcrete and polymer modification, applied in the chemical characteristics of fibers, single-component synthetic polymer rayon, textiles and papermaking, etc., can solve the problems of poor compatibility, weak cohesion, cracking, etc. Excellent slump retention performance, enhanced adsorption, better cohesion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

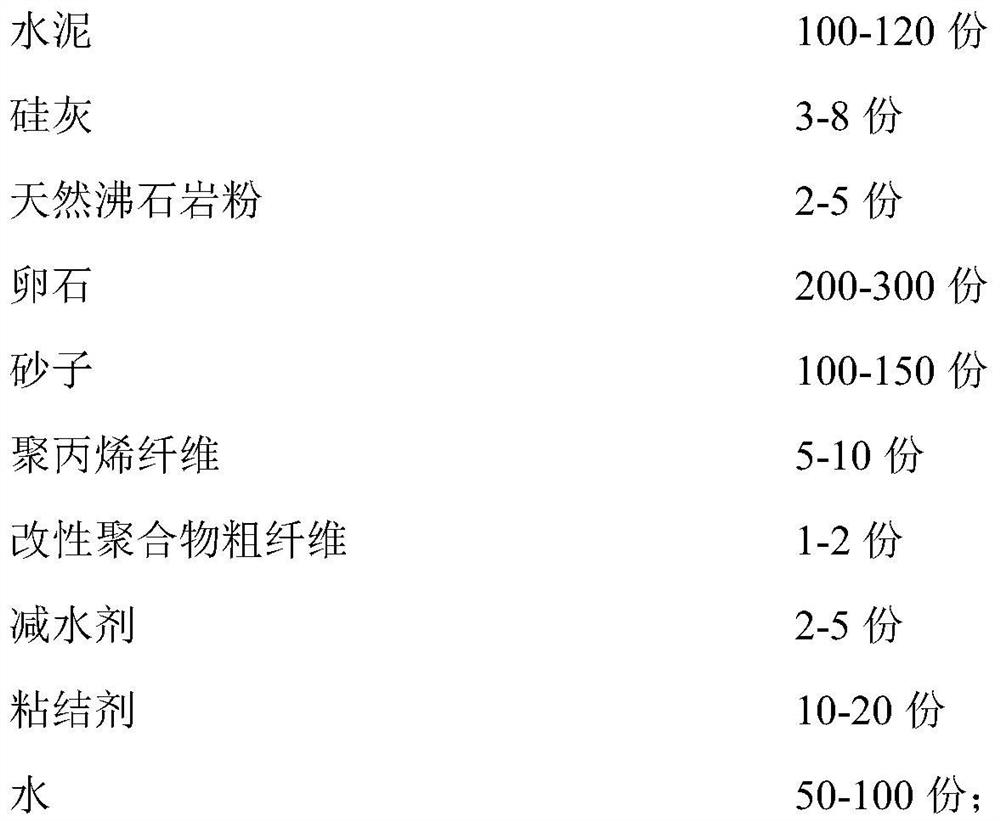

[0038] A shotcrete containing polymer modified fibers, comprising the following raw materials in parts by mass:

[0039]

[0040] in,

[0041] The modified polymer crude fiber is prepared from a polypropylene-polyethylene glycol block polymer, and the segment of the polyethylene glycol is terminated by monomethyl ether.

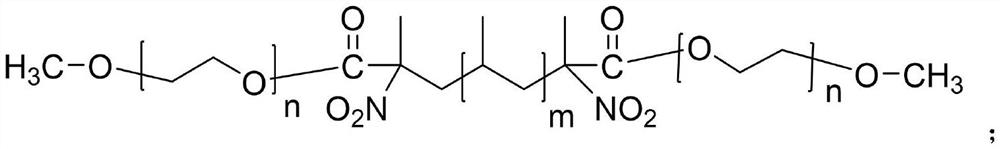

[0042] The polypropylene-polyethylene glycol block polymer has the following chemical structure:

[0043]

[0044] in,

[0045] m is about 3000;

[0046] n is 5.

[0047] The cement was Portland cement with a strength of 42.5.

[0048] The polyacrylic acid water reducing agent was purchased from Sumitomo, Japan, and the brand name is Carbomer HV-501.

[0049] The preparation method of the modified polymer crude fiber is as follows:

[0050] S1. Blend polypropylene with a degree of polymerization of about 3000 with 2 times the mass of concentrated nitric acid, react at 80°C for 1 hour, then pour into water, filter and dry in an oven to obtain a pol...

