Patents

Literature

315results about How to "Meet industrial production requirements" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

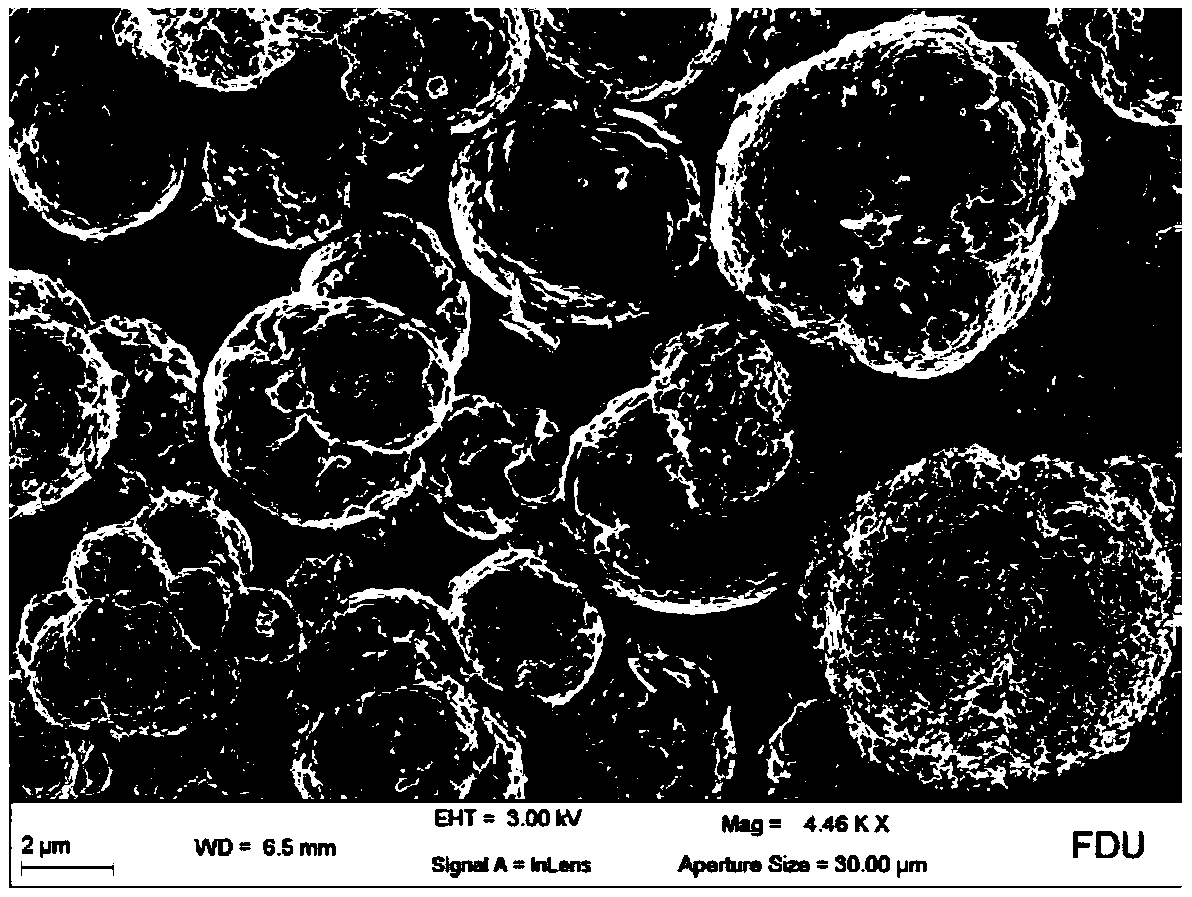

Nanostructured quasi-solid electrolyte applied to lithium ion batteries or lithium sulfur batteries and preparation method and application thereof

ActiveCN105070946AImprove conductivityImprove stabilitySolid electrolytesCell seperators/membranes/diaphragms/spacersSolid state electrolyteLithium sulfur

The invention discloses a nanostructured quasi-solid electrolyte applied to lithium ion batteries or lithium sulfur batteries and a preparation method and application thereof. The nanostructured quasi-solid electrolyte is a macro solid-state electrolyte material which is formed by an inorganic-organic hybrid framework material adsorbing ion conductive agent. The preparation method of the nanostructured quasi-solid electrolyte is as follows: in protective atmosphere, the inorganic-organic hybrid framework material is soaked in the ion conductive agent and sufficiently mixed, and redundant solvent is then volatilized. The prepared nanostructured quasi-solid electrolyte with high lithium ion conductivity can be substituted for both organic electrolyte and diaphragms in conventional lithium ion batteries, and thereby safety problems caused by the leakage of the organic electrolyte can be effectively prevented; a lithium battery assembled from the electrolyte can use a metal lithium plate as a cathode.

Owner:CENT SOUTH UNIV

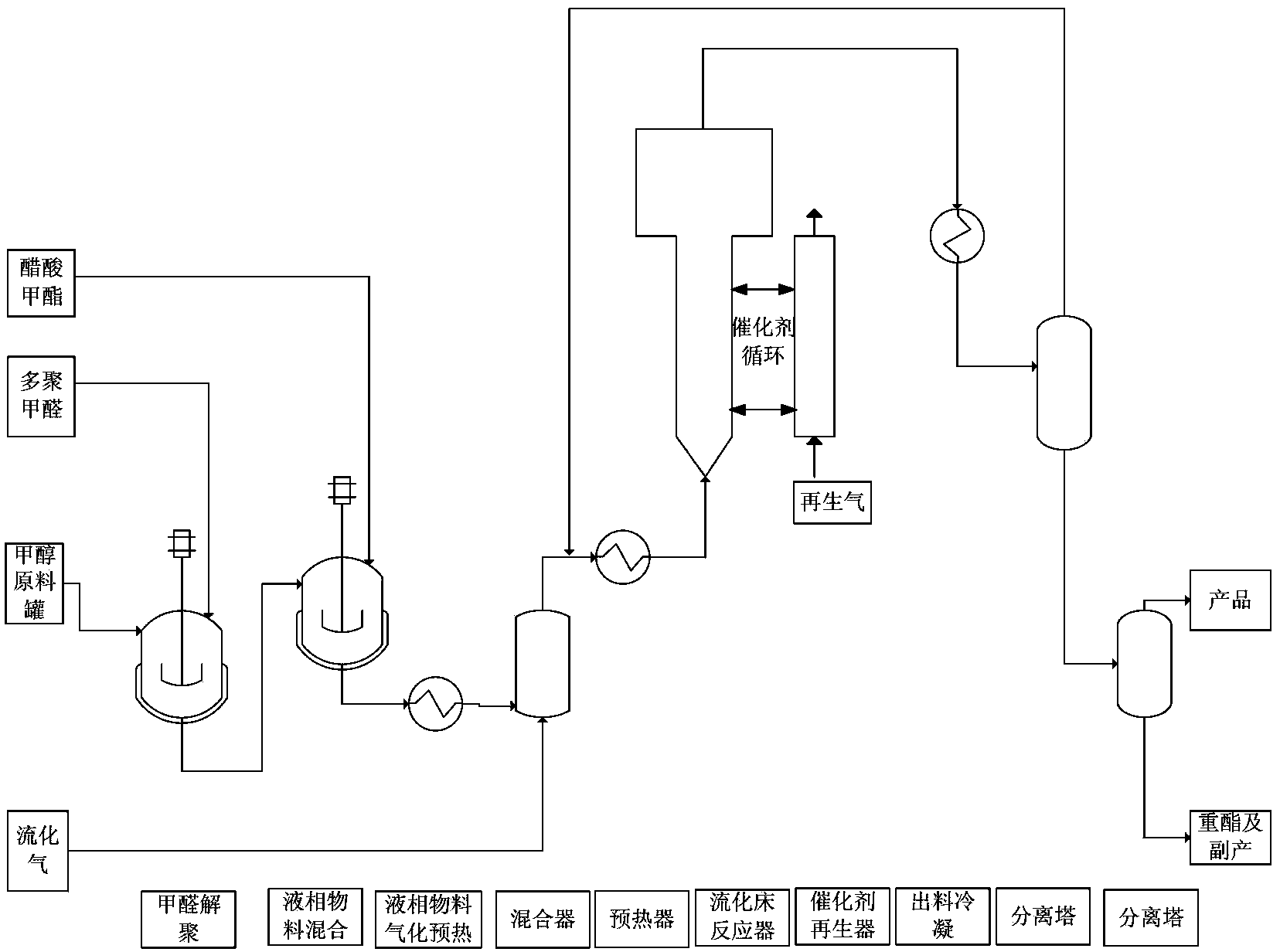

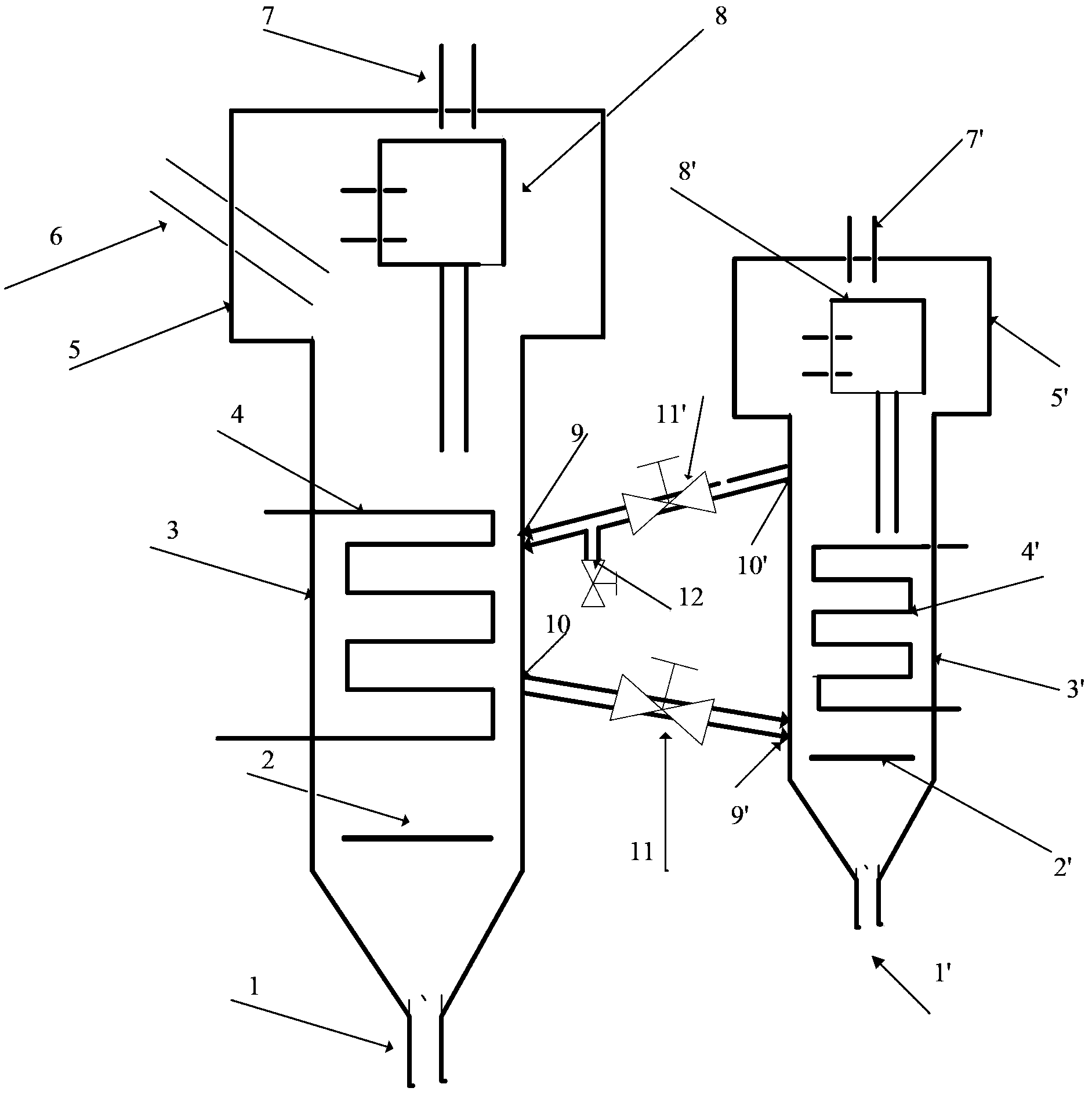

Method for preparing methyl methacrylate from methyl propionate and formaldehyde

ActiveCN102775302AImprove utilization efficiencyImprove efficiencyOrganic compound preparationCarboxylic acid esters preparationFluidized bedEconomic benefits

The invention provides a method for preparing methyl methacrylate from methyl propionate and formaldehyde. According to the method for preparing the methyl methacrylate from the methyl propionate and the formaldehyde, the fluidized bed reactor and the catalyst regenerator are coupled, so that the problem on the rapid deactivation of the catalyst is solved effectively, and the continuous production is realized. The method achieves important economic benefits.

Owner:BEIJING RISUN TECH CO LTD

Aluminiferous casting material for blast furnace tapping and preparation method thereof

The invention relates to an aluminiferous casting material for blast furnace tapping and a preparation method thereof, belonging to the technical field of fire-proof material. The main raw materials of the casting material contain industrial corundum powder, Si powder, high-temperature pitch grain powder, alumina concrete or calcium aluminum concrete, Aplha-Al2O3 superfine powder, SiO2 superfine powder and metallic silicon powder. Sodium tripolyphosphate or sodium hexametaphosphate is used as dispersing agent. Explosion-proof organic fiber and aluminum ash are added to acquire the casting material for blast furnace tapping. The casting material can be used, after adding 4% to 6% of water and mixing in the casting material, molding the mixture by pouring into a mould for blast furnace tapping, naturally hardening, drying, de-molding, drying at a temperature of 85 DEG C to 700 DEG C and removing water by performing thermal treatment. The casting material has high blast furnace slag resistant property and usability. By adopting the components Al2O3, Al, SiO2, etc., in the aluminum ash instead of the aluminum material and siliceous material in the casting material for blast furnace tapping, the invention can efficiently lower the cost of the casting material and find a new way to comprehensively use aluminum ash.

Owner:CHINA UNIV OF GEOSCIENCES (BEIJING)

