Patents

Literature

54results about How to "Viscosity Adjustment" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

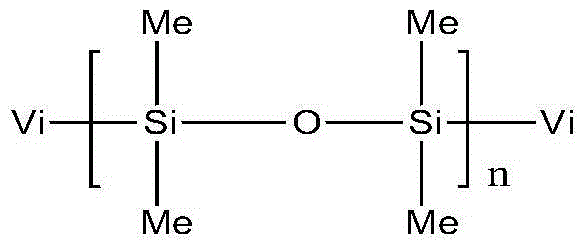

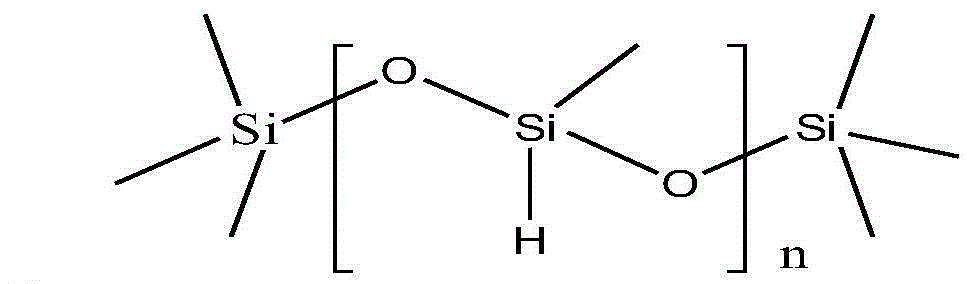

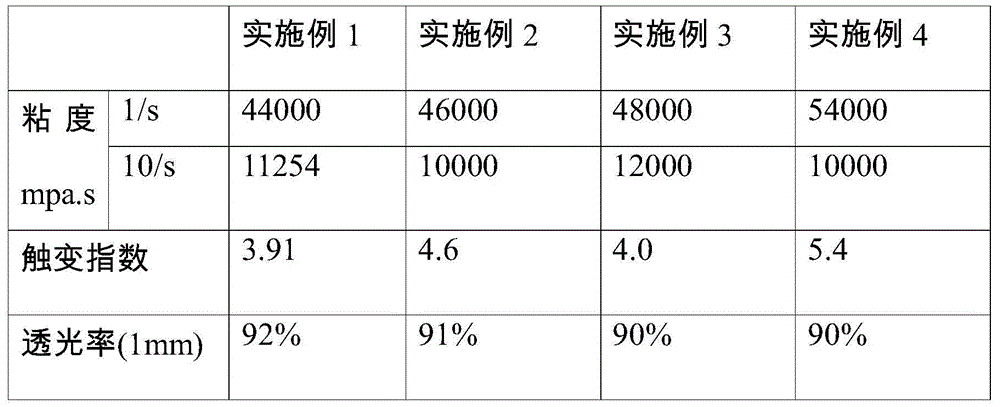

Organosilicone packaging glue for packaging LED lamp filament

InactiveCN104531056AGood thixotropyGood levelingNon-macromolecular adhesive additivesSemiconductor devicesChemistryTransmittance

The invention provides organosilicone packaging glue for packaging an LED lamp filament. The glue is prepared from a component A and a component B in a weight ratio of 1: 1, wherein the component A is prepared from the following raw materials in parts by weight: 80-90 parts of vinyl silicone oil, 10-20 parts of a thixotropic agent white carbon black and 0.1-0.3 part of a catalyst; the component B is prepared from the following raw materials in parts by weight: 75-95 parts of vinyl silicone oil, 5-15 parts of a catalyst, 2-5 parts of an adhesive and 0.1-0.3 part of an inhibitor. The LED lamp filament packaging silica gel provided by the invention is prepared from the components A and B. The component A provides the special thixotropic agent in the system, so that the glue has a good leveling property and strong operability while having good thixotropy. The light transmittance of cured glue is not decreased.

Owner:YANTAI DEBANG ADVANCED SILICON MATERIALS

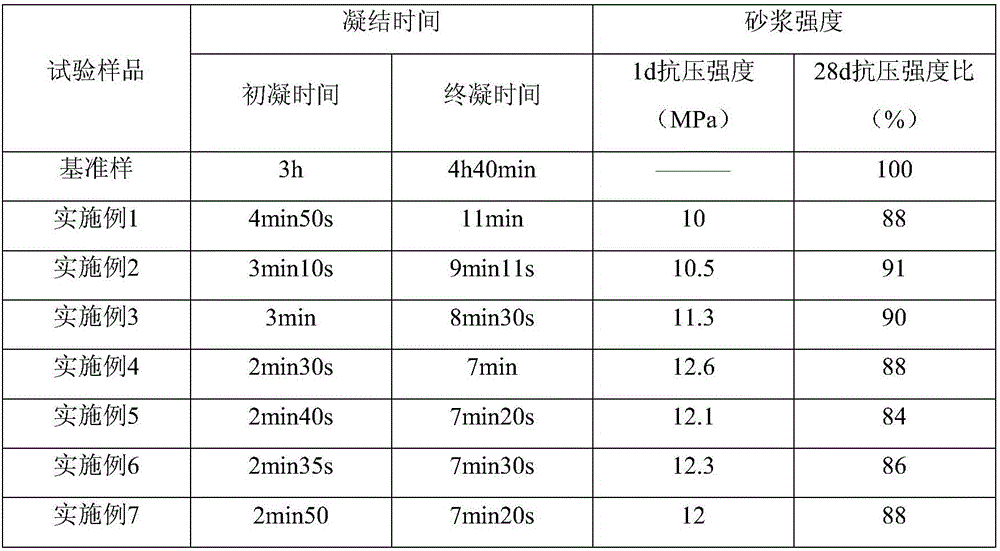

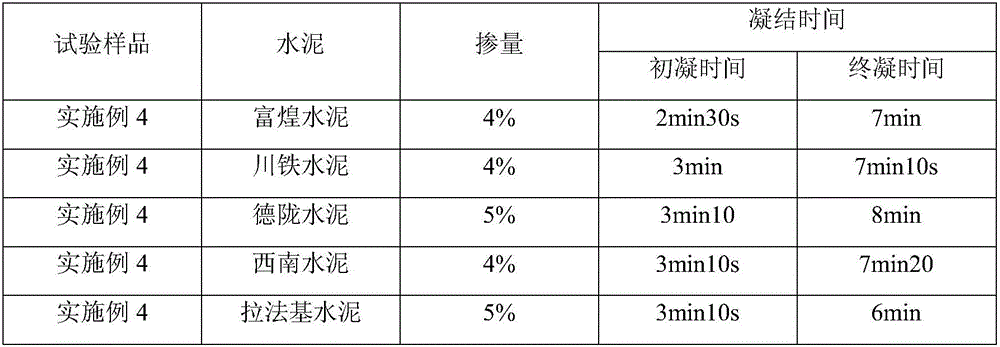

Low-resilience liquid accelerator for shotcrete and preparation method thereof

The invention discloses a low-resilience liquid accelerator for shotcrete and a preparation method thereof. The accelerator is prepared from the following raw materials in percent by mass: 20%-40% of sodium hydroxide, 25%-40% of aluminium hydroxide, 3%-10% of a synergist, 0.5%-2% of a setting accelerator, 0.003%-0.02% of a viscosity adjusting agent, and the balance water, wherein, the synergist is sodium silicate, the setting accelerator is an alcohol amine substance, and the viscosity adjusting agent is potassium chromate or sodium nitrite. The preparation method comprises the following technical steps: adding sodium hydroxide and the synergist into a reaction kettle, adding water, and starting an agitator and a heater; keeping the temperature after the temperature reaches a set temperature, adding aluminium hydroxide, and reacting with the constant temperature; adding the viscosity adjusting agent, stirring, heating, reacting with a constant temperature, then stopping heating, and naturally cooling; and adding the setting accelerator after the reaction system is cooled, and cooling to room temperature, so as to obtain the accelerator. The accelerator is short in setting time, low in resilience and moderate in viscosity, generates a little sediment, has good cement adaptability, and the preparation method for the accelerator is simple, practicable and energy-saving.

Owner:SHIJIAZHUANG CHANGAN YUCAI BUILDING MATERIALS

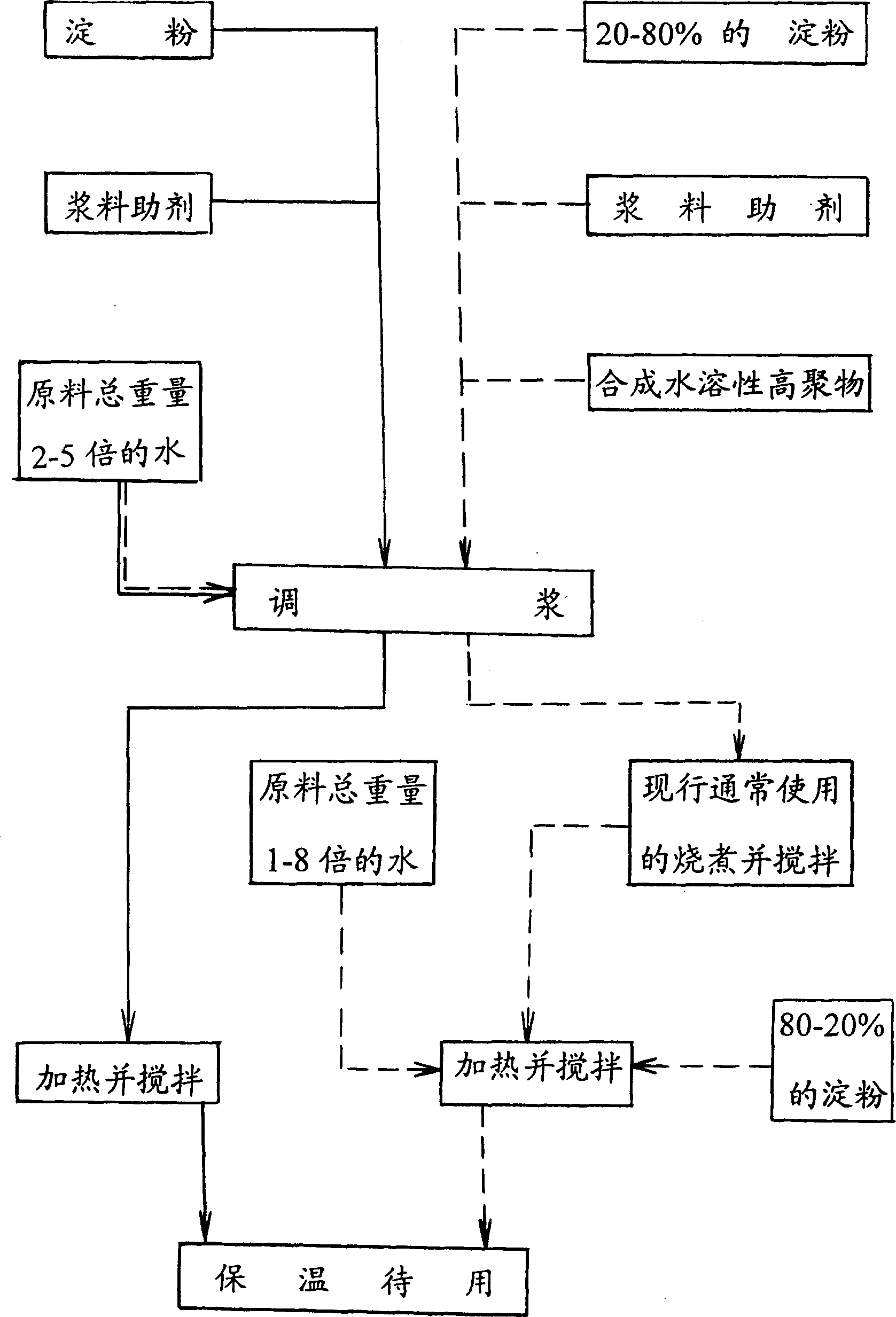

Yarn size producing method for textile warp

The present invention relates to a preparation method of size for sizing textile warp yarn. Said preparation method includes the following several steps: preparing size raw materials, including starch, size additive and water-soluble synthetic high polymer; adding water and stirring them; heating and stirring them uniformly, heating temperature is 40-65deg.C and heating time is 10 min; and heat-insulating at 40-65deg.C for 10 min so as to obtain the invented size.

Owner:徐建新 +2

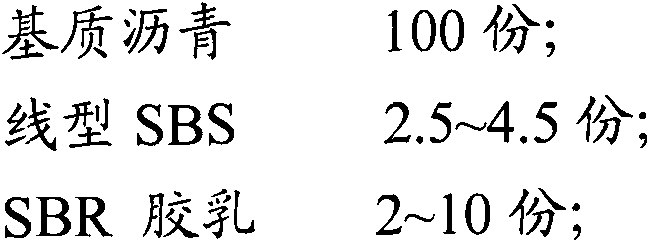

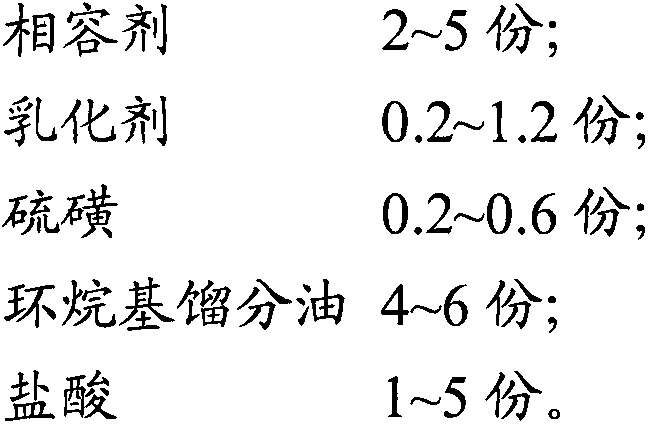

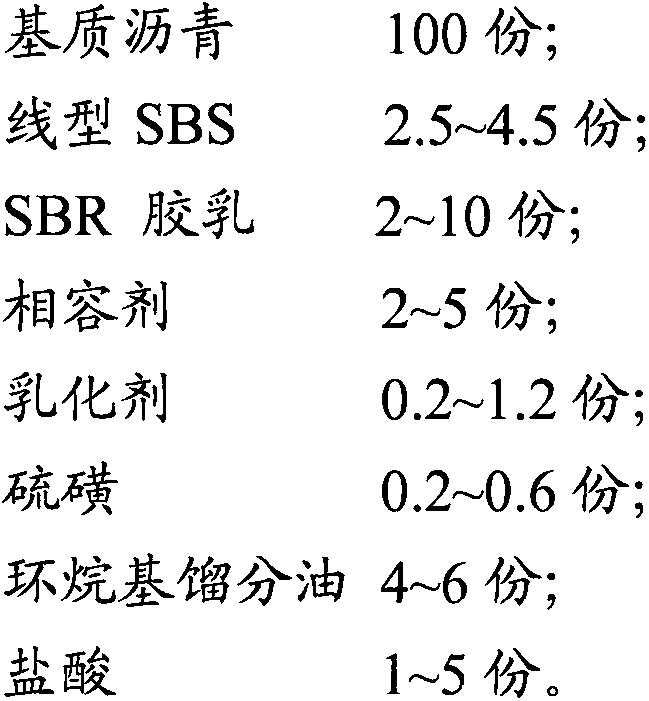

Modified emulsified asphalt and preparation method thereof

The invention provides modified emulsified asphalt which is prepared from base asphalt, linear SBS, SBR latex, a compatibilizer, an emulsifier, sulfur, naphthenic base distillate oil and hydrochloride. The SBR latex is large in polarity and can improve the adhesion performance of the modified emulsified asphalt; the linear SBS can improve the viscosity and the ductility of the asphalt; the compatibilizer can promote compatibility of the linear SBS, the SBR latex and the base asphalt and improve the storage stability of the modified asphalt; the sulfur can improve the storage stability of the modified asphalt; the naphthenic base distillate oil can regulate the viscosity of modified emulsion; and as for the provided modified emulsified asphalt, the softening point is 70.5 DEG C, the ductility reaches up to 57 (5 DEG C ductility / cm), the solid content reaches up to 65 percent, the viscosity is 6.5 (E25 / S), the storage stability is good, and the modified emulsified asphalt meets and is well over the requirements of JTGF40-2004 product specification of Ministry of Communications and can be suitable for a high-grade asphalt pavement and a related construction technology.