Embodiment 2

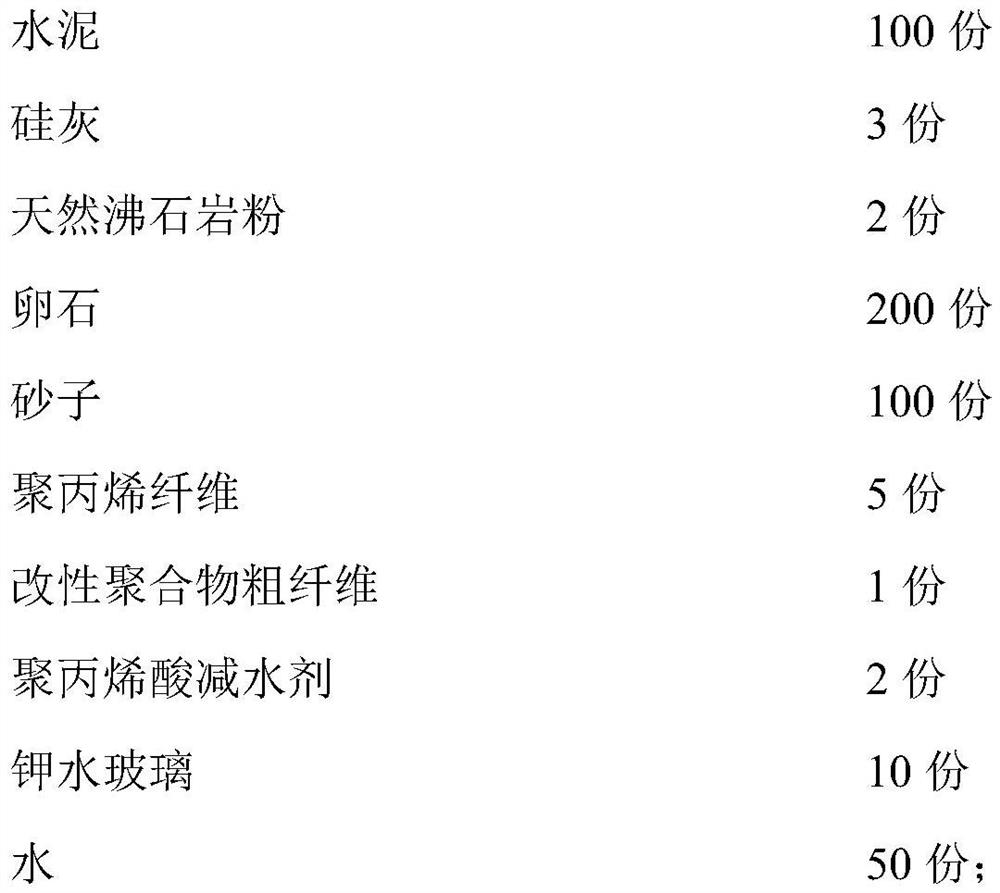

[0056] A shotcrete containing polymer modified fibers, comprising the following raw materials in parts by mass:

[0057]

[0058] in,

[0059] The modified polymer crude fiber is prepared from a polypropylene-polyethylene glycol block polymer, and the segment of the polyethylene glycol is terminated by monomethyl ether.

[0060] The polypropylene-polyethylene glycol block polymer has the following chemical structure:

[0061]

[0062] in,

[0063] M is about 8000;

[0064] n is 10.

[0065] The cement is Portland cement with a strength of 42.5R.

[0066] The polyether type polycarboxylate water reducing agent was purchased from Kaidi Building Materials, and the brand name is KD-501.

[0067] The preparation method of the modified polymer crude fiber is as follows:

[0068] S1. Polypropylene with a degree of polymerization of about 8000 is blended with 3 times the mass of concentrated nitric acid, reacted at 100° C. for 3 hours, then poured into water, filtered and ...

Embodiment 3

[0074] A shotcrete containing polymer modified fibers, comprising the following raw materials in parts by mass:

[0075]

[0076]

[0077] in,

[0078] The modified polymer crude fiber is prepared from a polypropylene-polyethylene glycol block polymer, and the segment of the polyethylene glycol is terminated by monomethyl ether.

[0079] The polypropylene-polyethylene glycol block polymer has the following chemical structure:

[0080]

[0081] in,

[0082] M is about 6000;

[0083] n is 8.

[0084] The cement was Portland cement with a strength of 52.5R.

[0085] The polyacrylic acid water reducing agent was purchased from Sumitomo, Japan, and the brand name is Carbomer HV-501.

[0086] The preparation method of the modified polymer crude fiber is as follows:

[0087] S1. Blend polypropylene with a degree of polymerization of about 6000 with 2 times the mass of concentrated nitric acid, react at 90° C. for 2 hours, then pour into water, filter, and dry in an ove...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com