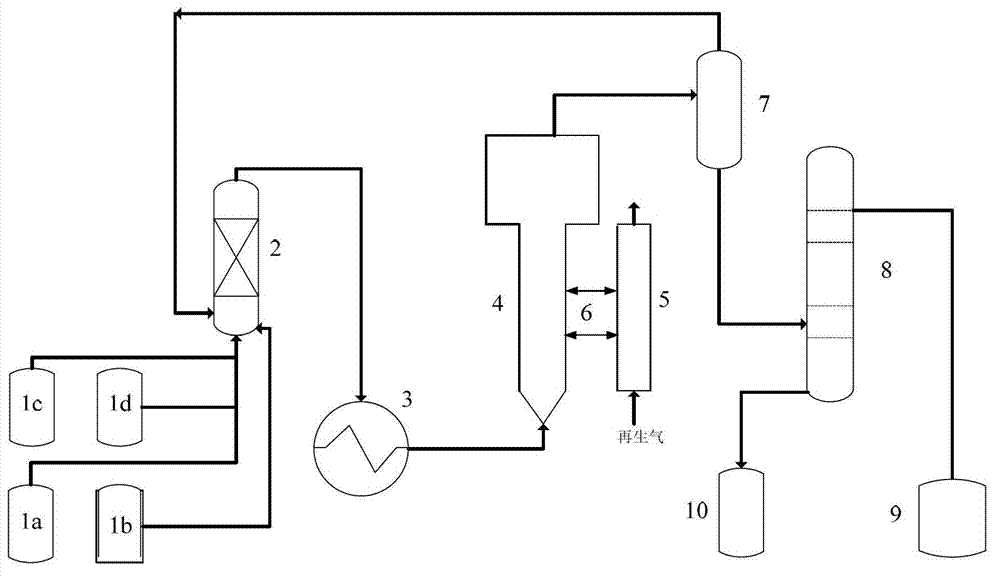

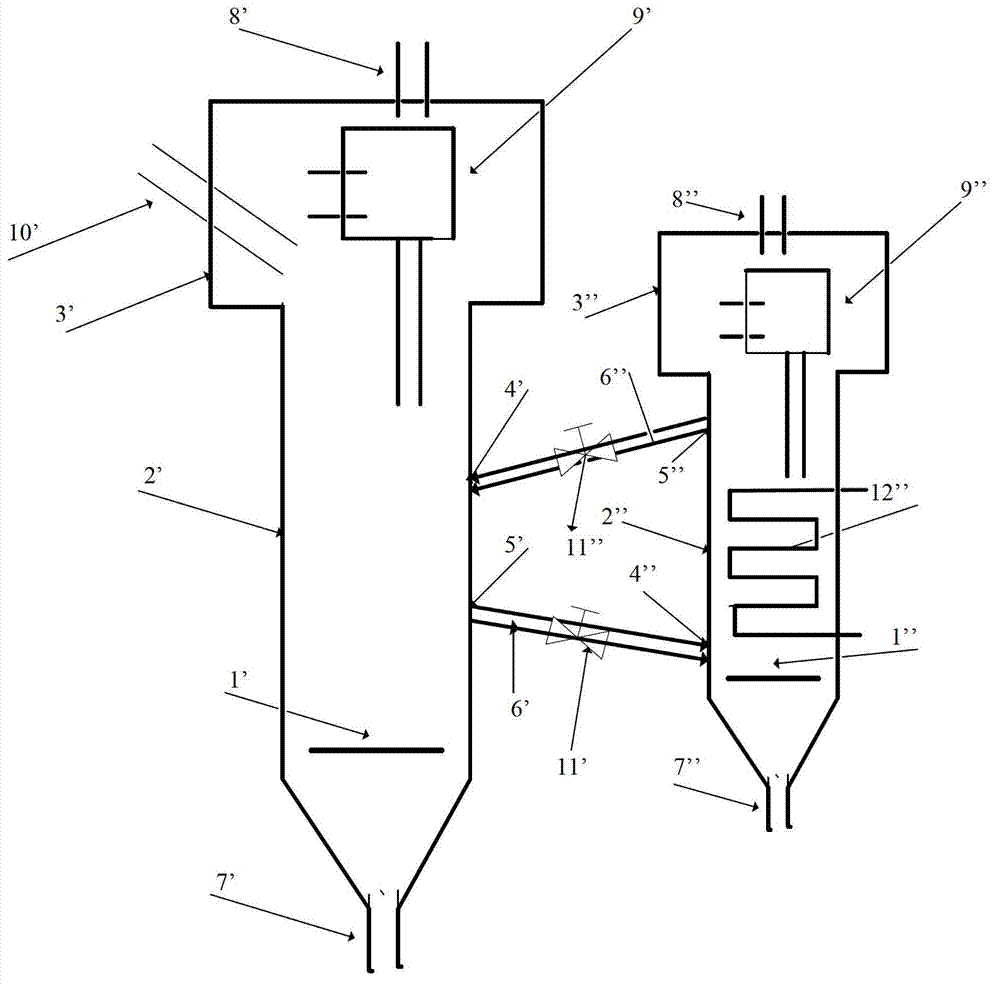

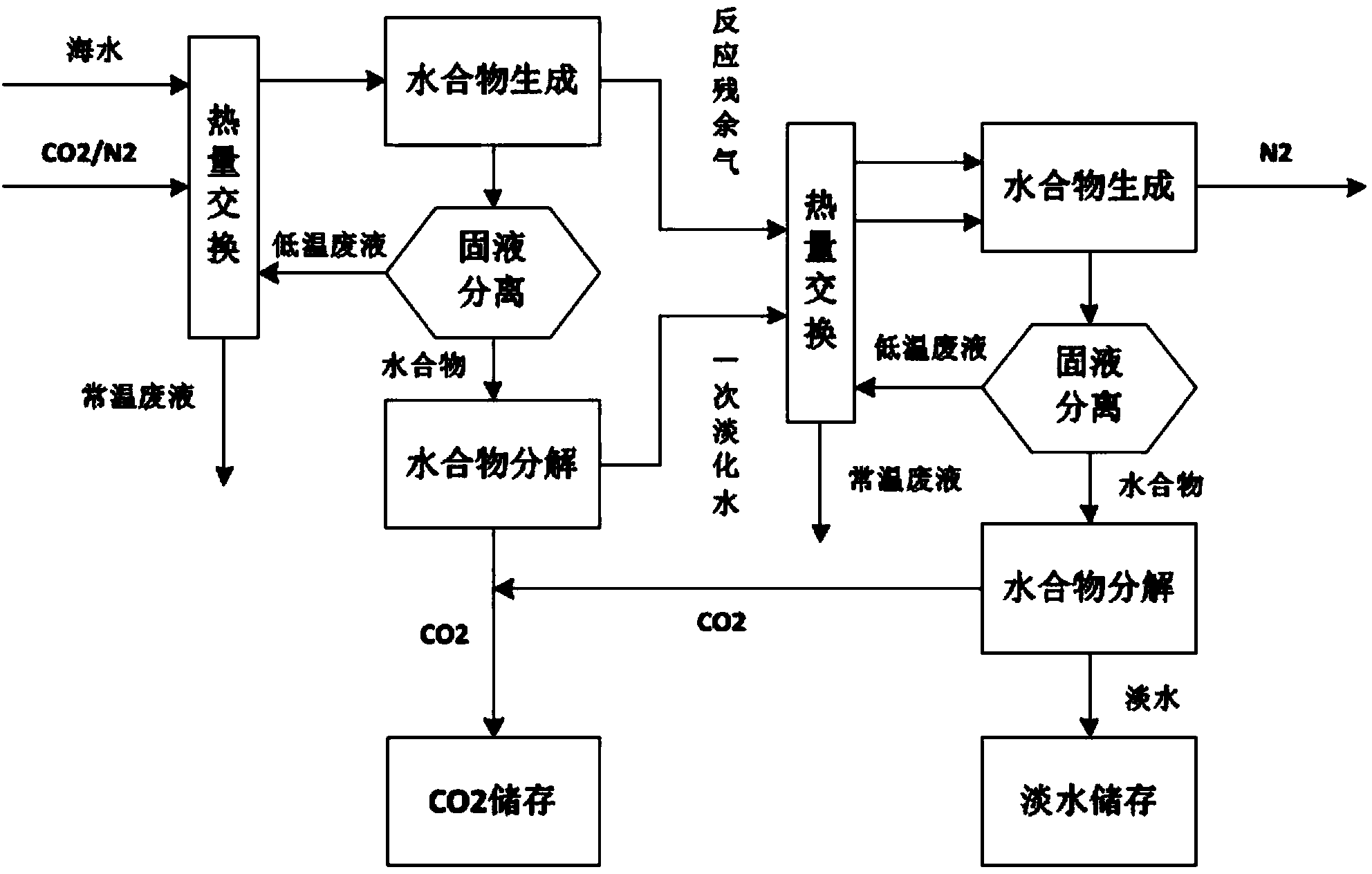

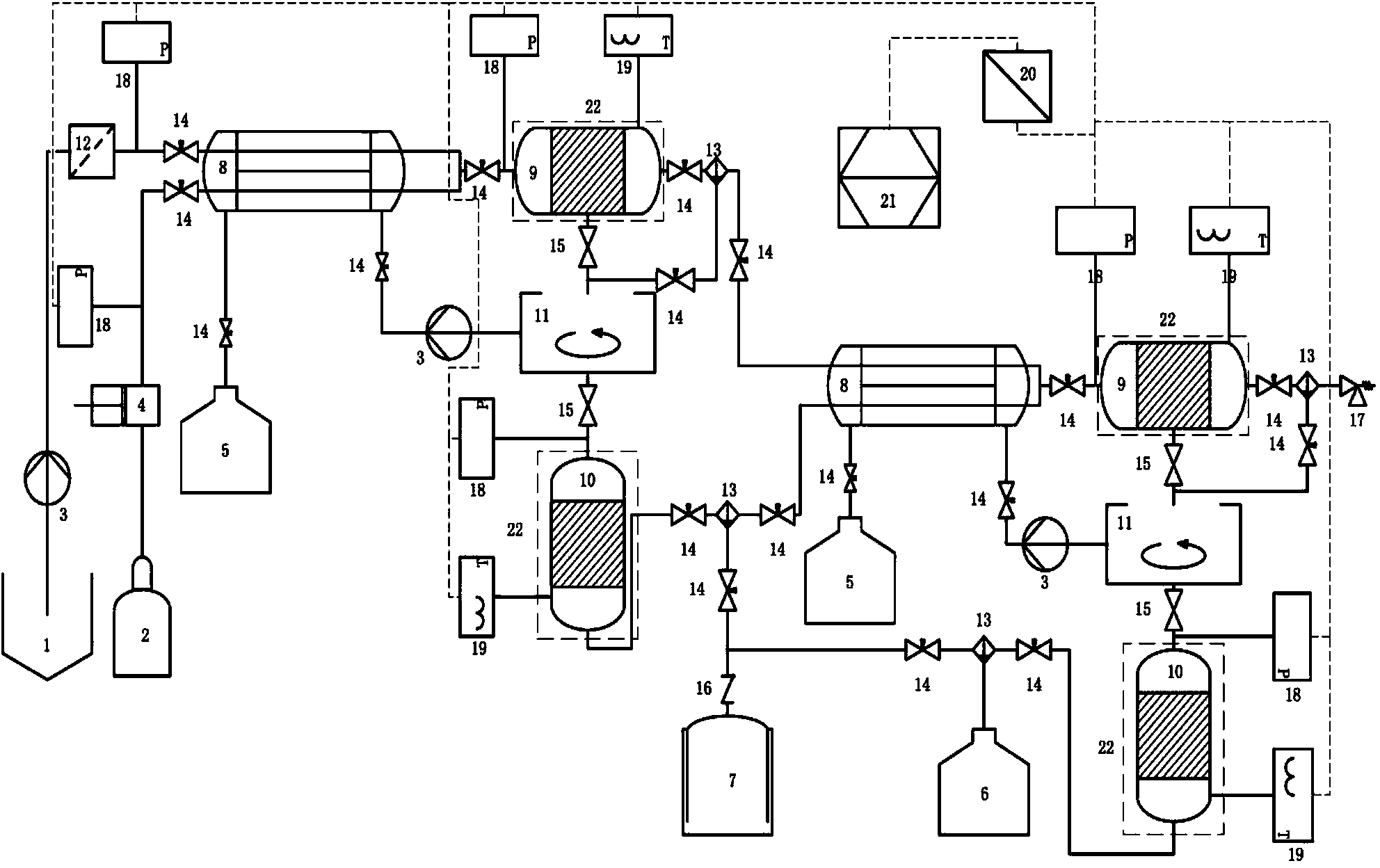

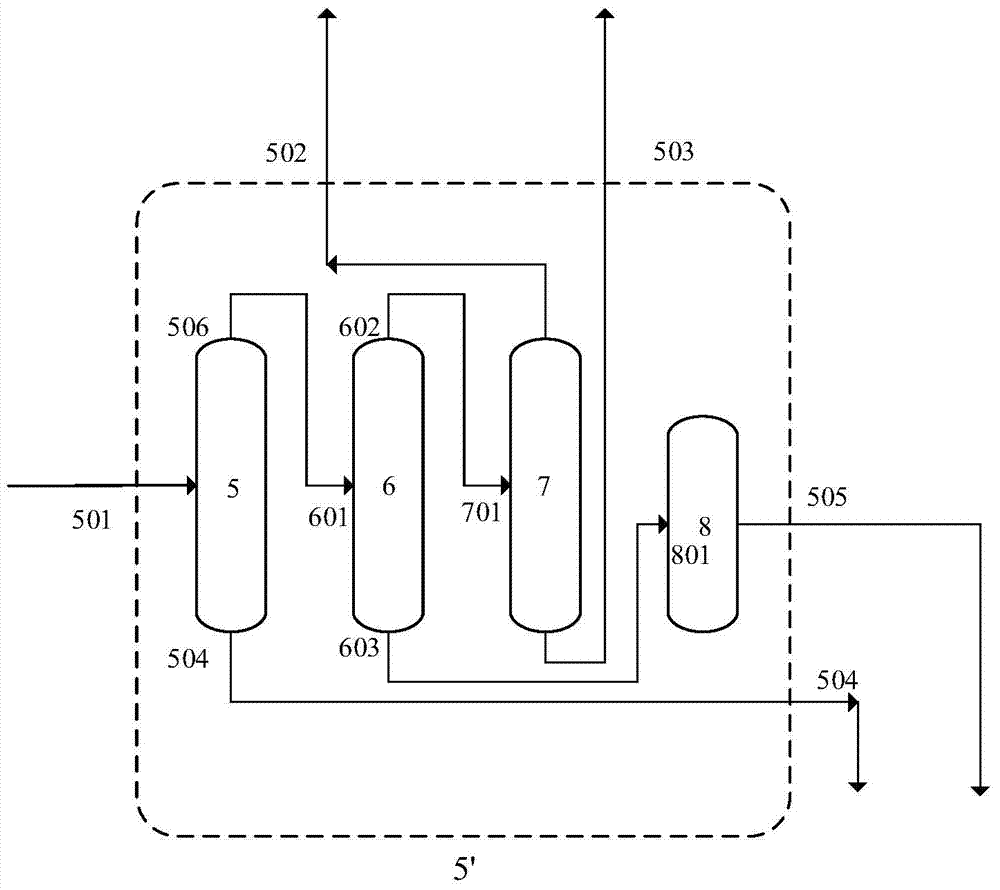

Carbon dioxide capturing and seawater desalting co-production device and method based on hydrate method

The invention provides a carbon dioxide capturing and seawater desalting co-production device and method based on a hydrate method, belonging to the technical field of hydrate application. The carbon dioxide capturing and seawater desalting co-production device comprises a gas-water conveying part, a hydrate generation and decomposition control part and a product storing and discharging part. The hydrate generation and decomposition control part comprises a front-grade structure and a rear-grade structure; a hydrate generation condition is gas supersaturation. A first-grade hydrate generates residual gas and decomposed water to be used as second-grade raw materials; after two grades of treatment, fresh water is obtained and stored; N2 is discharged to atmosphere by a gas exhausting safety valve; carbon dioxide is introduced into a gas tank to be stored. The carbon dioxide capturing and seawater desalting co-production device is applicable to the co-production of carbon dioxide capturing and seawater desalting of a fossil fuel power station in a coastal region, so as to meet the requirements of the carbon dioxide capturing of a smoke CO2 / N2 power station; a heat exchanger is used for pre-cooling so that the cold loss is reduced and the energy utilization rate is improved; the reaction speed is increased by high-speed agitation in a hydrate generation process; emissions comprise the N2 and concentrated seawater and have no pollution to the environment.

Owner:DALIAN UNIV OF TECH

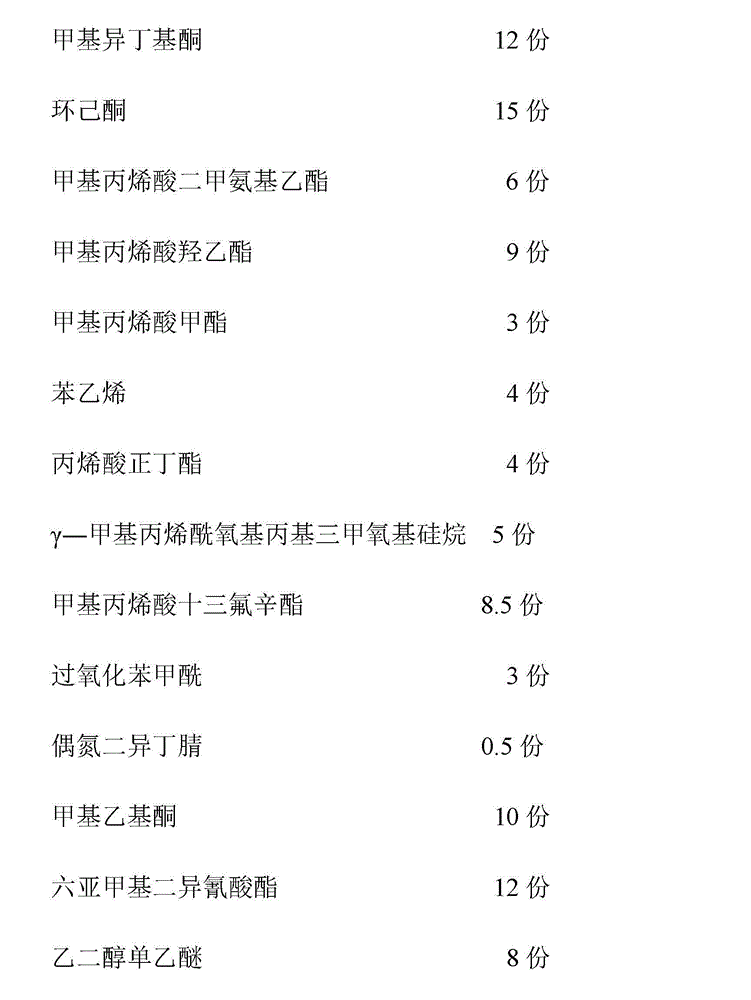

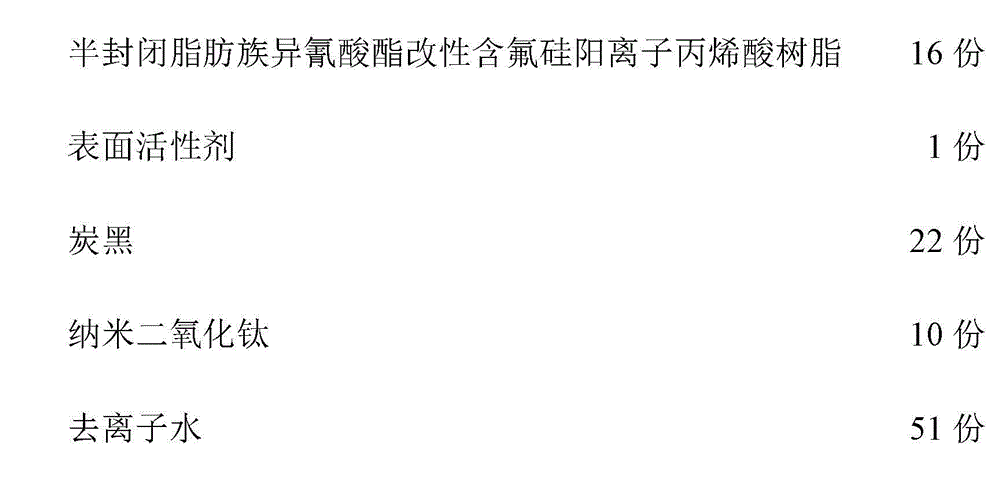

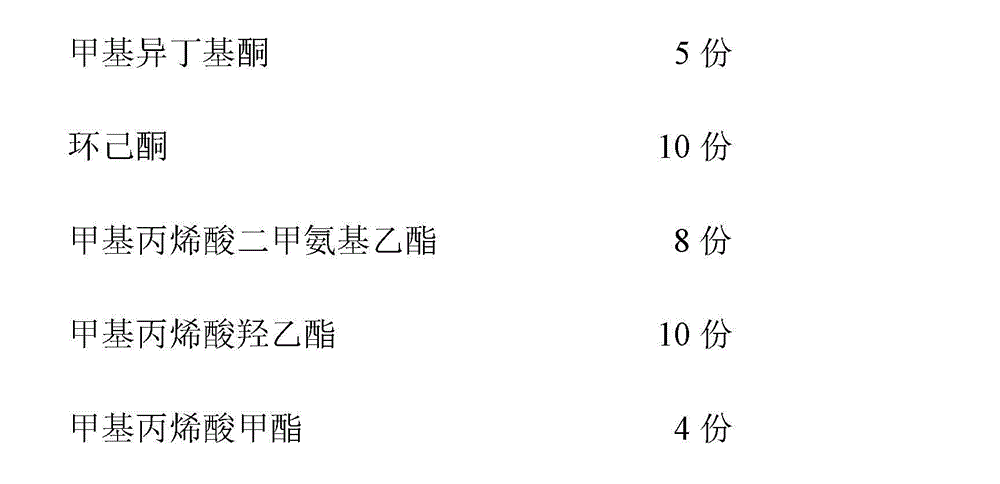

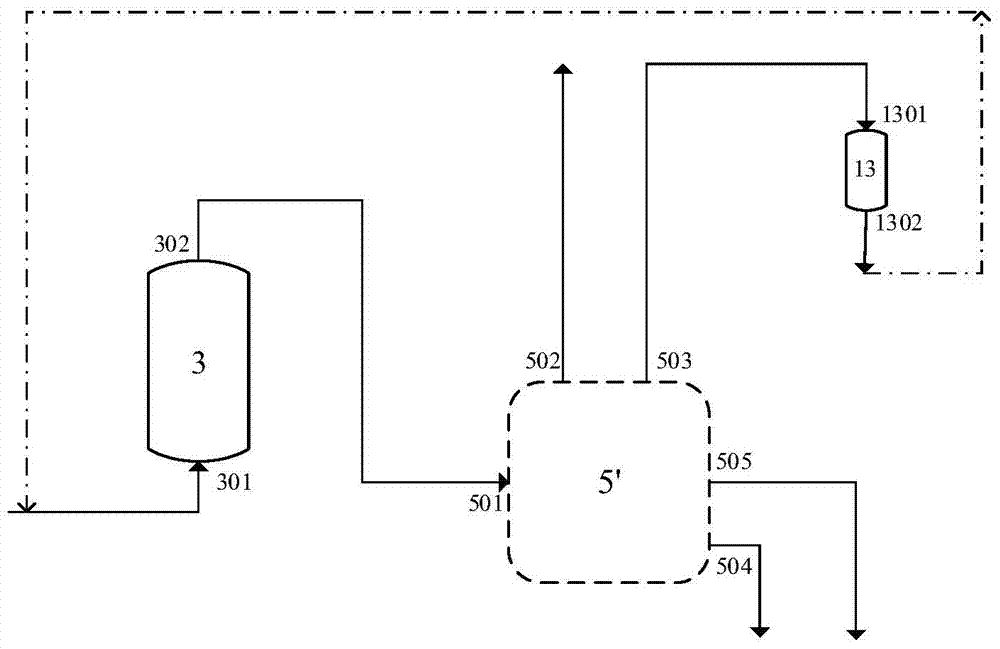

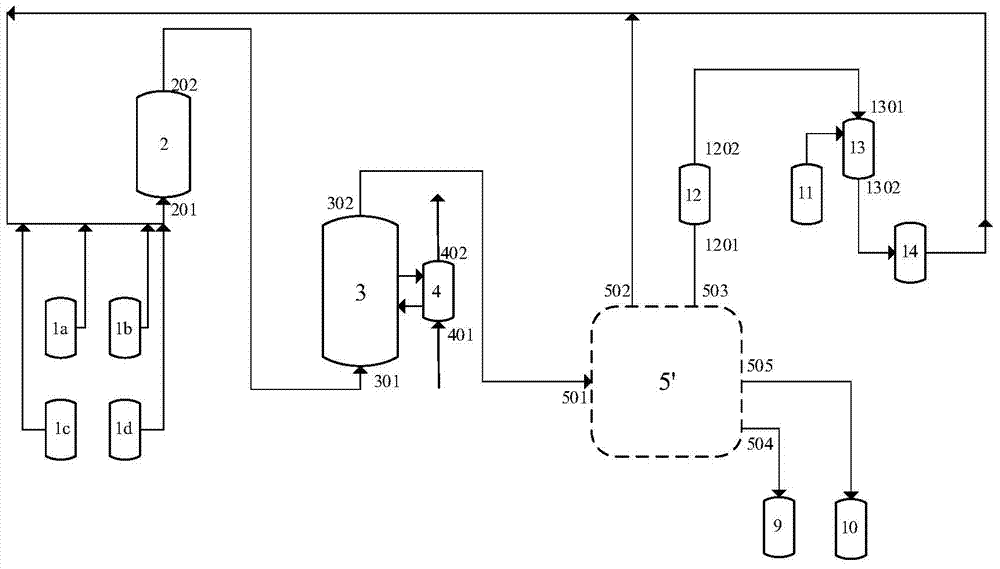

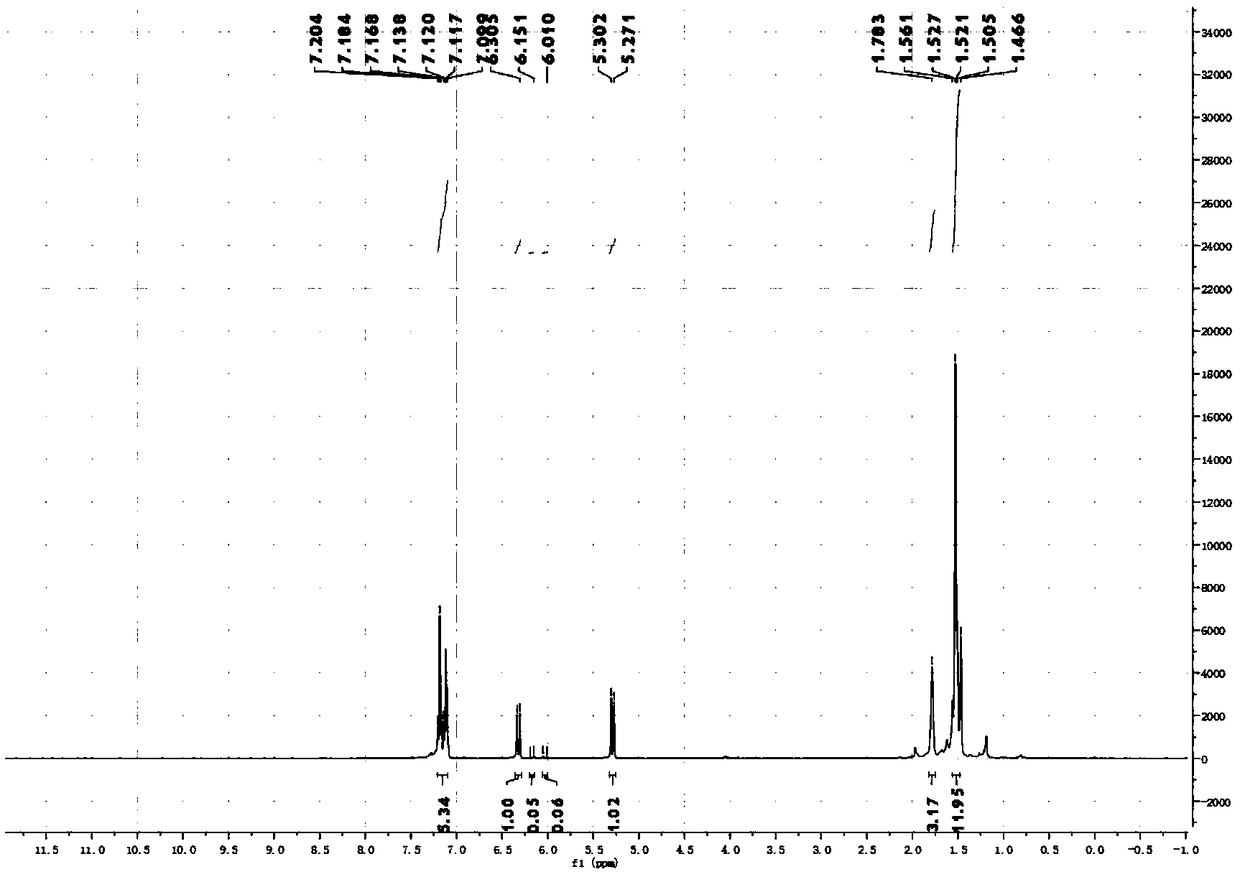

Self-cleaning fluorosilicone-modified acrylic acid cathode electrophoresis paint and preparation method thereof

ActiveCN103333596AImprove stain resistanceImprove stabilityPolyurea/polyurethane coatingsPaints for electrolytic applicationsPolymer scienceAcrylic resin

The invention relates to a self-cleaning fluorosilicone-modified acrylic acid cathode electrophoresis paint and a preparation method thereof. The paint is prepared from a fluorosilicone-modified acrylic acid emulsion and a nano silicon dioxide modified color paste in a ratio of 9:1, wherein the fluorosilicone-modified acrylic acid emulsion is prepared by stirring a semiclosed aliphatic isocyanate-modified fluorosilicone-containing cationic acrylic resin, a neutralizer and deionized water at high speed; and the nano titanium dioxide powder modified color paste is prepared by grinding a semiclosed aliphatic isocyanate-modified fluorosilicone-containing cationic acrylic resin, a surfactant and deionized water at high speed in a grinding tank. The paint provided by the invention has the advantages of high self stability and high tank liquor stability; and after the electrophoretic coating, the coating has the advantages of flat appearance, favorable mechanical properties, excellent acid and alkali resistance, high hydrophobicity and favorable pollution resistance (at most 10%), and the contact angle between the coating film surface and water can reach 130 degrees.

