Patents

Literature

56results about How to "Reduced risk of misalignment" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

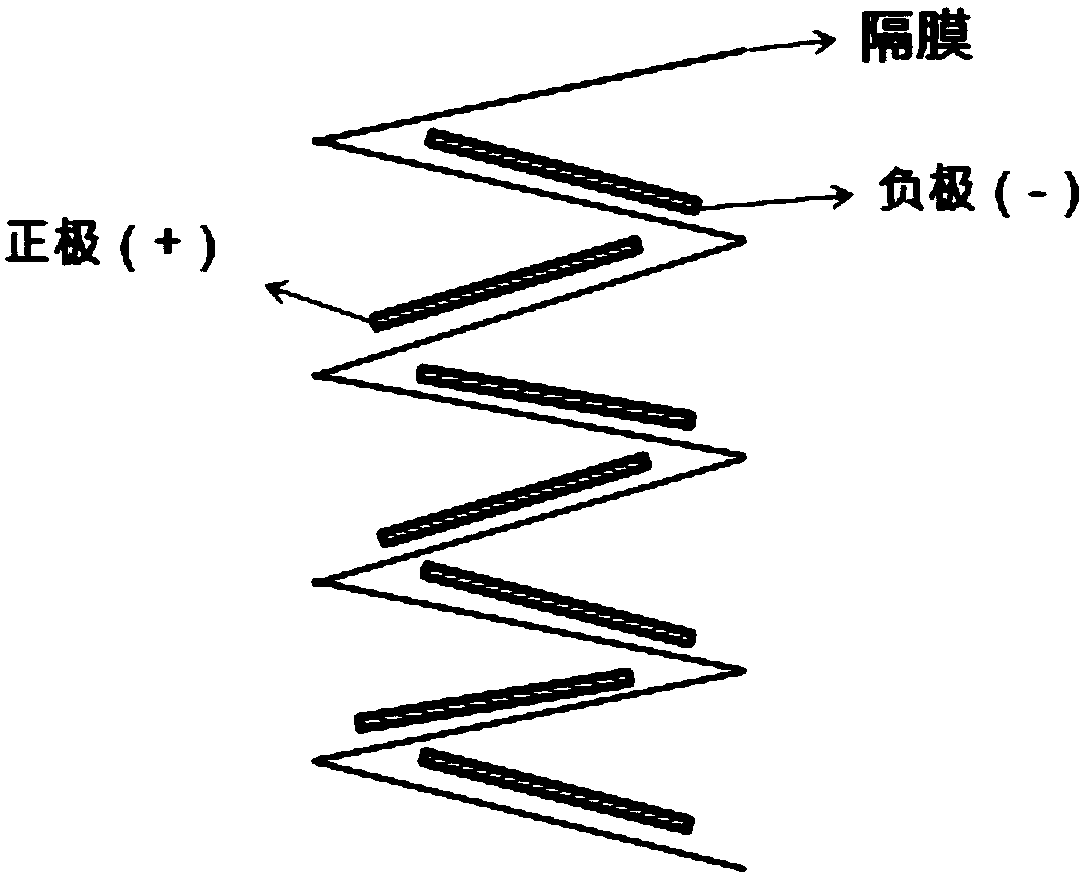

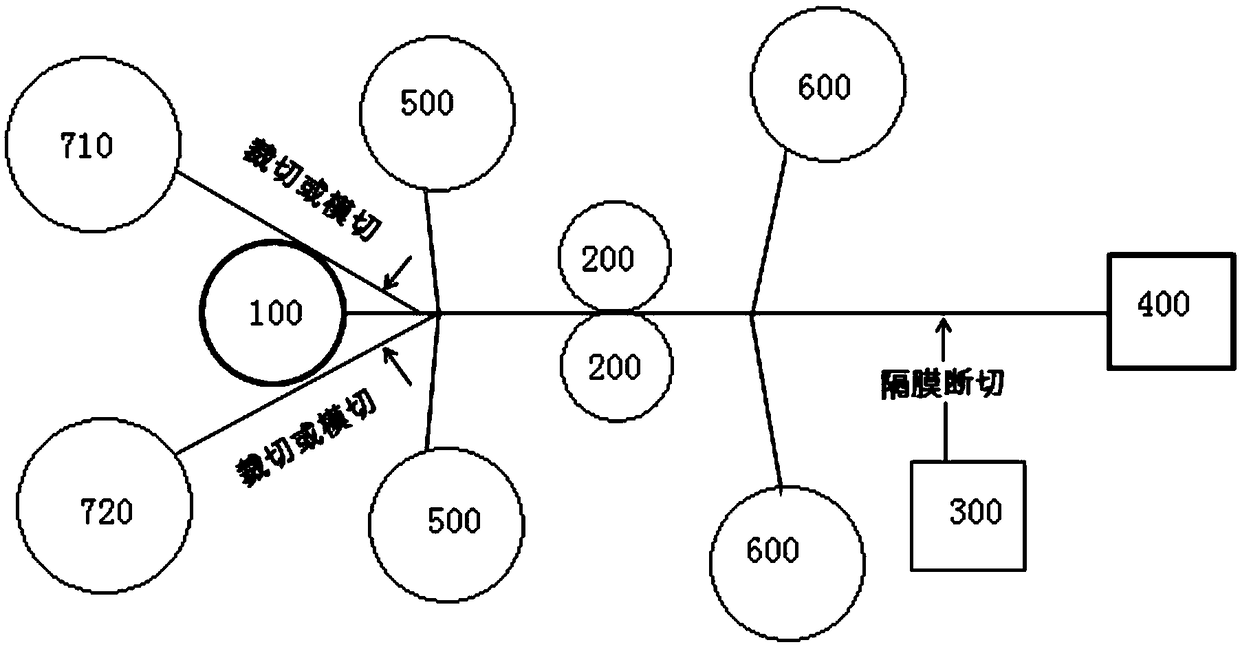

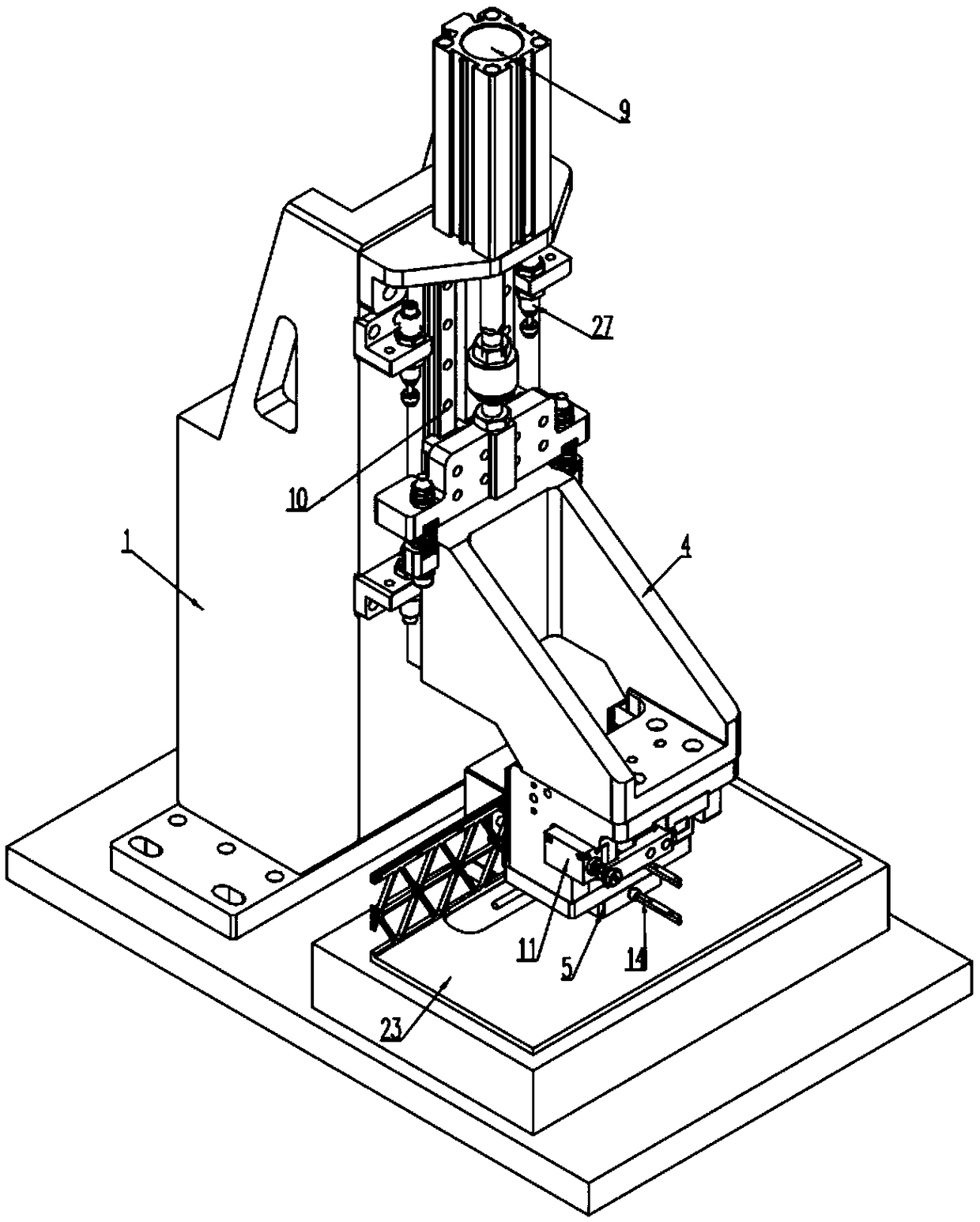

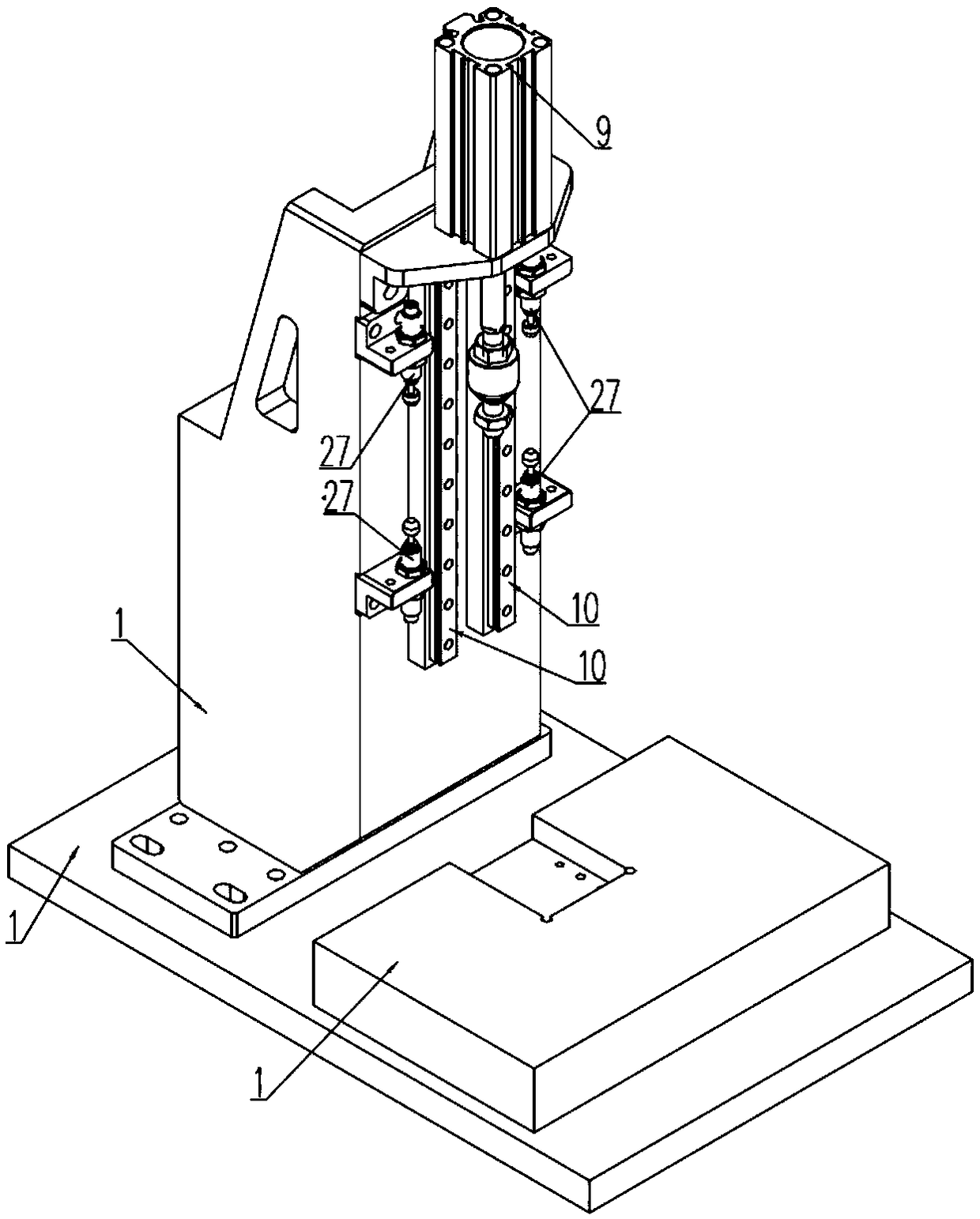

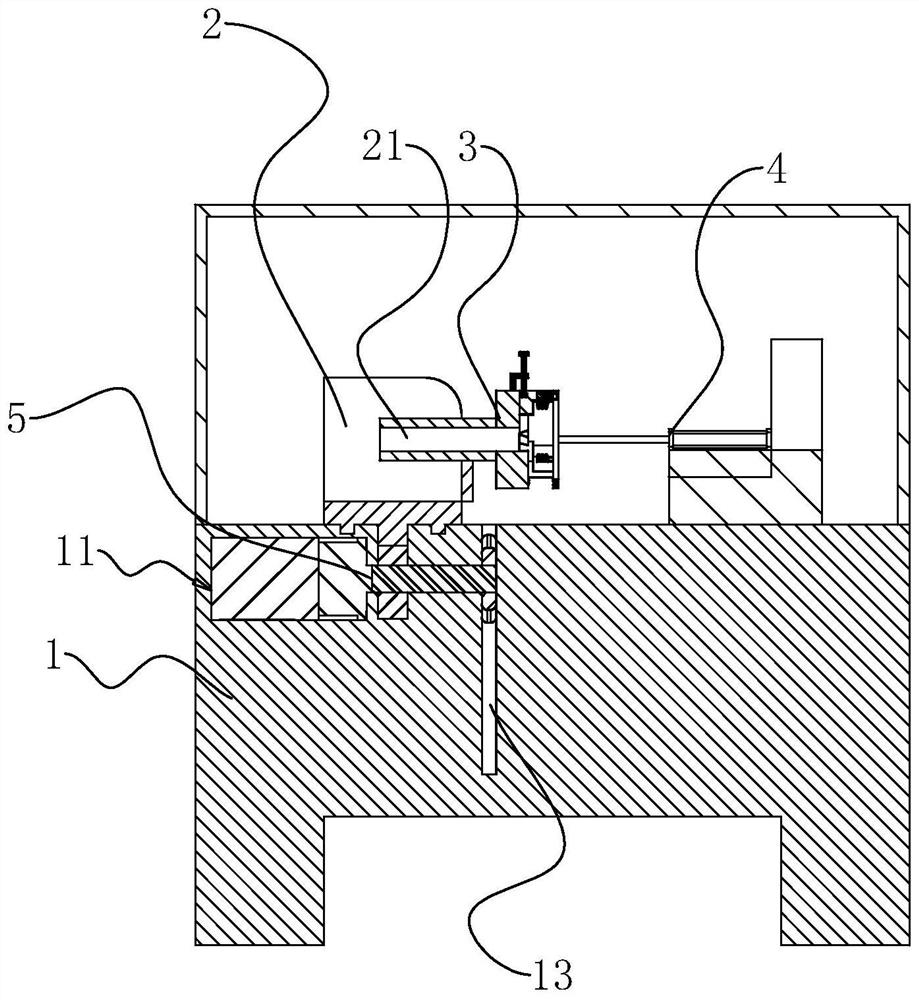

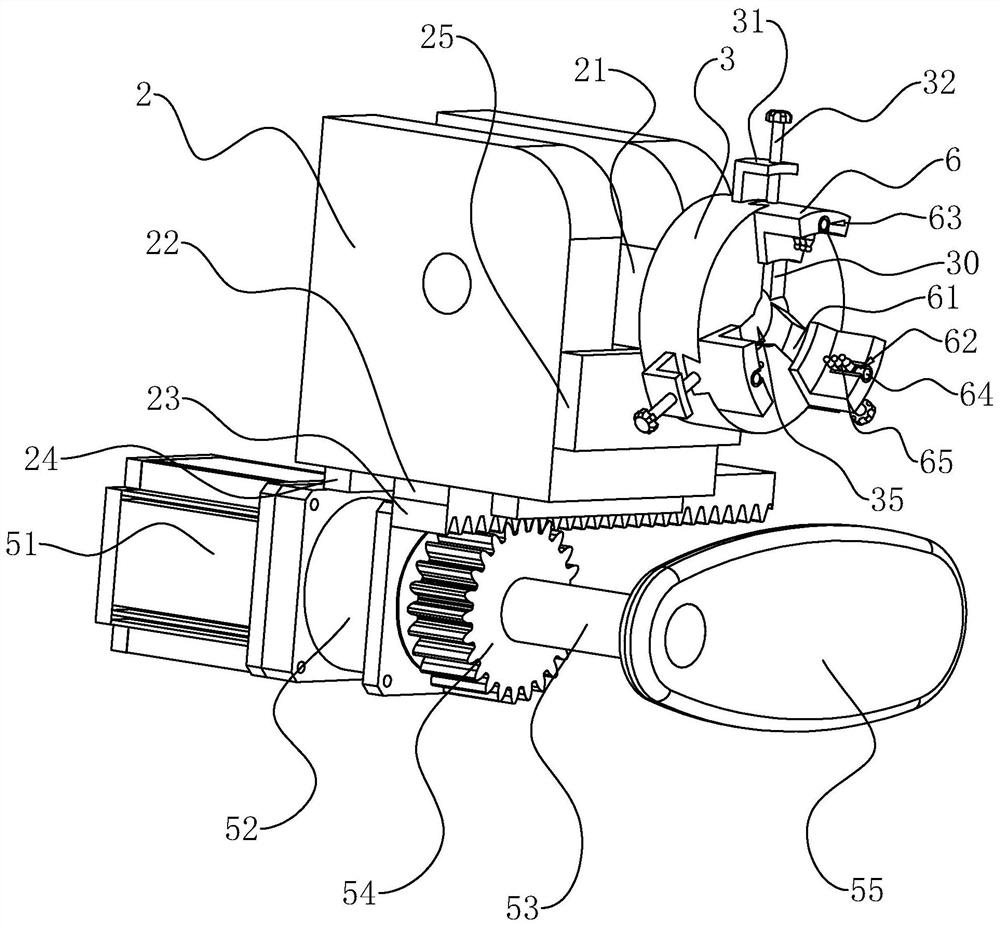

A lithium ion battery Z-shaped laminating device and process thereof

ActiveCN109244554AEliminate transfer deviceSave facilitiesFinal product manufactureElectrolyte accumulators manufactureButt jointElectrical battery

