High-purity fishy smell and foreign odor-free fish collagen protein peptide and preparation method thereof

A fish collagen peptide, high-purity technology is applied in the field of high value-added processing and utilization of aquatic product waste, which can solve the problems of insufficient deodorization and deodorization, increased product refining difficulty and production cost, and fishy collagen products. , to avoid damage and residues of harmful substances, increase the difficulty of refining and production costs, improve the efficiency of enzymatic hydrolysis and product yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

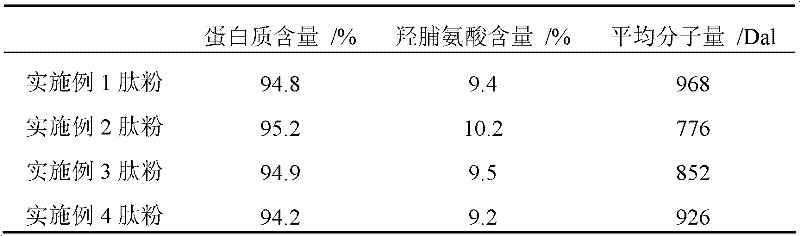

Examples

Embodiment 1

[0030] (1) Fish skin preparation: the fish skin after peeling and descaling the fresh tilapia is washed with deionized water and set aside;

[0031] (2) Degreasing and de-alternating protein: Cut the spare fish skin into pieces and mince, add 4 times the weight of the fish skin in a 4% NaCl solution and stir for 12 hours, then use a centrifuge to centrifuge at a speed of 6000r / min After 10 minutes, remove the waste liquid; add 2 times the weight of the precipitated part to deionized water at 60°C and stir for 30 minutes, then centrifuge at 4000r / min for 20 minutes, remove the waste liquid, and take the precipitate for later use;

[0032](3) Enzymolysis: Add the precipitate to 53°C deionized water and stir evenly to obtain fish skin slurry; ensure that the protein mass content in the fish skin slurry is 8%, control the constant temperature at 50°C, adjust the pH value of the fish skin slurry to 8.0, add Add 0.05% of the protein content of the fish skin slurry to the alkaline pr...

Embodiment 2

[0038] (1) Fish skin preparation: the fish skin after peeling and descaling the fresh tilapia is washed with deionized water and set aside;

[0039] (2) Degreasing and de-alternating protein: Cut the spare fish skin into pieces and mince, add 8 times the mass percentage of fish skin weight and be 2% NaCl solution and stir for 8 hours, and use a centrifuge to rotate at 4000r / min Centrifuge for 10 minutes, remove the waste liquid; add 3 times the weight of the precipitated part to 50°C deionized water and stir for 30 minutes, then centrifuge at 6000r / min for 10 minutes, remove the waste liquid, and take the precipitate for later use;

[0040] (3) Enzymolysis: Add the precipitate to 55°C deionized water and stir evenly to obtain fish skin slurry; ensure that the protein mass content in the fish skin slurry is 15%, control the constant temperature at 52°C, adjust the pH value of the fish skin slurry to 8.5, add After the alkaline protease Protex-6L with a protein content of 0.3% i...

Embodiment 3

[0046] (1) Fish skin preparation: The skin of fresh tilapia after peeling and descaling is quickly frozen at minus 38°C to deacidify, and it is washed and thawed with deionized water before processing;

[0047] (2) Degreasing and de-alternating protein: Cut the spare fish skin into pieces and mince, add 6 times the weight of the fish skin with a concentration of 3% NaCl solution and stir for 10 hours, and use a centrifuge to rotate at 5000r / min Centrifuge for 15 minutes, remove the waste liquid, add 3 times the weight of the precipitated part to 55°C deionized water and stir for 30 minutes, then centrifuge at 5000r / min for 15 minutes, remove the waste liquid, and take the precipitate for later use;

[0048] (3) Enzymolysis: Add the precipitate to 53°C deionized water and stir evenly to obtain fish skin slurry; ensure that the protein mass content in the fish skin slurry is 10%, control the constant temperature at 50°C, adjust the pH value of the fish skin slurry to 8.0, add Ad...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com