Patents

Literature

32results about How to "Easy processing and application" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

High adjacent position phenolic resin for toughness reinforcing of elastic body and method for producing the same

The invention discloses high ortho position formaldehyde phenol resin with elastic toughened, wherein, the elastic body reaches nm-level decentralization in the formaldehyde phenol resin, the content of the elastic body is 3 to 10 percent, and the ortho-para-ratio of the resin is 2.5 to 5. The invention also provides a preparation method of the formaldehyde phenol resin. The invention is characterized in that the high ortho position formaldehyde phenol resin with elastic toughened is prepared by adopting the way of in situ polymerization. Compared with the prior art, the high ortho position formaldehyde phenol resin with elastic toughened of the invention has the advantages of good fluidity, rapid curing and shaping, excellent toughness, simple preparation method, easy practice, etc.

Owner:ZHEJIANG JIAMIN PLASTIC

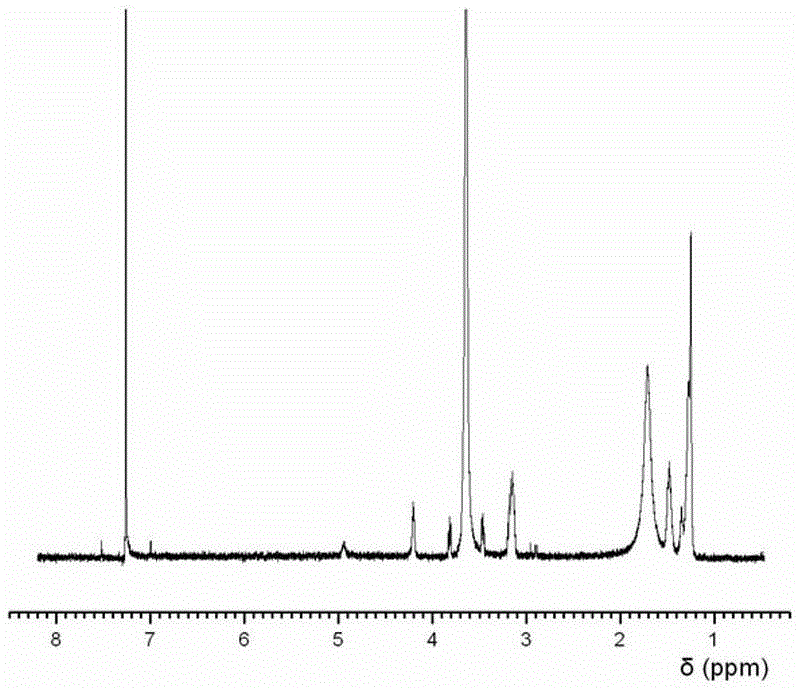

Application of polyurethane urea hydrogel with shape memory function

ActiveCN103539919AProvides effective mechanical propertiesEasy processing and applicationTemperature responsePolyethylene glycol

The invention relates to an application of a polyurethane urea hydrogel with a shape memory function. The polyurethane urea hydrogel is a copolymer of polyethylene glycol, diisocyanate and diamine. The polyurethane urea hydrogel provided by the invention has a temperature response shape memory function and a water response shape memory function at room temperature, and is capable of realizing deformation generation, fixation and restoration under the conditions of room temperature and water medium by means of good tensile properties of the prepared hydrogel and crystalline phase transformation of PEG (Polyethylene Glycol) in the process of dehydration crystallization and water-absorption decrystallization. The polyurethane hydrogel also has the characteristics of large elongation rate and high tensile strength and has application prospects in biomedical hydrogels, tissue engineering, hydrogel bracket materials and biomedical devices endowed with the shape memory function.

Owner:SUZHOU UNIV

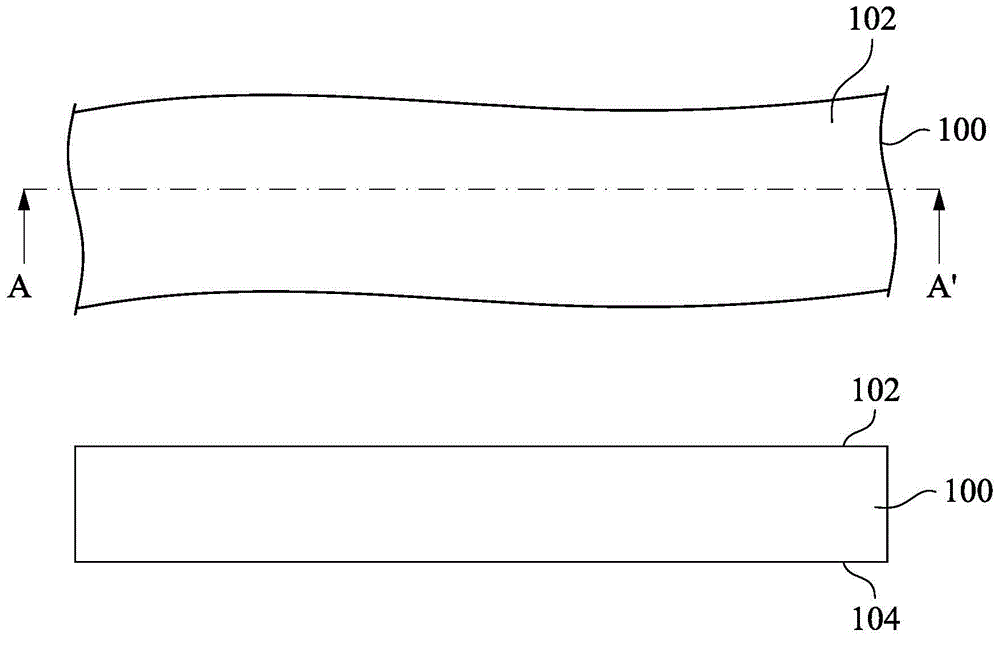

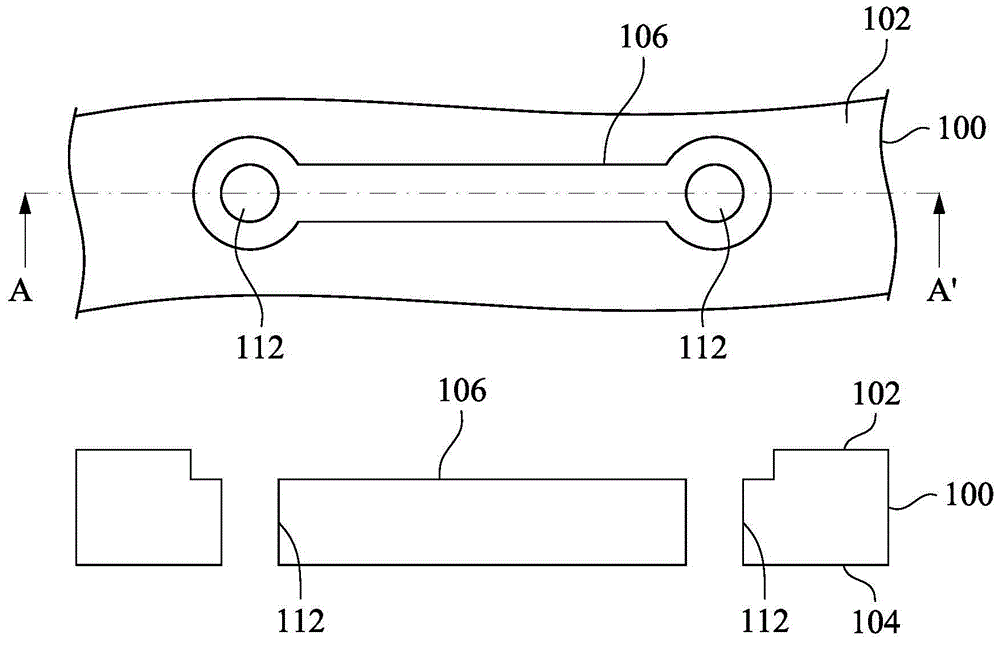

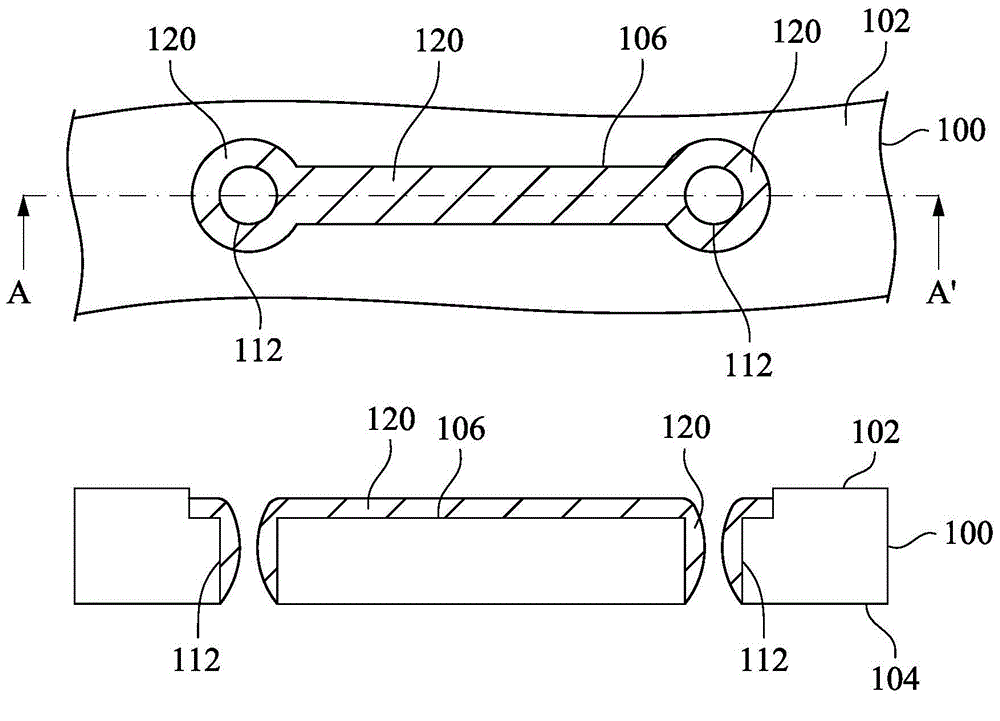

Printed circuit board and method for fabricating the same, and apparatus for fabricating printed circuit board

InactiveCN105323959ASimple processHigh precisionStacked PCBsConductive pattern formationCost effectivenessEngineering

The present invention discloses a printed circuit board and a method for fabricating the same, and an apparatus for fabricating printed circuit board. The printed circuit board includes a substrate having an upper surface; a first trench recessed from the upper surface of the substrate; a first via formed in the first trench and penetrating through the substrate; and a first conductive layer disposed in the first trench and the first via, the first trench being electrically connected to the first via. A method for fabricating the printed circuit board and an apparatus for fabricating the printed circuit board are also disclosed. The method and device utilize an ink-jet printing technology to fabricate the printed circuit board, can substantially simplify a technological process of the printed circuit board, and compared with a traditional technological process, can save many complex processes, improve the technological process and cost effectiveness, and reduce the pollution problem in a fabricating process.

Owner:蔡莳铨 +1

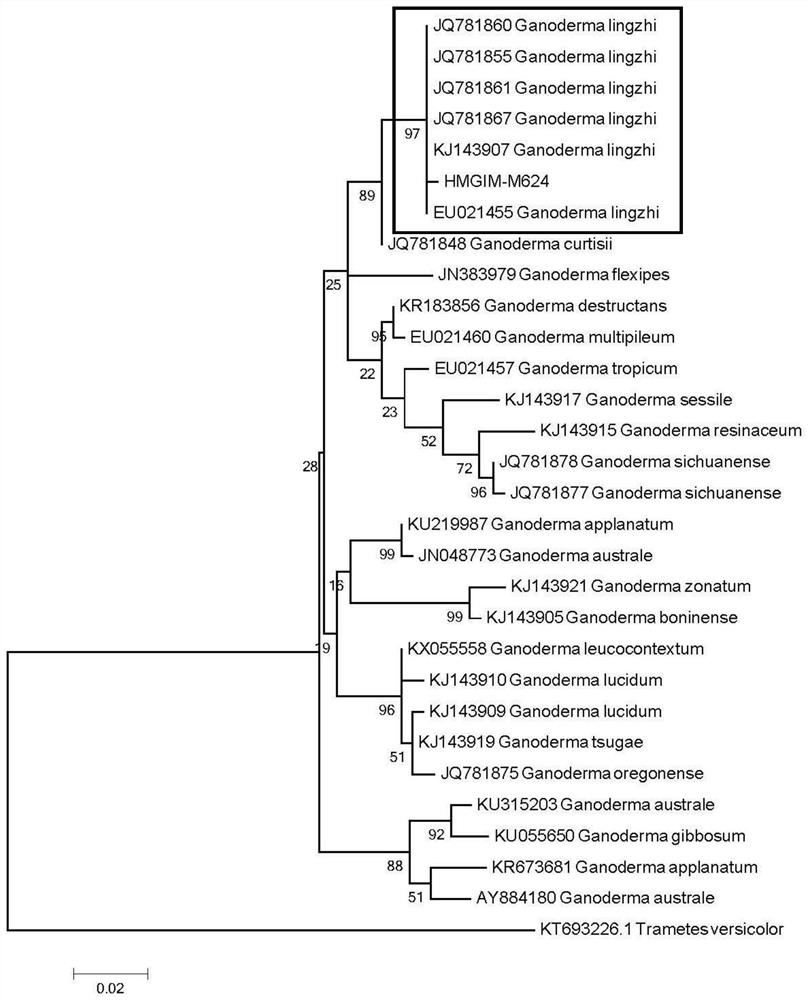

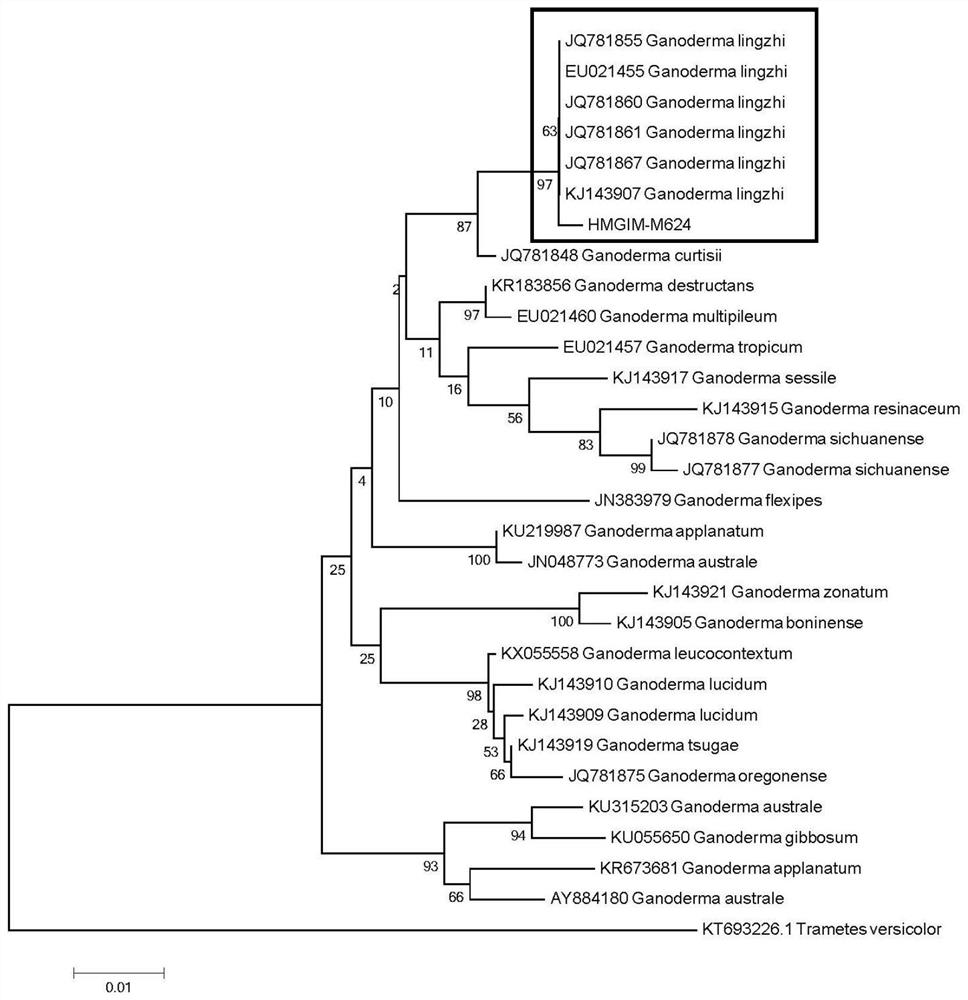

Ganoderma lucidum few-spore variety with high polysaccharide yield and artificial cultivation method thereof

ActiveCN112662566ALow sporulationReduce the impact of cultivation environment and machineryFungiMicroorganism based processesGanoderma lucidumMycelium

The invention discloses a ganoderma lucidum few-spore variety with high polysaccharide yield and an artificial cultivation method thereof. The preservation number of the ganodorma lucidum M624 is GDMCC No: 60889. The artificial cultivation method comprises the steps of mycelium culture of lucid ganoderma M624, lucid ganoderma emergence management and fruiting body harvesting. According to the invention, the ganoderma lucidum M624 with high yield of polysaccharides is obtained by screening, in substitute cultivation, the content of crude polysaccharides in sporocarp reaches 2.40+ / -0.09% and is far higher than 0.9% required by pharmacopeia, and the content of crude polysaccharides in substitute cultivated ganoderma lucidum in the industry is generally 0.9-1.5%; moreover, the ganoderma lucidum M624 is low in sporulation quantity, the influence on a cultivation environment and a machine can be reduced, and the requirement for ganoderma lucidum cultivation with sporocarp as a harvesting target is met. The method can improve the crude polysaccharide content of the ganoderma lucidum raw material from the source, enrich the current market ganoderma lucidum variety, is also suitable for industrial large-scale production, avoids the influence of a large amount of spore powder generated in the ganoderma lucidum spore spraying period on the environment and machines, and meets the industrial development requirements of ganoderma lucidum.

Owner:GUANGDONG INST OF MICROBIOLOGY GUANGDONG DETECTION CENT OF MICROBIOLOGY +1

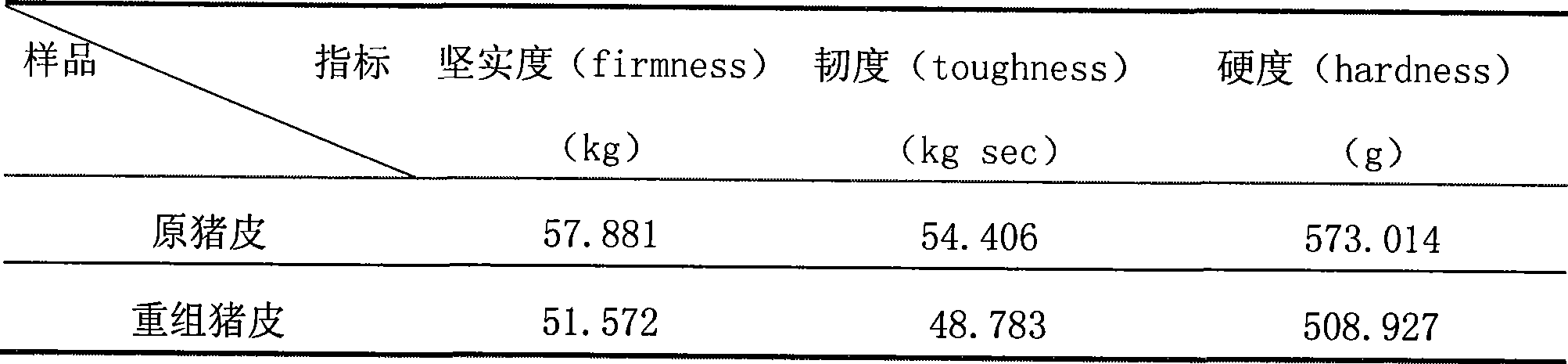

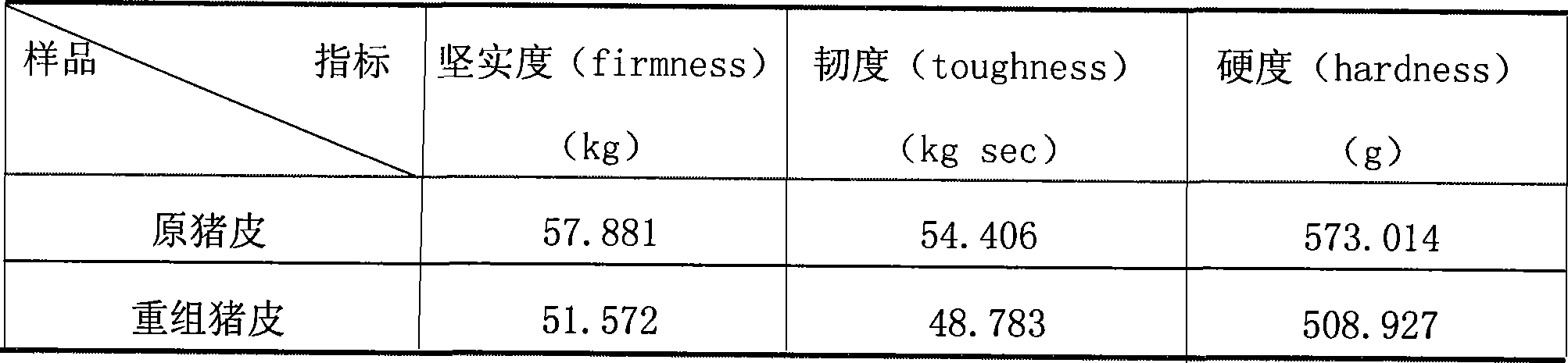

Method for producing recombined pigskin using leftover material of broken pigskin

InactiveCN101411504AReduce pollutionEasy processing and applicationFood preparationEnzyme catalysisProduct processing

The invention relates to a method for producing recombinant pigskin by using broken pigskin leftover materials, which comprises the following steps: (1) material selection; (2) acidolysis; (3) boiling; (4) filtering; (5) salination; (6) neutralization; (7) blending; (8) enzyme catalysis; (9) pouring and forming; and (10) air curing. The method uses broken pigskins including the broken pigskins produced through division processing, scourged pigskins, gore pigskins and the like as raw materials to produce the entire pigskin, and adopts a glutamine transaminage preparation to perform biocatalysis on the entire reaction system so as to achieve the recombination of the broken pigskins. Using the glutamine transaminage preparation to process the broken pigskins for recombination and forming, the recombinant pigskin cannot be re-dispersed due to freezing, slicing, stewing, cooking and the like. The method recombines the pigskins for reuse, which not only revalues the pigskins, but also reduces pollutions to the environment. The formed recombinant pigskin is convenient for processing and application, can substitute the prior pigskins in the process of low-temperature meat product processing, and greatly reduce the production cost.

