Production method for 6082 aluminum alloy profiles

A technology of aluminum alloy profiles and production methods, which is applied in the field of non-ferrous metals, can solve problems such as limited practical application range, and achieve the effects of excellent comprehensive mechanical properties, improved pass rate, and low width of coarse-grained rings

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

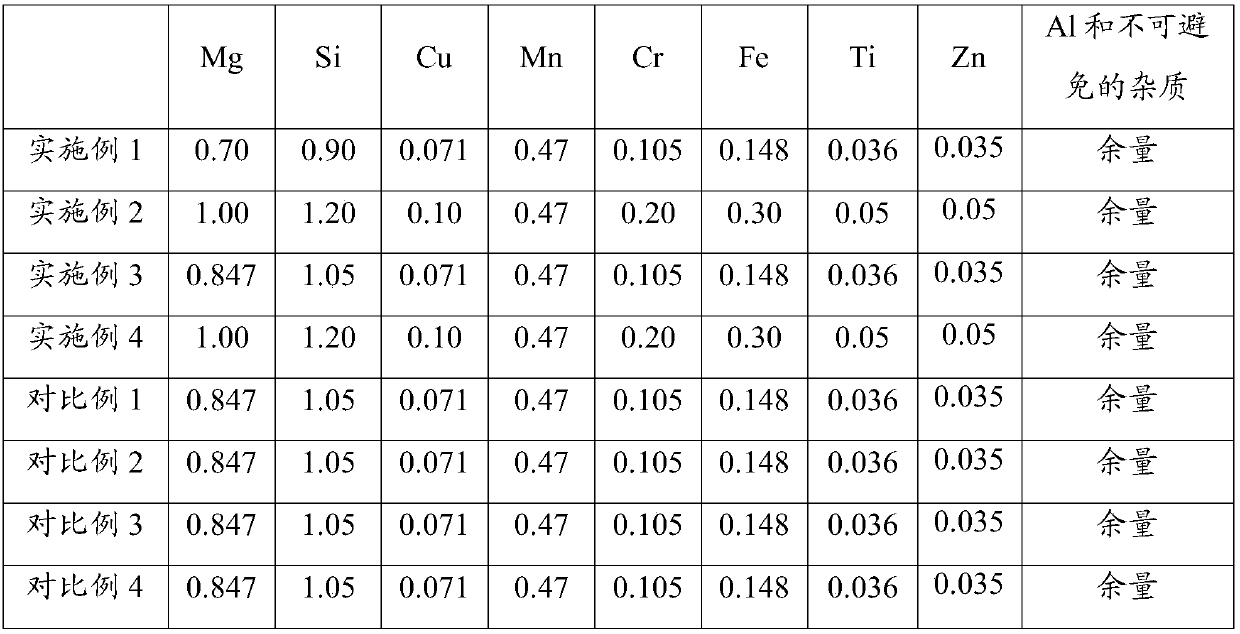

[0028] 1) Melting and casting aluminum alloy raw materials (see Table 1 for specific composition) to obtain aluminum alloy round ingots.

[0029] 2) Perform homogenization heat treatment on the aluminum alloy round ingot to obtain an aluminum alloy round bar. The process conditions are: homogenization temperature 570°C, homogenization holding time 12h; the aluminum alloy round bar obtained after homogenization is cooled by strong wind and water mist.

[0030] 3) Extruding the aluminum alloy round bar with an extruder to obtain an extruded product. The extrusion process conditions are: the temperature of the aluminum rod on the machine is 485°C, the extrusion speed is 2.5mm / s, and the profile outlet temperature is 520°C.

[0031] 4) Perform off-line quenching on the extruded product, the off-line quenching temperature is 535° C., the quenching holding time is 1.0 hour, and cooling is performed after holding the heat at a cooling rate of 240° C. / min;

[0032] 5) Carry out cutt...

Embodiment 2

[0034] 1) Melting and casting aluminum alloy raw materials (see Table 1 for specific composition) to obtain aluminum alloy round ingots.

[0035] 2) Perform homogenization heat treatment on the aluminum alloy round ingot to obtain an aluminum alloy round bar. The process conditions of homogenization heat treatment are: homogenization temperature 570°C, homogenization holding time 12h; the aluminum alloy round bar obtained after homogenization is cooled by strong wind and water mist.

[0036] 3) Extruding the aluminum alloy round bar with an extruder to obtain an extruded product. The extrusion process conditions are: the temperature of the aluminum rod on the machine is 485°C, the extrusion speed is 2.5mm / s, and the profile outlet temperature is 520°C.

[0037] 4) The extruded product is subjected to off-line quenching, the off-line quenching temperature is 535° C., the quenching holding time is 1.5 hours, and cooling is carried out after holding the heat at a cooling rate of...

Embodiment 3

[0040] 1) Melting and casting aluminum alloy raw materials (see Table 1 for specific composition) to obtain aluminum alloy round ingots.

[0041] 2) Perform homogenization heat treatment on the aluminum alloy round ingot to obtain an aluminum alloy round bar. The process conditions of homogenization heat treatment are: homogenization temperature 570°C, homogenization holding time 12h; the aluminum alloy round bar obtained after homogenization is cooled by strong wind and water mist.

[0042] 3) Extruding the aluminum alloy round bar with an extruder to obtain an extruded product. The extrusion process conditions are: the temperature of the aluminum rod on the machine is 500°C, the extrusion speed is 2.5mm / s, and the profile outlet temperature is 540°C.

[0043] 4) The extruded product is subjected to off-line quenching, the off-line quenching temperature is 540° C., the quenching holding time is 1.0 hour, and cooling is performed after holding the heat at a cooling rate of 24...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

| elongation | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com