Alkali-free and high-alumina borosilicate glass with low thermal expansion coefficient and preparation method of alkali-free and high-alumina borosilicate glass

A low thermal expansion coefficient, silicate glass technology, applied in glass manufacturing equipment, glass molding, manufacturing tools, etc., can solve problems such as difficult removal of bubbles, high temperature viscosity, and difficulty in melting, so as to increase difficulty and cost Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

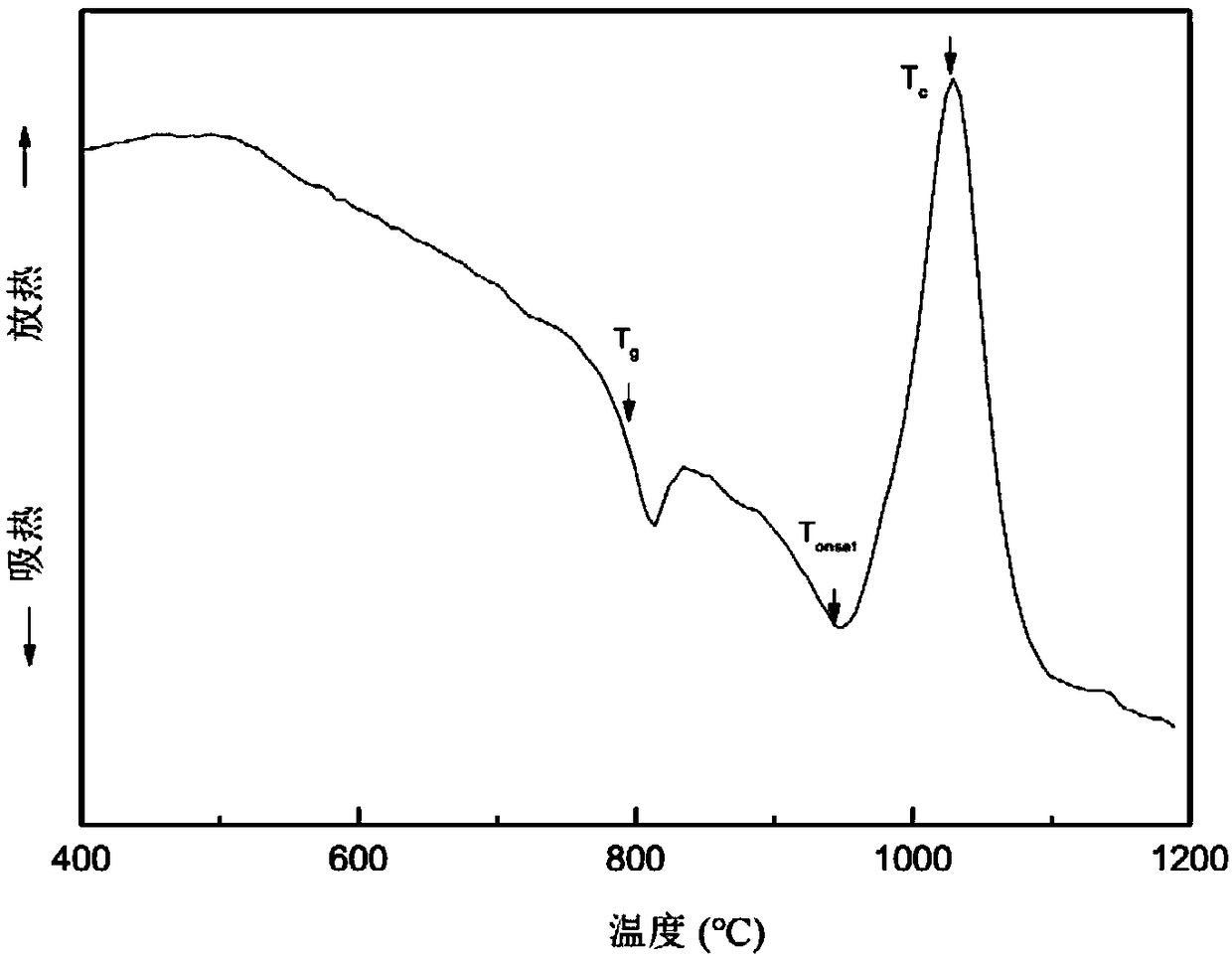

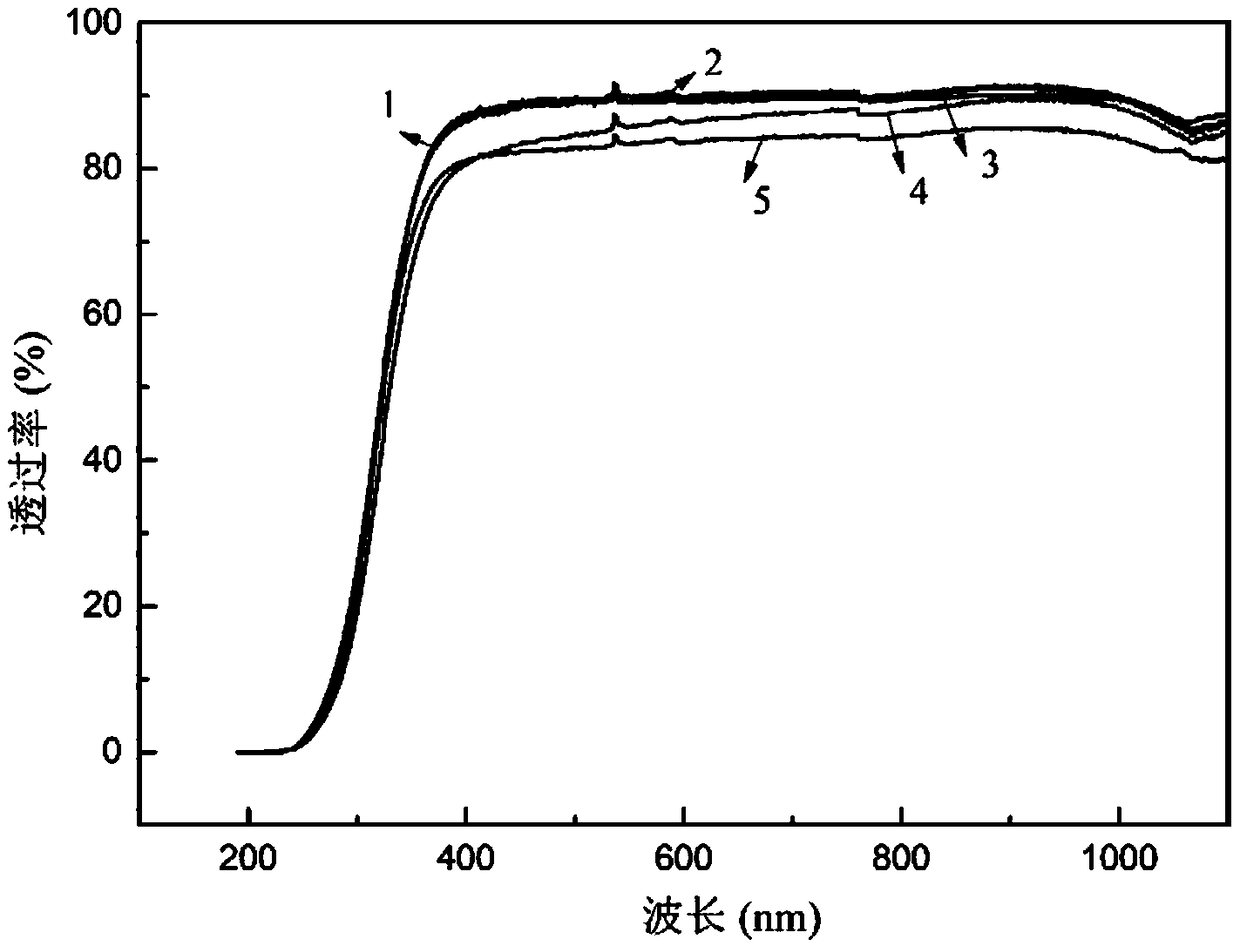

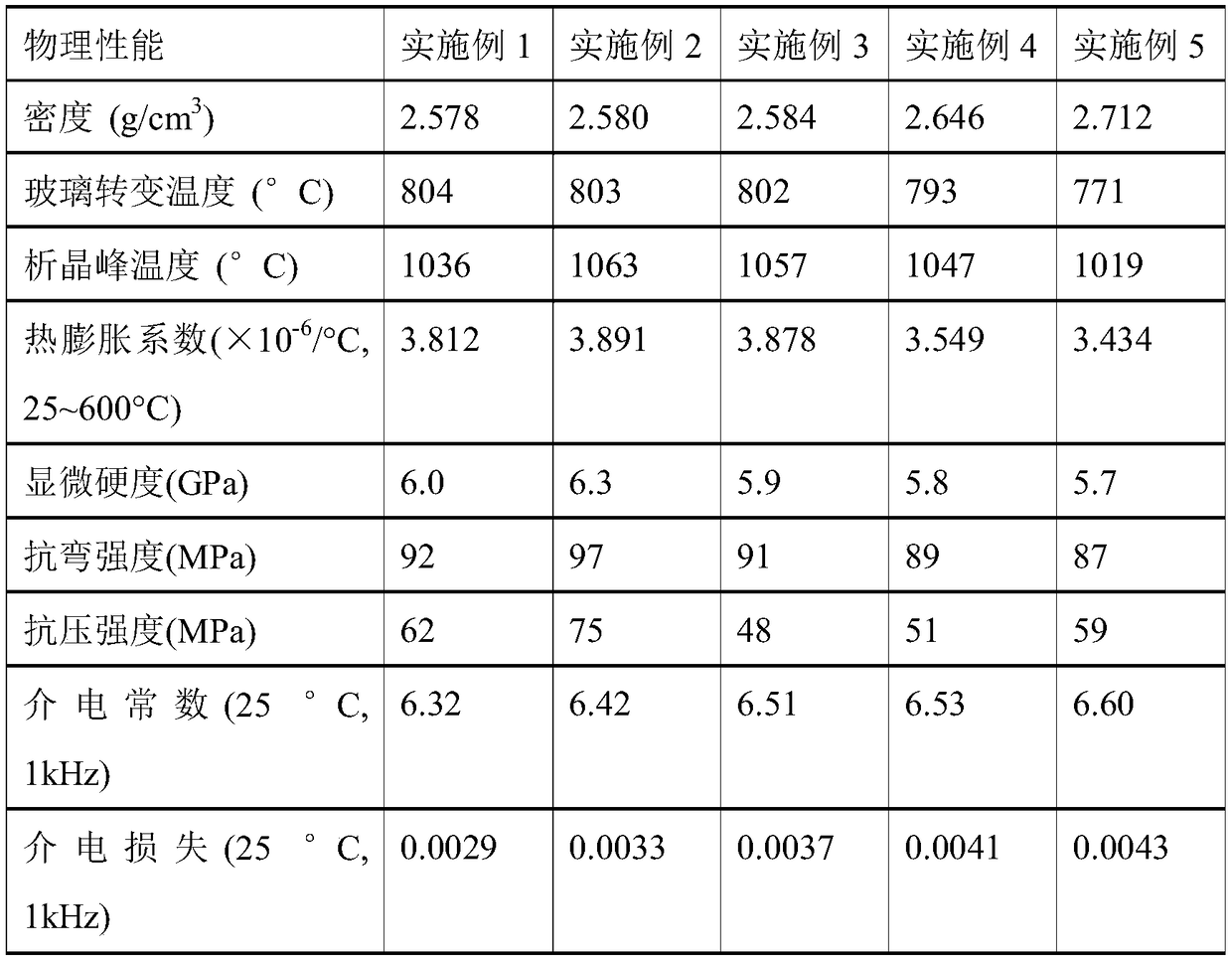

[0036] A low thermal expansion coefficient alkali-free high-alumina borosilicate glass prepared in this example comprises the following oxides and is composed of: MgO: 12.37%, ZnO: 0.13%, Al 2 o 3 : 31.45%, SiO 2 : 52.83%, B 2 o 3 : 3.22%. Accurately weigh the corresponding raw materials, mix all the raw materials fully and put them into a platinum crucible, raise the temperature to 1650 °C at a heating rate of 5 °C / min in a well-sealed