Preparation method of water-absorbing and oil-absorbing bifunctional resin

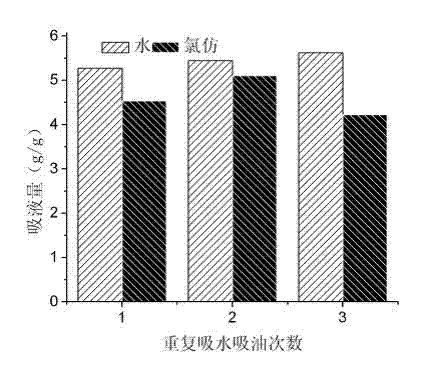

A dual-functional resin and oil-phase technology, applied in the field of functional polymer materials, can solve the problems of difficult uniform dispersion of hydrophilic substances, unstable water and oil absorption performance, difficult grafting reaction, etc., and achieves low production cost and repeated water and oil absorption. Strong ability and good product compatibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

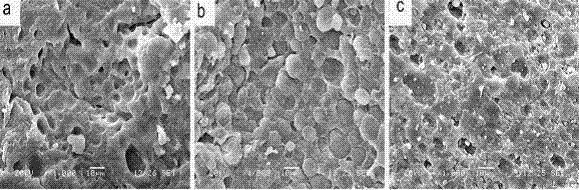

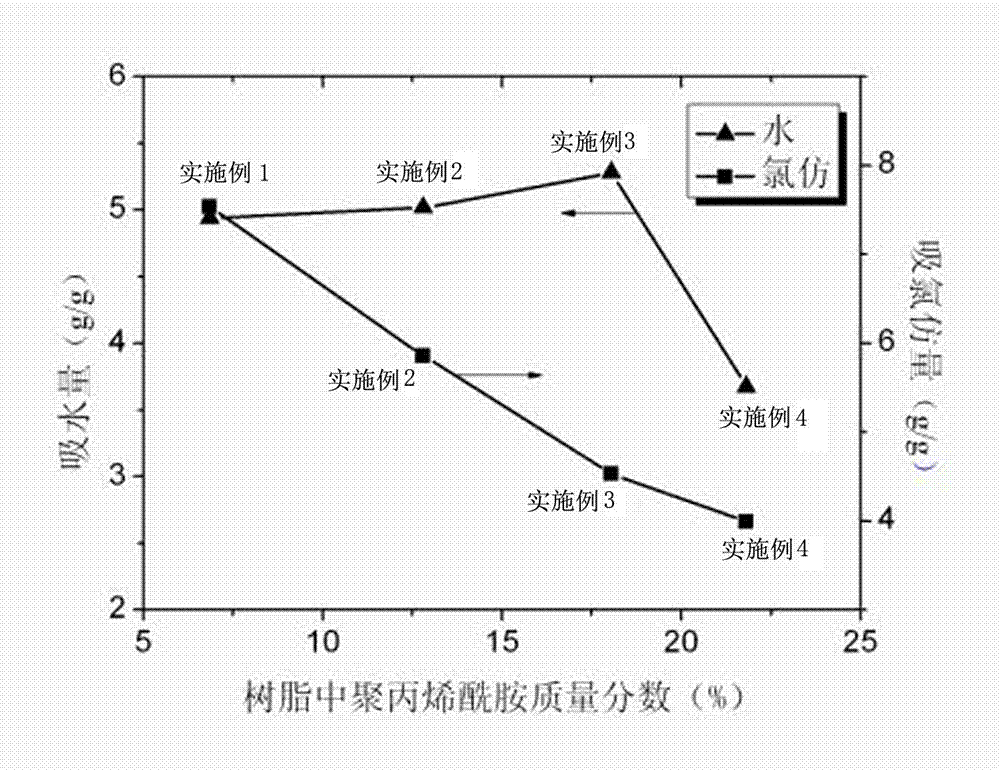

[0033] Add 1.06 g of Span 80 and 0.55 g of divinylbenzene into 6.25 g of n-butyl methacrylate, stir evenly, blow in nitrogen to remove oxygen, and obtain an oil phase. Weigh 0.5 g of acrylamide (7.03 mmol) and 0.1084 g of N,N-methylenebisacrylamide (0.7 mmol) respectively, and prepare an aqueous solution with a total mass of 32 g to obtain an aqueous phase. The water phase was added dropwise to the oil phase under high-speed stirring at 1200 rpm, and an emulsion was obtained after the dropwise addition. Weigh 0.18 g of ammonium persulfate (0.79 mmol) and 0.08 g of sodium bisulfite (0.77 mmol) respectively, and prepare a solution, and add the aqueous solution of ammonium persulfate and sodium bisulfite to the above-mentioned emulsion dropwise, Stirring was continued for 20 minutes until the emulsion stabilized. Finally, the emulsion was polymerized at 40 degrees Celsius for 24 hours until the reaction was complete, and the product was vacuum-dried to constant weight to obtain ...

Embodiment 2

[0042] Add 1.06 g of Span 80 and 0.55 g of divinylbenzene into 6.25 g of n-butyl methacrylate, stir evenly, blow in nitrogen to remove oxygen, and obtain an oil phase. Weigh 1 g of acrylamide (14.07 mmol) and 0.2168 g of N,N-methylenebisacrylamide (1.41 mmol) respectively, and configure them into an aqueous solution with a total mass of 32 g to obtain an aqueous phase. Add the water phase to the oil phase drop by drop under high-speed stirring at 1000~1300 rpm, and the emulsion is obtained after the dropwise addition. Weigh 0.18 g of ammonium persulfate (0.79 mmol) and 0.08 g of sodium bisulfite (0.77 mmol) respectively, and prepare solutions. Aqueous solutions of ammonium persulfate and sodium bisulfite were added dropwise to the above-mentioned emulsion, and stirring was continued for 20 minutes until the emulsion became stable. Finally, the emulsion was polymerized at 40 degrees Celsius for 24 hours until the reaction was complete, and the product was vacuum-dried to const...

Embodiment 3

[0045] Add 1.06 g of Span 80 and 0.55 g of divinylbenzene into 6.25 g of n-butyl methacrylate, stir evenly, blow in nitrogen to remove oxygen, and obtain an oil phase. Weigh 1.5 g of acrylamide (21.1 mmol) and 0.3253 g of N,N-methylenebisacrylamide (2.11 mmol) respectively, and prepare an aqueous solution with a total mass of 32 g to obtain an aqueous phase. Add the water phase to the oil phase drop by drop under high-speed stirring at 1000~1300 rpm, and the emulsion is obtained after the dropwise addition. Weigh 0.18 g of ammonium persulfate (0.79 mmol) and 0.08 g of sodium bisulfite (0.77 mmol) respectively, and prepare solutions. Aqueous solutions of ammonium persulfate and sodium bisulfite were added dropwise to the above-mentioned emulsion, and stirring was continued for 20 minutes until the emulsion became stable. Finally, the emulsion was polymerized at 40 degrees Celsius for 24 hours until the reaction was complete, and the product was vacuum-dried to constant weight ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com