Owner:HAOLISEN COATING SHANGHAI +1

Method for producing methyl methacrylate by methyl acetate and formaldehyde

InactiveCN104513163AImprove utilization efficiencyCan maintain high activity for a long timeOrganic compound preparationCarboxylic acid esters preparationFixed bedHigh activity

The invention relates to a method for producing methyl methacrylate, in particular to the method for producing the methyl methacrylate by taking methyl acetate and formaldehyde as raw materials. According to the adopted method, a fluidized bed reactor and a fixed bed reactor are used in a combined manner; unreacted methyl acetate serving as a raw material is cyclically utilized after being separated; methyl propionate generated by conducting hydrogenation on acrylic acid generated by the reaction can be sold as a byproduct, and can also be cyclically utilized with methyl acetate as a process raw material. An aldolization catalyst continuously flows between the fluidized bed reactor and a catalyst regenerator to realize a reaction regeneration process; the utilization rate of the catalyst is greatly improved; the continuity of production is realized. The fluidized bed reactor meets industrial production requirements; the high activity of the catalyst can be maintained for a long time; the use efficiency of the catalyst can be improved; the overall conversion rate is improved by the cycling of unreacted raw materials; the economic benefits are increased.

Owner:BEIJING RISUN TECH CO LTD

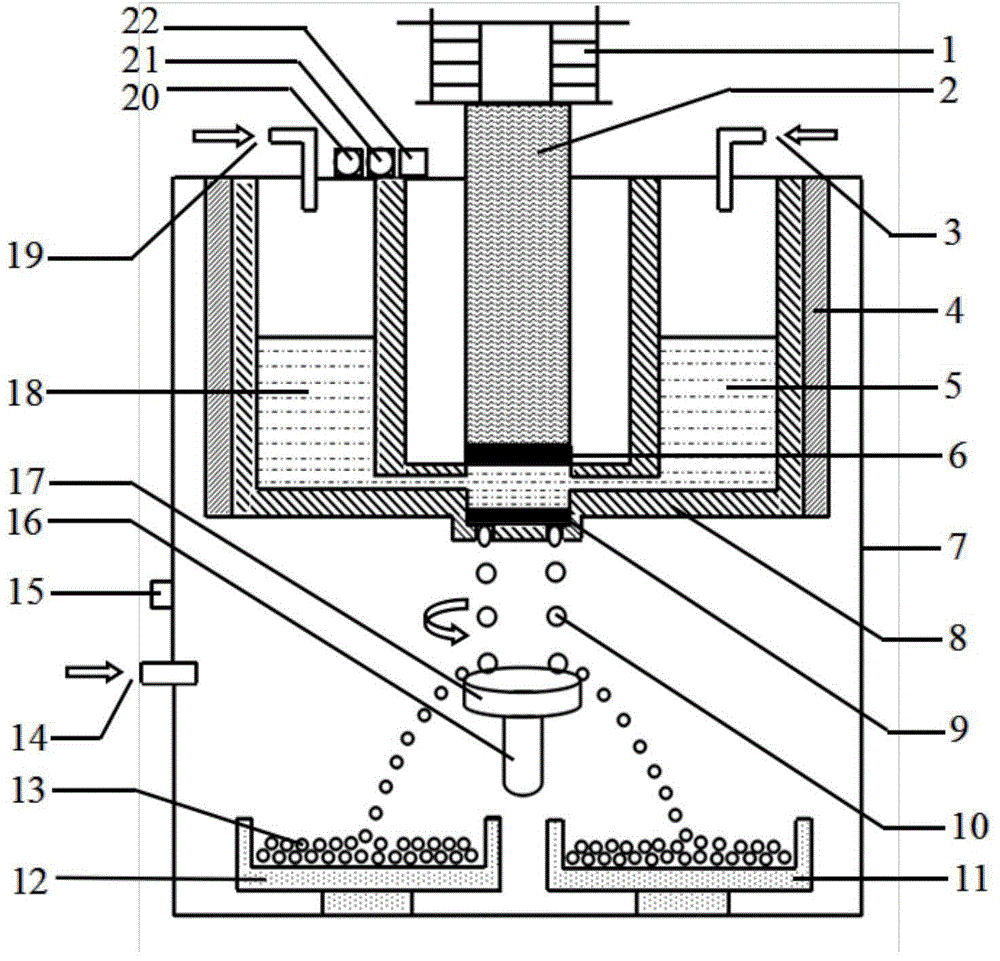

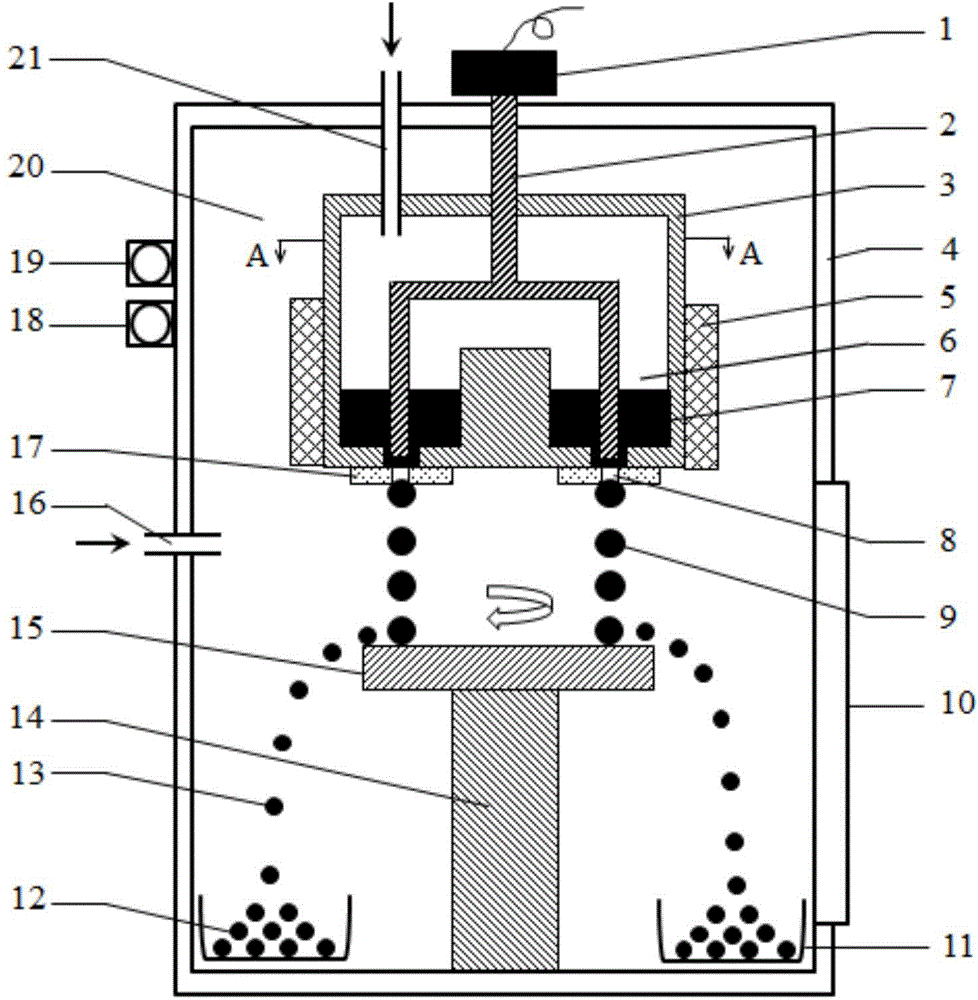

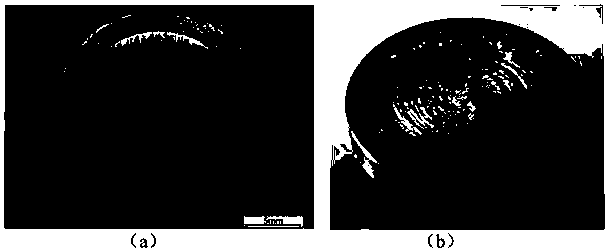

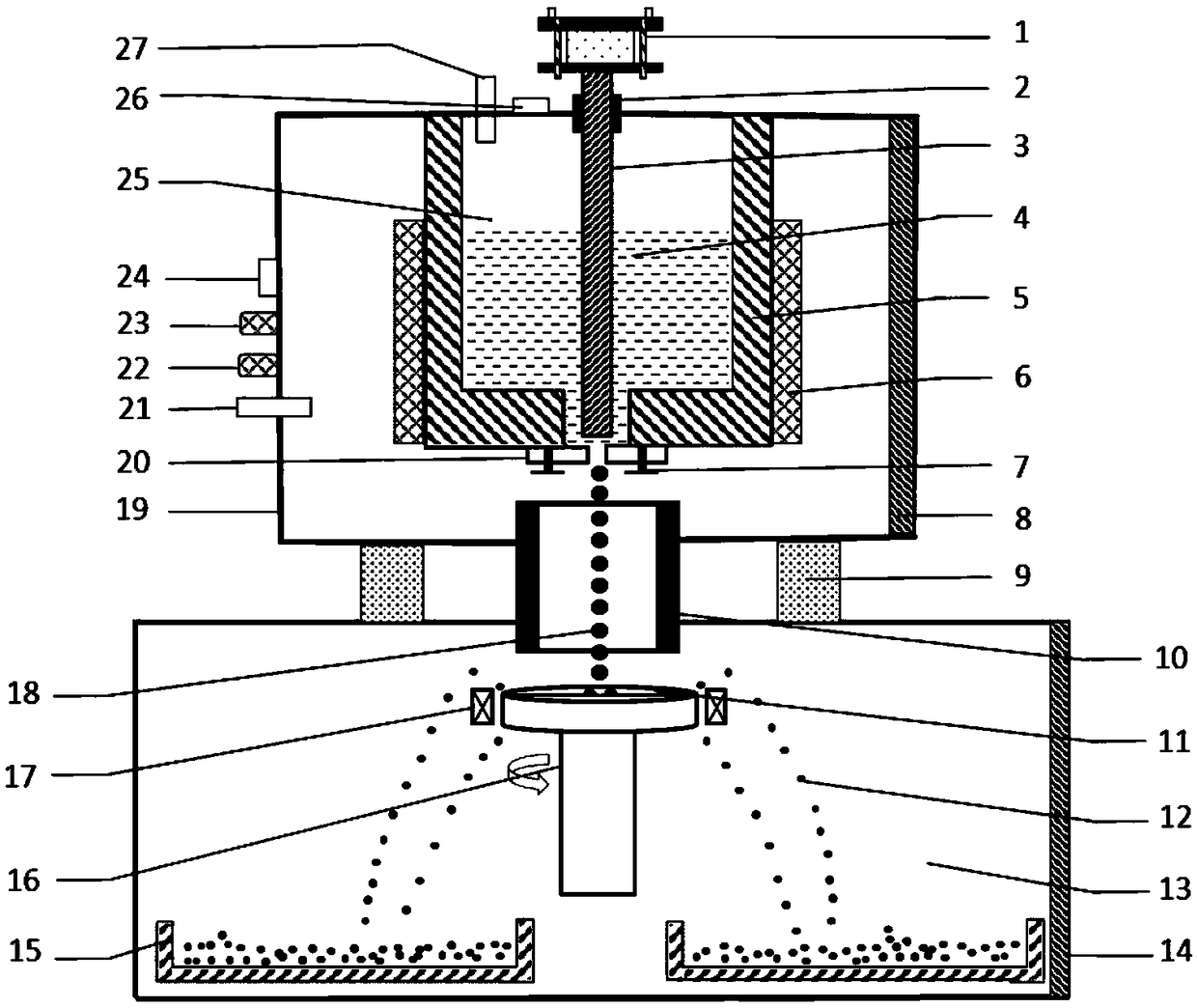

High efficiency superfine spherical metal powder preparation method and device

The invention discloses a high-efficiency superfine spherical metal powder preparation device, which comprises a shell, a crucible and a powder collecting area, and is characterized in that the crucible is in a circular structure that the inside and the outside are nested, the bottom of the inner accommodating cavity of the crucible and the bottom of the outer accommodating cavity of the crucible are provided with central holes which are through; a space used for flowing molten metal is arranged between the bottom of the inner accommodating cavity and the bottom of the outer accommodating cavity; a tabletting is arranged above the central hole of the inner accommodating cavity, and a drive rod contacts with the tabletting; the central hole bottom of the outer accommodating cavity is provided with a gasket with a hole; the powder collecting area comprises a catch tray and a rotating disk, wherein the catch tray is arranged on the bottom of the shell and the rotating disk is arranged above the catch tray and is connected with a motor. The invention further discloses a method of preparing the superfine spherical metal powder, the method mainly combines a pulse microcellular injection method and a centrifugal atomization method, and the superfine spherical metal powder meeting the usage requirements that the grain size distribution range is narrow, the sphericity is high, the spreadability and the mobility are good, and the production efficiency is high can be prepared.

Owner:DALIAN UNIV OF TECH

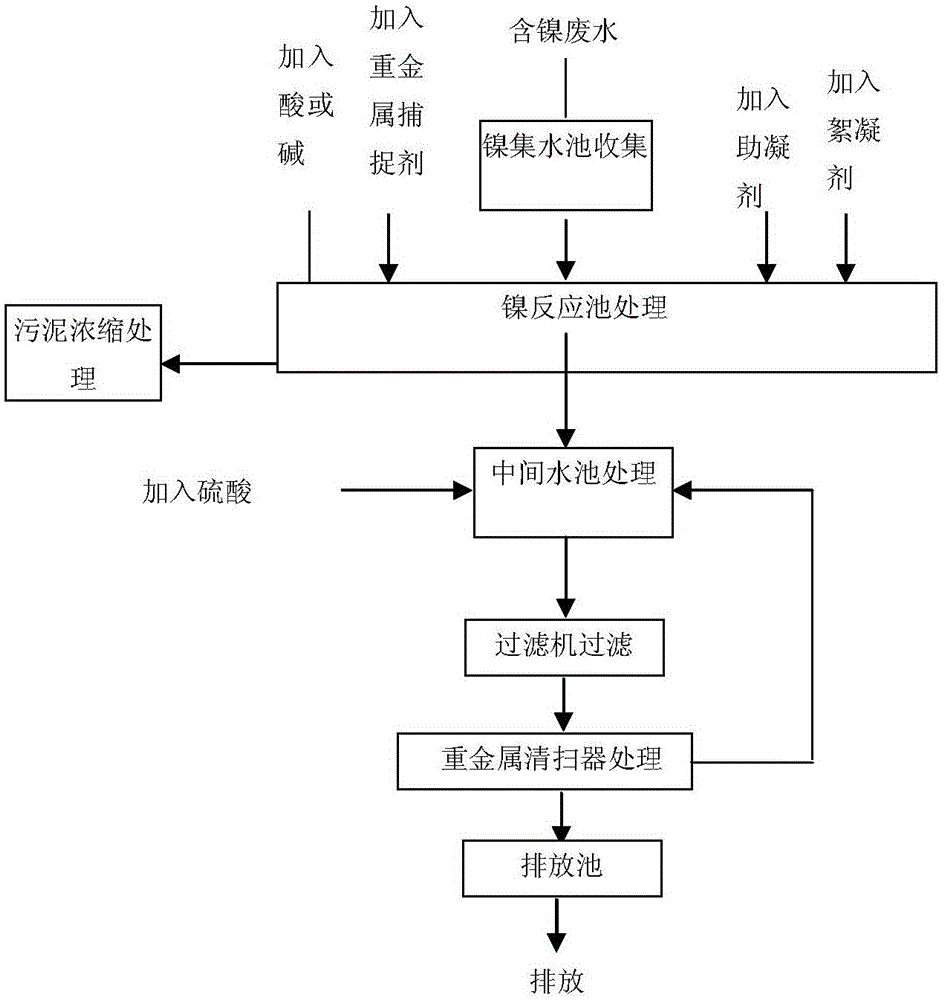

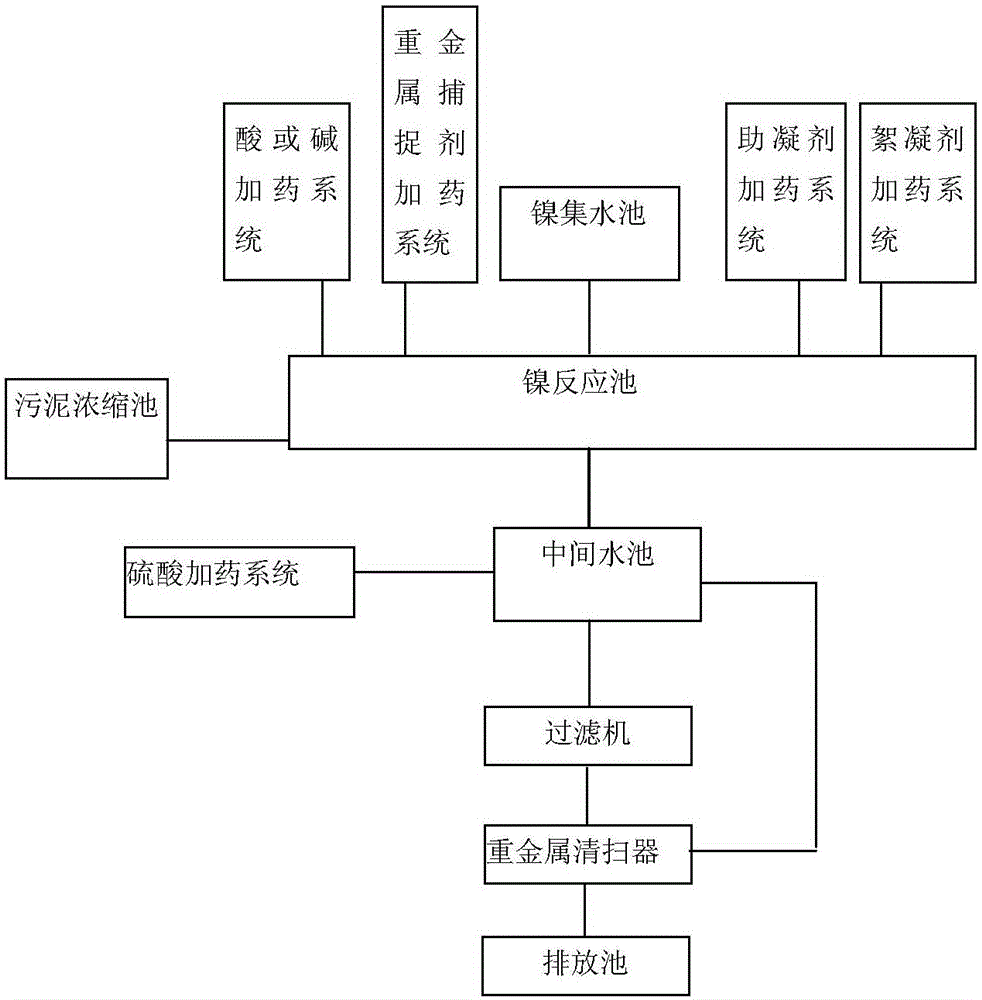

Treatment method and system of nickel-containing wastewater conforming to Water Pollutant Table III Discharge Standard

InactiveCN105084603AMeet industrial production requirementsEasy to operateWater contaminantsMultistage water/sewage treatmentScavengerEmission standard

The invention discloses a treatment method and system of nickel-containing wastewater conforming to Water Pollutant Table III Discharge Standard. The method comprises the following steps: sending nickel-containing wastewater into a wastewater collecting tank, and pumping into a nickel reaction tank by a water pump to perform pretreatment; regulating the pH value, adding a heavy metal capturing agent, thoroughly mixing to react, adding a coagulant aid and a flocculant, sufficiently and uniformly stirring, and standing to precipitate or sending into a solid-liquid separation device; sending into an intermediate water tank, and adding a sulfuric acid solution to regulate the pH value to 7-8; and pumping water in the intermediate water tank into a heavy metal scavenger by a filtering machine, and treating to achieve the Table III Limit Discharge Standard. The method and system solve the problem that the existing nickel-containing wastewater in electroplating industry can not satisfy the Table III Discharge Standard in Water Pollutant Special Limits, so that the electroplating nickel-containing wastewater can stably satisfy the discharge requirements.