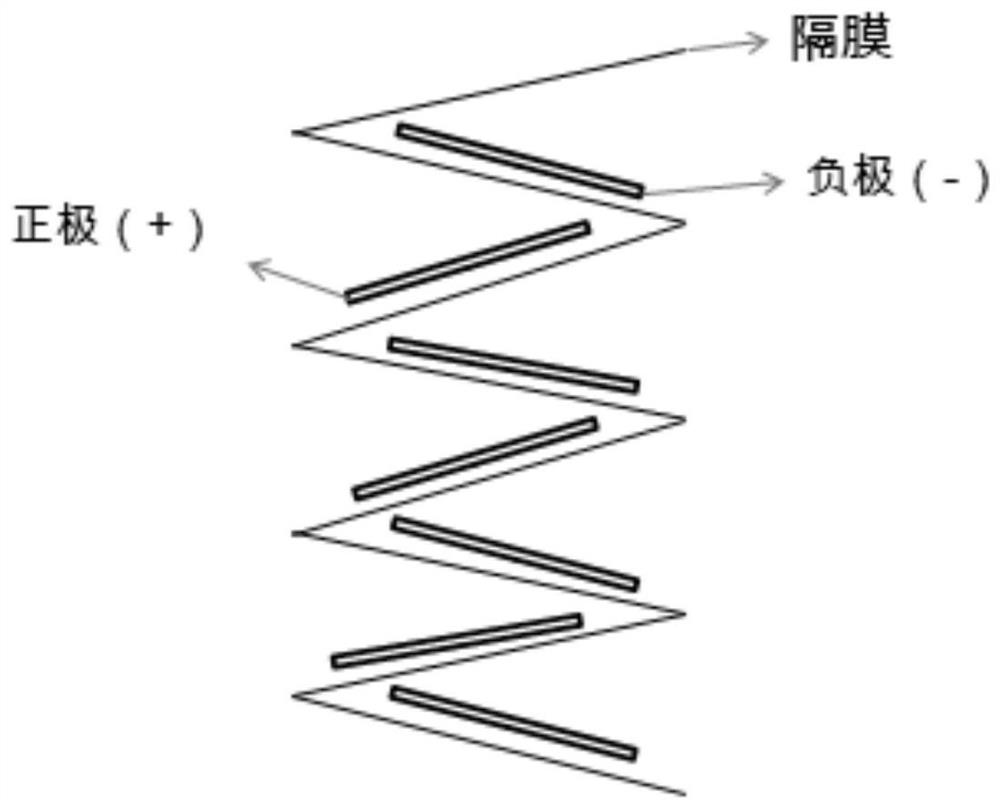

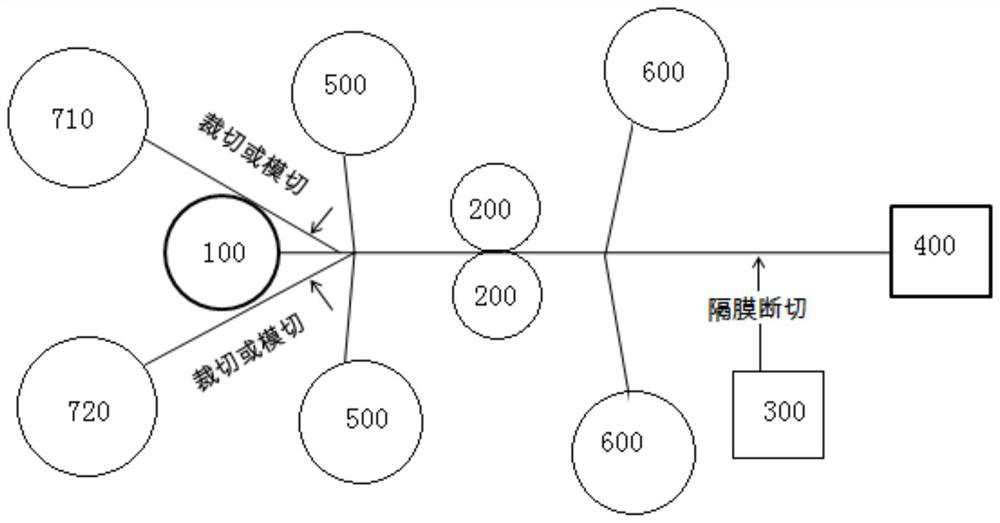

A lithium ion battery Z-shaped laminating device and a process thereof are disclosed. That lithium ion battery Z-shaped laminating device comprises a diaphragm, a plurality of negative electrode pieces are uniformly arranged on the upper surface of the diaphragm, and a plurality of positive electrode pieces are arranged on the lower surface of the diaphragm; a hot-pressing compound device; a diaphragm cutting device; a lithium ion battery z-shape lamination process comprise that following steps of: (1) firstly die cutting or cutting the positive electrode roll and the negative electrode roll,then bonding the die-cut or cut negative electrode sheet and the positive electrode sheet on the upper surface and the lower surface of the diaphragm respectively, and performing staggered distribution of the positive electrode sheet and the negative electrode sheet; 2, hot pressing that diaphragm with each negative electrode sheet and the positive electrode sheet; (3) finally, Z-shaped folding and cutting the diaphragm. The invention realizes seamless butt joint between die-cutting or cutting and Z-shaped laminate, eliminates pole piece transfer device and equipment, and uses hot-pressing composite method to fix pole piece, thus reducing the risk of pole piece dislocation in the transfer process of bare cell.

Owner:江苏卡耐新能源有限公司 +4

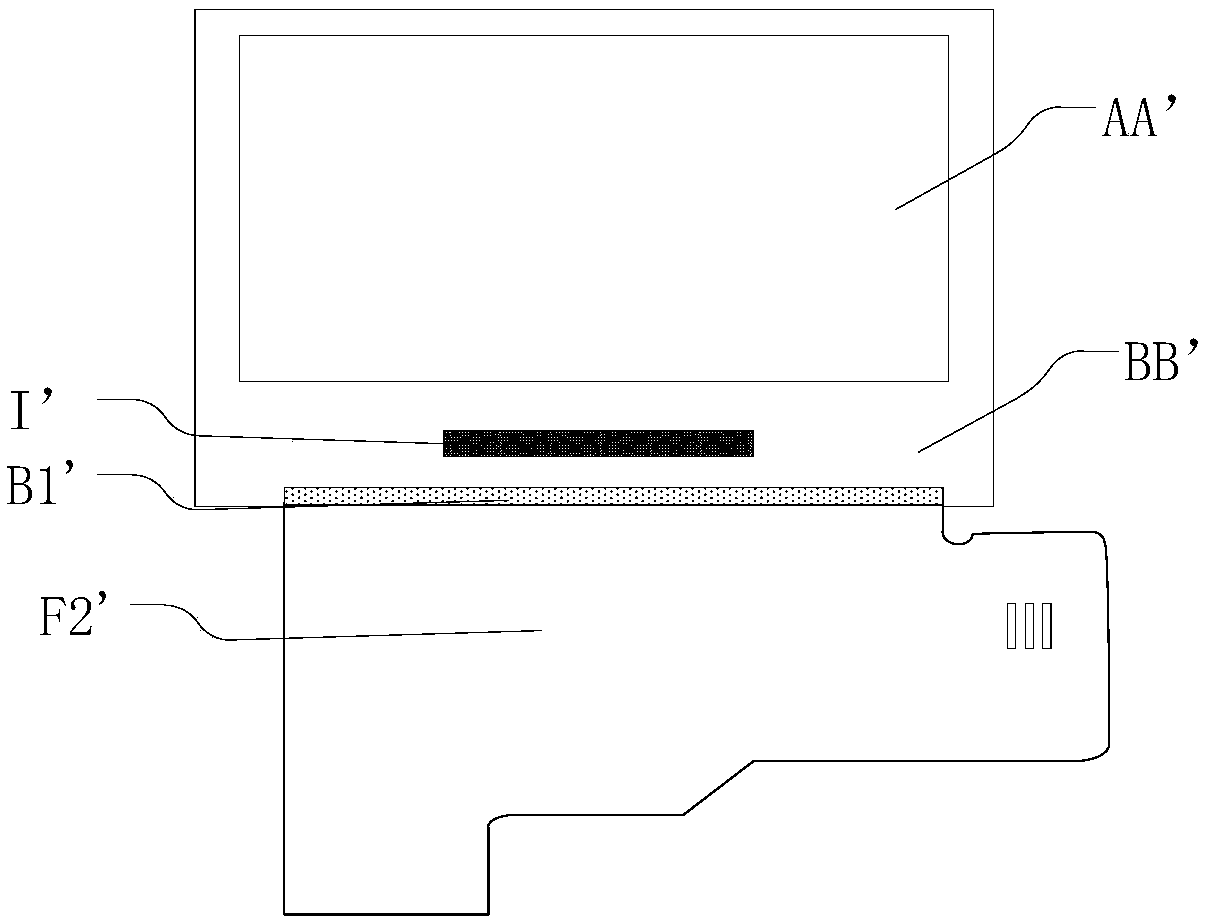

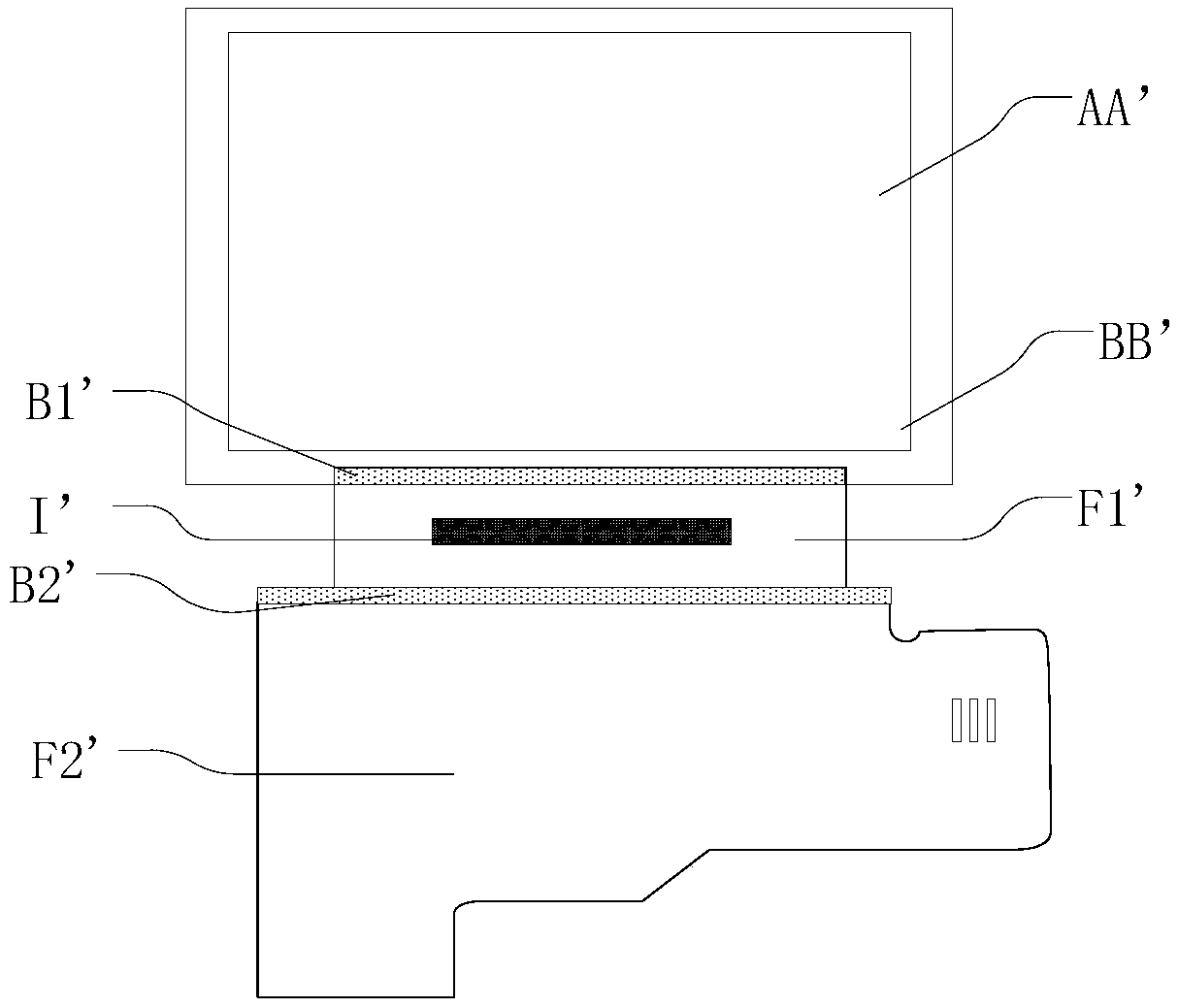

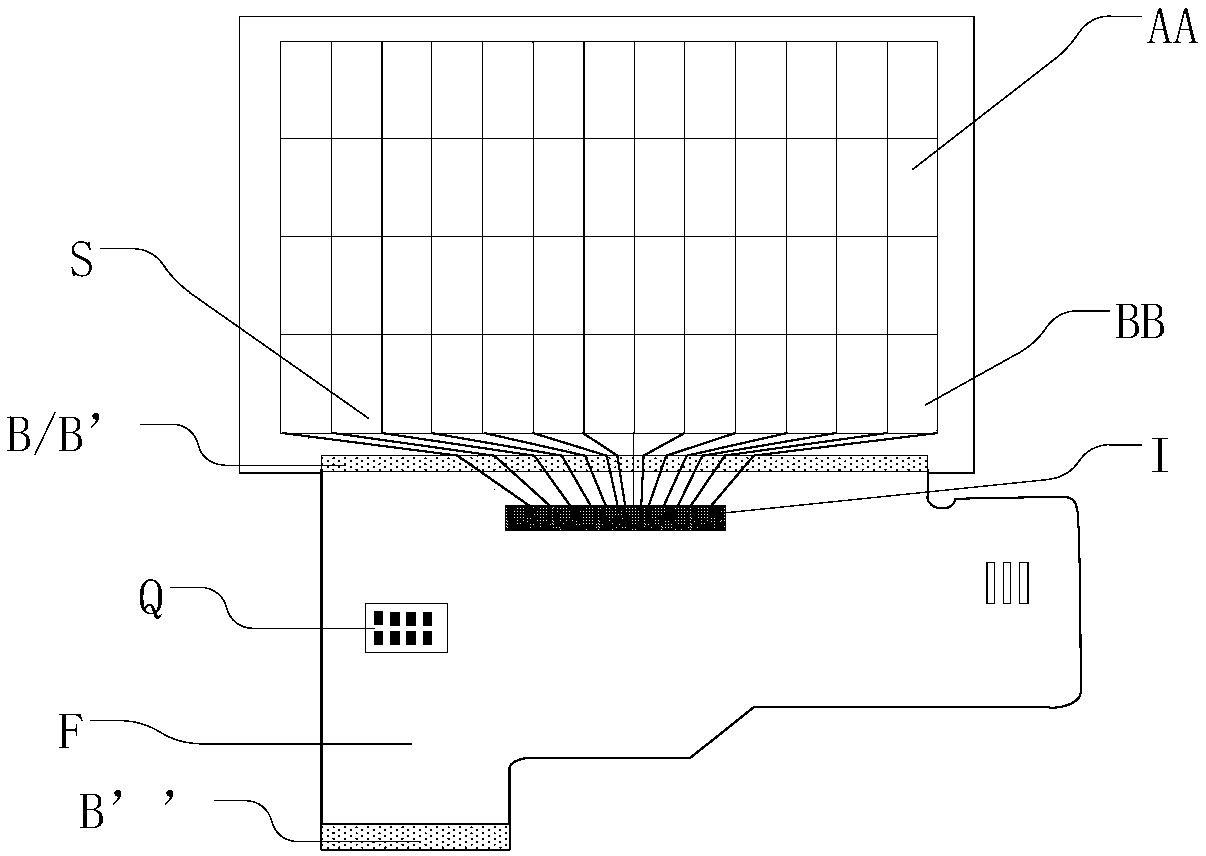

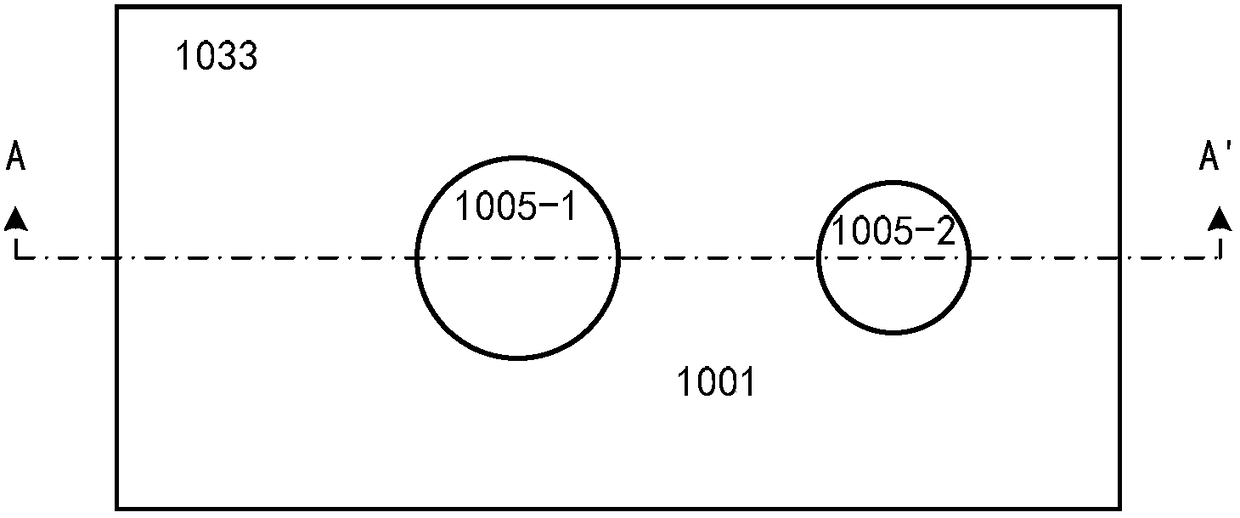

Liquid crystal display module and liquid crystal display device

InactiveCN109597252AIncrease productivityImprove warpageNon-linear opticsPrinted circuit non-printed electric components associationLiquid-crystal displayElectricity

The present invention provides a liquid crystal display module and a liquid crystal display device. The liquid crystal display module comprises: a display panel; a flexible circuit board and an integrated circuit chip, wherein the flexible circuit board comprises a first end and a second end; the first end comprises a second binding terminal; the second binding terminal of the first end is connected to a first binding terminal of a non-display area; the flexible circuit board comprises at least two conductive layers; the flexible circuit board further comprises at least two rows of bonding pads between the first end and the second end; each row of the bonding pads comprises a plurality of sub-bonding pads; the conductive layers are exposed by the sub-bonding pads; the flexible circuit board further comprises a component group; and the integrated circuit chip is electrically connected to the sub-bonding pads through conductive adhesive. The module provided by the invention has the technical effects that the production efficiency can be improved; the cost is reduced; the risk of pressing deviation is reduced; the product yield is increased; the problem that the integrated circuit chip is easy to break is improved; and the package reliability of the integrated circuit chip is increased.

