Nanostructured quasi-solid electrolyte applied to lithium ion batteries or lithium sulfur batteries and preparation method and application thereof

A lithium-ion battery, lithium-sulfur battery technology, applied in the direction of solid electrolyte, organic electrolyte, non-aqueous electrolyte, etc., can solve the problems of poor cycle performance, low safety capacity, etc., to improve conductivity, ensure no loss, and improve transmission efficiency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] The preparation component is metal organic framework MIL-53(Al)+EC-DMC-EMC-LiPF 6 Quasi-solid electrolyte, mass ratio 1:3.

[0037] According to technical requirements, MIL-53(Al) was prepared first. Weigh 1.7g of aluminum nitrate hexahydrate and 0.5g of terephthalic acid, add to 25mL of DMF (N,N-dimethylformamide), then add 5mL of deionized water, and heat for 24 hours under the protection of argon to obtain a white powder After cooling down to room temperature, it was soaked in DMF for 3 times, 50 mL each time, for 12 hours, and then the solvent was evaporated under vacuum at 80°C to obtain MIL-53(Al) white powder. Weigh MIL-53(Al) and EC-DMC-EMC-LiPF 6The electrolyte solution is mixed at a mass ratio of 1:3, placed in a clean glass bottle and stirred for 24 hours, and it becomes a viscous white paste after mixing evenly. Spread the intermediate state electrolyte evenly on the positive electrode sheet, and place it for 8 hours to evaporate the excess solvent on the...

Embodiment 2

[0039] The prepared components are metal-organic framework MIL-53(Al)+PTFE+EC-DMC-EMC-LiBOB quasi-solid thin film electrolyte with a mass ratio of 1:1.

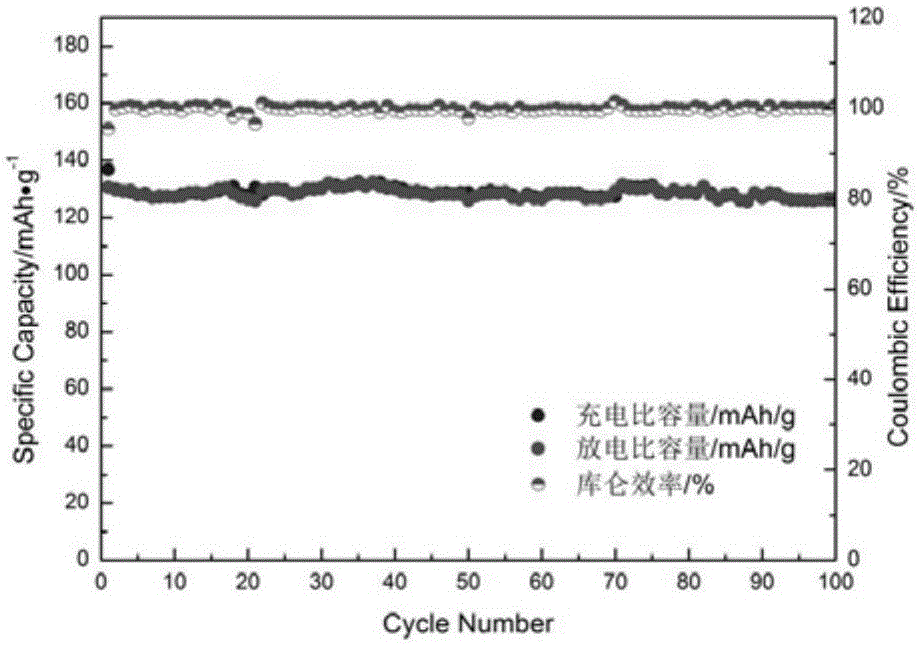

[0040] According to technical requirements, MIL-53(Al) was prepared first. Weigh 1.7g of aluminum nitrate hexahydrate and 0.5g of terephthalic acid, add to 25mL of DMF (N,N-dimethylformamide), then add 5mL of deionized water, and heat for 24 hours under the protection of argon to obtain a white powder After cooling down to room temperature, it was soaked in DMF for 3 times, 50 mL each time, for 12 hours, and then the solvent was evaporated under vacuum at 80°C to obtain MIL-53(Al) white powder. Weigh the isopropanol solution of MIL-53(Al) and PTFE and mix them evenly, then use the pair of rollers to press into sheets to make a frame film. Soak the prepared film in EC-DMC-EMC-LiPF 6 After 12 hours in the electrolyte, the excess solvent on the surface was volatilized to prepare an electrolyte film, and its conductivity was te...

Embodiment 3

[0042] A quasi-solid electrolyte suitable for high-temperature conditions is prepared whose components are metal-organic framework MOF-5+EC-DMC-EMC-PS-LFTSI+3%PAA.

[0043] According to the technical requirements, first synthesize MOF-5, weigh 1.50mmol zinc nitrate hexahydrate and 0.50mmol terephthalic acid, add them to 49mL DMF, then add 1mL deionized water, and heat for 7 hours under the protection of argon to obtain white powder crystals After cooling down to room temperature, it was impregnated with DMF for 3 times, 50 mL each time for 12 hours, then exchanged and activated with dichloromethane solvent for 3 times, 50 mL each time for 12 hours, and then evaporated the solvent under vacuum at 40°C to obtain MOF-5 White powder. Mix MOF-5, EC-DMC-EMC-PS-LFTSI at a mass ratio of 2:3, and stir it in a glass bottle for 24 hours to form a viscous light yellow paste-like quasi-solid electrolyte, then add 3% wt of PAA, continue to stir until the components are evenly mixed. Place...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

| electrical conductivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com