Robot gripping system based on visual guidance

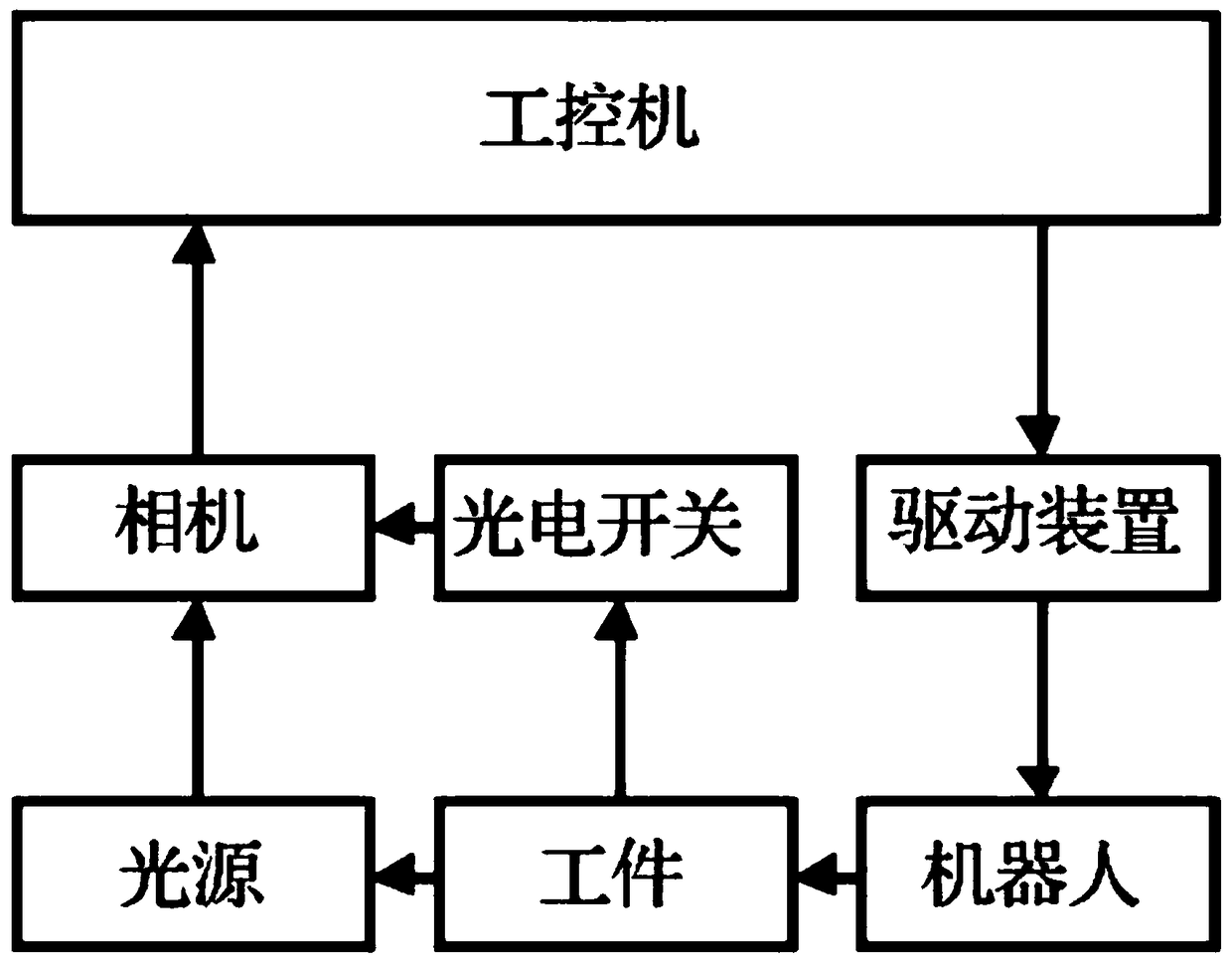

A vision-guided, robotic technology, applied in manipulators, program-controlled manipulators, manufacturing tools, etc., can solve problems such as grasping failures, limiting the flexibility and work efficiency of industrial robots, and robots not being able to adapt in time, to improve the level of automation, high The effect of positioning accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0042] In the use of this system, the CCD camera is fixedly installed above the conveyor belt, and the conveyor belt runs continuously. The workpiece enters the field of view of the camera from one end of the conveyor belt, and the timer is set to trigger the camera to collect a frame of image every 0.5s. The image size is 640×480, and it is matched by the template. The method determines the centroid position of the workpiece, calculates the movement speed of the workpiece through the displacement of the workpiece in the moving direction of the two frames of images and the time interval between the two frames of images, and predicts the position of the workpiece in the next clock cycle through the Kalman filter, and plans The motion trajectory of the robot makes the pose of the end effector of the robot coincide with the target pose when the workpiece moves to the position to be grasped. Finally, through the inverse solution of robot kinematics, the pose information is converted...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com