Owner:杭州太一科技有限公司

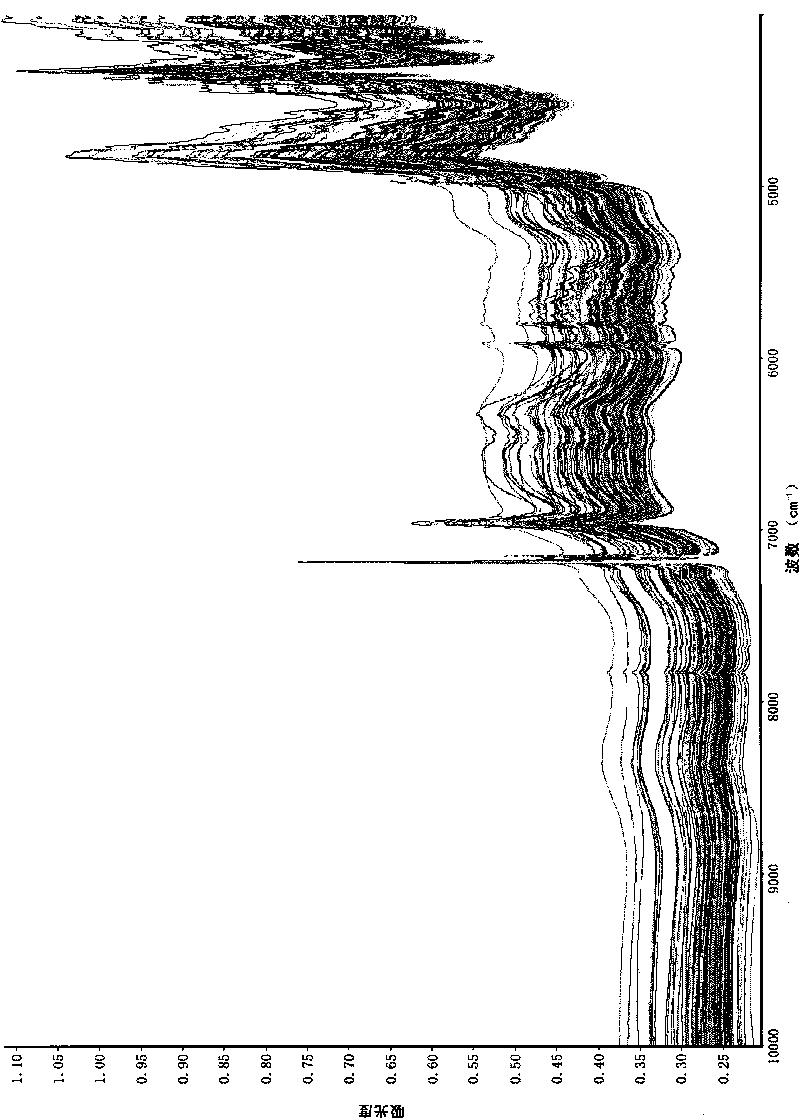

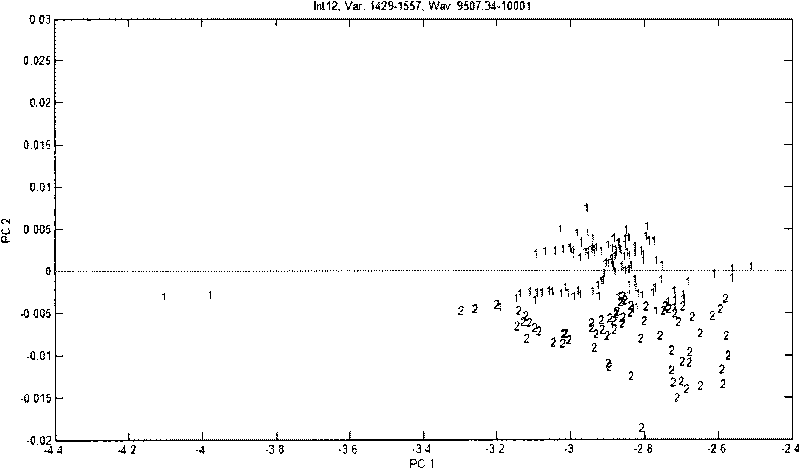

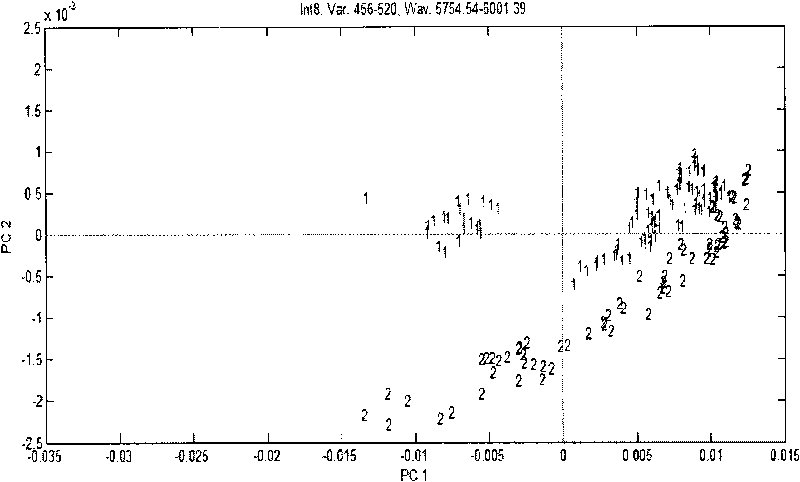

Method for distinguishing coating quality of medicine preparation

ActiveCN101713731AGuaranteed reasonableness and validityReduce distractionsComputing modelsColor/spectral properties measurementsBiomedical engineeringSupport vector machine

The invention belongs to the field of medicine preparations, which in particular relates to a method for distinguishing the coating quality. More concretely, the invention relates to a method for distinguishing the coating quality of a medicine preparation. In the method provided by the invention, a qualitative distinguishing model of the coating quality is quickly constructed by combining the methods of a near-infrared spectrum method, an interval principal component analysis method, a support vector machine method and the like, the comprehensive evaluation of the coating quality of the medicine preparation is realized, and the distinguishing accuracy basically reaches the requirement of industrial production. Relative to a traditional method or experiential judgment, the distinguishing method provided by the invention can quickly, nondestructively, reliably and accurately distinguish the coating quality of the medicine preparation in a coating process in an on-line way.

Owner:河北鑫民和质检技术服务有限公司

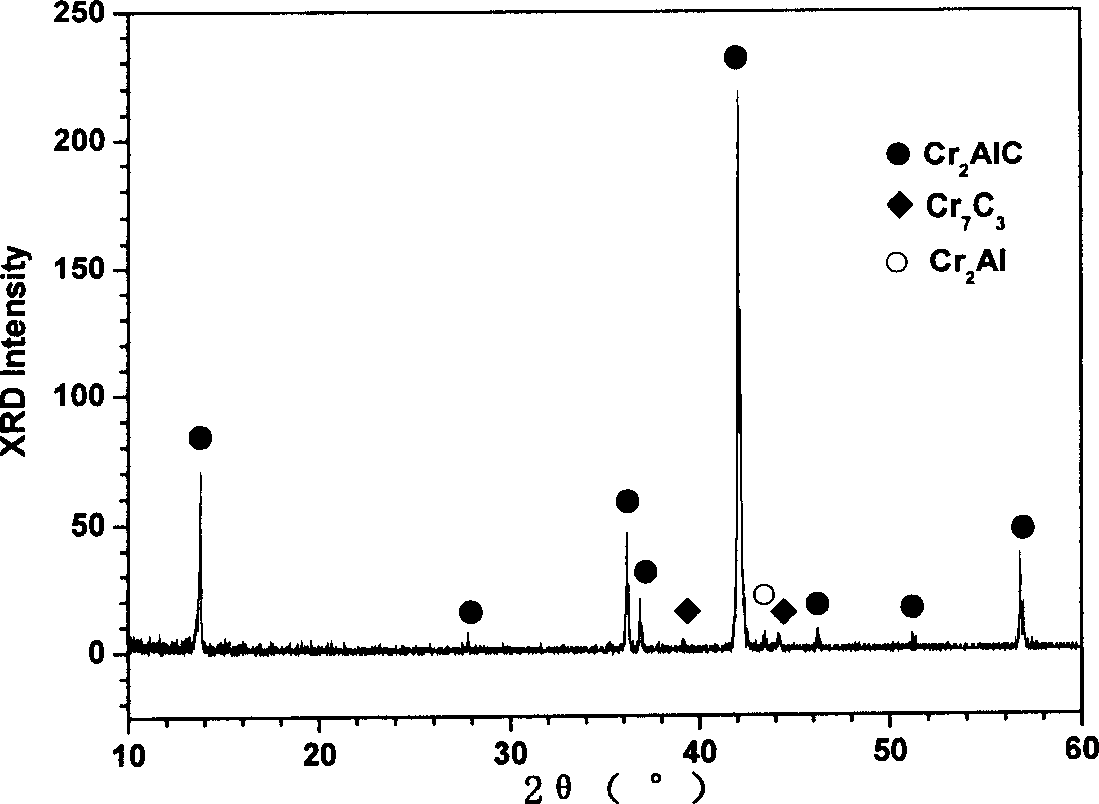

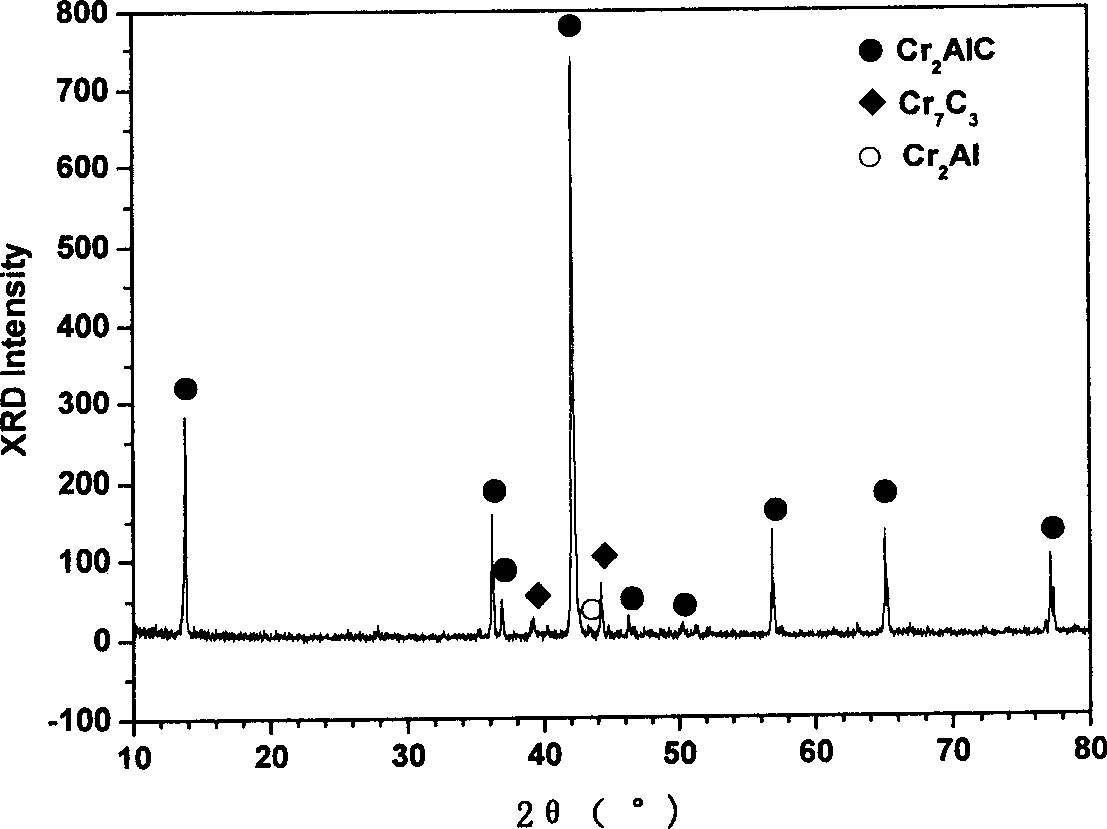

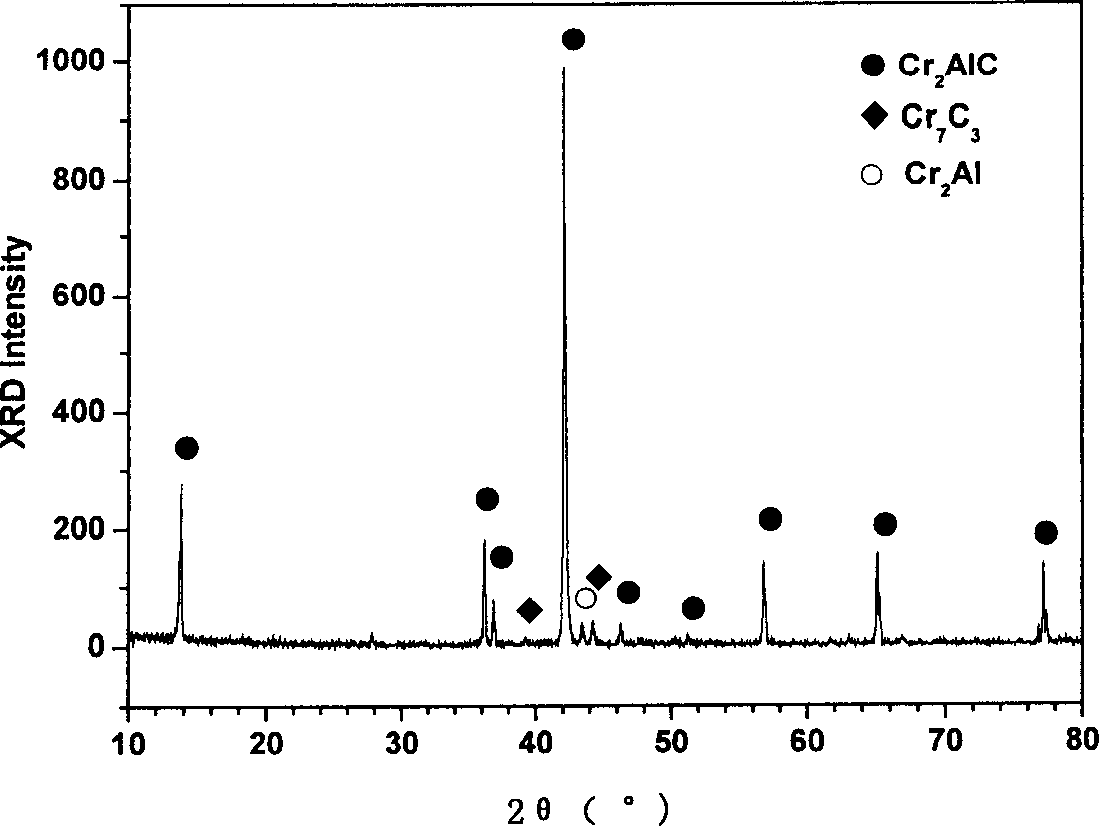

Method for preparing Cr2AlC by molten salt process

The invention discloses a preparing method of Cr2AlC powder through molten salt method, which comprises the following steps: (1) adopting chromium powder, aluminum powder and graphite as raw material; allocating materials according to Cr2AlC chemical gauge with surplus aluminum; (2) heating to 900-1200 deg.c at 10-40 deg.c per min protected by Ar gas; insulating; cooling to prepare Cr2AlC powder. The invention can provide high-purity powder, which is fit for examining study and industrial manufacturing.

Owner:SHANGHAI INST OF CERAMIC CHEM & TECH CHINESE ACAD OF SCI

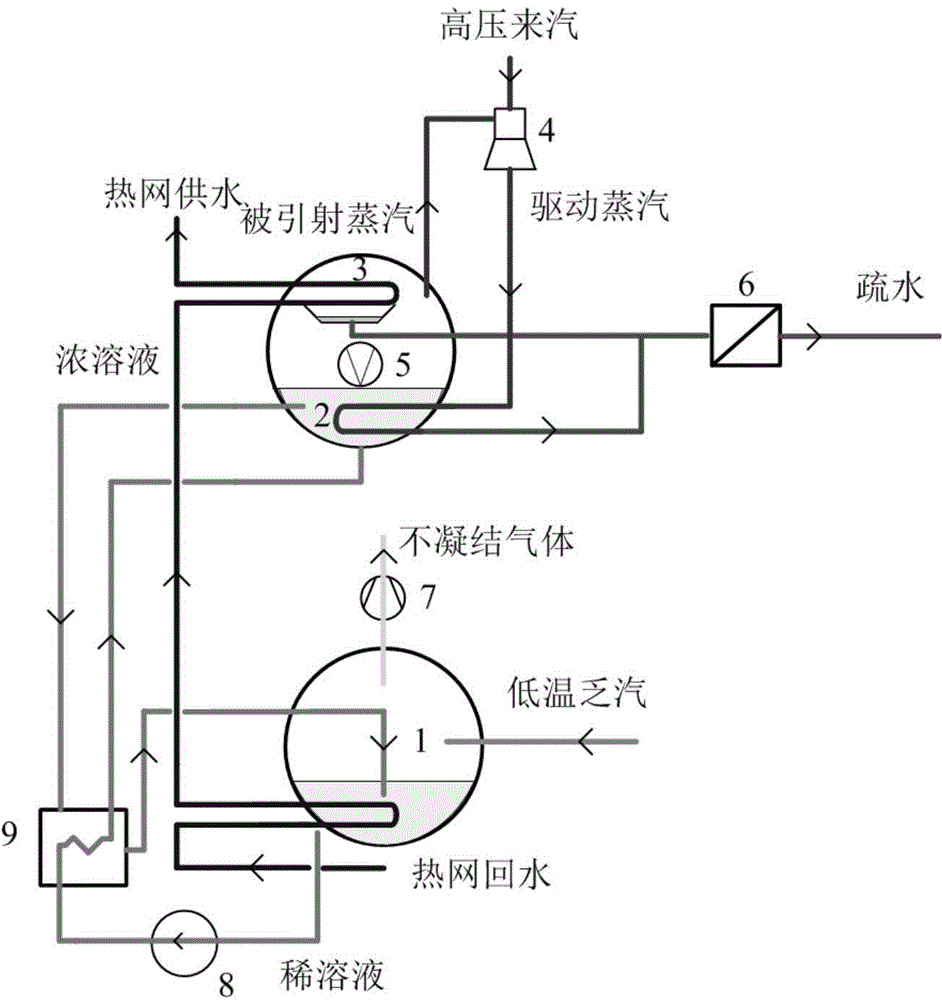

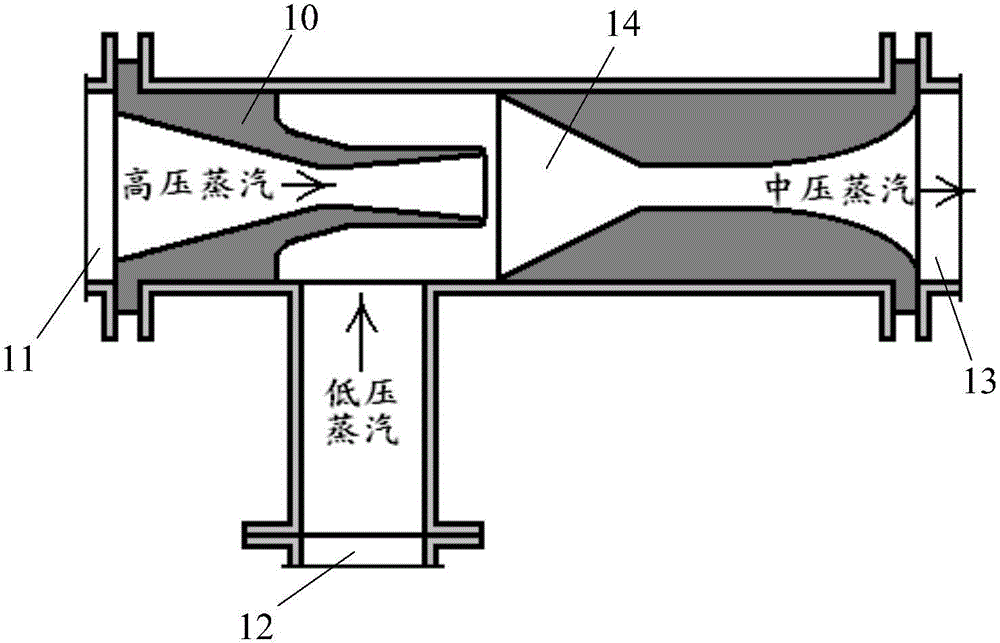

Steam type spraying-dead steam direct absorption type compound heat pump system

InactiveCN104390388AEfficient use ofReduce pump powerMechanical apparatusFluid circulation arrangementSteam pressureNet return

The invention discloses a steam type spraying-dead steam direct absorption type compound heat pump system. The steam type spraying-dead steam direct absorption type compound heat pump system comprises an absorber, a generator, a condenser and a spraying device; low-temperature dead steam is directly introduced into the absorber and is absorbed by a working medium in the absorber; a working medium outlet of the absorber is connected with a working medium inlet of the generator by a pipeline; a working medium outlet of the generator is connected with a working medium inlet of the absorber by a pipeline to form a working medium loop; heat net returned water is heated by the absorber and the condenser in sequence and is used as heat net supply water to be output. According to the steam type spraying-dead steam direct absorption type compound heat pump system, the spraying device is introduced, and middle-pressure steam formed by low-pressure steam generated by utilizing a high pressure inlet steam to inject the generator is used as driving steam of a heat pump so that the operation unsafety problem of the system, caused by the fact that the steam pressure is too high is avoided; meanwhile, the efficient utilization of steam energy is realized; the heat pump system is used for directly absorbing the low-temperature dead steam and an evaporator link in a traditional heat pump system is saved; the system investment is reduced; meanwhile, a middle heat exchanging process is reduced so that the system performance is greatly improved.

Owner:XI AN JIAOTONG UNIV

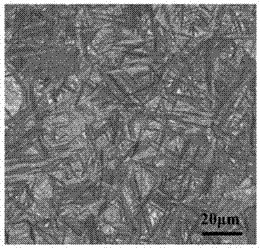

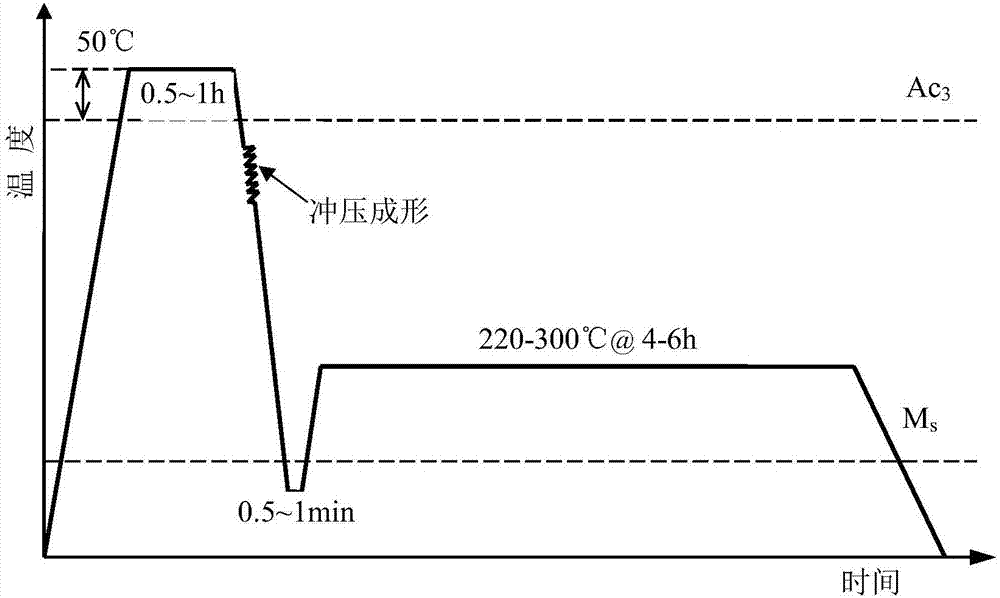

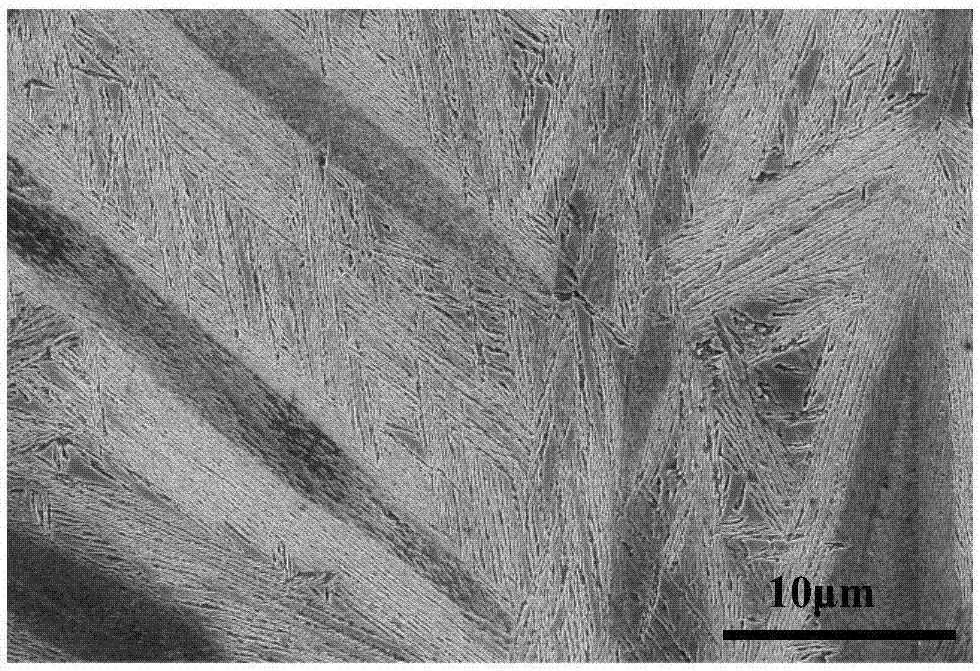

Preparation method for ultrahigh-strength thermoforming steel for car

The invention discloses a preparation method for ultrahigh-strength thermoforming steel for a car, and belongs to the technical field of high-strength steel. The preparation method comprises the following steps of: combining stamping forming with low-temperature bainite isothermal treatment; comprehensively utilizing refining technologies such as micro-alloy refining, controlled-rolling controlled-cooling refining, pre-deforming and low-temperature bainite isothermal treatment, thereby obtaining an ultra-fine structure which consists of carbide-free bainite, a little blocky type retained austenite and martensite with volume fraction smaller than 10%, and the ultra-fine structure has tensile strength of 1500-2200 MPa, and ductility of 10-20%. A preparation process for ultrahigh-strength steel comprises the following technological process: smelting, continuous casting, hot rolling, cutting, thermal stamping forming and low-temperature bainite isothermal treatment. During thermal stamping forming, a cut hot-rolled plate is re-heated to Ac3+50 DEG C for austenization, and heat is preserved for 0.5-1 hour, and then, the plate is immediately moved onto thermal stamping equipment to perform stamping forming; the quick cooling and quenching effect of a thermal stamping mould is utilized for cooling super-cooled austenite to a temperature lower than Ms point, is subjected to isothermal treatment for 0.5-1 minute, is quickly put into a salt-bath furnace or a resistance furnace of 200-300 DEG C to perform isothermal treatment for 4-6 hours, is subjected to isothermal bainite transformation, and is taken out for being air-cooled to the room temperature.

