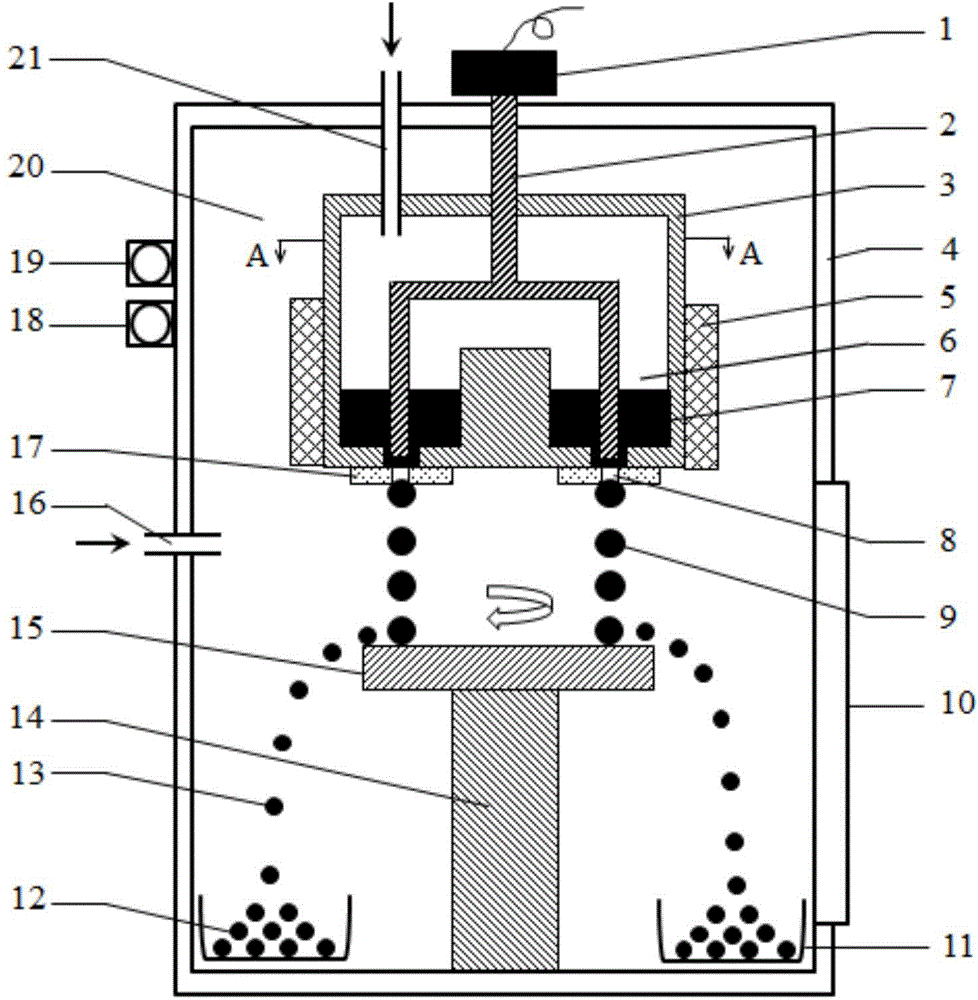

Method and device for efficiently preparing superfine spherical metal powder with high melting point

A metal powder and melting point technology, which is applied in the field of high melting point metal powder preparation, can solve the problems of poor sphericity, poor spreadability and fluidity, etc., and achieve the effects of high sphericity, increased output, and uniform and controllable size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

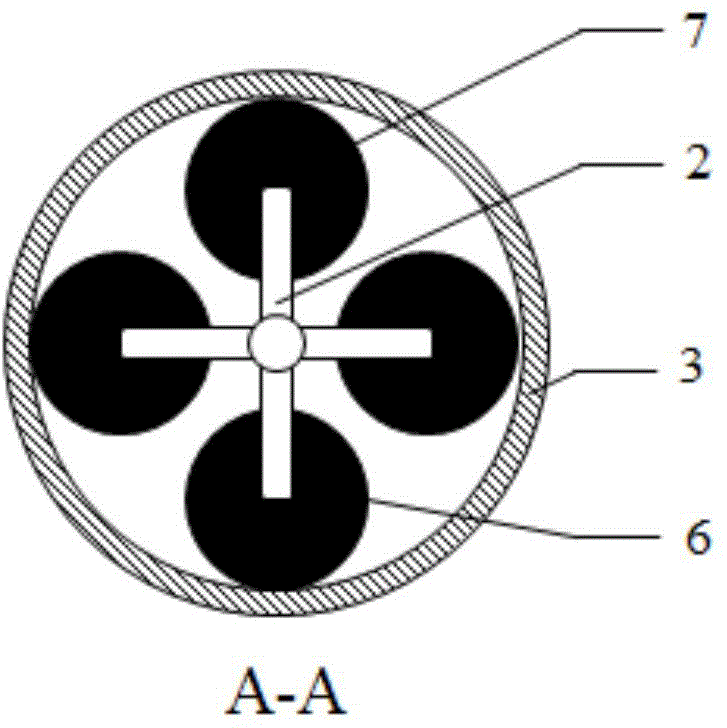

Method used

Image

Examples

Embodiment 1

[0044] The specific embodiment that prepares copper spherical metal powder with above-mentioned device and method is:

[0045] First, the copper block is broken into block particles with a particle diameter of 2 cm, and is loaded into the crucible 3. The amount of copper particles loaded reaches 2 / 3 of the capacity of the crucible 3, and then the material is a pad with small holes made of graphite. The sheet 17 is installed on the bottom of the crucible 3 by screws, and the chamber door 10 is closed; the crucible 3 and the chamber 20 are pumped to a low vacuum of 1Pa-5Pa with a mechanical pump 18, and then a high vacuum is pumped to 10Pa with a diffusion pump 19. -3 Pa, filled with high-purity inert protective gas argon to atmospheric pressure; set the heating temperature to 1400°C, energize the induction heater 5, and continue to keep warm for 30 minutes after the temperature reaches 1400°C, so that all the copper particles in the crucible 3 are melted into a melt 7 Open the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com