Modified kaolin waterproof sealant and preparation method thereof

A waterproof sealing, kaolin technology, applied in the direction of adhesives, epoxy resin glue, non-polymer adhesive additives, etc., to achieve the effect of improving industrial production efficiency, enhancing product performance, and being conducive to popularization and use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

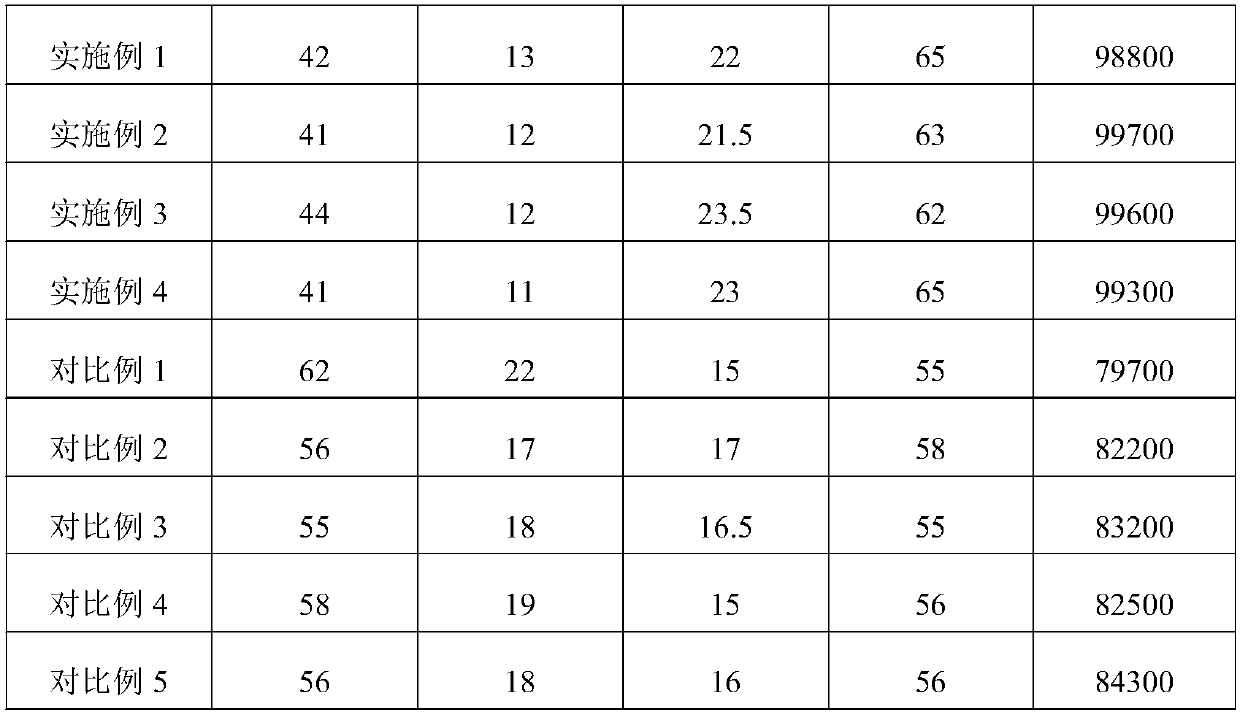

Embodiment 1

[0024] A modified kaolin waterproof sealant, in parts by weight, comprising the following raw materials: 22 parts of hydrophobic modified kaolin, 11 parts of bisphenol A epoxy resin, 8 parts of palmitic acid, 9 parts of EPA, and 11 parts of lignin acid , 7 parts of silicone oil, 10 parts of glass fiber, 4 parts of porcelain powder, 5 parts of asbestos powder, 3 parts of quartz powder, 4 parts of mica powder, 2 parts of phthalic acid, 1 part of chlorinated paraffin, 1 part of epoxy soybean oil, 1.5 parts of tributyl citrate, 2 parts of acetyl tributyl citrate, 2 parts of vinyltriamine, 1.5 parts of aminoethylpiperazine AE, 1 part of m-phenylenediamine m-PDA, 1 part of MPD, 1 part of methanol, 1 part of ethanol, 1 part of ethylene glycol, 1 part of water-soluble amide, 1.2 parts of calcium chloride, 2 parts of acetoacetamide, 1 part of flavonol, 2 parts of monohydroxybenzoic acid, 2 parts of gallic acid, 1 part of glyoxal , 1 part of glutaraldehyde, 1 part of water-soluble silan...

Embodiment 2

[0031] A modified kaolin waterproof sealant, a modified kaolin waterproof sealant, in parts by weight, comprising the following raw materials: 32 parts of hydrophobic modified kaolin, 14 parts of bisphenol A epoxy resin, 9 parts of palmitic acid , 10 parts of EPA, 12 parts of lignin acid, 12 parts of silicone oil, 12 parts of glass fiber, 5 parts of porcelain powder, 8 parts of asbestos powder, 6 parts of quartz powder, 6 parts of mica powder, 3 parts of phthalic acid, 2 parts of chlorinated paraffin 1.5 parts of epoxy soybean oil, 1 part of vinyltriamine, 1.5 parts of aminoethylpiperazine AE, 3 parts of m-phenylenediamine m-PDA, 3 parts of MPD, 1 part of water-soluble amide, 3 parts of calcium chloride, 2 parts of acetoacetamide, 1 part of flavonol, 2 parts of monohydroxybenzoic acid, 3 parts of water-soluble silane, 1 part of triethanolamine, 2 parts of p-chlorobenzoic acid.

[0032] The present invention also provides a kind of preparation method of modified kaolin waterpro...

Embodiment 3

[0038] A modified kaolin waterproof sealant, a modified kaolin waterproof sealant, in parts by weight, comprising the following raw materials: 36 parts of hydrophobic modified kaolin, 16 parts of bisphenol A epoxy resin, 13 parts of palmitic acid , 14 parts of EPA, 15 parts of lignin acid, 13 parts of silicone oil, 15 parts of glass fiber, 7 parts of porcelain powder, 9 parts of asbestos powder, 7 parts of quartz powder, 7 parts of mica powder, 1.5 parts of phthalic acid, 2 parts of chlorinated paraffin 1 part, 2 parts of epoxy soybean oil, 1.5 parts of tributyl citrate, 1.5 parts of acetyl tributyl citrate, 1 part of vinyltriamine, 2 parts of aminoethylpiperazine AE, 2 parts of m-phenylenediamine m-PDA, 4 parts of MPD, 2 parts of methanol, 3 parts of ethanol, 1.5 parts of ethylene glycol, 1 part of water-soluble amide, 3 parts of calcium chloride, 1 part of acetoacetamide, 1.5 parts of flavonol, 1.2 parts of monohydroxybenzoic acid, 2 parts of gallic acid 1.5 parts of glyoxal...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com