A serial rubber continuous mixing device

A tandem and mixing technology, which is applied in the field of tandem rubber continuous mixing devices, can solve the problems of high rotor processing costs, many process parameters, and increased production costs, and achieves increased temperature control range, simple device structure, The effect of high degree of automation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

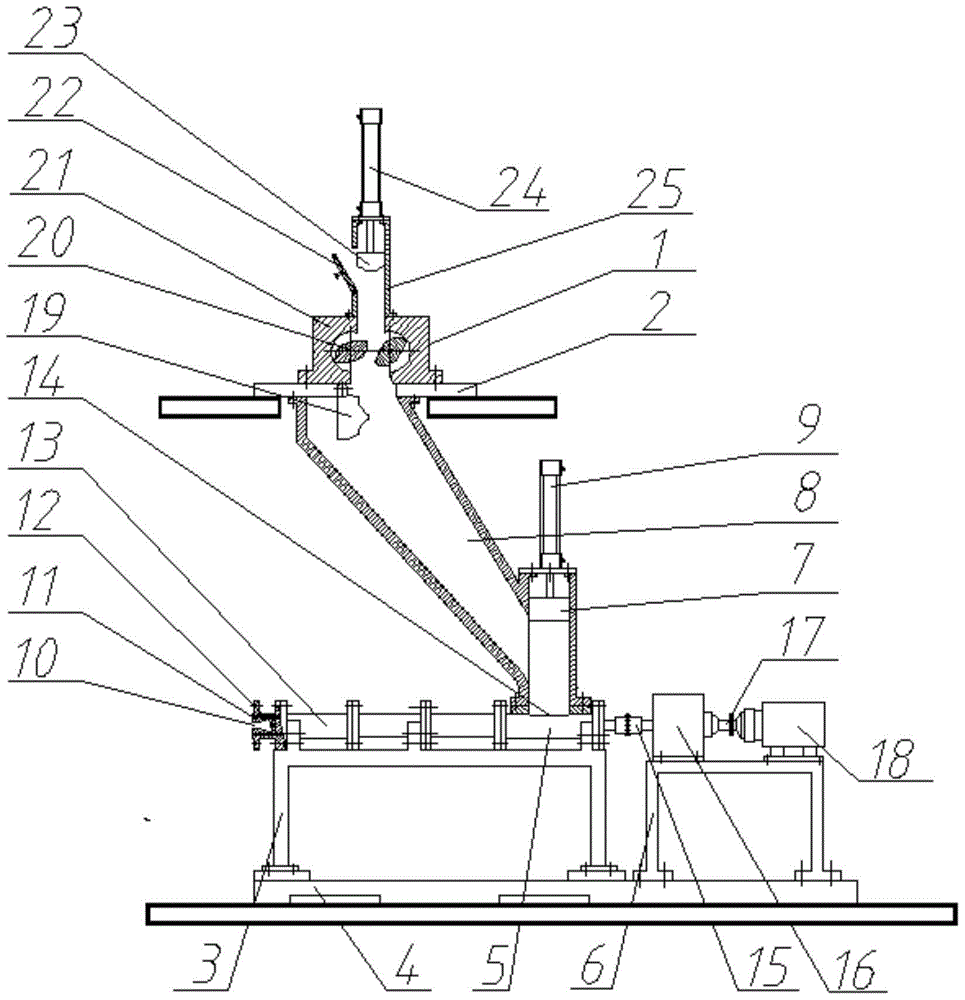

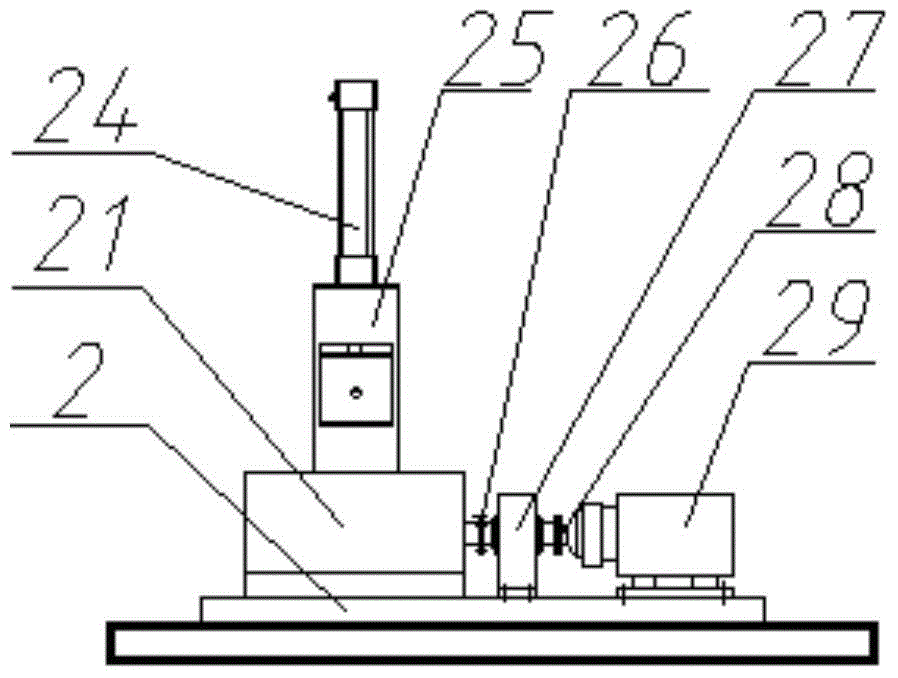

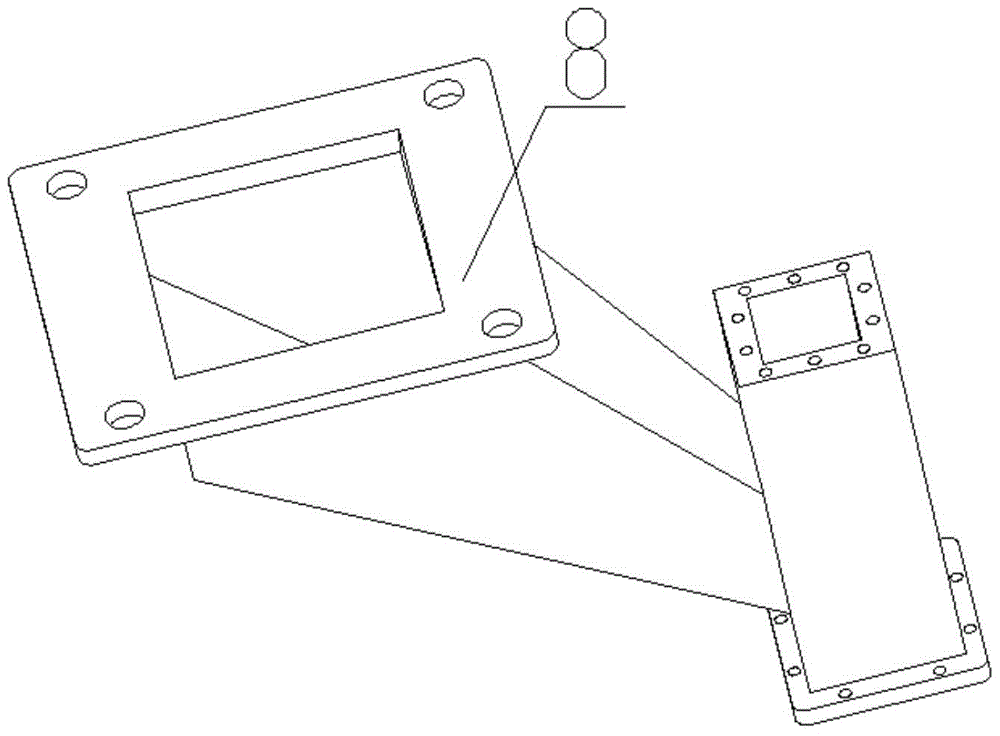

[0018] In this embodiment, the serial continuous rubber mixing device has an upper and lower two-layer structure as a whole, and the main structure includes an internal mixer 1, No. Machine 5, No. Ⅱ frame 6, pressing mass 7, storage hopper 8 and No. 2 oil cylinder 9, No. 1 frame 3 and No. 2 frame 6 are respectively connected to the No. 2 base 4 by bolts, and the No. 1 base 2. The internal mixer 1 for initial mixing of rubber materials is fixedly connected with bolts, and the counter-rotating double-rotor continuous mixer 5 is fixed on the No. 1 frame 3 and No. 2 frame 6 by bolts for two-stage mixing. , the lower end of the internal mixer 1 and the upper end of the counter-rotating double-rotor continuous mixer 5 are connected through the storage hopper 8, and the upper left end of the storage hopper 8 is connected with the No. 1 base 2 by bolts, and its right upper end passes through The No. Ⅱ oil cylinder 9 is fixedly installed with bolts, and the lower end of the No. Ⅱ oil c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com