Owner:CHINA NAT OFFSHORE OIL CORP +2

Viscosity adjustable crosslinked polymer displacement agent and preparation method thereof

InactiveCN102127411AApplicable to a wide range of reservoirsLower injection costsDrilling compositionPolymer scienceCrosslinked polymers

The invention discloses a viscosity adjustable crosslinked polymer displacement agent and a preparation method thereof. The displacement agent comprises polymer, a crosslinking agent, a viscosity regulator and water for preparation, wherein the concentration of the polymer in the prepared crosslinked polymer displacement agent is 500-1,000mg / L; the concentration of the crosslinking agent is 30-120mg / L; the concentration of the viscosity regulator is 0-8mg / L; and the pH value of the water for preparation is 7.5-8.5. The preparation method comprises the following steps of: adding solution of crosslinking agent into solution of polymer, and uniformly stirring; adding solution of viscosity regulator and uniformly stirring; and regulating the viscosity of the crosslinked polymer displacement agent by regulating the using amount of the crosslinking agent and a crosslinking aid. Experiments show that: compared with 1,200mg / L polymer solution contrast, the displacement agent can improve the recovery ratio by 0 to 5 percent, and saves raw material cost by 10 to 20 percent.

Owner:BEIJING HAIEN RUNDE CHEM SCI & TECH

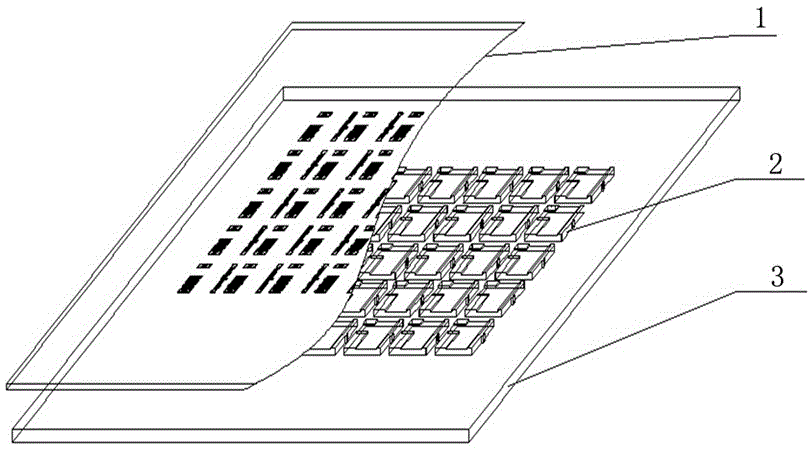

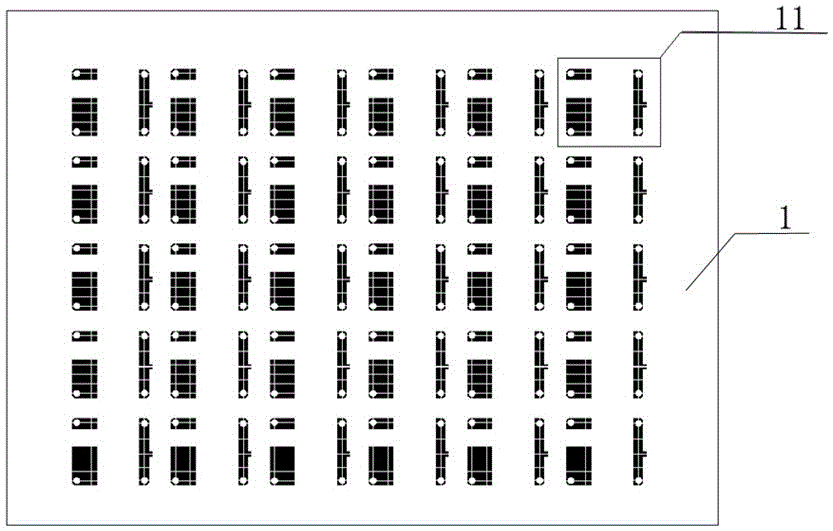

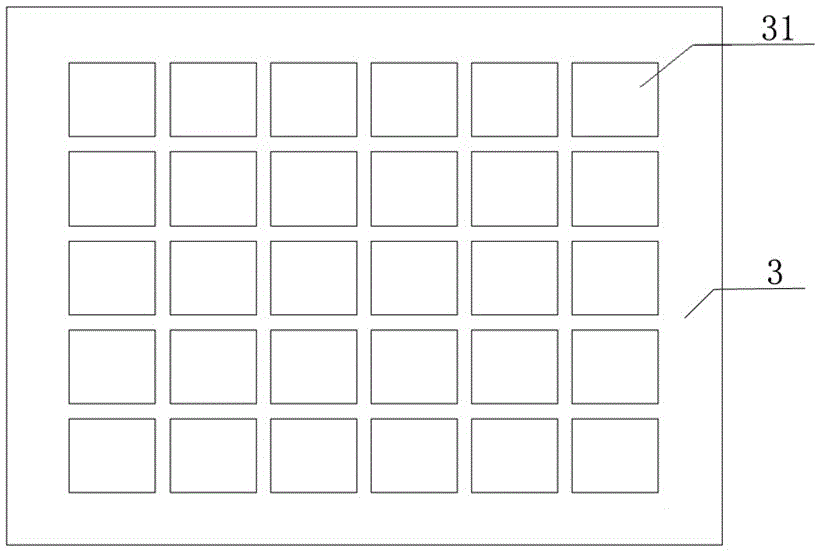

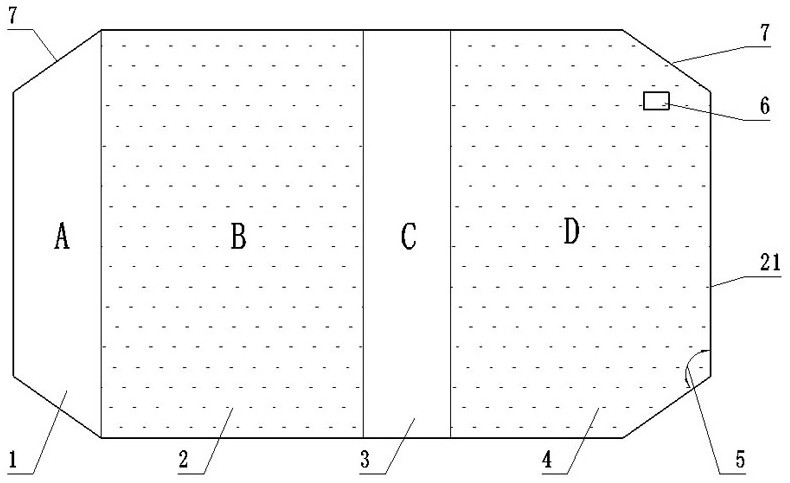

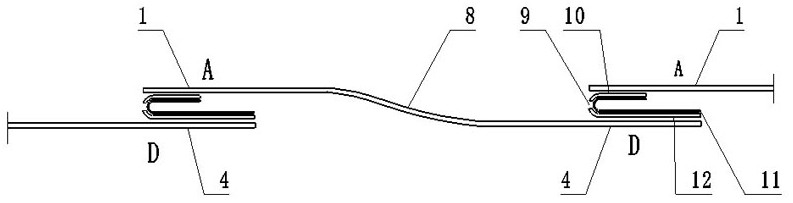

Machining method for soldering micro-strip boards by using printing solder paste

ActiveCN106513897AEasy to operateImprove the efficiency of printing solder pasteSoldering apparatusEngineeringSolder paste

The invention relates to a machining method for soldering micro-strip boards by using printing solder paste. The machining method comprises the following operation steps: (1) the micro-strip boards and substrates are cleaned; (2) four or more cleaned substrates are respectively placed in positioning grooves of positioning baseplates; (3) net plates are placed on the four or more substrates; and mesh units uniformly distributed on the net plates are respectively corresponding to the four or more substrates; (4) the net plates are uniformly coated with the printing solder paste; and (5) the net plates are taken down; the corresponding micro-strip boards are placed on the uniformly deposited solder paste; and each micro-strip board is corresponding to one substrate to form a welding module. The conventional steps of pressing block fixation, welding, pressing block disassembly, cleaning and detection are performed; reflow soldering is adopted; and the reflow soldering is performed by four temperature phases. The machining method saves such complex operation flows as solid-state soldering lug shearing, size control, oxide layer removal, screw hole protection, solder resisting adhesive tape protection and flux coating, reduces the machining cost, and is high in product soldering rate and suitable for batch production.

Owner:CHINA ELECTRONIC TECH GRP CORP NO 38 RES INST

Gas-shielded flux-cored wire for welding of SUS316L austenitic stainless steel deep-cooling low-temperature storage and transportation container and device

ActiveCN107971657AAdjust the melting pointAdjustable viscosityArc welding apparatusWelding/cutting media/materialsManganeseSodium titanate

The invention discloses a gas-shielded flux-cored wire for welding of a SUS316L austenitic stainless steel deep-cooling low-temperature storage and transportation container and device and the preparation method thereof. The as-shielded flux-cored wire comprises a steel strip and a flux core wrapped in the steel strip, and the flux core comprises the following components of, by weight, 4.25-5.85 parts of natural rutile, 0.8-1.9 parts of quartz sand, 0.7-1.8 parts of sodium titanate, 0.25-0.3 part of sodium fluoride, 0.125-0.275 part of calcined alpha alumina, 0. 27wt% of calcined alpha aluminaand 0.025-0.15 part of nitrogen-containing ferrochromium, 0.085-0.05 part of spray silicon iron, 1.05-1.45 parts of electrolytic manganese, 3.6-4.85 parts of metal chromium, 6.42-6.85 parts of atomized iron powder, 1. 9-2.5 parts of nickel powder, and 1.0-1.35 parts of molybdenum. The gas-shielded flux-cored wire has the advantages that efficient semi-automatic and automatic welding technologies are achieved, the welding efficiency is high, splashing is low, the appearance is attractive, the welding current is wide, and the voltage adaptability strong.

Owner:ATLANTIC CHINA WELDING CONSUMABLES

Thiol-modified polyurethane adhesive prepolymer and preparation method thereof

InactiveCN110669192ARealize chain extensionAchieve regulationPolyureas/polyurethane adhesivesAdhesive cementPolymer science

The invention provides a thiol-modified polyurethane adhesive prepolymer. The thiol-modified polyurethane adhesive prepolymer is prepared from a thiol compound, isocyanate and an organic tin initiator; and the thiol compound contains two or more -SH groups, and the isocyanate contains two or more -NCO groups. Components with different proportions and contents are adopted to prepare the polyurethane adhesive prepolymer with different sulfydryl contents and viscosities according to actual application requirements.

Owner:SHANDONG EFIRM BIOCHEMISTRY & ENVIRONMENTAL PROTECTION CO LTD

Preparation method for chinlon spinning oiling agent composition

InactiveCN104611921AHas UV protection propertiesThe solution function is relatively simpleFibre typesAntistatic agentFoaming agent

The invention provides a preparation method for chinlon spinning oiling agent composition. The preparation method includes the following steps: step I, while stirring, adding a smoothening agent, a stabilizer, an antistatic agent, a cohesive agent and a viscosity improving agent in a reaction still, heating to 20-80 DEG C to enable all the substances to be fully mixed, preserving the heat for 10-50 min to obtain an oiling agent A; step II, cooling the oiling agent A to the room temperature, slowly adding a pH modifier in the oiling agent A, stirring for 10-40 min at the room temperature to obtain an oiling agent B; step III, adding a nanometer additive in the oiling agent B, stirring the mixed solution in an accelerated manner, raising the temperature to 20-60 DEG C to enable the nanometer additive to be uniformly dispersed in the oiling agent, and finally adding a fungi-proofing agent, an anti-UV agent and a fire retardant in sequence, continuing stirring for 20-40 min to obtain the chinlon spinning oiling agent composition.

Owner:NANTONG HUALUN CHEM FIBER

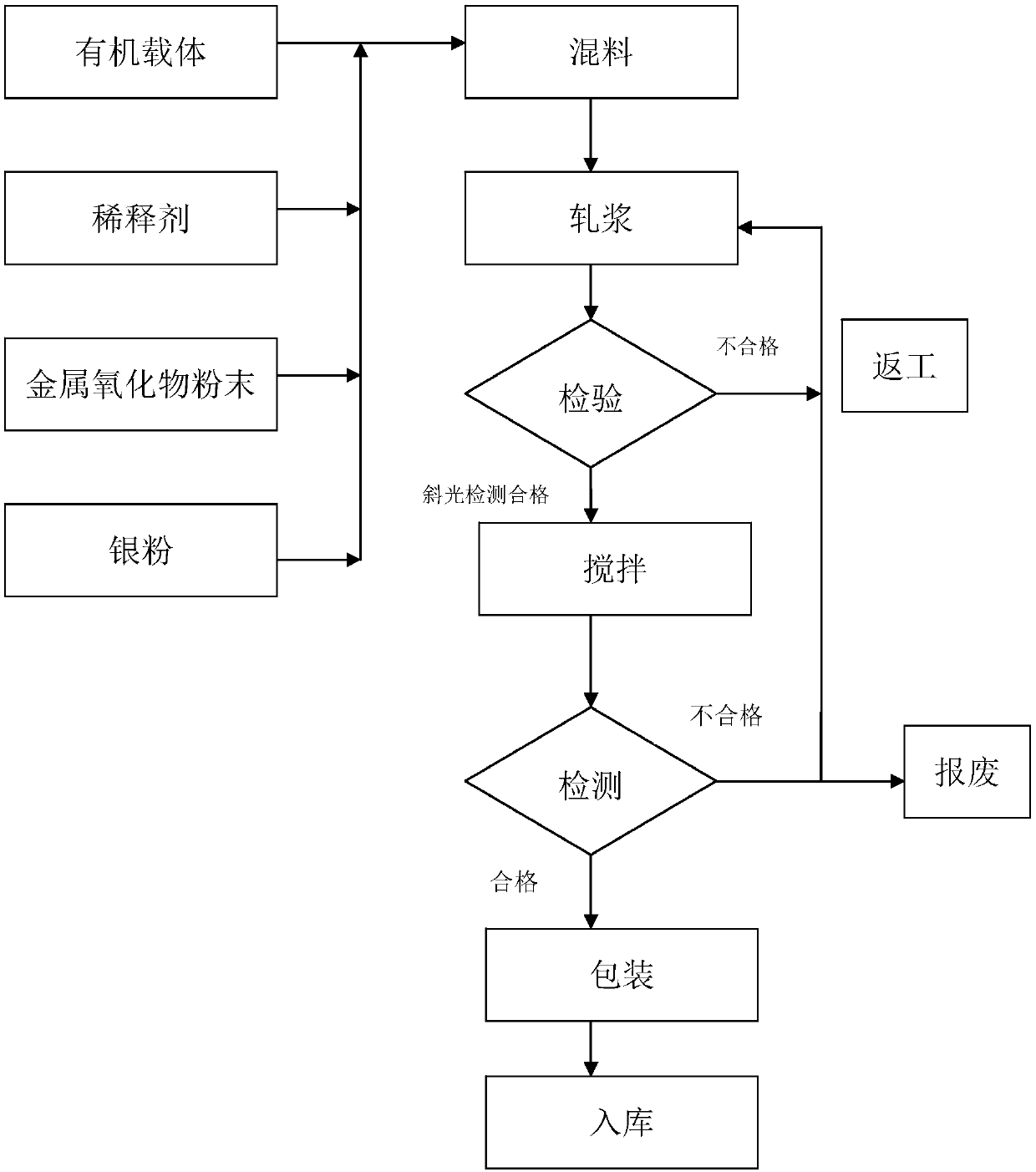

Electronic silver paste for annular varistor and preparation method thereof

ActiveCN109686470AImprove solder resistancePrevent the phenomenon of solder corrosion silverNon-conductive material with dispersed conductive materialCable/conductor manufactureSilver pasteGlass frit bonding

The invention relates to electronic silver paste for an annular varistor. The electronic silver paste is composed of the following components: 30-50% of ultrafine silver powder, 20-40% of spherical silver powder, 10-30% of organic carrier, 5.0-15% of metal oxide and 2-10% of thinner. The invention also provides a preparation method of the electronic silver paste for the annular varistor. The preparation method includes mixing the organic carrier and the thinner in a mixer, then adding the metal oxide powder, and finally adding the ultrafine silver powder and the spherical silver powder slowlyinto the mixer to obtain uniform slurry. The electronic silver paste does not contain a glass powder binder phase with the spherical silver powder added, so that the silver paste has good solderability and high solder resistance. The silver paste is relative simple in component and low in cost due to the fact that the glass powder binder phase is not contained.