Owner:WUHAN TIANMA MICRO ELECTRONICS CO LTD

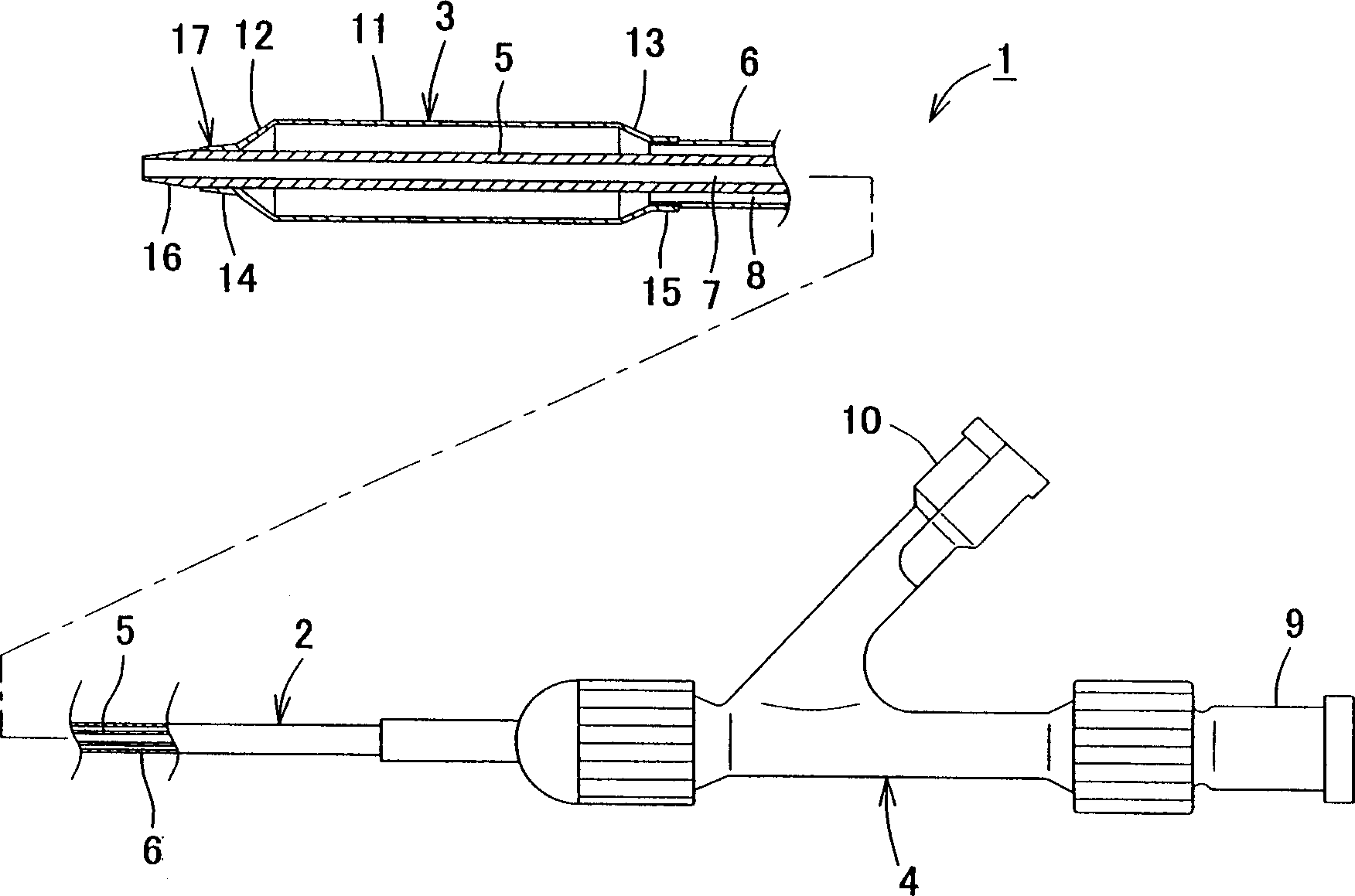

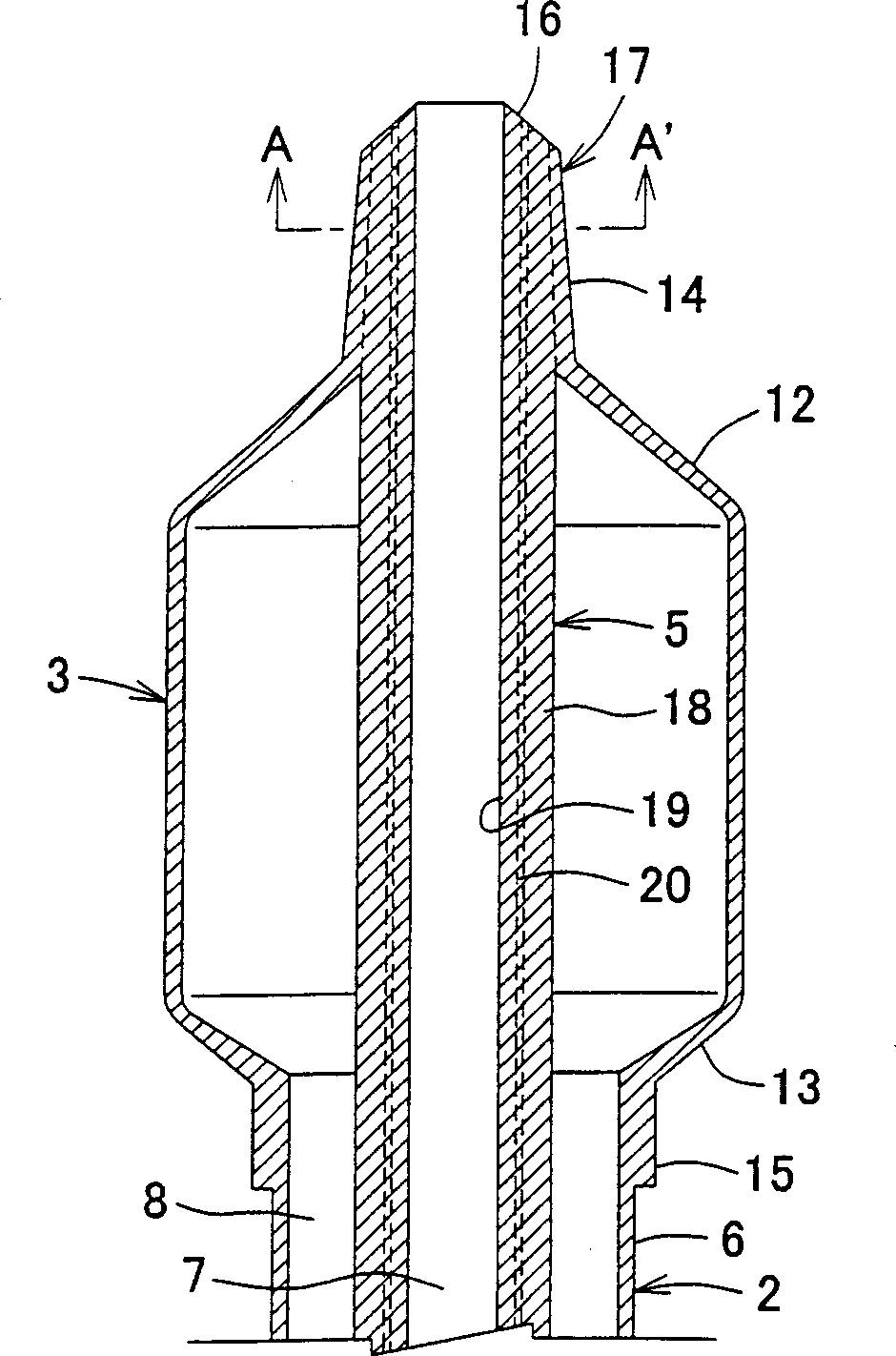

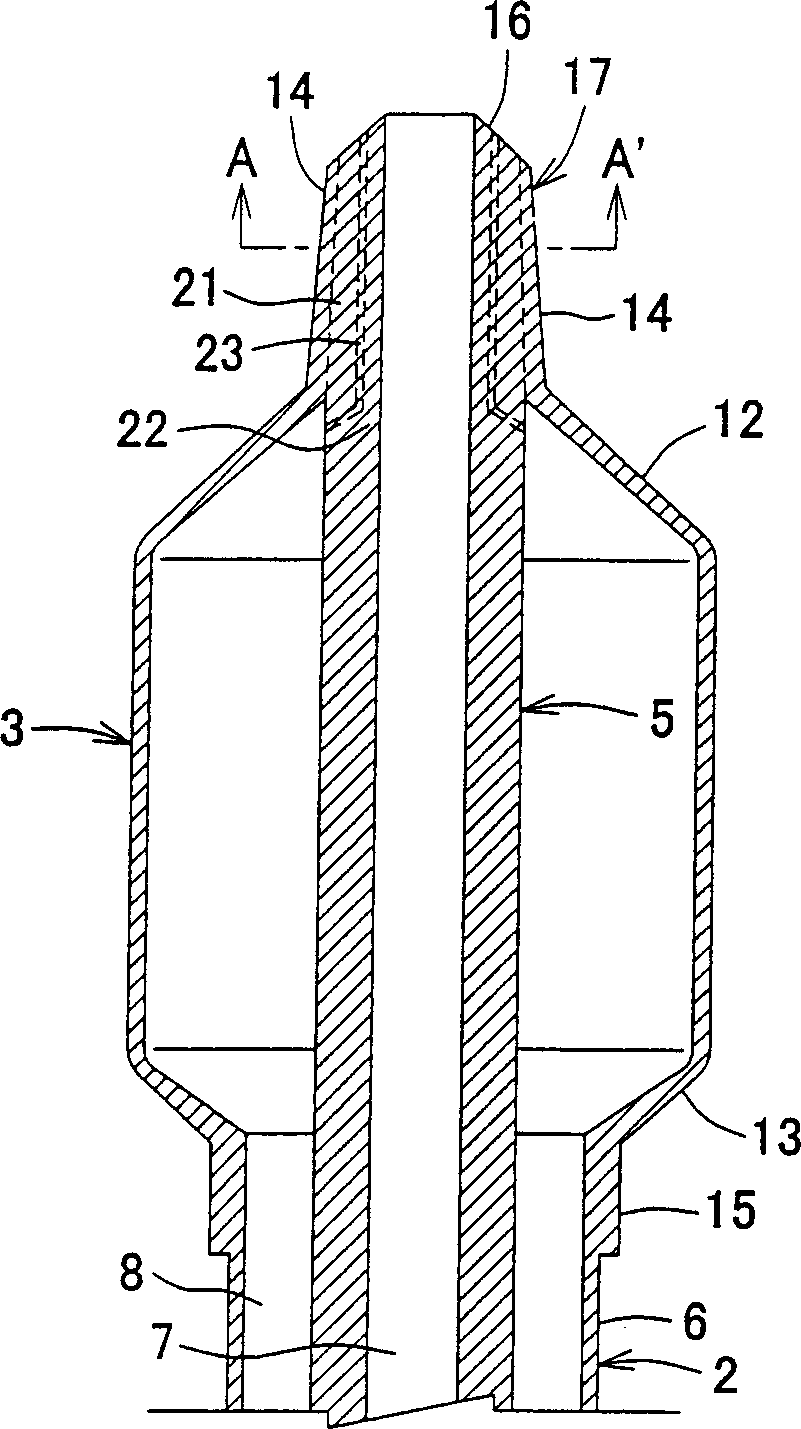

Balloon catheter

The present invention is a balloon catheter used primarily in treatment and surgery for the purpose of dilating lesion sites such as strictures or blockages in passages in the human body. The balloon catheter of the present invention has a structure wherein a guide wire passing tubular member is deployed passing through the interior of the expansion body, and the outer surface of the tubular member and the expansion body are concentrically fused near the distal end of the catheter. This is a balloon catheter that is characterized by the fact that the Shore hardness of the material configuring the outermost surface of the tubular member is smaller than the Shore hardness of the material configuring the expansion body. It is therefore possible to flexibly adjust the tip portion formed by securing the expansion body and the guide wire passing tubular member.

