Magnesite briquetting process suitable for fused magnesite smelting

A technology of magnesite and fused magnesia, applied in the direction of magnesia, etc., can solve the problem that magnesite powder cannot be produced with fused magnesite, and achieve strong bonding at room temperature, enhanced controllability, and easy filling Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

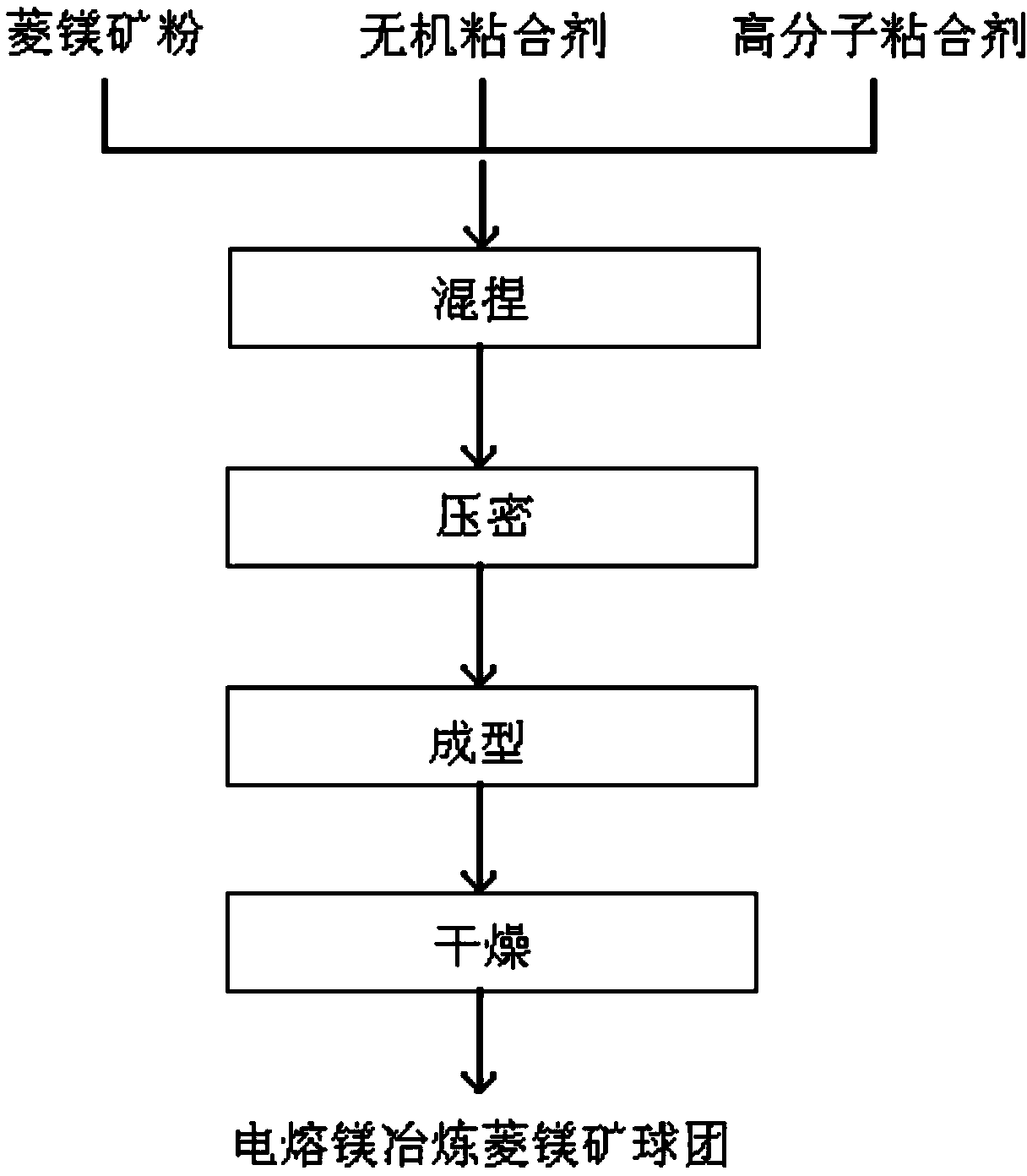

[0039] figure 1 It is the preparation method of magnesite pellets smelted by electro-fused magnesium in Example 1.

[0040] This embodiment discloses a magnesite pellet smelted by electro-fused magnesium. The magnesite pellet smelted by electro-fused magnesium is an ellipsoid, and the x, y, and z axes are 30 mm, 40 mm, and 50 mm respectively. Compared with the existing positive spherical shape, the electric fused magnesium smelting magnesite pellets of the present invention can reduce the fluidity of the pellets, enhance the controllability, and be easy to fill; can form a stable material layer above the molten pool and form Preheating belt; in the electrode lifting type, it will not hinder the electrode activity.

[0041]The electric fused magnesium smelting magnesite pellets include: magnesite powder, inorganic binder and polymer binder, wherein the inorganic binder accounts for 20% of the total mass, and the polymer binder accounts for 0.02% of the total mass. %, the rest...

Embodiment 2

[0050] This embodiment discloses a magnesite pellet smelted with electro-fused magnesium, the composition of which is the same as that of Example 1, the preparation method is basically the same as that of Example 1, and the difference is that the pelleting pressure of step (4) in this embodiment is 30MPa.

Embodiment 3

[0060] This embodiment discloses a magnesite pellet smelted by electro-fused magnesium. The magnesite pellet smelted by electro-fused magnesium is an ellipsoid, and the x, y, and z axes are respectively 15mm, 20mm, and 25mm. Compared with the existing positive spherical shape, the electric fused magnesium smelting magnesite pellets of the present invention can reduce the fluidity of the pellets, enhance the controllability, and be easy to fill; can form a stable material layer above the molten pool and form Preheating belt; in the electrode lifting type, it can avoid being hindered by the spherical material group to move the electrode.

[0061] The electric fused magnesium smelting magnesite pellets include: magnesite powder, lightly burned powder and carboxymethyl cellulose, and the lightly burned powder has a particle size of less than 0.35mm. The degree of substitution of carboxymethyl cellulose is greater than 0.6, the purity is greater than 55%, and the viscosity is great...

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com