Owner:广东羚光新材料股份有限公司

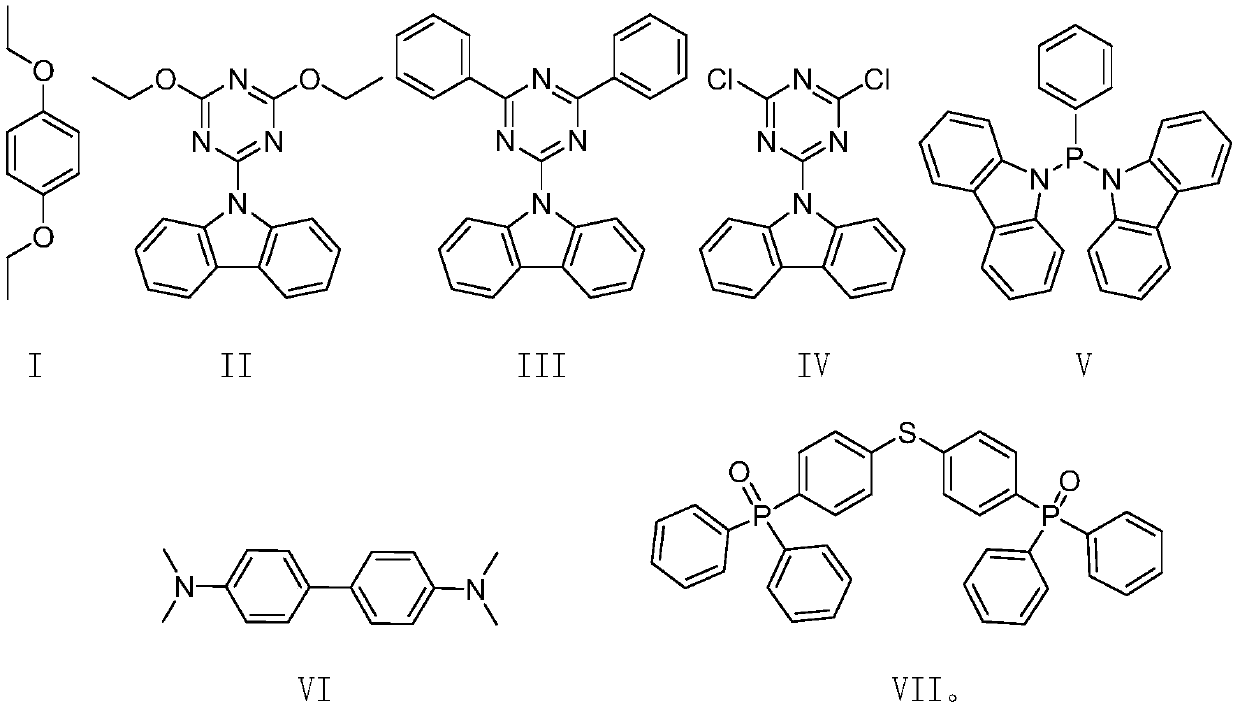

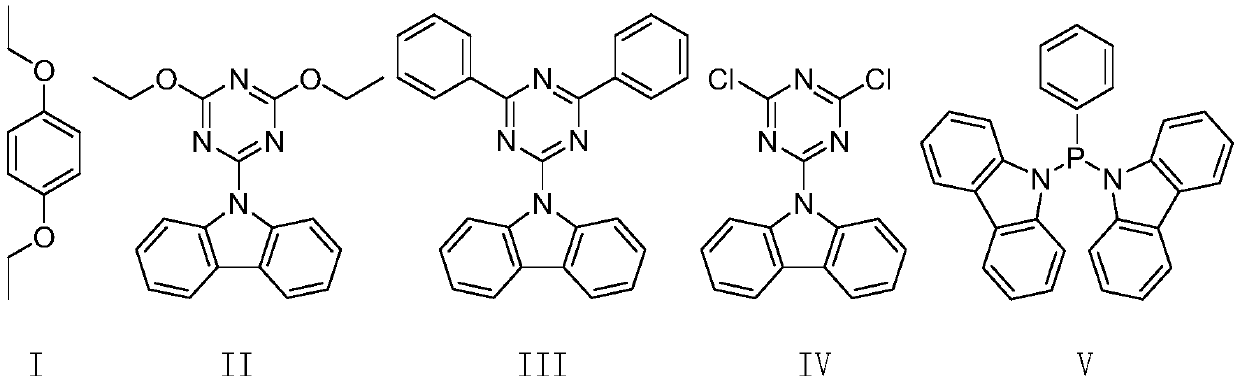

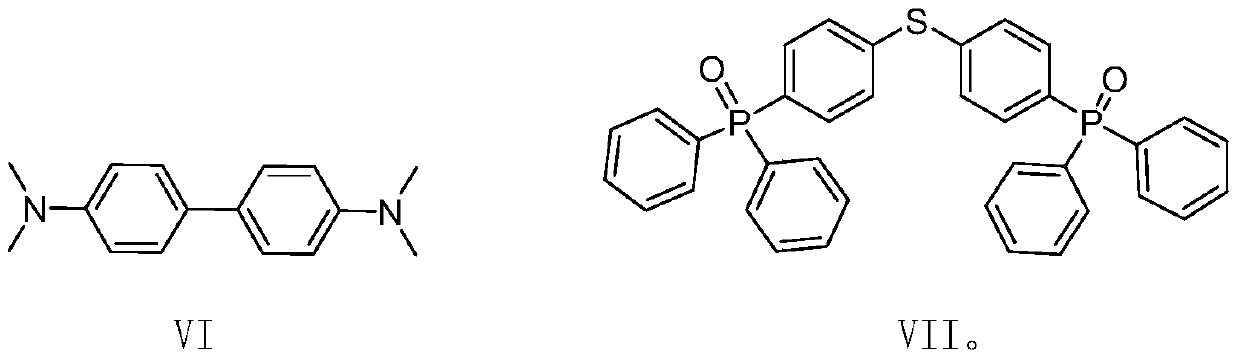

Graphene-based fluorine-containing photo-curing anticorrosive paint and preparing method thereof

InactiveCN110117426AIncrease the degree of cross-linkingImprove salt spray resistanceAnti-corrosive paintsPhotoinitiatorChemistry

The invention relates to a graphene-based fluorine-containing photo-curing anticorrosive paint and a preparing method thereof. The anticorrosive paint is prepared from, by mass, 60-70 parts of fluorine-containing oligomer resin, 5-10 parts of a photoinitiator, 2-5 parts of an auxiliary initiator, 20-25 parts of an active diluting agent, 0.1-3 parts of graphene, 0.1-1 part of a dispersing agent, 0.1-1 part of a levelling agent, 0.1-1 part of an anti-setting agent and 0.1-1 part of a defoaming agent. The preparing method of the metal paint comprises the steps that raw materials are proportionally weighed, the graphene, the fluorine-containing acrylate resin, the active diluting agent and other additives are mixed and mechanically stirred to disperse uniformly and then are ultrasonically dispersed, and after the mixture is dispersed evenly, the graphene-based fluorine-containing photo-curing anticorrosive paint is obtained. The graphene-based fluorine-containing photo-curing anticorrosivepaint has the advantages that the corrosive resistance, the chemical resistance and the weather resistance of the paint are excellent, and the solidified anticorrosive paint can be rapidly obtained through a photo-curing method and is environmentally friendly.

Owner:BEIJING UNIV OF CHEM TECH

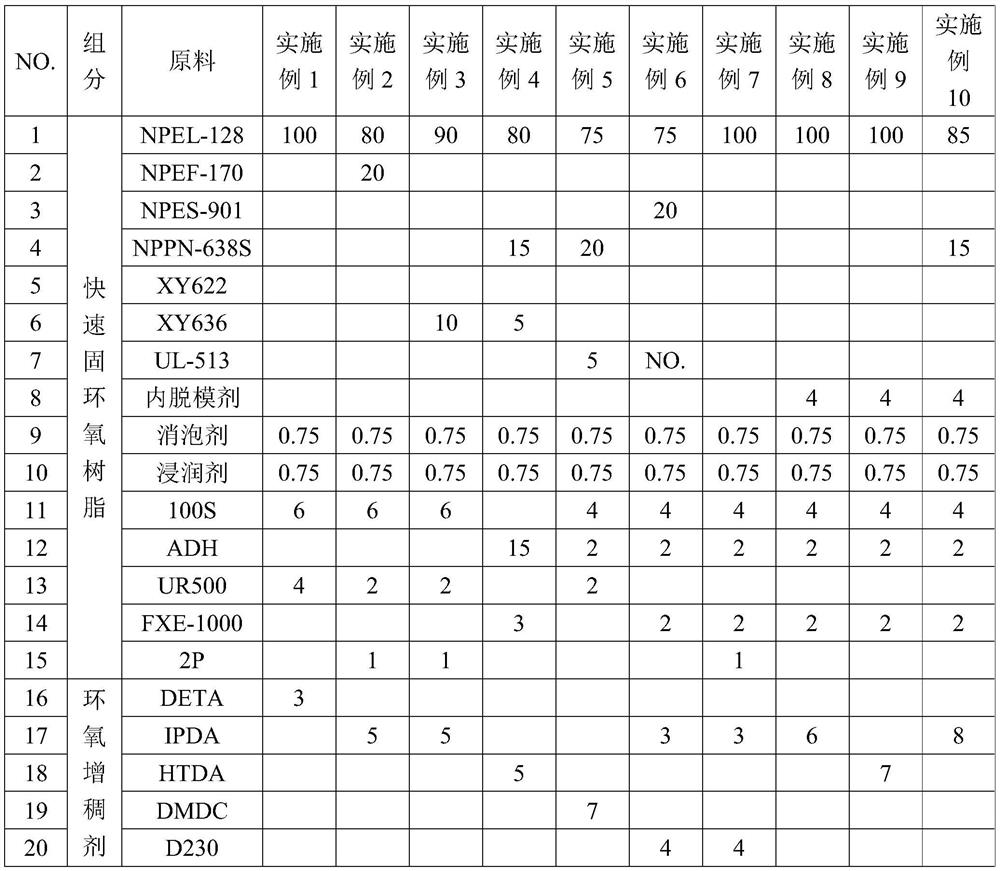

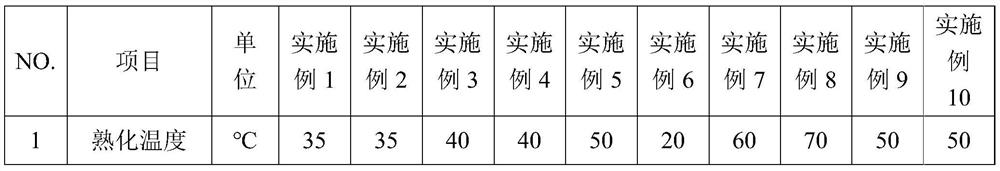

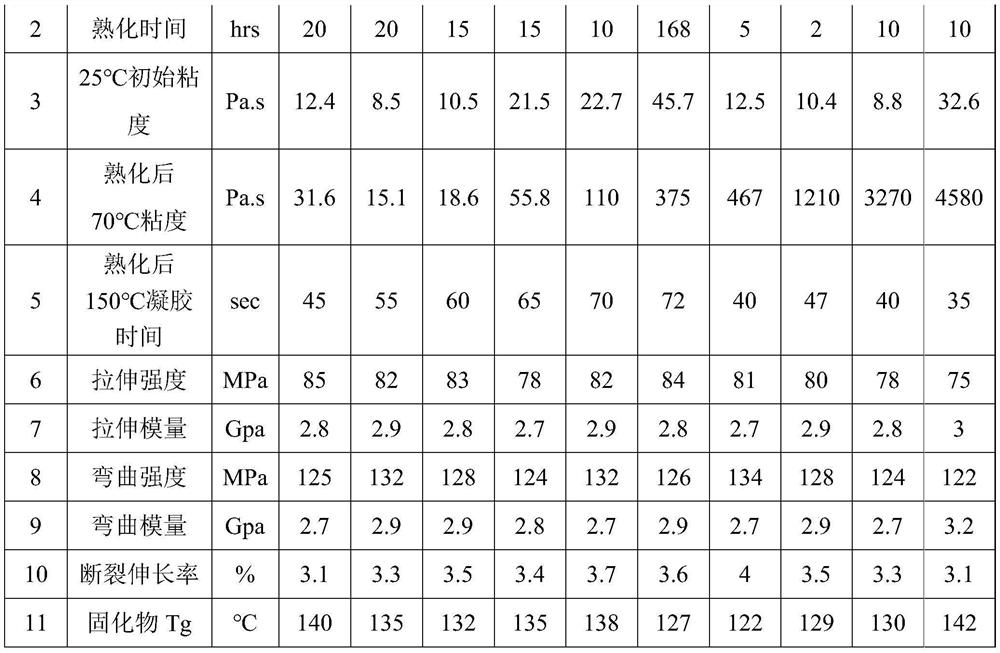

Epoxy resin composition capable of being quickly thickened and fiber reinforced composite material semi-cured material thereof

The invention discloses an epoxy resin composition capable of rapid thickening and a fiber reinforced composite material semi-cured material thereof, the epoxy resin composition is composed of rapid curing epoxy resin and an epoxy thickening agent containing active hydrogen, and the initial viscosity of the epoxy resin composition capable of rapid thickening at 25 DEG C is 5-100 Pa.s. The epoxy resin is low in viscosity and beneficial to infiltration of reinforced fibers, amino reactive hydrogen of an epoxy thickener and epoxy functional groups are subjected to a rapid cross-linking reaction at the temperature of 20-70 DEG C for thickening, the viscosity is 2,000-500,000 Pa.s at the temperature of 25 DEG C after thickening, and the epoxy resin fiber reinforced composite semi-cured materialstable in storage is formed. The invention also discloses a fiber reinforced composite material semi-cured material such as a chopped fiber sheet molding compound, a chopped fiber felt prepreg, a continuous fiber or fabric prepreg and the like, which is prepared by infiltrating a plurality of reinforced fibers into the epoxy resin composition and carrying out a thickening reaction at 20-70 DEG Cfor 1-200 hours.

Owner:ADESSO ADVANCED MATERIALS WUXI CO LTD

Improvement of energy efficiency in hydraulic systems

InactiveCN101336285AImprove energy efficiencyImprove system performanceBase-materialsFluid-pressure actuator componentsMechanical energyEngineering

The present invention describes use of a fluid having a VI of at least 130 to improve the en- ergy efficiency of a hydraulic system. Furthermore, the present invention relates to a hy- draulic system comprising a hydraulic fluid having a VI of at least 130, a unit for creating mechanical power, a unit that converts mechanical power into hydraulic energy, and a unit that converts hydraulic energy into mechanical work. Preferentially, engine speed can be reduced to decrease load and stress while delivering the same amount of hydraulic power.