Owner:UNIV OF SCI & TECH BEIJING

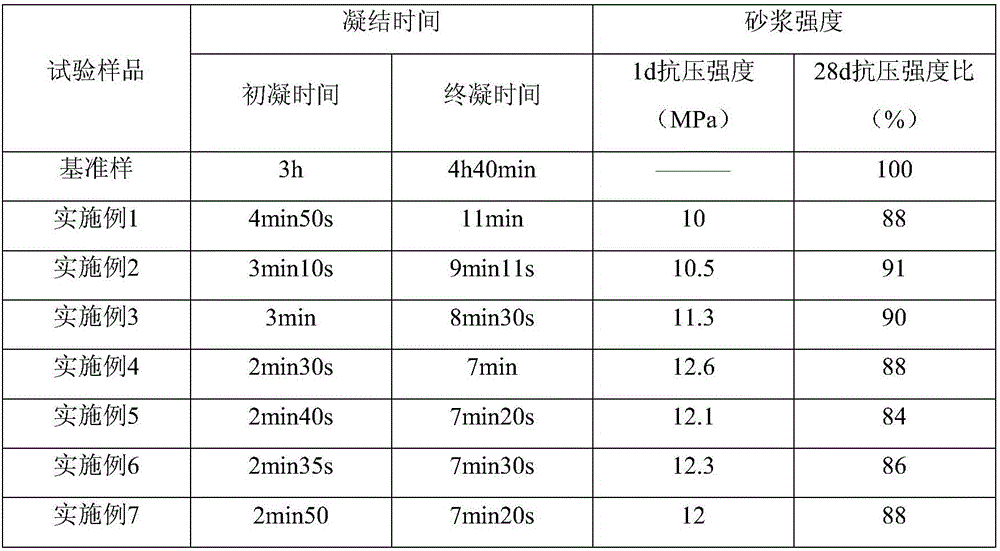

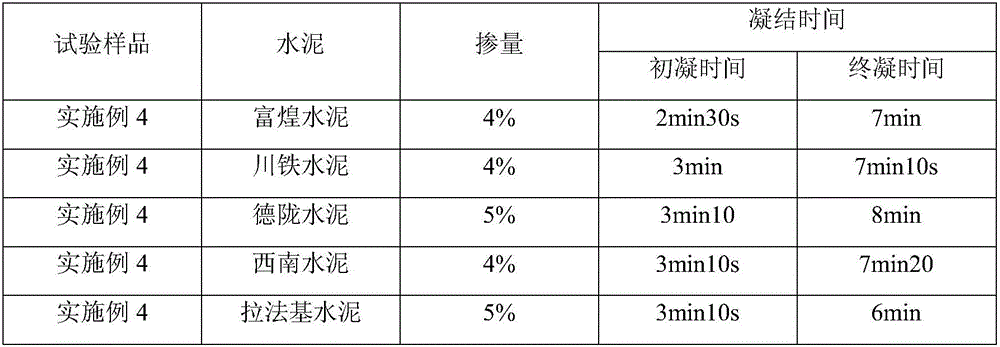

Low-resilience liquid accelerator for shotcrete and preparation method thereof

The invention discloses a low-resilience liquid accelerator for shotcrete and a preparation method thereof. The accelerator is prepared from the following raw materials in percent by mass: 20%-40% of sodium hydroxide, 25%-40% of aluminium hydroxide, 3%-10% of a synergist, 0.5%-2% of a setting accelerator, 0.003%-0.02% of a viscosity adjusting agent, and the balance water, wherein, the synergist is sodium silicate, the setting accelerator is an alcohol amine substance, and the viscosity adjusting agent is potassium chromate or sodium nitrite. The preparation method comprises the following technical steps: adding sodium hydroxide and the synergist into a reaction kettle, adding water, and starting an agitator and a heater; keeping the temperature after the temperature reaches a set temperature, adding aluminium hydroxide, and reacting with the constant temperature; adding the viscosity adjusting agent, stirring, heating, reacting with a constant temperature, then stopping heating, and naturally cooling; and adding the setting accelerator after the reaction system is cooled, and cooling to room temperature, so as to obtain the accelerator. The accelerator is short in setting time, low in resilience and moderate in viscosity, generates a little sediment, has good cement adaptability, and the preparation method for the accelerator is simple, practicable and energy-saving.

Owner:SHIJIAZHUANG CHANGAN YUCAI BUILDING MATERIALS

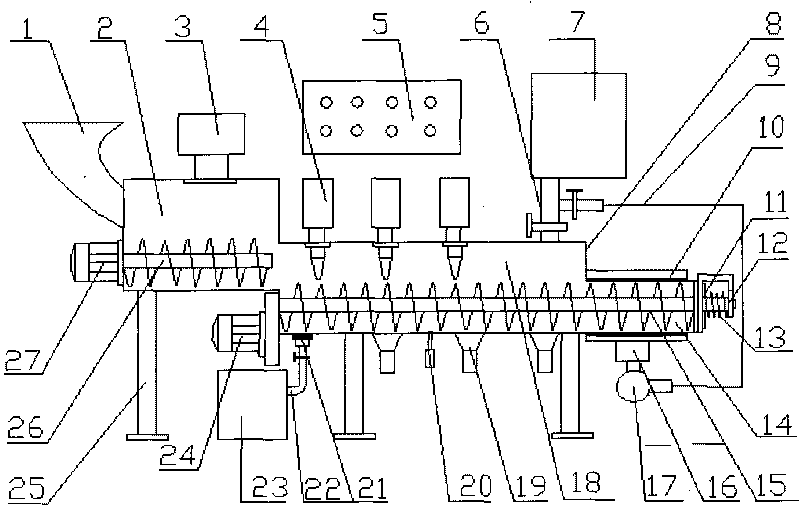

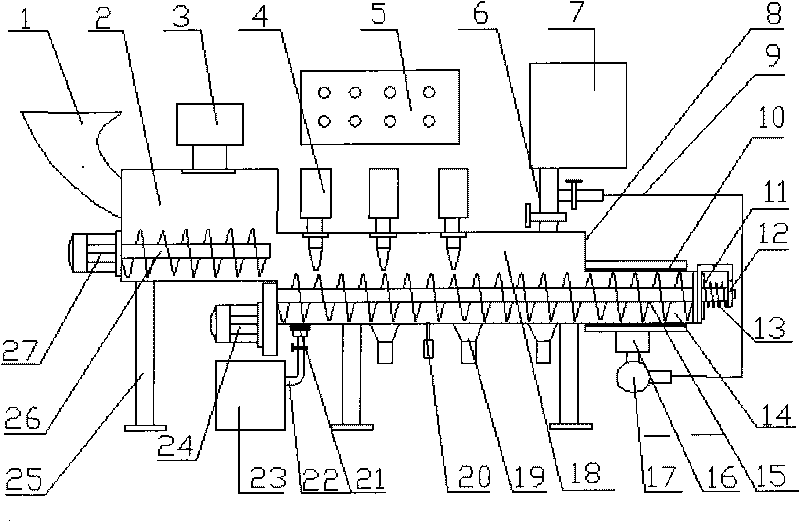

Tea microwave and ultrasonic wave combined dynamic countercurrent extraction method and equipment

The invention discloses tea microwave and ultrasonic wave combined dynamic countercurrent extraction method and equipment. Microwave-ultrasonic wave combination stage-by-stage time-division extraction is adopted to give full play to the characteristics and the advantages of a microwave and ultrasonic wave extraction technology. In the whole extraction process, the flow direction of an extraction solvent is opposite to that of tea, thereby realizing a dynamic countercurrent continuous extraction function, being beneficial to extracting active ingredients of the tea and maximizing the tea extraction function and the efficiency; the rear end of extraction equipment is provided with a solid-liquid separation device, so that tea dregs after extraction can be dehydrated for realizing the comprehensive utilization of the tea dregs on one hand, and on the other hand, the filtered tea liquid can be circulated and utilized, thereby reducing the loss of the active ingredients in the tea liquid;the whole extraction process is completed at lower temperature, thereby being beneficial to preventing the active ingredients in the tea from being damaged by high temperature up to the hilt, saving the usage amount of the extraction solvent, reducing pollution and lowering the cost. The invention can realize industrial large-scale extraction production.

Owner:DAMIN FOODSTUFF ZHANGZHOU CO LTD

Preparation method and application of non-molybdenum sulfide mineral flotation and separation inhibitor

The invention discloses a preparation method and application of a non-molybdenum sulfide mineral flotation and separation inhibitor. The preparation method for the flotation and separation inhibitor comprises the step of enabling phosphorus pentasulfide and alkaline compounds to react with water-soluble macromolecules, and thus the flotation and separation inhibitor can be obtained. According to the preparation method for the non-molybdenum sulfide mineral flotation and separation inhibitor, operation is easy, the process conditions are mild, the raw material cost is low, and the industrial production requirements are met; and moreover, the prepared product directly serves as the non-molybdenum sulfide mineral inhibitor applied to flotation and separation of molybdenum sulfide minerals and non-molybdenum sulfide minerals, the molybdenum sulfide minerals and the non-molybdenum sulfide minerals can be effectively separated, the grade of molybdenum concentrates is improved, and the flotation and separation inhibitor is particularly suitable for flotation and separation of molybdenite, copper sulfide ore, galena, pyrite, jamesonite, arsenopyrite, bismuth sulfide ore and the like.

Owner:CENT SOUTH UNIV

Synthesis method for methyl acrylate from methyl acetate and formaldehyde

InactiveCN103435483AReduce self-aggregationEasy to solveOrganic compound preparationCarboxylic acid esters preparationFormaldehyde synthesisFluidized bed

The invention relates to a synthesis method for methyl acrylate from methyl acetate and formaldehyde. According to the method, a catalyst is regenerated in a catalyst regenerator, the problem of rapid inactivation of the catalyst is overcome through coupling of a fluidized bed reactor and the catalyst regenerator, and continuous production is realized.

Owner:旭阳化学技术研究院有限公司

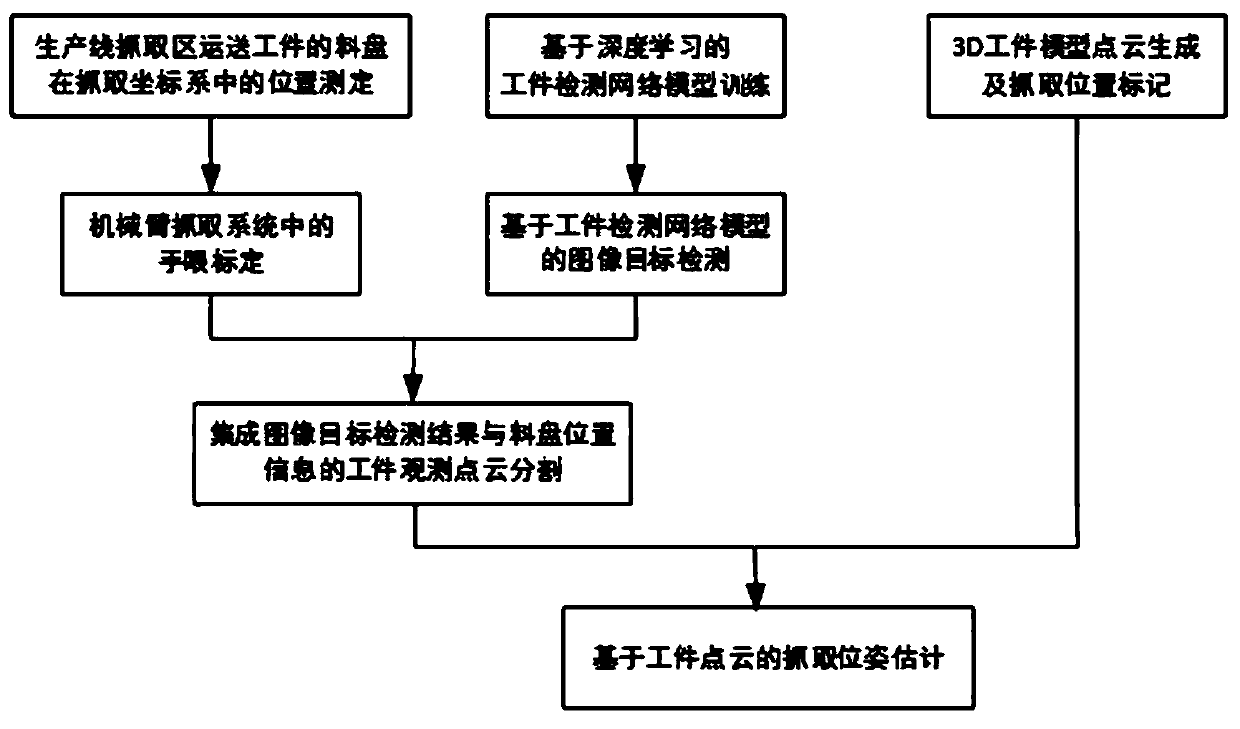

Method of grabbing shape symmetrical workpiece with high precision by using low precision depth camera

ActiveCN110014426AReduce running timeImprove integrityProgramme-controlled manipulatorProduction linePoint cloud

The invention relates to a method of grabbing a shape symmetrical workpiece with a high precision by using a low precision depth camera. The method comprises the following steps: 1) measuring a position of a conveying workpiece tray in a grabbing area of a production line in a grabbing coordinate system O-XYZ; 2) carrying out hand-eye calibration on a grabbing system of a mechanical arm to obtaina homogeneous coordinate transfer matrix T1 between a camera coordinate system and the grabbing coordinate system; 3) generating a 3D workpiece model point cloud and marking the grabbing position; 4)constructing a workpiece detection network model based on deep learning and training the model; 5) carrying out 2D image target detection according to the trained workpiece detection network model; 6)integrating an image target detection result and tray position information, and cutting the 3D workpiece model point cloud to obtain a workpiece observation point cloud; and 7) estimating a grabbinggesture according to the cut workpiece observation point cloud. Compared with the prior art, visual guidance can be carried out by using the low precision depth camera to achieve the grabbing precision with visual guidance by a high precision depth camera.

Owner:TONGJI UNIV

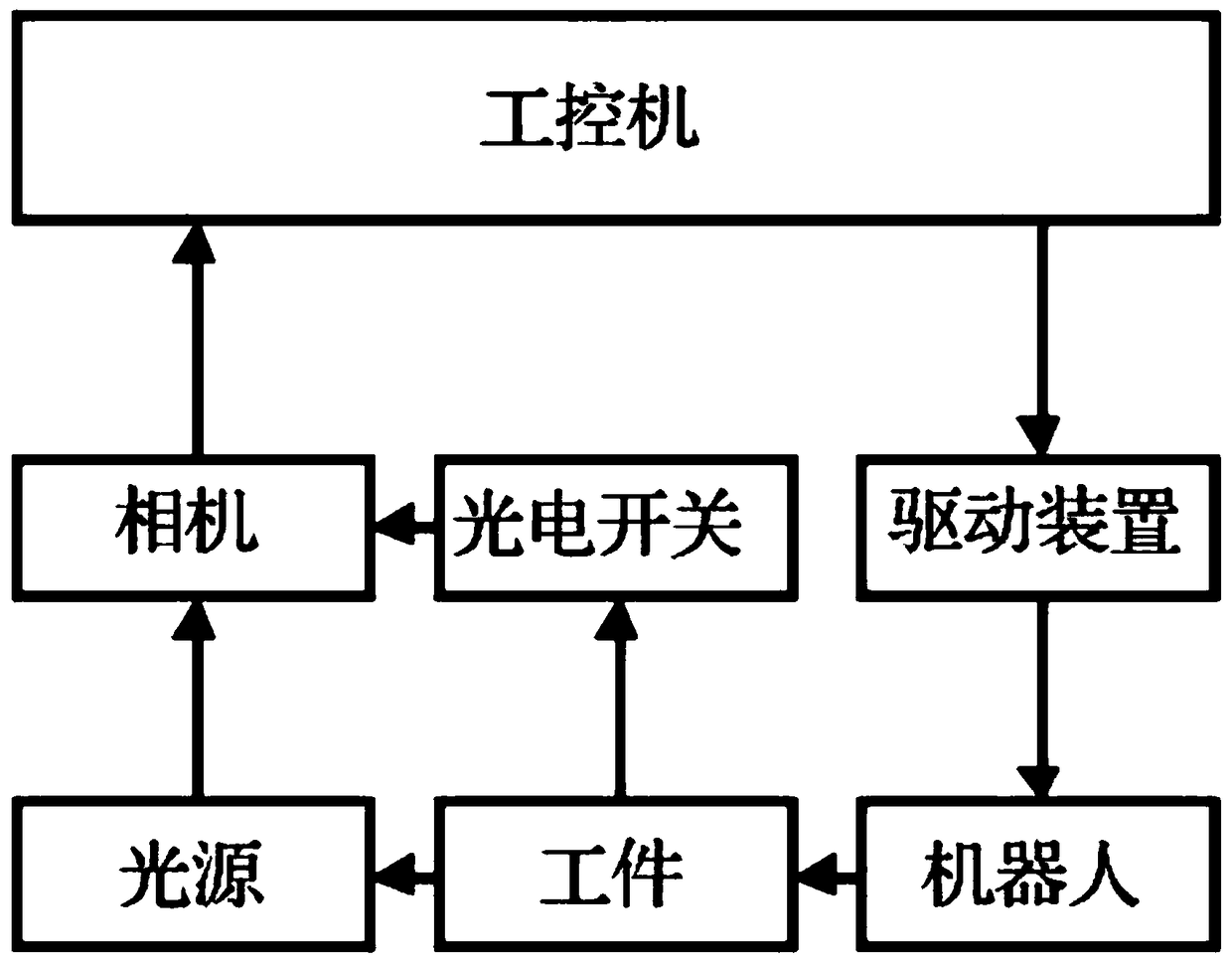

Robot gripping system based on visual guidance

InactiveCN109454638AIncrease the level of automationHigh positioning accuracyProgramme-controlled manipulatorVision basedRobot end effector

The invention discloses a robot gripping system based on visual guidance. The robot gripping system comprises a CCD camera, a lens, a light source, an industrial control computer and an industrial control robot; the CCD camera is an industrial camera, and communicates with a computer through a gigabit Ethernet; and the CCD camera is installed above a conveyor belt. The lens is a prime lens. The light source is an LED ring light source. Image information collected by the CCD camera is received, and converted into robot control signals for controlling the actual position of a robot end-effectorupon completion of workpiece recognition with an image processing algorithm. The industrial control robot is provided with six rotating joints, driven by an AC servo motor, and used for gripping operation on a production line. The robot gripping system is higher in locating accuracy, and meets industrial production requirements; and the robot gripping system is of great significance in improvementof automation level of the production line.