Owner:KANEKA CORP

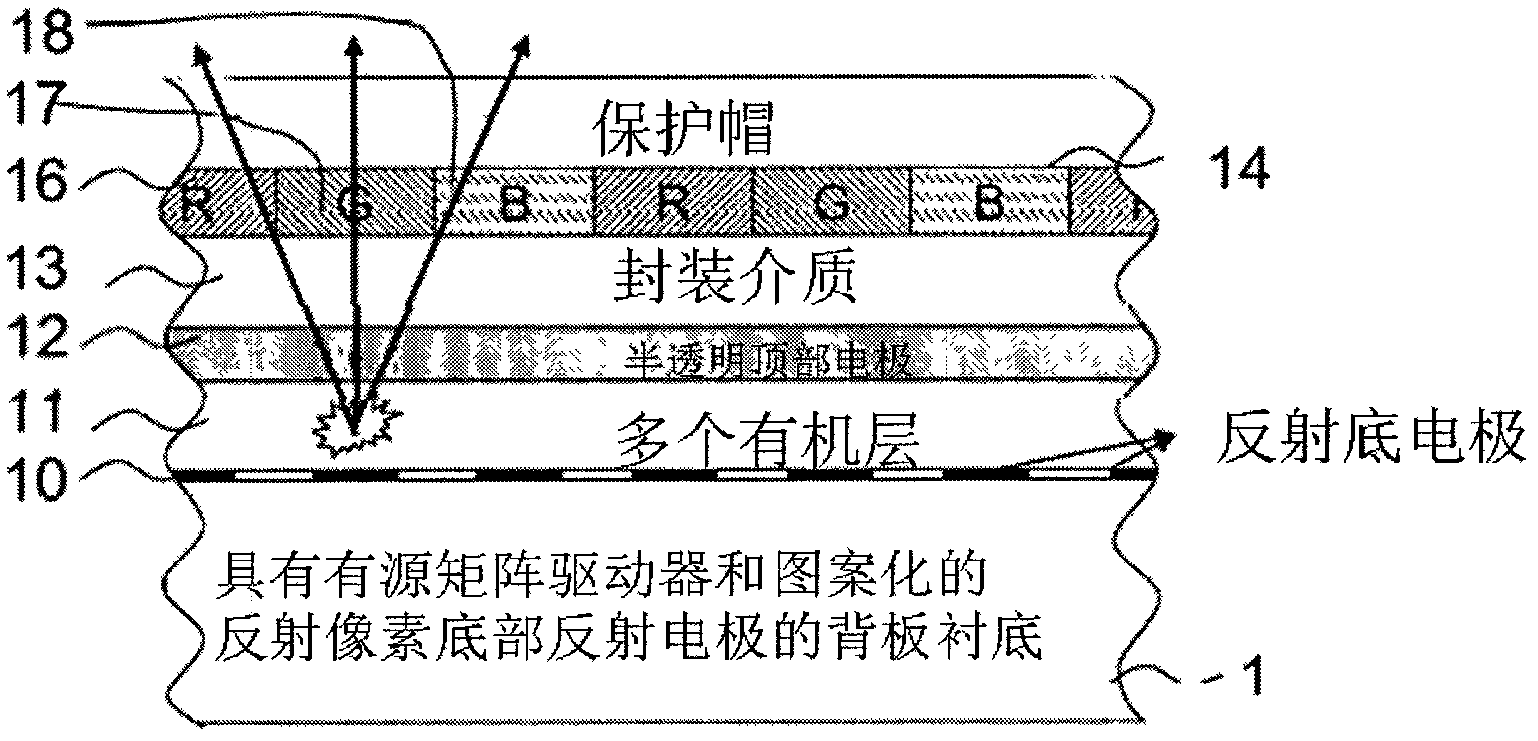

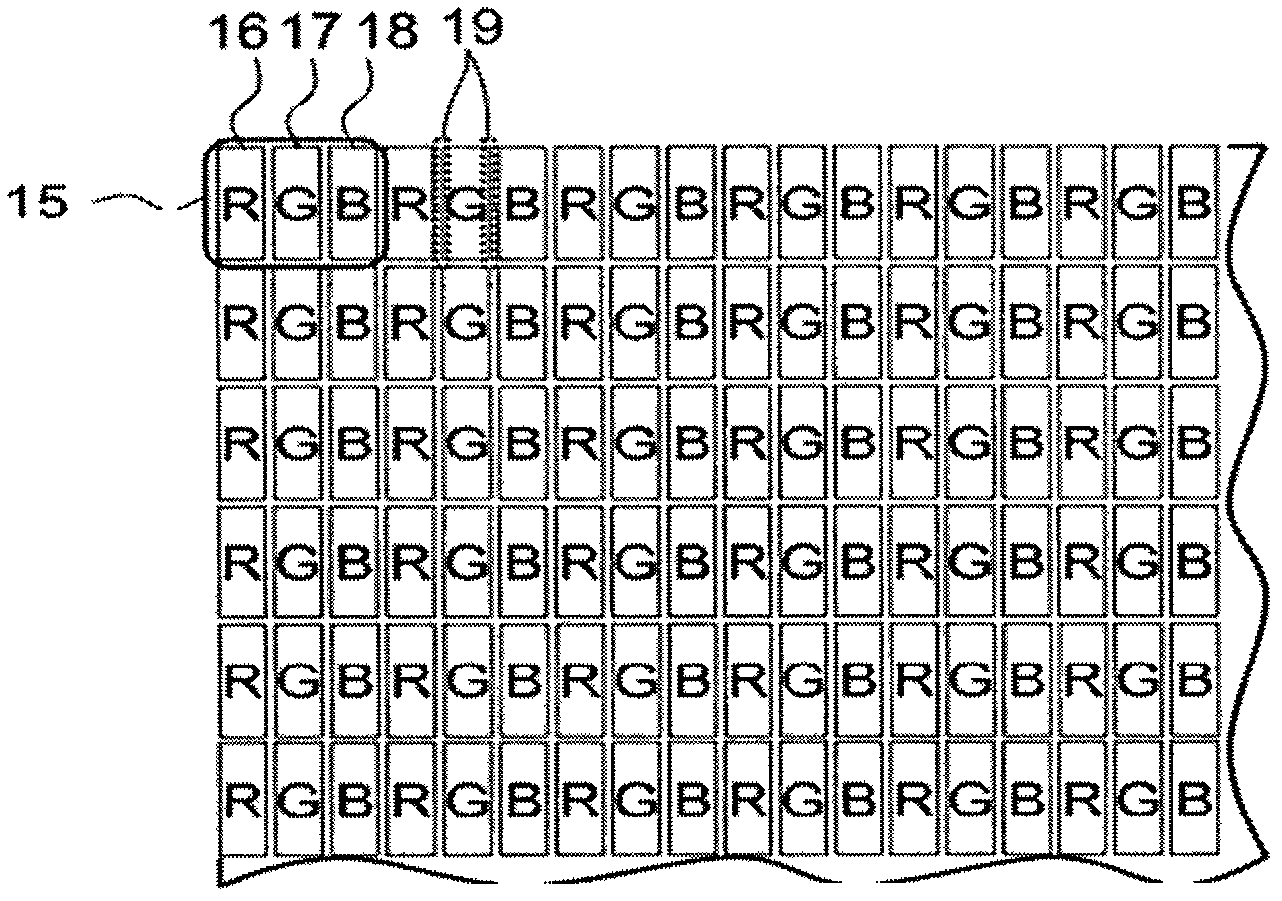

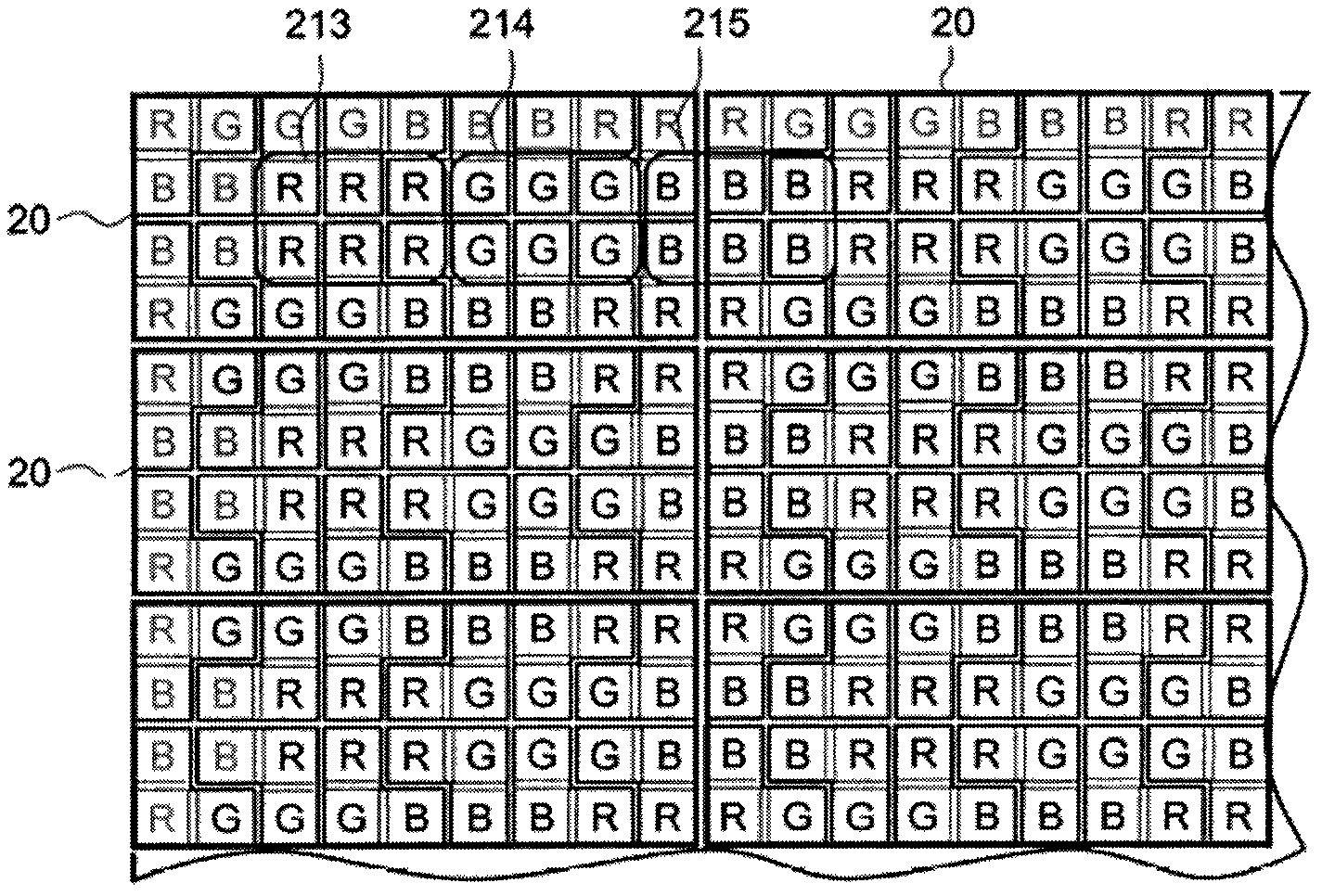

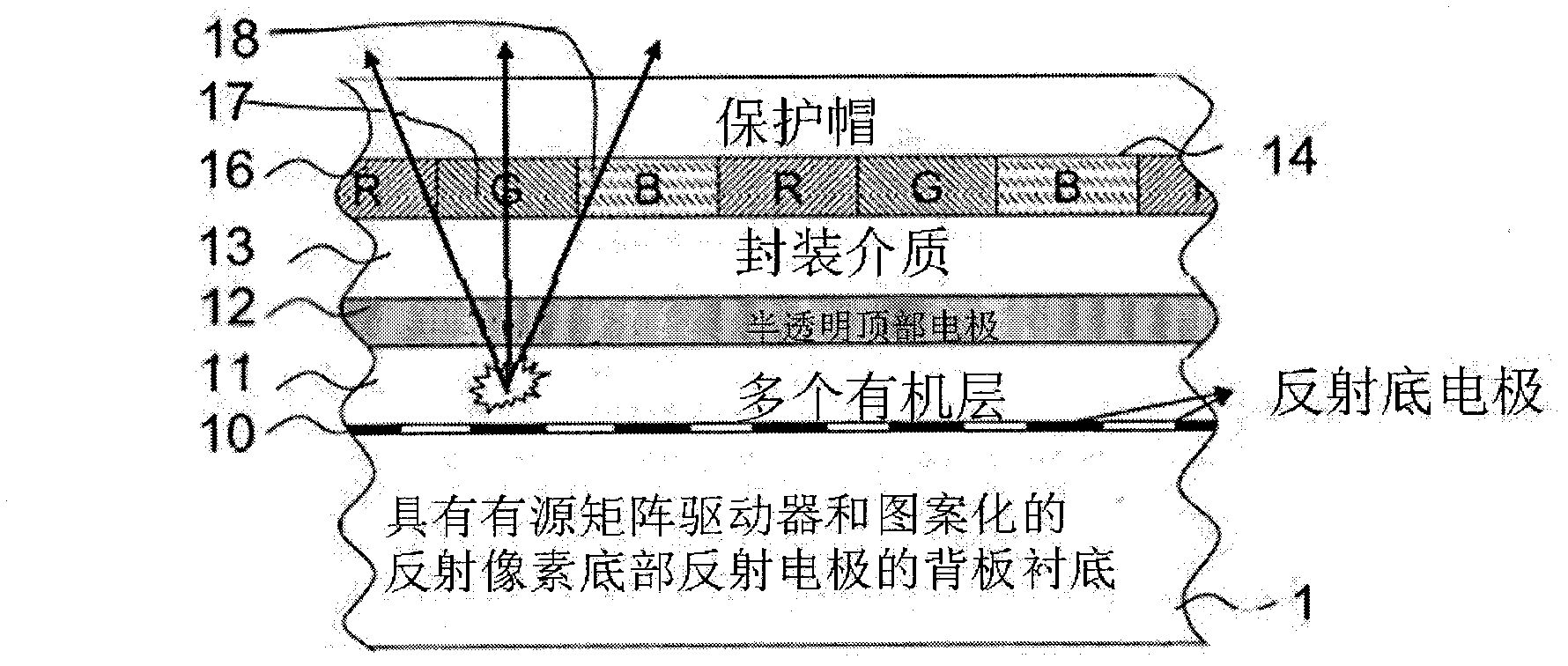

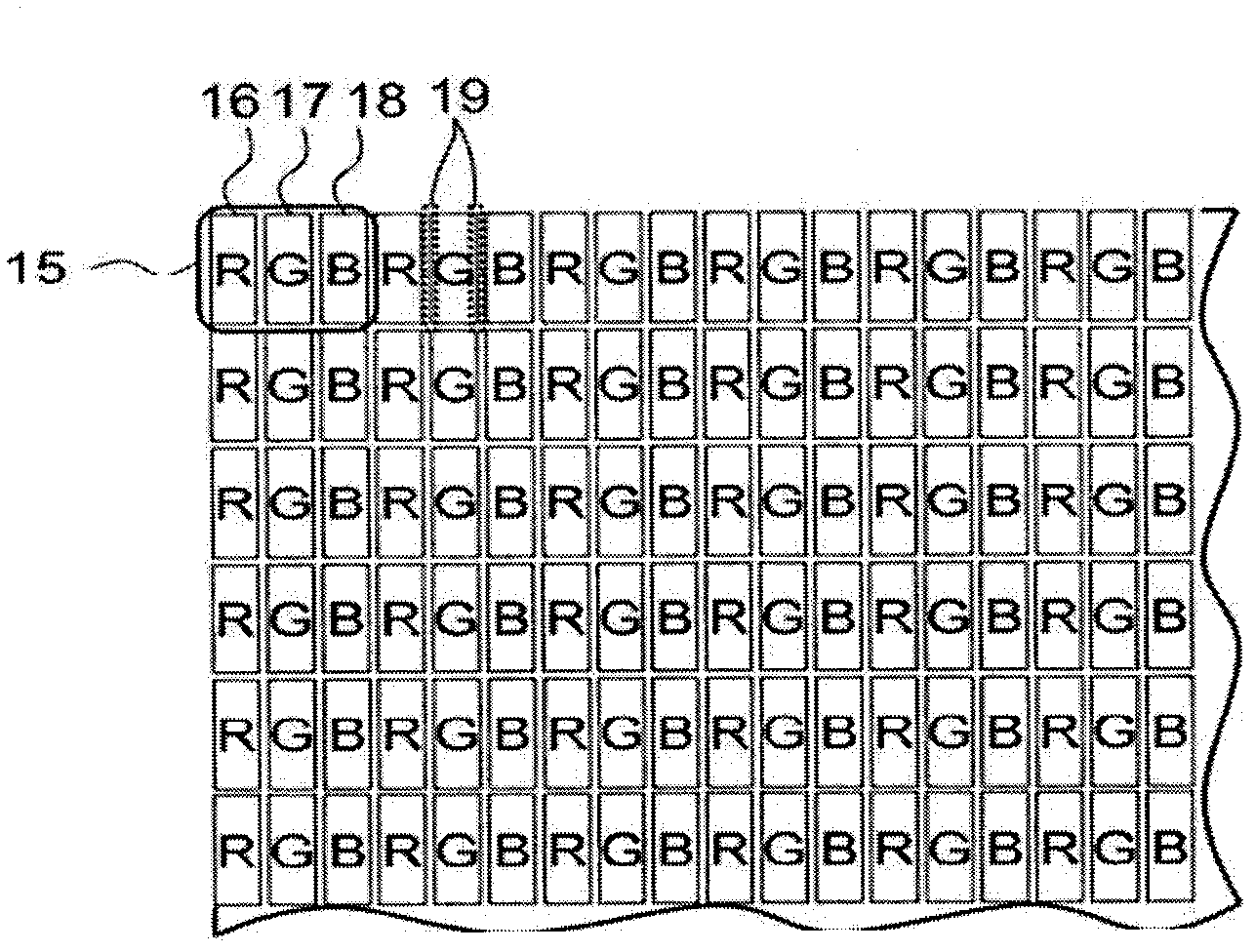

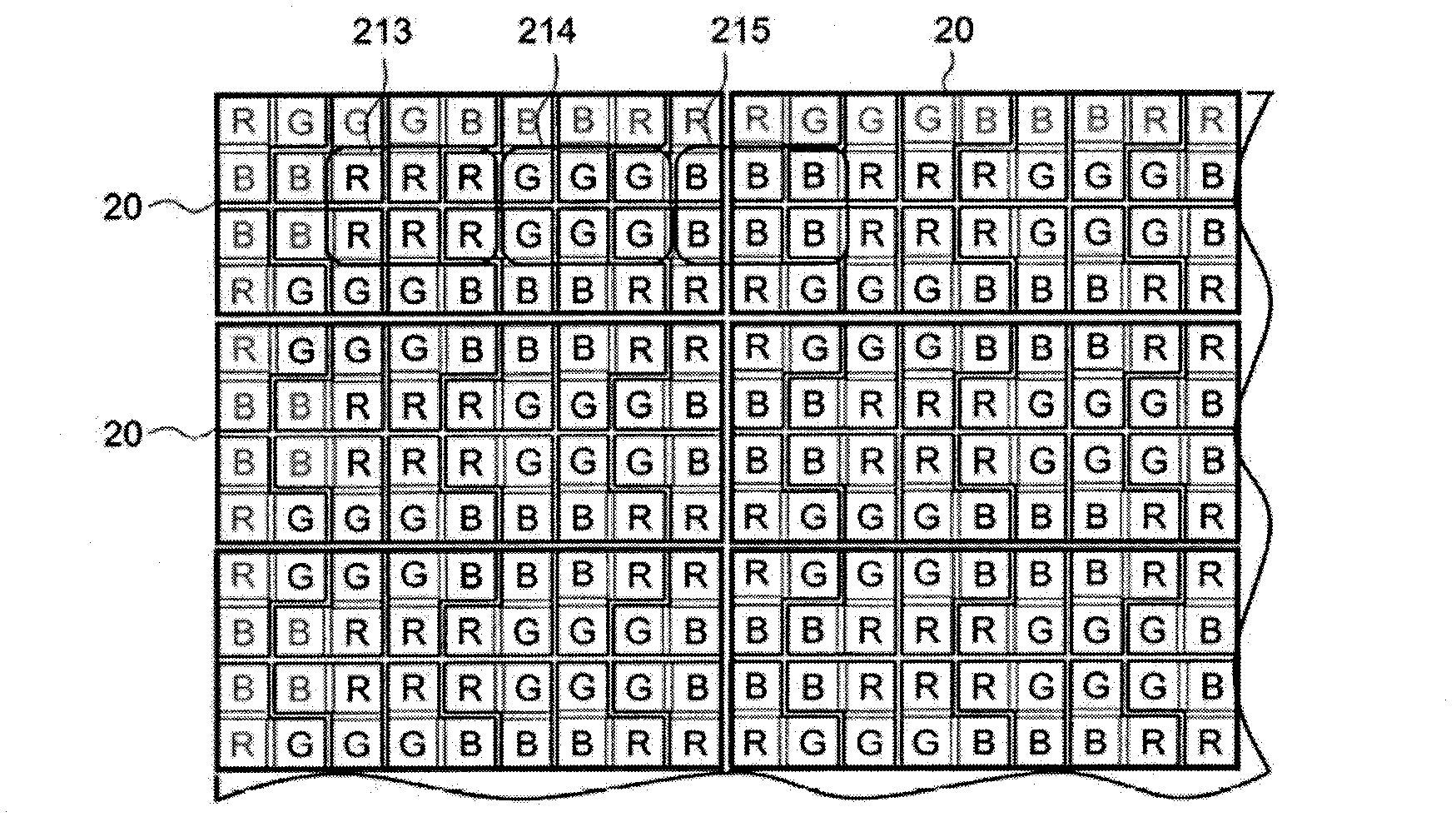

Colored color filter of organic electroluminescence device

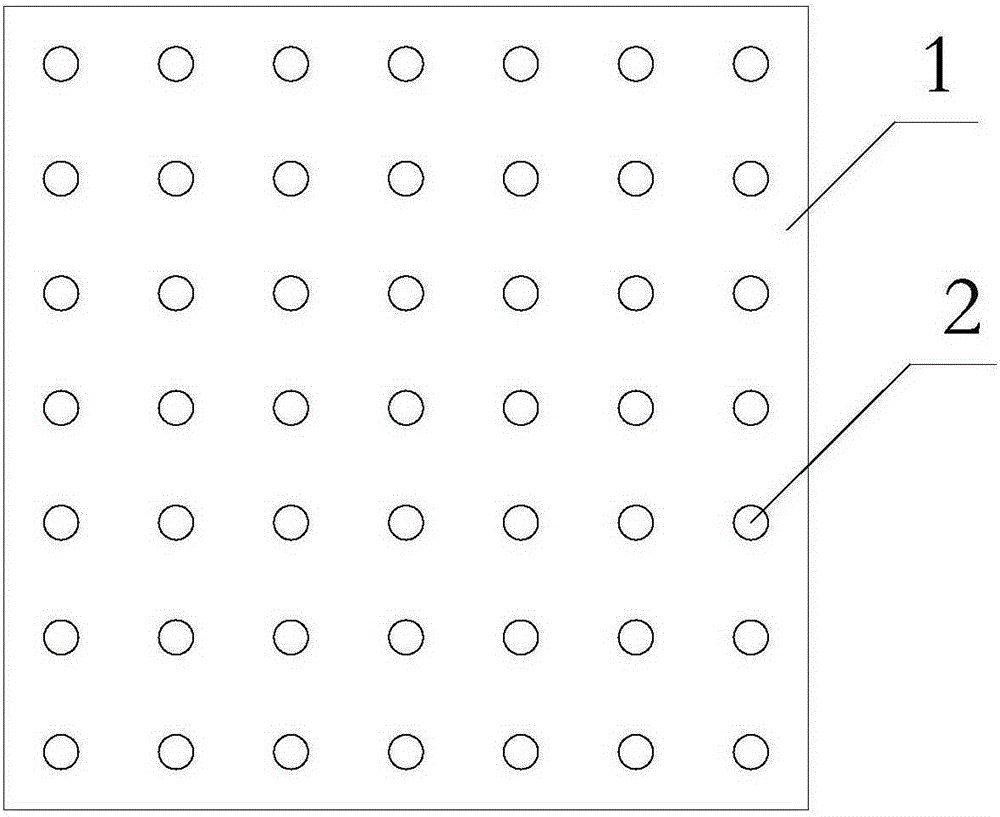

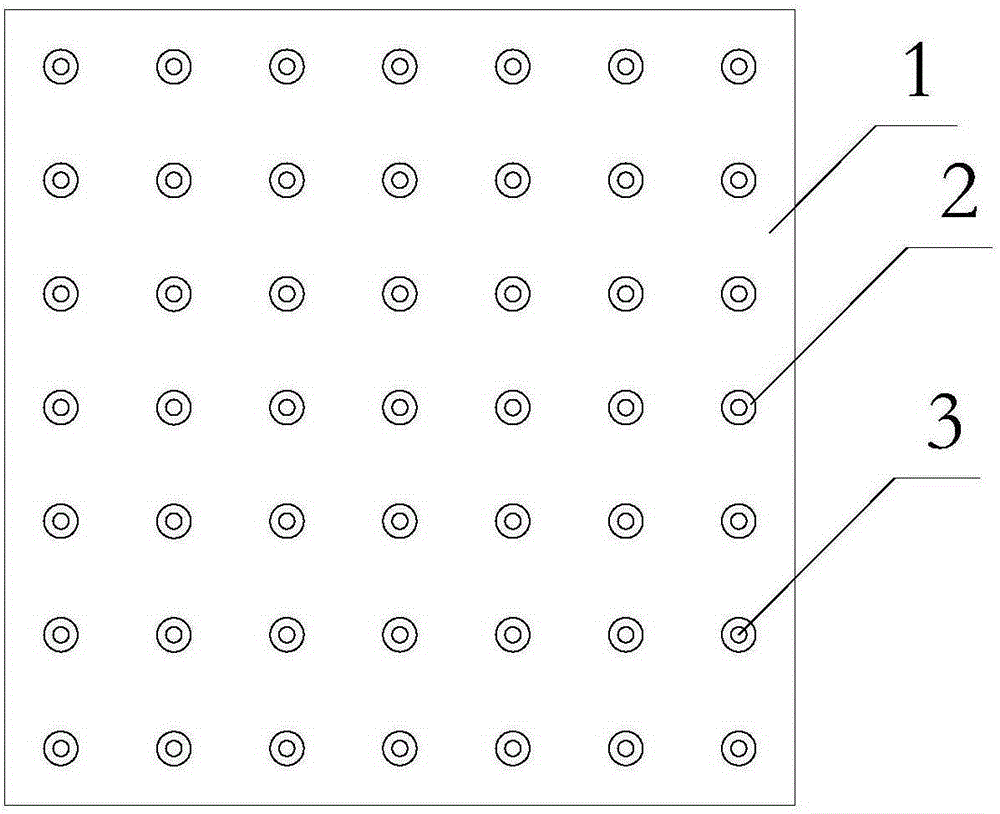

InactiveCN102830452AReduced risk of misalignmentOptical filtersSolid-state devicesOrganic electroluminescenceComputer vision

The invention provides a colored color filter which comprises a plurality of repeated pixel units, wherein each pixel unit comprises a plurality of pixels; each pixel includes a subpixel R, a subpixel G and a subpixel B, wherein the subpixel R, the subpixel G and the subpixel B of each pixel are arranged in an L shape or reversed L shape; and a plurality of pixels are arranged in a compensating way, so that the subpixels with the same color can be arranged together.

Owner:GUANGDONG SINODISPLAY TECH

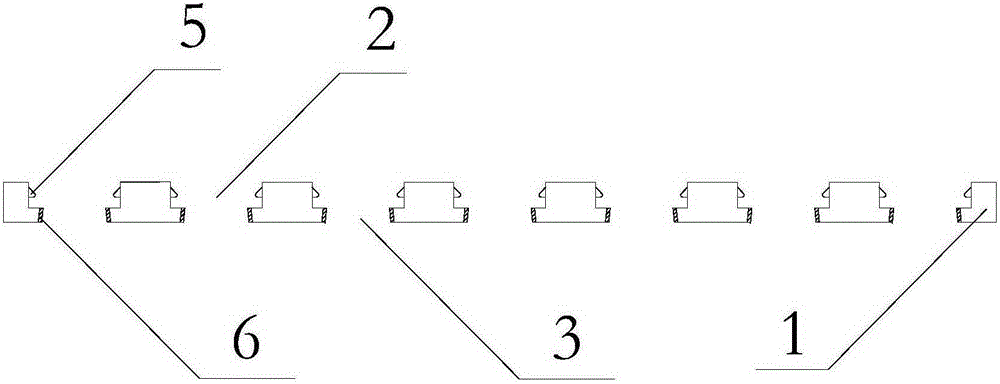

Sequentially etched and plated lead frame structure without island prepacked plastic sealed material and producing method thereof

ActiveCN102324415ASimple designReduce material costsSemiconductor/solid-state device detailsSolid-state devicesEngineeringLead frame

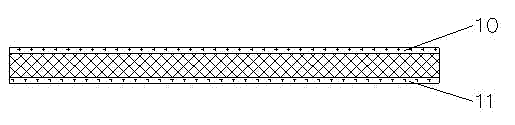

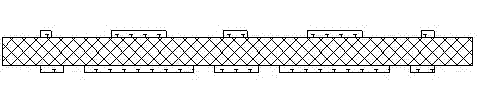