Owner:EVONIK ROHMAX ADDITIVES GMBH

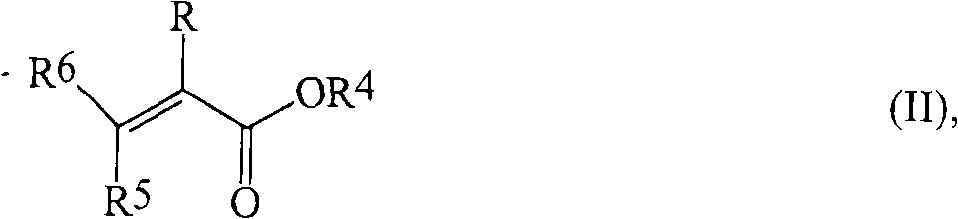

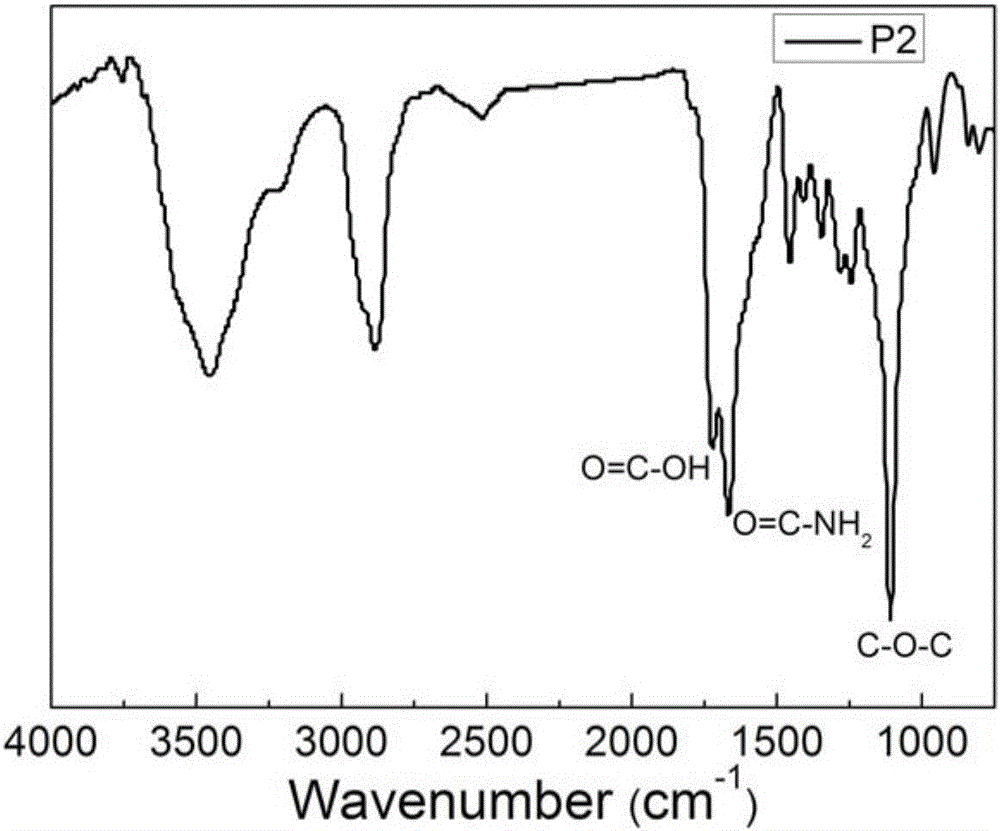

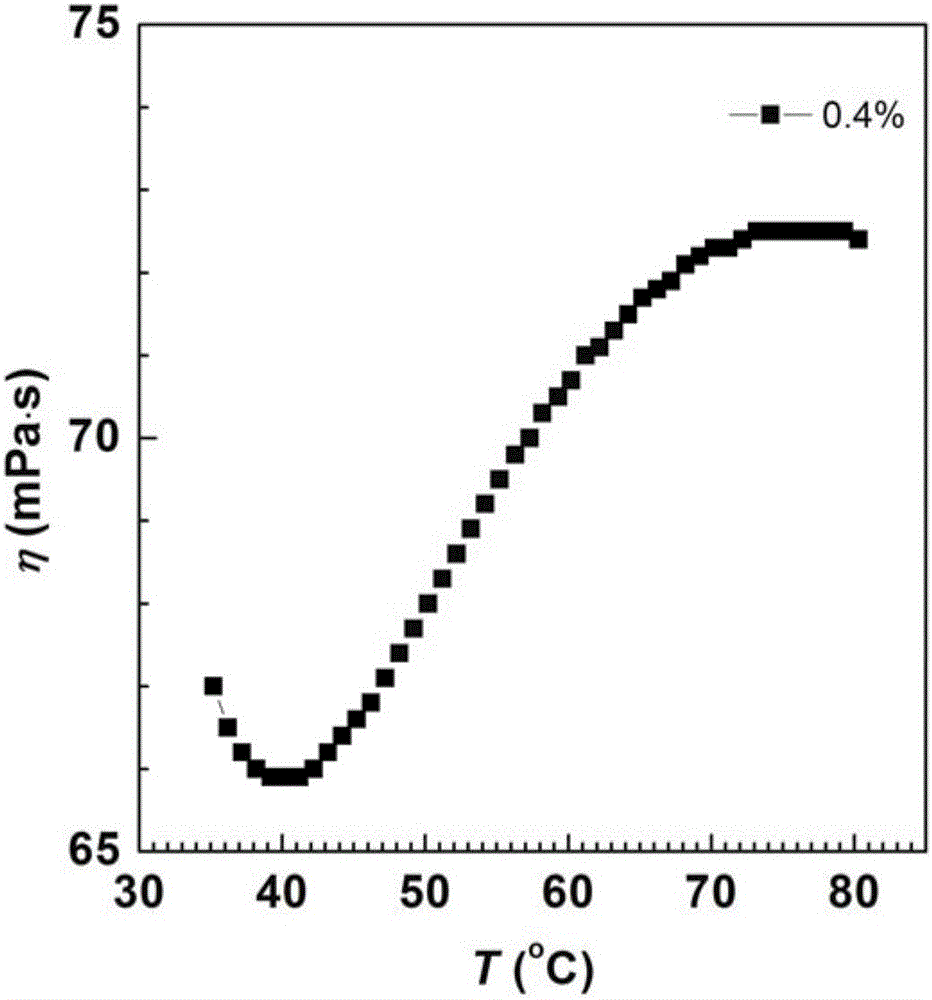

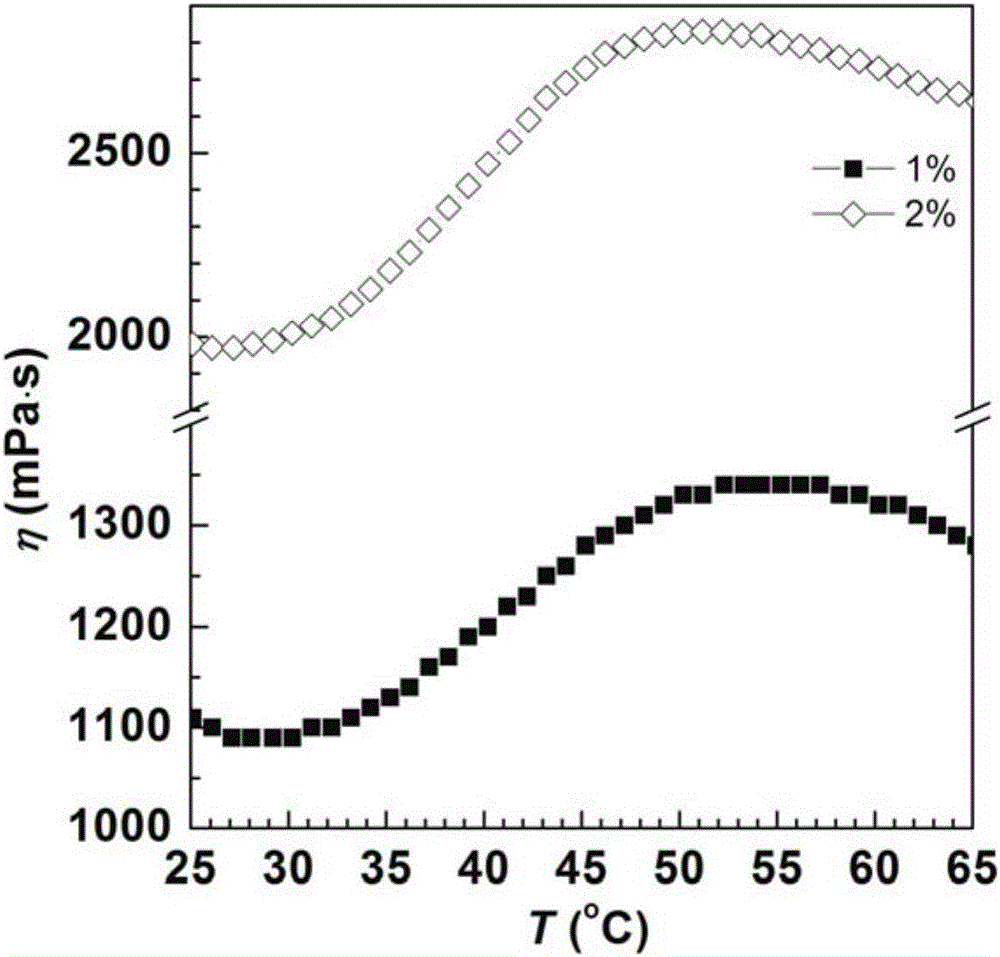

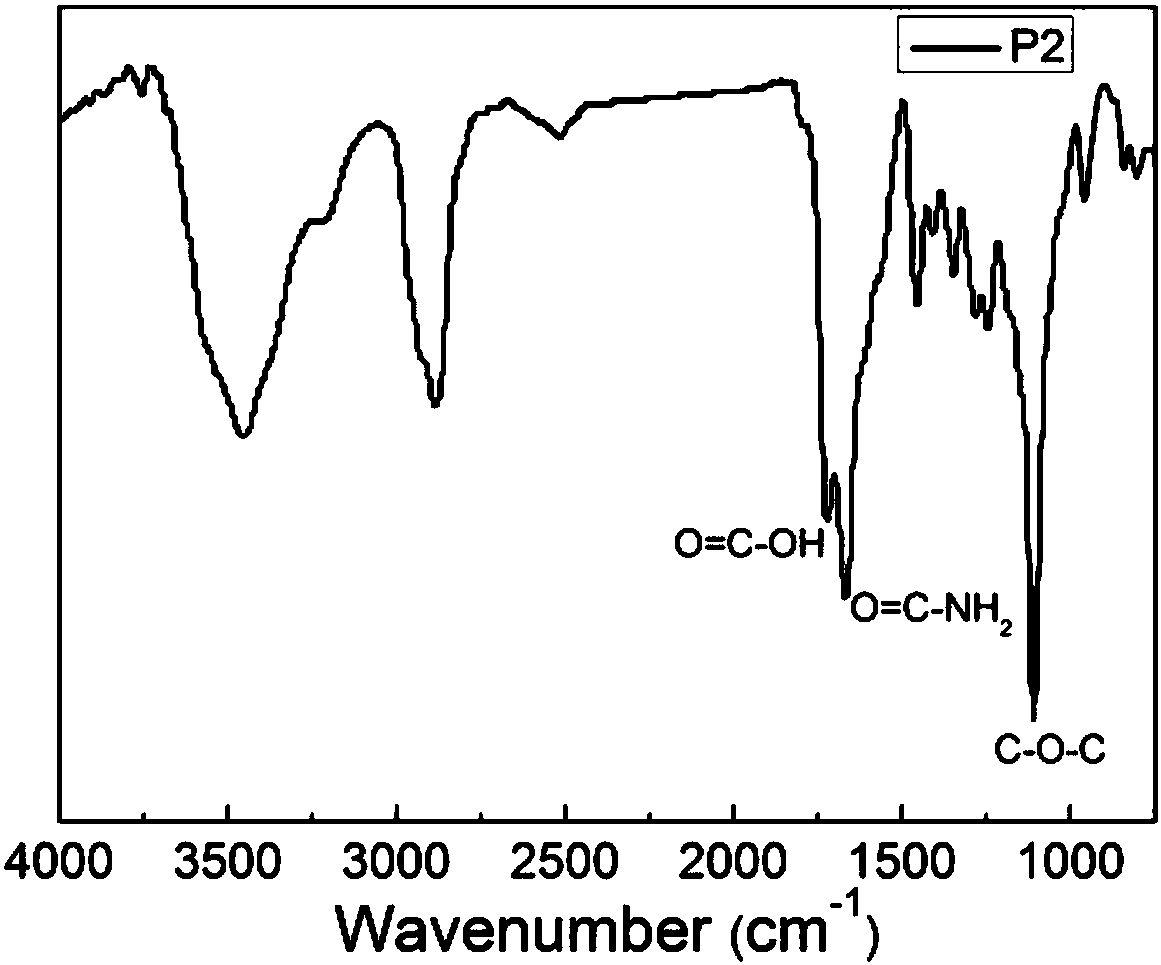

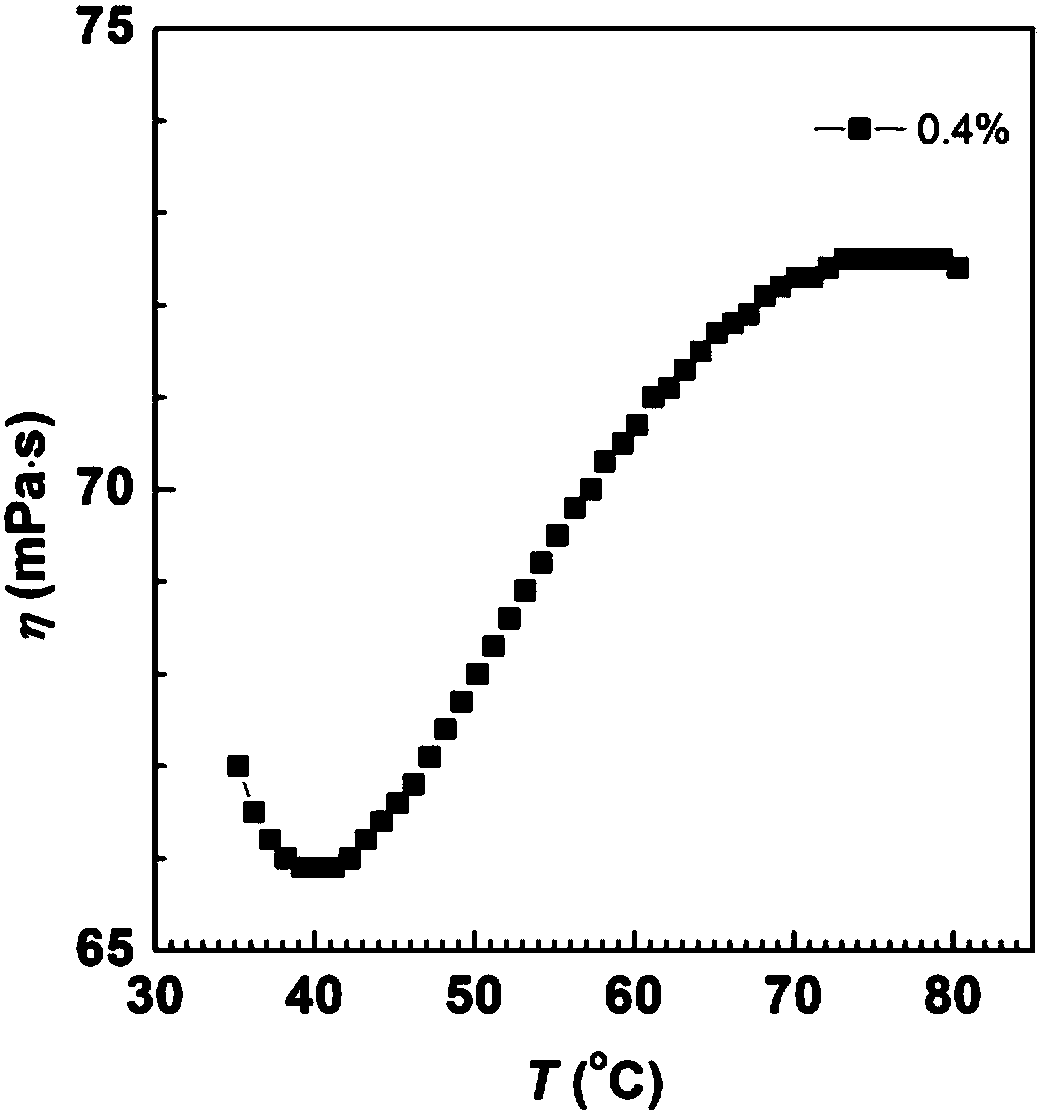

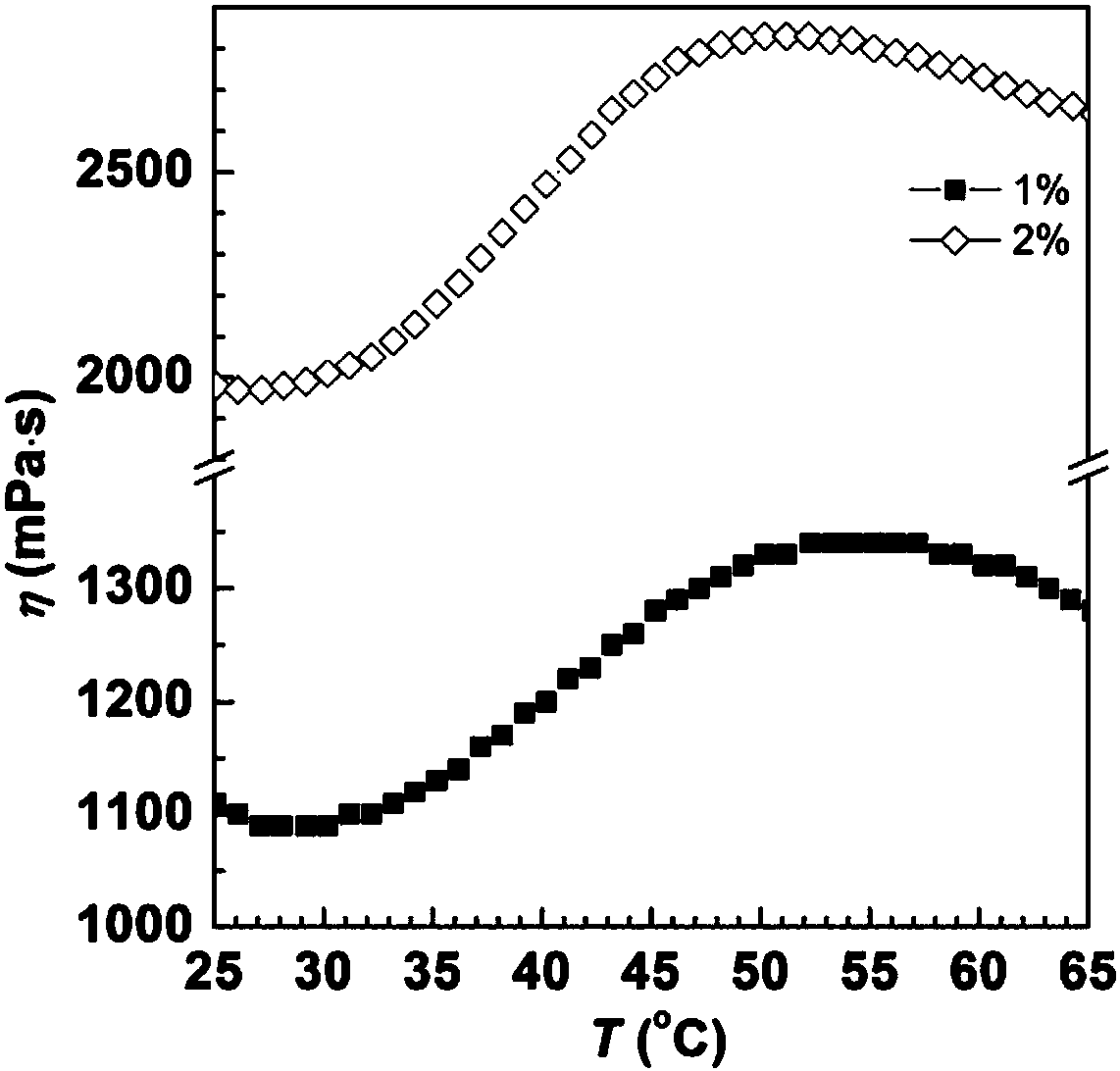

Thermo-thickening polymer based on graft modification of polyether and preparation method thereof

ActiveCN106084144AGood thermal viscosity increasing performanceLow heat viscosity builder concentrationDrilling compositionHydrophilic monomerOrganic solvent

The invention provides a preparation method for a thermo-thickening polymer based on graft modification of polyether. The preparation method comprises the following steps: (1) dissolving a dispersant in an organic solvent to form a first solution, dissolving polyether and neutral or / and alkaline hydrophilic monomer in deionized water to form a second solution and mixing the first solution and the second solution in a reactor so as to obtain a water phase-organic phase mixed reaction system, wherein the usage amount of deionized water is adequate for complete dissolving of polyether and the neutral or / and alkaline hydrophilic monomer; and (2) introducing nitrogen or inert gas to remove oxygen in the reactor, adding an initiator into the water phase-organic phase mixed reaction system under stirring and then carrying out a reaction with stirring at 65 to 80 DEG C for 2 to 8 h under the protection of nitrogen or inert gas. The invention also provides the prepared thermo-thickening polymer based on graft modification of polyether. The method provided by the invention can decrease the thermoassociating concentration of the thermo-thickening polymer and reduce usage cost.

