Photosensitive resin composition for photocuring rapid prototyping and preparation method and application of photosensitive resin composition

A photosensitive resin and composition technology, applied in the field of 3D printing, can solve the problems of low photosensitive resin molding conversion rate, inability to effectively improve the conversion rate, poor dimensional accuracy, etc., and achieve good surface accuracy and dimensional stability, Shore hardness The effect of high, high glass transition temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0061] Among them, in the preparation process of modified nano-spherical silica 1#, hyperbranched epoxy resin HyPerE102 was selected; in the preparation process of modified nano-spherical silica 2#, hyperbranched epoxy resin HyPerDE1050 was selected.

[0062] The photosensitive resin compositions of the various embodiments of the present invention and comparative examples are prepared through the following processes: cationic photocurable components, free radical photocurable components, cationic photoinitiators, free radical photoinitiators, modified nano-spherical silica , antioxidant and thermal cationic initiator were stirred and mixed for 60 minutes at 25°C to obtain the product.

[0063] The photosensitive resin compositions of each embodiment and comparative example were subjected to critical exposure energy, curing depth, laser filling scanning speed, flexural strength, flexural modulus, tensile strength, elongation at break, Shore hardness, surface resistance and notch...

Embodiment 1~7 and comparative example 1~6

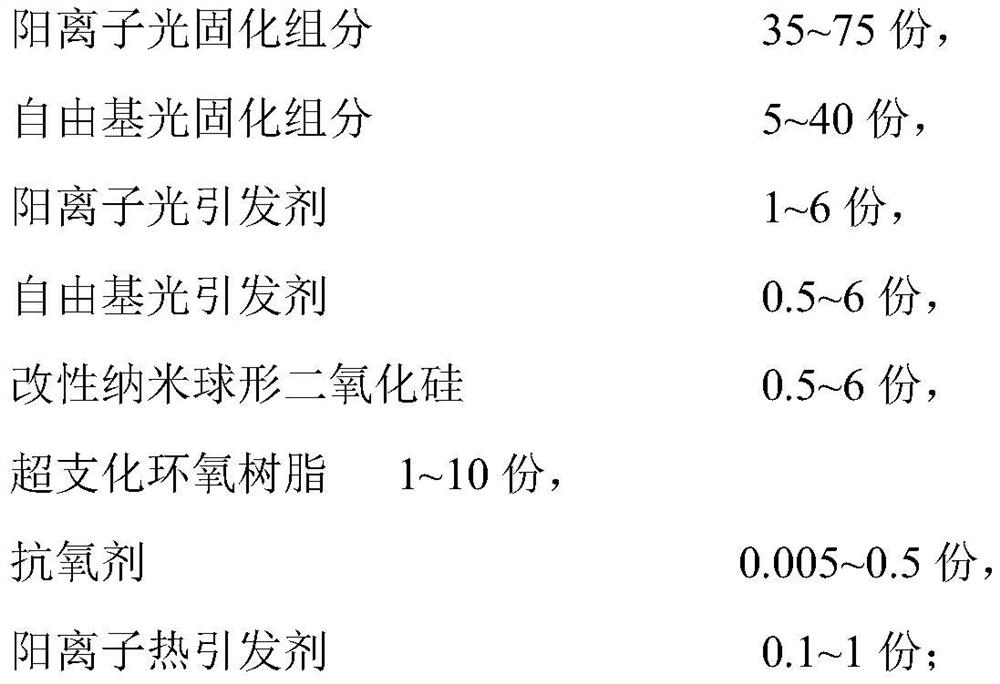

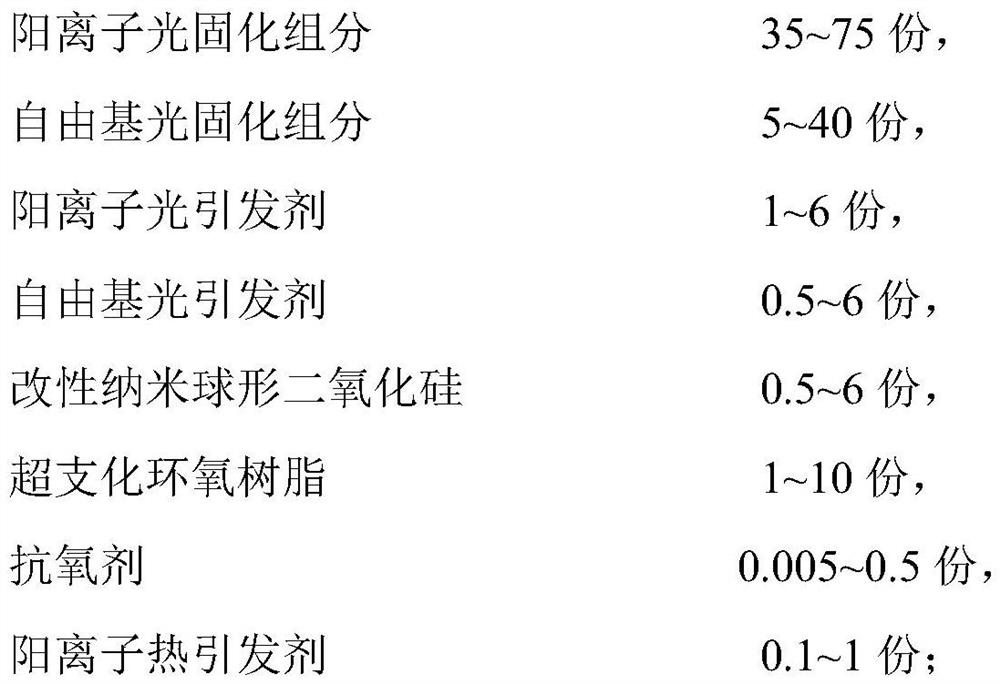

[0074] The present embodiment and comparative example provide a series of photosensitive resin compositions, the formulations of which are shown in Table 1 below.

[0075] The formula (part) of table 2 embodiment 1~7 and comparative example 1~5

[0076]

[0077]

[0078] In addition, a commercially available white material was used as Comparative Example 6.

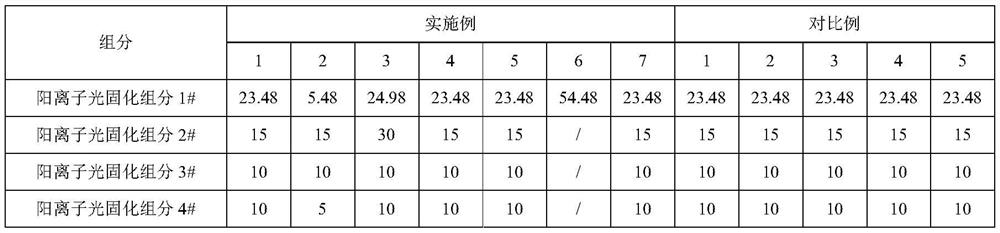

[0079] The properties of the photosensitive resin compositions of the examples and comparative examples were measured according to the above-mentioned method, and the results are shown in Table 2.

[0080] The performance test result of each embodiment and comparative example of table 2

[0081]

[0082] It can be seen from Table 2 that the addition of surface-treated modified nano-spherical silica to the photosensitive resin composition provided by each embodiment of the present invention has basically no effect on the viscosity of the resin system, and there is no delamination and settlement after being placed...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com