The invention relates to a sequentially etched and plated lead frame structure without an island prepacked plastic sealed material and a producing method thereof. The structure comprises pins (2), wherein front faces of the pins (2) are plated with first metal layers (5); back faces of the pins (2) are plated with second metal layers (6); etching regions between the pins (2) and the pins (2) are filled with plastic sealed materials (4); and the plastic sealed materials (4) are aligned with the front face and the back face of a metal substrate (9). The sequentially etched and plated lead framestructure provided by the invention has the following advantages: a layer of expensive high temperature resistant soft organic adhesive film needs not to be attached on the bottom of the lead frame; various problems possibly generated in loading, routing and encapsulating are avoided in the background; the yield of the finished products is largely increased; convenience can be brought to the circuit board design while loading is made without a metal island; and the front face and the back face of the lead frame are etched at the same time so that the complicatedness of at least 50% can be reduced in the procedure, the cost is reduced and the malposition risk caused by secondary alignment can be reduced.

Owner:JCET GROUP CO LTD

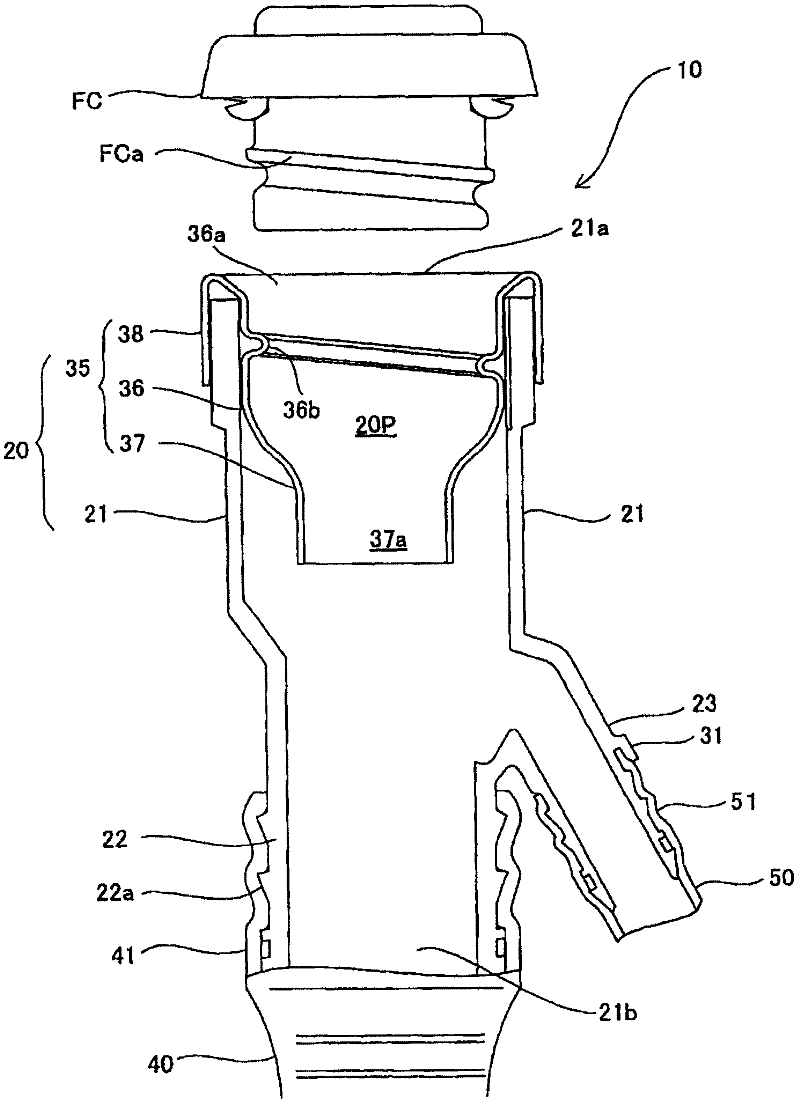

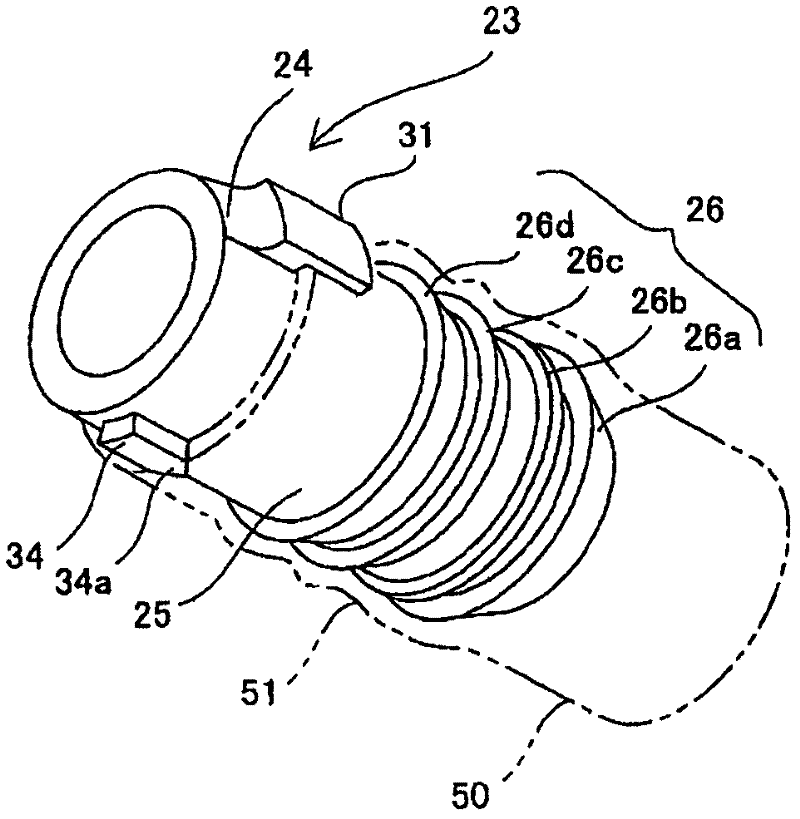

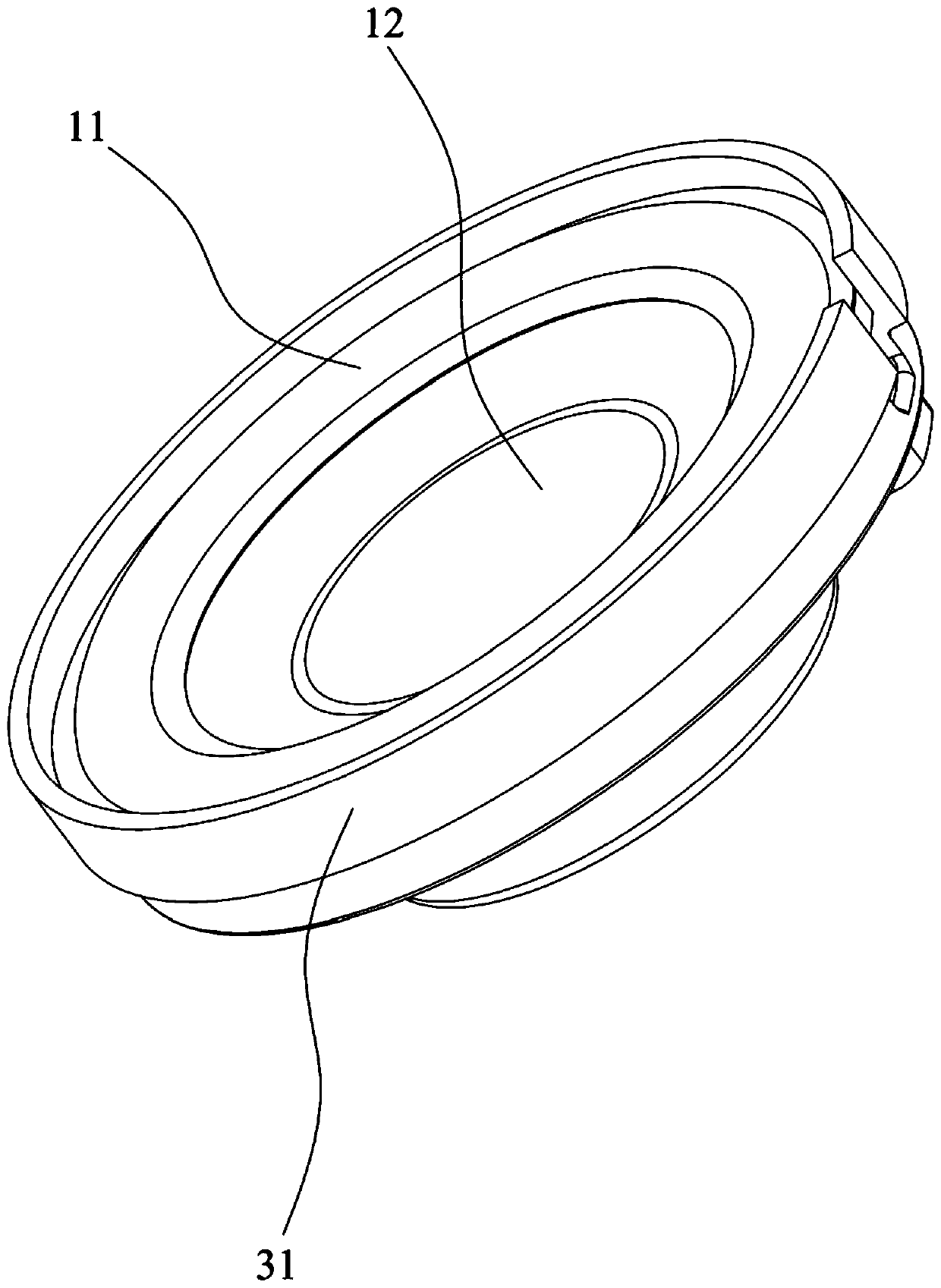

Fuel injection system

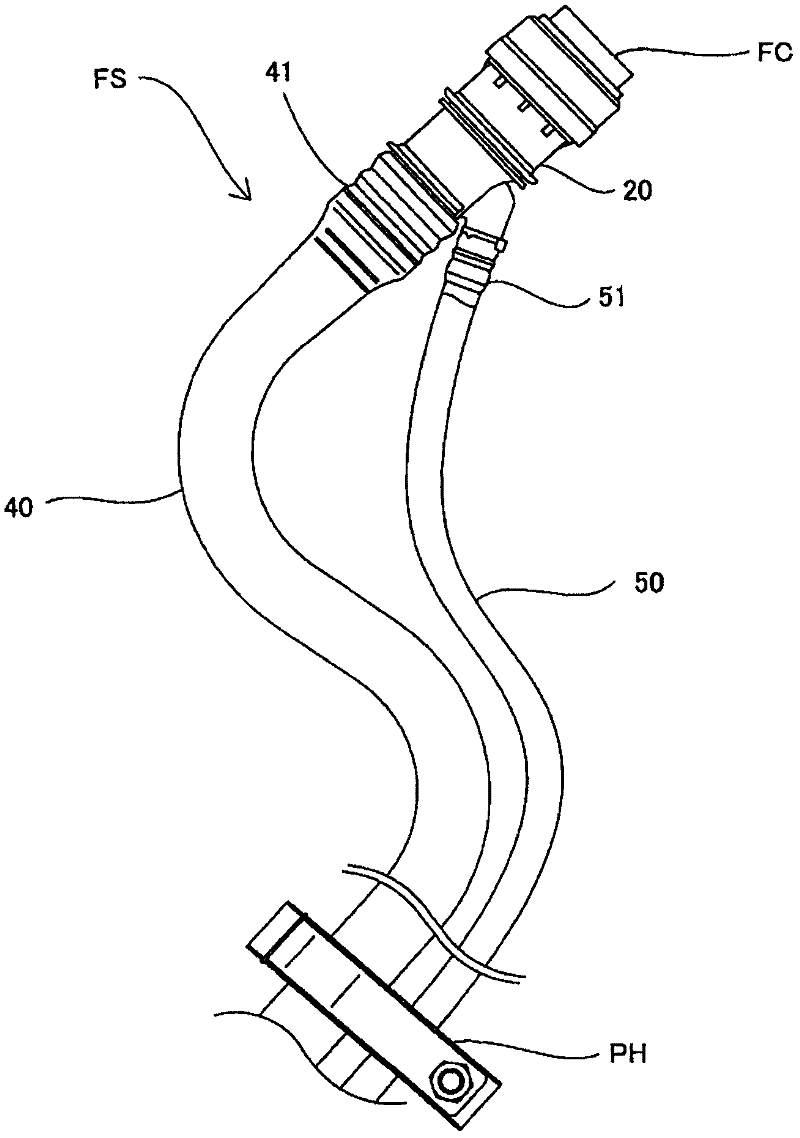

ActiveCN102180433AReduced risk of misalignmentPrevent rotationInternal combustion piston enginesLiquid transferring devicesEngineeringFuel line