Owner:SICHUAN UNIV

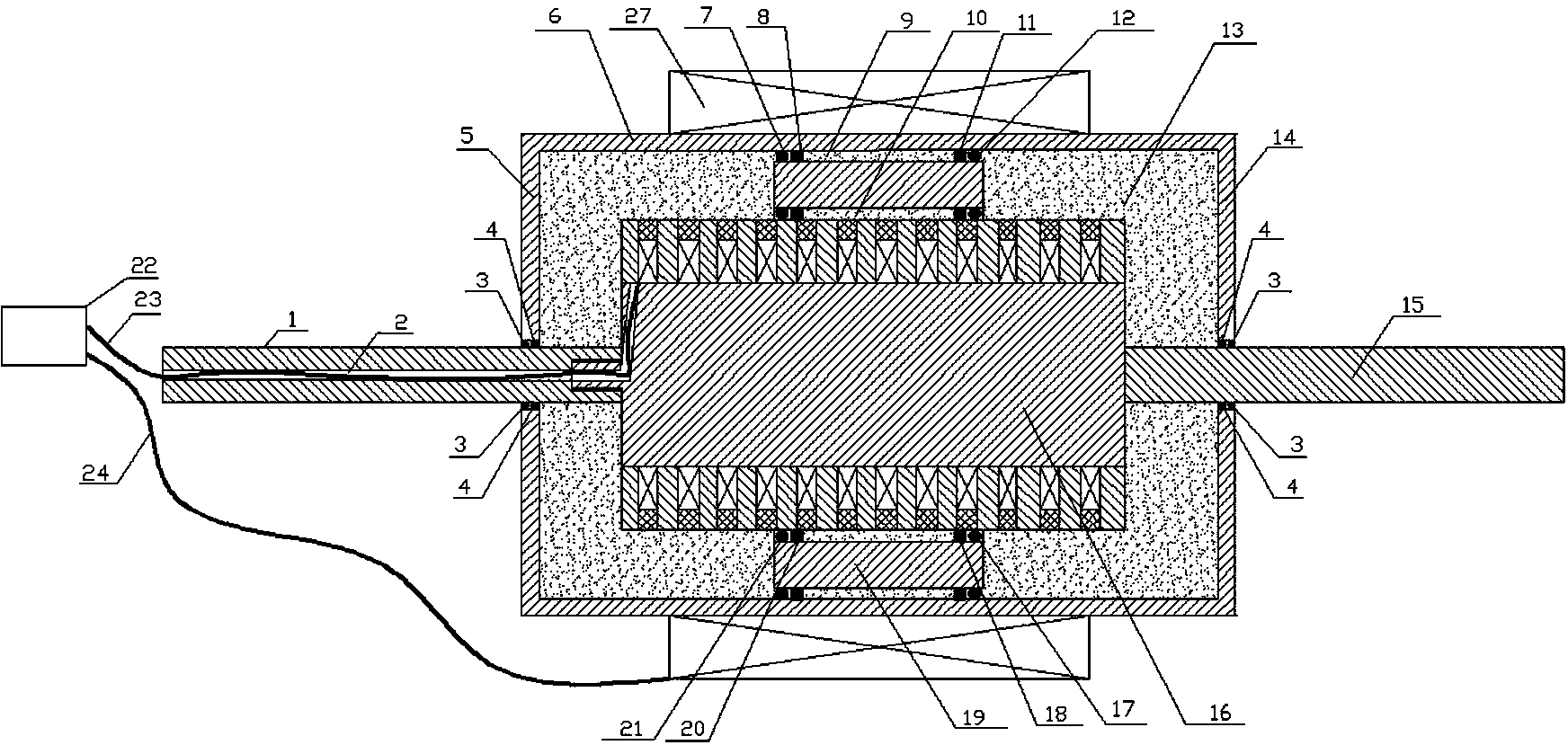

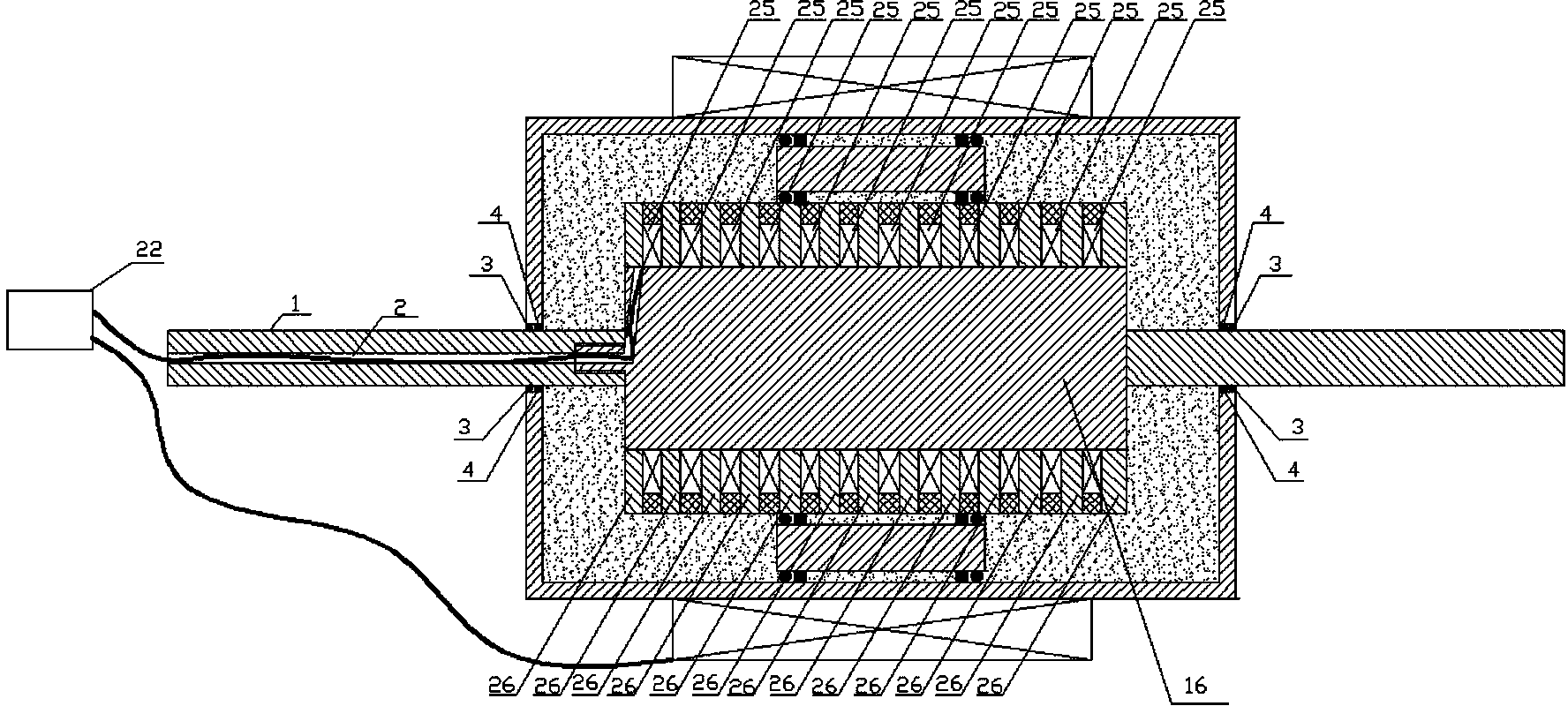

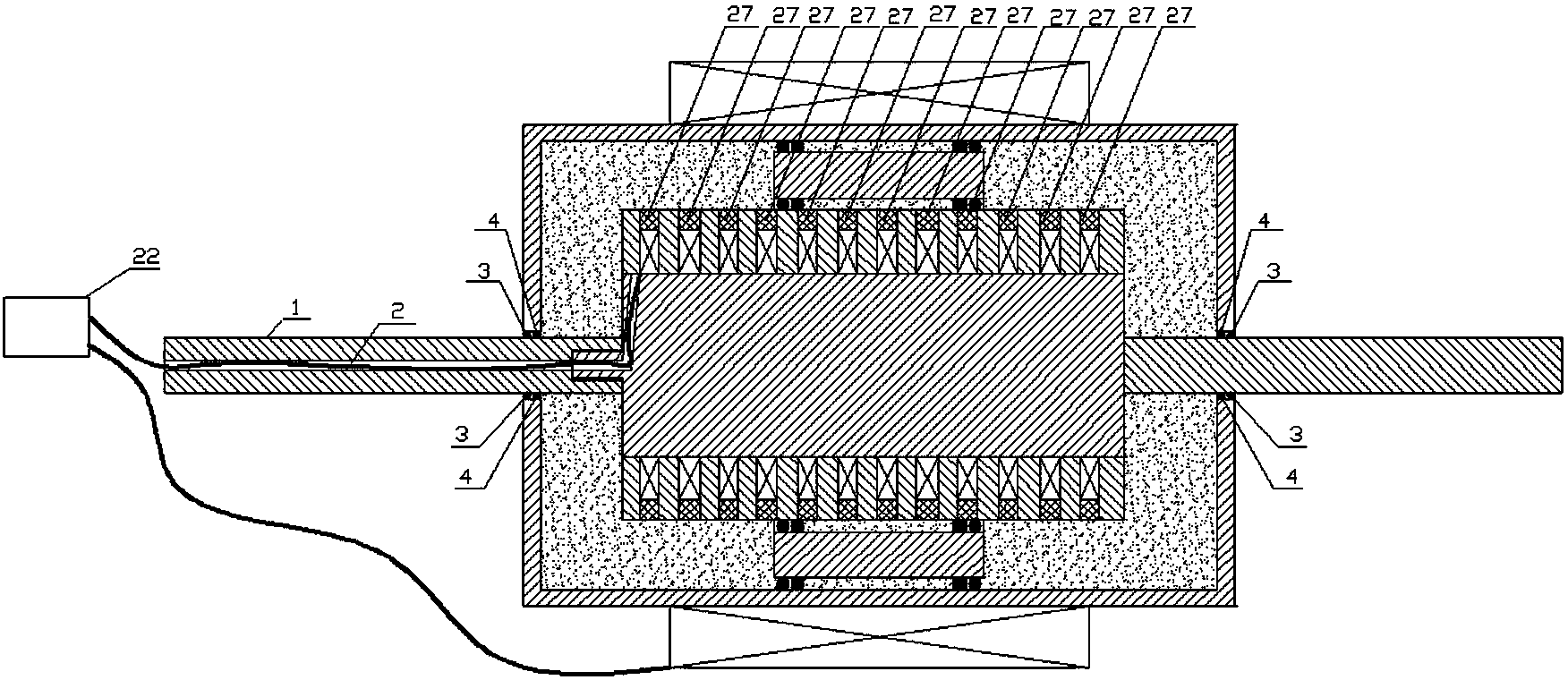

Magnetorheological damper with float ring and double outlet rods

ActiveCN104033526ALarge damping forceLarge adjustment rangeNon-rotating vibration suppressionEngineeringMechanical engineering

The invention discloses a magnetorheological damper with a float ring and double outlet rods. The magnetorheological damper comprises a working cylinder, the float ring, a piston, two piston rods and an external electromagnet. End covers are fixed to two ends of the cylindrical working cylinder; a plurality of identical annular discs are fixed onto the same core column to form the piston, and excitation coils are wound in annular gaps among the various annular discs of the piston; the piston is mounted in the working cylinder, and magnetorheological fluid flowing gaps are reserved between the outer peripheral wall of the piston and the inner peripheral wall of the float ring and between the outer peripheral wall of the float ring and the inner peripheral wall of the working cylinder; one ends of the two piston rods are respectively fixed to two ends of the piston, and the other ends of the two piston rods extend out of the two ends of the working cylinder via sealing devices and sliding bearings on the two end covers of the working cylinder; the gaps in the working cylinder, between the inner peripheral wall of the float ring and the outer peripheral wall of the piston and between the outer peripheral wall of the float ring and the inner peripheral wall of the working cylinder are filled with magnetorheological fluid; the external electromagnet is fixed onto the outer circumference of the working cylinder.

