Printed circuit board and method for fabricating the same, and apparatus for fabricating printed circuit board

A technology of printed circuit boards and manufacturing methods, which is applied in the direction of printed circuit manufacturing, stacked printed circuit boards, printed circuits, etc., can solve the problems of pollution, cost, and precision that cannot meet the development and application requirements of printed circuit boards, and achieve reduction Contamination, thickness reduction, process improvement and cost-effective effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The following will clearly illustrate the spirit of the present invention with the accompanying drawings and detailed descriptions. Any person with common knowledge in the technical field can change and modify the technology taught by the present invention after understanding the preferred embodiments of the present invention. without departing from the spirit and scope of the present invention. And for the sake of clarity, many specific details will be described together in the following description. However, those skilled in the art will appreciate that in some embodiments of the present invention, these specific details are not necessary and should not be used to limit the present invention. In addition, for the sake of simplification of the drawings, some conventional structures and elements will be shown in a simple and schematic manner in the drawings.

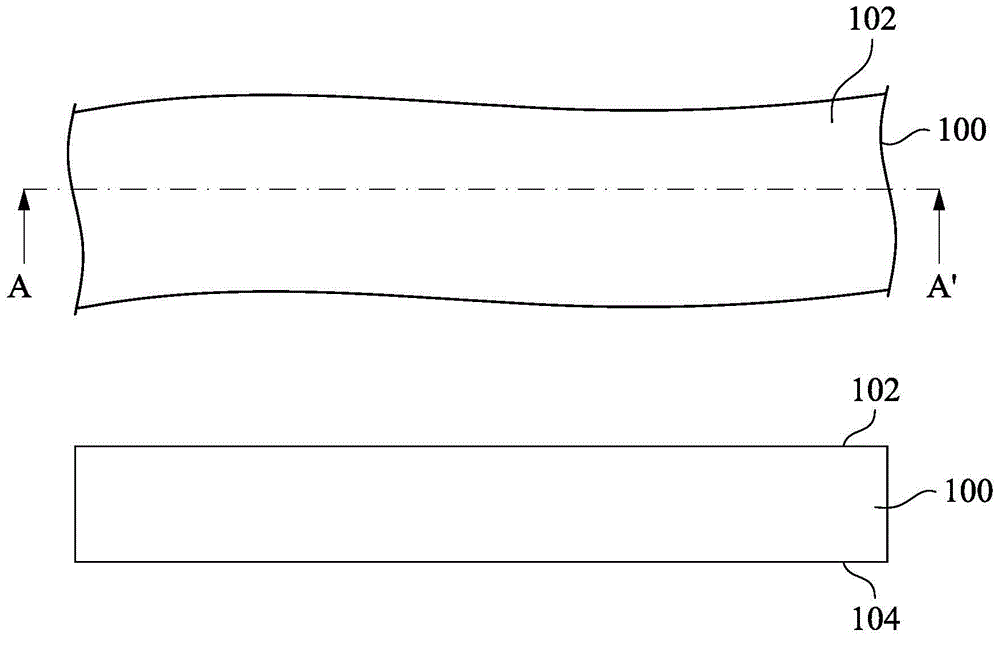

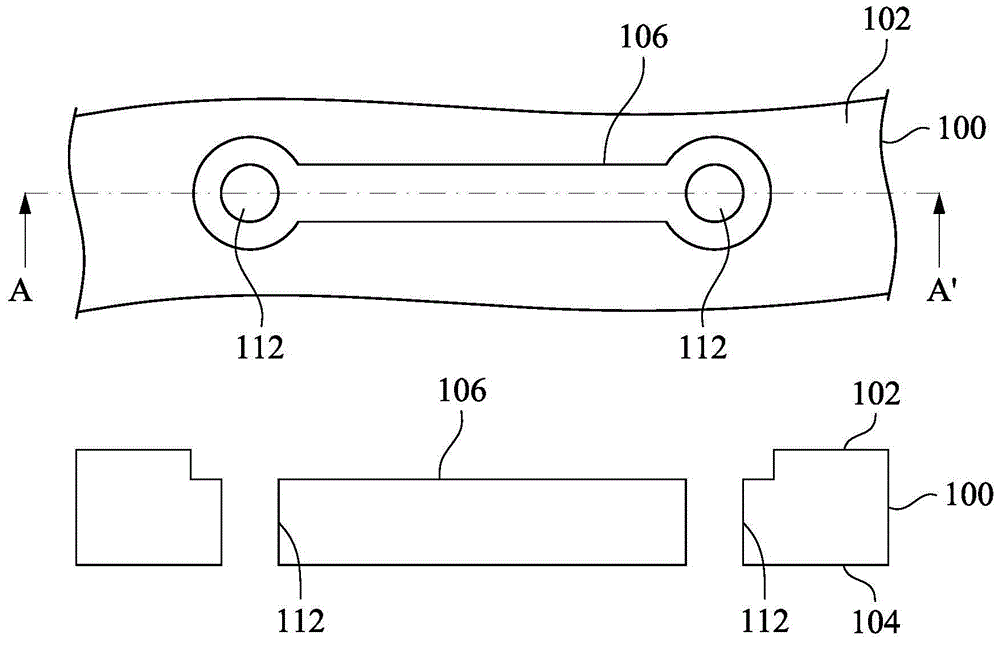

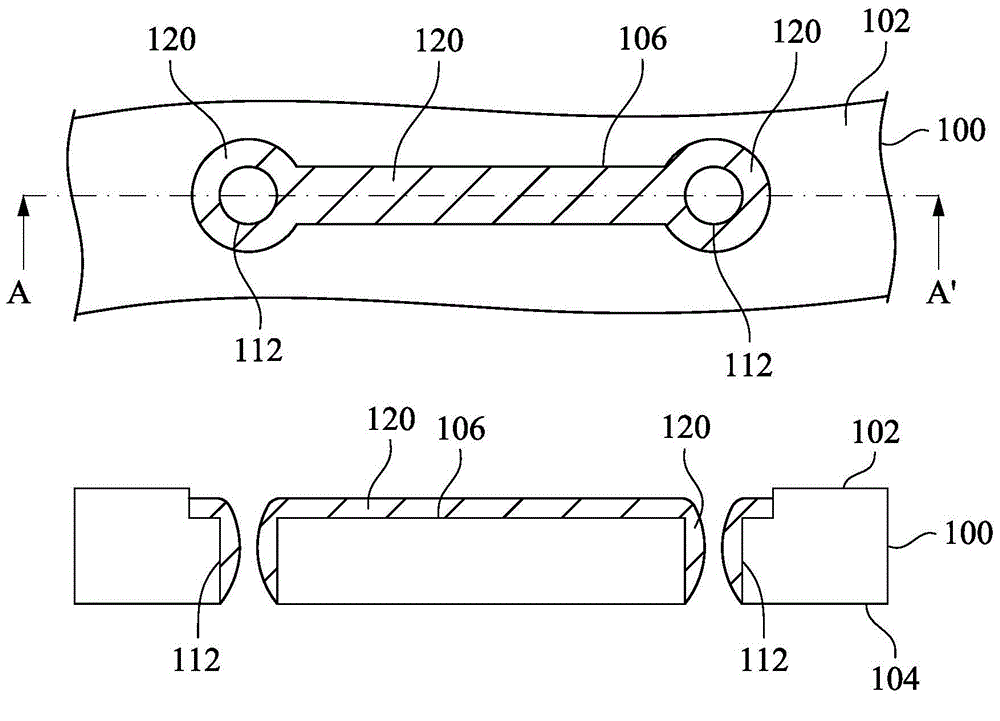

[0030] see Figures 1A to 1F , Figures 1A to 1F It is a plan view and a schematic cross-sectional view of a m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com