The invention discloses a fuel injection system (FS), which comprises an oiling port (20), a pipe joint part (23) and a fuel pipe (50) equipped with a conductive layer for being connected with the pipe joint part (23). The pipe joint part comprises a connection body (25), a disengaging protruding part (26) connected with the outer circumferential surface of the connection body (25) so as to be ring-shaped with the external diameter thereof greater than the inner diameter of the fuel pipe and a grounding connection part (31). The grounding connection part equipped with a fastening part (32) isarranged on the outer circumferential surface of the connection body so as to be protruded with an L-shaped cross-section thereof. An insertion gap (31s) is between the grounding connection part and the outer circumferential surface of the connection body is defined. The fastening part (32) is equipped with a connection protruding part (32b). The end portion of the pipe joint end (51) is allowed to pass through the disengaging protruding part (26). The pipe joint end (51) is pressed to be arranged on the connection body (25) so as to be fit into the insertion gap. Therefore, the connection protruding part is electrically connected with the external layer of the pipe joint end.

Owner:TOYODA GOSEI CO LTD

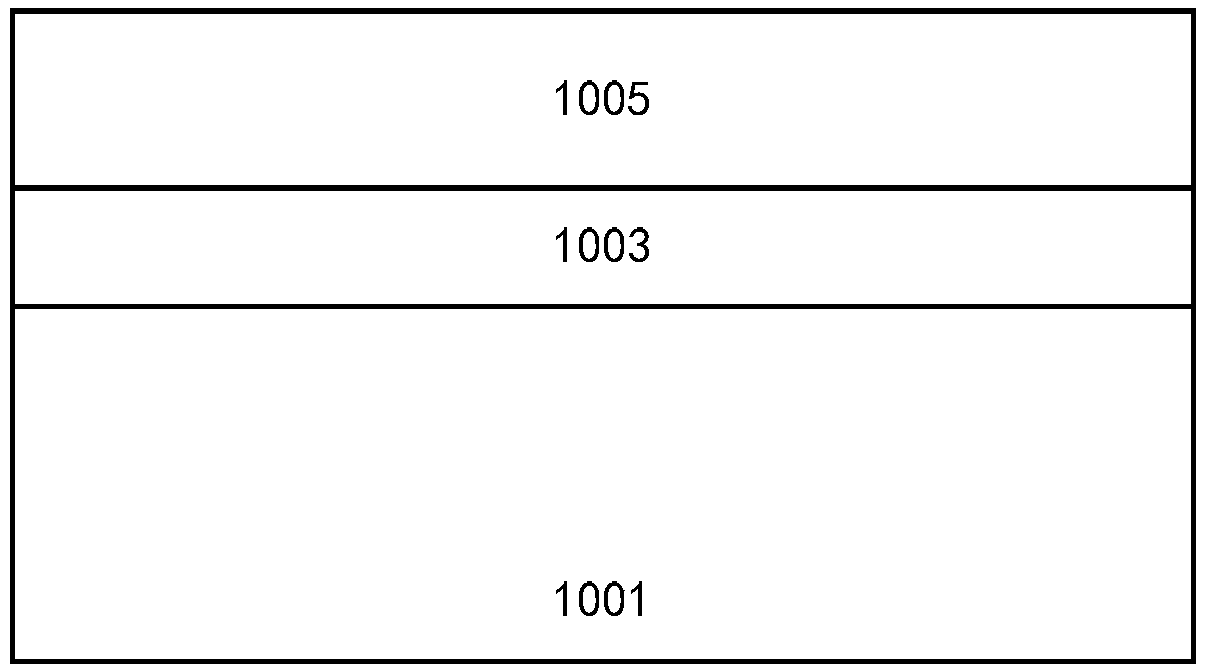

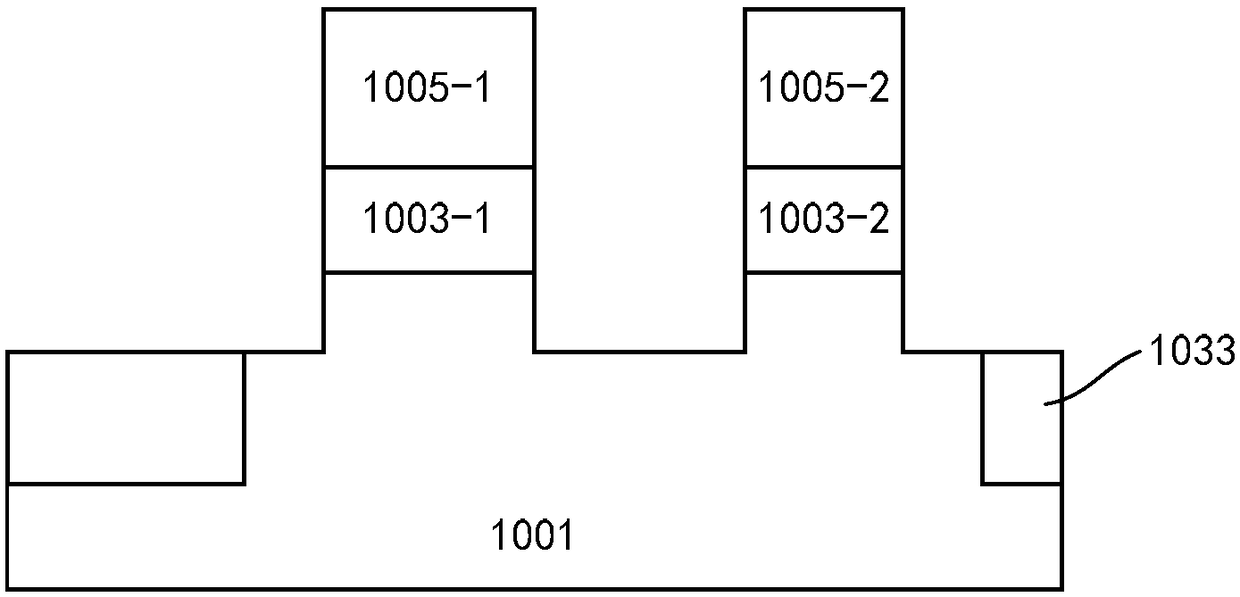

Semiconductor device and manufacturing method thereof, and electronic device including same

ActiveCN108110059AReduced risk of misalignmentImprove integration densityTransistorSemiconductor/solid-state device manufacturingPower semiconductor deviceGate stack

The invention discloses a semiconductor device. The semiconductor device includes a substrate; a vertical active area formed on the substrate, wherein the vertical active area includes a first source / drain region, a channel region, and a second source / drain region, and the first source / drain region includes a horizontal extension portion extending out of the active area above the first source / drain region; gate stack formed on an outer periphery of the channel region, wherein the gate stack includes a horizontal extension portion; a stack contract portion from a position above the horizontal extension portion of the first source / drain region to the horizontal extension portion of the first source / drain region, wherein the stack contact portion includes three structures which are vertically and successively arranged; and the three structures include a lower portion, an intermediate portion, and an upper portion, wherein the lower portion at least includes elements identical to elements forming the first source / drain region, the intermediate portion at least includes elements identical to elements forming the channel region, and the upper portion at least includes elements identical to elements forming the second source / drain region.