Owner:昆山睿力得软件技术有限公司

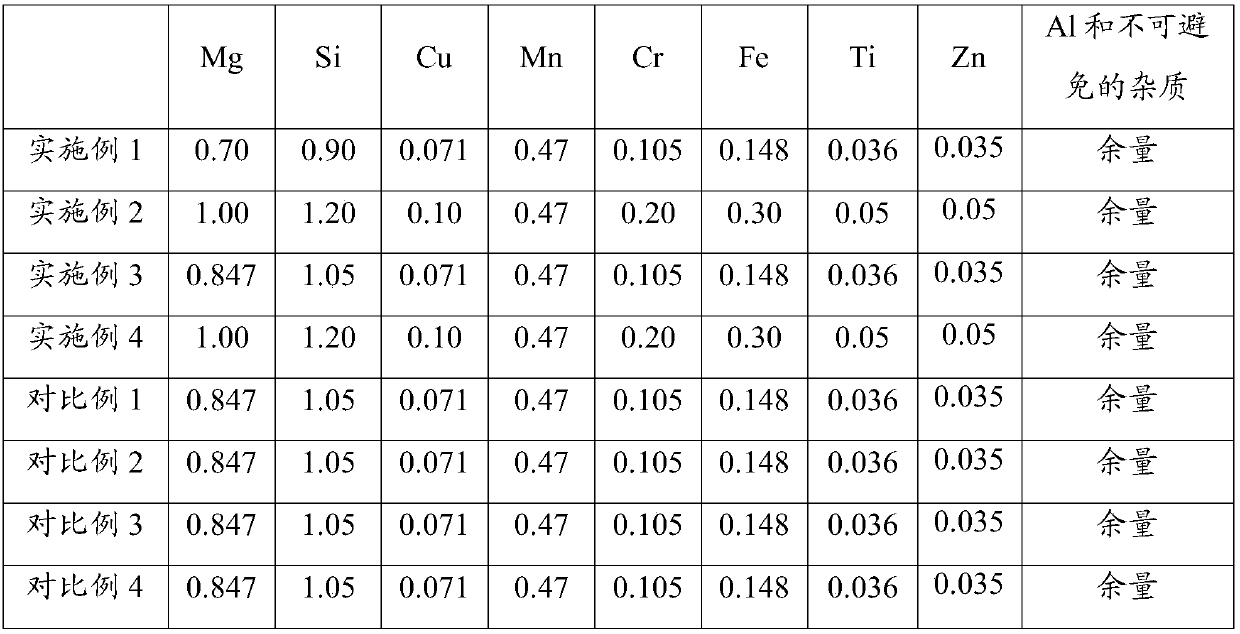

Production method for 6082 aluminum alloy profiles

The invention provides a production method for 6082 aluminum alloy profiles. The production method obtains the aluminum alloy profiles through the steps of smelting casting, uniform heat treatment, extrusion, quenching, cutting, straightening, sawing, framing, aging and the like. By means of the production method, by controlling the feeding temperature, extrusion speed, outlet temperature in the extrusion step and the cooling rate in the quenching step in the production process of the aluminum alloy profiles, the mechanical properties such as yield strength, pull strength and elongation of thealuminum alloy profiles are improved, the pass rate of the aluminum alloy profiles is increased accordingly, and the fact that the subsequent production can be carried out smoothly is ensured.

Owner:中亿丰金益(苏州)科技有限公司

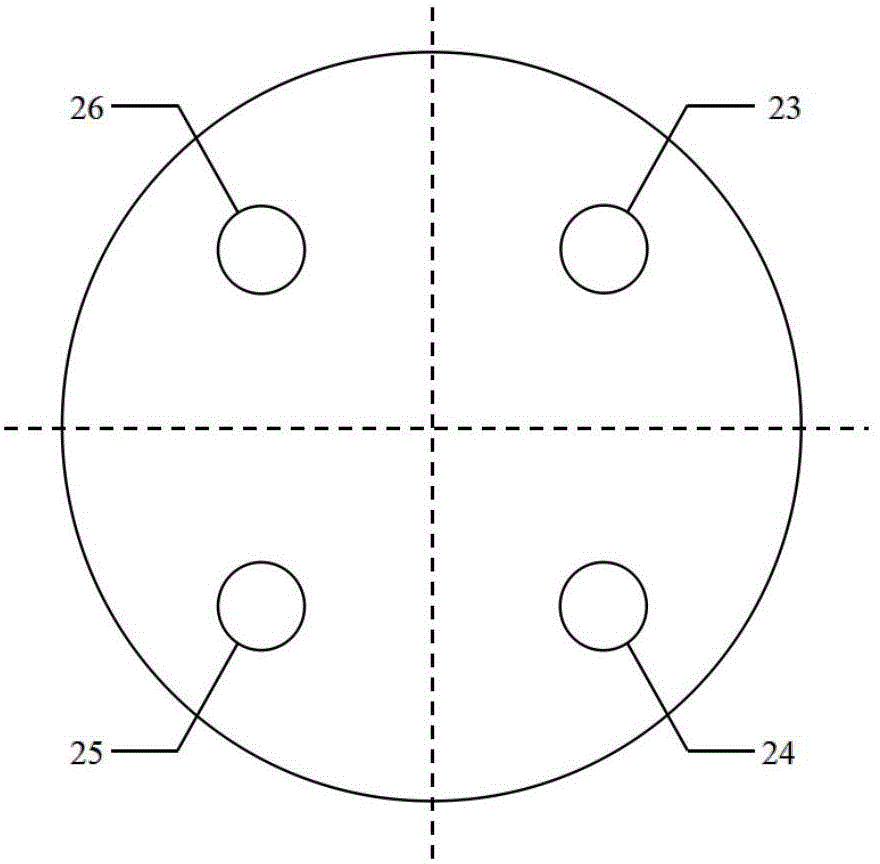

Method and device for efficiently preparing superfine spherical metal powder with high melting point

The invention discloses a device for efficiently preparing superfine spherical metal powder with a high melting point. The device comprises a shell, and a crucible and a powder collecting area which are arranged in a chamber of the shell, and is characterized in that a plurality of melting pools with the same volume are formed inside the crucible, and gaskets with small holes which are communicated with the chamber are fixed at the bottoms of the melting pools; a transmission rod comprises transmission support rods with the number the same as that of the melting pools, and the bottoms of the transmission support rods are aligned with circular holes in the gaskets with small holes; a thermocouple is arranged inside the crucible, and an induction heater is arranged outside the crucible; and the powder collecting area comprises a rotating disk which is used for atomizing metal droplets and is arranged at the bottom of the chamber and connected with a motor, and a collecting tank is also formed in the bottom of the chamber. The invention also discloses a method for efficiently preparing superfine spherical metal powder with the high melting point. By mainly combining a pulse micropore injection method with a centrifugal atomization method, the method can be used for preparing superfine spherical metal powder which is narrow in particle size distribution interval, high in sphericity, good in spreadability and liquidity, and high in production efficiency, and meets the 3D printing and using requirements.

Owner:DALIAN UNIV OF TECH +1

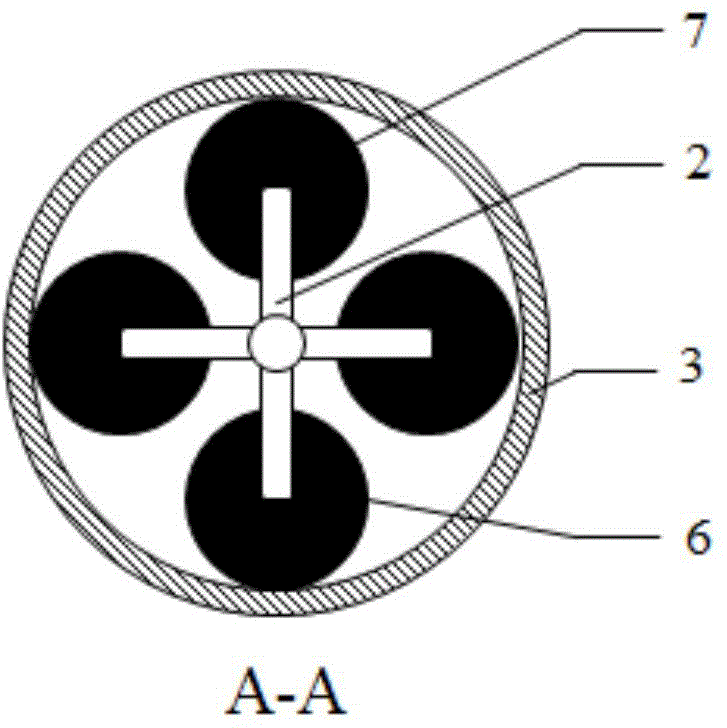

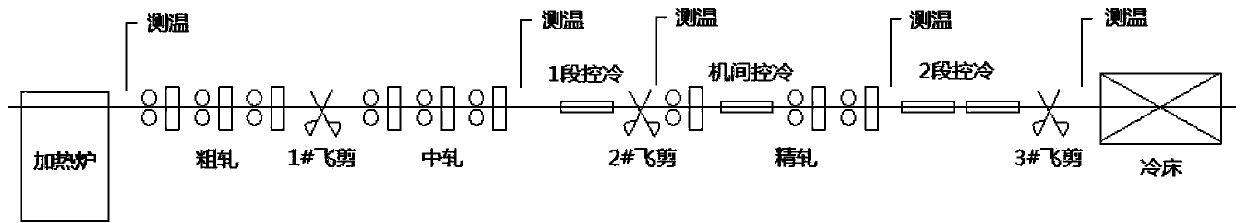

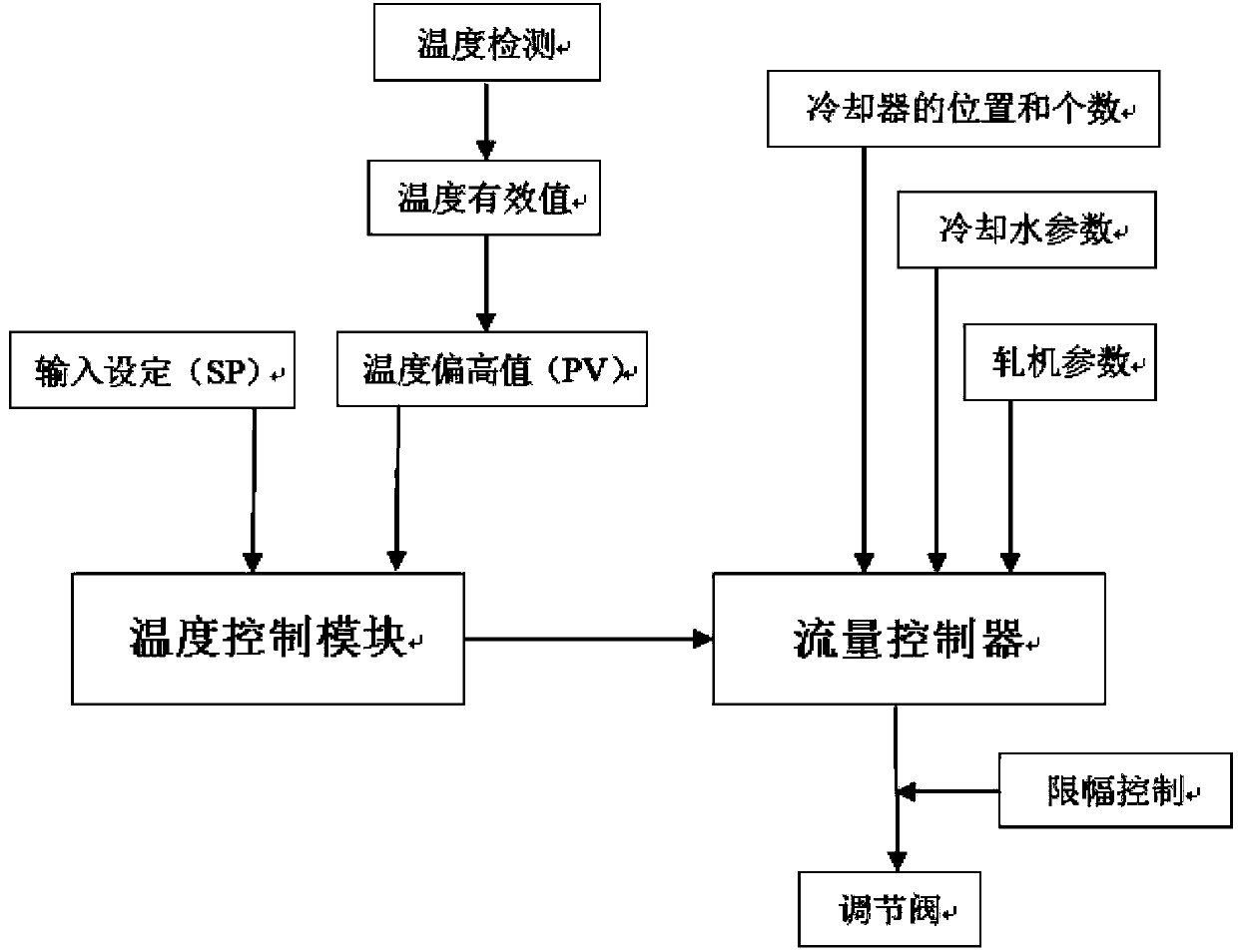

Automatic temperature control method for rod material cold control system

ActiveCN103464474ARealize fully automatic controlHigh precisionTemperature control deviceAutomatic controlEngineering

The invention provides an automatic temperature control method for a rod material cold control system, and belongs to the technical field of rod material heat treatment. The method comprises the following control steps including temperature detection treatment: the effective value of actual temperature detection equipment is judged, and the actual detection value is corrected; automatic temperature regulation: the automatic temperature regulation is realized on the temperature after the pre-cooling section before the rod material fine rolling, and the automatic temperature regulation is realized on the cold bed inlet temperature of the rod materials. The problems of temperature control precision and stability of the rod materials are effectively solved. The method has the advantages that all cold control equipment realizes the automatic operation, and the distribution of the core part temperature and the surface temperature of the rod materials after the cold control automatic control is stable, so the intensity and the toughness of steel materials are improved, the steel material tissue is improved, and in addition, electric energy sources and water energy sources are saved through automatically controlling a cooling water pump and a valve group.

Owner:BEIJING SHOUGANG AUTOMATION INFORMATION TECH

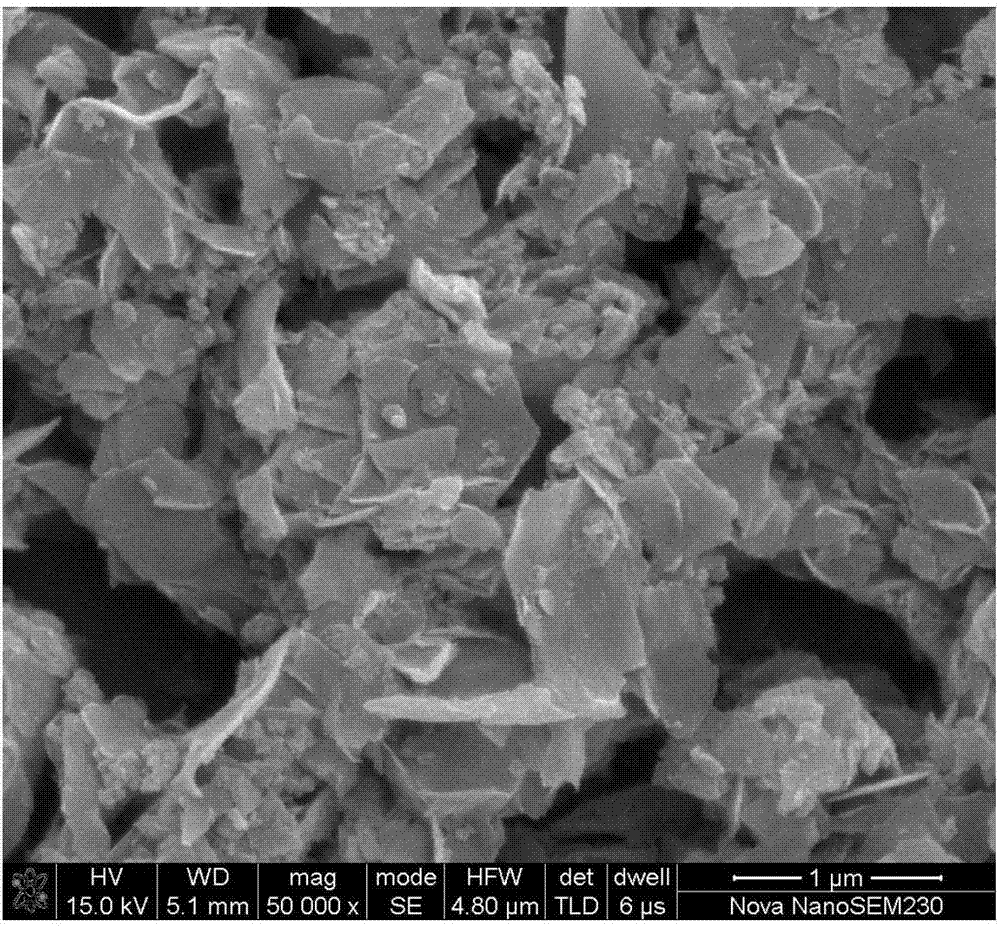

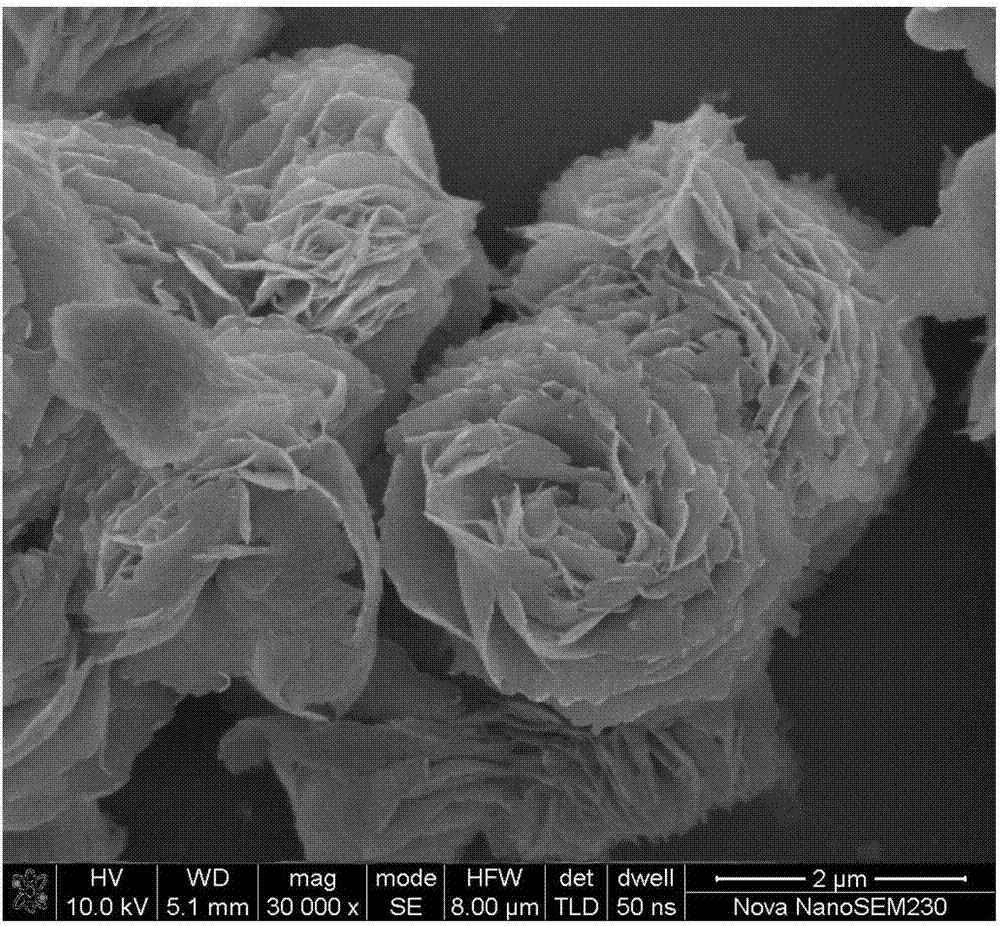

Preparation method of metastable phase bismuth oxide and application thereof in photocatalytic degradation of organic pollutants

ActiveCN107029770AEasy to separateQuick migrationPhysical/chemical process catalystsWater/sewage treatment by irradiationPhotocatalytic degradationLight response

The invention discloses a preparation method of metastable phase bismuth oxide and application thereof in photocatalytic degradation of organic pollutants. The preparation method comprises the following steps: carrying out hydrothermal reaction on an aqueous solution which contains ammonium bismuth citrate, urea and hexadecyl trimethyl ammonium bromide to obtain bismuthyl carbonate microflowers; and calcining the bismuthyl carbonate microflowers in an air environment to obtain the metastable phase bismuth oxide beta-Bi2O3 / Bi2O2.33@Bi2O2CO3. The preparation method is simple and controllable to operate, and is environmentally friendly. The synthesized metastable phase bismuth oxide has the advantages of visible-light response, large specific surface area, high catalytic activity and the like, has the characteristics of rapidness and high efficiency in a process of visible-light catalytic degradation of the organic pollutants, and can be widely applied to the technical field of treatment of the organic pollutants.