Owner:ZHENGZHOU UNIVERSITY OF LIGHT INDUSTRY

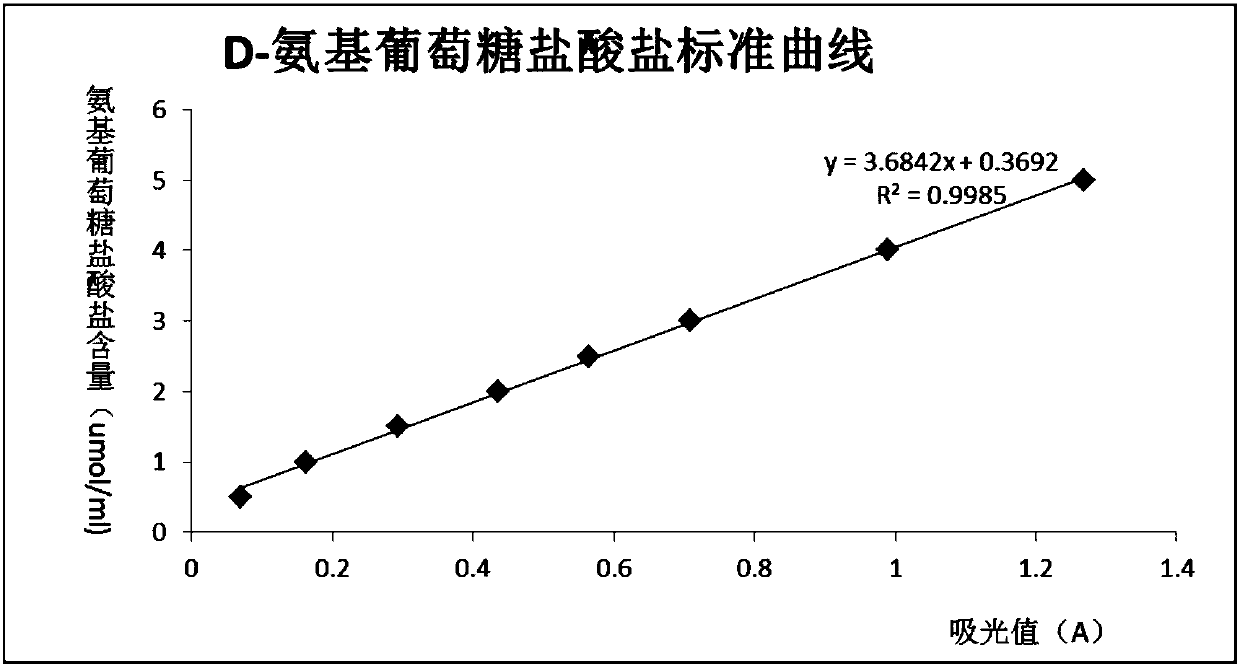

Bacillus subtilis for producing chitosanase and application thereof

PendingCN108018245AIncrease productionIncrease enzyme activityBacteriaMicroorganism based processesBiotechnologyProtein structure

The invention belongs to the field of biotechnology, and particularly relates to a bacillus subtilis for producing chitosanase and application thereof. The chitosanase produced by the bacillus subtilis has high yield and strong enzyme activity, and has a different protein structure from ordinary chitosanase, and provides a new idea for in-depth study of chitosanase molecule mechanism. The ordinarychitosanase has good activity only when the ordinary chitosanase is in weakly alkaline to weakly acidic conditions, and the chitosanase found in the invention has better performance in weak alkaline,neutral, weakly acidic and relatively strong acidic conditions. At the same time, the chitosanase discovered in the invention can not only act on soluble chitosan but also on insoluble high-poly chitosan, omitting pre-treatment of chitosan degradation; final reaction products are dipolyglucosamine and tripolyglucosamine, the bacillus subtilis for producing the chitosanase is simple in composition, is convenient for subsequent further processing applications, and greatly saves production costs.

Owner:CHENGDU INST OF BIOLOGY CHINESE ACAD OF S

Triply coated fiber, pump combiner, fiber grating and fiber laser

ActiveCN110187437AHigh damage thresholdImprove stabilityLaser detailsOptical fibre with multilayer core/claddingGratingFiber gratings

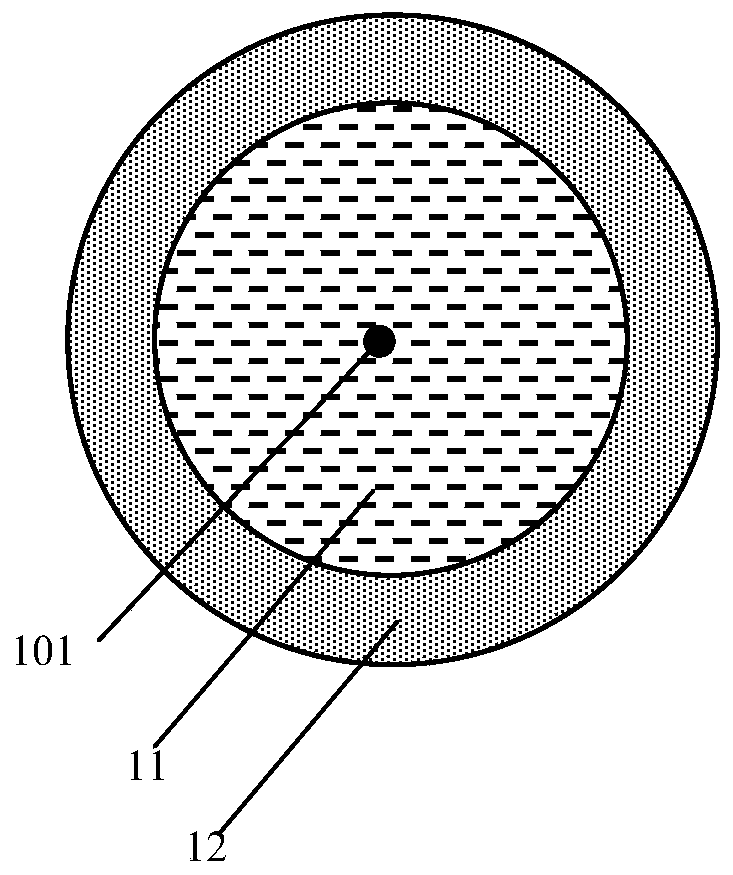

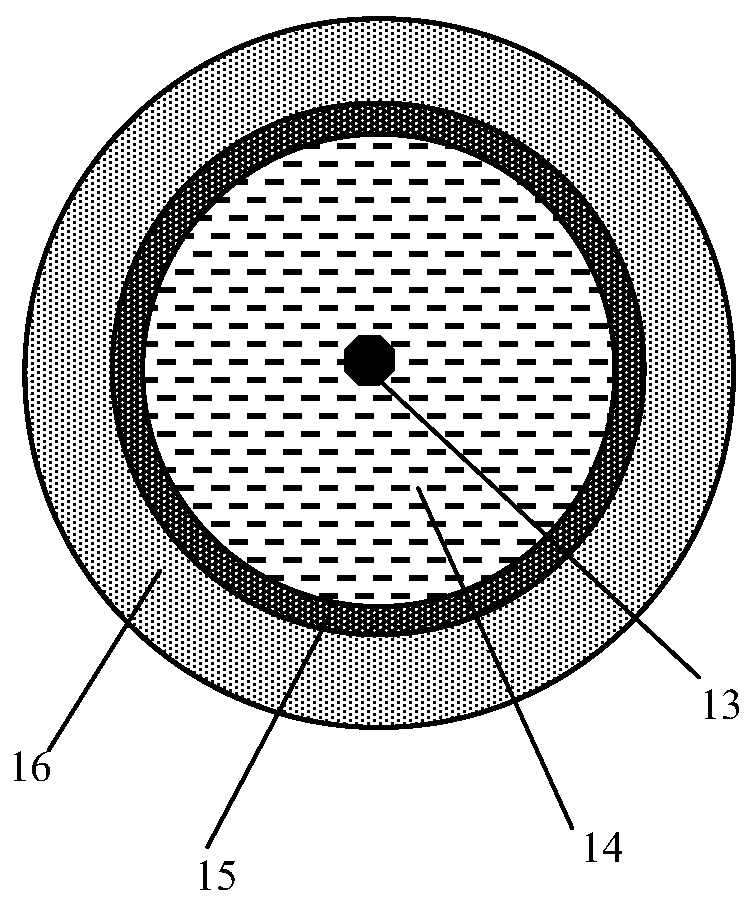

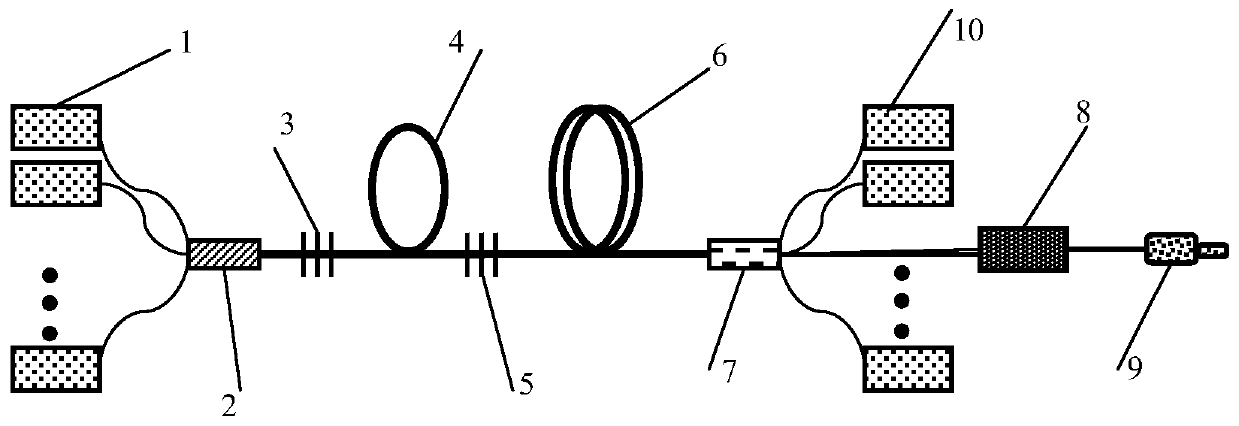

The invention is suitable for the optical field, and provides a triply coated fiber, a pump combiner, a fiber grating and a fiber laser. A triply coated passive fiber comprises a fiber core, an innercladding layer covering outside the fiber core, an outer cladding layer covering outside the inner cladding layer, and a coating layer covering outside the outer cladding layer, the diameter of the fiber core is 10-50micrometer, the diameter of the inner cladding layer is 250-800micrometer, the diameter of the outer cladding layer is greater than the diameter of the inner cladding layer, the diameter of the outer cladding layer is 300-1000micrometer, or, the diameter of the inner cladding layer is 80-100micrometer, and the diameter of the outer cladding layer is 110-130micrometer. In the triply coated passive fiber, the outer cladding layer wrapping outside the inner cladding layer greatly reduces damage of pump light to the organic coating, the coating as a full reflection interface has ultrahigh damage threshold, so that the fiber laser is more reliable and stable.

Owner:MAXPHOTONICS CORP

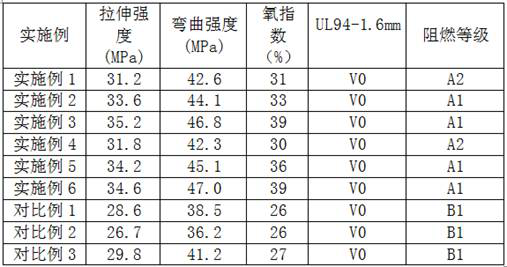

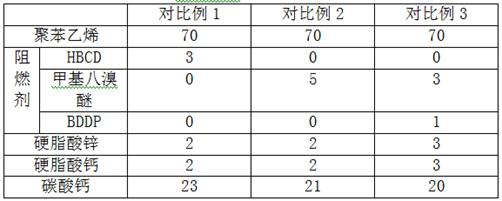

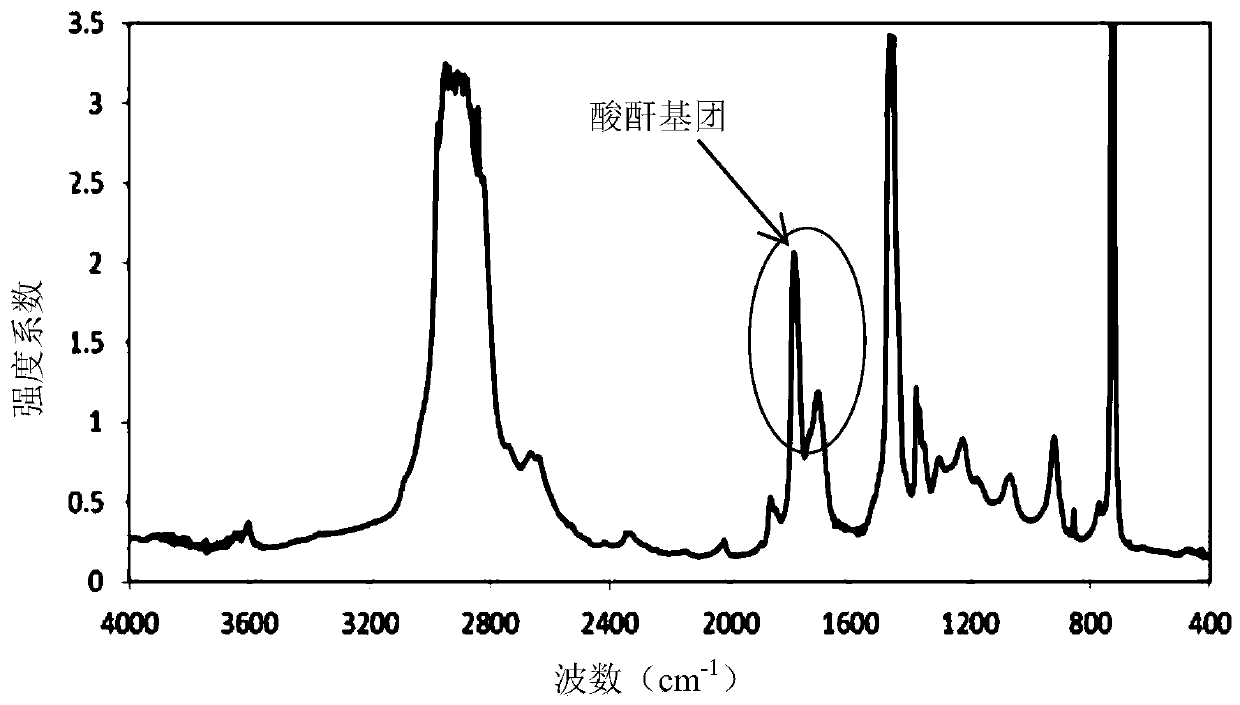

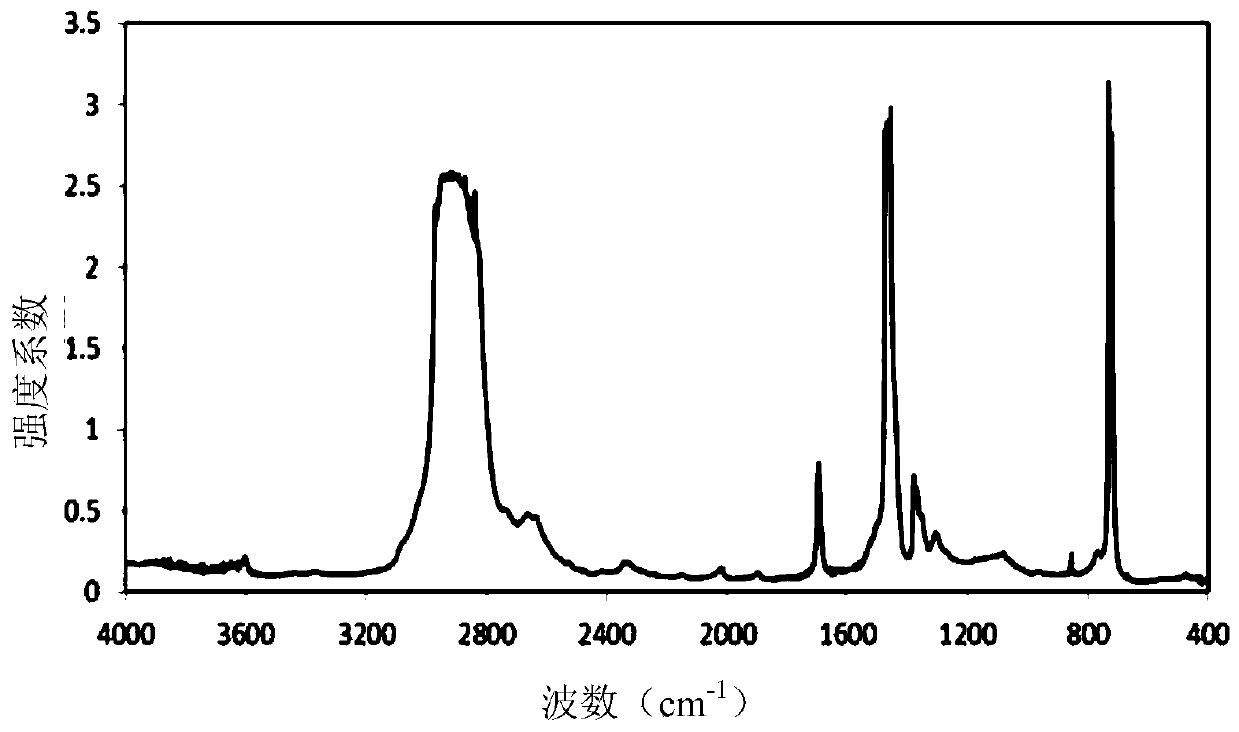

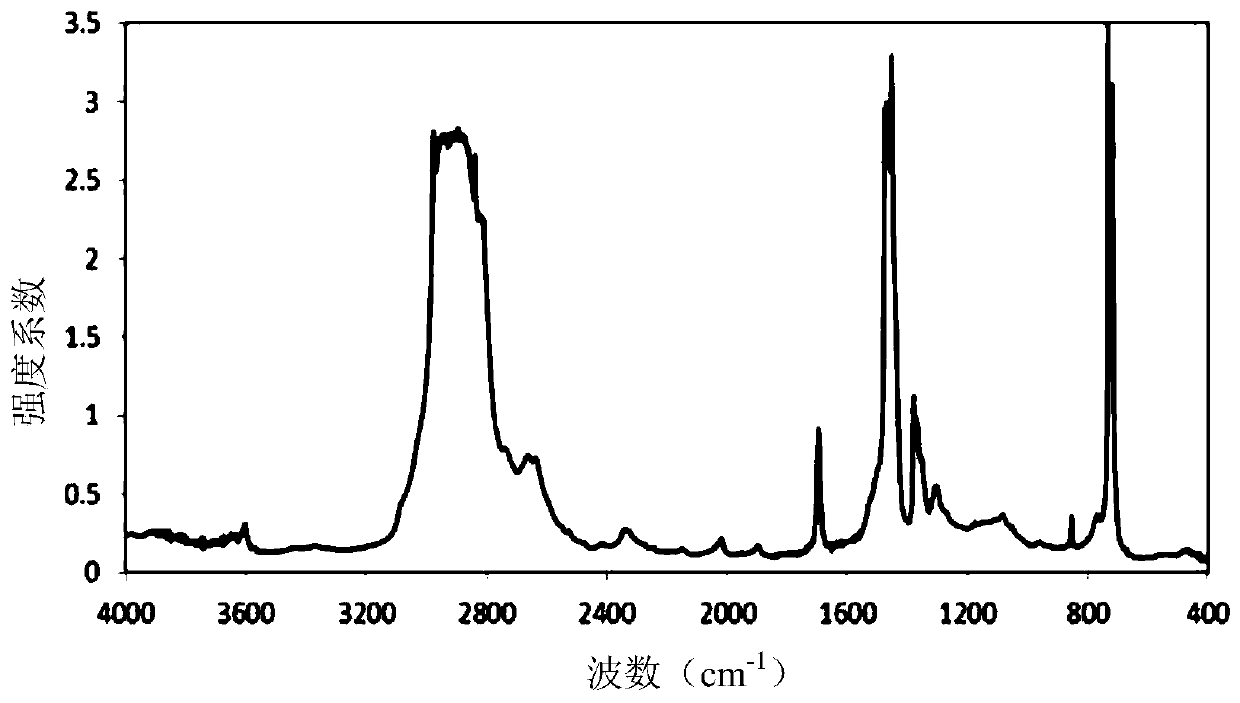

Methyl octabromo-ether flame-resistant polystyrene composite material, and preparation method thereof

