Patents

Literature

45results about How to "High Shore hardness" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Modified ultra-high molecular weight polyethylene resin

The invention discloses a production formula and a manufacturing method of a modified ultra-high molecular weight polyethylene resin. The modified ultra-high molecular weight polyethylene resin comprises an ultra-high molecular weight polyethylene resin, molybdenum disulfide, nano graphite, superfine talcum powder, ethylene bis stearamide, polytetrafluoroethylene and benzoyl peroxide. The modified ultra-high molecular weight polyethylene resin has ultra high wear resistance and favorable temperature tolerance and self-lubricating property. Compared with the resin before the modification, the modified resin has the advantages that the heat distortion temperature is increased by 38 DEG C, the Shore hardness is improved by 20 degrees, the friction factor is decreased by 40%, and the expansion factor is decreased by 30%. The modified resin is widely used for producing products such as gears, valves, artificial joints, skis, oil field transfer pipelines and the like.

Owner:王崇高

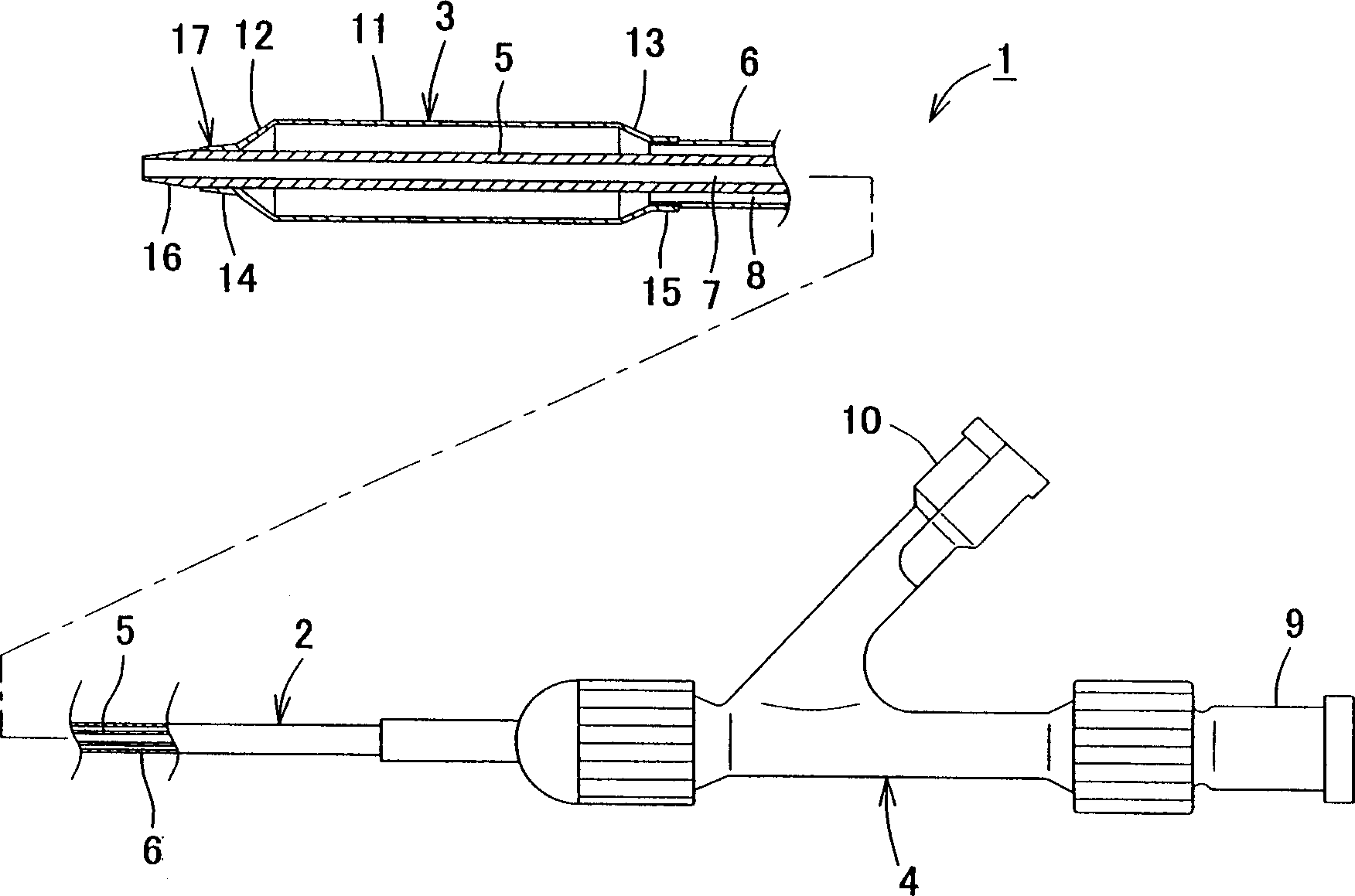

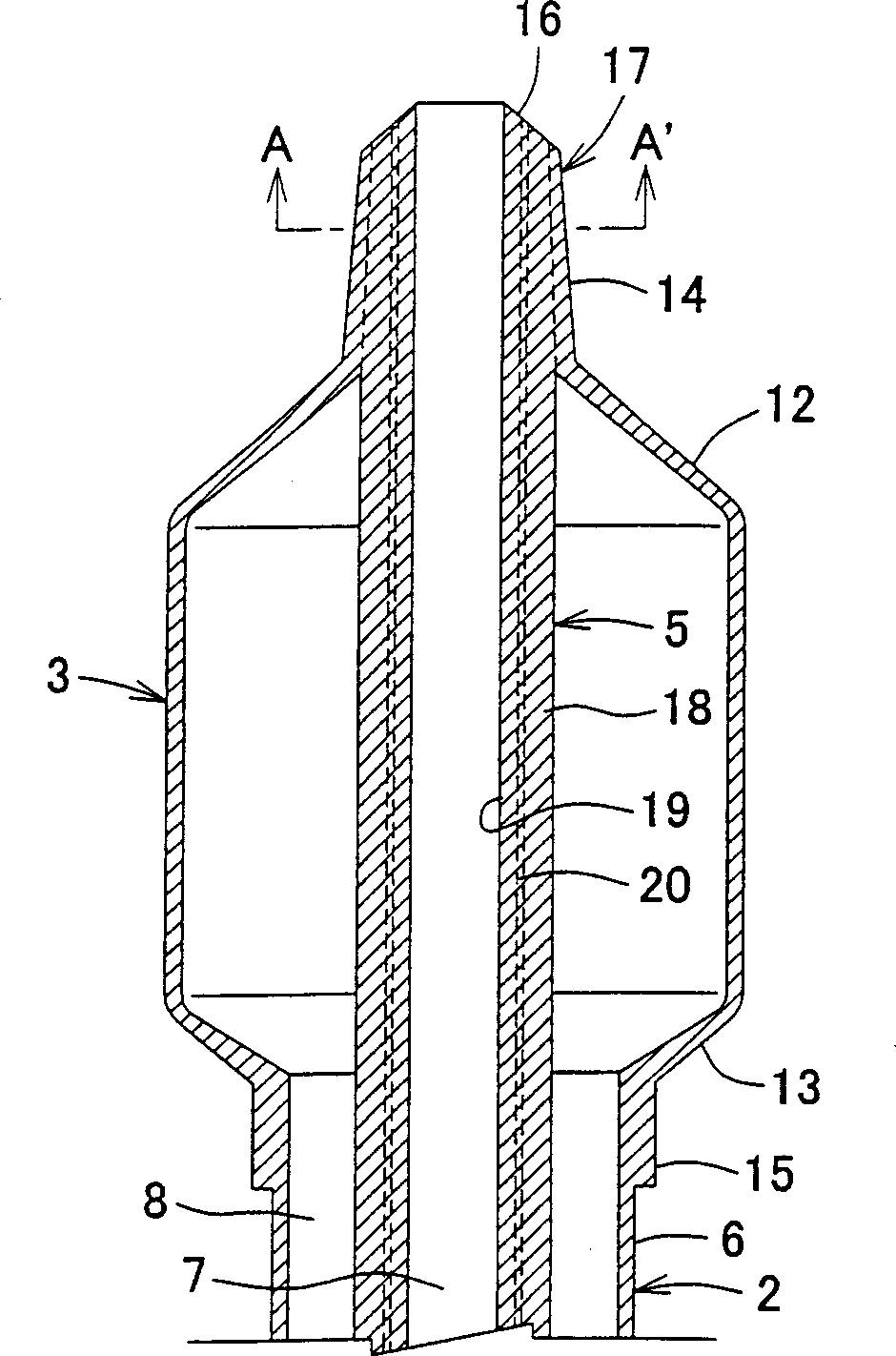

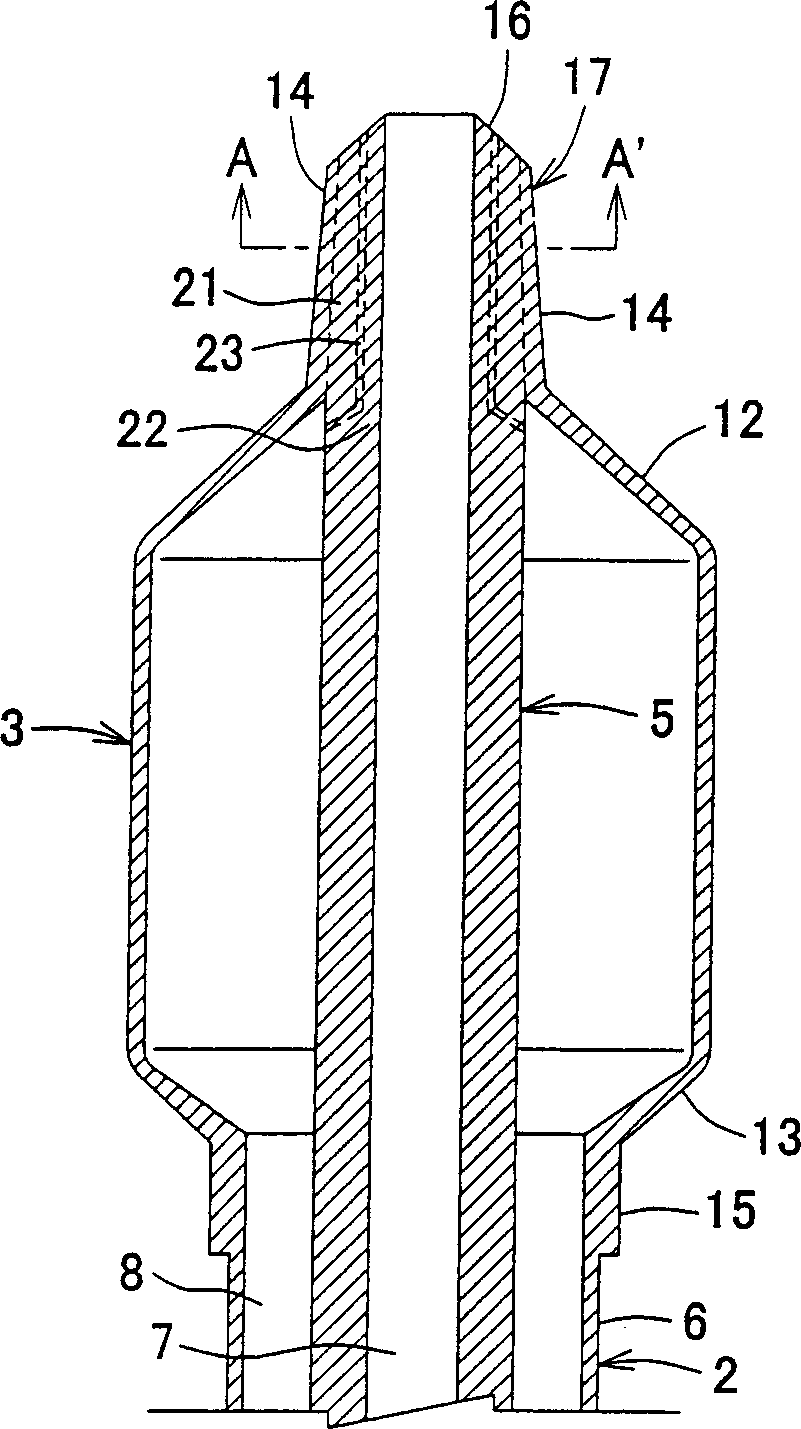

Balloon catheter

The present invention is a balloon catheter used primarily in treatment and surgery for the purpose of dilating lesion sites such as strictures or blockages in passages in the human body. The balloon catheter of the present invention has a structure wherein a guide wire passing tubular member is deployed passing through the interior of the expansion body, and the outer surface of the tubular member and the expansion body are concentrically fused near the distal end of the catheter. This is a balloon catheter that is characterized by the fact that the Shore hardness of the material configuring the outermost surface of the tubular member is smaller than the Shore hardness of the material configuring the expansion body. It is therefore possible to flexibly adjust the tip portion formed by securing the expansion body and the guide wire passing tubular member.

Owner:KANEKA CORP

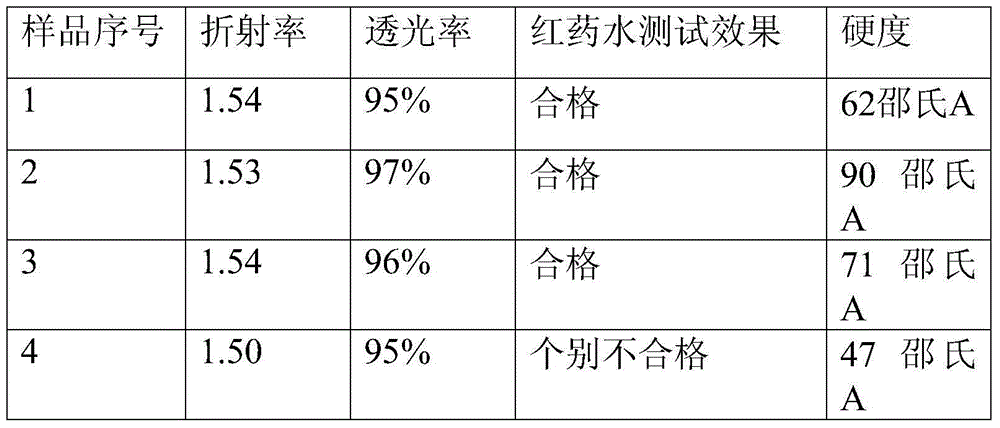

High-power LED packaging adhesive composition

InactiveCN104592932AThe test effect is goodHigh Shore hardnessNon-macromolecular adhesive additivesOther chemical processesTransmittanceChemistry

The invention discloses high-power LED packaging adhesive composition which is prepared from the following raw materials in parts by weight: 10-90 parts of phenyl vinyl silicon resin, 0-5 parts of MDQ resin, 0.002-0.005 parts of a platinum catalyst, 15-40 parts of high-phenyl hydrogen-containing silicone oil or 20-50 parts of high-phenyl hydrogen-containing silicone resin and 0-3 parts of a tackifier, the phenyl vinyl silicon resin, the MDQ resin and the platinum catalyst form a component A; the high-phenyl hydrogen-containing silicone oil or the high-phenyl hydrogen-containing silicone resin and the tackifier form a component B; the vinyl content ratio of the component A to the component B is 1.1-1.4. A preparation method for the high-power LED packaging adhesive composition comprises the following steps: mixing the component A with the component B, defoaming, putting a defoamed mixture into a drying oven with the temperature of 80 DEG C for 2 hours, heating to 150 DEG C, keeping the temperature for 3 hours, and cooling to the room temperature to obtain the high-power LED packaging adhesive composition. The high-power LED packaging adhesive composition has the refractive index of more than 1.52 and the light transmittance of more than 95% before and after being cured, and is good in mercurochrome test effect, high in shore hardness and suitable for high-power LED packaging.

