Titanium alloy plate and machining method

A processing method and technology of titanium alloy, applied in the field of titanium alloy sheet and processing, can solve the problems of unsatisfactory comprehensive mechanical ability and high manufacturing cost of titanium alloy, and achieve the effects of improving room temperature and high temperature strength, reducing weight and improving elastic modulus

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

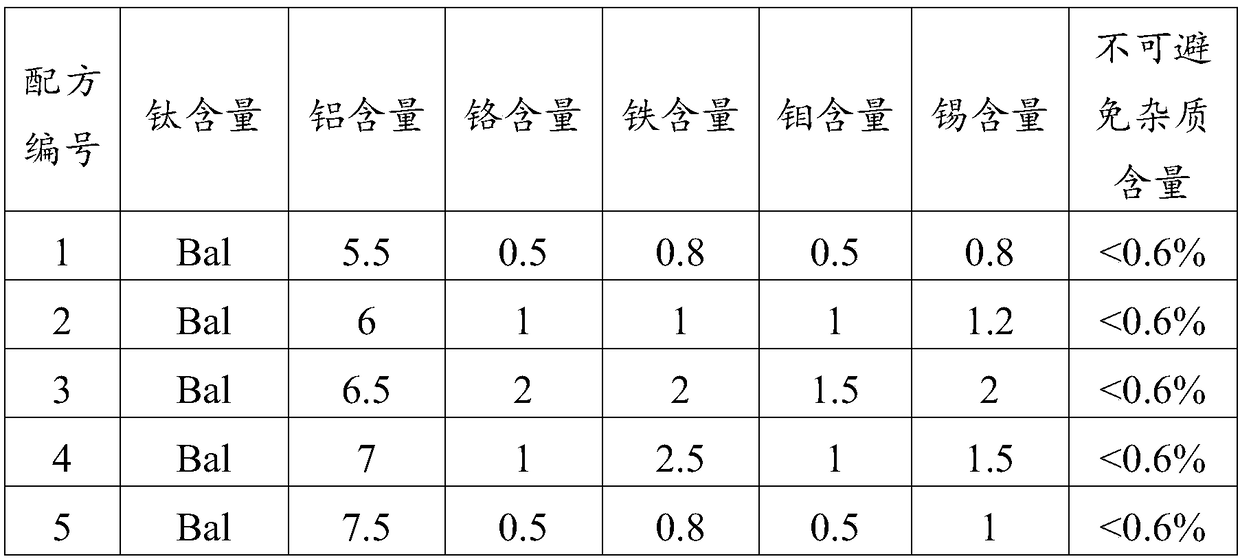

[0030] This embodiment provides a titanium alloy plate, which is composed of the following components in weight percentage: 5.5% to 7.5% Al, 0.5% to 2% Cr, 0.8% to 2.8% Fe, 0.5% to 1.5% Mo, 0.8% ~2% Sn, the balance being Ti and unavoidable impurities.

[0031] In this embodiment, 5.5% to 7.5% of the α-stabilizing element Al is added to increase the room temperature and high temperature strength of the alloy, reduce the weight of the alloy, and increase the elastic modulus of the alloy. Among them, when the weight percentage of Al is lower than 5.5%, superplasticity cannot be guaranteed in a wide temperature range, and when the weight percentage of Al is higher than 7.5%, Ti 3 Al precipitates and workability deteriorates. Moreover, it can be understood that the weight percentage of Al can vary in a range of 0.1%, that is, the weight percentage of Al can be 5.5%, 5.6%, 5.7%...7.4%, 7.5%.

[0032] In this embodiment, 0.5%-2% of eutectoid β-stabilizing element Cr is added to inc...

example 1

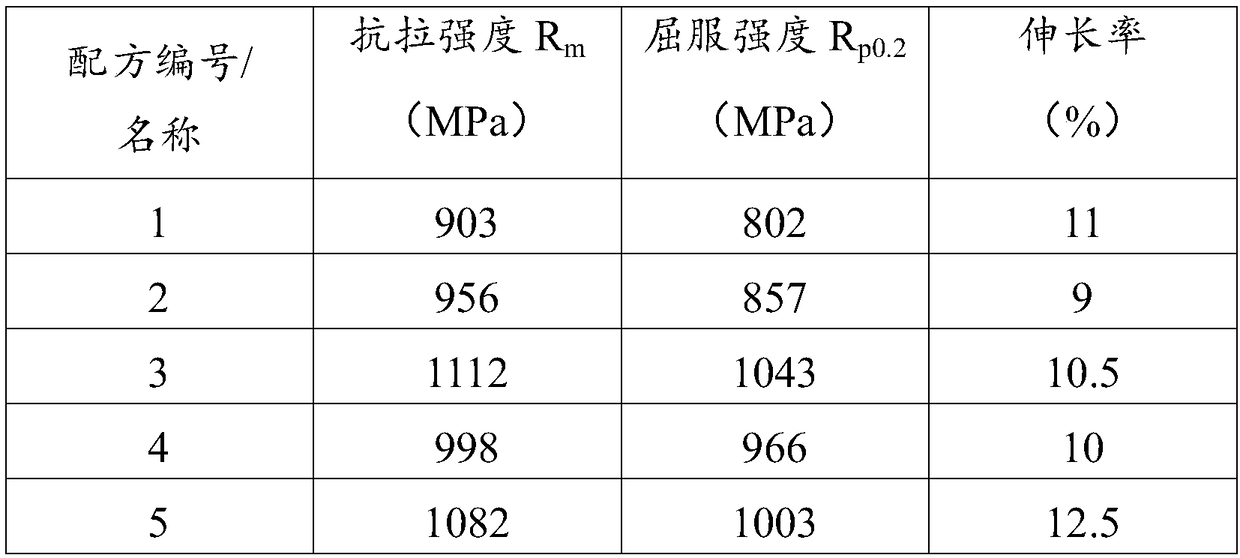

[0037] Example 1: The titanium alloy plate is composed of the following components in weight percentage: 5.5% Al, 0.5% Cr, 0.8% Fe, 0.5% Mo, 0.8% Sn, and the balance is Ti and unavoidable impurities. The tensile strength R of the titanium alloy plate m (MPa), yield strength R p0.2(MPa), elongation (%) are: 903MPa, 802MPa and 11%, respectively.

example 2

[0038] Example 2: The titanium alloy plate is composed of the following components in weight percentage: 6.0% Al, 1.0% Cr, 1.0% Fe, 1.0% Mo, 1.2% Sn, and the balance is Ti and unavoidable impurities. The tensile strength R of the titanium alloy plate m (MPa), yield strength R p0.2 (MPa), elongation (%) are: 956MPa, 857MPa and 9%, respectively.

PUM

| Property | Measurement | Unit |

|---|---|---|

| yield strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com