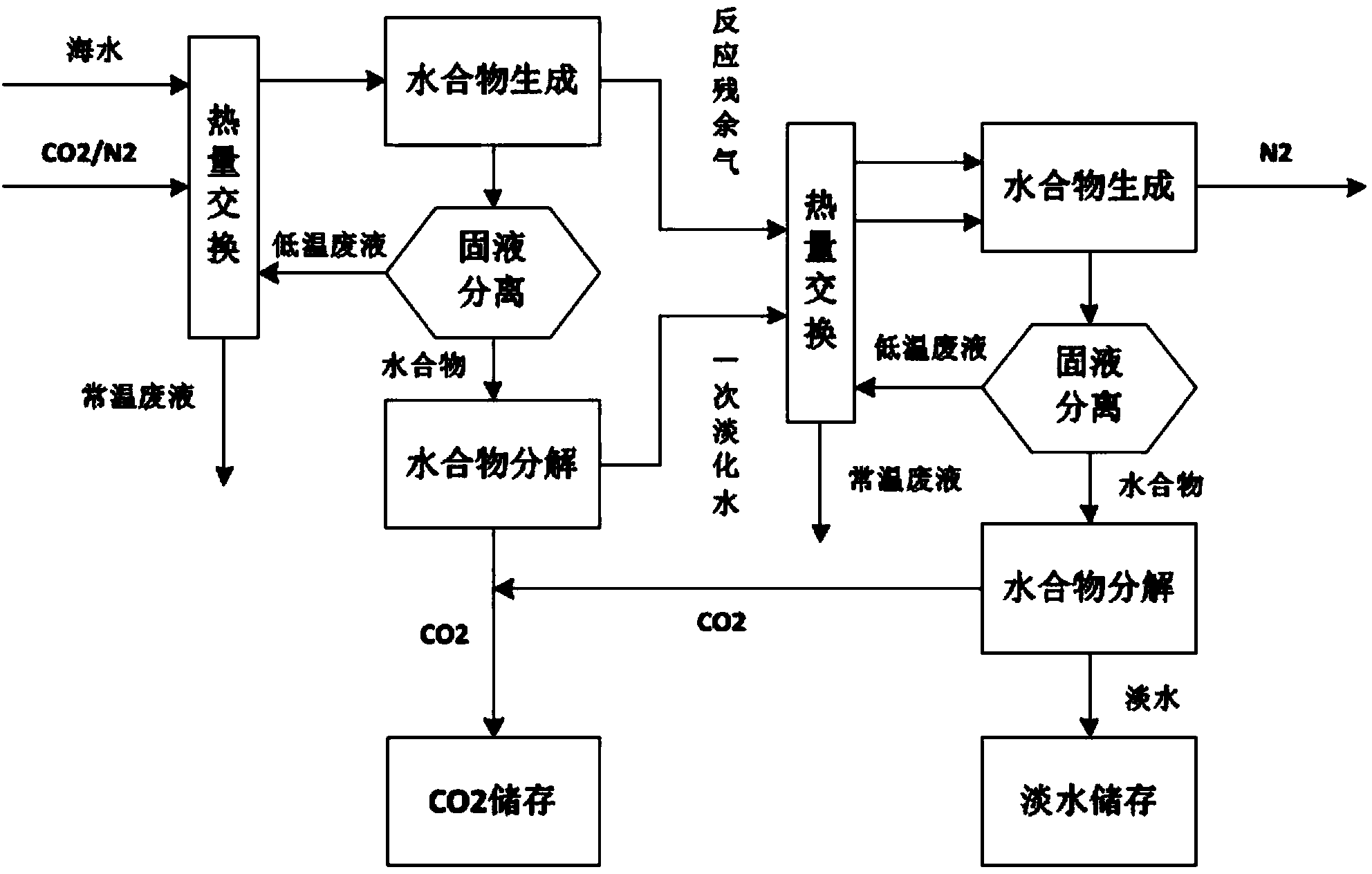

Carbon dioxide capturing and seawater desalting co-production device and method based on hydrate method

A carbon dioxide and hydrate technology, applied in chemical instruments and methods, carbon compounds, seawater treatment, etc., can solve problems such as blanks, and achieve the effects of improving recovery rate, reducing cooling loss, and reasonable and compact system structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