Owner:INST OF CHEM MATERIAL CHINA ACADEMY OF ENG PHYSICS +1

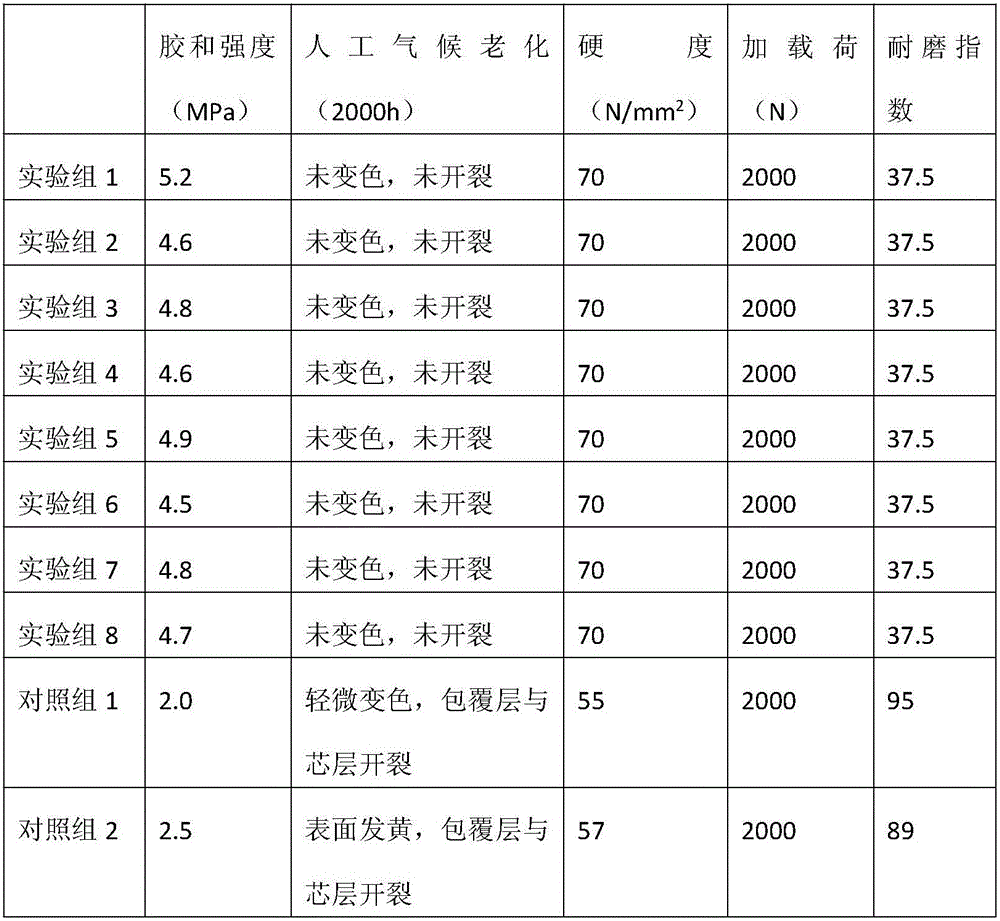

Wood-plastic coextruded fabric

The invention relates to the technical field of chemical production and in particular relates to a wood-plastic coextruded fabric. The wood-plastic coextruded fabric is prepared from the following raw materials in parts by weight: 30 percent to 60 percent of polyolefin resin, 5 percent to 20 percent of a polypropylene grafting material, 10 percent to 40 percent of reinforced resin and 1 percent to 10 percent of a functional auxiliary agent. According to the wood-plastic coextruded fabric, all components are organically compounded and a binding force between the prepared coextruded fabric and a wood-plastic core layer is great; the wood-plastic coextruded fabric has ultrahigh bonding strength; the covered wood-plastic core layer can be toughened; the wood-plastic weather resistance, corrosion resistance, high-temperature resistance, toughness and mechanical strength are improved.

Owner:HUANGSHAN BANNER TECH

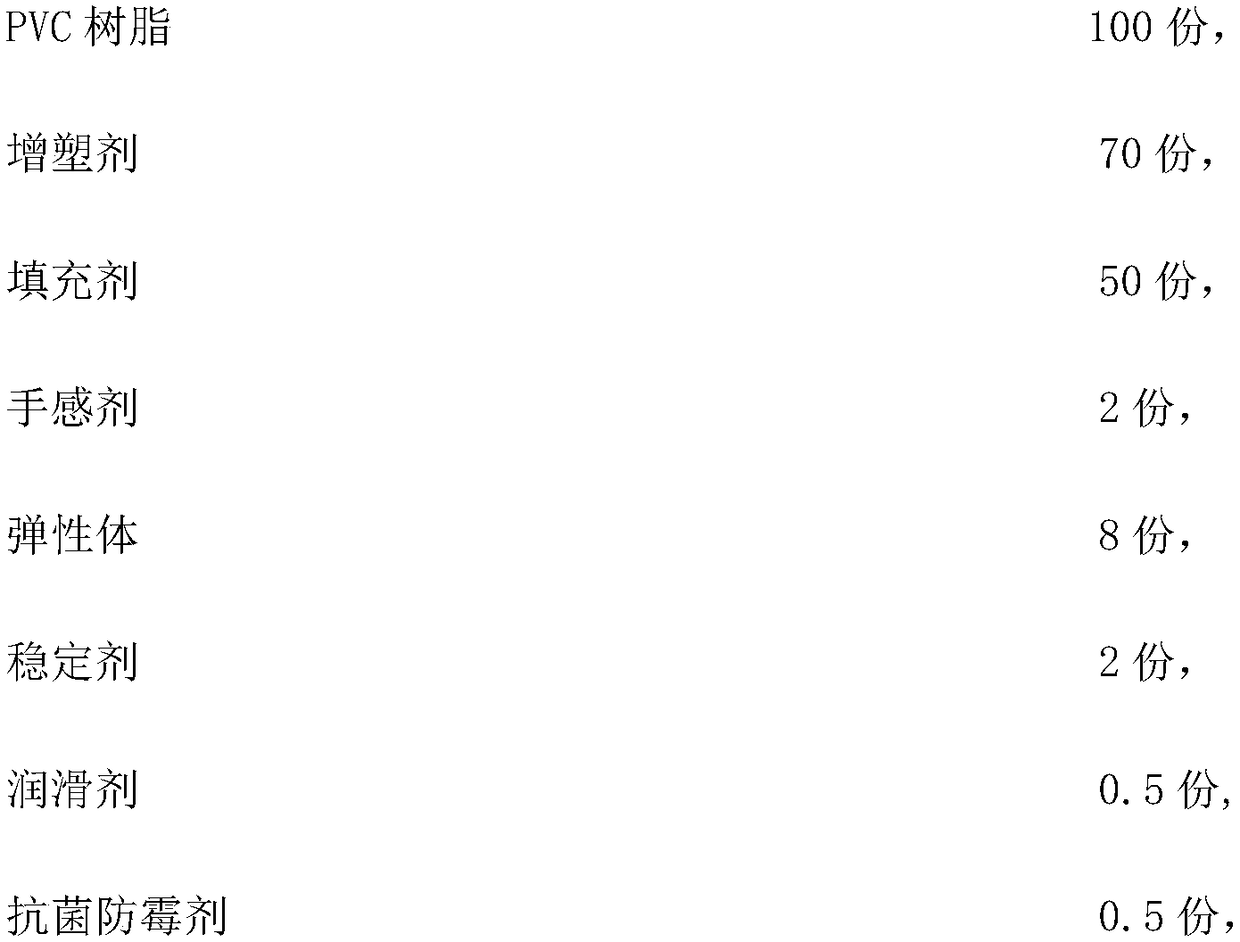

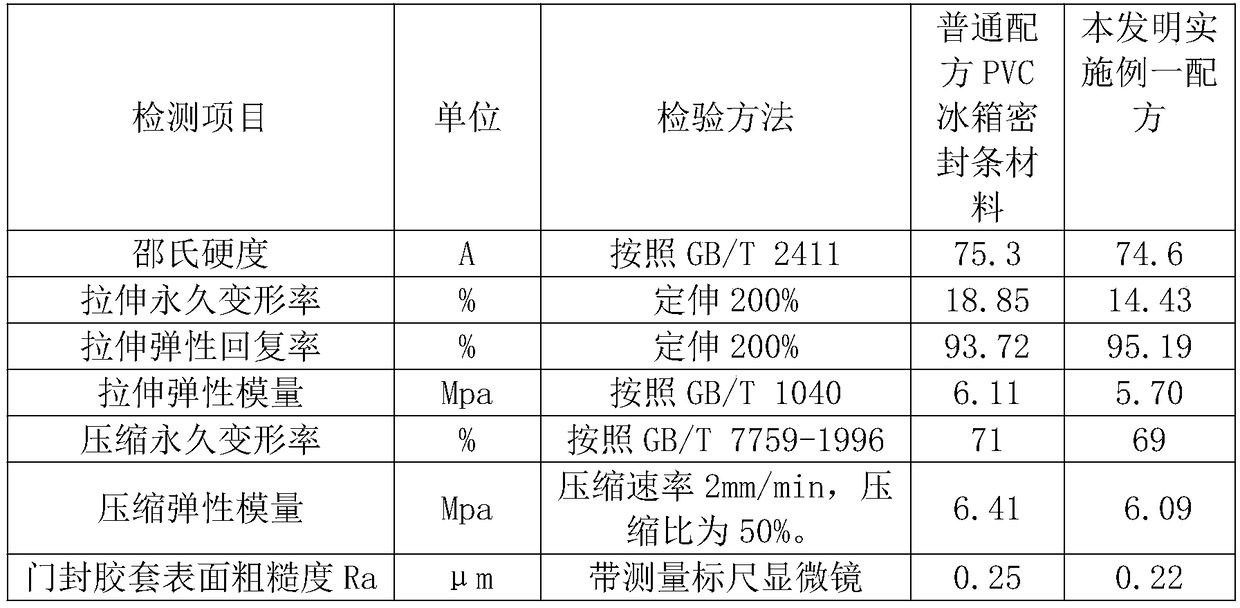

Smooth and delicate PVC door sealing material and preparation method thereof

The invention discloses a smooth and delicate PVC door sealing material and a preparation method thereof. The smooth and delicate PVC door sealing material is composed of PVC resin, plasticizer, filler, feeling agent, elastomer, stabilizer, lubricant and antibacterial mildew preventive. The preparation method for the smooth and delicate PVC door sealing material includes the steps of weighing; powder mixing; mixing; extrusion forming and hot cutting. According to the smooth and delicate PVC door sealing material and the preparation method thereof, the problem that an existing soft PVC materialincreasingly cannot meet the requirements of the market for the surface softness and fine texture of the product is solved. A polar group in the feeling agent and a PVC material system generate an attachment point by H bond bonding, a smooth main chain in the feeling agent is attached to the surface of the PVC material to form a smooth and continuous film, a convex-concave phenomenon of the product surface is improved, the surface roughness and surface defects are reduced, the smoothness and softness are improved, the smooth and delicate texture degree of the product surface can be improved lastingly, and the smooth and delicate PVC door sealing material is suitable as a low temperature flexible refrigerator door sealing material.

Owner:ANHUI BANGRUI NEW MATERIAL TECH CO LTD

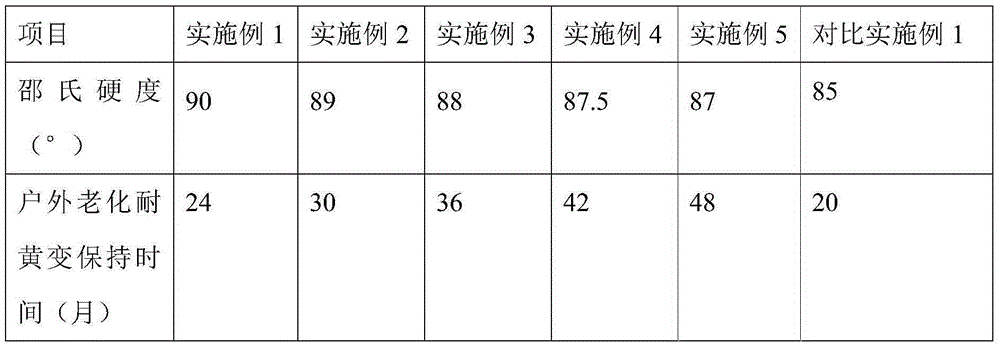

High-transparency, high-hardness and anti-yellowing epoxy resin AB glue for surfaces of environment-friendly building materials

ActiveCN105255417AHigh transparencyHigh Shore hardnessNon-macromolecular adhesive additivesMacromolecular adhesive additivesHardnessRenewable resource

The invention provides a high-transparency, high-hardness and anti-yellowing epoxy resin AB glue for the surfaces of environment-friendly building materials, which consists of a component A and a component B; the component A consists of the following ingredients in parts by weight: 80 to 90 parts of bisphenol A epoxy resin, 10 to 20 parts of nanoscale silicon dioxide / epoxy polymer toughener, 0.05 to 0.2 parts of wetting and anti-cratering additive, 0.2 to 0.8 parts of anti-ultraviolet barrier and 0.5 to 1.0 part of coupling agent; the component B consists of the following ingredients in parts by weight: 95 to 97 parts of polyether amine, 3 to 5 parts of alicyclic amine and 0.2 to 0.6 parts of coupling agent; the mass ratio of the component A to the component B is (2 to 2.5):1. The epoxy resin AB glue adopting the technical solution of the invention has high transparency and high Shore hardness, moreover, yellowing resistance reaches more than 3 years, and the epoxy resin AB glue can be applied in surface coating or coating for renewable resource ceramic plates, artificial marble, artistic ceramic plates and the like.

Owner:SHENCAI TECH SHENZHEN CO LTD

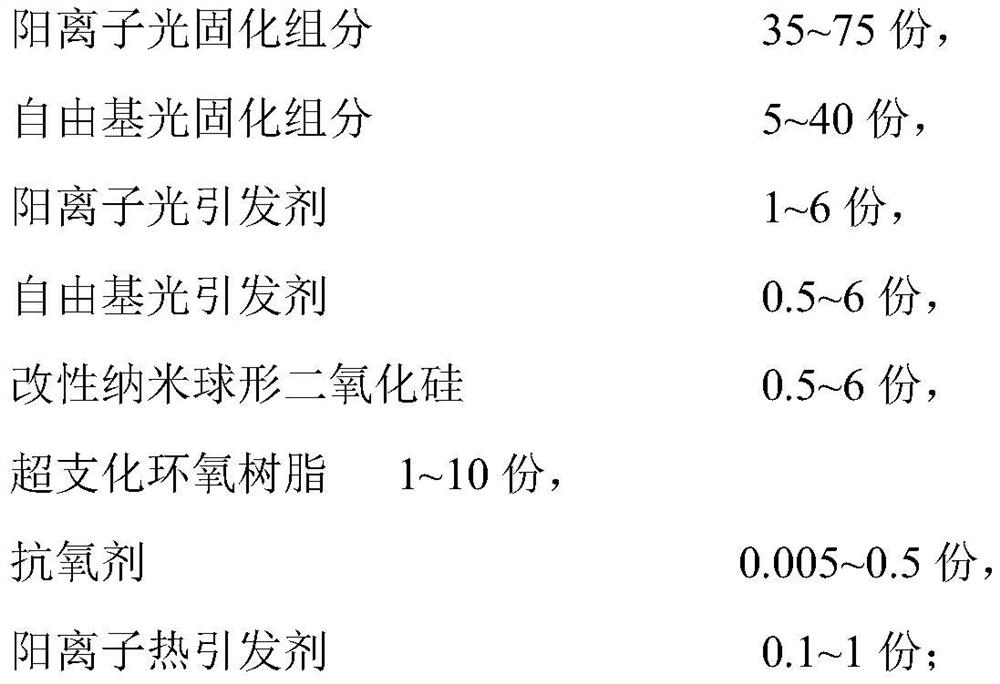

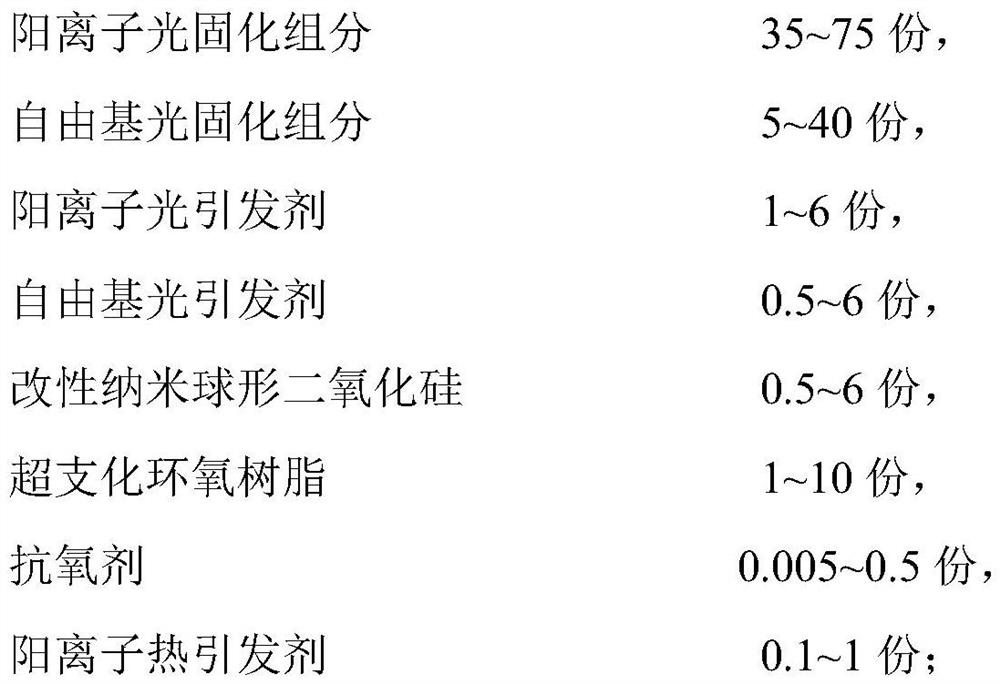

Photosensitive resin composition for photocuring rapid prototyping and preparation method and application of photosensitive resin composition

ActiveCN112724605AImprove heat resistanceImprove mechanical propertiesAdditive manufacturing apparatusEpoxyPolymer science

The invention relates to a photosensitive resin composition for photocuring rapid prototyping as well as a preparation method and application of the photosensitive resin composition. The photosensitive resin composition comprises a cationic photocuring component, a free radical photocuring component, a cationic photoinitiator, a free radical photoinitiator, modified nano spherical silicon dioxide, hyperbranched epoxy resin, an antioxidant and a cationic thermal initiator. The photosensitive resin composition provided by the invention has high mechanical properties and shore hardness, and the dimensional stability and heat resistance of a later model are high.