Owner:STATE GRID CORP OF CHINA +1

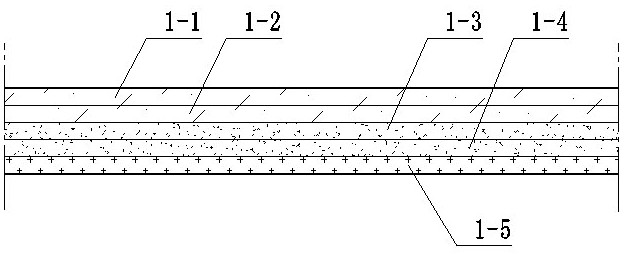

One-pack type unhardening adhesive film waterproofing material using waste rubber and method for manufacturing same

ActiveCN103298896AIncrease elasticityViscosity adjustmentReclaimed rubber coatingsOther rubber coatingsWaste rubberBitumen emulsion

The present invention relates to a one-pack type unhardening adhesive film waterproofing material using waste rubber and to a method for manufacturing same, by mixing waste rubber chips with oil, heating, and grinding same into fine powder using mechanical breaking stress, and more particularly, to an one-pack type unhardening adhesive film waterproofing material using waste rubber and to a method using waste rubber that is extracted by adding heat to waste rubber to suppress the elasticity of the material, grinding the waste rubber chips into fine powder using mechanical breaking stress, and mixing with emulsified asphalt, SBR, and NR to extract the waste rubber. The present invention comprises the following steps: mixing 10 to 15 parts by weight of the waste rubber chips and 20 to 25 parts by weight of oil and heating same to 200 to 230 DEG C, and then using mechanical breaking stress to render the waste rubber chips into fine powder; mixing with 29.6 to 40 parts by weight of emulsified asphalt; mixing with 8 to 13 parts by weight of filler material, 1 to 2 parts by weight of a surfactant, and 0.1 to 0.4 parts by weight of anti-aging material while maintaining the temperature at 90 to 100 DEG C; and mixing 3 to 6 parts by weight of SBR for adjusting viscosity.

Owner:瑞新株式会社

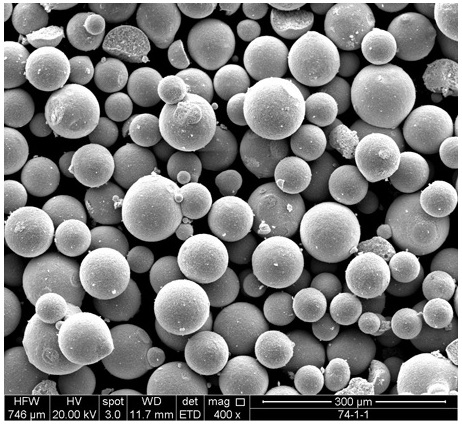

Preparation method of solid spherical ITO granulation powder

The invention discloses a preparation method of solid spherical ITO granulation powder. The method comprises the following steps: preparing indium oxide powder and tin oxide powder into a slurry; adding a dispersing agent into the slurry, fully grinding, adding a binder, uniformly mixing, heating the slurry or adjusting the pH value of the slurry to control the viscosity of the slurry to be 100-1500mPa. S, and finally carrying out spray drying on the slurry to obtain the solid spherical ITO granulation powder. According to the preparation method, sufficient grinding and dispersing of the ITO granulation powder can be guaranteed, the solid spherical ITO granulation powder can be prepared, operation is convenient, and the requirement for high-performance target material preparation is met.

Owner:725TH RES INST OF CHINA SHIPBUILDING INDAL CORP

Material formula and production process of automatic winding packaging film

ActiveCN111761899AModerate thicknessStable antistaticFlexible coversWrappersLinear low-density polyethyleneLow-density polyethylene

The invention relates to agricultural harvesting crop packaging materials, and particularly relates to a material formula and a production process of an automatic winding packaging film during harvesting and packaging operation of cotton, silage and the like. The material formula of the automatic winding packaging film material comprises the following raw materials in percentage by mass: linear low-density polyethylene, high-pressure low-density polyethylene, metallocene polyethylene, color masterbatch, an anti-aging agent, an ultraviolet light absorber and an antistatic agent. The productionprocess of the automatic winding packaging film mainly comprises the steps of preparing materials; blowing a film; conducting gluing; manufacturing film rolling units; and connecting the film rollingunits into a finished rolled film. By means of the material formula, the prepared packaging film is moderate in material thickness, stable in anti-aging and anti-static performance, high in anti-buffering strength, good in retraction rate and good in anti-piercing performance. The production process is reasonable in flow design, economical and practical, material bag sealing is enabled to be tightand firm, and the produced packaging film can be rapidly separated in the material packaging process.