Owner:CENT SOUTH UNIV

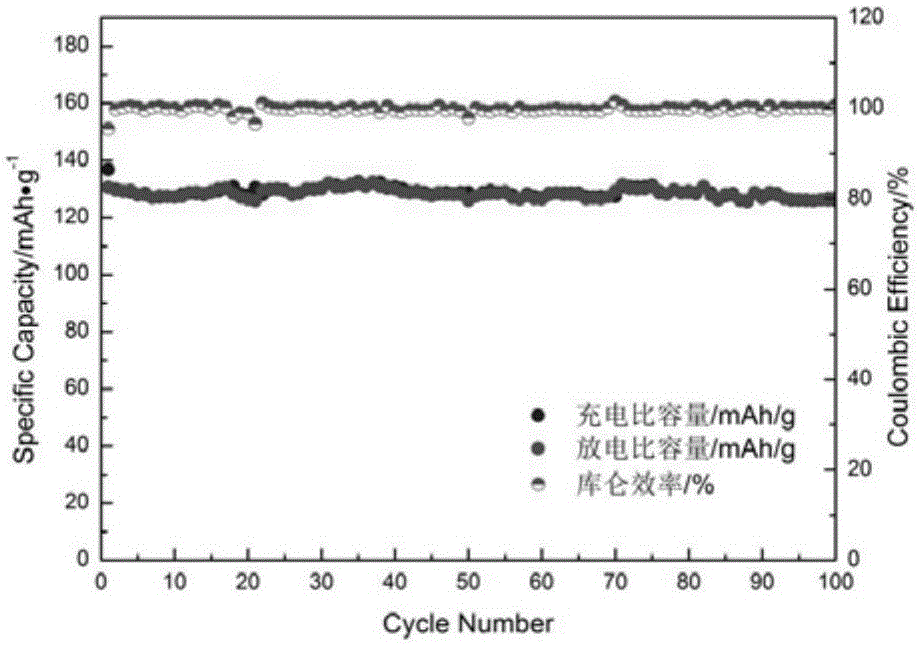

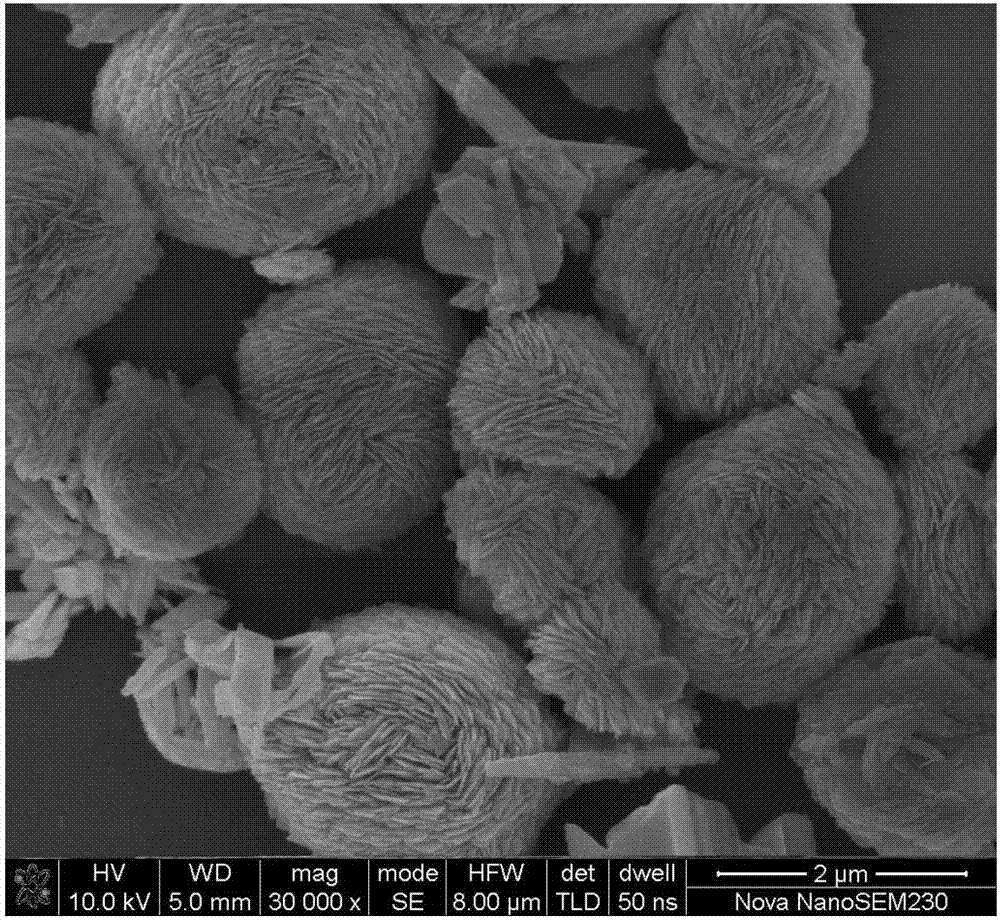

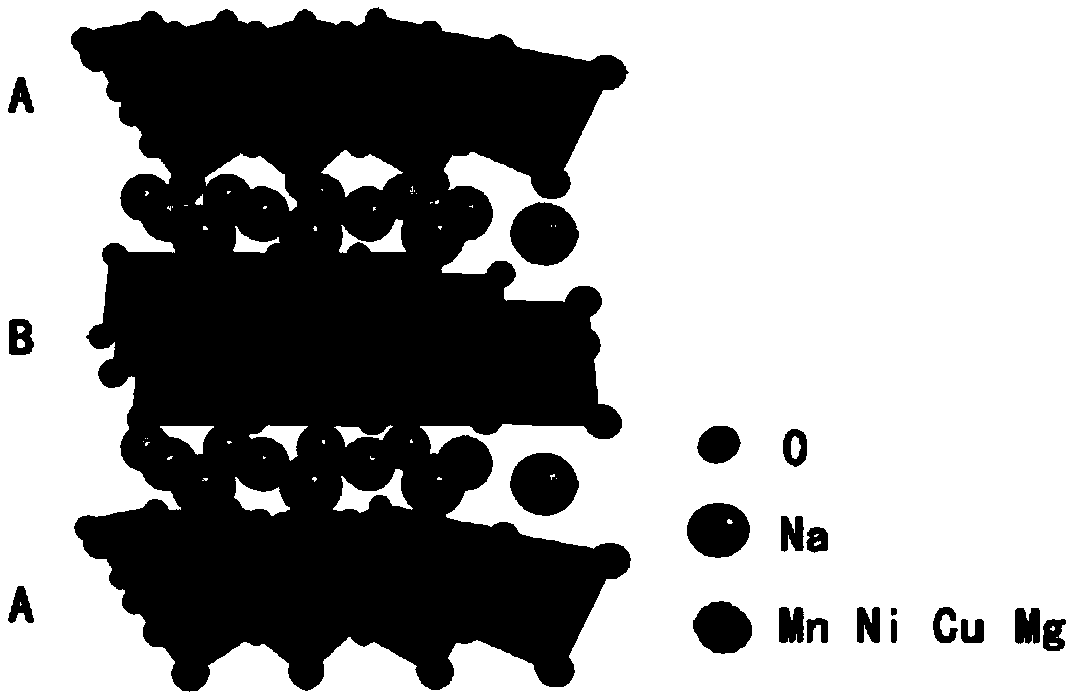

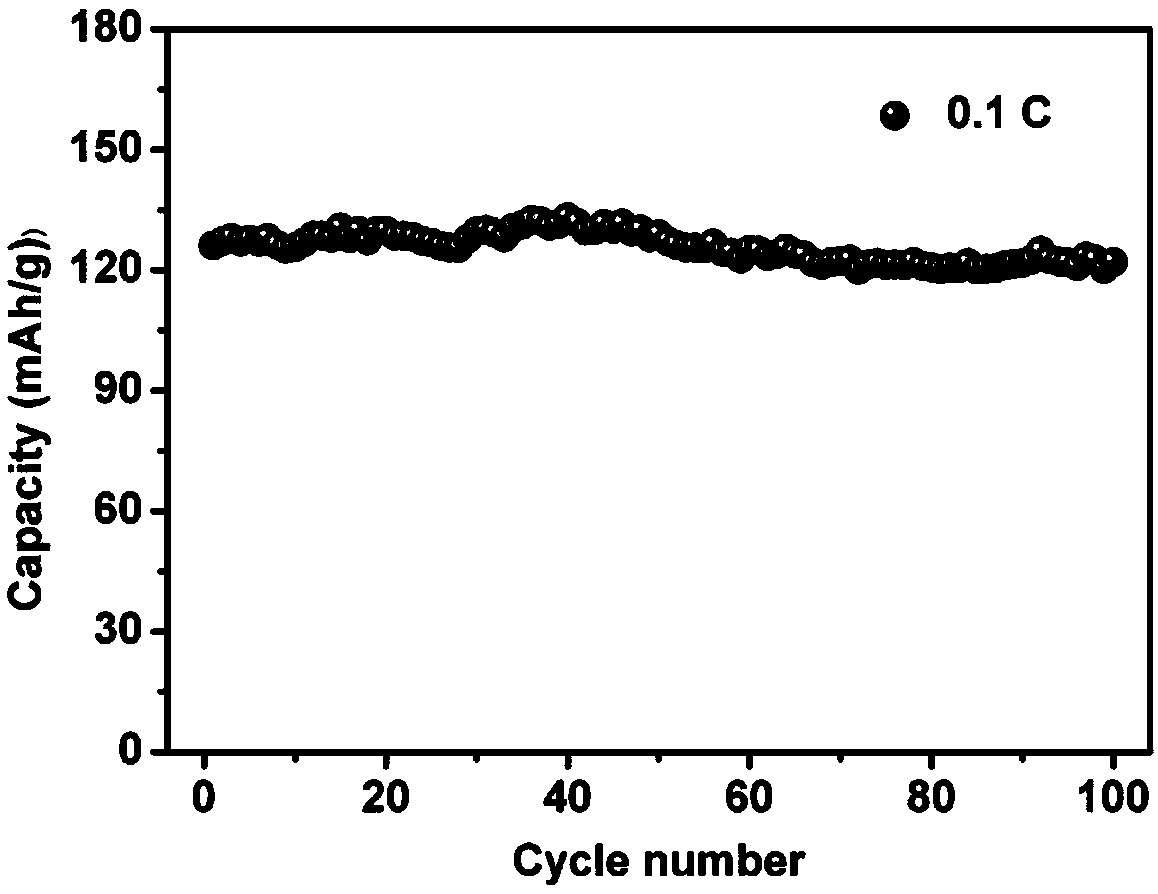

A spherical sodium ion battery positive electrode quaternary material and a preparation method thereof

ActiveCN108987711AIncrease energy densityHigh and medium voltageCell electrodesSecondary cellsHigh energySodium-ion battery

The invention discloses a spherical sodium ion battery positive electrode quaternary material and a preparation method thereof, belonging to the technical field of sodium ion batteries, its chemical formula is: Na0.5Mn0.6Ni0.2CuxMgyO2, x represents the doping amount of Cu and y represents the doping amount of Mg, wherein 0 (x <=0. 1, 0 (y <= 0. 1, x+y=0. 2), the spherical sodium ion battery positive electrode quaternary material of the invention has high energy density, high voltage, long cycle life and excellent rate performance; The spherical sodium ion battery positive electrode quaternarymaterial of the invention is P2 type structure, and the material has sodium ions (Nae and Naf) at two positions, and the ratio of the sodium ions is Nae: Naf=0. 25: 0.25, which has strong symmetry, thereby improving the stability of the structure in the charging and discharging process; The invention has the advantages of simple preparation process, stable performance, low cost, obvious modification of electrochemical performance, and can meet the requirements of industrial production.

Owner:CENT SOUTH UNIV

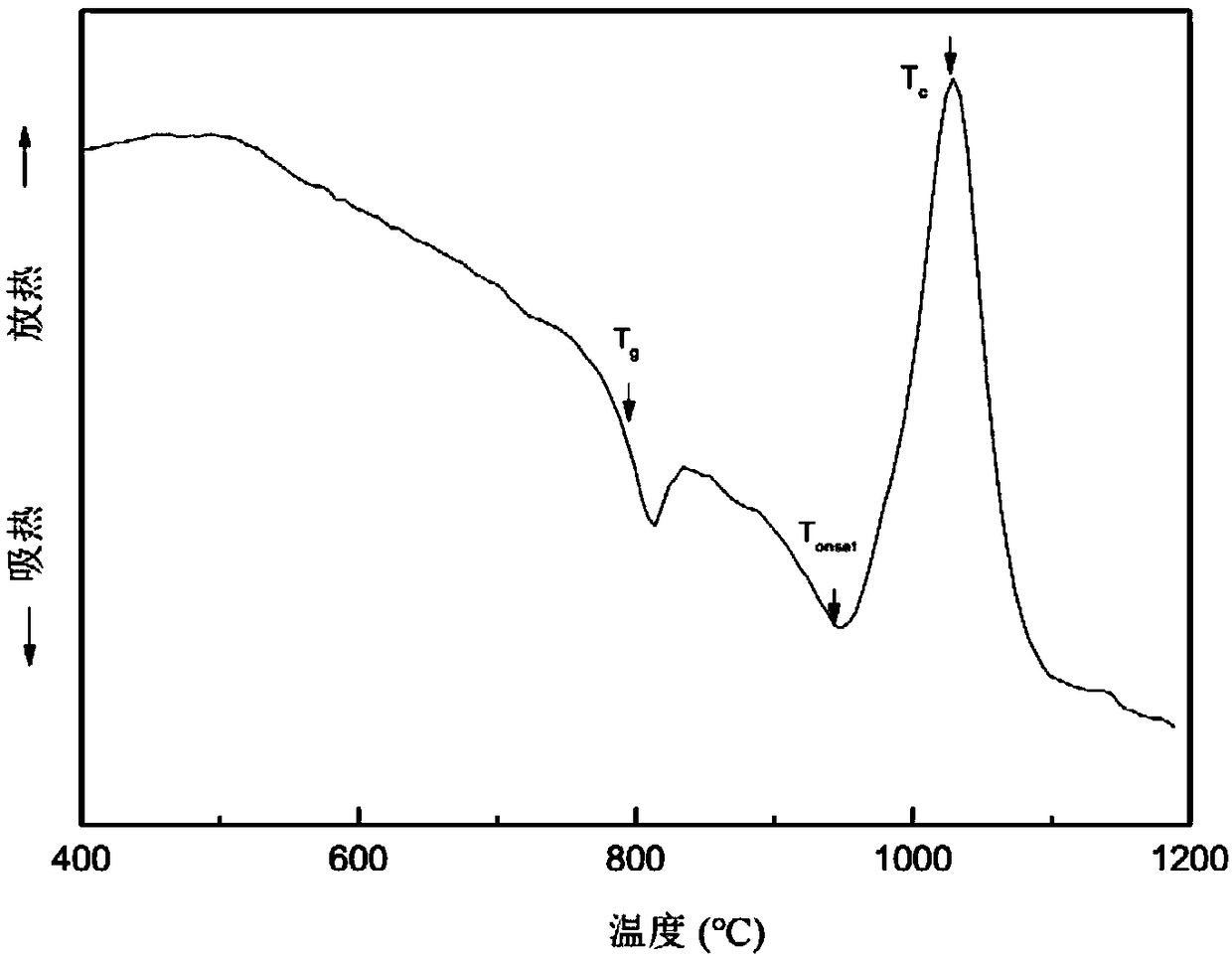

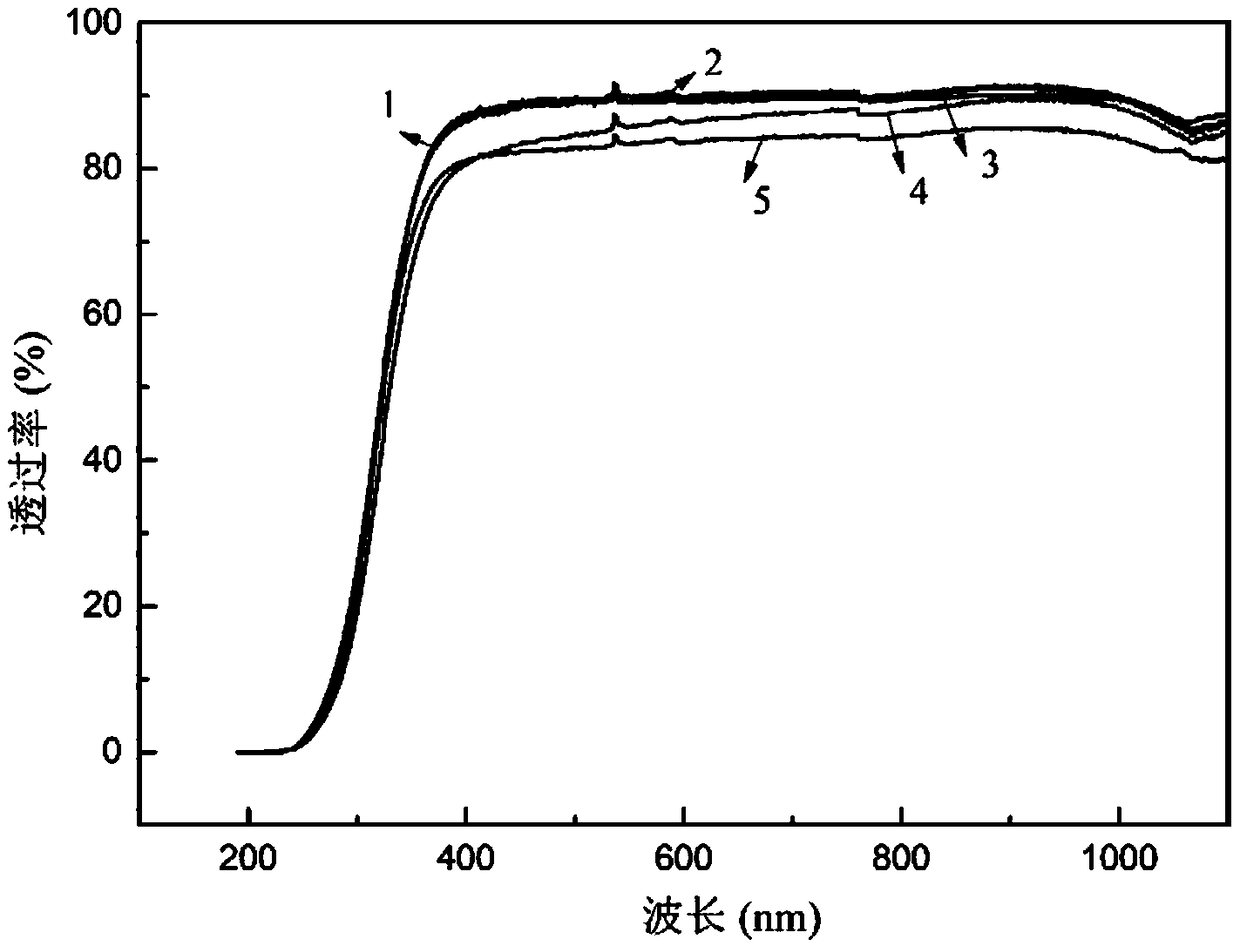

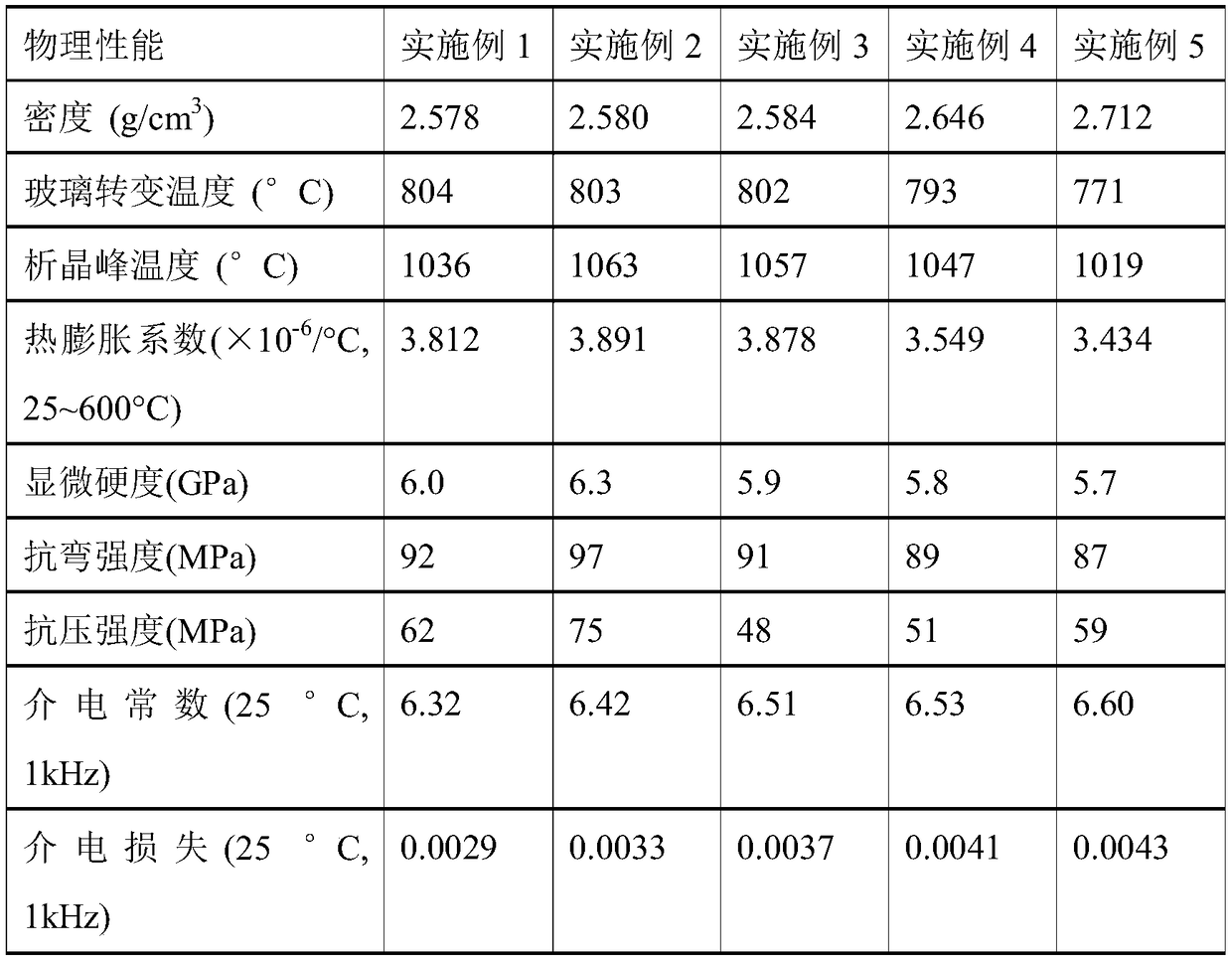

Alkali-free and high-alumina borosilicate glass with low thermal expansion coefficient and preparation method of alkali-free and high-alumina borosilicate glass

PendingCN108658454AIncrease the difficultyIncrease costGlass shaping apparatusAlkali freeThermal expansion

The invention discloses alkali-free and high-alumina borosilicate glass with a low thermal expansion coefficient and a preparation method of the alkali-free and high-alumina borosilicate glass. MgO ispartially replaced with high Al2O3, low SiO2 and ZnO, MgO, ZnO, Al2O3, SiO2 and borate are taken as raw materials, B2O3 is introduced by boric acid, zinc borate, magnesium borate or aluminum borate,the glass comprises oxides as follows: 5.85%-12.37% of MgO, 0.13%-11.81% of ZnO, 29.60%-31.45% of Al2O3, 49.71%-52.83% of SiO2 and 3.03%-3.22% of B2O3, and total mass of MgO and ZnO is 12.50%-17.66%.The preparation process is simple, the melting temperature is low, and the prepared glass has low density, low thermal expansion coefficient, low dielectric loss and moderate dielectric constant and is applied to a hybrid circuit substrate, an encapsulating material or a flat-panel display.