Owner:SUN YAT SEN UNIV

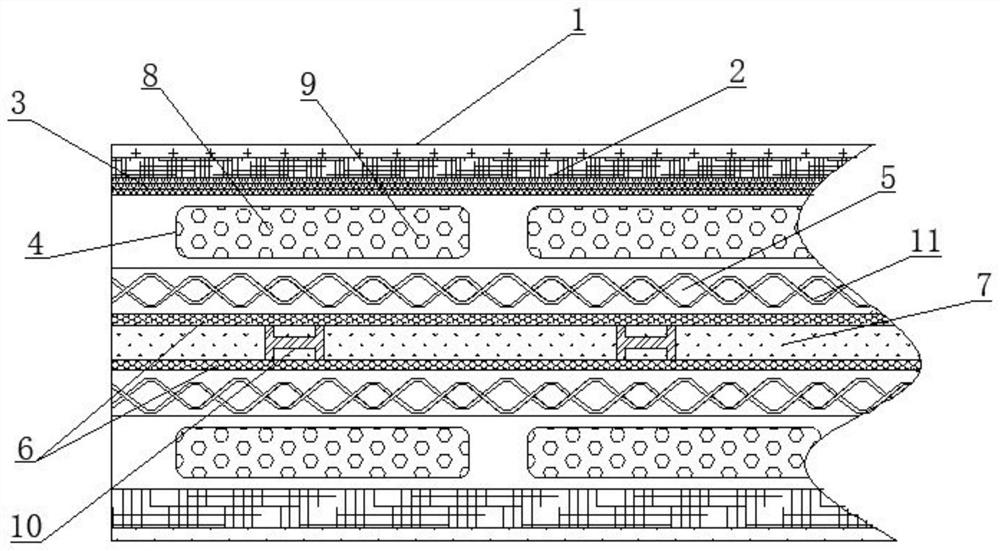

Method for improving shore degree of sound insulation cotton

PendingCN112721383ARaise the ShoreImprove sound insulationLamination ancillary operationsSynthetic resin layered productsMetal fibersMaterials science

The invention relates to a method for improving the shore degree of sound insulation cotton. The method comprises the following specific steps: weaving to obtain a light metal net layer and a hollow metal net layer; embedding elastic reinforcing ribs in a foam plastic layer; penetrating an elastic layer, drilling holes on the elastic layer, and filling light metal fiber; embedding mixed fibers in a soft resin plate layer; carrying out laminating treatment on the mixed fiber layer; and finally, stacking the layers in sequence, hot-pressing and pressing to obtain the sound insulation cotton, and sealing the edge by using an anti-aging film. According to the designed method for improving the shore hardness of the sound insulation cotton, double-layer woven metal nets are additionally arranged in the sound insulation cotton, the resin plate and the elastic layer are arranged between the metal nets, and the sound insulation effect and shore hardness of the sound insulation cotton are improved through the metal nets, the resin plates and the elastic layers; and the shore hardness and the sound insulation effect are further enhanced through the mixed fibers on the surface layer, so that the shore degree and the sound insulation effect of the sound insulation cotton are integrally improved, and the sound insulation cotton has good market potential value and application prospect and has practicability and creativity.

Owner:HUBEI TIANYUN NOISE REDUCTION & ANTIVIBRATION NEW MATERIAL

Rubber base plate for subway rail transit as well as composition and preparation method of rubber base plate

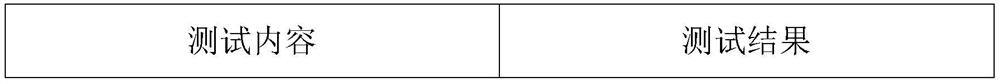

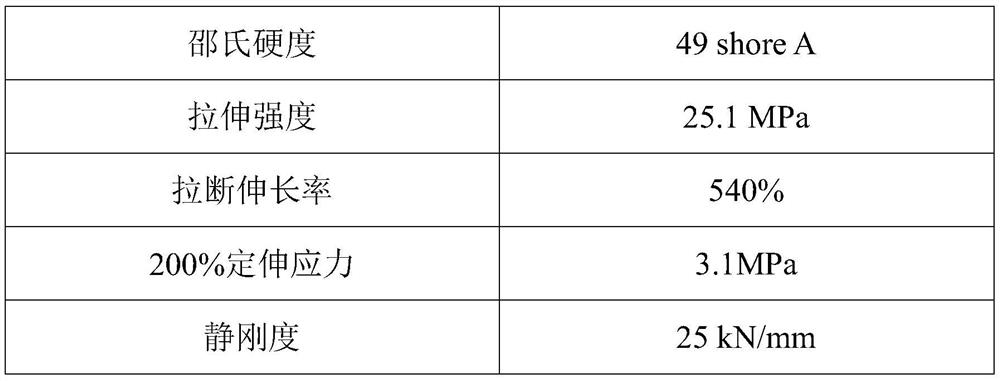

ActiveCN112961410AHigh Shore hardnessHigh tensile strengthFlat articlesRubber materialPolymer science

The invention provides a rubber base plate for subway rail transit as well as a composition and a preparation method of the rubber base plate, and belongs to the field of rubber materials. The composition for the rubber base plate for the subway rail transit comprises 100 parts of matrix rubber, 20-100 parts of a filling agent, 0-5 parts of a silane coupling agent, 5-35 parts of an active agent, 0-15 parts of a plasticizer, 3-10 parts of a pigment, 1-3 parts of an anti-aging agent, 3-15 parts of a functional auxiliary agent, 0.3-2.5 parts of a vulcanizing agent and 2-8 parts of a vulcanization accelerator. Compared with a traditional black rubber base plate, the rubber base plate for subway rail transit prepared from the composition has the advantages that the shore hardness, tensile strength and other mechanical properties are remarkably improved, and the rubber base plate is suitable for various current rail transit road sections.

Owner:ZHEJIANG TIANTIE IND

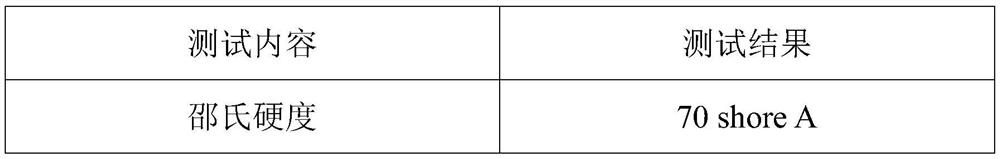

Specific acidic plastic plate for photovoltaic diamond wire cutting and preparation method thereof

The invention discloses a specific acidic plastic plate for photovoltaic diamond wire cutting and a preparation method thereof. The plastic plate comprises the following raw materials: matrix resin and an auxiliary agent, and is prepared through the steps of raw material mixing, granulation, extrusion molding, polishing, cutting, detection, packaging and the like. The plastic plate prepared by theinvention meets the requirement of a large circulation system of a diamond wire cutting process, is easy to recycle, can be recycled, and meets the environmental protection requirement of continuousutilization; in a silicon rod cutting process using the diamond wire, impurities adhering to the diamond wire are reduced, the abrasion probability of the diamond wire is reduced, the cost is saved, the superior product rate of silicon wafers is increased, and therefore the production efficiency is effectively improved. Compared with the prior art, the prepared plastic plate is better in shore hardness and equivalent in pH value and conductivity, and has remarkable progress.

Owner:广西拓源新材料有限公司

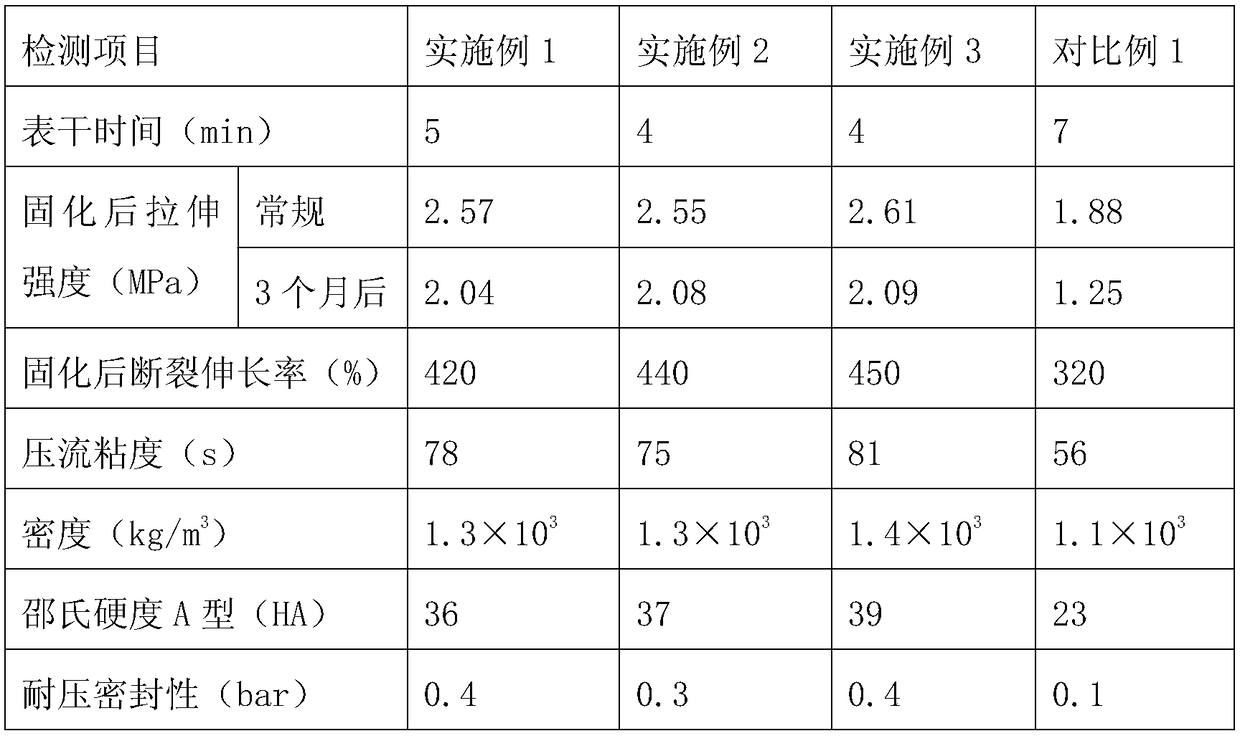

High-strength sealant for electronic product and preparation method of high-strength sealant

InactiveCN109337589AGood flow viscosityGood Shore hardnessNon-macromolecular adhesive additivesOrganic non-macromolecular adhesiveEpoxyPhosphate

The invention provides a high-strength sealant for an electronic product and a preparation method of the high-strength sealant. The high-strength sealant is prepared from the following components: waste rubber, epoxy resin, acrylic acids, monolauryl phosphate, dioctyl phthalate, polyether polyol, nano calcium carbonate, titanium dioxide, epoxidized soybean oil, modified lignin, isocyanate, a silane coupling agent, an amine catalyst and an antioxidant. The sealant prepared according to the preparation method provided by the invention has good pressure flow viscosity, Shore hardness, elongationat break and tensile strength, is high in pressure tightness, firm in adhesion, long in service life, excellent in performance and wide in application range; the preparation method is simple, and theraw material cost is relatively low; therefore, the high-strength sealant is suitable for industrial large-scale production.