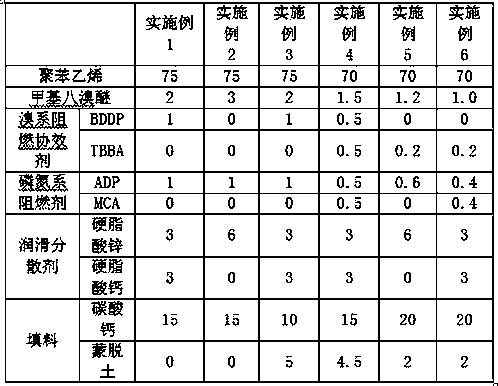

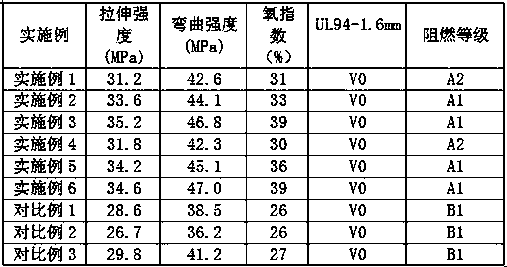

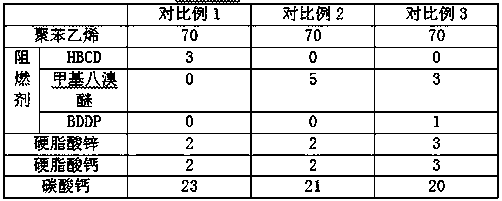

The invention discloses a methyl octabromo-ether flame-resistant polystyrene composite material, and a preparation method thereof. The methyl octabromo-ether flame-resistant polystyrene composite material comprises, by weight, 70 to 90 parts of polystyrene, 1 to 10 parts of methyl octabromo ether, 0.2 to 5 parts of a bromine-series flame retardant synergist, 1 to 10 parts of phosphorus-nitrogen-series flame retardant, 1 to 10 parts of a lubricating dispersant, and 1 to 20 parts of a filler. The invention also discloses the preparation method of the methyl octabromo-ether flame-resistant polystyrene composite material. The preparation method comprises following steps: the components are uniformly stirred, and are introduced into an extruder for extrusion, wherein the temperature of the extruder is controlled to be 170 to 210 DEG C. According to the preparation method, methyl octabromo ether is adopted to replace the commonly used polystyrene flame retardant hexabromocyclododecane, and at the same time, the phosphorus-nitrogen-series flame retardant is added for synergistic effect, so that the prepared polystyrene composite material has excellent resistance and excellent mechanical properties at the same time, the tensile strength is 31.2-34.6MPa, the bending strength is 42.3 -47.0MPa, and limit oxygen index is 30-39%.

Owner:山东兄弟科技股份有限公司

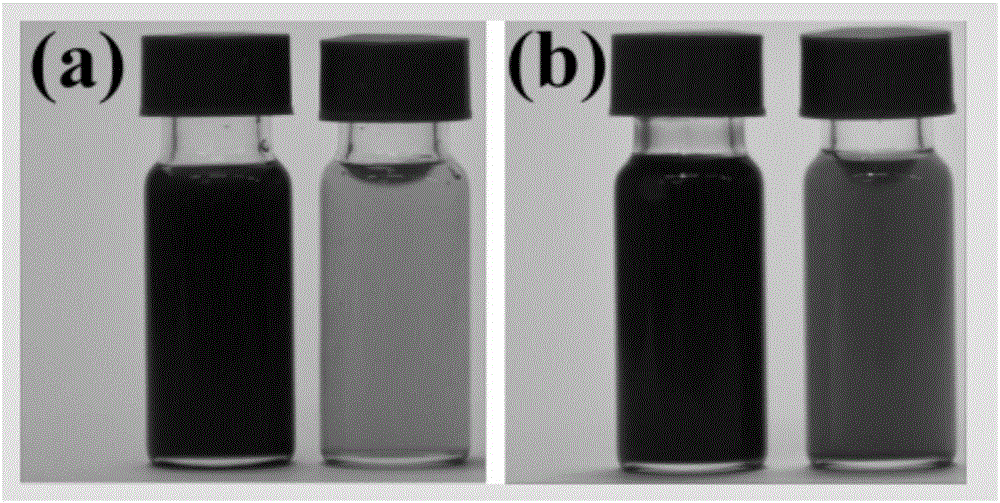

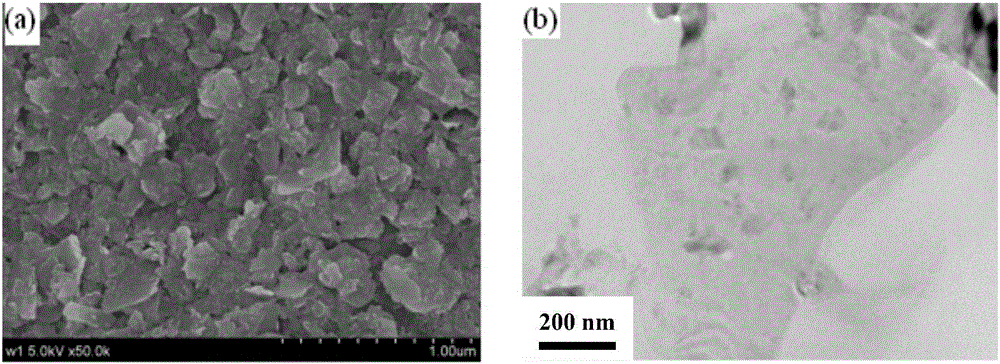

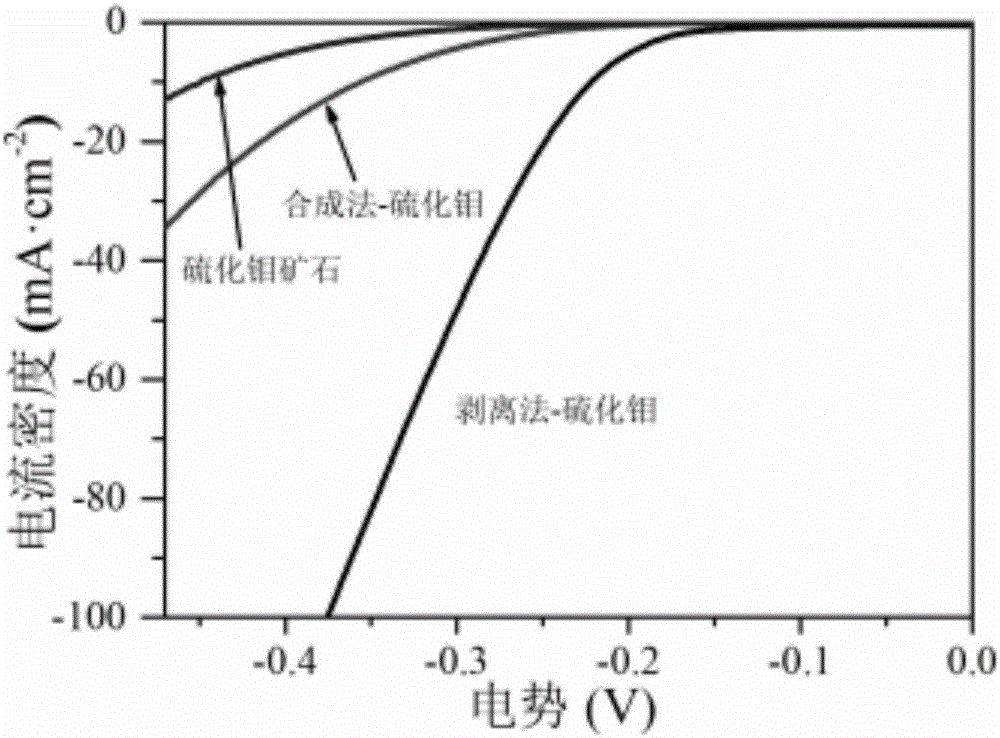

High-concentration molybdenum disulfide nanometer sheet dispersion liquid, and preparation method and application thereof

InactiveCN106587155AImprove performanceLow costCell electrodesMolybdenum sulfidesHigh concentrationOrganic solvent

The invention relates to high-concentration molybdenum disulfide nanometer sheet dispersion liquid, and a preparation method and application thereof. The concentration of the dispersion liquid is 1 to 20mg / mL. The preparation method comprises the following steps of adding molybdenites into an organic solvent; performing ultrasonic treatment for 5 to 30h to obtain the molybdenum disulfide nanometer sheet dispersion liquid; performing centrifugal screening and suction filtration to obtain molybdenum disulfide nanometer sheets; transferring the molybdenum disulfide nanometer sheets into a low-boiling point solvent by a solvent transferring method; performing ultrasonic dispersion; and obtaining the high-concentration molybdenum disulfide nanometer sheet dispersion liquid. The method provided by the invention is simple, and achieves an environment-friendly effect; and the preparation method for preparing the high-concentration molybdenum disulfide nanometer sheet dispersion liquid solves the problems of easy glomeration and poor stability of the molybdenum disulfide nanometer sheets produced and prepared in the prior art.

Owner:DONGHUA UNIV

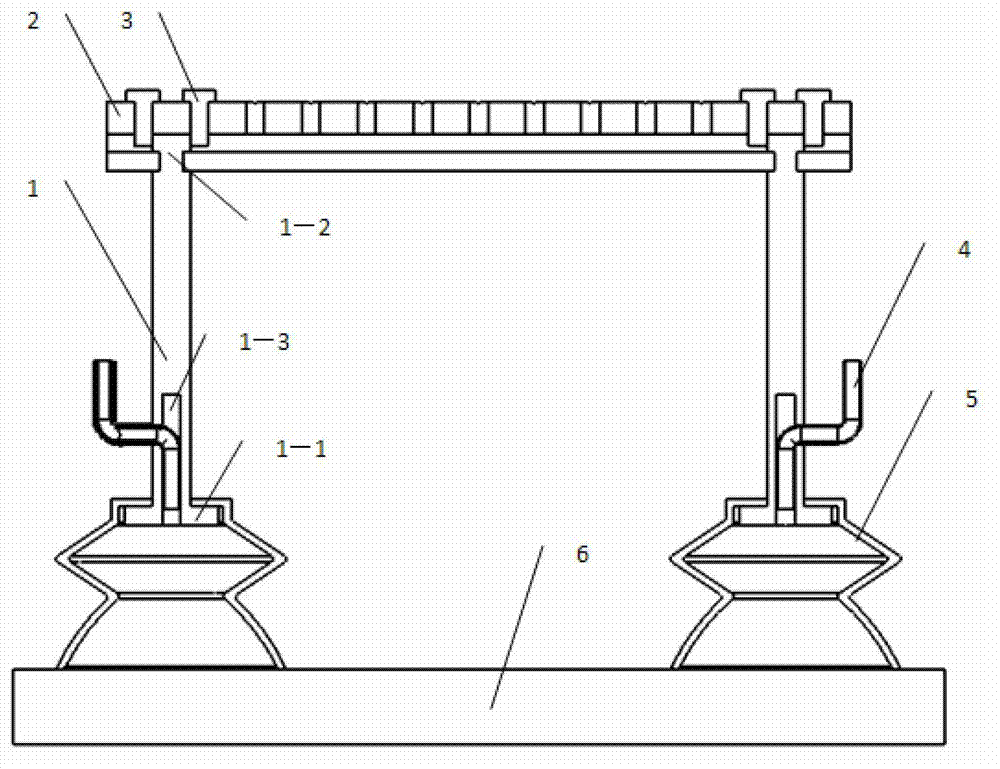

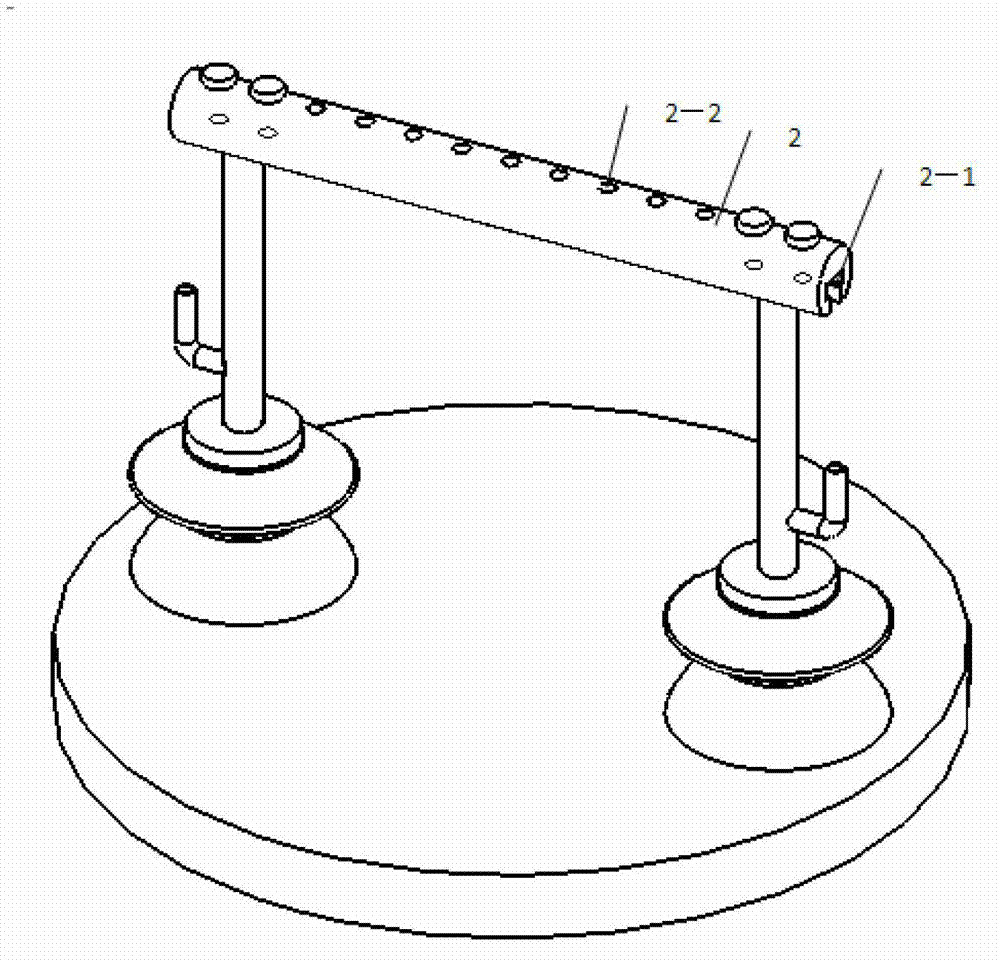

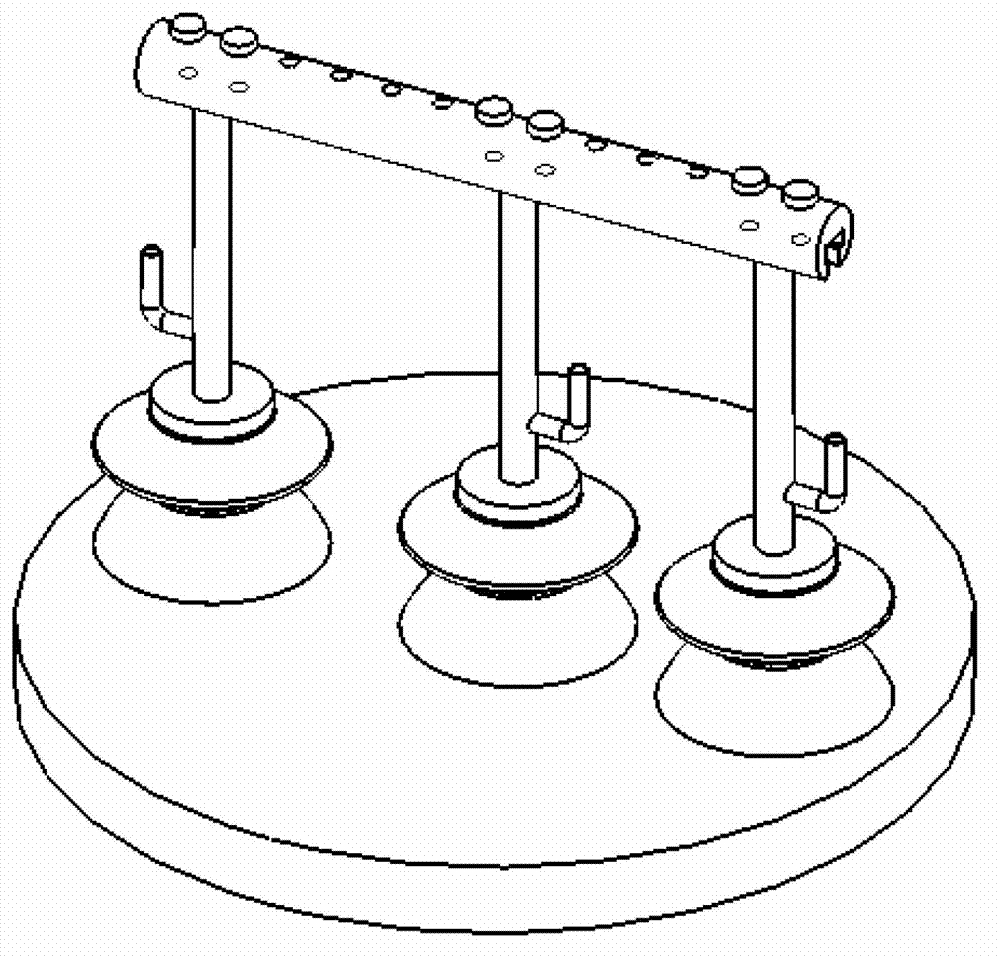

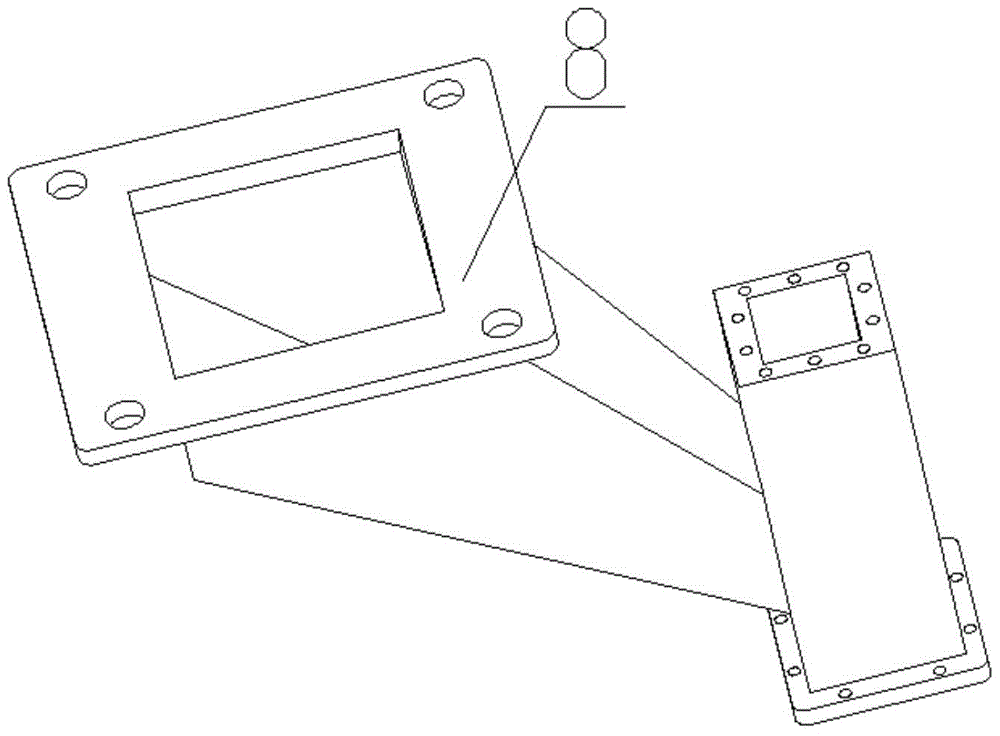

Adjustable vacuum chuck device

InactiveCN103112682ASimple device structureEasy processing and applicationManual conveyance devicesEngineeringNozzle

The invention provides an adjustable vacuum chuck device and relates to the technical field of optical lens manufacturing and adjustment. The adjustable vacuum chuck device can be used for carrying and adjustment of optical lenses. The adjustable vacuum chuck device comprises stand columns, a cross bar, positioning screws, vacuum suction tubes and suction nozzles. The distance between the stand columns is adjusted according to the calibers of the optical lenses, the positioning screws are screwed up, the vacuum suction tubes are controlled to suck or vent air, and then the adjustable vacuum chuck device can be used for suction and carrying of the optical lenses. The adjustable vacuum chuck device is simple in supporting structure, easy to machine and manufacture, and capable of effectively guaranteeing the nondestructive carrying and adjustment of the optical lenses.