Owner:CENT SOUTH UNIV

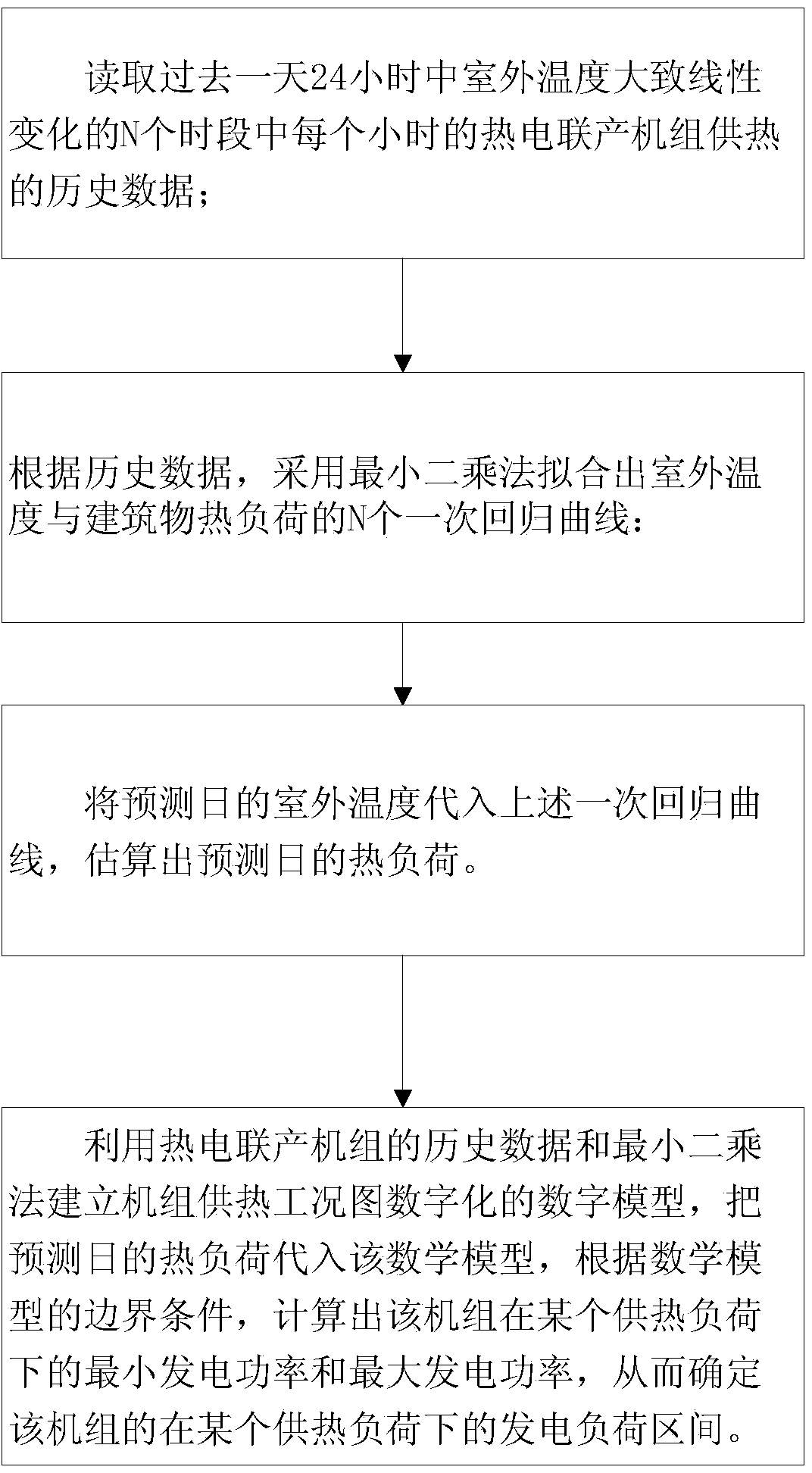

Electric load predication optimization method for N-section intervals of combined heat and power generation set

ActiveCN103745281AForecasting generation loadReduce power generation loadForecastingSystems intergating technologiesMathematical modelCogeneration

The invention discloses an electric load predication optimization method for N-section intervals of a combined heat and power generation set. The method comprises the following steps: reading heating historical data of the combined heat and power generation set in each hour in N time intervals when approximate linear change of the outdoor temperature occurs in 24 hours of the past day, fitting N linear regression curves of the outdoor temperature and the thermal load of a building through a least square method according to the historical data, substituting the outdoor temperature in a predicate day into the linear regression curves, estimating the thermal load of predicate day, establishing a digital model of a set heating condition diagram through the historical data of the combined heat and power generation set and the least square method, substituting the thermal load of predicate day into the digital model, and calculating the minimum generated power and the maximum generated power of set at certain thermal load according to boundary conditions of the digital model, so as to fix a generation load interval of the set at certain thermal load. The method can be used for accurately predicating thermal load and electric load intervals of a heating system of the combined heat and power generation set in the next 24 hours.

Owner:STATE GRID CORP OF CHINA +2

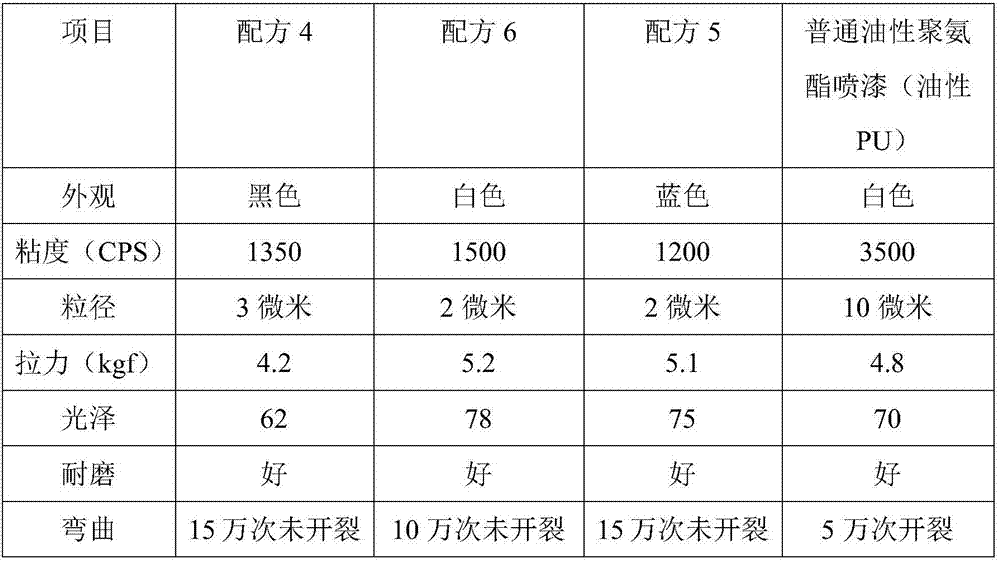

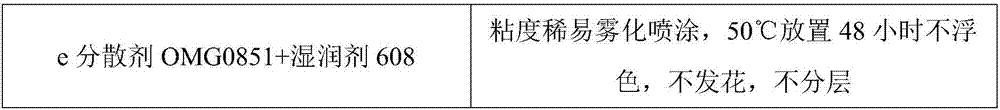

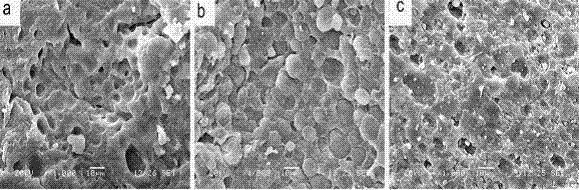

Waterborne polyurethane spray paint for fabric and shoe materials and preparation method of waterborne polyurethane spray paint

InactiveCN107418418AGood dispersionLow viscosityPolyurea/polyurethane coatingsEmulsion paintsDispersion stabilityBiological activation

The invention discloses waterborne polyurethane spray paint for fabric and shoe materials and a preparation method of the waterborne polyurethane spray paint. The waterborne polyurethane spray paint is prepared from components such as waterborne polyurethane, water, toner and auxiliaries. The spray paint is good in dispersion stability, high in dyeing degree, good in brilliance, easy to process, free of sagging, free of bubbles, good in levelling, physical property and activation property, easy for secondary processing and free of polishing, can be bent for 130 thousand times or more, and is especially suitable for materials such as the fabric and the shoe materials.

Owner:HUNAN XINLIHUA NANO TECH

Tobacco stem pulping process for producing tobacco flake in method similar to papermaking

The tobacco stem pulping process for producing tobacco flake in method similar to papermaking includes: soaking tobacco stem in hot water of 40-70 deg.c for 1-2.5 hr to extract and solid-liquid separation to obtain solid tobacco stem and tobacco stem extracting liquid; beating tobacco stem fiber in conventional process with primary beating degree of 10-25 deg SR, secondary beating degree of 13-26 deg SR and final beating degree of 14-30 deg SR. The present invention has improved technological process and indexes and the tobacco flake has raised filling performance and capacity of lowering tar releasing amount of cigarette. The present invention can meet the requirement of industrial production and raise the utilization rate of tobacco flake.

Owner:CHINA TOBACCO HUNAN INDAL CORP

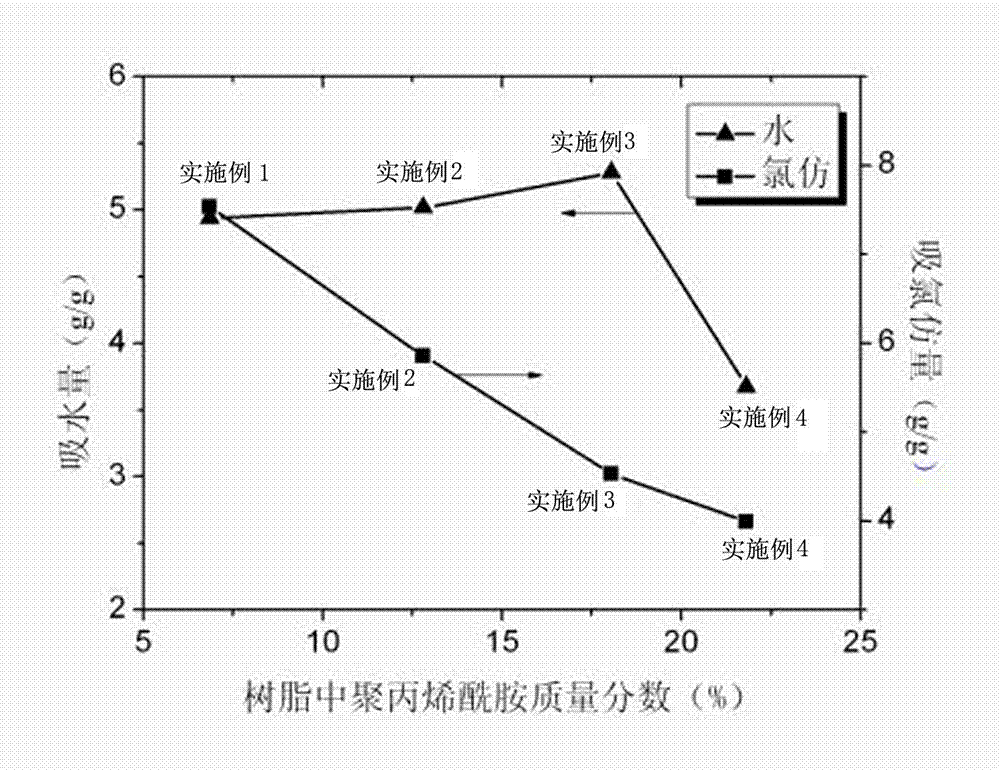

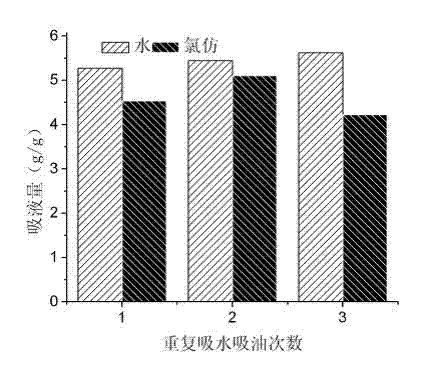

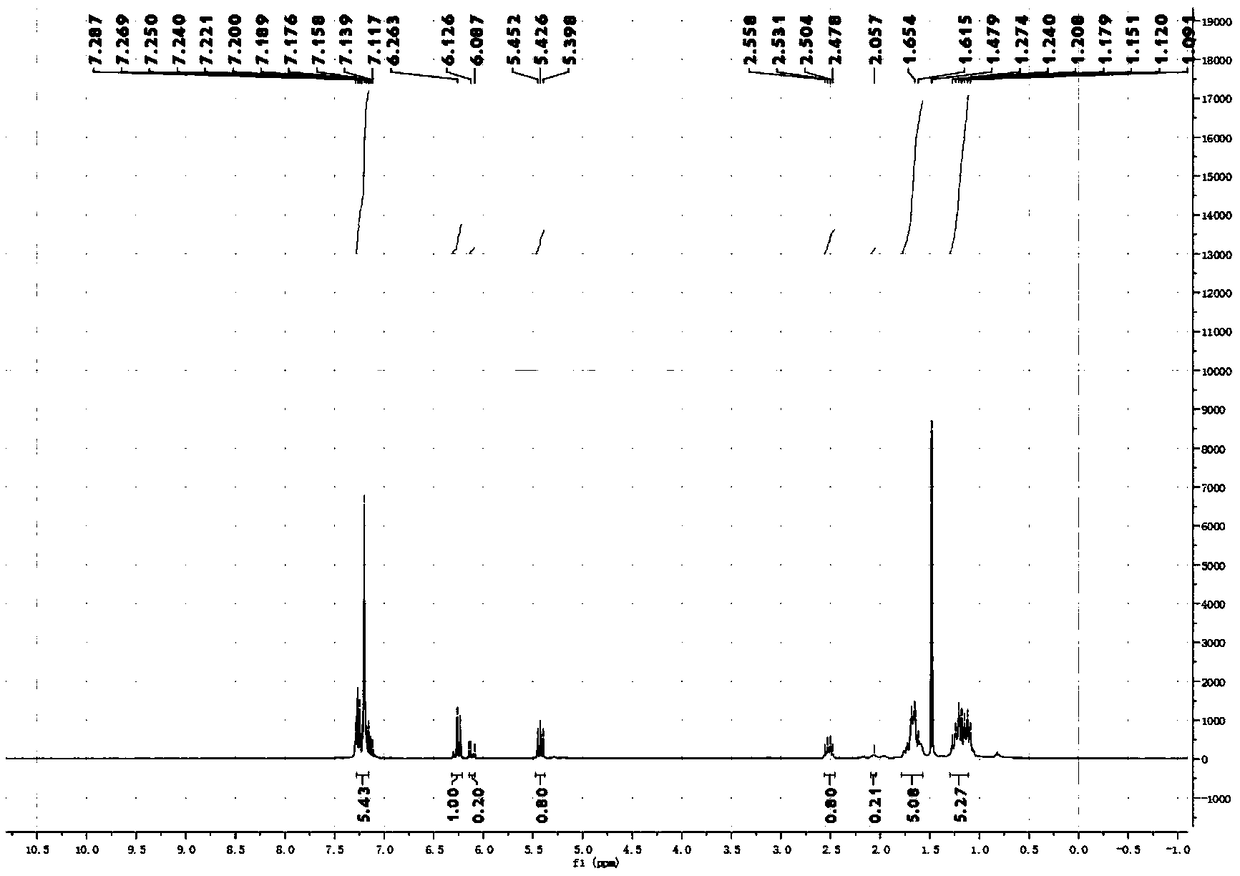

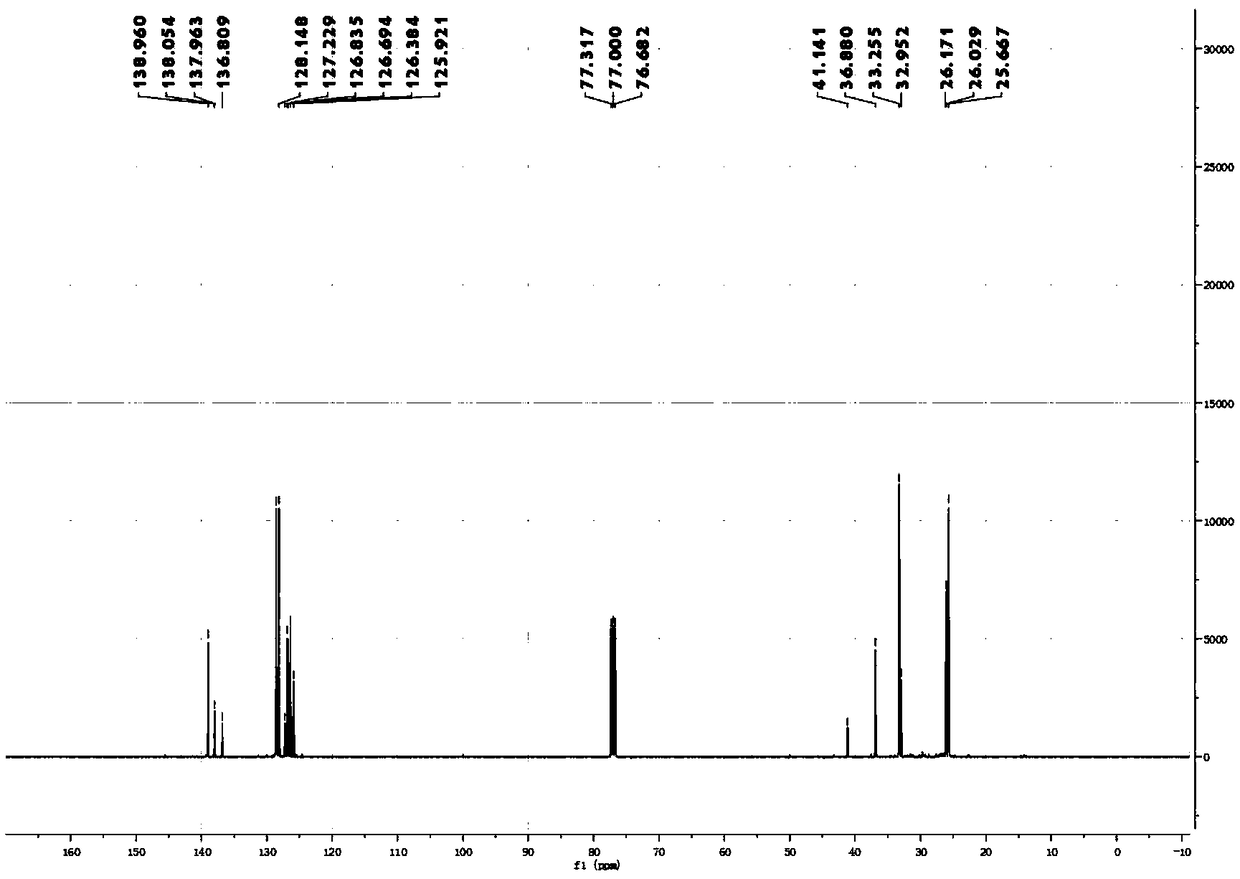

Preparation method of water-absorbing and oil-absorbing bifunctional resin

The invention relates to a preparation method of water-absorbing and oil-absorbing bifunctional resin. The method comprises the following steps: 1) first adding an emulsifier and an oil-soluble cross-linker into an oil phase monomer, stirring evenly, and introducing nitrogen gas for a few minutes to obtain an oil phase; 2) weighing an aqueous phase monomer, and preparing an aqueous solution to obtain a water phase; 3) dropwise adding the water phase to the oil phase to obtain an emulsion; and 4 ) dropwise adding an solution prepared from an initiator to the emulsion, continuing to stir for 20-60 min until a stable state of the emulsion, placing the emulsion in an environment at 20-50 DEG C for polymerization, reacting for 24 h, and treating the products by vacuum drying to a constant weight, so as to obtain the water-absorbing and oil-absorbing bifunctional resin. The preparation method provided by the invention has simple process, safe operation and mild reaction conditions; and the obtained resin has water-absorbing and oil-absorbing double functions and strong repeated water absorption ability, can meet needs in a variety of areas, and has broad market prospects and potential use value.

Owner:武汉工大科技园发展有限公司

Method for synthesizing cis-olefin by catalyzing decarboxylation coupling reaction of NHP ester and aryl-terminated alkyne with iridium

InactiveCN109293468AHigh yieldHigh selectivityCarbamic acid derivatives preparationOrganic compound preparationIridiumAryl

The invention provides a method for synthesizing Z-selective olefin by catalyzing a decarboxylation coupling reaction of an NHP ester and aryl-terminated alkyne with iridium. The aryl-terminated alkyne and its derivative and the NHP ester undergo a one-pot reaction under the irradiation of blue lights under the catalysis of iridium to obtain the corresponding Z-selective olefin compound. The method has the advantages of simple process and high cis-selectivity.

Owner:CENT SOUTH UNIV

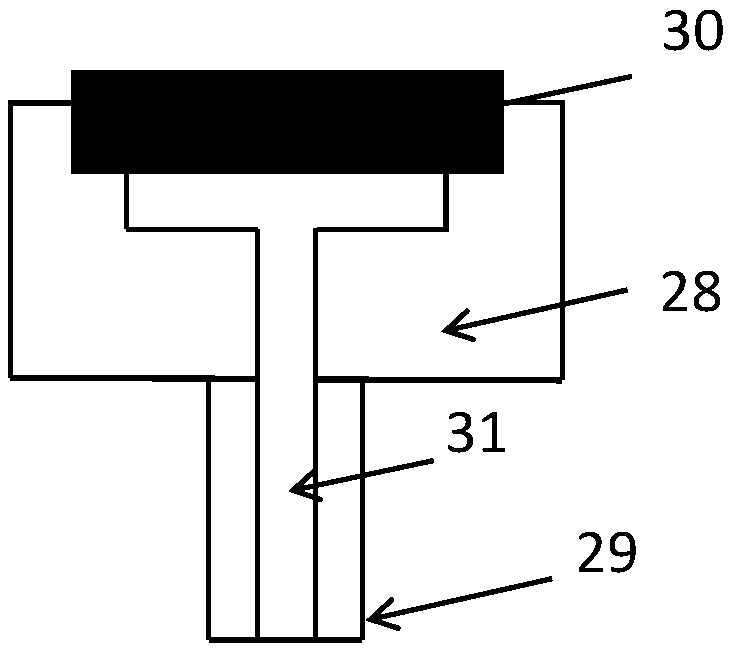

Device and method for preparing spherical metal powder for 3D printing

The invention provides a device and method for preparing spherical metal powder for 3D printing. The device for preparing the spherical metal powder comprises a shell, a crucible and a collecting bin,wherein the crucible is arranged in the shell, and the collecting bin is arranged on the lower portion of the shell. The device for preparing the spherical metal powder for the 3D printing is characterized in that a rotating disc arranged in a powder collection area is of a inlaying structure, materials with poor thermal conductance are selected as a substrate part of the rotating disc, metal materials with a wetting angle less than 90 degrees with liquid drops are selected to be inlayed into a main part to be used as an atomized plane, and a ventilation hole is formed in the rotating disc. The invention further discloses a method for preparing the spherical metal powder for the 3D printing, a pulse microporous injection method and a centrifugal atomization method are mainly combined, a rotating disc structure is matched, and the surface of the rotating disc is subjected to induction heating, so that molten metal breaks through a split mode of traditional molten metal, a fibrous splitmode which can be realized only when an atomization medium is an aqueous solution or an organic solution is realized, high melting point metal powder which meets requirements is prepared, the particle size is fine and grain size is controllable, the sphericity is high, no satellite droplet is achieved, the mobility and the spreadability are good, and the preparation method is suitable for industrialized production.

Owner:DALIAN UNIV OF TECH +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com