Owner:HEFEI TONGYOU ELECTRONICS TECH CO LTD

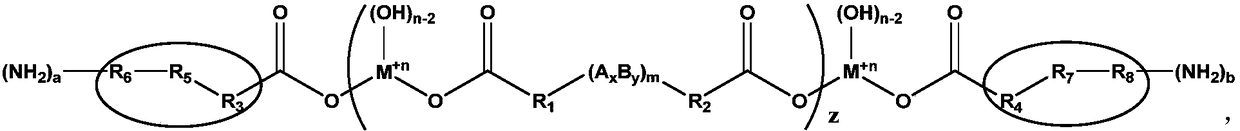

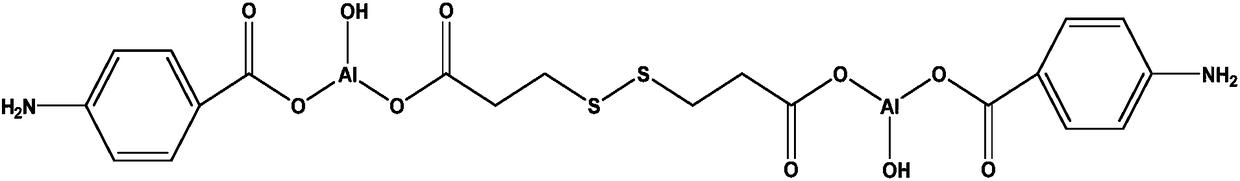

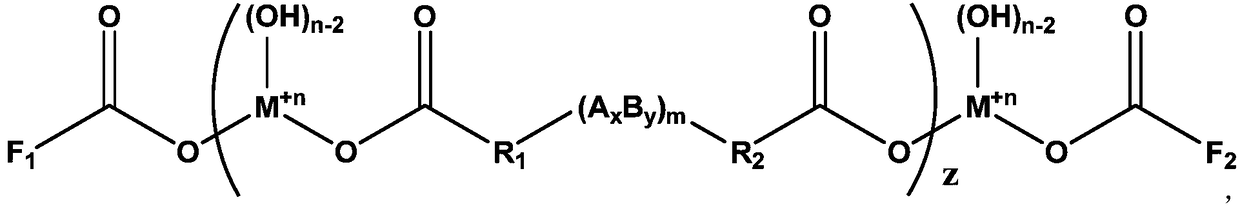

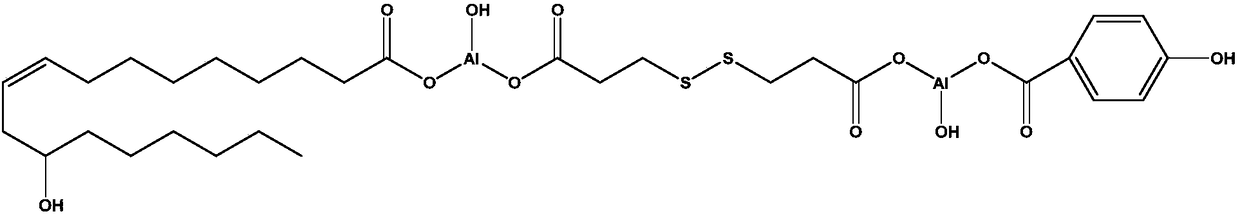

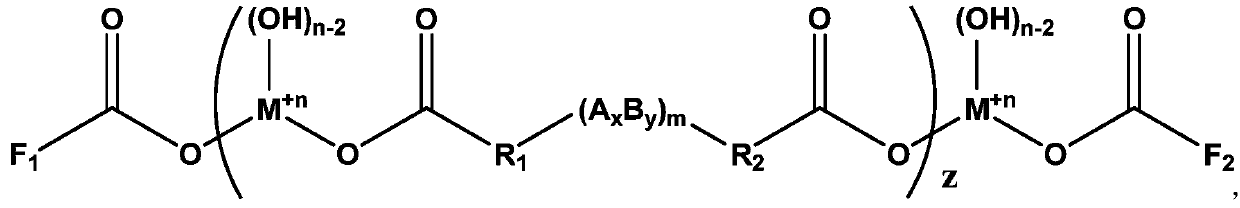

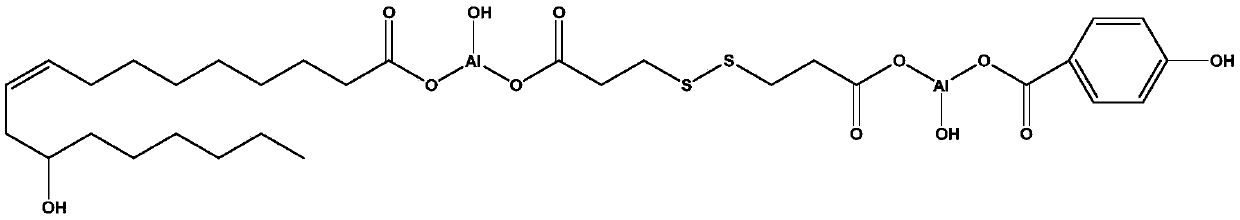

Amino compound rubber additive as well as preparation and application thereof

ActiveCN108218905ASimple preparation processComponent raw materials are readily availableOrganic compound preparationGroup 3/13 element organic compoundsChemical LinkageAlicyclic Hydrocarbons

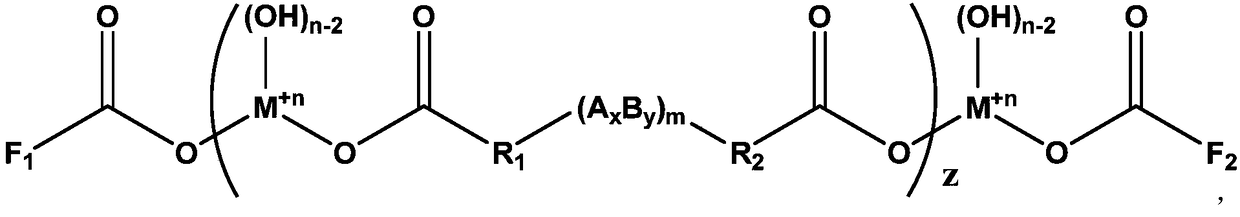

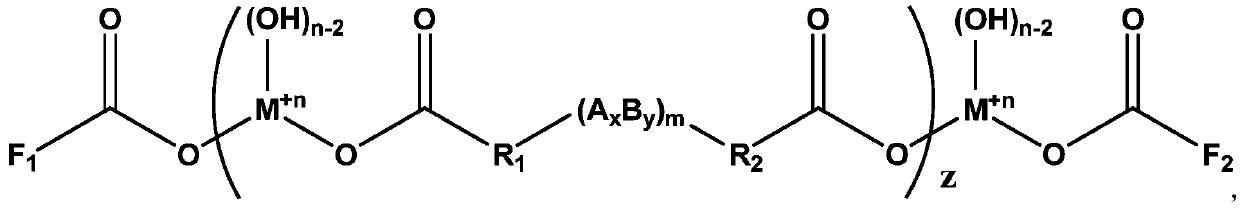

The invention relates to an amino compound rubber additive as well as preparation and application thereof. The chemical structural formula of the additive is shown in the description, wherein n is anoxidation state of a metal element M; n=2, 3 or 4; A is one of oxygen, sulfur, carbon, nitrogen, phosphorus or silicon; x is more than or equal to 0 and less than or equal to 10; B is one of oxygen, sulfur, carbon, nitrogen, phosphorus or silicon; y is more than or equal to 0 and less than or equal to 10; (AxBy)m indicates that atoms are connected by chemical bonds; x and y are not 0 at the same time; m is more than or equal to 0 and less than or equal to 10; z is less than or equal to 50; R1 and R2 are fatty chains, alicyclic hydrocarbons or aromatic compounds with 0 to 50 carbon atoms; R3, R4, R6 and R8 are saturated or unsaturated fatty chains or alicyclic hydrocarbons with 0 to 50 carbon atoms; R5 and R7 are aromatic ring compounds; a and b are positive integers. The prepared additivecan be applied to rubber, and improves the hardness, wet skid resistance, dynamic-mechanical properties and tensile property of the rubber; a part of rubber compositions containing the additive have higher Shore hardness, elongation at break, wet skid resistance and dynamic elastic modulus.

Owner:TONGJI UNIV

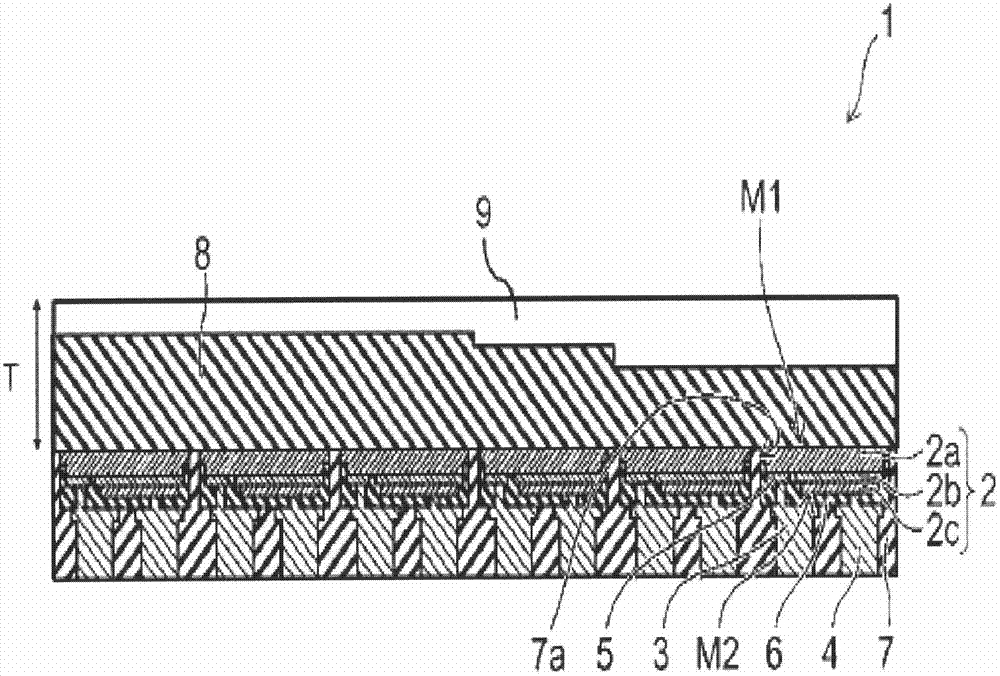

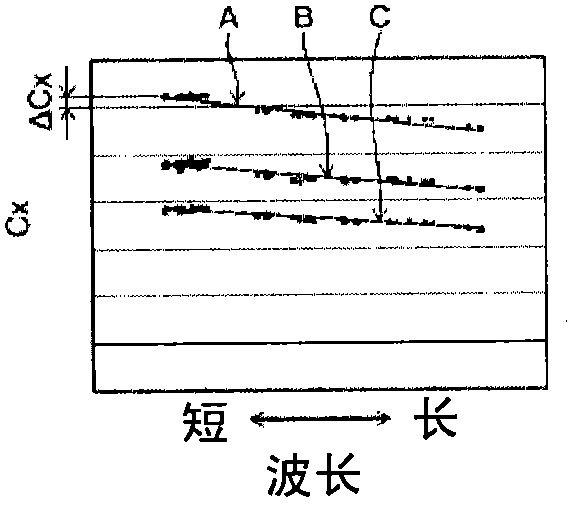

Semiconductor light-emitting device and manufacturing method of the same

InactiveCN103035826AHigh modulus of elasticityHigh Shore hardnessSolid-state devicesSemiconductor devicesPhosphorLight emitting device

According to one embodiment, a light-emitting unit (2) which emits light, a wavelength conversion unit (8) which includes a phosphor and which is provided on a main surface of the light-emitting unit, and a transparent resin (9) which is provided on top of the wavelength conversion unit, are prepared. The transparent resin has a greater modulus of elasticity and / or a higher Shore hardness than the wavelength conversion unit (8).

Owner:KK TOSHIBA

Dental thermo-forming material

InactiveUS20120024299A1High Shore hardnessDifferent Shore hardnessLayered productsLip/mouth protectorsShoreEngineering

A thermo-forming foil or plate made of a thermoplastic elastomer for the production of dental splints. To integrate reinforcements for various applications into individual areas of the splint, the thermo-forming foil or plate is made of segments comprised of different materials and lying side by side in the plane of the thermo-forming foil or plate, these materials having different Shore hardness.

Owner:SCHEU DENTAL

Fluororesin composition and its molded product

Disclosed are injection-moldable fluororesin compositions of melt flowable fluororesin and mesoporous silica. The fluororesin compositions are melt flowable and have a melt flow rate of from 2 to 60 g / 10 min. The mesoporous silica has an average pore diameter of from 2 to 50 nm, and the pores of the mesoporous silica are filled with the melt flowable fluororesin. The fluororesin compositions have excellent melt moldability for manufacturing molded products from the fluororesin composition that demonstrate high hardness.

Owner:THE CHEMOURS CO FC LLC +1

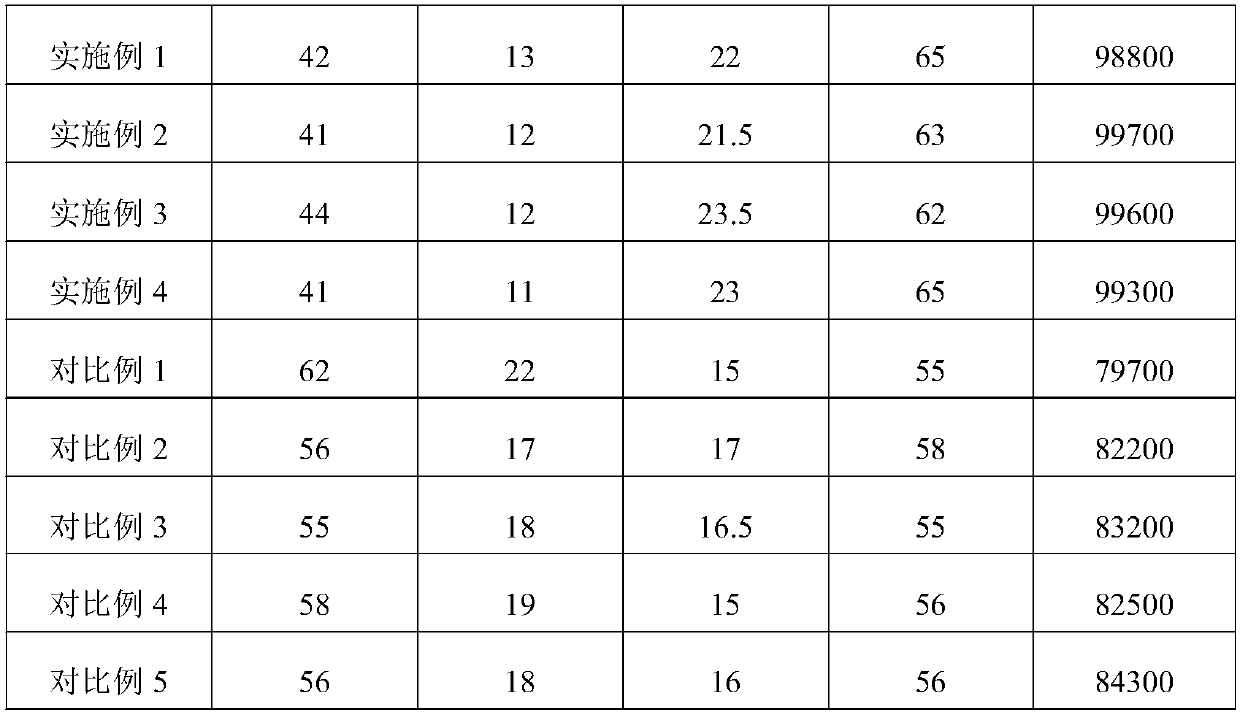

Modified kaolin waterproof sealant and preparation method thereof

InactiveCN107936893AHigh strengthHigh hardnessNon-macromolecular adhesive additivesWax adhesivesAntioxidantDrying time

The invention discloses a modified kaolin waterproof sealant and a preparation method thereof. The modified kaolin waterproof sealant is prepared from the following raw materials in parts by weight: 22 to 36 parts of hydrophobic modified kaolin, 11 to 16 parts of bisphenol A epoxy resin, 8 to 13 parts of palmitic acid, 9 to 14 parts of EPA, 11 to 15 parts of lignoceric acid, 7 to 13 parts of silicone oil, 10 to 15 parts of glass fiber, 4 to 7 parts of porcelain powder, 5 to 9 parts of asbestos powder, 3 to 7 parts of quartz powder, 4 to 17 parts of mica powder, 1.5 to 5 parts of plasticizers,1 to 4 parts of curing agents, 1.2 to 3 parts of anti-freeze agents, 2 to 4.5 parts of antioxidants, 1 to 3 parts of coupling agents and 1.5 to 3 parts of accelerants. The modified kaolin waterproof sealant is prepared through the steps of pulping, crosslinking reaction, precipitation, vacuum reaction, stirring, cooling, packaging, sealing and the like. The modified kaolin waterproof sealant has the advantages that the surface drying time and the gelation time are short; the strength and the hardness are high; the viscosity is high.

Owner:广西汇智生产力促进中心有限公司

Crosslinkable compositions based on organosilicon compounds

InactiveCN1891775AEasy to prepareImprove machinabilityFibre treatmentWoven fabricsParticulatesSilanes

The present invention relates to compositions comprising: (A, B) organosilicon compounds crosslinked by addition reactions; (D) at least one ovoid to spherical solid and at least one lamellar solid; and other at least An ingredient (E) selected from the group consisting of: (1) hydrocarbon compounds having at least 8 carbon atoms, wherein the hydrocarbon backbone can optionally be replaced by heteroatoms whose free valences are completely replaced by hydrogen or monovalent hydrocarbon groups Saturated; (2) silanes of the general formula (RO) 4-nSiXn, wherein the definitions of R and X are as described in the specification; (3) organic zirconium compounds or organic titanium compounds of the general formula (RO) 4-nMXn, wherein R , X and M are as defined in the description; optional (4) organic solvent, wherein the friction coefficient of the vulcanized rubber is lower than that of the formulation without particles (D).