Owner:INST OF MICROELECTRONICS CHINESE ACAD OF SCI

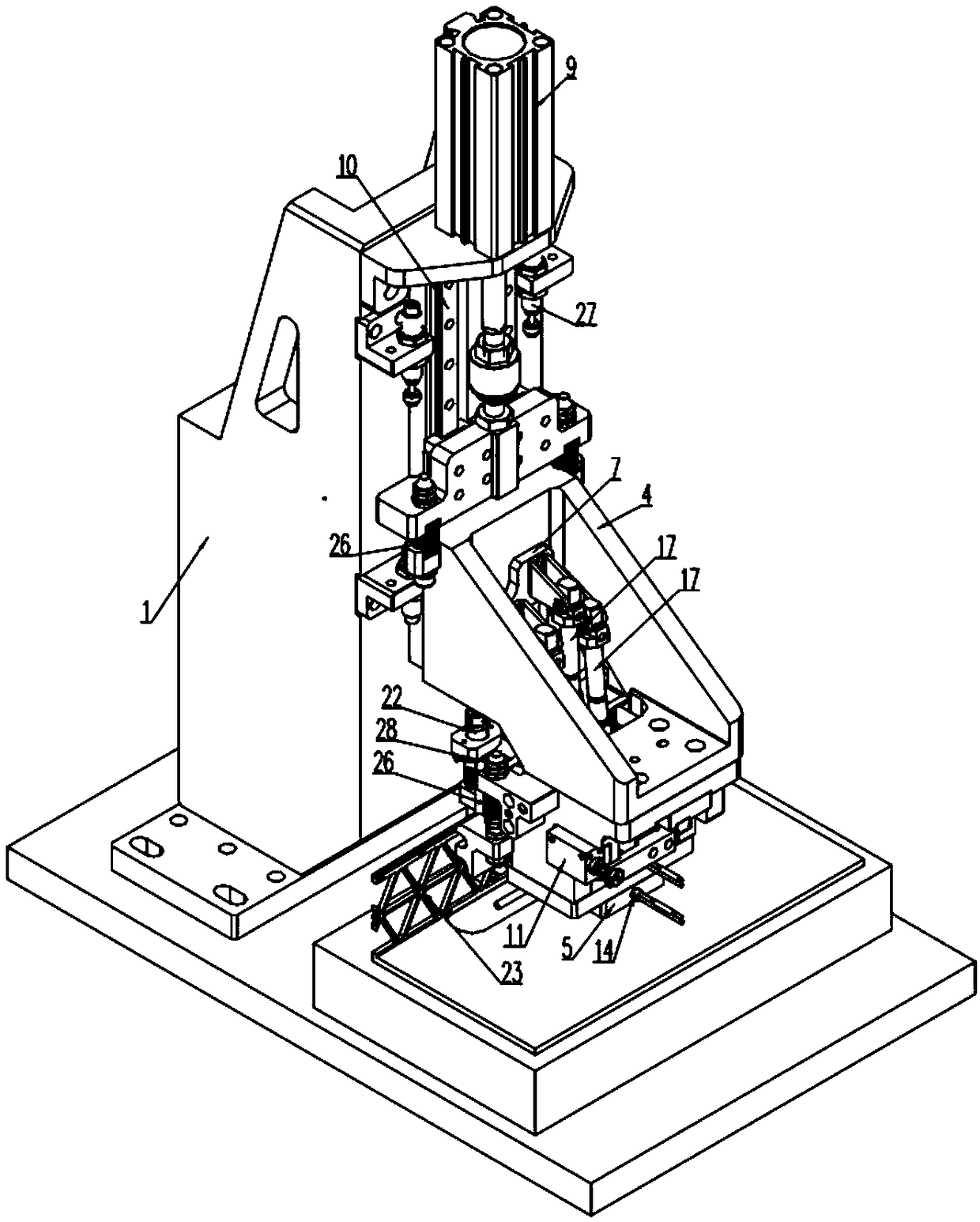

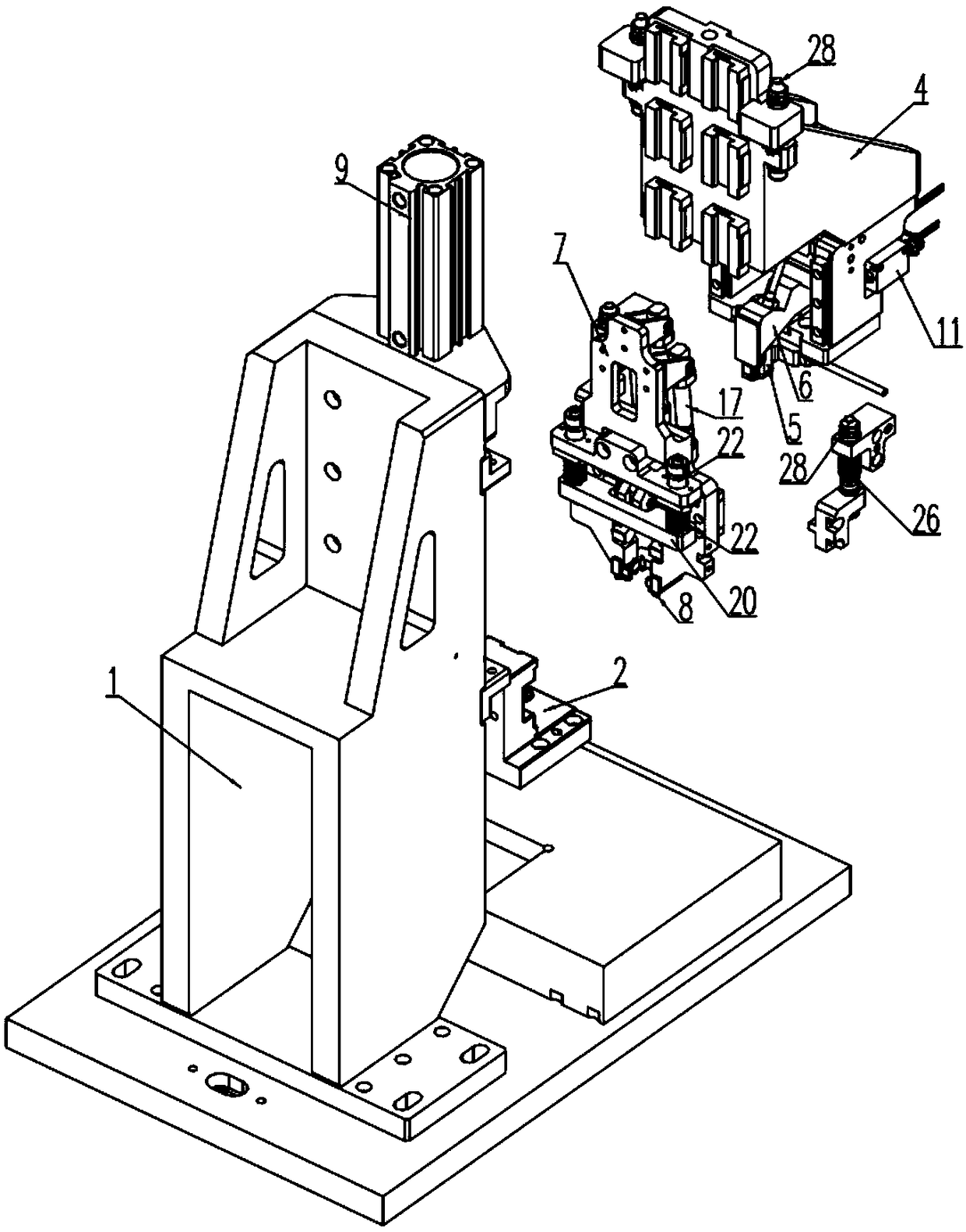

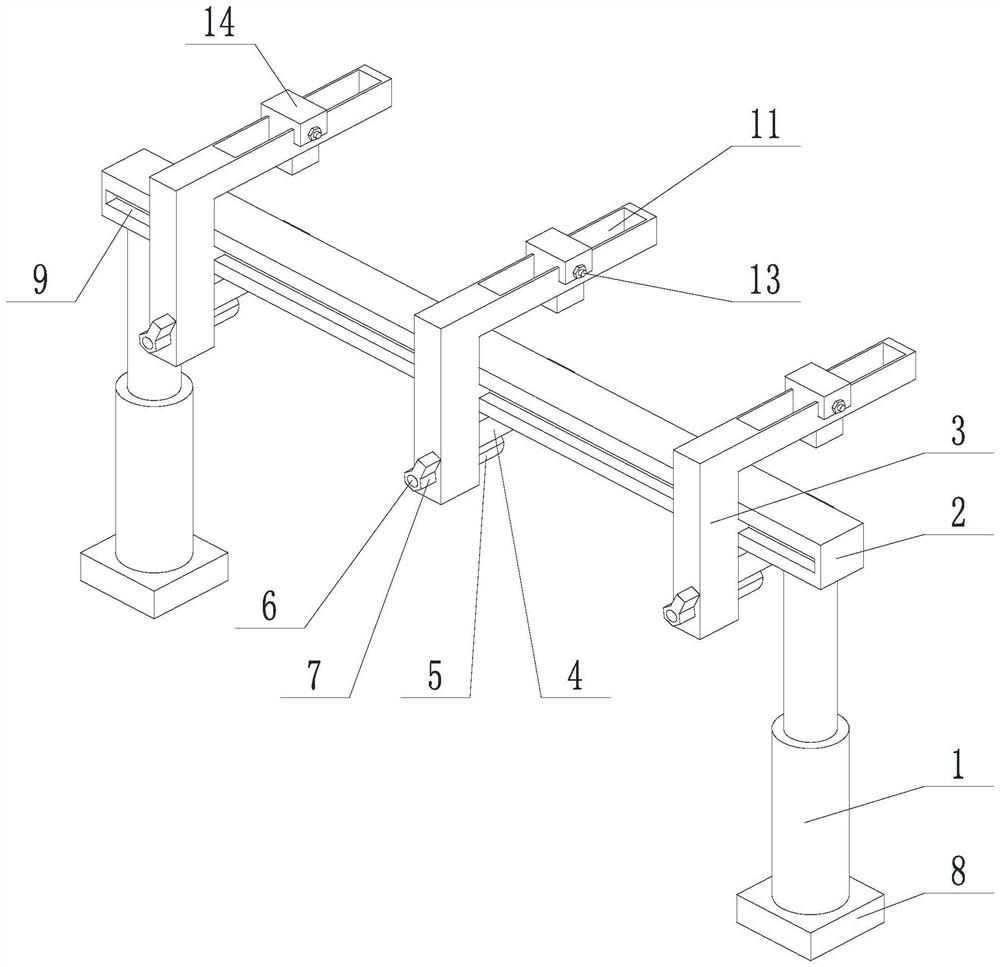

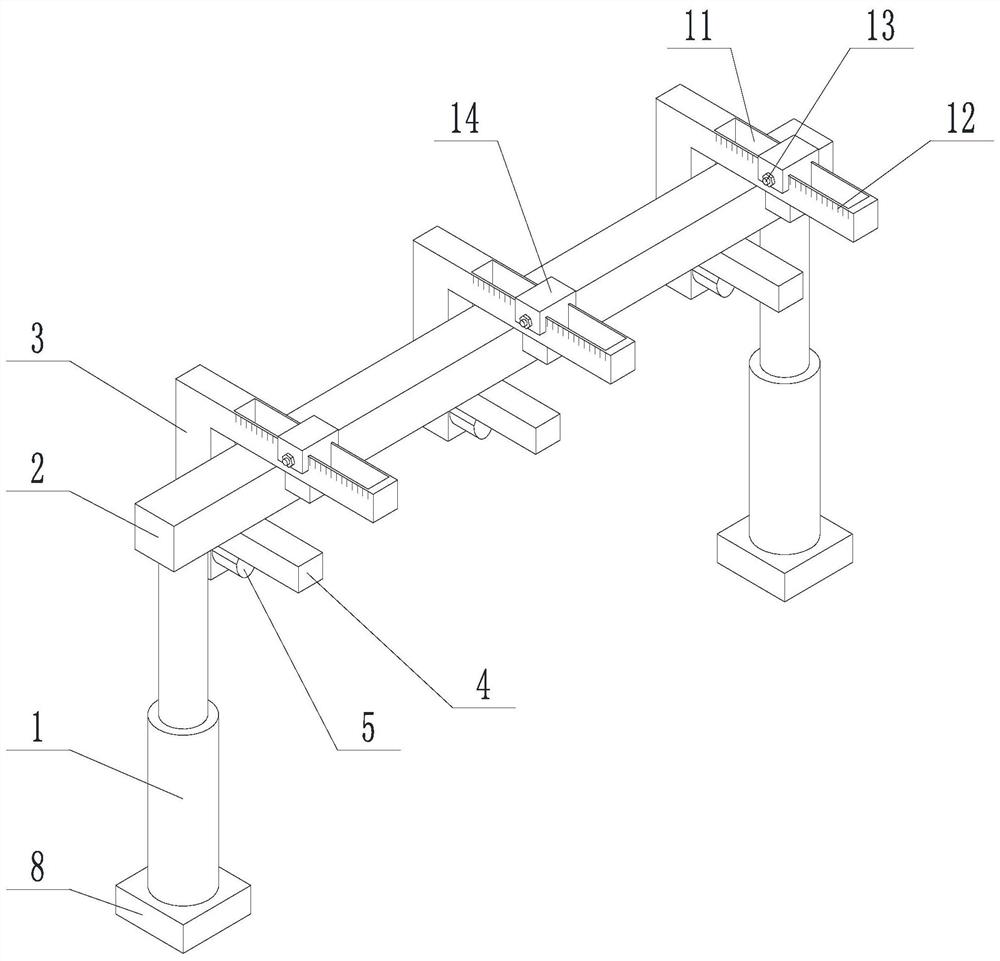

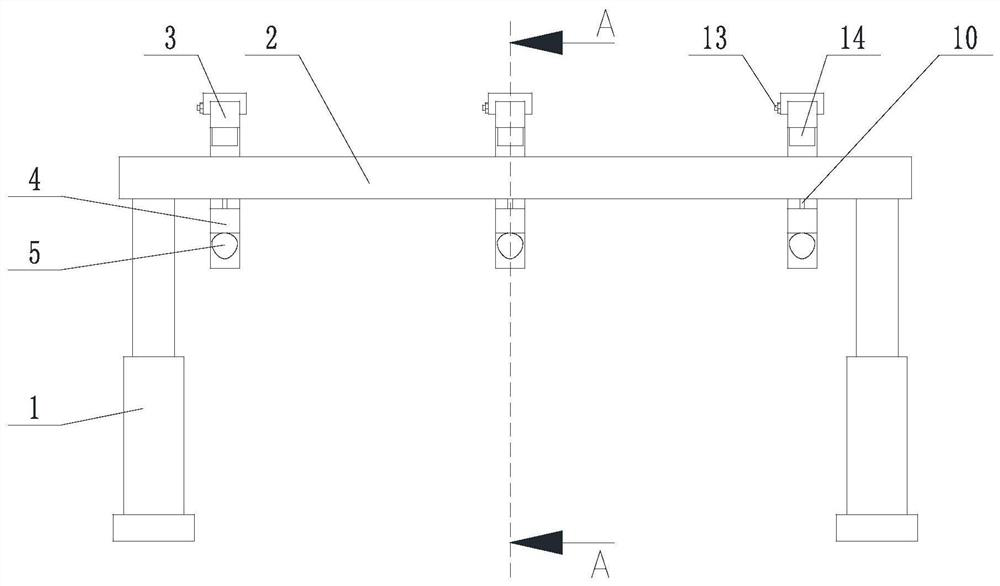

Equipment used for conducting positioning and pressure maintaining on L-shaped part

The invention provides equipment used for conducting positioning and pressure maintaining on an L-shaped part, and belongs to the technical field of pressure maintaining equipment. The equipment comprises a base, a positioning part, a first frame, a first pressing fit part, a second pressing fit part, a second frame, a horizontal segment positioning structure and a vertical segment positioning structure. When the equipment is used for maintaining the pressure of the L-shaped part, part dislocation can be effectively avoided, the quality of the whole product is kept, and meanwhile the mechanismhas the advantage that commissioning is convenient.

Owner:SUZHOU RS TECH

Color filter of top luminescent type organic electroluminescent display

InactiveCN102830454AReduced risk of misalignmentOptical filtersSolid-state devicesComputer visionOrganic electroluminescence

Owner:GUANGDONG SINODISPLAY TECH

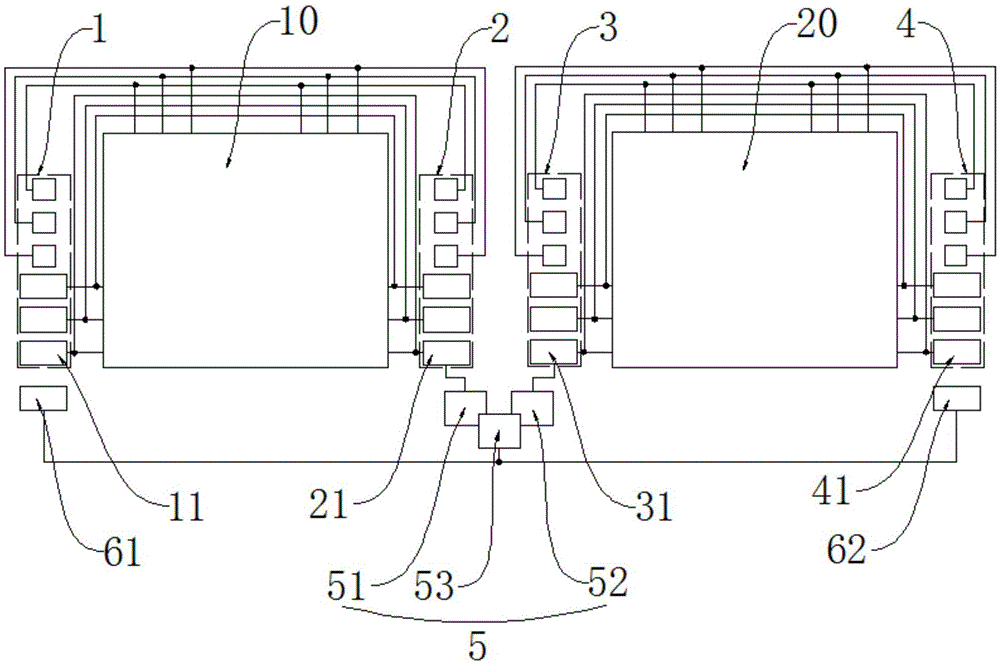

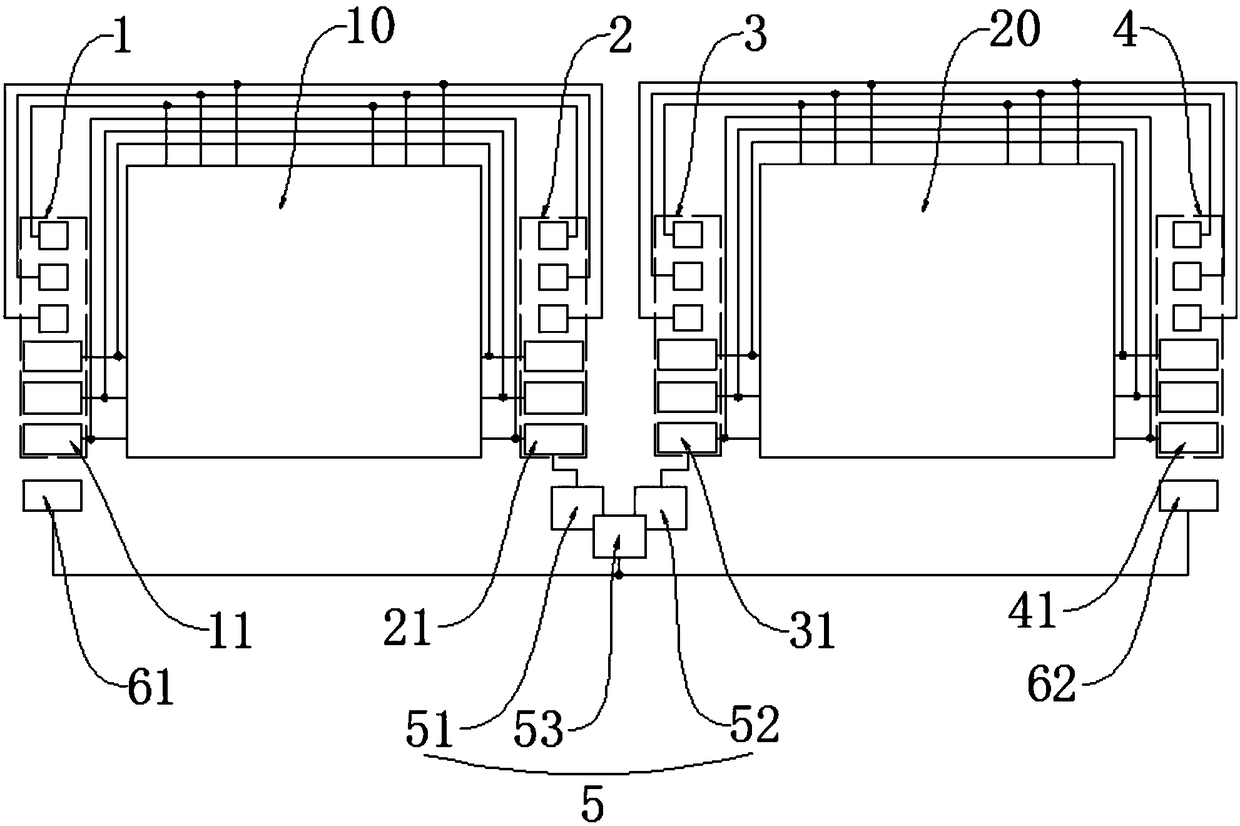

Liquid crystal light alignment circuit and liquid crystal panel

ActiveCN105549270AReduced risk of misalignmentImprove yieldNon-linear opticsLiquid-crystal displayEngineering