Owner:INST OF OPTICS & ELECTRONICS - CHINESE ACAD OF SCI

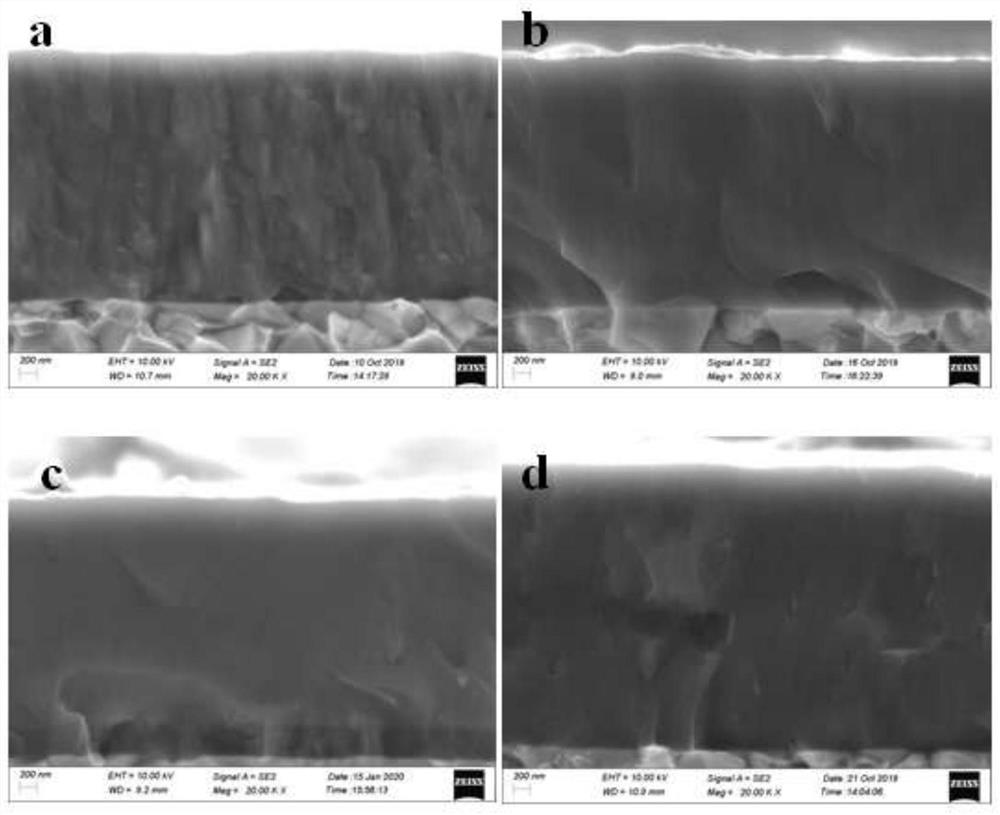

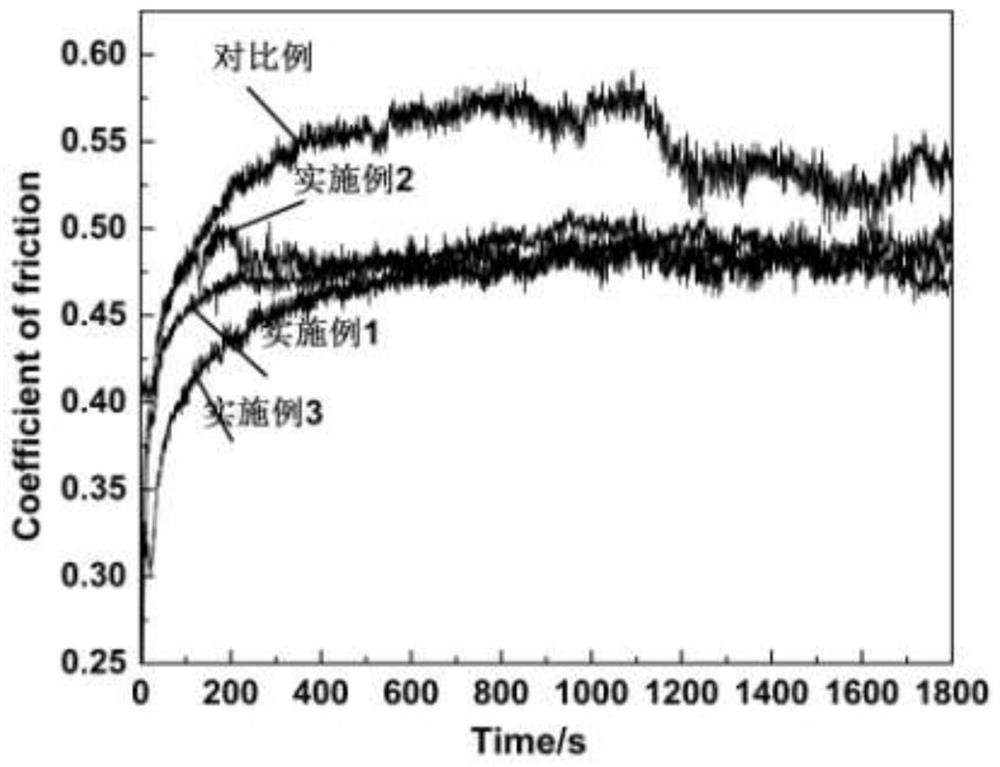

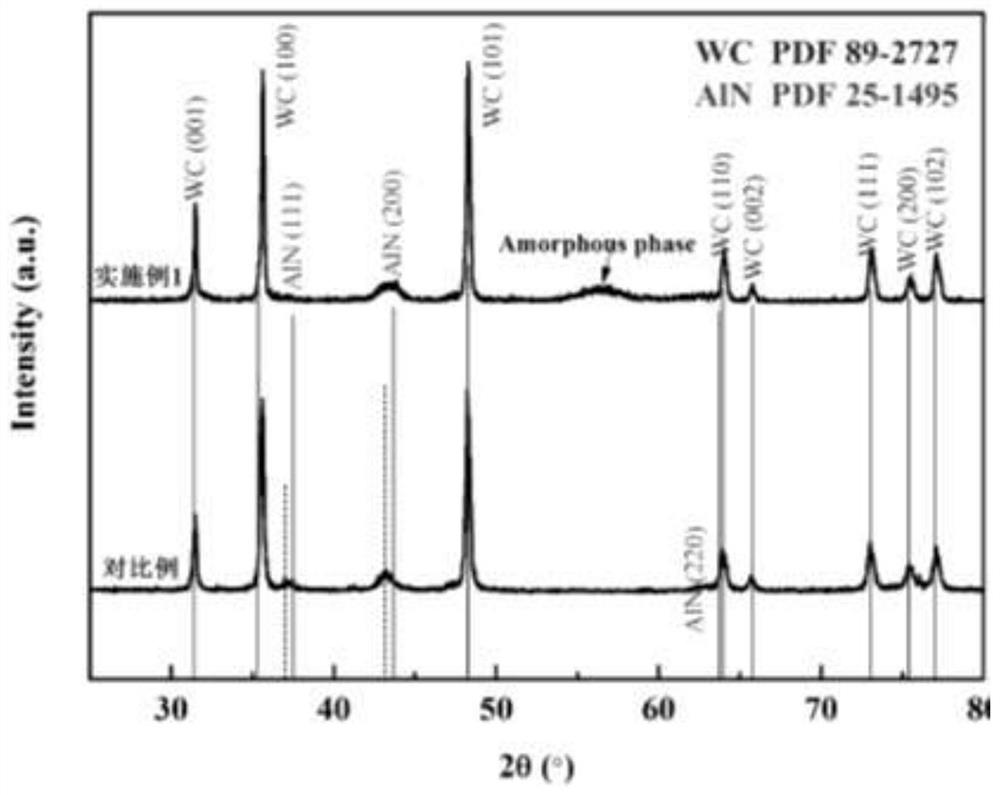

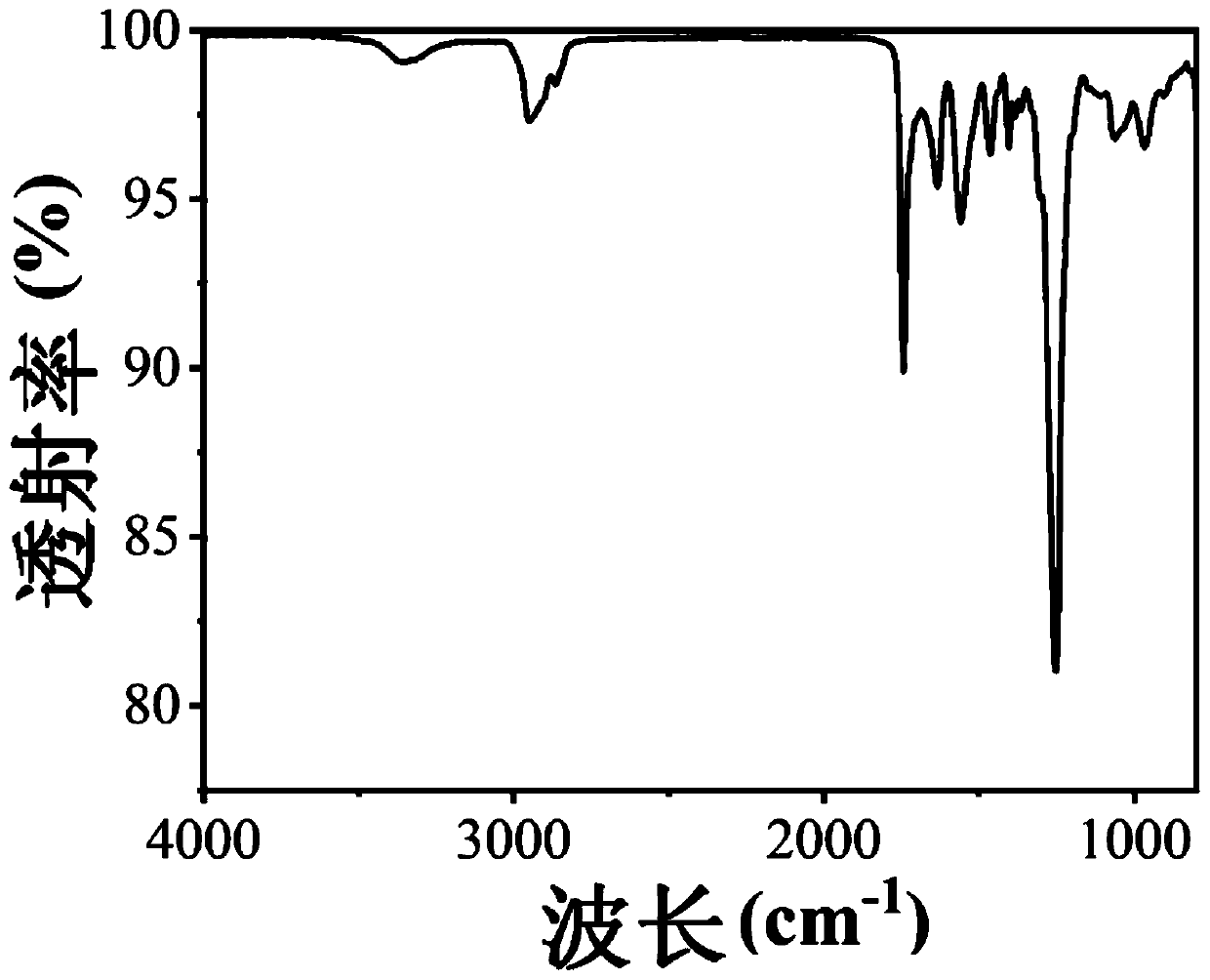

Nanocrystalline amorphous composite coating, preparation method thereof and cutter

ActiveCN111910159ASmall elastic modulus changesLittle changeVacuum evaporation coatingSputtering coatingWear resistanceSi element

The invention provides a TiAl (Nb, Si, C) N-containing nanocrystalline amorphous composite coating, a preparation method thereof and a cutter. The composite coating is a nanocrystalline amorphous TiAl(Nb, Si, C) N coating formed by physical vapor deposition. The TiAlN composite coating with a hardening and wear-resistant Si element, a toughening Nb element and an antifriction C element co-doped in an optimal proportion maintains the characteristics of excellent comprehensive performance and no short plate and good 'wooden barrel effect' of a TiAlN-based coating, meanwhile, the adhesive force,wear resistance and high-temperature stability of the coating can be greatly improved, and the integration of toughness and wear resistance of the coating is realized. The preparation method is simple in process, easy to operate in actual production, low in production cost and suitable for large-scale popularization.