Owner:新疆棉锦农业科技有限公司

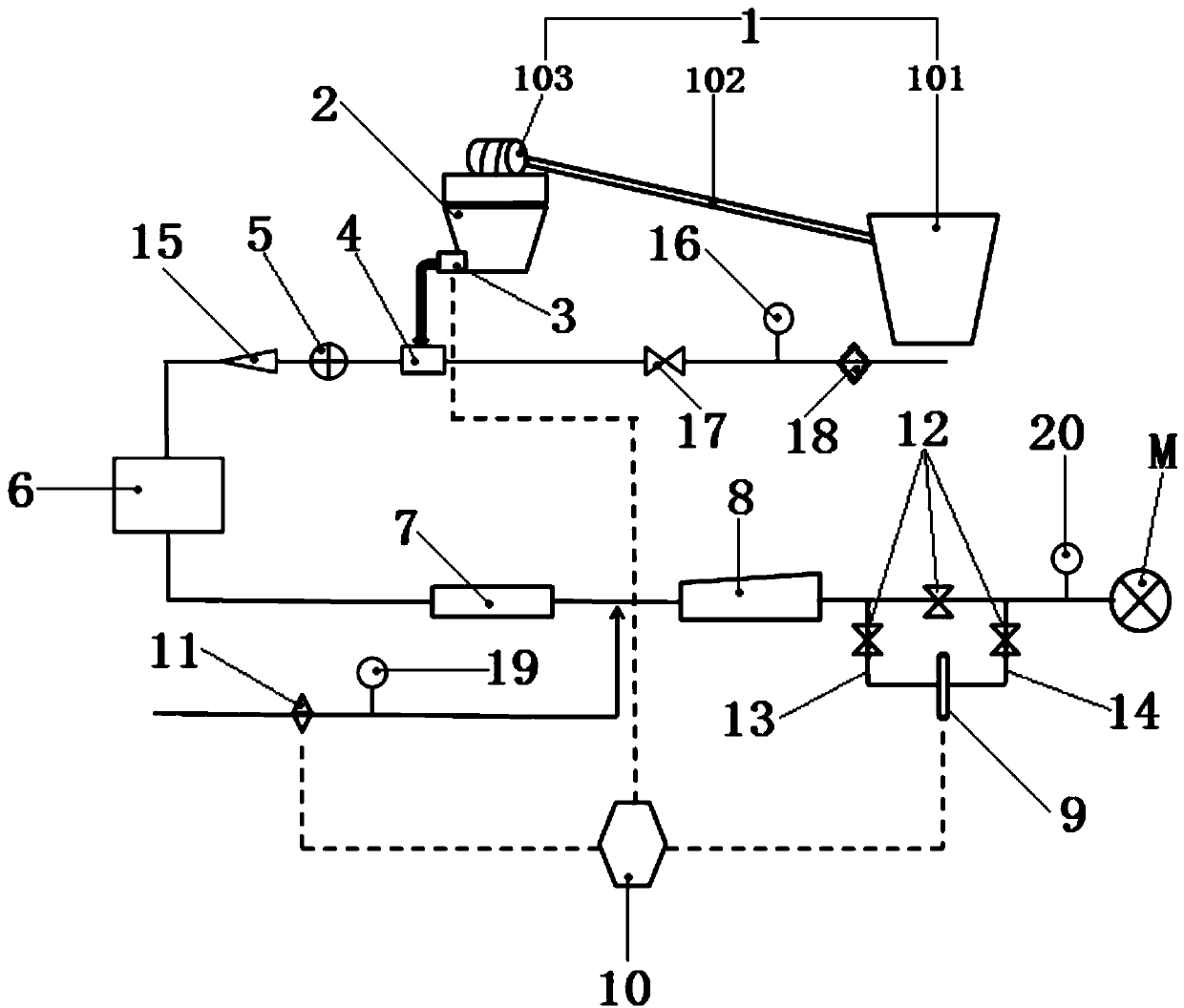

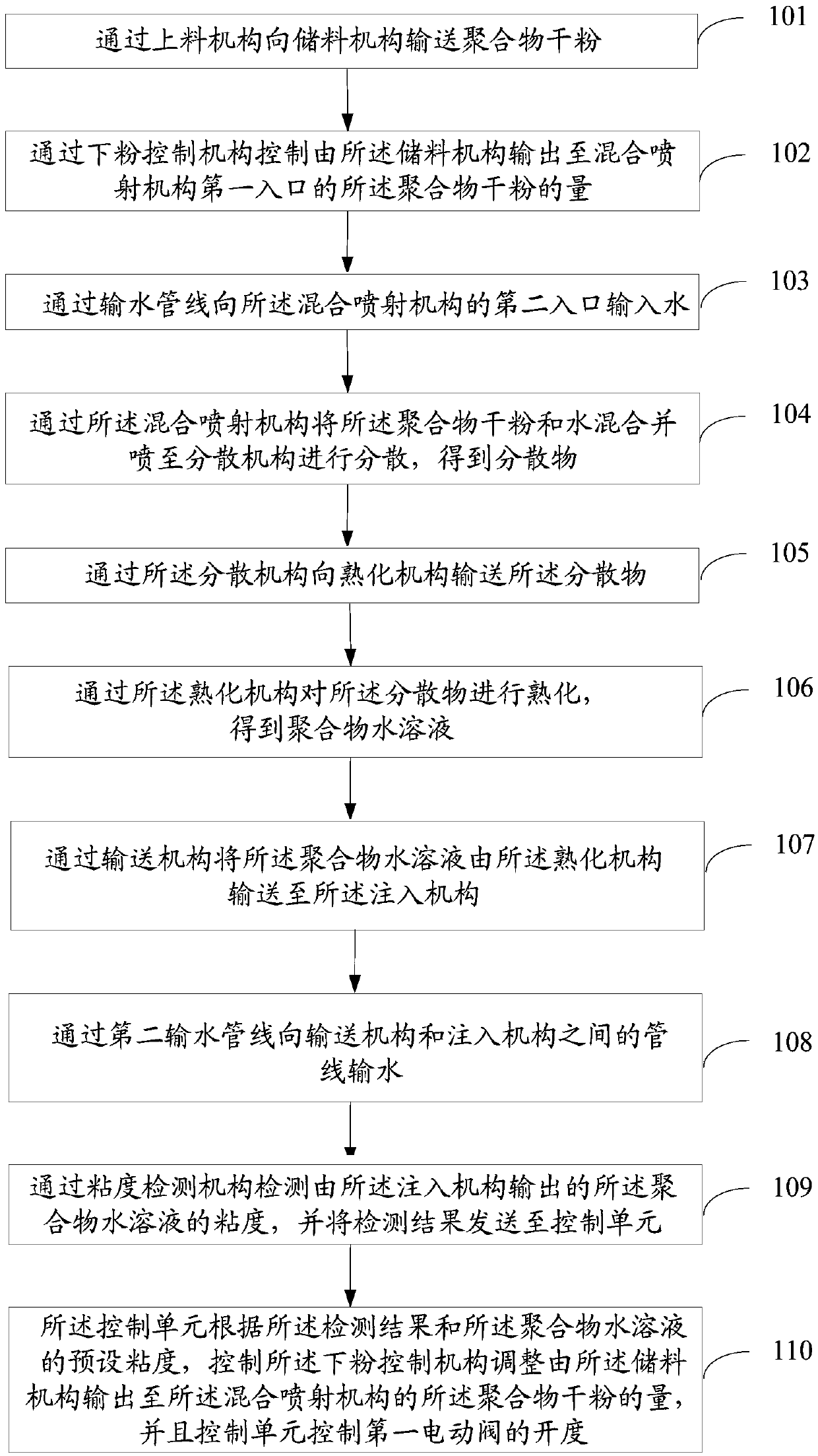

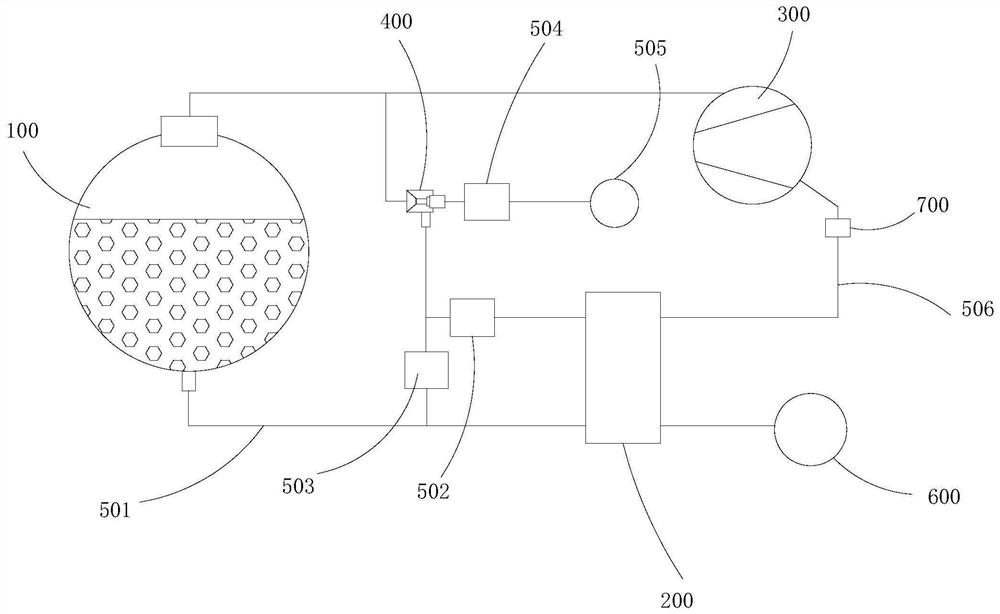

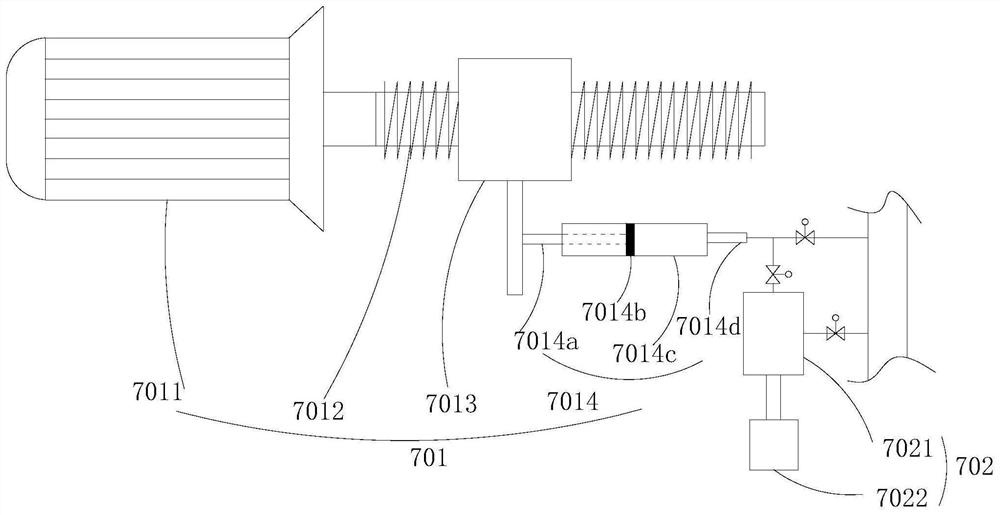

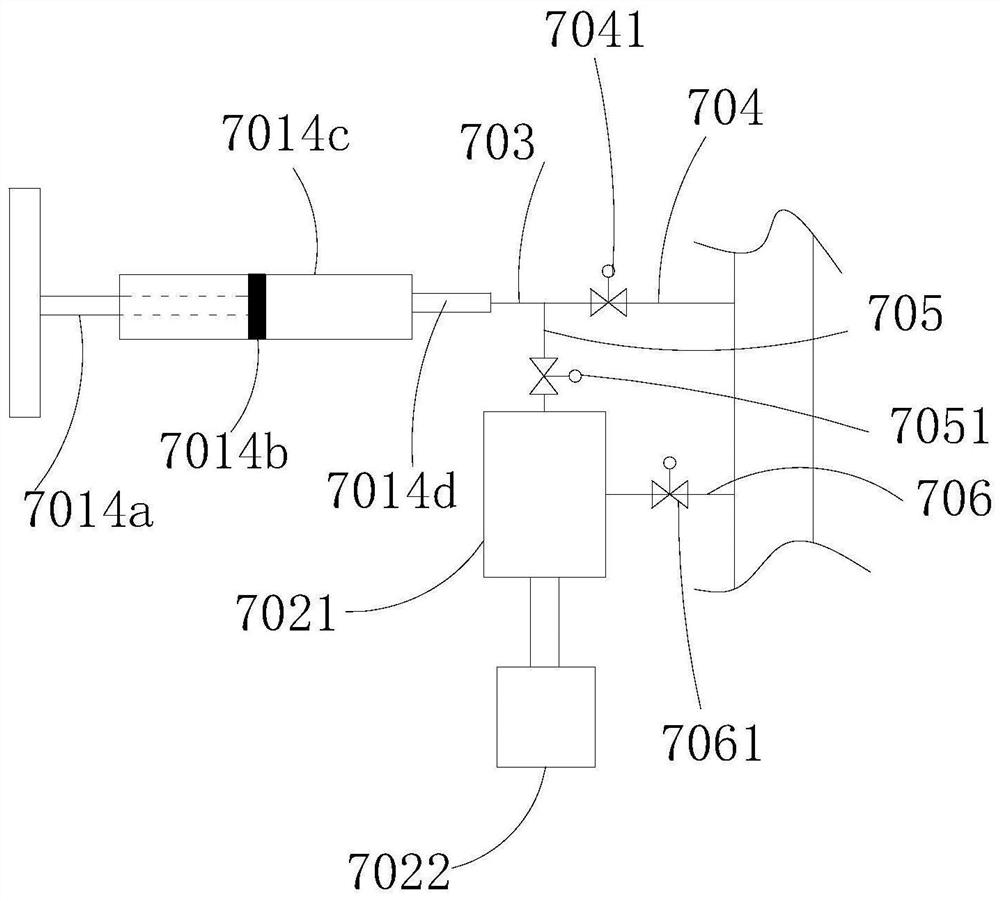

Polymer aqueous solution preparation device and method for polymer flooding

InactiveCN109758958AAvoid wastingViscosity adjustmentFlow mixersMixer accessoriesPolymer scienceLine tubing

The invention discloses a polymer aqueous solution preparation device and method for polymer flooding and belongs to the technical field of oil displacement. The device comprises a feeding mechanism,a storage mechanism, a powder discharge control mechanism, a mixed jet mechanism, a dispersion mechanism, a curing mechanism, a conveying mechanism, an injection mechanism, a viscosity detection mechanism and a control unit, wherein the feeding mechanism is used for conveying dry polymer powder to the storage mechanism; an inlet of the powder discharge control mechanism is communicated with an outlet of the storage mechanism, an outlet of the powder discharge control mechanism is communicated with a first inlet of the mixed jet mechanism through a pipeline, and a second inlet of the mixed jetmechanism is communicated with a first water delivery pipeline; an outlet of the mixed jet mechanism is sequentially communicated with the dispersion mechanism, the curing mechanism, the conveying mechanism, the injection mechanism and a target wellhead through pipelines; the viscosity detection mechanism is used for detecting viscosity of the polymer aqueous solution output by the injection mechanism; the control unit is electrically connected with the powder discharge control mechanism and the viscosity detection mechanism. The device is simple in structure and can adjust viscosity of the polymer aqueous solution.

Owner:PETROCHINA CO LTD

Transparent silicone sealant with long lasting phosphorescence function, and preparation method and application thereof

InactiveCN110724490AIncrease viscosityImprove thixotropyNon-macromolecular adhesive additivesPolymer sciencePtru catalyst

The invention provides a transparent silicone sealant with a long lasting phosphorescence function, and a preparation method and an application thereof. The sealant is prepared from, by mass, 40-50 parts of 107 glue with the viscosity of 70000-90000 mPas, 5-15 parts of 107 glue with the viscosity of 450000-550000 mPas, 5-15 parts of fumed silica, 4-8 parts of a cross-linking agent, 0.3-1.2 parts of a silane coupling agent, 0.1-0.2 part of a catalyst, 2-8 parts of an organic long lasting phosphorescence agent and 20-40 parts of white oil. The preparation method is simple; the organic lasting phosphorescence agent adopted in the invention has low cost, and has good compatibility with colloid; and the sealant prepared by coordinating all the raw materials has the advantages of long lasting phosphorescence function, good transparency, good insulativity and good mechanical and adhesive properties, and is suitable for sealing outdoor buildings, electric power outdoor power transformation equipment and the like.

Owner:SHANDONG DONGYUE ORGANIC SILICON MATERIAL

High flame-retardant epoxy resin heavy anticorrosive paint

InactiveCN106318106AImprove corrosion resistanceGood flexibilityCarboxyl rubber coatingsAnti-corrosive paintsDiacetone alcoholEpoxy

The invention discloses a high flame-retardant epoxy resin heavy anticorrosive paint. The raw materials include: epoxy resin, polyurethane, organic silicon resin, carboxyl terminated butyronitrile liquid rubber, triethylamine, zinc borate, nano-calcium carbonate, modified nano titanium dioxide, polyaniline modified glass flake, graphite, diacetone alcohol, propanediol butyl ether, propylene glycol methyl ether acetate, xylene, methylnonylketone, gluconic acid, water, a leveling agent, a defoaming agent, and hydroxymethyl cellulose. The high flame-retardant epoxy resin heavy anticorrosive paint provided by the invention can resist the corrosion of strong acid and strong alkali, also has good impact resistance, excellent flame retardance and corrosion resistance, and has long service life.

Owner:ANHUI KAILIN ADVANCED MATERIAL CO LTD

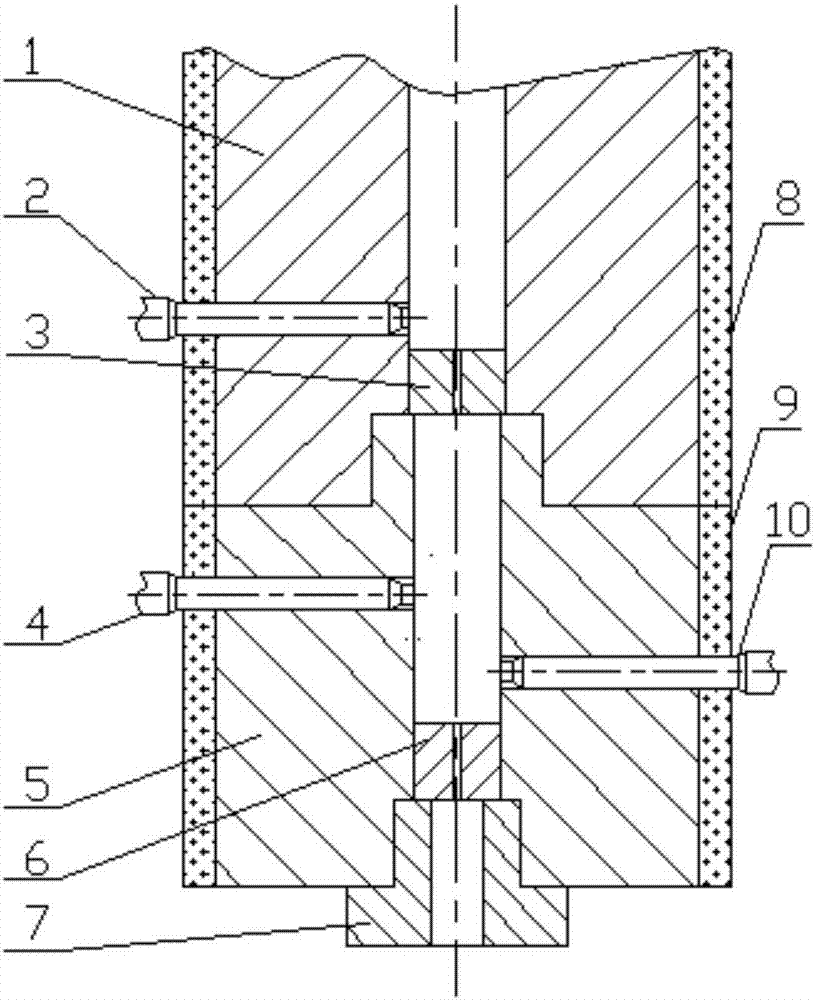

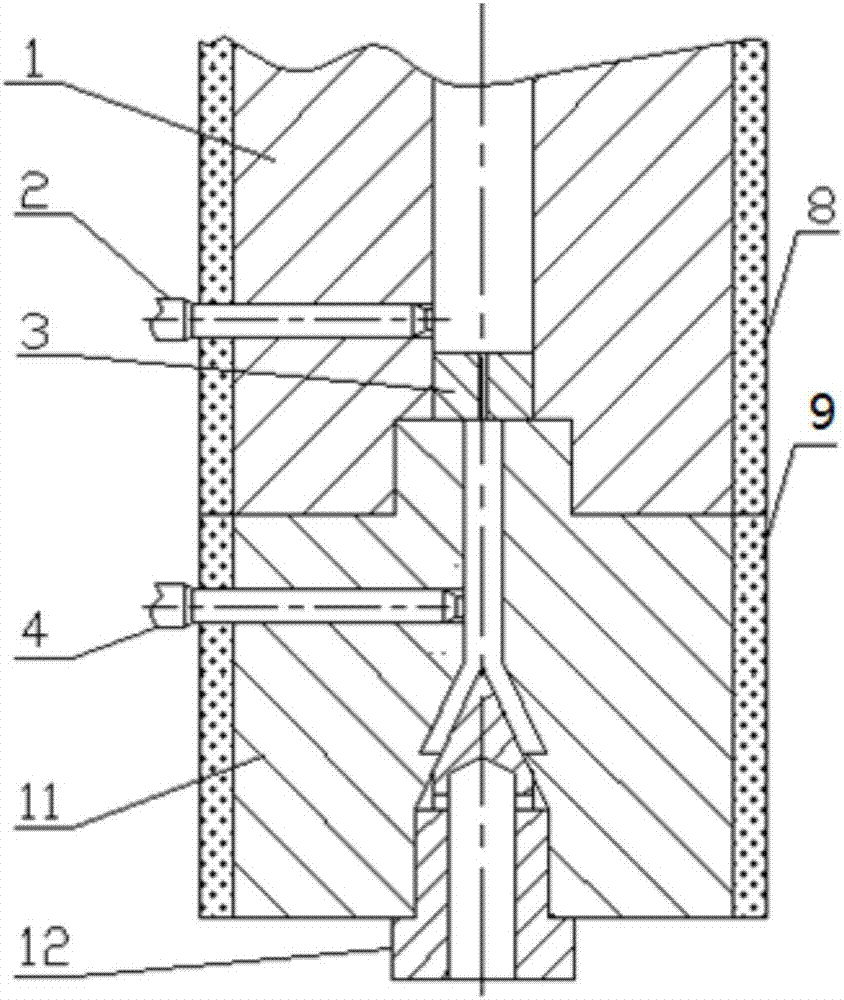

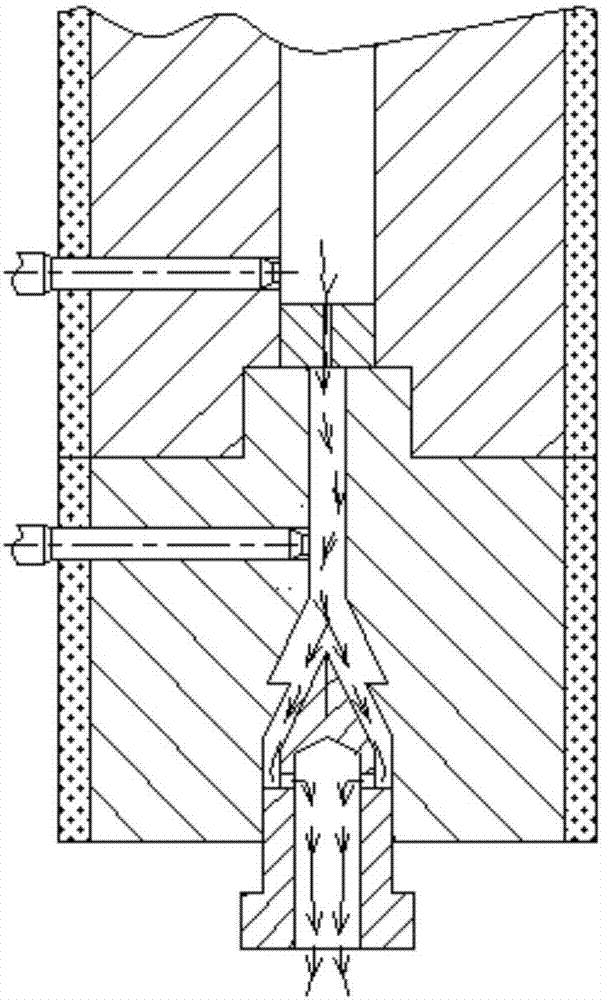

Die assembly for double-stage differential pressure type capillary rheometers

InactiveCN107219152AIncrease pressureViscosity adjustmentFlow propertiesDifferential pressureEngineering

The invention provides a die assembly for double-stage differential pressure type capillary rheometers. The die assembly comprises a first barrel and a second barrel, the end of the first barrel is provided with a cylindrical socket, the socket is concentric with the cavity of the first barrel, and moreover, the diameter of the socket is greater than the diameter of the cavity; the top end of the second barrel is provided with a cylindrical boss, the boss is concentric with the cavity of the second barrel, the boss matches the diameter of the socket of the first barrel, and the boss of the second barrel is inserted in the socket of the first barrel; a first die is arranged in the end of the cavity of the first barrel, a first pressure sensor is arranged on the barrel wall close to the first die, and the first pressure sensor runs through a first heating jacket and the wall of the first barrel to communicate with the cavity. The die assembly not only can increase the pressure of the inlet of the first die, but also can test the viscosity of high polymer melt under two different pressures each time, so that the efficiency of an experiment is greatly increased, and the die assembly can also compare the viscosity changes of the high polymer melt under different pressures at the same time.