silicon-molybdenum rod resistance furnace, and keep it for 3 hours to obtain a uniform glass melt ; Then pour the glass melt into a preheated stainless steel mold for molding, anneal at 680°C for 10 hours, and cool to room temperature with the furnace, and finally obtain a colorless, transparent, uniform, and bubble-free bulk glass. figure 1 It is the DSC curve chart of the alkali-free high aluminum borosilicate glass material prepared in Example 1.

Embodiment 2

[0038] A low thermal expansion coefficient alkali-free high-alumina borosilicate glass prepared in this embodiment comprises the following oxides: MgO: 12.09%, ZnO: 0.63%, Al 2 o 3 : 31.38%, SiO 2 : 52.69%, B 2 o 3 : 3.21%. Accurately weigh the corresponding raw materials, mix all the raw materials fully and put them into a corundum crucible, raise the temperature to 1650°C at a heating rate of 5°C / min in a well-sealed molybdenum silicon rod resistance furnace, and keep it for 3 hours to obtain a uniform glass melt , and then pour the glass melt into a preheated stainless steel mold for molding, anneal at 680°C for 10 hours, and cool to room temperature with the furnace, and finally obtain a colorless, transparent, uniform, and bubble-free bulk glass.

Embodiment 3

[0040] A low thermal expansion coefficient alkali-free high-alumina borosilicate glass prepared in this embodiment comprises the following oxides and is composed of: MgO: 11.74%, ZnO: 1.25%, Al 2 o 3 : 31.28%, SiO 2 : 52.53%, B 2 o 3 : 3.20%. Accurately weigh the corresponding raw materials, mix all the raw materials fully and put them into a quartz crucible, raise the temperature to 1650 °C at a heating rate of 5 °C / min in a well-sealed silicon-molybdenum rod resistance furnace, and keep it for 2 hours to obtain a uniform glass melt , and then pour the glass melt into a preheated stainless steel mold for molding, anneal at 680°C for 10 hours, and cool to room temperature with the furnace, and finally obtain a colorless, transparent, uniform, and bubble-free bulk glass.

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| strain point | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com