Owner:ZHUZHOU HUARUI PRECISION CUTTINGS TOOLS CO LTD

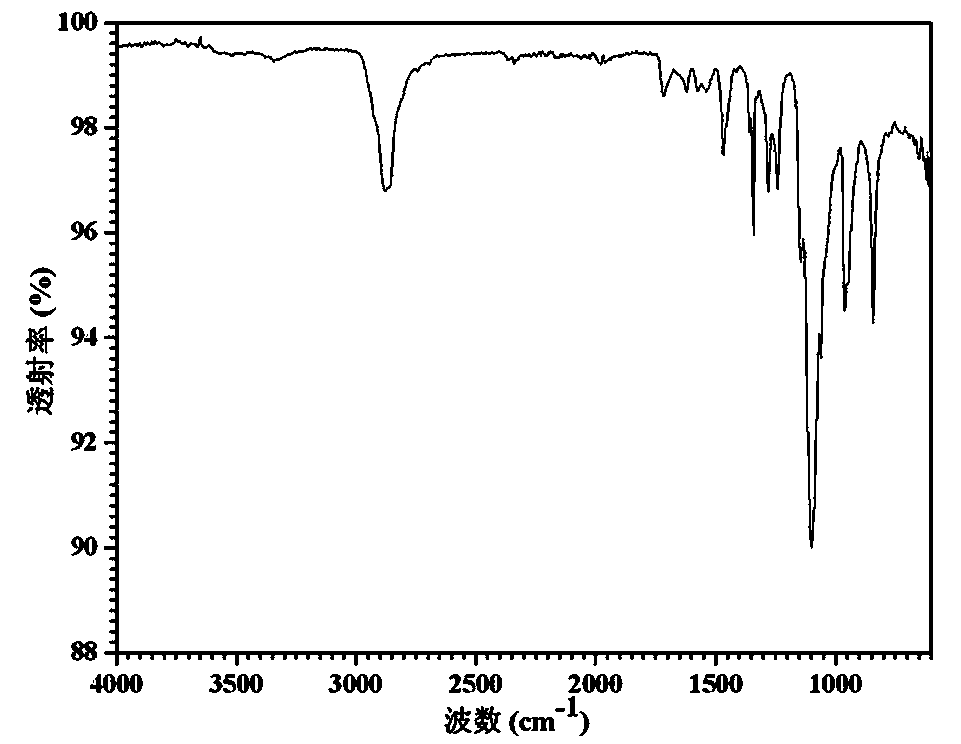

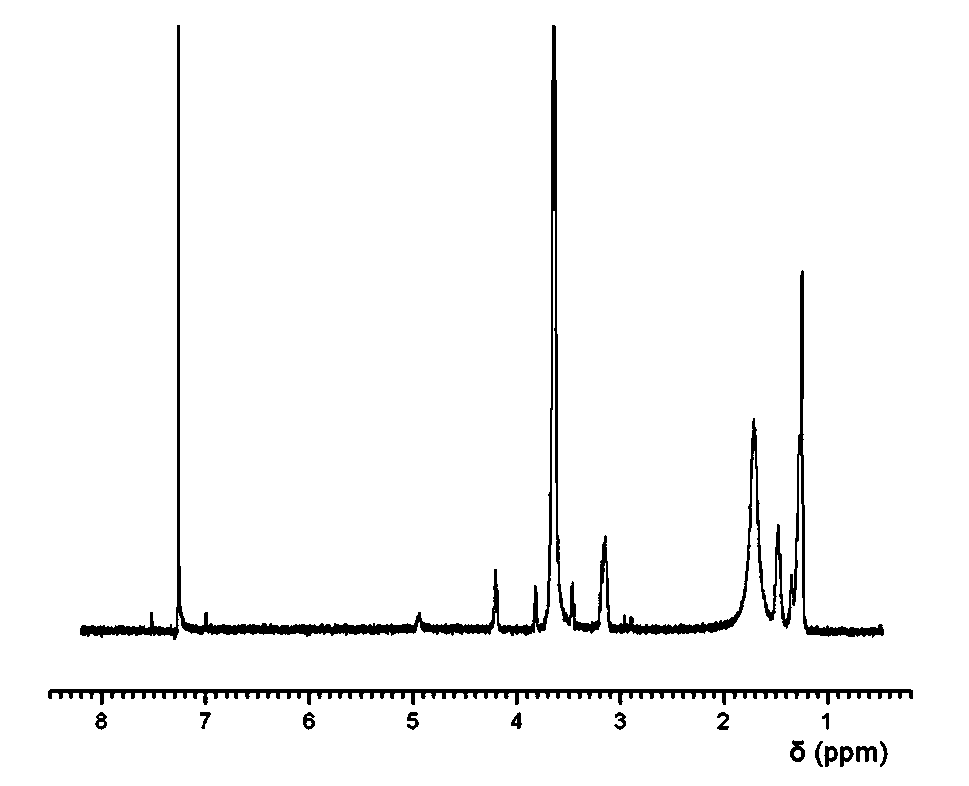

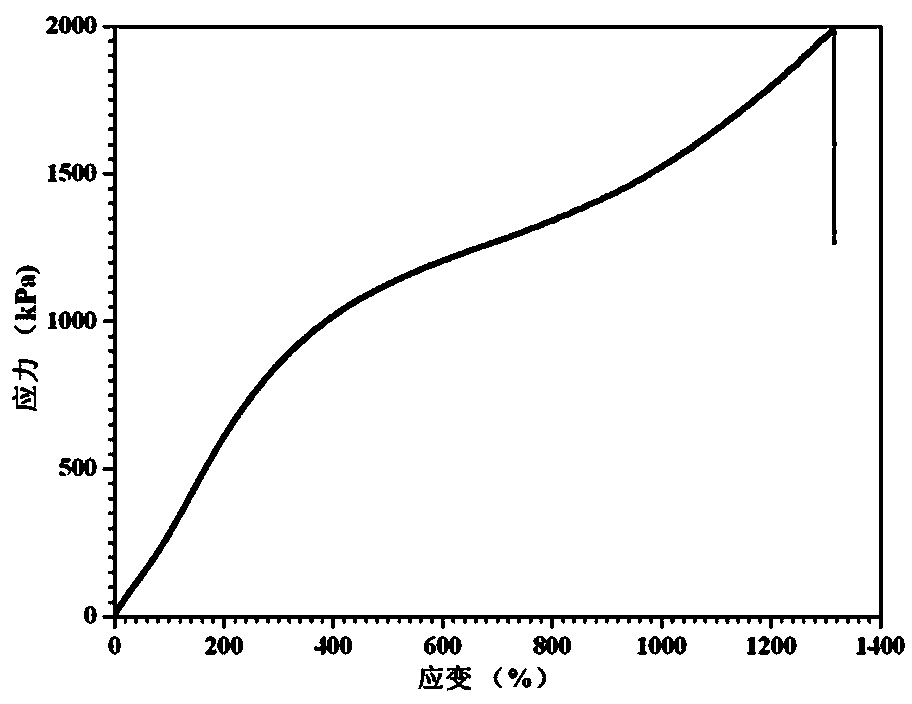

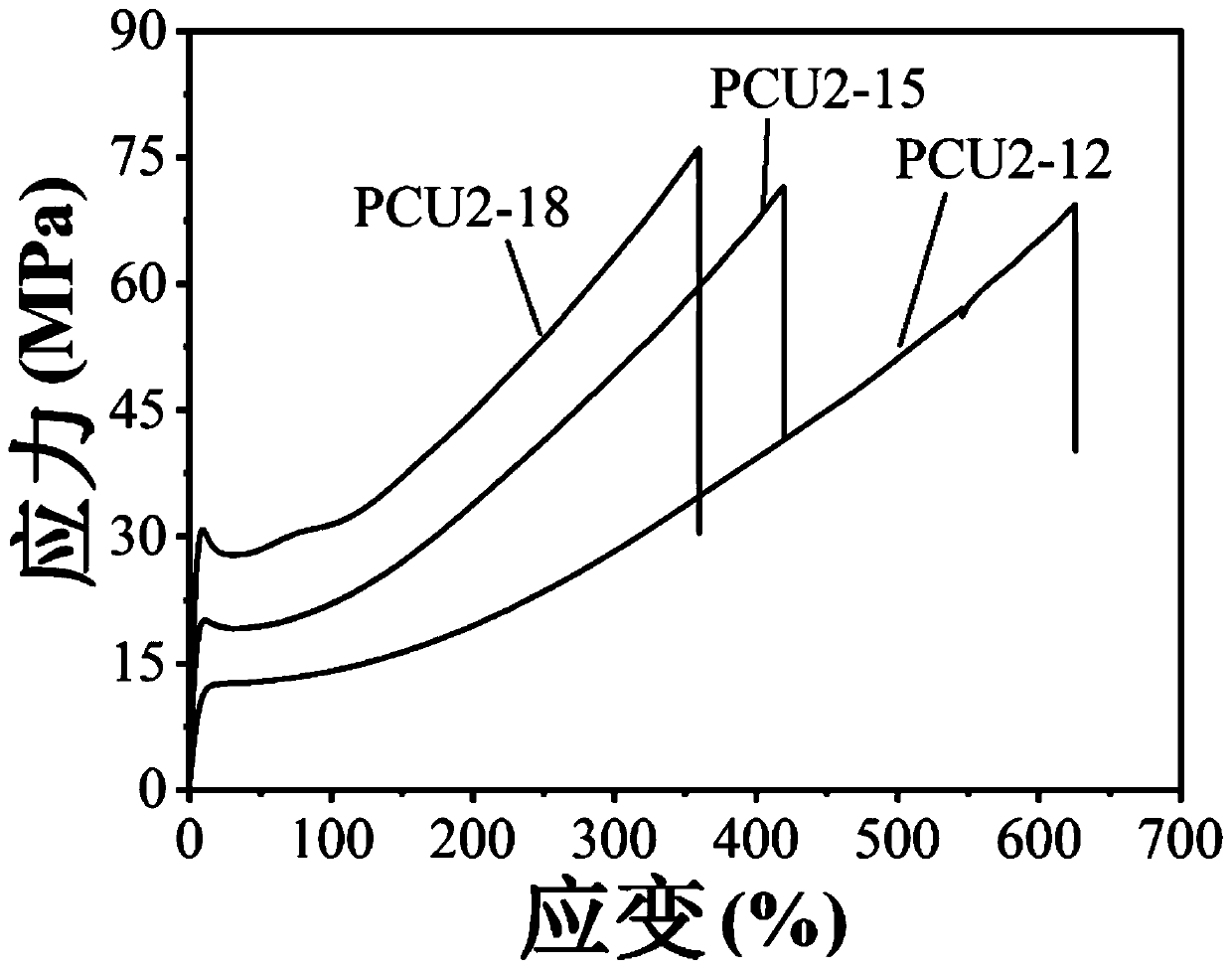

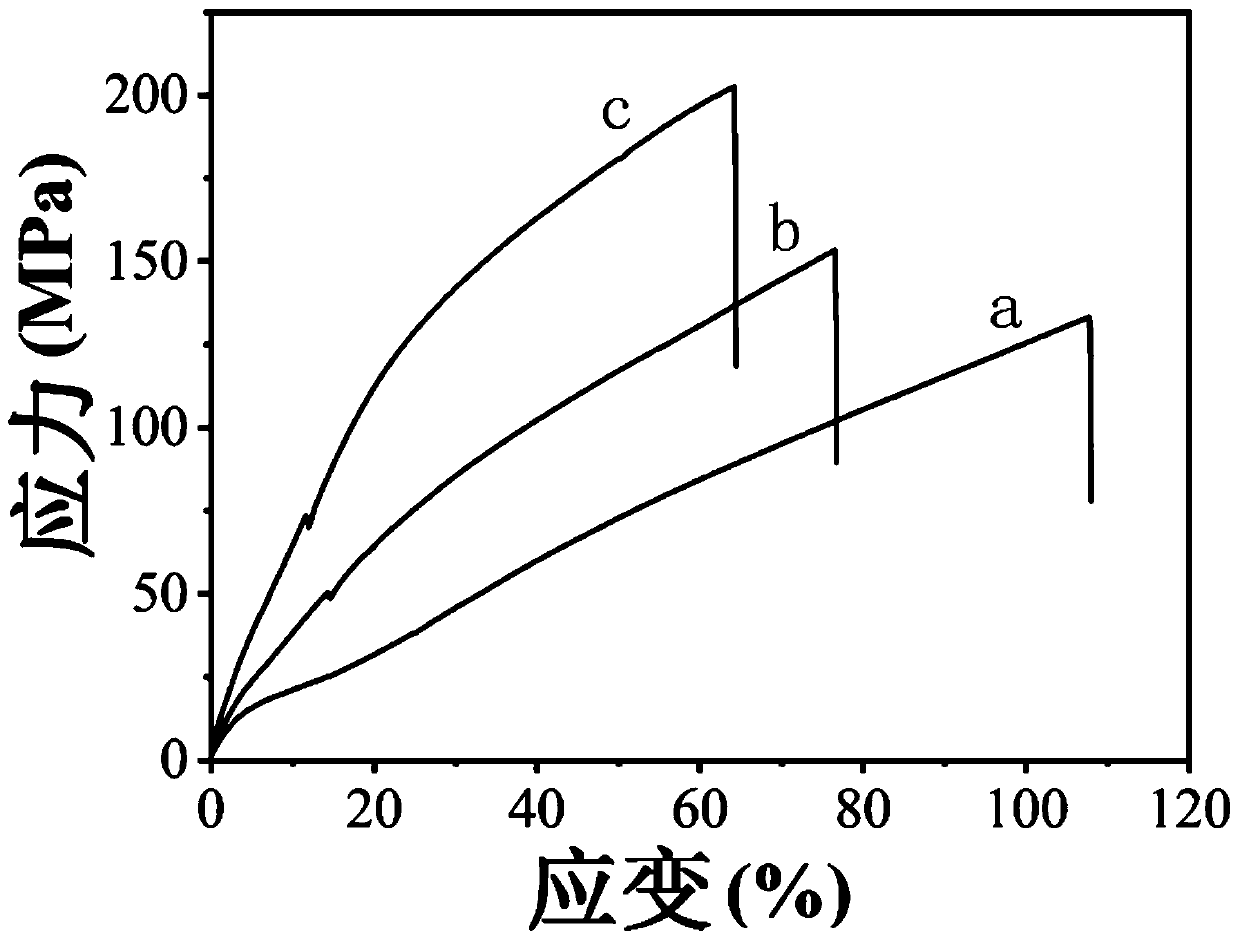

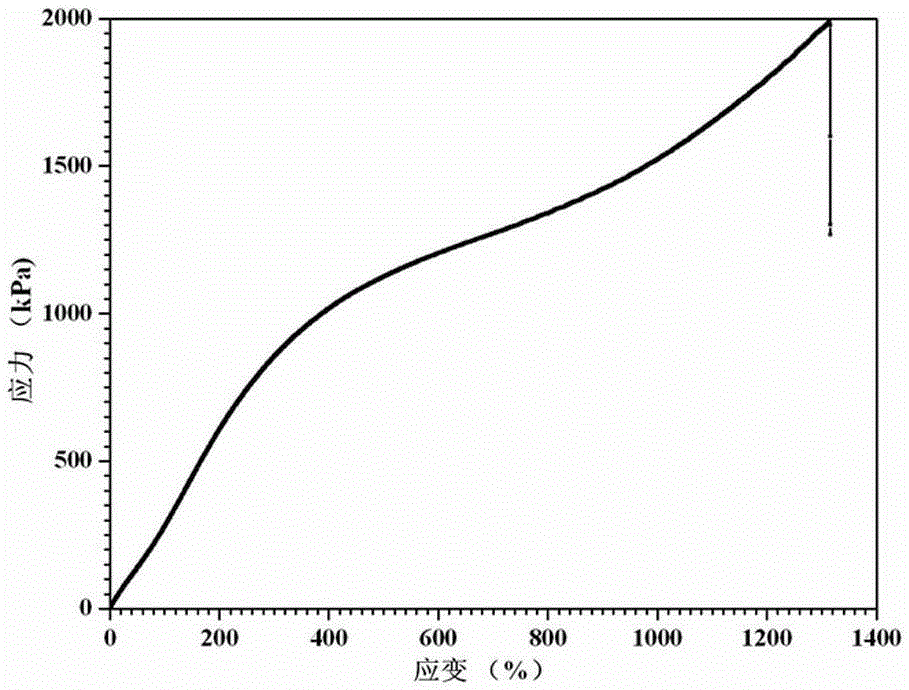

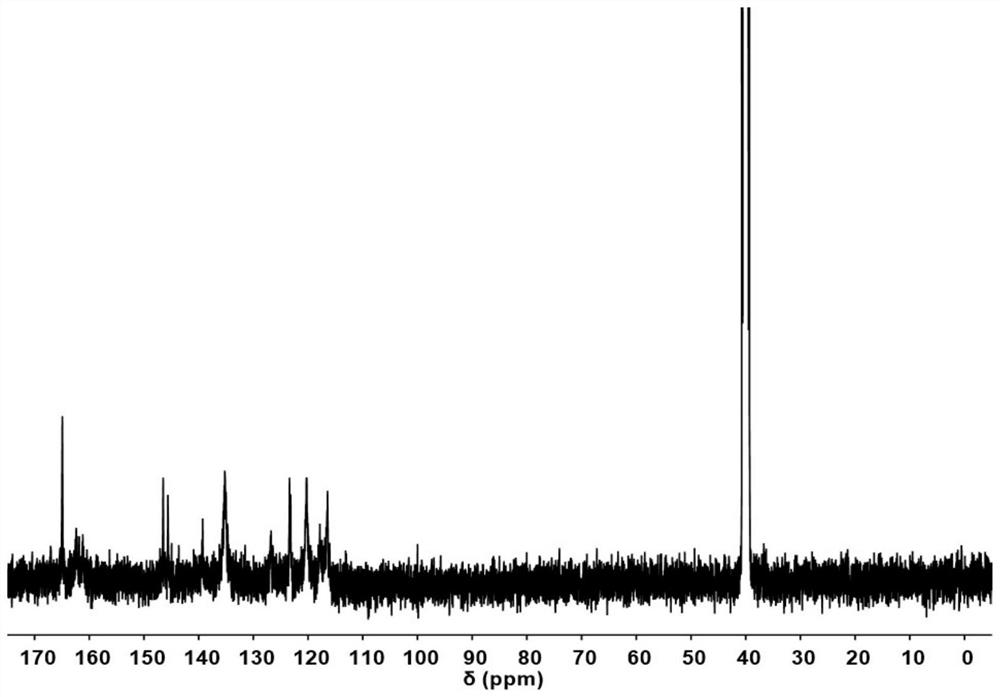

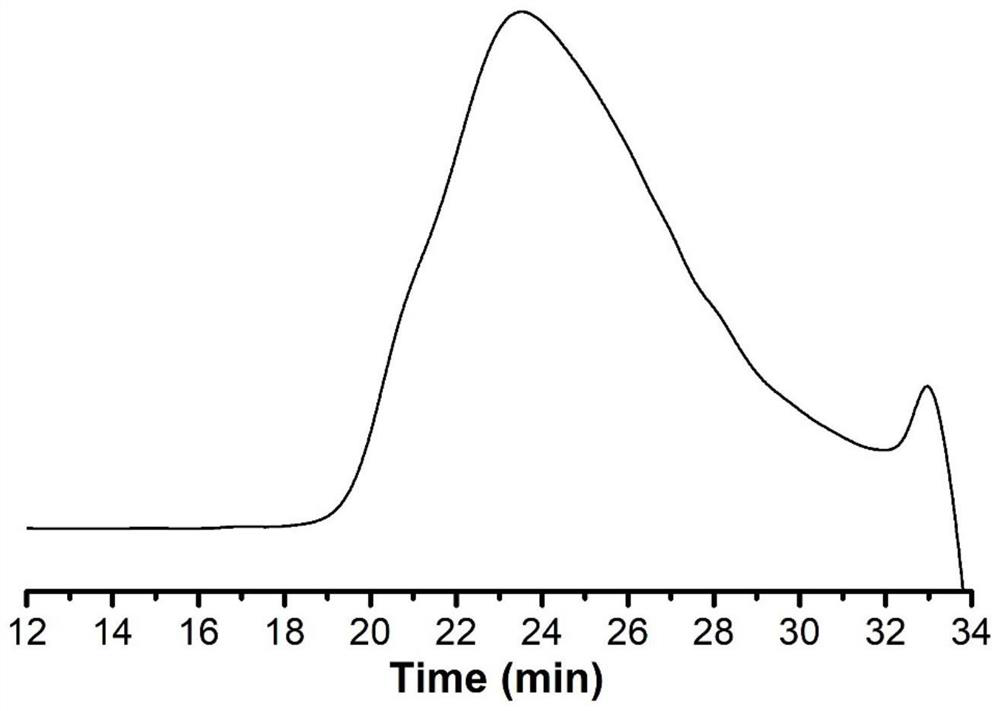

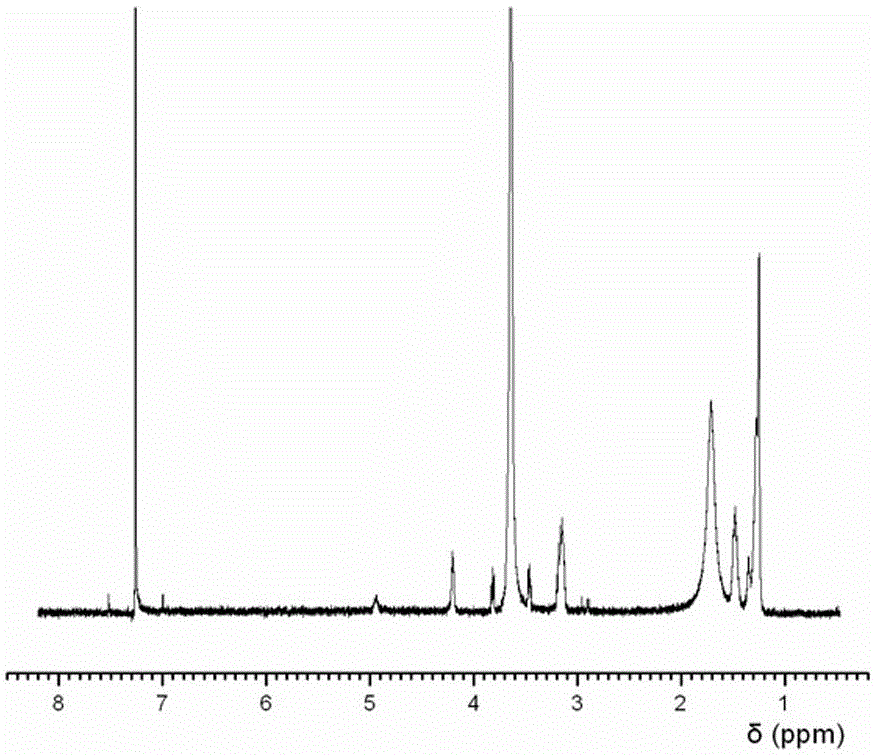

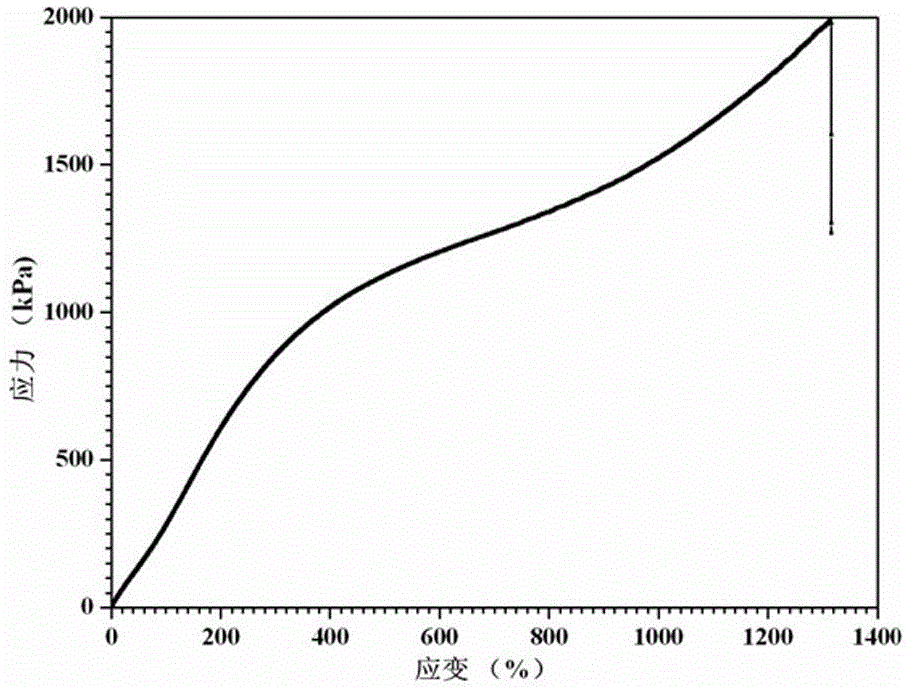

Polyurethane urea, preparation method thereof and super-tough polyurethane urea based thereon

InactiveCN110627996AImprove mechanical propertiesEasy processing and applicationPolyesterPolymer science

The invention relates to degradable polyurethane urea containing multiple ureido groups and having excellent mechanical properties, a preparation method thereof and super-tough polyurethane urea basedthereon. The preparation method of the polyurethane urea includes: adding excessive diisocyanate and a catalyst into an organic solvent of oligomer diol and chain extender diol to carry out prepolymerization reaction, and then adding water as a chain extender for reaction. The content of ureido in a molecular chain can be regulated by adjusting the molar ratio of polyester diol to diisocyanate. The super-tough polyurethane urea can be further prepared on the basis of the polyurethane urea, molecular chain orientation is carried out on the super-tough polyurethane urea at high temperature, andthe super-tough polyurethane urea is fixed for a certain period of time under a tensile state at certain elongation, so that the molecular chain can be fully directionally arranged, thus further improving the mechanical strength. The polyurethane urea provided by the invention has the characteristics of high tensile strength and degradability, and has application prospects in the field of biomedical materials.

Owner:SUZHOU UNIV

A kind of methyl octabromoether flame retardant polystyrene composite material and preparation method thereof

The invention discloses a methyl octabromoether flame-retardant polystyrene composite material and a preparation method thereof. The methyl octabromoether flame-retardant polystyrene composite material comprises, in parts by weight: polystyrene 70‑ 90 parts, 1‑10 parts of methyl octabromoether, 0.2‑5 parts of brominated flame retardant synergist, 1‑10 parts of phosphorus nitrogen flame retardant, 1‑10 parts of lubricating and dispersing agent, 1‑20 parts of filler. The invention also discloses a preparation method thereof. After the components are uniformly stirred, they are extruded through an extruder, and the temperature of the extruder is 170-210°C. In the present invention, methyl octabromoether is used to replace the commonly used polystyrene flame retardant hexabromocyclododecane, and phosphorus nitrogen flame retardants are added as a synergistic effect, so that the prepared polystyrene composite material has excellent flame retardancy In addition to flame performance, it has excellent mechanical properties, with tensile strength of 31.2-34.6MPa, bending strength of 42.3-47.0MPa, and limiting oxygen index of 30-39%.

