Ultraviolet curing epoxy adhesive as well as preparation method and application thereof

An epoxy adhesive, ultraviolet light technology, applied in the direction of epoxy resin glue, adhesive, adhesive type, etc., can solve the problem of strong acid and strong alkali resistance needs to be further improved

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

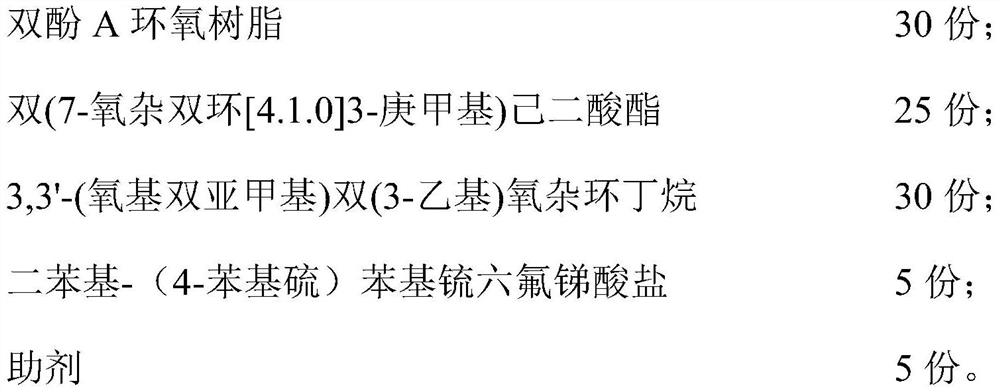

[0040] In this embodiment, a UV-curable epoxy adhesive is provided. The raw materials for the preparation of the UV-curable epoxy adhesive include the following components in parts by weight:

[0041]

[0042] Among them, the additives include defoamer (TEGO Airex 920), silane coupling agent (KH550), tackifier (AerosilR974) and color paste (Clariant red D3GD); based on the mass of additives as 100%, TEGO Airex The content of 920 is 10%, the content of KH550 is 50%, the content of Aerosil R974 is 35%, and the content of Clariant Red D3GD is 5%.

[0043] The preparation method comprises the following steps:

[0044] (1) 3,3'-(oxybismethylene)bis(3-ethyl)oxetane and diphenyl-(4-phenylthio)phenylsulfonium hexafluoroantimonate Mix at 1000rpm for 40min;

[0045] (2) Add bisphenol A epoxy resin and bis(7-oxabicyclo[4.1.0]3-heptylmethyl)adipate to the mixture of step (1), mix 35min with the rotating speed of 1300rpm;

[0046] (3) Add additives to the mixture in step (2), and sti...

Embodiment 2

[0048] In this embodiment, a UV-curable epoxy adhesive is provided. The raw materials for the preparation of the UV-curable epoxy adhesive include the following components in parts by weight:

[0049]

[0050] Wherein, the auxiliary agent includes defoamer (TEGO Airex 920), silane coupling agent (KH560), tackifier (AerosilR202) and color paste (light-easy chemical red F5RK); The content of TEGO Airex 920 is 50%, the content of KH560 is 10%, the content of Aerosil R202 is 39%, and the content of light-facilitable chemical red F5RK is 1%.

[0051] The preparation method comprises the following steps:

[0052] (1) Mix 1,4-butanediol diglycidyl ether with diphenyl-(4-phenylthio)phenylsulfonium hexafluoroantimonate at a speed of 1500rpm for 30min;

[0053] (2) Add bisphenol F epoxy resin and bis(7-oxabicyclo[4.1.0]3-heptylmethyl)adipate to the mixture of step (1), and mix for 25min at a speed of 1600rpm;

[0054] (3) Add additives to the mixture in step (2), and stir for 40 mi...

Embodiment 3

[0056] In this embodiment, a UV-curable epoxy adhesive is provided. The raw materials for the preparation of the UV-curable epoxy adhesive include the following components in parts by weight:

[0057]

[0058] Wherein, the auxiliary agent includes defoamer (Deqian 6800), silane coupling agent (KH550), tackifier (Aerosil R202) and color paste (Light Yi Chemical Red F5RK); the mass of the auxiliary agent is 100%, The content of Deqian 6800 is 25%, the content of KH550 is 25%, the content of Aerosil R202 is 47%, and the content of Guangyi Chemical Red F5RK is 3%.

[0059] The preparation method comprises the following steps:

[0060] (1) Neopentyl glycol diglycidyl ether was mixed with diphenyl-(4-phenylthio)phenylsulfonium hexafluoroantimonate at a speed of 2000rpm for 20min;

[0061] (2) Add diglycidyl tetrahydrophthalate and bis(7-oxabicyclo[4.1.0]3-heptylmethyl)adipate to the mixture of step (1), at a speed of 2000rpm Mix for 20 minutes;

[0062] (3) Add additives to th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Shore hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com