High-power LED packaging adhesive composition

A technology of LED packaging and composition, applied in the direction of non-polymer adhesive additives, adhesives, adhesive additives, etc., can solve the problems of UV resistance and heat aging performance that are difficult to meet the requirements of new LED packaging, and achieve good test results , Shore hardness effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

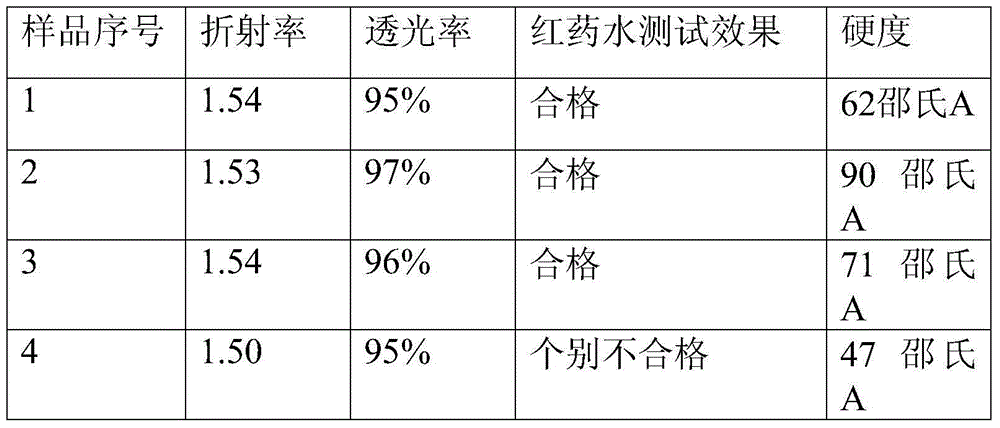

Examples

Embodiment 1

[0024] Component A: 50 parts of phenyl vinyl silicone resin with 3% vinyl molar content and 50% phenyl molar content, transparent liquid MDQ resin with 40% phenyl molar content and 1% vinyl molar content 4 0.003 parts of platinum catalyst; the viscosity of phenylvinyl silicone resin at 25°C is 10Pa·s, the platinum catalyst is a compound of dimethyldiphenyldivinyldisiloxane and platinum, dimethyl diphenyl The refractive index of the phenyl divinyl disiloxane is greater than 1.5, and the content of platinum in the platinum catalyst is 2 wt%.

[0025] Component B: 25 parts of high phenyl hydrogen-containing silicone oil with a phenyl molar content of 35%, a refractive index greater than 1.50, and a viscosity of less than 1Pa·s, and 3 parts of a tackifier; the tackifier is selected from vinyltrimethoxysilane coupling Agent V06;

[0026] The ratio of vinyl content in components A and B is 1.1.

[0027] Mix components A and B evenly, completely defoam, place in an oven at 80°C for...

Embodiment 2

[0029] Component A: 70 parts of phenyl vinyl silicone resin with 5% vinyl molar content and 30% phenyl molar content, transparent liquid MDQ resin with 50% phenyl molar content and 2% vinyl molar content 2 0.005 parts of platinum catalyst; the viscosity of phenylvinyl silicone resin at 25°C is 15Pa·s, the platinum catalyst is a compound of methylphenylvinylsiloxane and platinum, methylphenylvinylsiloxane The refractive index of the alkane is greater than 1.5, and the content of platinum in the platinum catalyst is 2 wt%.

[0030] Component B: 25 parts of high phenyl hydrogen-containing silicone resin with a phenyl molar content of 45%, a refractive index greater than 1.50, and a viscosity of less than 1Pa·s, and 2 parts of a tackifier; the tackifier is vinyltrimethoxysilane Joint agent A-171; high phenyl hydrogen-containing silicone resin is a compound of phenyl hydrogen-containing silicone resin with different viscosities.

[0031] The ratio of vinyl content in components A ...

Embodiment 3

[0034] Component A: 90 parts of phenyl vinyl silicone resin with a vinyl molar content of 2% and a phenyl molar content of 38%, a transparent liquid MDQ resin with a phenyl molar content of more than 30% and a vinyl molar content of 4% 2 0.005 parts of platinum catalyst; the viscosity of phenylvinyl silicone resin at 25°C is 20Pa·s, the platinum catalyst is a compound of methylphenylvinylsiloxane and platinum, methylphenylvinylsiloxane The refractive index of the alkane is greater than 1.5, and the content of platinum in the platinum catalyst is 2 wt%.

[0035] Component B: 40 parts of high phenyl hydrogen-containing silicone resin with a phenyl molar content of 45%, a refractive index greater than 1.50, and a viscosity of less than 1 Pa·s, and 3 parts of a tackifier; the tackifier is vinyltrimethoxysilane The mixture of the joint agent KBM-1003 and WD-21, the two are mixed at a mass ratio of 1:1; the high phenyl hydrogen-containing silicone resin is a compound of phenyl hydro...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Viscosity | aaaaa | aaaaa |

| Viscosity | aaaaa | aaaaa |

| Viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com