Owner:WACKER CHEM GMBH

Abrasion-resistance high-strength shoe material and preparing method thereof

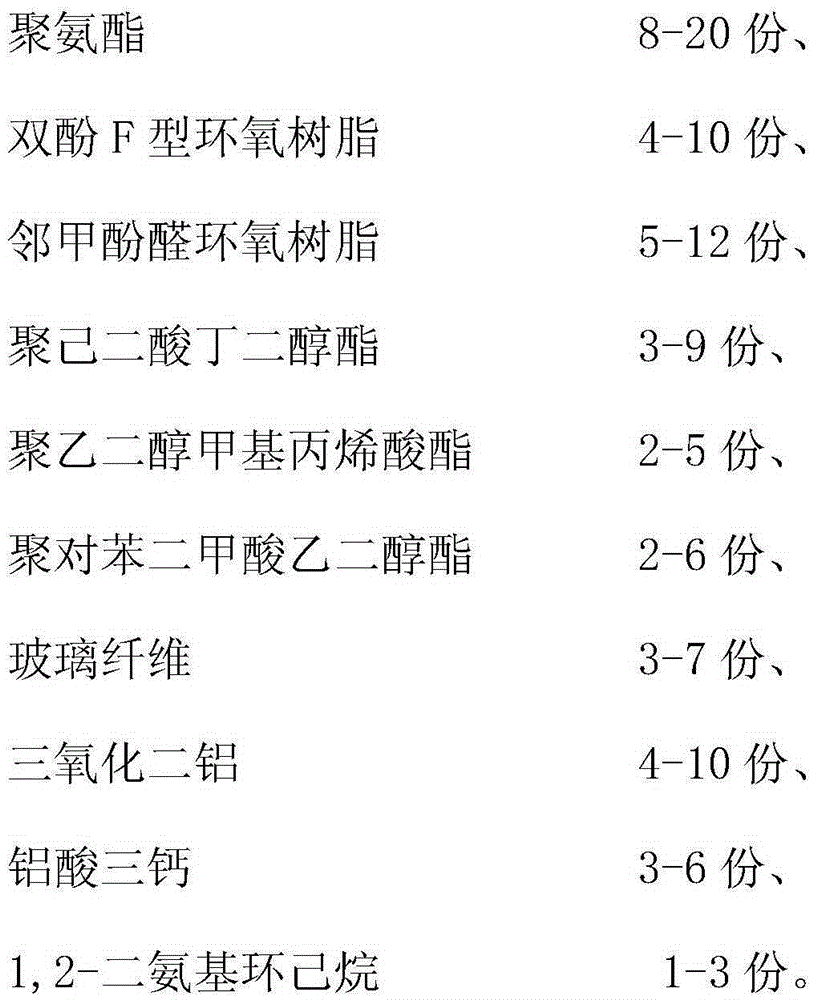

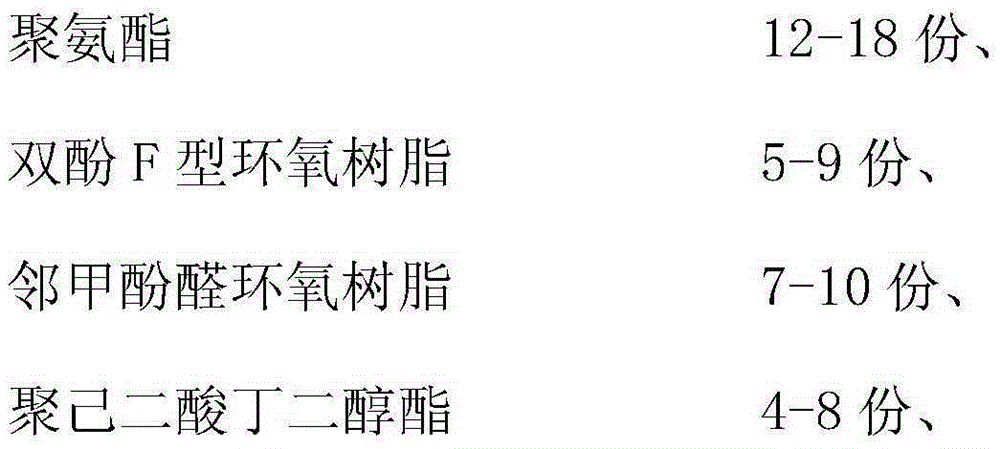

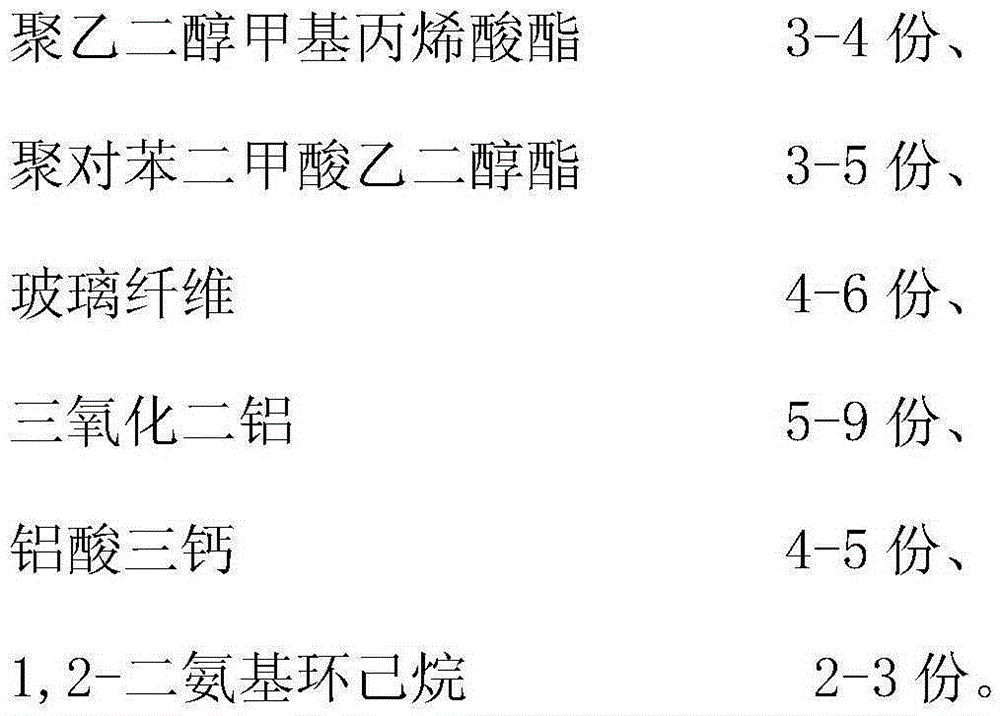

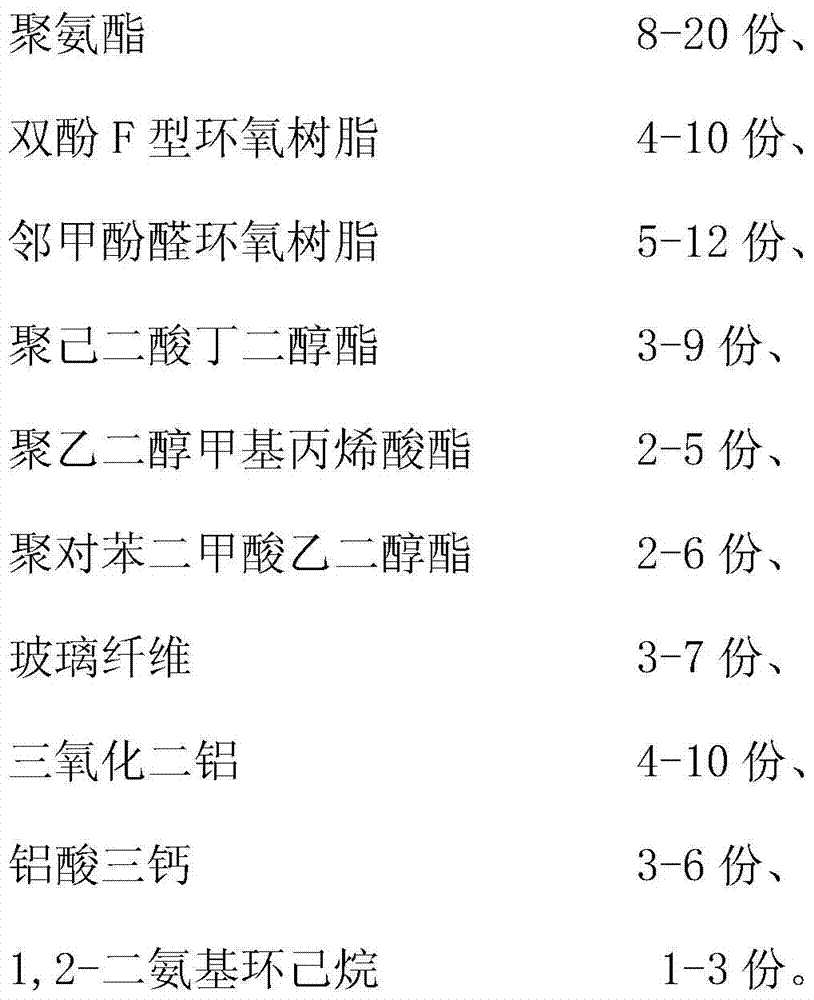

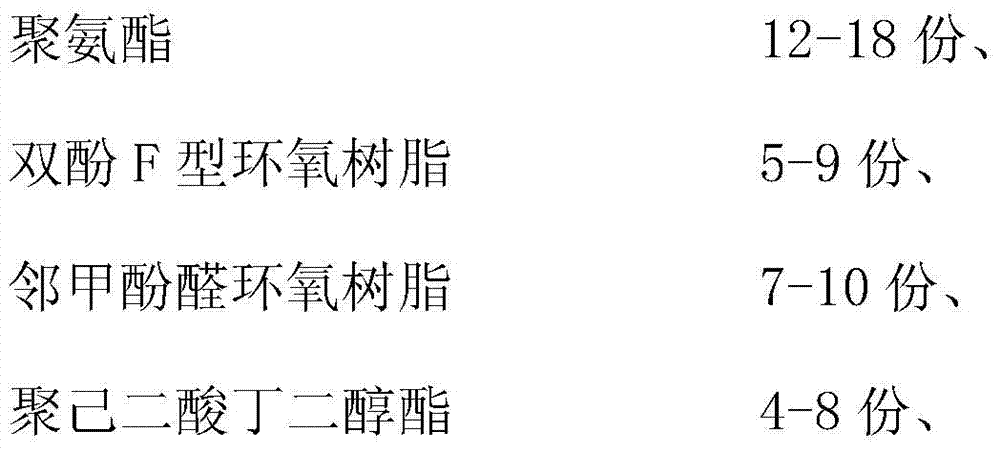

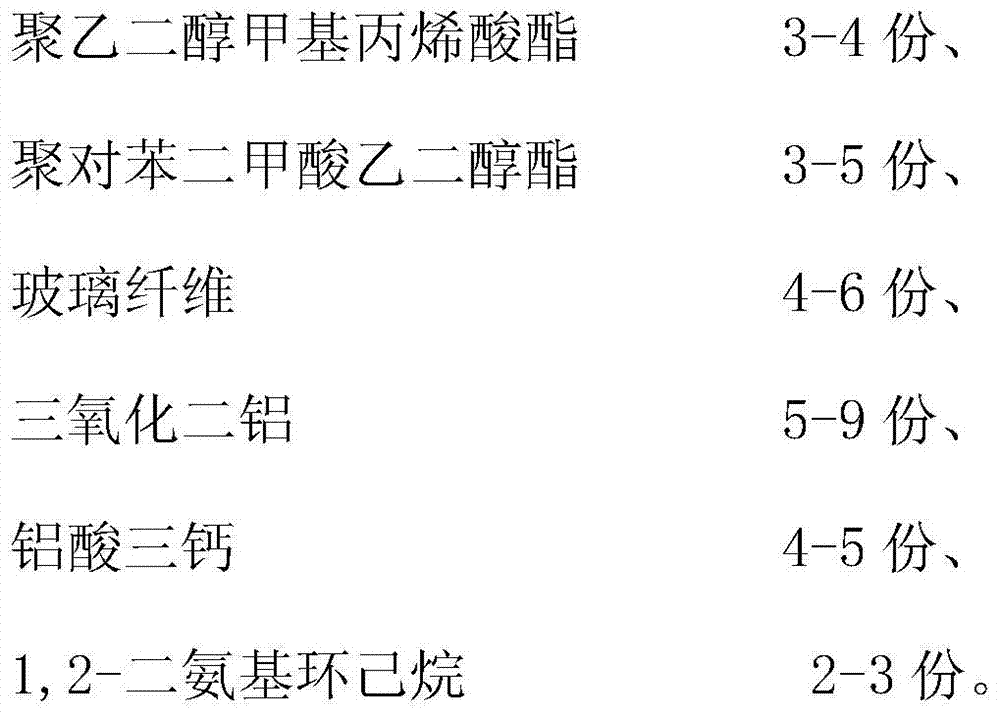

The invention discloses an abrasion-resistance high-strength shoe material and a preparing method thereof. The shoe material is prepared from, 8-20 parts of polyurethane, 4-10 parts of bisphenol-F epoxy resin, 5-12 parts of o-cresol formaldehyde epoxy resin, 3-9 parts of poly ethylene succinate, 2-5 parts of polyethylene glycol methacrylate, 2-6 parts of polyethylene terephthalate, 3-7 parts of glass fibers, 4-10 parts of aluminum oxide and 3-6 parts of tricalcium aluminate. The preparing method comprises the following steps that firstly, aluminum oxide and tricalcium aluminate are ground through an ultrafine grinder; secondly, polyurethane, bisphenol-F epoxy resin, o-cresol formaldehyde epoxy resin, poly ethylene succinate, polyethylene glycol methacrylate, polyethylene terephthalate and the glass fibers are stirred; thirdly, aluminum oxide and tricalcium aluminate are added and stirred; fourthly, finally, 1,2-diaminocyctohexane is added and stirred, and then the shoe material is sheeted. The shoe material is resistant to abrasion and high in strength.

Owner:吴江市阳光塑胶制品有限公司

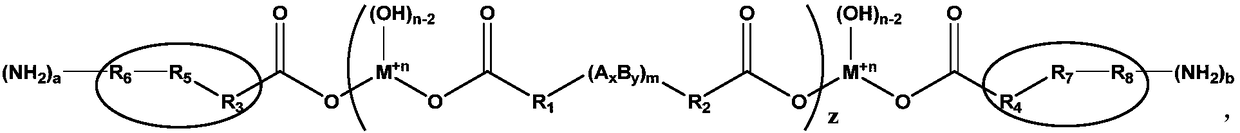

Additive with functional group double-terminated structure as well as preparation and application of additive

ActiveCN108250484ASimple preparation processComponent raw materials are readily availableCosmetic preparationsNon-macromolecular adhesive additivesChemical structureAlicyclic Hydrocarbons

The invention relates to an additive with a functional group double-terminated structure as well as a preparation and application of the additive. The additive has a chemical structural formula as shown in the specification, wherein n is an oxidation state of metal M and is equal to 2, 3 or 4; A is one of oxygen, sulfur, carbon, nitrogen, phosphorus and silicon, and x is larger than or equal to 0and is smaller than or equal to 10; B is one of oxygen, sulfur, carbon, nitrogen, phosphorus and silicon, and y is larger than or equal to 0 and is smaller than or equal to 10; (AxBy)m shows that atoms are connected by chemical bonds, and x and y are not zero at the same time; m is larger than or equal to 0 and is smaller than or equal to 10; z is smaller than or equal to 50; R1 and R2 are aliphatic chains, alicyclic hydrocarbons or aromatic compounds of which the carbon atom numbers do not exceed 50; and F1 and F2 are organic groups with functional groups and have different structures. The additive prepared by using the preparation method can be introduced to rubber compositions so as to comprehensively improve the hardness, wet skid resistance, dynamic mechanical property and tensile property of rubber, and even, in parts of exemplary embodiments, the rubber compositions containing the additive with the functional group double-terminated structure have improved Shore hardness, elongation at break and wet skid resistance.