Owner:BEIJING UNIV OF CHEM TECH

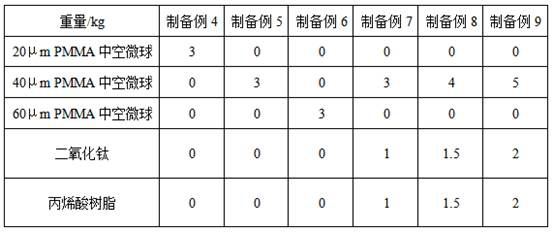

Matt UV printing ink and preparation method thereof

ActiveCN114369389AGood matting effectStable and uniform matting effectInksPolymer scienceMicrosphere

The invention relates to the technical field of electronic appliances, and particularly discloses matte UV ink and a preparation method thereof. The matte UV ink comprises the following substances in parts by weight: 60-80 parts of polyurethane resin, 0.2-1 part of extinction wax powder, 0.2-1 part of a wetting dispersant, 0.2-1 part of a leveling agent, 15-25 parts of a diluent, 2-10 parts of a filler and 1-2 parts of other auxiliaries, the polyurethane resin is polyurethane resin modified by a modifier, and the modifier comprises PMMA hollow microspheres; the preparation method comprises the following steps: S1, pre-dispersing; and S2, ink preparation. The matte UV ink disclosed by the invention can be used for printing marks on electronic and electrical appliances, and has the advantages of being stable in gloss, not easy to float, uniform in extinction, and smooth in flatness; in addition, the preparation method disclosed by the invention has the advantages of simplicity and convenience in operation and uniform dispersion.

Owner:宁波瑞联特油墨有限公司

Ejecting thermosyphon multifunctional oil return device for heat pump unit

PendingCN112923605AImprove performanceViscosity real-time feedbackCompressorRefrigeration safety arrangementEngineeringRefrigerant

The invention relates to an ejecting thermosyphon multifunctional oil return device for a heat pump unit. The ejecting thermosyphon multifunctional oil return device comprises an evaporator, a cooling heat exchanger, a compressor and an ejector. The evaporator is sequentially connected with the cooling heat exchanger and the compressor through a refrigerant liquid inlet pipeline; the ejector is respectively connected to the evaporator and the compressor through pipeline connection; the cooling heat exchanger is connected with an oil tank and further connected with the ejector through a cooling electromagnetic valve; a bypass electromagnetic valve is arranged between the ejector and the refrigerant liquid inlet pipeline, and the ejector is further connected with a condenser gas pipeline through a condensed gas electromagnetic valve; and a lubricating oil detection device is arranged on the cooling oil pipe between the compressor and the cooling heat exchanger. Oil temperature control and system oil return are achieved at the same time, the cost can be reduced, and the compressor efficiency and the system performance are improved; and lubricating oil entering the compressor is detected online through a viscosity detection device, so that the temperature of the lubricating oil entering the compressor is adjusted in time, and the lubricating effect of the lubricating oil is guaranteed.

Owner:一冷豪申新能源(上海)有限公司

Low-heat-release epoxy resin composition and preparation method thereof

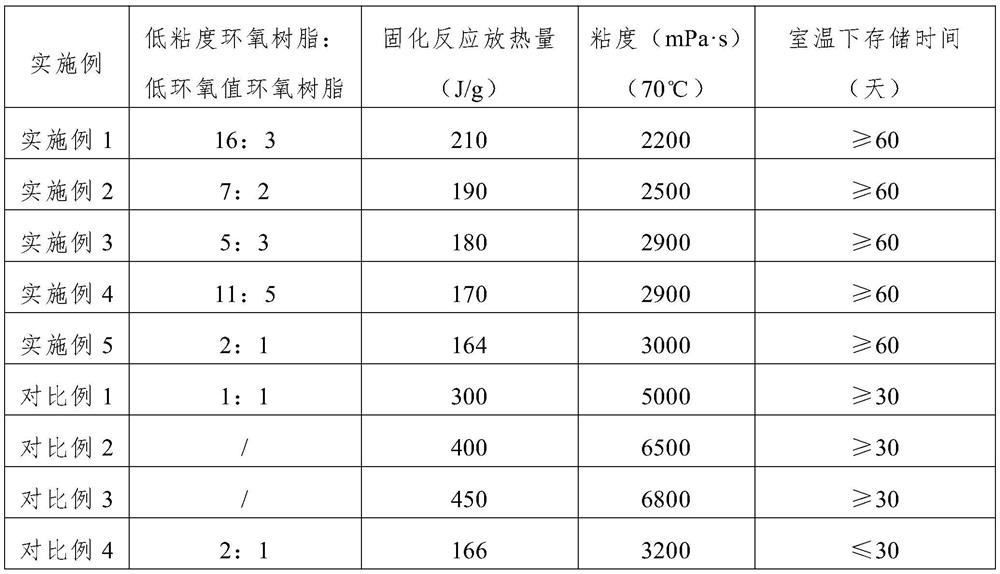

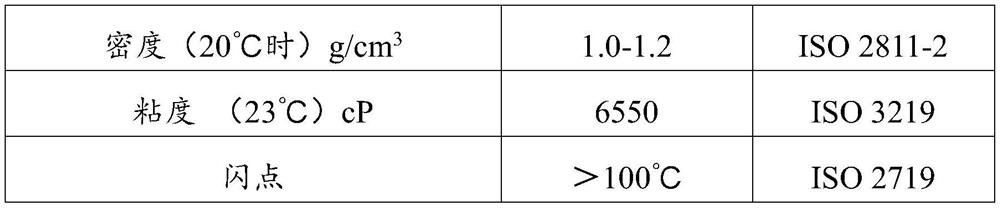

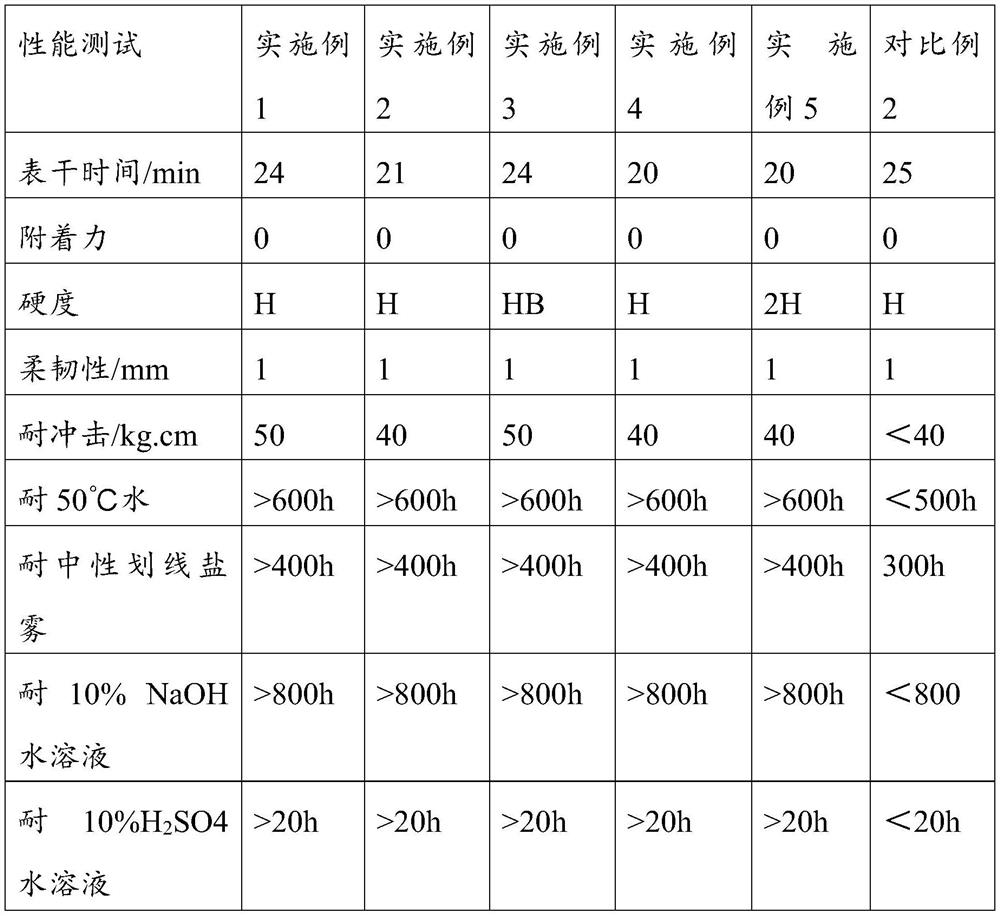

The invention provides a low-heat-release epoxy resin composition and a preparation method thereof, the low-heat-release epoxy resin composition comprises an epoxy resin mixture, a curing agent and an accelerant, wherein the epoxy resin mixture is composed of low-viscosity epoxy resin and low-epoxy-value epoxy resin, the content of the low-viscosity epoxy resin is 50-80 parts by mass, the content of the low-epoxy-value epoxy resin is 15-30 parts by mass, the content of the curing agent is 4-16 parts by mass, the content of the accelerant is 0.5-5.5 parts by mass, the viscosity of the low-viscosity epoxy resin ranges from 10,000 mPa.s to 15,000 mPa.s, the epoxy value of the low-epoxy-value epoxy resin is not higher than 0.3, and a mass ratio of the low-viscosity epoxy resin to the low-epoxy-value epoxy resin is (50-80): (15-30). The epoxy resin composition prepared by the invention has the advantages of low heat release in curing reaction, long storage time and good manufacturability.

Owner:AEROSPACE INST OF ADVANCED MATERIALS & PROCESSING TECH

Emulsion type epoxy curing agent and preparation method thereof

ActiveCN112341604AEasy to prepareRaw materials are easy to getEpoxy resin coatingsEndcappingPolymer science

The invention provides a quick-drying emulsion type epoxy curing agent and a preparation method thereof. According to the preparation method, polyether amine with certain hydrophilicity reacts with excessive epoxy resin to form an amphiphilic prepolymer; and residual epoxy groups continuously reacts with proper excessive micromolecular polyamine due to the fact that the epoxy groups are greatly excessive, and therefore, an emulsion type epoxy curing agent with certain active hydrogen content can be formed; due to the existence of unreacted primary amine in the polyamine, the working life of the curing agent is shortened, so that the monofunctional epoxy compound is subsequently added to block the primary amine; and finally, water is added for emulsification, so that the emulsion type epoxycuring agent can be obtained. The synthesis method of the emulsion type epoxy curing agent is simple; a catalyst and a solvent do not need to be added; the raw materials are easy to obtain; the VOC content is zero; the application range of the emulsion type epoxy curing agent is wide; a paint film prepared from the emulsion type epoxy curing agent is high in surface drying speed, and related mechanical properties, salt spray resistance and other properties of the paint film are excellent; and therefore the emulsion type epoxy curing agent has a great industrial application prospect.

Owner:上海华谊涂料有限公司

Gas-shielded flux-cored wire for welding sus316l austenitic stainless steel cryogenic storage containers and equipment

ActiveCN107971657BAdjust the melting pointAdjustable viscosityArc welding apparatusWelding/cutting media/materialsFerrosiliconManganese

The invention discloses a gas-shielded flux-cored wire for welding of a SUS316L austenitic stainless steel deep-cooling low-temperature storage and transportation container and device and the preparation method thereof. The as-shielded flux-cored wire comprises a steel strip and a flux core wrapped in the steel strip, and the flux core comprises the following components of, by weight, 4.25-5.85 parts of natural rutile, 0.8-1.9 parts of quartz sand, 0.7-1.8 parts of sodium titanate, 0.25-0.3 part of sodium fluoride, 0.125-0.275 part of calcined alpha alumina, 0. 27wt% of calcined alpha aluminaand 0.025-0.15 part of nitrogen-containing ferrochromium, 0.085-0.05 part of spray silicon iron, 1.05-1.45 parts of electrolytic manganese, 3.6-4.85 parts of metal chromium, 6.42-6.85 parts of atomized iron powder, 1. 9-2.5 parts of nickel powder, and 1.0-1.35 parts of molybdenum. The gas-shielded flux-cored wire has the advantages that efficient semi-automatic and automatic welding technologies are achieved, the welding efficiency is high, splashing is low, the appearance is attractive, the welding current is wide, and the voltage adaptability strong.

Owner:ATLANTIC CHINA WELDING CONSUMABLES

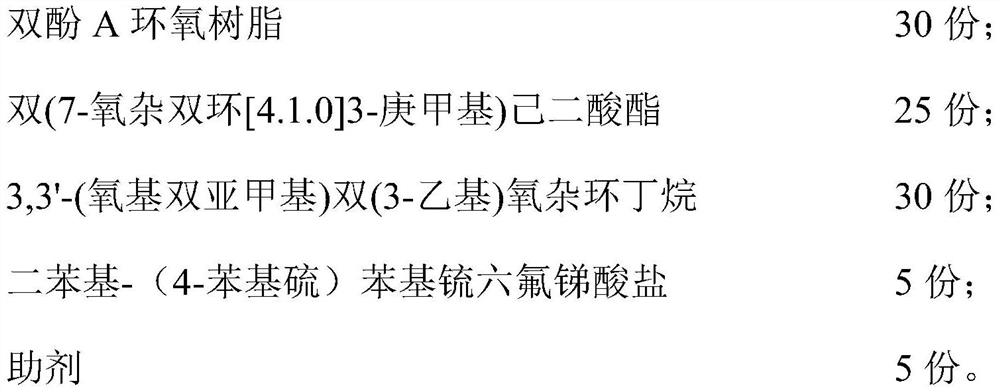

Ultraviolet curing epoxy adhesive as well as preparation method and application thereof

ActiveCN112680159AStrong adhesion at room temperatureHigh Shore hardnessEpoxy resin adhesivesHigh concentrationPolymer science

The invention provides an ultraviolet curing epoxy adhesive and a preparation method and application thereof. The ultraviolet curing epoxy adhesive is prepared from the following raw materials in parts by weight: 30-60 parts of basic epoxy resin, 20-30 parts of toughened epoxy resin, 10-30 parts of an epoxy diluent, 1-5 parts of a photoinitiator and 1-10 parts of an auxiliary agent, wherein the basic epoxy resin, the toughened epoxy resin and the epoxy diluent all have symmetrical molecular structures. By adding the basic epoxy resin, the toughening epoxy resin and the epoxy diluent which are symmetrical in molecular structure, the prepared ultraviolet curing epoxy adhesive can resist high-concentration acid-base etching liquid, is easy to trim and tear when used as UV glass edge sealing adhesive, is free of solvent addition in the preparation process, and meets the environment-friendly requirement; and the viscosity of the adhesive can be adjusted according to actual requirements.

Owner:上海仁速新材料有限公司

Emulsified salt type cream for cleaning face and preparation method

An emulsified salt type face cleaning cream for moistening skin and treating acne, itching and inflammation is proportionally prepared from anionic surfactant, non-ionic surfactant, sodium chloride, the cellulose resisting salting-out, stearic acid, polyol, lumectant, hydrophilic lanolin, deionized water and essence. Its preparing process is also disclosed.

Owner:云南能源投资股份有限公司 +1

Thermal tackifying polymer based on polyether graft modification and preparation method thereof

ActiveCN106084144BGood thermal viscosity increasing performanceLow heat viscosity builder concentrationDrilling compositionHydrophilic monomerOrganic solvent

The invention provides a preparation method for a thermo-thickening polymer based on graft modification of polyether. The preparation method comprises the following steps: (1) dissolving a dispersant in an organic solvent to form a first solution, dissolving polyether and neutral or / and alkaline hydrophilic monomer in deionized water to form a second solution and mixing the first solution and the second solution in a reactor so as to obtain a water phase-organic phase mixed reaction system, wherein the usage amount of deionized water is adequate for complete dissolving of polyether and the neutral or / and alkaline hydrophilic monomer; and (2) introducing nitrogen or inert gas to remove oxygen in the reactor, adding an initiator into the water phase-organic phase mixed reaction system under stirring and then carrying out a reaction with stirring at 65 to 80 DEG C for 2 to 8 h under the protection of nitrogen or inert gas. The invention also provides the prepared thermo-thickening polymer based on graft modification of polyether. The method provided by the invention can decrease the thermoassociating concentration of the thermo-thickening polymer and reduce usage cost.

Owner:SICHUAN UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com