Owner:山东兄弟科技股份有限公司

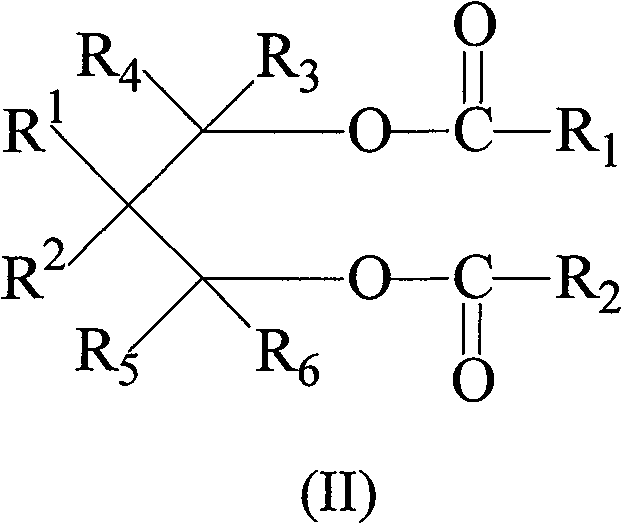

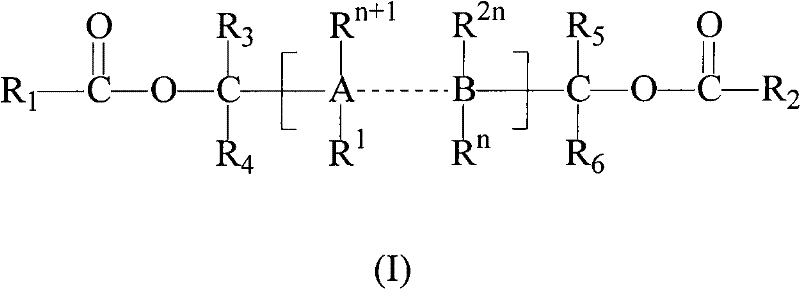

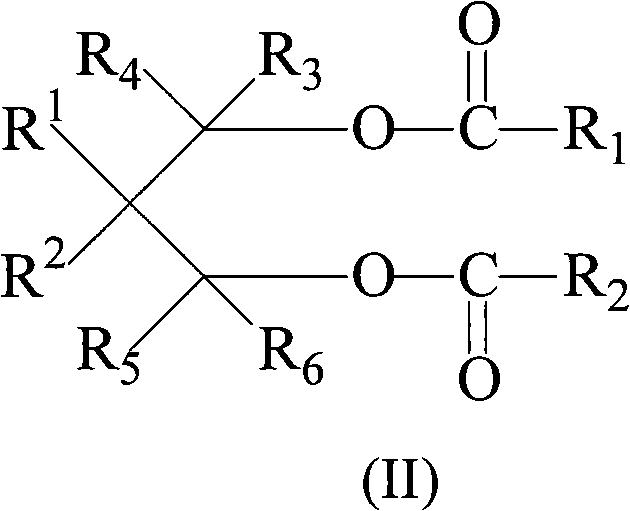

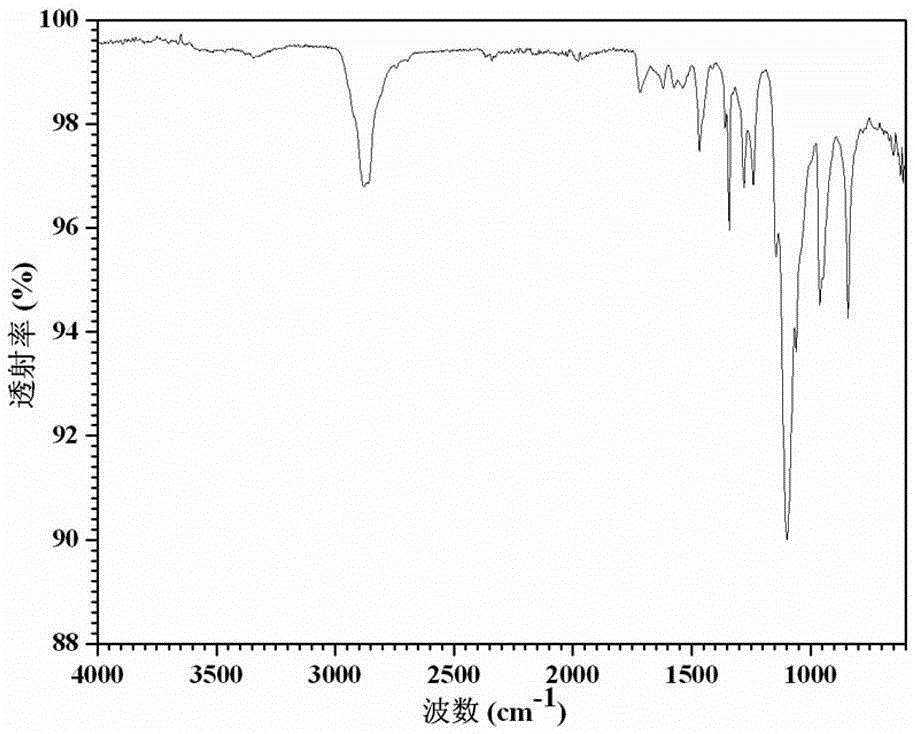

A kind of catalyst component and catalyst for propylene polymerization

ActiveCN101643519BThe preparation process is simple and controllableFew reaction stepsAlcoholElectron donor

Owner:CHINA PETROLEUM & CHEM CORP +1

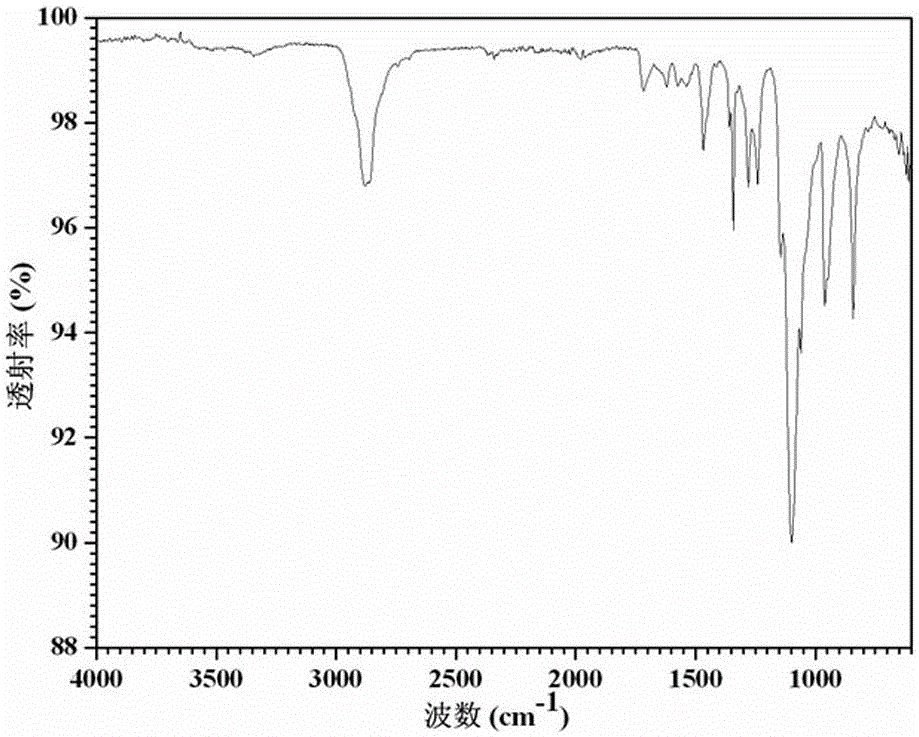

A kind of polyurethane urea hydrogel and preparation method thereof

InactiveCN103524697BProvides effective mechanical propertiesEasy processing and applicationOrganic solventPolyethylene glycol

The invention relates to polyurethaneurea hydrogel and preparation methods therefor. The preparation methods comprise two preparation methods. The first preparation methods is as follows: diisocyanate and catalysts are added in a polyethylene glycol (PEG) organic solution for reaction, then diamine chain extender is added, and products are obtained in the organic solvent after precipitation, wherein, the molar ratio of PEG, diisocyanate and diamine is 1:2:1. The second preparation method is as follows: N,N'-dicarbonyl diimidazole is added in a PEG organic solution for reaction, then excess diamine chain extender is added, macromolecules with amidogens at two ends are obtained, finally, diisocyanate is added, and products are obtained in the organic solvent after precipitation, wherein, the molar ratio of PEG and diisocyanate is 1:2. The polyurethaneurea hydrogel has advantages of large elongation and high tensile strength, and has shape memory functions. The polyurethaneurea hydrogel has application prospects at aspects of biomedical hydrogel, tissue engineering, hydrogel support materials, biomedical devices with shape memory functions and the like.

Owner:SUZHOU UNIV

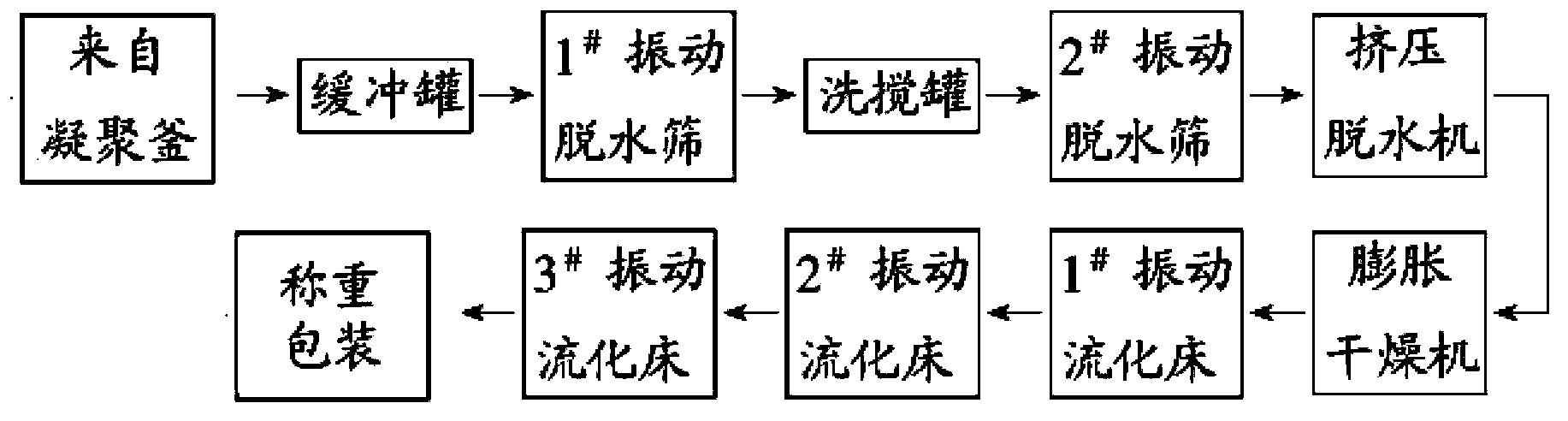

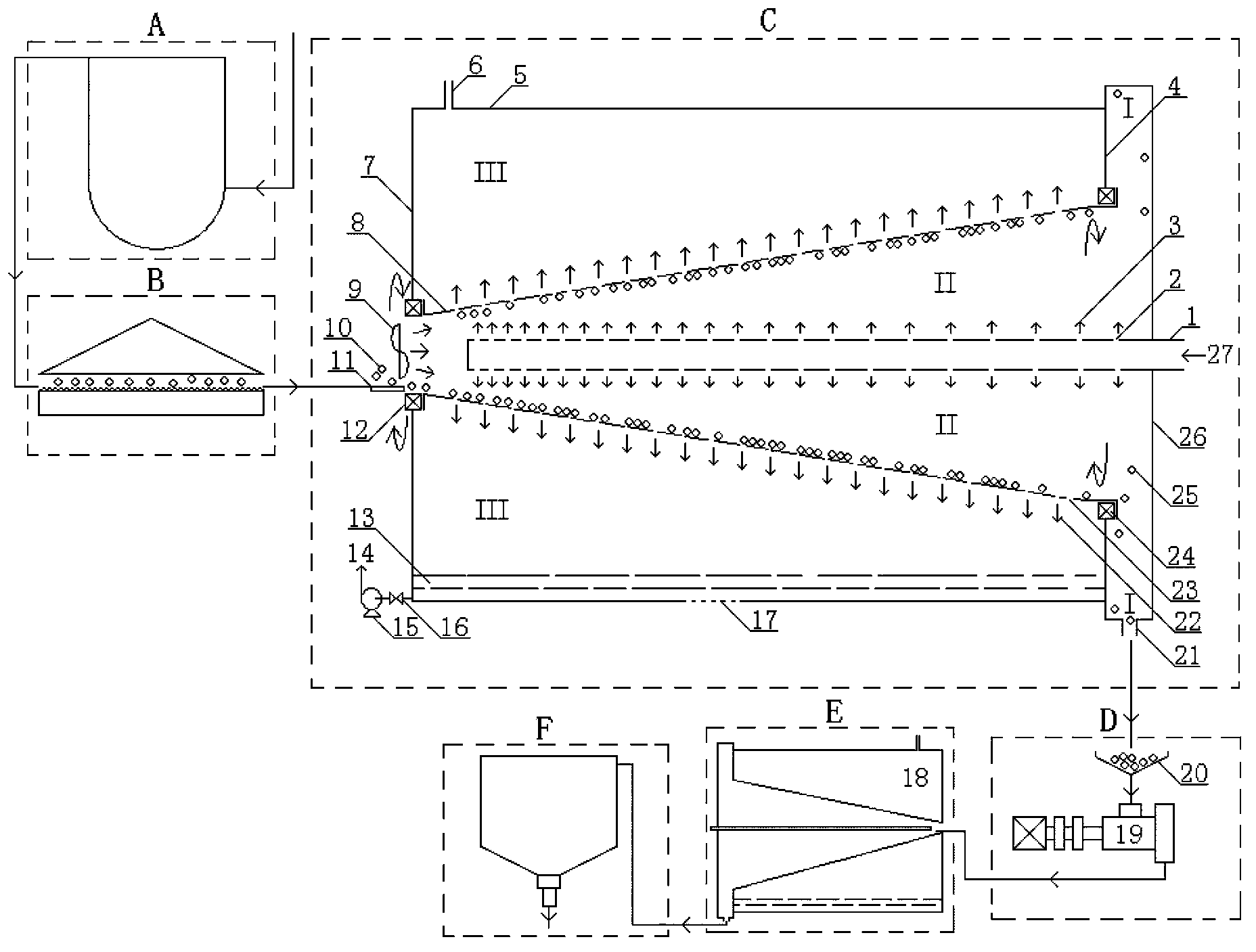

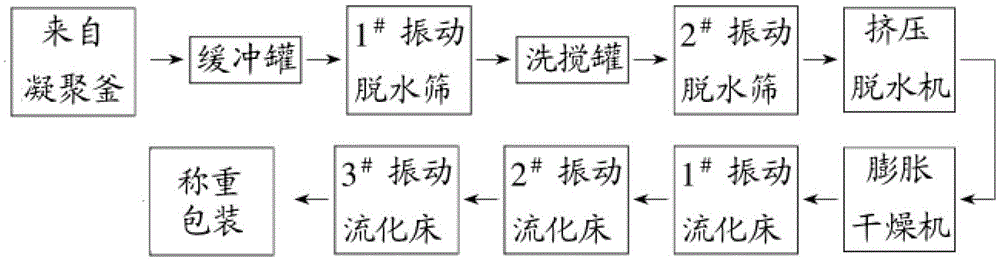

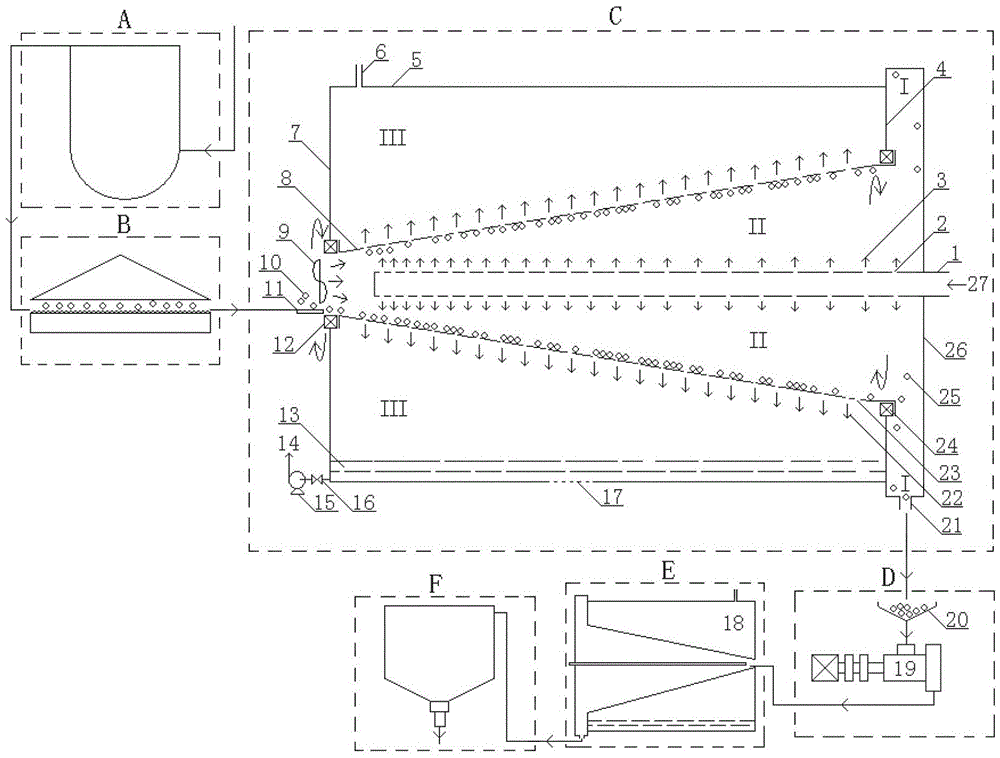

Devolatilization method and equipment of thermoplastic elastomers

The invention relates to a devolatilization method and equipment of thermoplastic elastomers. Water colloidal particles after the vibration dehydration are directly fed in a conical centrifugal dryer of a primary drying station for devolatilizing; dry colloidal particles after the devolatilization are fed in a pelletizing station, are pelletized by a screw extruder, and are fed in a conical centrifugal dryer of a secondary drying station for further drying; the drying hot wind temperature is 40-120 DEG C, and the wind volume is 10-600 L / s; the extruding temperature of the screw extruder is 100-200 DEG C, and the extruding pressure is 1-10 MPa; screen holes are formed in the screen surface of the conical centrifugal dryer for drying; small screen ports are connected with a driving bearing, and large screen ports are connected with a driven bearing; the driving bearing is driven through power equipment to rotate; and the conical centrifugal dryers are additionally provided with hot wind pipes, exhaust ports, cleaning ports and liquid level tanks. The method has such advantages as short technological process, less equipment floor, thorough devolatilization, stable index control, low content of product gels and large bulk density.

Owner:PETROCHINA CO LTD

Method for preparing high-purity lutein ester by using tagetes extract

ActiveCN107987002AEnable recyclingIncrease contentOrganic chemistryBulk chemical productionSolventEthyl acetate

The invention relates to the field of food processing, and aims at providing a method for preparing high-purity lutein ester by using tagetes extract. The method has the advantages that the sources ofthe raw materials are wide, the production cost is low, and the solvent can be reutilized. The method comprises the following steps of adding the tagetes extract into a supercritical CO2 (carbon dioxide) extracting tank, extracting and purifying, so as to obtain high-purity tagetes extract I; guiding the high-purity tagetes extract I into a stainless steel tank, adding ethyl acetate of which themass is equal to 5 to 10 times of the mass of the high-purity tagetes extract I, fully mixing and stirring, stirring for 30 to 45min at the temperature of 30 to 45 DEG C, enabling a high-speed centrifuging machine to centrifuge, and collecting precipitate II; adding an absolute ethyl alcohol solution of which the mass is equal to 5 to 6 times of the mass of the precipitate II into the stainless steel tank, mixing with the precipitate II, fully mixing the mixture, enabling the high-speed centrifuging machine to centrifuge, and collecting precipitate III; scraping the precipitate III into a stainless steel tray, uniformly dispersing, placing into a vacuum drying box, and drying under the vacuum condition, so as to obtain the finished product of the high-purity lutein ester.