Owner:TONGJI UNIV

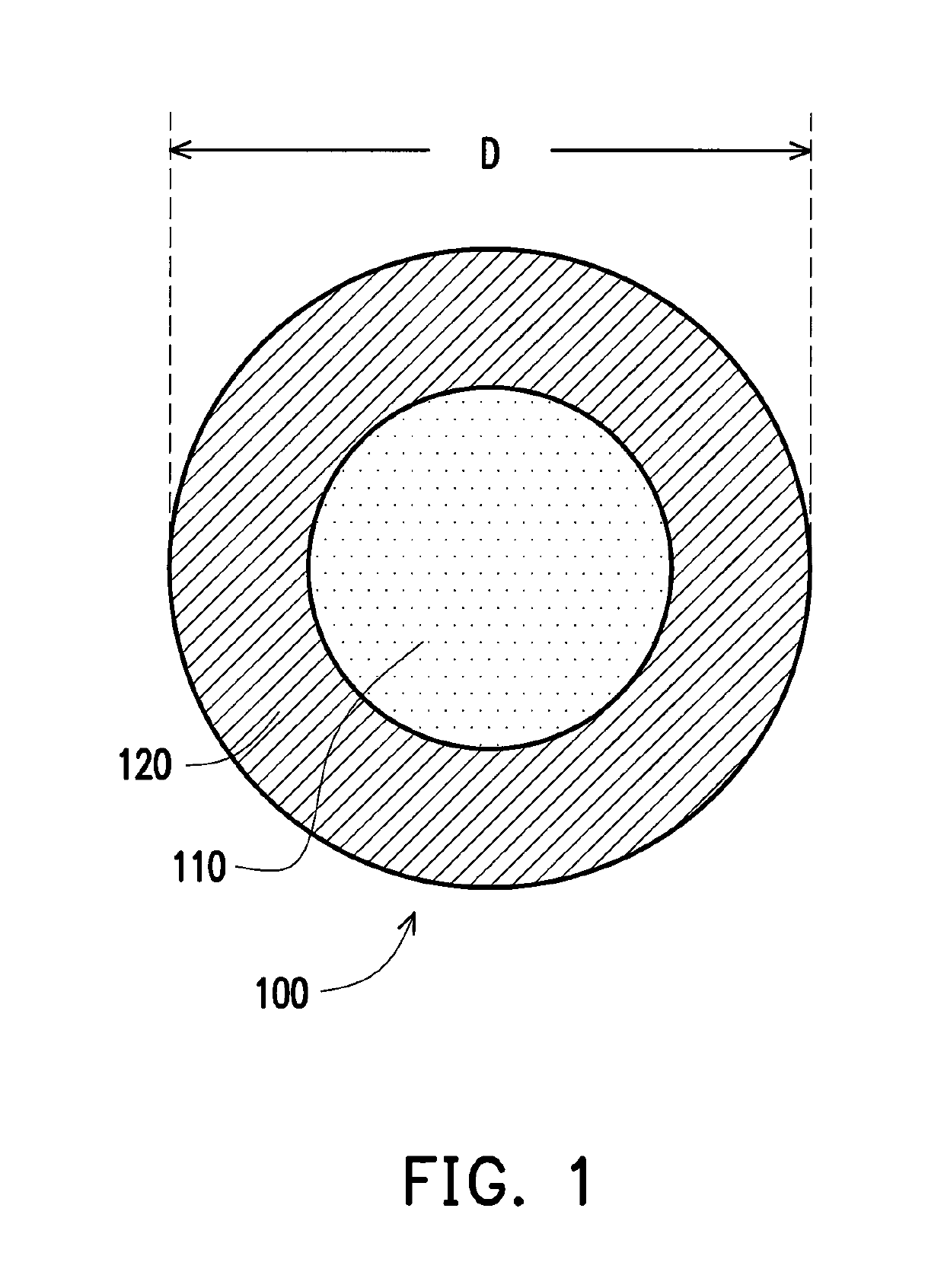

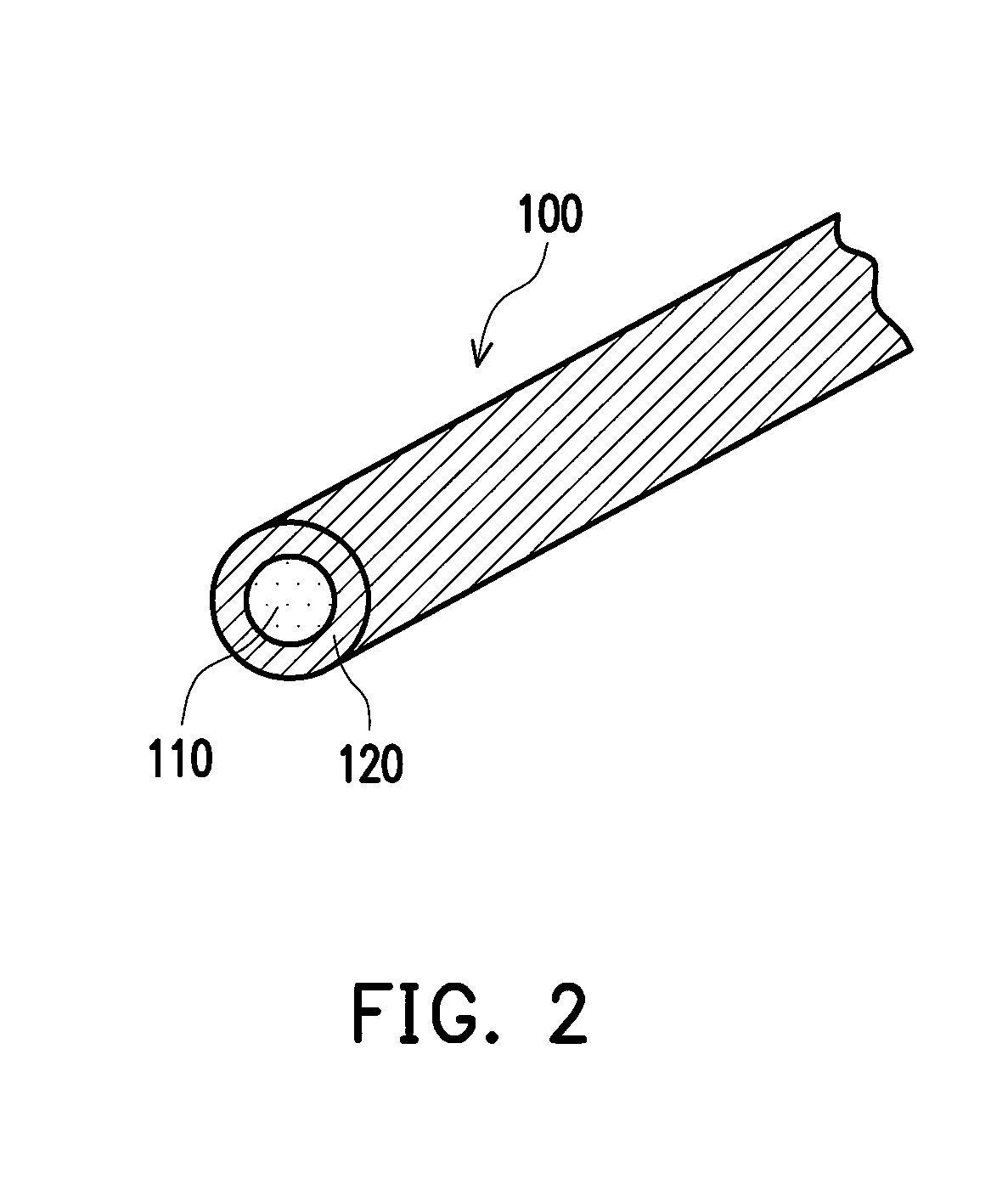

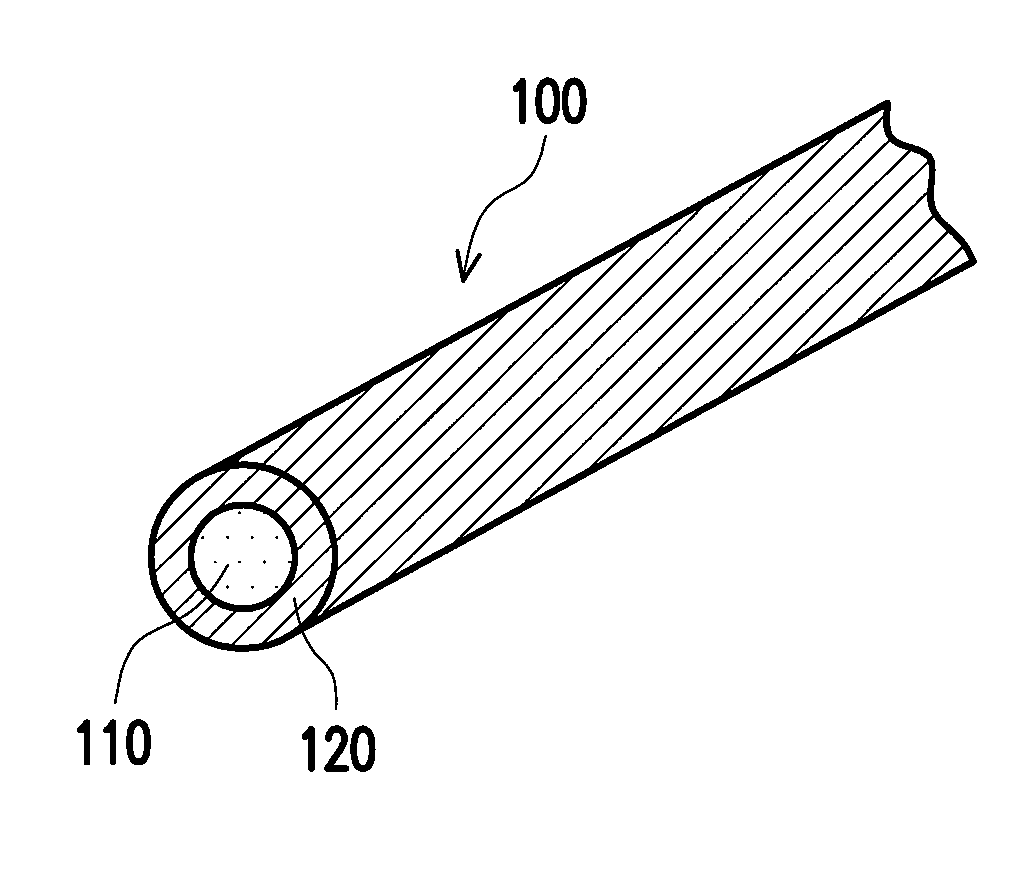

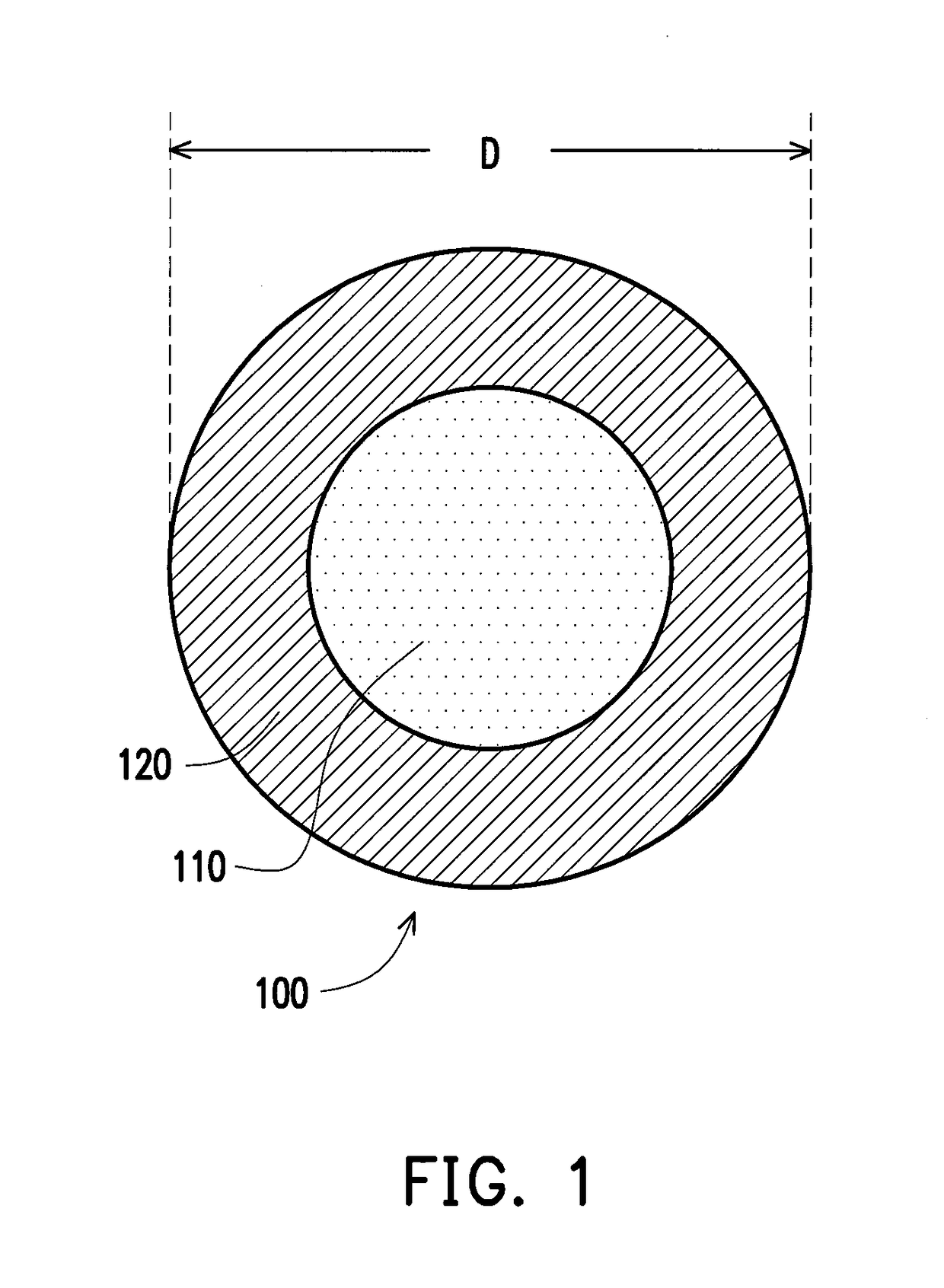

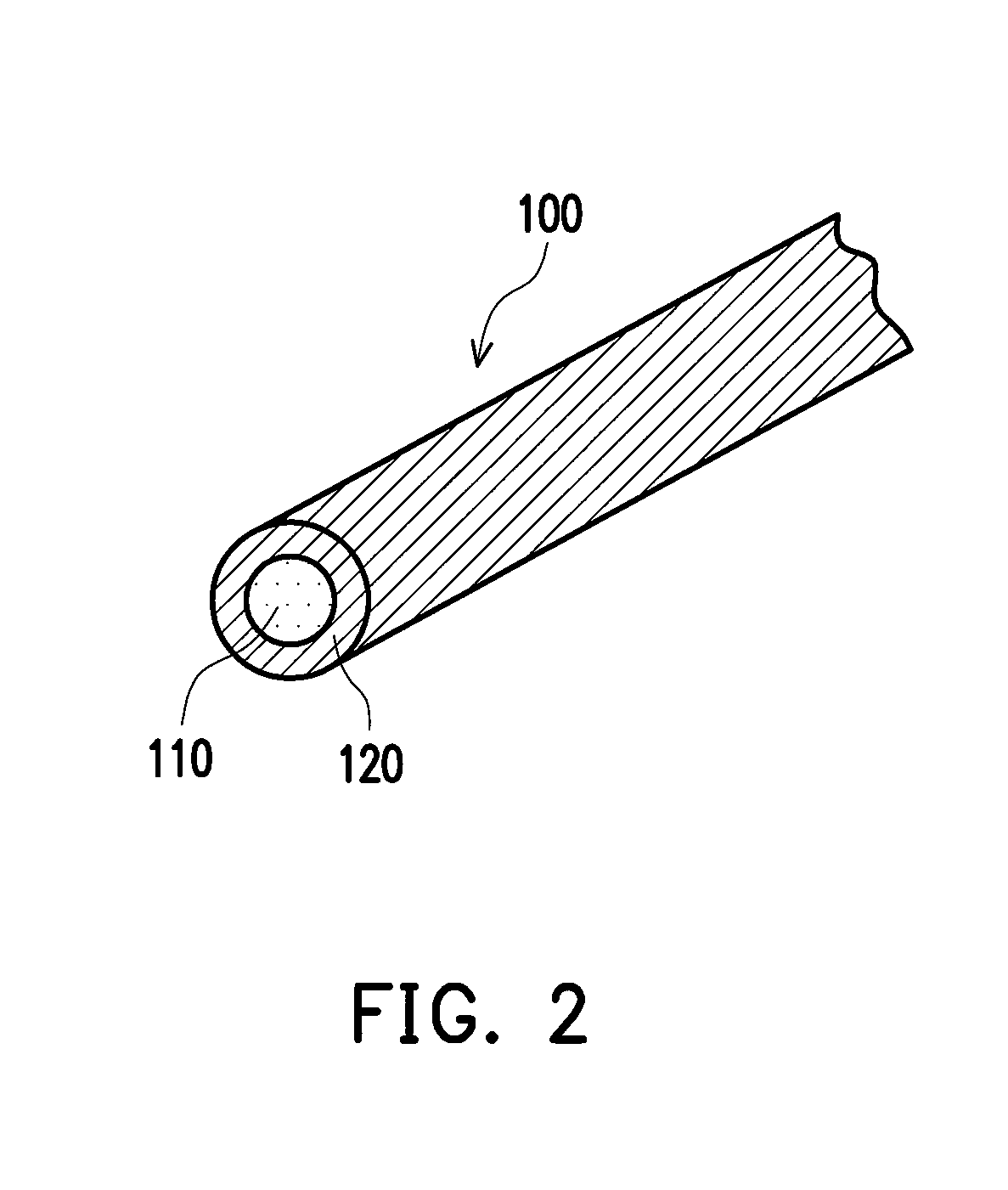

Printing material for three-dimensional printing apparatus

InactiveUS10428164B2Smooth trafficHigh Shore hardnessAdditive manufacturing apparatus3D object support structuresHardnessShore

A printing material for a three-dimensional (3D) printing apparatus is provided. The printing material includes a core and a shell covering the core, wherein the Shore hardness of the core is A45-A90, the Shore hardness of the shell is D40-D85, the Shore hardness of the shell is higher than the Shore hardness of the core, the volume percentage of the shell is 10% to 30%, and the volume percentage of the core is 70% to 90%. Since the printing material has a specific structure, feed abnormality during the printing material passing through a narrow inlet hole and guide tube may be prevented in the use of low-hardness material as the core.

