A kind of polystyrene-b-polyisoprene/tackifying resin composite rubber particle and its preparation method and application

A polyisoprene and polystyrene technology, applied in building components, building insulation materials, buildings, etc., to achieve the effect of small elastic flow, low Tg, and good bonding performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

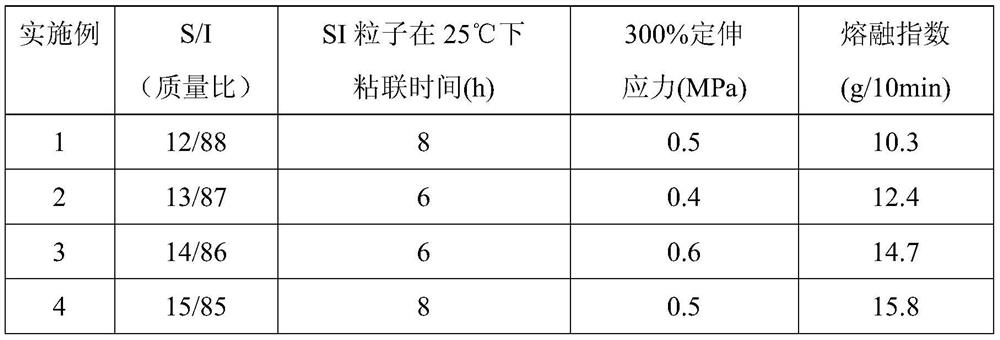

Embodiment 1

[0053] Add 3500 mL of cyclohexane solution with a mass fraction of 10% n-hexane in a 5-liter polymerization kettle under nitrogen protection, then add 0.08 mL of anisole, and heat the solvent in the polymerization kettle to 50-60 °C with a hot water bath. After ℃, add 50g of styrene into the polymerization kettle and start stirring, then inject 8.5mL of 0.5mol / L n-butyllithium into the polymerization kettle with a syringe, and react for 20-25min; then add 366g of isoprene, After reacting at 50-90°C for 25 minutes; the measured polymer (S-I) number average molecular weight Mn=98700, wherein the number average molecular weight of block polystyrene Mn(s)=12700, the isoprene segment in the polymer is 1, The 4-adduct content is 85.6%, and the 3,4-adduct content is 14.4%.

Embodiment 2

[0055] The relevant conditions in Example 1 were kept unchanged, except that the amount of n-butyllithium was selected as 9.0 mL, anisole was 0.05 mL, and the amount of isoprene was 334 g. Results The number average molecular weight of the synthesized polymer (S-I) was Mn=93300, among which the number average molecular weight of block polystyrene was Mn(s)=11400, and the content of isoprene block 1,4-adduct in the polymer was 88.5 %, 3,4-adducts 11.5%.

Embodiment 3

[0057] The relevant conditions in Example 1 are kept unchanged, only the amount of n-butyllithium is selected as 9.5 mL, anisole is 0.05 mL, and the amount of isoprene is 307 g. Results The number average molecular weight of the synthesized polymer (S-I) Mn = 85400, the number average molecular weight of block polystyrene Mn (s) = 10600, the content of 1,4-adduct of isoprene segment in the polymer is 88.6 %, 3,4-adducts 11.4%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| softening point | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

| peel strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com