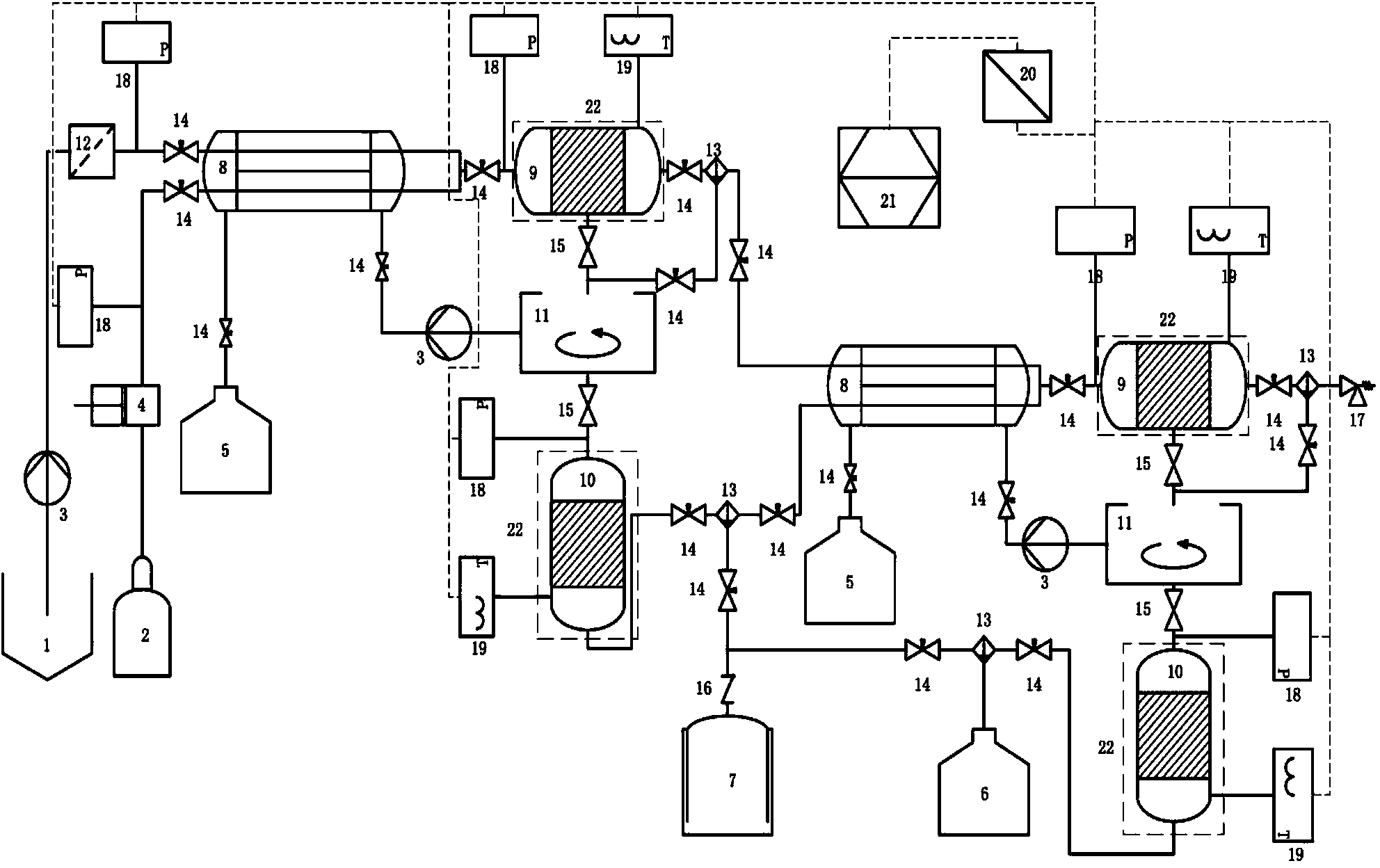

[0019] Specific embodiments of the present invention will be described in detail below in conjunction with the technical solution and the drawings.

[0020] As shown in the figure, according to the described device structure connection, the method of using this device for co-production of carbon dioxide capture and seawater desalination is as follows:

[0021] (1) Gas-water transportation: seawater is introduced into the clarification tank 1, the water pump 3 pumps the seawater into the filter 12, and the gas in the gas source 2 is pressurized by the gas booster pump 4 to twice the equilibrium pressure of the carbon dioxide hydrate phase After left and right, together with seawater enter the tube heat exchanger 8 in the first stage for pre-cooling, the gas-liquid pressure before entering the tube heat exchanger is monitored by the pressure sensor 18, and the mixed gas and seawater pass through the tube heat exchanger outlet The valve 14 enters the hydrate formation reactor 9;

[002...

PUM

| Property | Measurement | Unit |

|---|---|---|

| compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com