Owner:XYZPRINTING +1

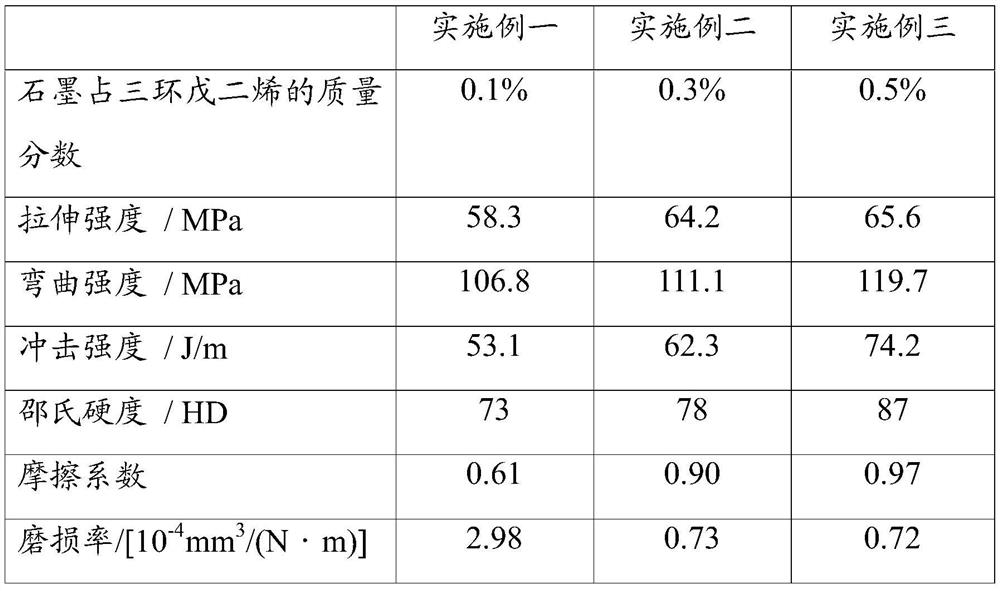

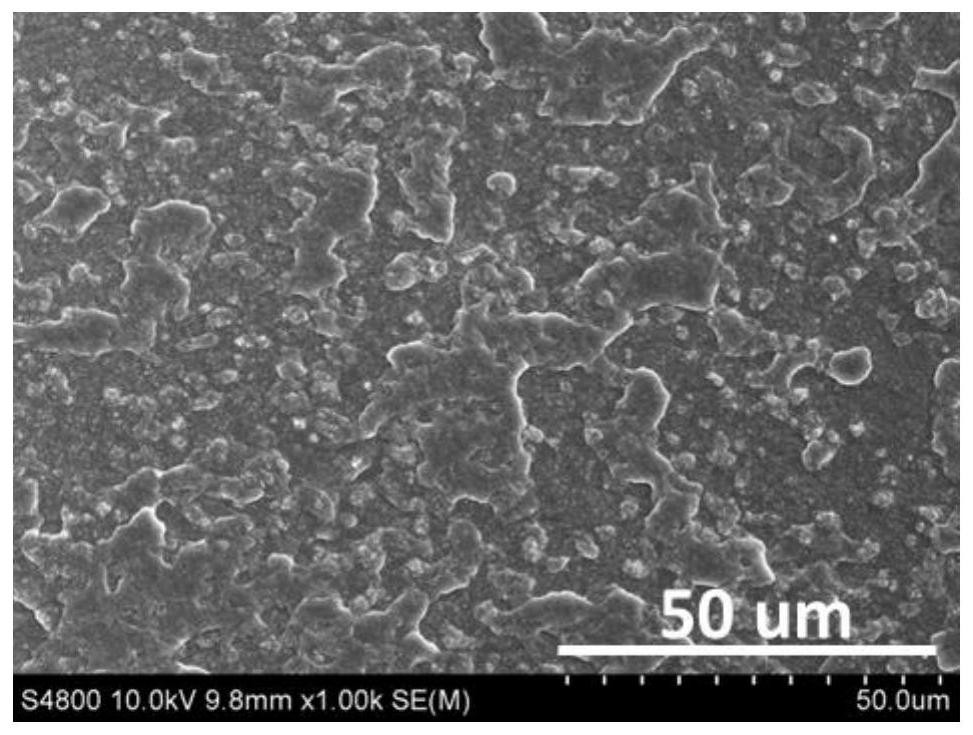

Graphite modified polytricyclopentadiene PTCPD composite material and preparation method thereof

The invention discloses a graphite modified polytricyclopentadiene PTCPD composite material and a preparation method thereof. The composite material comprises graphite and tricyclopentadiene, and the graphite and the tricyclopentadiene are polymerized into a polytricyclopentadiene / graphite composite material under the action of a catalyst. The graphite is expanded graphite or graphite oxide modified by a surfactant or a coupling agent. The graphite modified polytricyclopentadiene composite material provided by the invention solves the technical problems of insufficient rigidity and poor heat resistance of a polydicyclopentadiene material in the prior art, and through graphite modification, the composite material has better heat resistance, the surface of the material is not easy to thermally deform, and the wear resistance is enhanced. The graphite modified polytricyclopentadiene composite material also has the excellent characteristics of acid resistance, alkali resistance, brine corrosion resistance, halogen gas corrosion resistance, fatigue resistance and the like, and is wide in application range.

Owner:ZHEJIANG HUTONG MOULD CO LTD

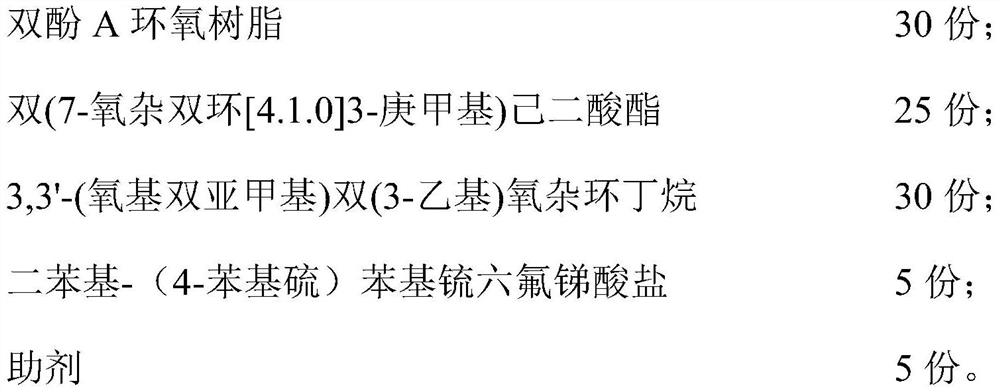

Ultraviolet curing epoxy adhesive as well as preparation method and application thereof

ActiveCN112680159AStrong adhesion at room temperatureHigh Shore hardnessEpoxy resin adhesivesHigh concentrationPolymer science

The invention provides an ultraviolet curing epoxy adhesive and a preparation method and application thereof. The ultraviolet curing epoxy adhesive is prepared from the following raw materials in parts by weight: 30-60 parts of basic epoxy resin, 20-30 parts of toughened epoxy resin, 10-30 parts of an epoxy diluent, 1-5 parts of a photoinitiator and 1-10 parts of an auxiliary agent, wherein the basic epoxy resin, the toughened epoxy resin and the epoxy diluent all have symmetrical molecular structures. By adding the basic epoxy resin, the toughening epoxy resin and the epoxy diluent which are symmetrical in molecular structure, the prepared ultraviolet curing epoxy adhesive can resist high-concentration acid-base etching liquid, is easy to trim and tear when used as UV glass edge sealing adhesive, is free of solvent addition in the preparation process, and meets the environment-friendly requirement; and the viscosity of the adhesive can be adjusted according to actual requirements.

Owner:上海仁速新材料有限公司

Method for producing wood plastic wallboard

The invention discloses a method for producing a wood plastic wallboard. The method comprises the following steps: drying calcium sulfate to remove water, mixing calcium sulfate, an aluminate couplingagent, stearic acid and oxidized polyethlene wax in a high / low-speed mixing machine, crushing the plant fiber, grinding the plant fiber to obtain plant fiber powder, drying the plant fiber powder, during the process, and adding a modifier and oxidized polyethlene wax to obtain modified plant fiber; uniformly stirring waste plastic, modified plant fiber, a modified functional material and other auxiliary agents at the temperature of 60 DEG C, 85 DEG C, 100 DEG C and 125 DEG C in order and mixing the materials to obtain a mixture, and processing the mixture to obtain the wallboard. The functional material is synthesized, during the process, a coupling agent, stearic acid and oxidized polyethlene wax can be fusion, the materials are fully attached on the surface of calcium sulfate for modification, the material, the plastic, wood powder and other chemical raw materials are subjected to a full chemical reaction while mixing, and the impact strength resistance and shore hardness can be increased for the product.

Owner:湖南博川生物质新材料科技有限公司

Method for preparing white ceramic by use of natural zeolite

The invention relates to a method for preparing white ceramic by the use of natural zeolite. The method for preparing white ceramic by the use of natural zeolite is characterized by comprising the following steps of: 1) crushing the natural zeolite, and grinding to 100 meshes to obtain a zeolite powder; 2) preparing a modified zeolite powder by adopting one of the following two method: (1) mixingthe zeolite powder, sodium chloride, sodium hydroxide and water according to the mass ratio of 10: (0.6-10): (2-10): 30-45, heating and stirring for 12 hours, staying for 48 hours, washing by the useof water, and drying to obtain the modified zeolite powder; (2) mixing the zeolite powder, a waste alkali liquor in caustic soda industry and water according to the mass ratio of (10-15): (6-12): 45,heating and stirring for 12 hours, staying for 48 hours, washing by the use of water, and drying to obtain the modified zeolite powder; 3) mixing the zeolite powder and the modified zeolite powder with the modified zeolite powder being 10-90 wt% of the zeolite powder and the modified zeolite powder, tabletting for moulding, and sintering at high temperature to obtain the white ceramic. By the adoption of the method, the white ceramic has high R457 white value, high acid fastness, high alkali fastness and high Shore hardness.

Owner:CHINA UNIV OF GEOSCIENCES (WUHAN)

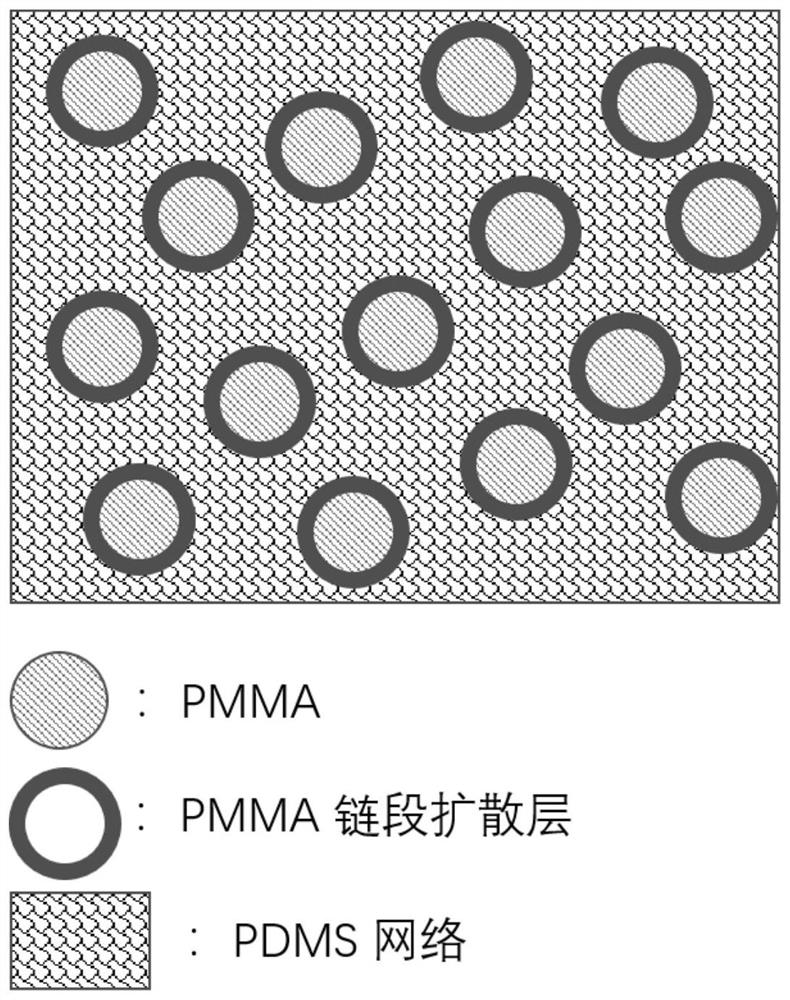

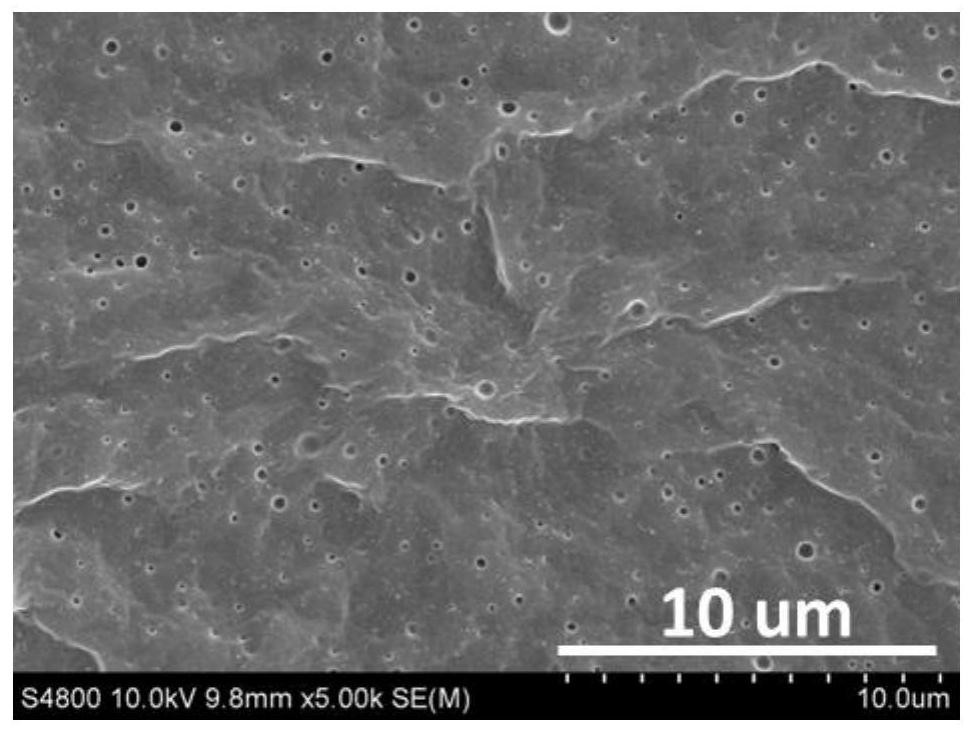

Blended polymer material of polyalkyl methacrylate and silicone rubber as well as preparation method and application thereof

The invention provides a blended polymer material of polyalkyl methacrylate and silicone rubber as well as a preparation method and application thereof. Under the compatibilization and dispersion effects of a compatibilizer, an in-situ polymerization method is adopted, polyalkyl methacrylate is used as a dispersion phase to be dispersed in a continuous phase of a polysiloxane network to form an island structure, and hundred-nanometer-scale polymethacrylate reinforced particles are generated in situ in an organosilicon polymer. The preparation of the polyalkyl methacrylate and silicone rubber blended polymer material with comprehensive excellent performance is realized, the bonding performance and hardness of the silicone rubber are remarkably improved, excellent mechanical strength and good breaking elongation are achieved, the damping temperature range is widened, and the preparation cost of the silicone rubber is greatly reduced. And the high-temperature storability and the high-temperature usability are relatively stable.