Owner:邯郸市美康生物科技有限公司

Method for producing recombined pigskin using leftover material of broken pigskin

The invention relates to a method for producing recombinant pigskin by using broken pigskin leftover materials, which comprises the following steps: (1) material selection; (2) acidolysis; (3) boiling; (4) filtering; (5) salination; (6) neutralization; (7) blending; (8) enzyme catalysis; (9) pouring and forming; and (10) air curing. The method uses broken pigskins including the broken pigskins produced through division processing, scourged pigskins, gore pigskins and the like as raw materials to produce the entire pigskin, and adopts a glutamine transaminage preparation to perform biocatalysis on the entire reaction system so as to achieve the recombination of the broken pigskins. Using the glutamine transaminage preparation to process the broken pigskins for recombination and forming, the recombinant pigskin cannot be re-dispersed due to freezing, slicing, stewing, cooking and the like. The method recombines the pigskins for reuse, which not only revalues the pigskins, but also reduces pollutions to the environment. The formed recombinant pigskin is convenient for processing and application, can substitute the prior pigskins in the process of low-temperature meat product processing, and greatly reduce the production cost.

Owner:ZHENGZHOU UNIVERSITY OF LIGHT INDUSTRY

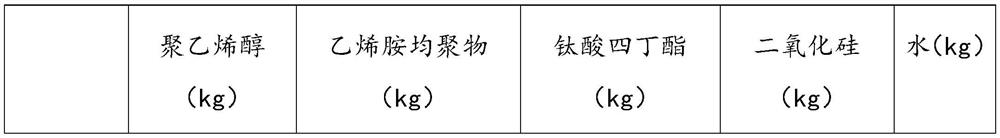

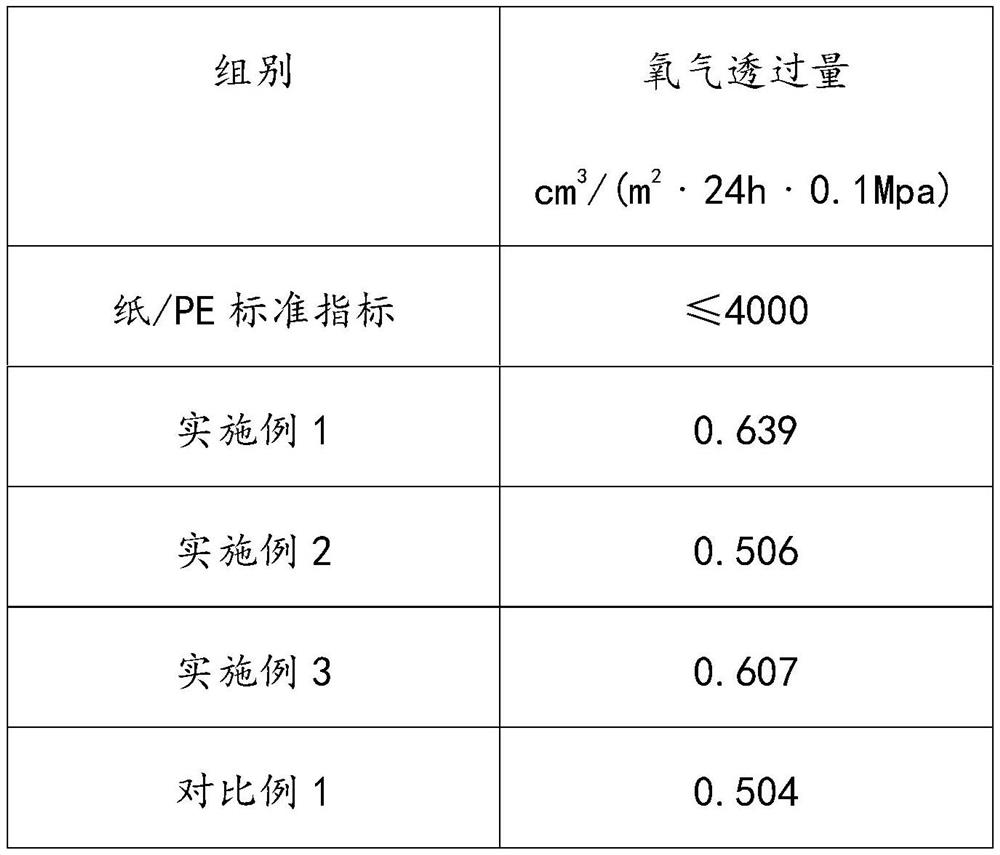

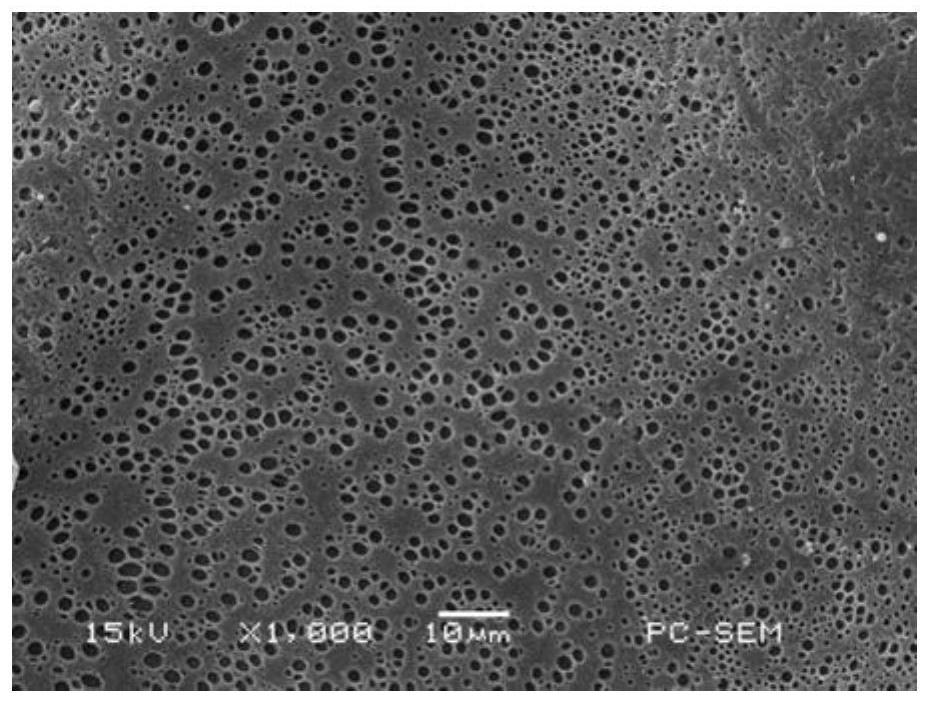

Barrier coating and high-barrier composite material applied in barrier coating

InactiveCN111690300AGood gas barrierStrong adhesionSynthetic resin layered productsPaper/cardboard layered productsPolyvinyl alcoholAluminum foil

The invention relates to the field of packaging materials, in particular to a barrier coating and a high-barrier composite material applied in the barrier coating. The barrier coating is prepared fromthe following raw materials in percentage by mass: 8 to 20 percent of polyvinyl alcohol, 1 to 10 percent of vinylamine homopolymer, 0.1 to 0.2 percent of tetrabutyl titanate, 0.1 to 0.2 percent of silicon dioxide and the balance of water. The polyvinyl alcohol, the vinylamine homopolymer, the tetrabutyl titanate and the silicon dioxide in a specific mass ratio are added into the water for a mixing reaction, the effect of modifying the polyvinyl alcohol is achieved, the polyethylene barrier coating with high barrier performance is finally obtained, and compared with the aluminum foil, the polyethylene barrier coating has the advantage of being easy to recycle and meets the development requirement for environmental protection.

Owner:ZHEJIANG GOLDSTONE PACKING

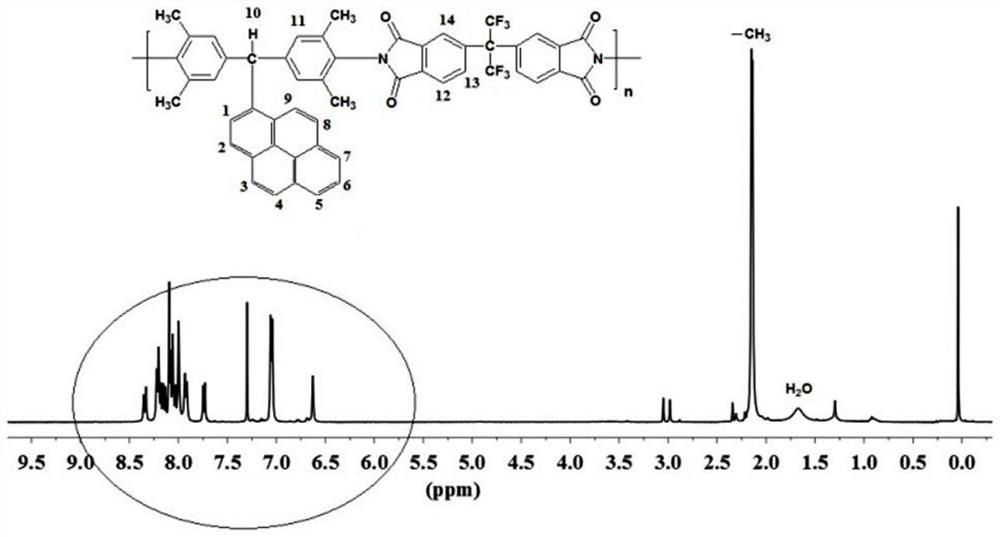

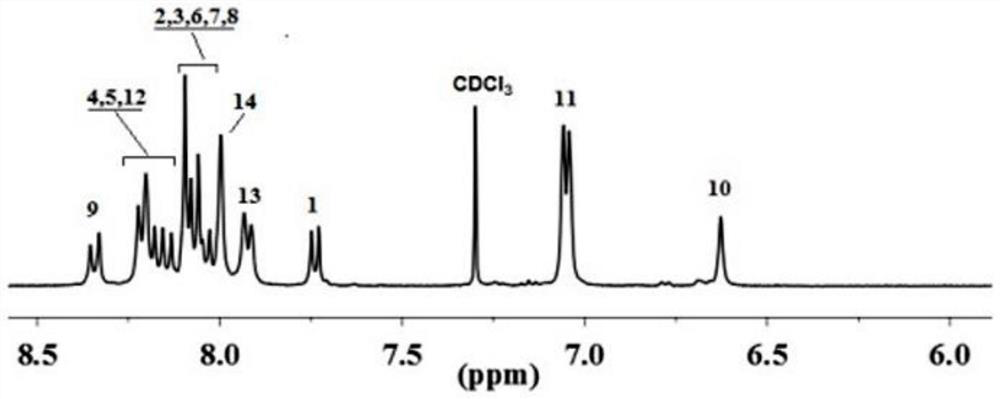

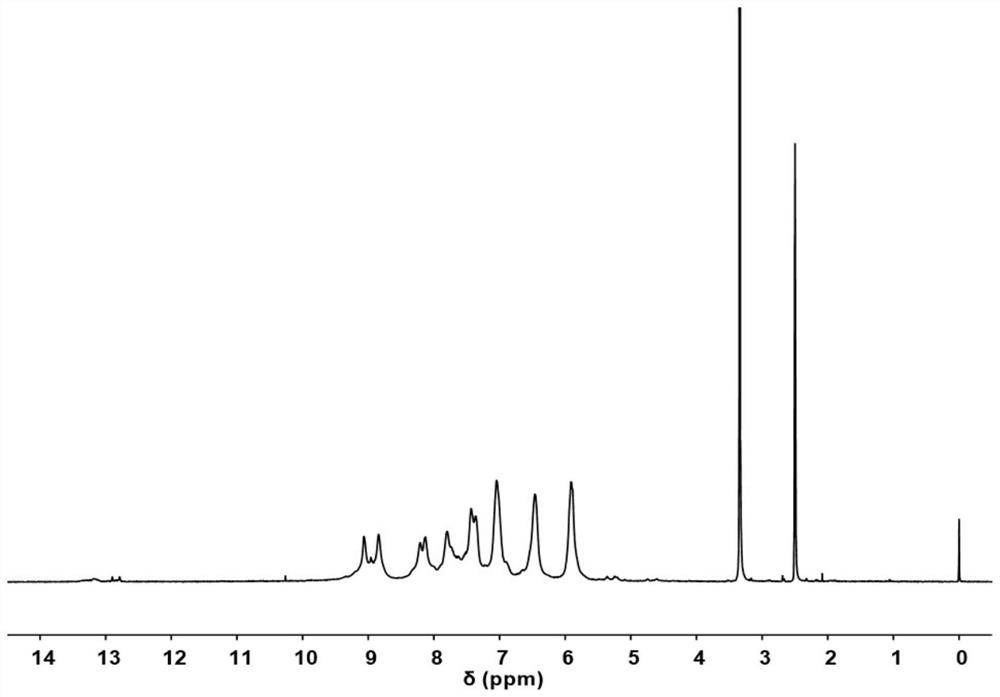

Fluorescent polymer, Fe 3+ detection test paper and preparation method and application thereof

PendingCN114015045AImprove light and heat stabilityEnhanced Fluorescent ResponseFluorescence/phosphorescenceLuminescent compositionsFluorescent polymerPhotopolymer

The invention discloses a fluorescent polymer and a preparation method thereof. Trifluoromethyl is introduced into the fluorescent polymer, so that the light and heat stability of the polymer can be improved; the technology is beneficial to improvement of fluorescence response in the aspect of metal ion detection, so that the fluorescent probe has relatively good fluorescence-metal ion responsiveness and can be used for fluorescence detection of metal ions, and meanwhile, the polymer has good dissolvability and is convenient to process and apply. The synthesized fluorescent polymer is prepared into a solution, the metal Fe 3+ detection test paper is prepared through an impregnation method, the test paper has fluorescence enhanced responsiveness to metal Fe 3+ and further has the advantages of being portable, high in sensitivity, simple in detection operation and the like, so that the metal Fe 3+ can be rapidly, simply and conveniently detected by dripping the solution to be detected on the test paper.

Owner:CHANGZHOU UNIV

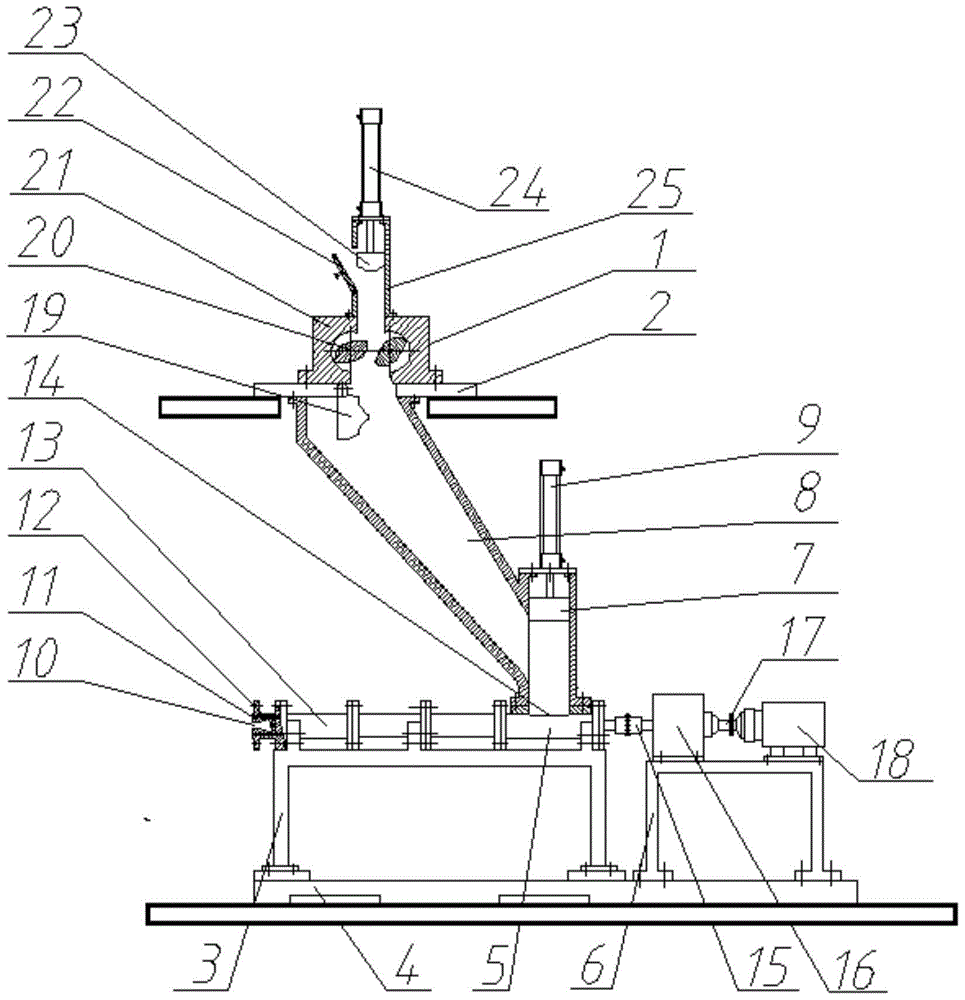

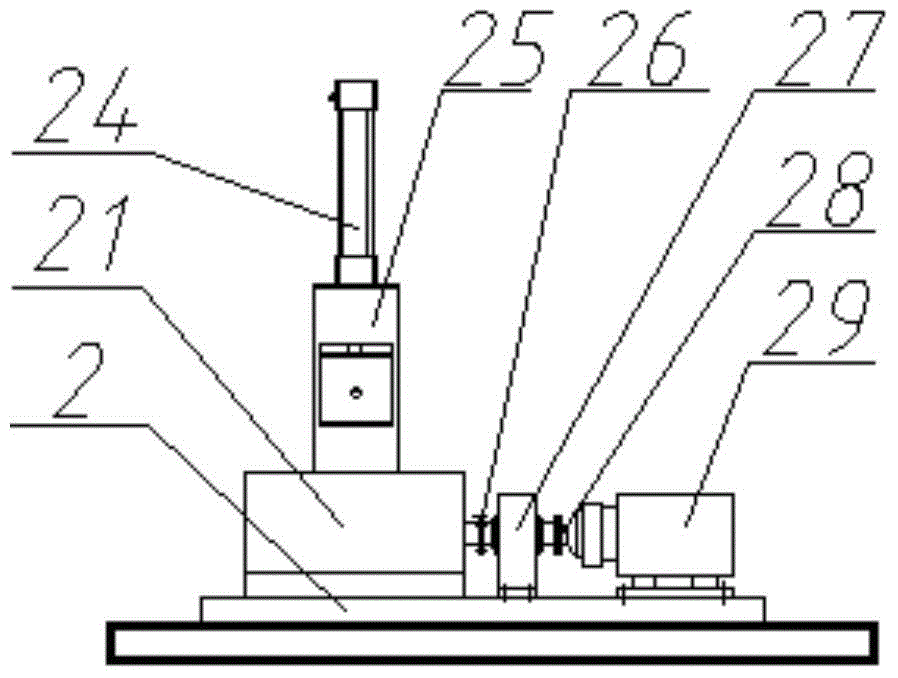

A serial rubber continuous mixing device

ActiveCN104354236BSolve the problem of insufficient control precisionSimple structureRubber materialButt joint

The invention relates to a tandem type continuous rubber mixing device, belonging to the technical field of rubber production equipment. The tandem type continuous rubber mixing device is of an upper and lower layer type structure integrally; a rack I and a rack II are fixedly connected to a base II through bolts respectively; a base I is fixedly connected with an internal mixer used for initially mixing rubber materials through bolts; an anisotropic dual-rotor continuous mixer is fixedly arranged on the rack I and the rack II through bolts for performing two-section mixing; the lower end of the internal mixer is in butt joint with the upper end of the anisotropic dual-rotor continuous mixer through a storage hopper in a communicating manner; the upper end of the left side of the storage hopper is connected with the base I through bolts; the upper end of the right side of the storage hopper is fixedly provided with an oil cylinder II through bolts; a weight is arranged at the lower end of the oil cylinder II in a connecting manner through a transmission rod and used for pressing initially mixed rubber in the storage hopper, which is discharged from the internal mixer, into the anisotropic dual-rotor continuous mixer. The tandem type continuous rubber mixing device is simple in structure, simple and convenient to assemble, high in controllability, low in energy consumption, mature in technology and convenient to machine and apply.

Owner:QINGDAO UNIV OF SCI & TECH

A kind of hfc/c ceramic precursor polymer and preparation method thereof

The invention discloses an HfC / C ceramic precursor polymer material and a preparation method thereof. The polymer has a coordination structure of hafnium and tetraiminetetraphenol, and can be pyrolyzed and converted into HfC / C ceramics at a temperature above 1600° C., and its ceramic yield is not lower than 55 wt%. The preparation method of the polymer is to synthesize the hafnium source compound and the tetraimine tetraphenol monomer through a one-pot polymerization reaction. The polymer precursor prepared by the invention is expected to be used as an impregnated matrix for ceramic matrix composite materials and anti-oxidation carbon / carbon composite materials, so as to improve their ultra-high temperature anti-oxidation properties.