Owner:INST OF CHEM CHINESE ACAD OF SCI

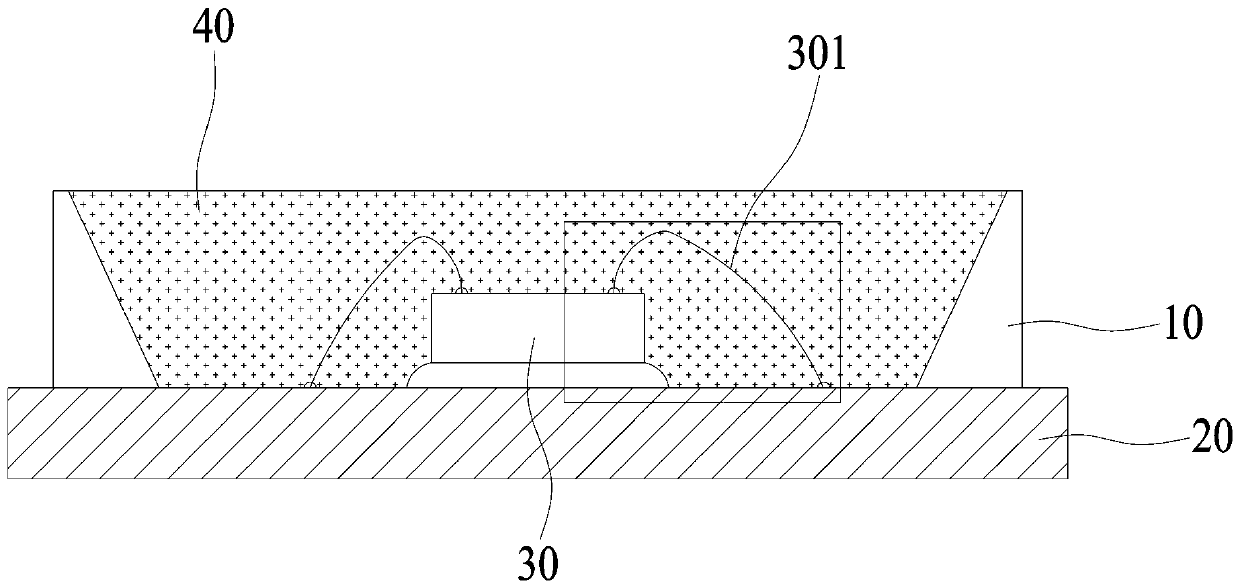

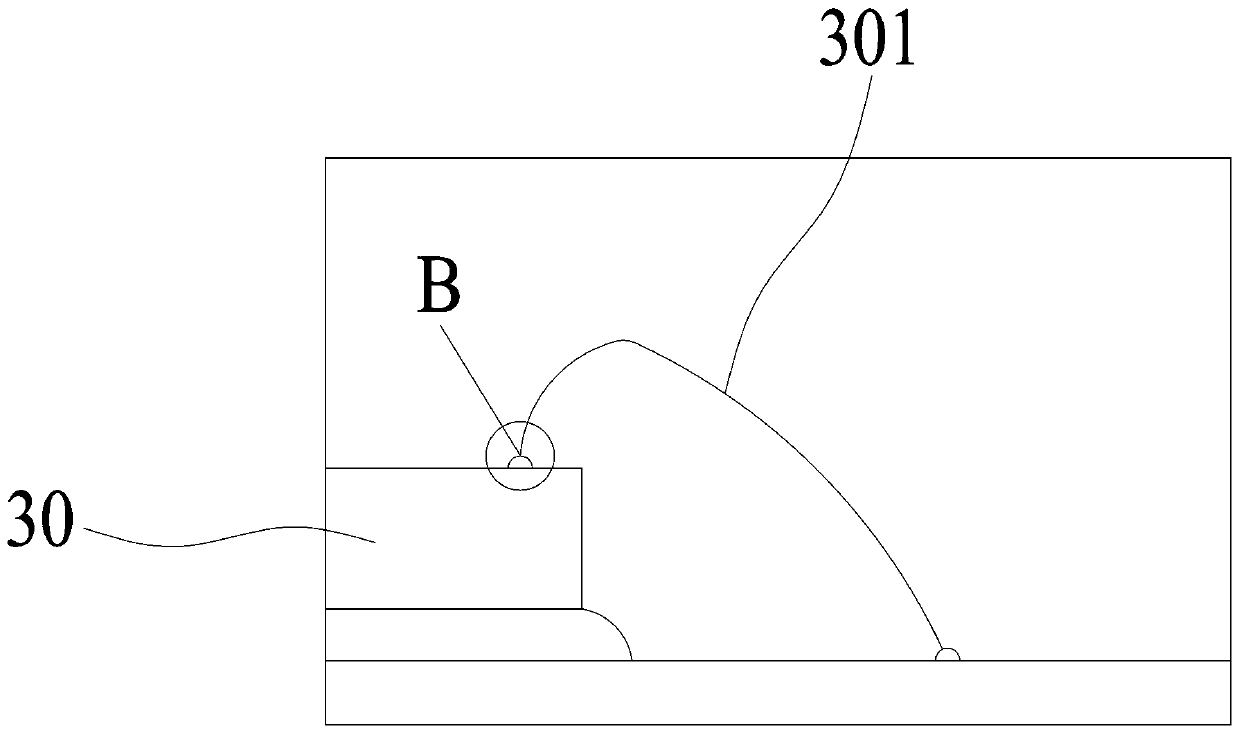

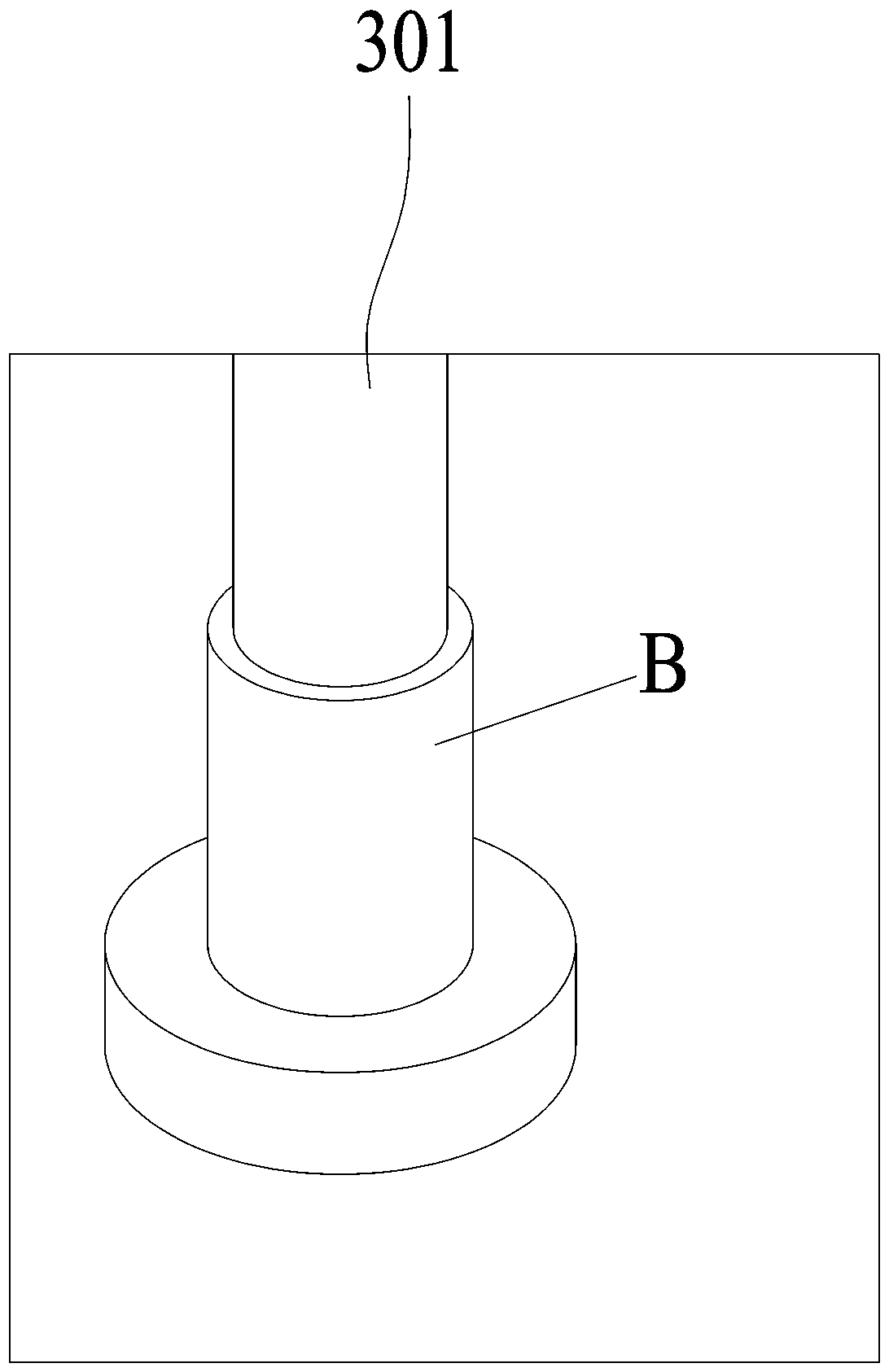

LED chip package support and production method thereof

PendingCN109888077AHigh Shore hardnessSmall Shore hardnessSemiconductor devicesVulcanizationSurface mounting

The invention discloses an LED chip package support. The LED chip package support comprises a base, a reflection cup, an LED chip, a first silica gel layer and a second silica gel layer, wherein the reflection cup is arranged on the base, a lower surface of the LED chip is surface-mounted onto the base and is arranged at the bottom of the reflection cup, a positive electrode and a negative electrode of the LED chip are connected with a pin by a connection wire, the first silica gel layer is arranged at the bottom of the reflection cup, the second silica gel layer is arranged on the first silica gel layer, the second silica gel layer covers an upper surface of the LED chip, the shore hardness of the first silica gel layer is larger than the shore hardness of the second silica gel layer, andfluorescent powder is mixed in the second silica gel layer. The invention also discloses a production method of the LED chip package support. By the LED chip package support, the vulcanization-prevention performance of an SMD LED is improved, the cold and hot impact resistant performance of the SMD LED is also improved, and meanwhile, the production cost is reduced.

Owner:福建省信达光电科技有限公司

Wear-resistant high-strength shoe material and preparation method thereof

The invention discloses a wear-resistant and high-strength shoe material and a preparation method thereof. The shoe material includes 8-20 parts of polyurethane, 4-10 parts of bisphenol F epoxy resin, and 5-20 parts of o-cresol aldehyde epoxy resin. 12 parts, 3-9 parts of polybutylene adipate, 2-5 parts of polyethylene glycol methacrylate, 2-6 parts of polyethylene terephthalate, 3-7 parts of glass fiber, 4-10 parts of aluminum oxide, 3-6 parts of tricalcium aluminate; the preparation method comprises the following steps: (1) pulverizing aluminum oxide and tricalcium silicate with an ultrafine pulverizer; (2) Polyurethane, bisphenol F type epoxy resin, o-cresol novolac epoxy resin, polybutylene adipate, polyethylene glycol methacrylate, polyethylene terephthalate, glass fiber stirring; ( 3) Then add aluminum oxide and tricalcium aluminate and stir; (4) finally add 1,2-diaminocyclohexane and stir, and then press the shoe material into tablets to become a wear-resistant and high-strength shoe material.

Owner:吴江市阳光塑胶制品有限公司

Fluororesin composition and its molded product

Disclosed are injection-moldable fluororesin compositions of melt flowable fluororesin and mesoporous silica. The fluororesin compositions are melt flowable and have a melt flow rate of from 2 to 60 g / 10 min. The mesoporous silica has an average pore diameter of from 2 to 50 nm, and the pores of the mesoporous silica are filled with the melt flowable fluororesin. The fluororesin compositions have excellent melt moldability for manufacturing molded products from the fluororesin composition that demonstrate high hardness.

Owner:THE CHEMOURS CO FC LLC +1

A kind of functional group double-capped additive and its preparation and application

ActiveCN108250484BSimple preparation processComponent raw materials are readily availableCosmetic preparationsNon-macromolecular adhesive additivesChemical structureAlicyclic Hydrocarbons

The invention relates to an additive with a functional group double-terminated structure as well as a preparation and application of the additive. The additive has a chemical structural formula as shown in the specification, wherein n is an oxidation state of metal M and is equal to 2, 3 or 4; A is one of oxygen, sulfur, carbon, nitrogen, phosphorus and silicon, and x is larger than or equal to 0and is smaller than or equal to 10; B is one of oxygen, sulfur, carbon, nitrogen, phosphorus and silicon, and y is larger than or equal to 0 and is smaller than or equal to 10; (AxBy)m shows that atoms are connected by chemical bonds, and x and y are not zero at the same time; m is larger than or equal to 0 and is smaller than or equal to 10; z is smaller than or equal to 50; R1 and R2 are aliphatic chains, alicyclic hydrocarbons or aromatic compounds of which the carbon atom numbers do not exceed 50; and F1 and F2 are organic groups with functional groups and have different structures. The additive prepared by using the preparation method can be introduced to rubber compositions so as to comprehensively improve the hardness, wet skid resistance, dynamic mechanical property and tensile property of rubber, and even, in parts of exemplary embodiments, the rubber compositions containing the additive with the functional group double-terminated structure have improved Shore hardness, elongation at break and wet skid resistance.

Owner:TONGJI UNIV

Printing material for three-dimensional printing apparatus

ActiveUS20180229441A1Smooth trafficHigh Shore hardnessAdditive manufacturing apparatus3D object support structuresHardnessShore

A printing material for a three-dimensional (3D) printing apparatus is provided. The printing material includes a core and a shell covering the core, wherein the Shore hardness of the core is A45-A90, the Shore hardness of the shell is D40-D85, the Shore hardness of the shell is higher than the Shore hardness of the core, the volume percentage of the shell is 10% to 30%, and the volume percentage of the core is 70% to 90%. Since the printing material has a specific structure, feed abnormality during the printing material passing through a narrow inlet hole and guide tube may be prevented in the use of low-hardness material as the core.

Owner:XYZPRINTING +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com