Owner:INST OF CHEM CHINESE ACAD OF SCI

A kind of devolatilization method and equipment of thermoplastic elastomer

Owner:PETROCHINA CO LTD

Cross-linkable grafted polyethylene composition, cross-linked grafted polyethylene product, preparation method and product

ActiveCN106478887BGood safe processing windowEasy processing and applicationCross-linkPhosphorous acid

Owner:神华(北京)新材料科技有限公司

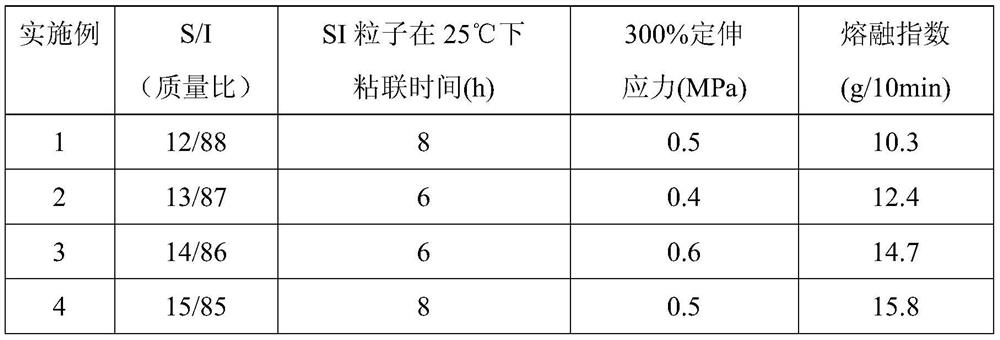

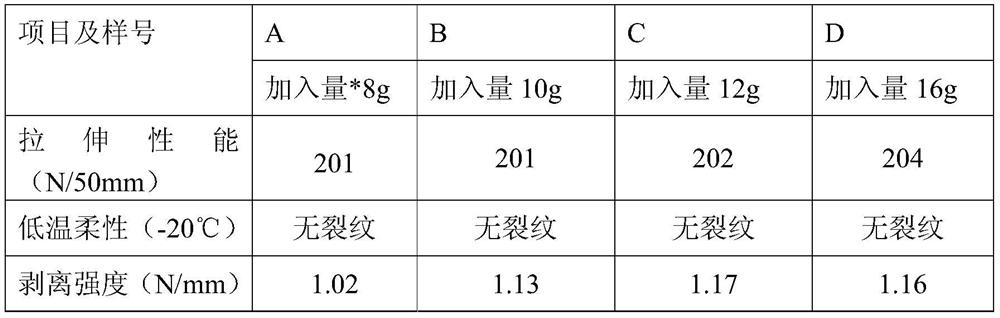

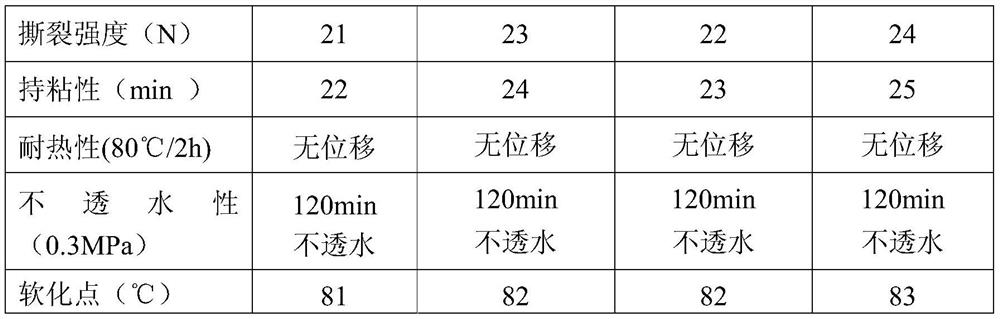

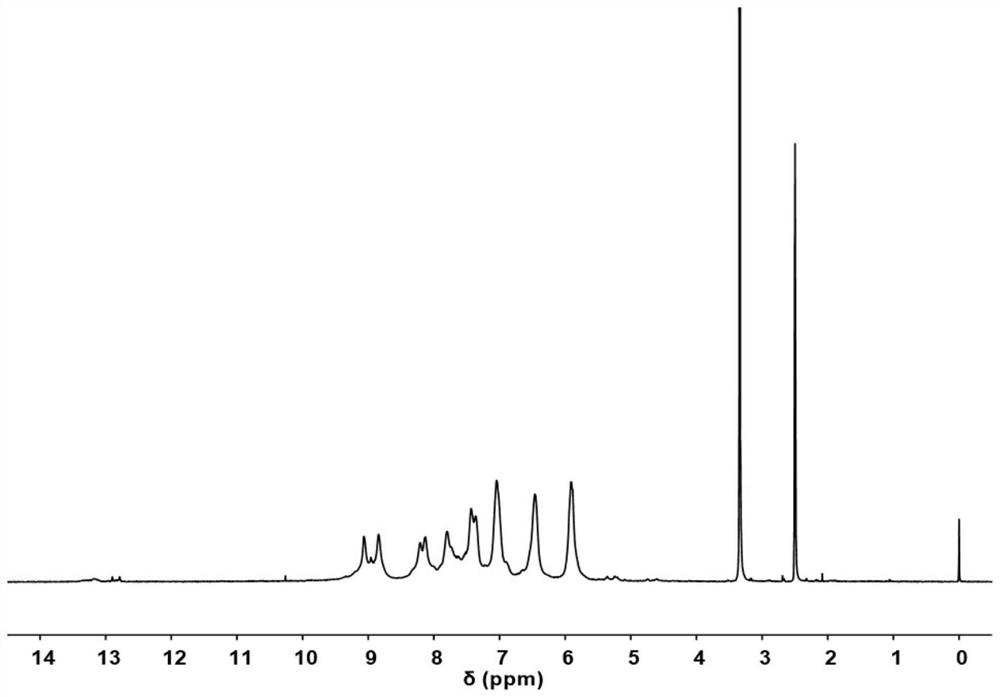

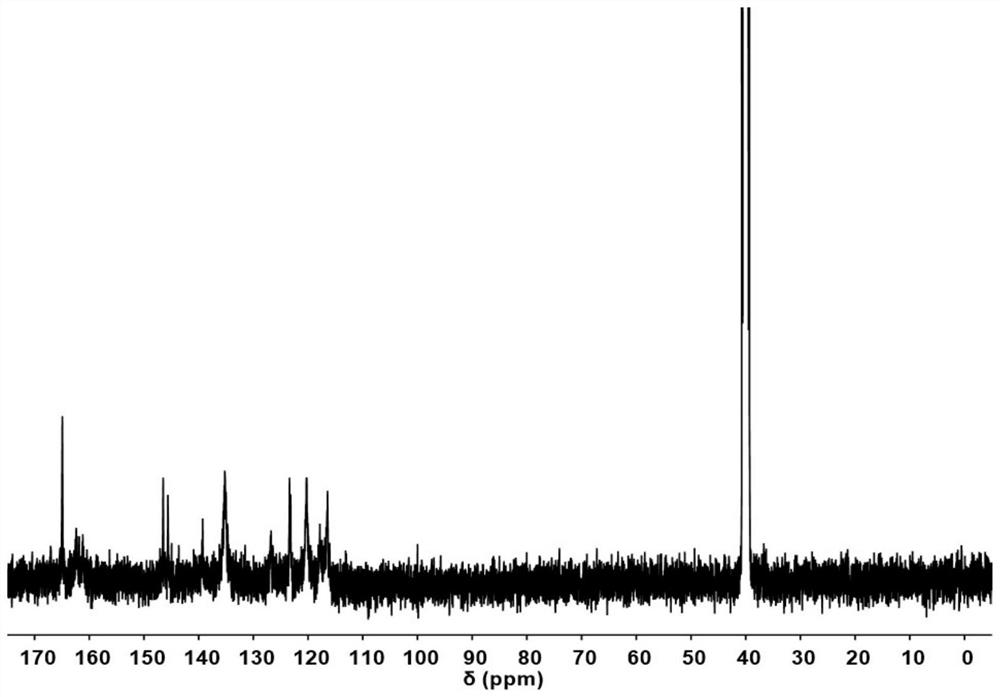

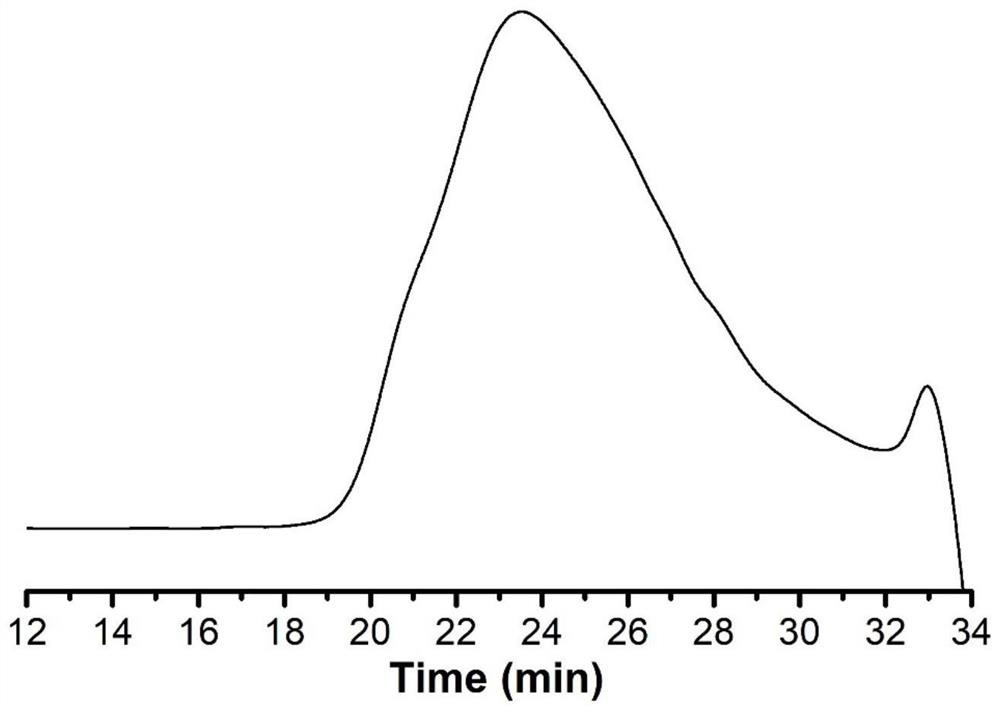

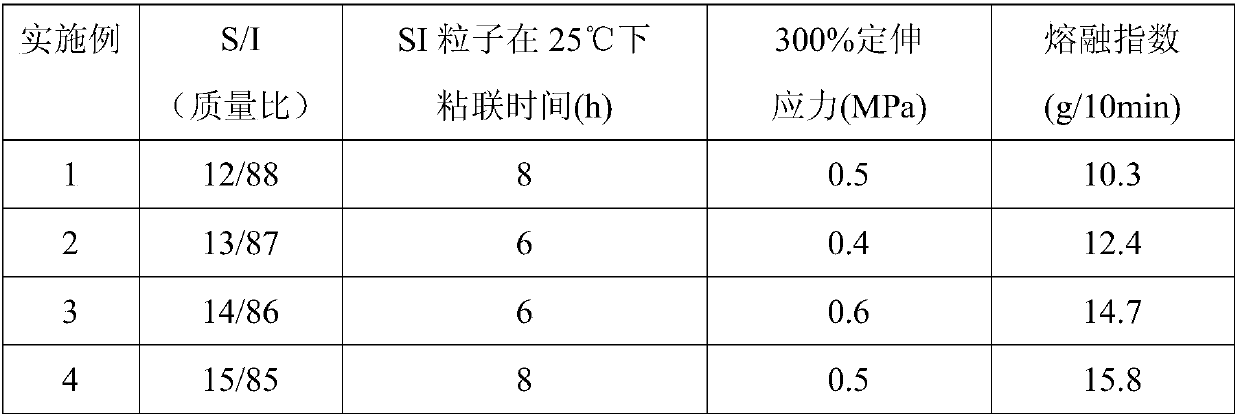

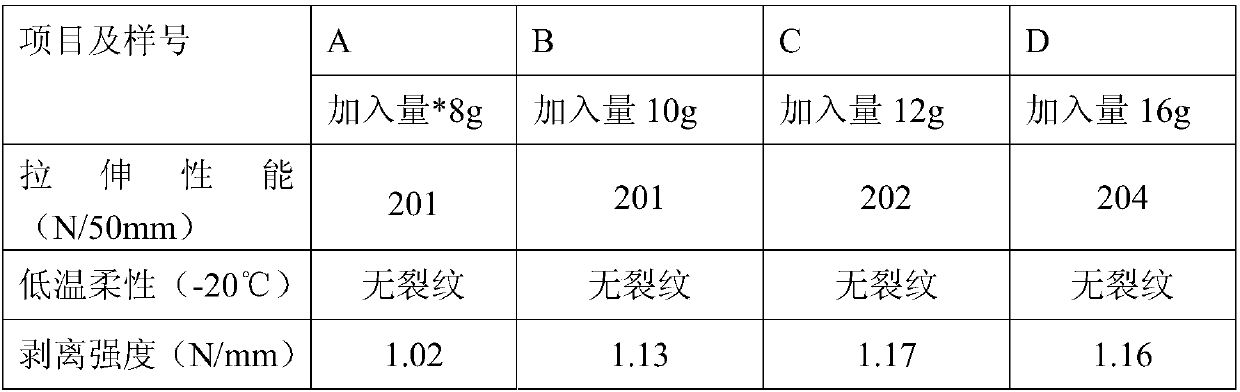

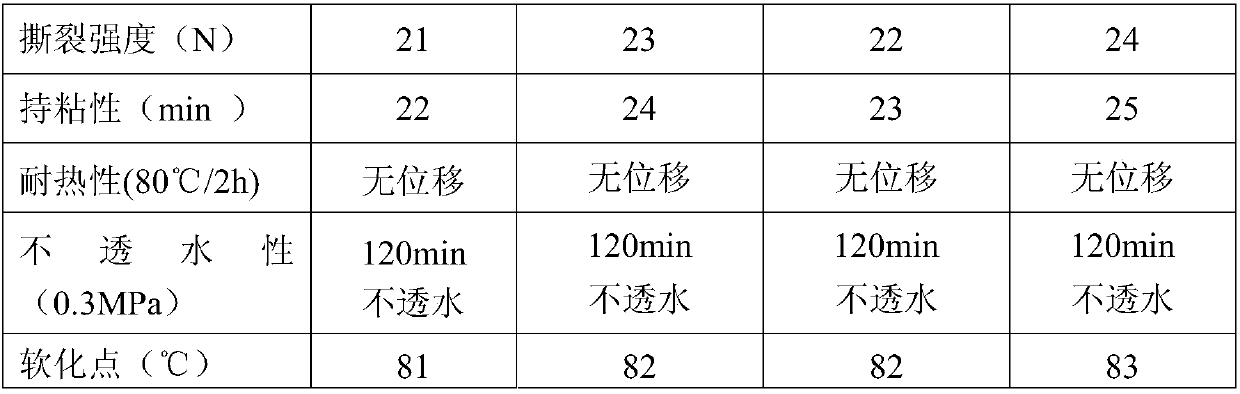

A kind of polystyrene-b-polyisoprene/tackifying resin composite rubber particle and its preparation method and application

The invention discloses a polystyrene-b-polyisoprene / tackifying resin composite rubber particle and a preparation method and application thereof. The composite rubber particle comprises polystyrene-b-polyisoprene and tackifying resin components. The preparation method includes: preparing polystyrene-b-polyisoprene sol in an anionic polymerization system, adding tackifying resin into the sol, dissolving, mixing and performing condensation, solvent removal and granulation to obtain the polystyrene-b-polyisoprene / tackifying resin composite rubber particle. The composite rubber particle is free ofcold flow and adhesion at the room temperature and has a great self-adhesion performance under the action of rubber oil, and the tackifying resin composite rubber particle is great in resistance to high and low temperatures and excellent in sand and concrete surface adhesion performance in high-wax high-softening-point asphalt modification, is also high in water resistance and ductility and realizes expansion of high-wax asphalt application.

Owner:CHINA PETROLEUM & CHEM CORP +1

HfC/C ceramic precursor polymer and preparation method thereof

The invention discloses an HfC / C ceramic precursor polymer material and a preparation method thereof. The polymer has a coordination structure of hafnium and tetramine tetraphenol, and can be pyrolyzed and converted into HfC / C ceramic at the temperature of 1600 DEG C or above, and the ceramic yield is not lower than 55 wt%. The preparation method of the polymer is characterized in that a hafnium source compound and a tetraimine tetraphenol monomer are subjected to a one-pot polymerization reaction to synthesize the polymer. The polymer precursor prepared by the method is expected to be used asa dipping matrix of a ceramic matrix composite material and an antioxidant carbon / carbon composite material so as to improve the ultrahigh-temperature oxidation resistance of the ceramic matrix composite material and the antioxidant carbon / carbon composite material.

Owner:INST OF CHEM CHINESE ACAD OF SCI

Single-component room-temperature-vulcanized fluorosilicone rubber and preparation method thereof

Owner:安徽斯迈特新材料股份有限公司

Polystyrene-b-polyisoprene/tackifying resin composite rubber particle and preparation method and application thereof

The invention discloses a polystyrene-b-polyisoprene / tackifying resin composite rubber particle and a preparation method and application thereof. The composite rubber particle comprises polystyrene-b-polyisoprene and tackifying resin components. The preparation method includes: preparing polystyrene-b-polyisoprene sol in an anionic polymerization system, adding tackifying resin into the sol, dissolving, mixing and performing condensation, solvent removal and granulation to obtain the polystyrene-b-polyisoprene / tackifying resin composite rubber particle. The composite rubber particle is free ofcold flow and adhesion at the room temperature and has a great self-adhesion performance under the action of rubber oil, and the tackifying resin composite rubber particle is great in resistance to high and low temperatures and excellent in sand and concrete surface adhesion performance in high-wax high-softening-point asphalt modification, is also high in water resistance and ductility and realizes expansion of high-wax asphalt application.

Owner:CHINA PETROLEUM & CHEM CORP +1

A production method for preparing high-purity lutein ester from marigold extract

ActiveCN107987002BEnable recyclingIncrease contentOrganic chemistryBulk chemical productionEthyl acetateSolvent

The invention relates to the field of food processing, and aims at providing a method for preparing high-purity lutein ester by using tagetes extract. The method has the advantages that the sources ofthe raw materials are wide, the production cost is low, and the solvent can be reutilized. The method comprises the following steps of adding the tagetes extract into a supercritical CO2 (carbon dioxide) extracting tank, extracting and purifying, so as to obtain high-purity tagetes extract I; guiding the high-purity tagetes extract I into a stainless steel tank, adding ethyl acetate of which themass is equal to 5 to 10 times of the mass of the high-purity tagetes extract I, fully mixing and stirring, stirring for 30 to 45min at the temperature of 30 to 45 DEG C, enabling a high-speed centrifuging machine to centrifuge, and collecting precipitate II; adding an absolute ethyl alcohol solution of which the mass is equal to 5 to 6 times of the mass of the precipitate II into the stainless steel tank, mixing with the precipitate II, fully mixing the mixture, enabling the high-speed centrifuging machine to centrifuge, and collecting precipitate III; scraping the precipitate III into a stainless steel tray, uniformly dispersing, placing into a vacuum drying box, and drying under the vacuum condition, so as to obtain the finished product of the high-purity lutein ester.

Owner:邯郸市美康生物科技有限公司

Application of a polyurethane urea hydrogel with shape memory function

ActiveCN103539919BProvides effective mechanical propertiesEasy processing and applicationTemperature responseRoom temperature

The invention relates to the application of a polyurethane urea hydrogel with shape memory function. The hydrogel is a copolymer of polyethylene glycol, diisocyanate and diamine. The polyurethane urea hydrogel provided by the present invention not only has a temperature-responsive shape memory function, but also has a water-responsive shape memory function at room temperature, and can also rely on the good tensile properties of the prepared hydrogel and the dehydration crystallization-absorption decrystallization process of PEG The deformation generation, immobilization and recovery under the conditions of room temperature and aqueous medium are realized by the accompanying crystalline phase transition in the material. It also has the characteristics of large elongation and high tensile strength, and has application prospects in biomedical hydrogels, tissue engineering, hydrogel scaffold materials, and biomedical devices endowed with shape memory functions.

Owner:SUZHOU UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com