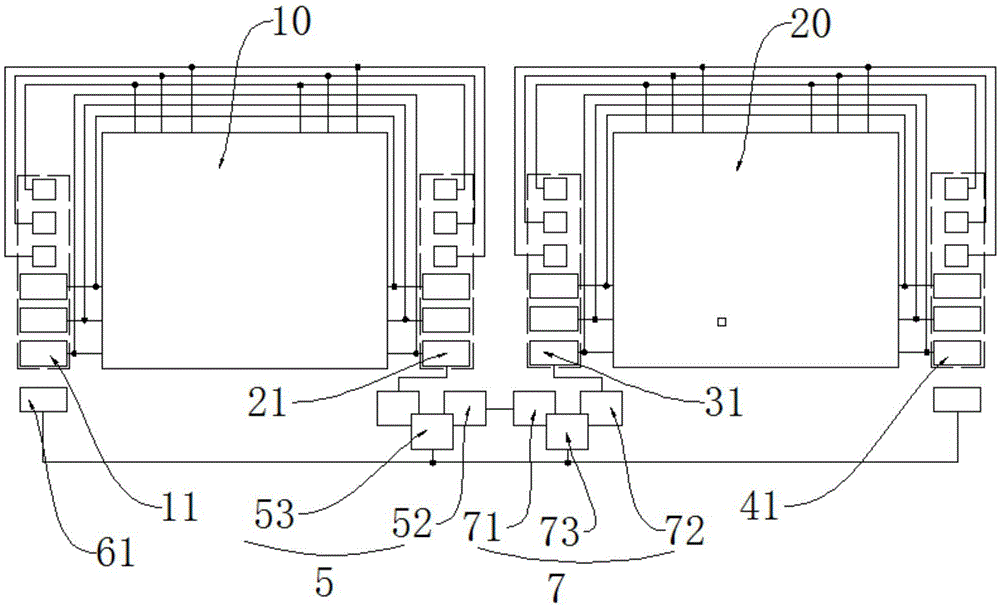

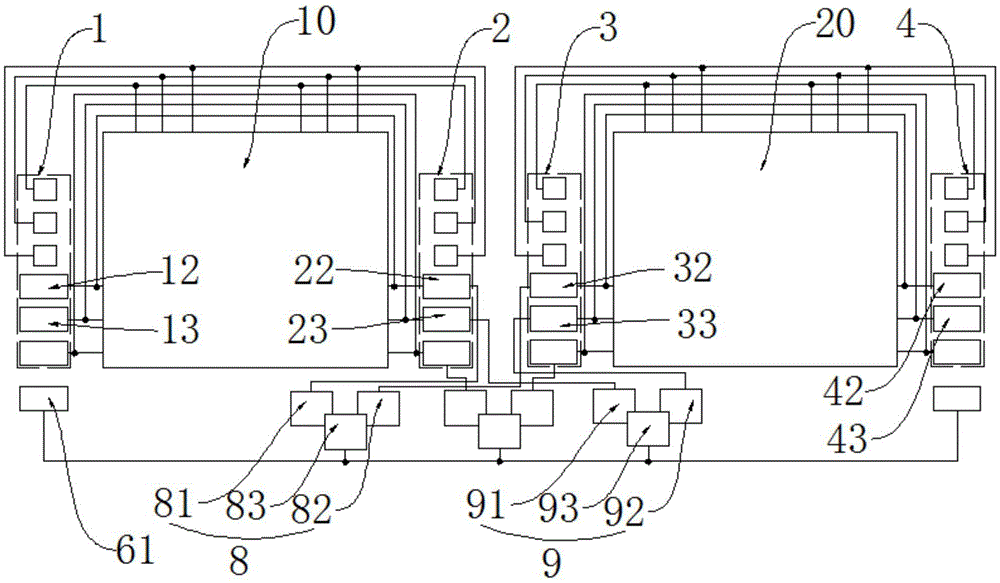

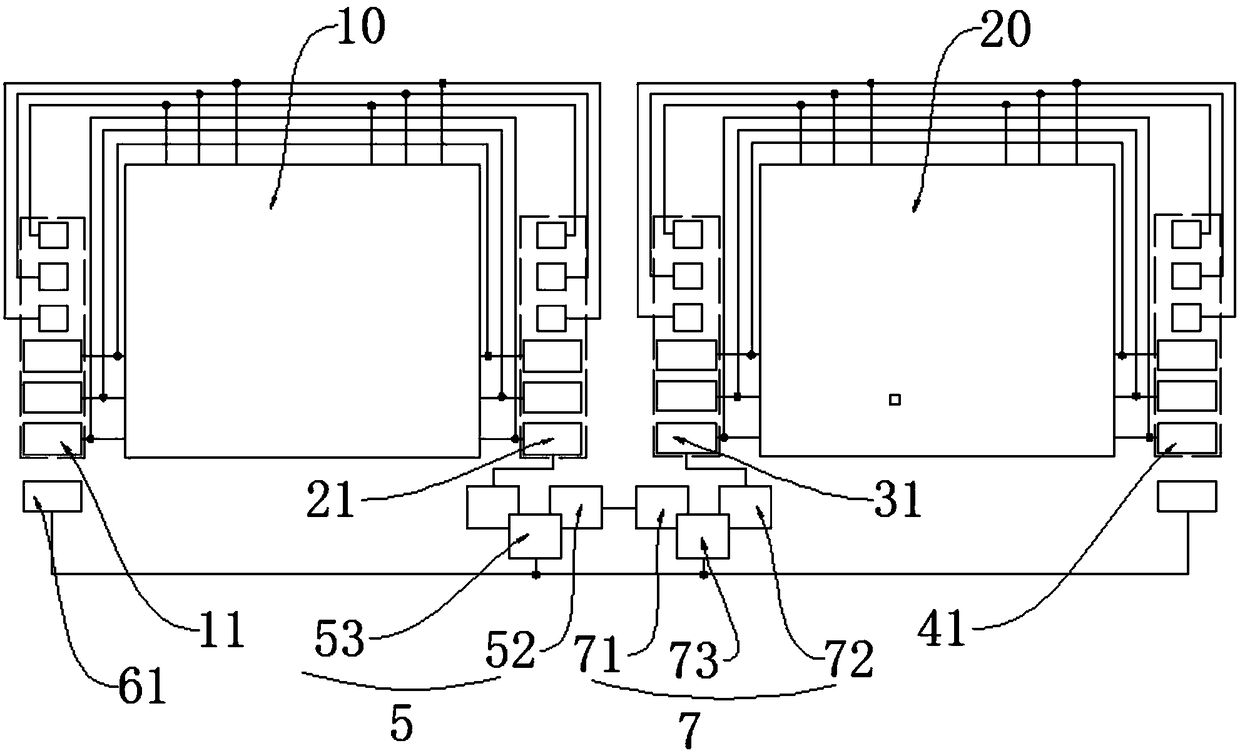

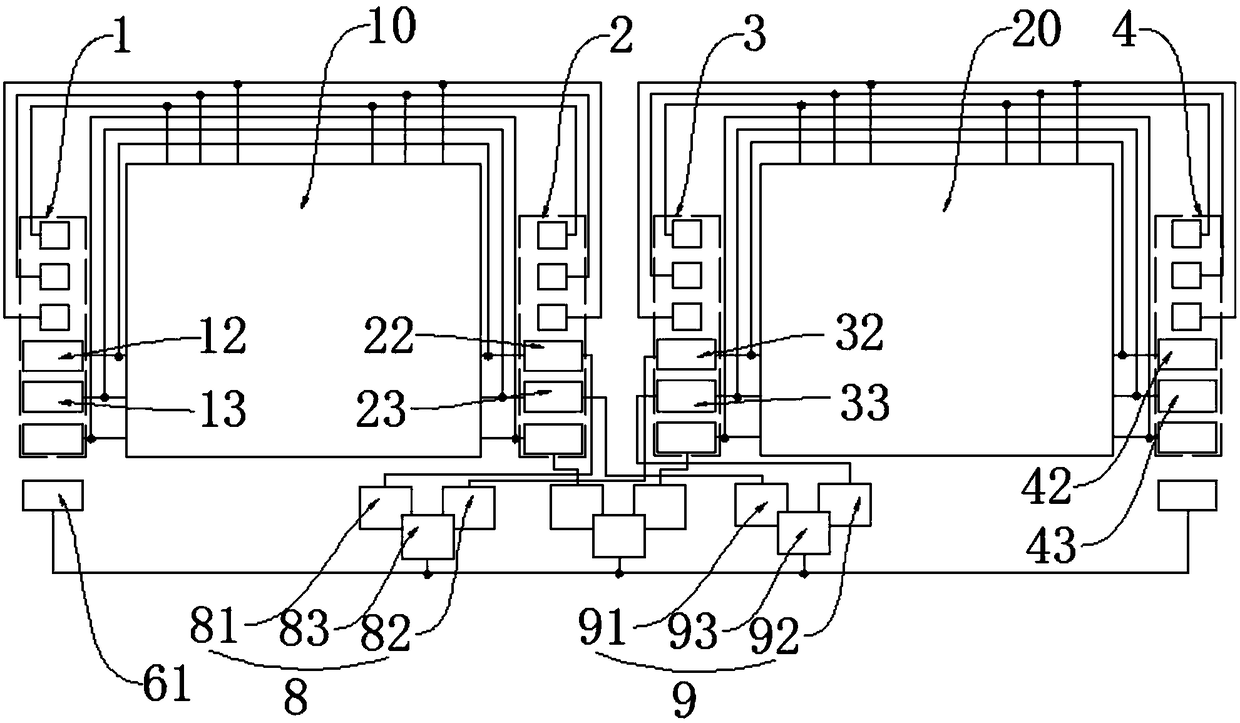

The invention discloses a liquid crystal light alignment circuit which comprises a first liquid crystal display panel, a second liquid crystal display panel, a first public electrode, a second public electrode, a third public electrode, a fourth public electrode, a first field effect transistor and a first welding disc, wherein the first public electrode and the second public electrode are connected together and are both connected with the first liquid crystal display panel; the third public electrode and the fourth public electrode are connected together and are both connected with the second liquid crystal display panel; the source area of the first field effect transistor is connected with the second public electrode; the drain area of the first field effect transistor is connected with the third public electrode; the first welding disc is connected with the grid area of the first field effect transistor; when the first public electrode and the first liquid crystal display panel or the fourth public electrode and the second liquid crystal display panel are abnormally connected, the first welding disc can be electrified to communicate the second public electrode with the third public electrode. By adopting the liquid crystal light alignment circuit, normal liquid crystal light alignment voltage can be provided. The invention further discloses a liquid crystal panel.

Owner:TCL CHINA STAR OPTOELECTRONICS TECH CO LTD

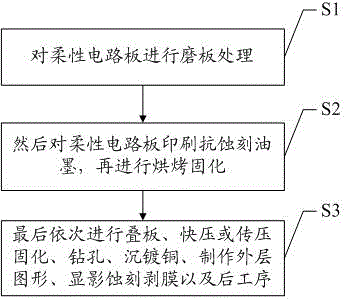

Manufacturing method of flexible circuit board employing ink instead of adhesive tape and flexible circuit board

InactiveCN106028685AStrong combinationSimple production processPrinted circuit fillers/particles/fibers/reinforcementMultilayer circuit manufactureBinding forceCopper plating

The invention discloses a flexible circuit board manufacturing method and a flexible circuit board using ink instead of adhesive tape. The production method includes the steps: A. grinding the flexible circuit board; B. printing anti-etching ink on the flexible circuit board, and then baking and curing; Holes, copper plating, making outer layer graphics, development, etching and stripping, and post-processing. In the production method of the present invention, the adhesive tape is replaced by ink. After the ink is printed and cured, it can withstand high temperature and high pressure. It can effectively improve the accuracy and reduce the risk of misalignment. It can be directly peeled off in the later stage, which is simple, convenient and fast.

Owner:SHENZHEN KINWONG ELECTRONICS

Sequentially etched and plated lead frame structure with island prepacked plastic sealed material and producing method thereof

ActiveCN102324414AReduce material costsReduce processing costsSemiconductor/solid-state device detailsSolid-state devicesEngineeringLead frame

The invention relates to a sequentially etched and plated lead frame structure with an island prepacked plastic sealed material and a producing method thereof. The structure comprises an island (1) and pins (2), wherein front faces of the island (1) and the pins (2) are plated with first metal layers (5); back faces of the island (1) and the pins (2) are plated with second metal layers (6); etching regions between the island (1) and the pins (2) and between the pin (2) and the pin (2) are all filled with plastic sealed materials (4); and the plastic sealed materials (4) are aligned with the first metal layers (5) and the second metal layers (6). The sequentially etched and plated lead frame structure provided by the invention has the following advantages: a layer of expensive high temperature resistant soft organic adhesive film needs not to be attached on the bottom of the lead frame; various problems possibly generated in loading, routing and encapsulating are avoided in the background; the yield of the finished products is largely increased; and the front face and the back face of the lead frame are etched at the same time so that the complicatedness of at least 50% can be reduced in the procedure, the cost is reduced and the malposition risk caused by secondary alignment can be reduced.

Owner:JCET GROUP CO LTD

Yarn bobbin package

ActiveCN105314261APlace stableImprove drum transport efficiencyRigid containersContainers with multiple articlesYarnBobbin

The invention relates to a yarn bobbin package which comprises a plurality of lining plates. The upper surface of each lining plate is provided with a plurality of first grooves, and the lower surface of each lining plate is provided with second grooves which are identical with the first grooves in number and in one-to-one correspondence with the first grooves. The first grooves are communicated with the second grooves in a one-to-one vertical alignment mode. Each lining plate is provided with through holes identical with the first grooves in number. The lining plates are overlapped in sequence, yarn bobbins to be packaged are fixed between every two adjacent lining plates, the upper ends of the yarn bobbins to be packaged are embedded into the second grooves of the upper lining plates, and the lower ends of the yarn bobbins to be packaged are embedded into the first grooves of the lower lining plates, so that the whole package is formed. According to the yarn bobbin package, the defect that in a traditional mode, yarn bobbins collide with one another and consequently the yarn quality is affected due to the fact that the yarn bobbins deviate from positions in the transporting process is overcome; it is ensured that the yarn bobbins are firmly stored in the whole package, the packaging efficiency and the yarn bobbin transporting efficiency are improved, transportation losses are lowered, and the transportation cost is reduced; the yarn bobbin package is simple in structure and low in cost.

Owner:WUHAN HEMP BIOLOGICAL TECH CO LTD

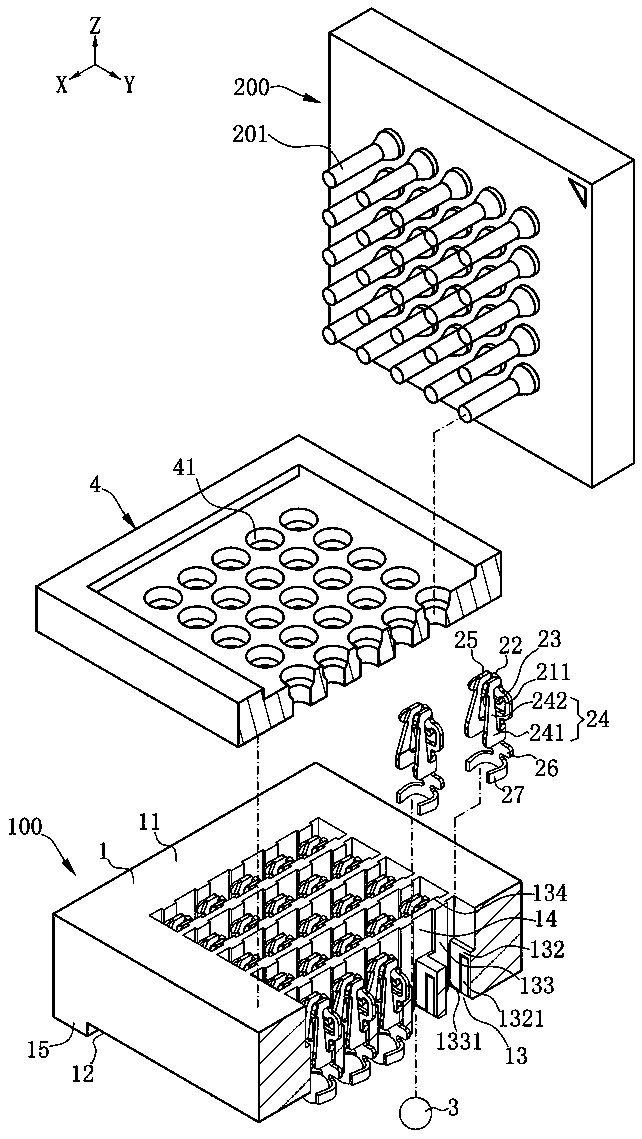

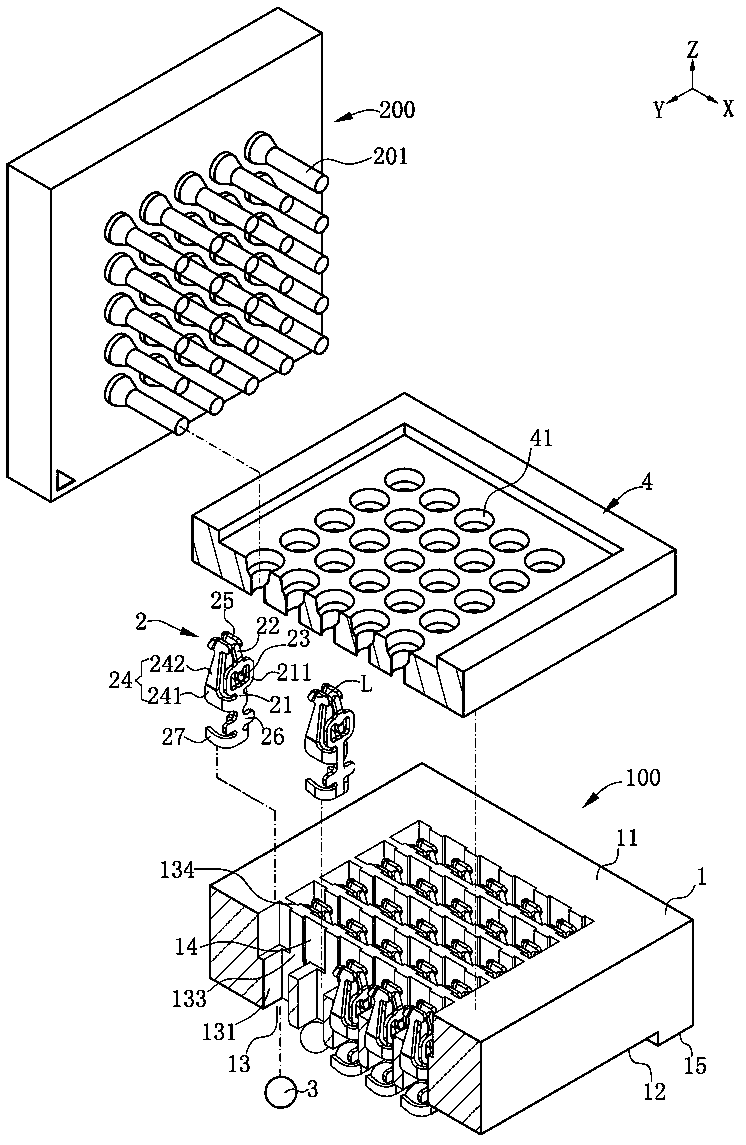

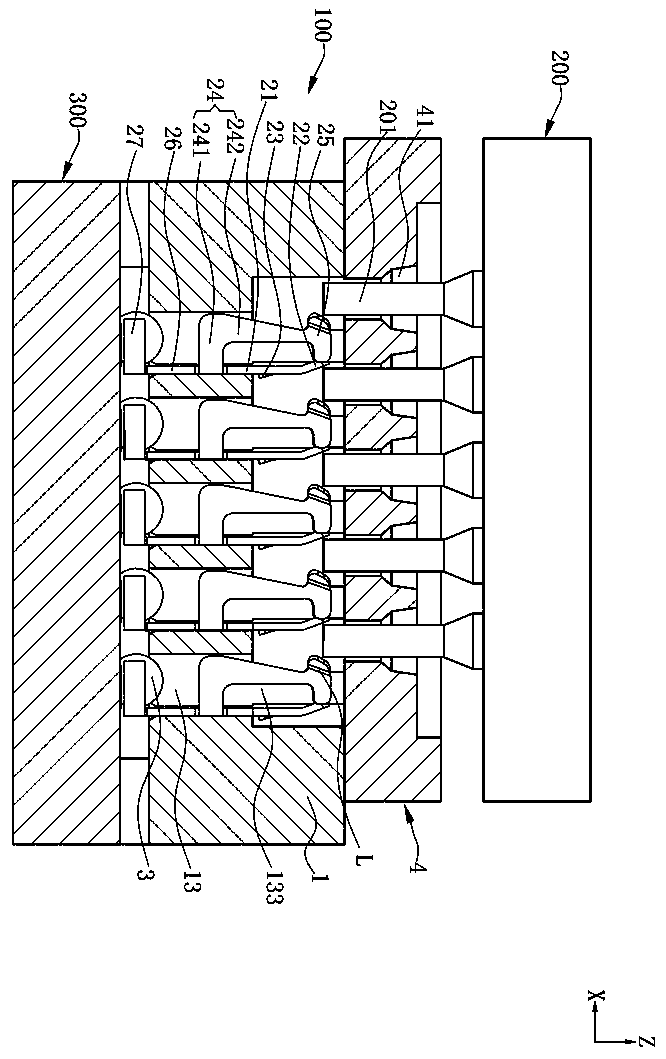

Electric connector

ActiveCN108832335AReduce the risk of misalignmentEnough elastic pressureElectric discharge tubesCoupling contact membersEngineeringElectrical and Electronics engineering

The invention discloses an electric connector used for electrically connecting a chip module provided with a plurality of pins. The electric connector is characterized by comprising an insulating bodyand a plurality of terminals, wherein a plurality of accommodating tanks are formed in the insulating body, and an avoiding space is arranged between every two adjacent accommodating tanks so that the accommodating tanks are connected with each other; the terminals are correspondingly accommodated in the accommodating tanks, each terminal comprises a base and two arms formed by extending upwardsfrom the base, the two arms are provided with two clamping parts, two guiding parts formed by bending forwards from the two clamping parts and extending towards the mutually separated direction and aninclined part formed by bending forwards from the base and extending upwards, the front side face of the inclined part is provided with a contact face, the contact face and the two clamping parts areused for clamping the corresponding pin together, the rear side face of the inclined part is provided with a guide face, and the top of the guide face is higher than the bottom face of the avoiding space; when the chip module is installed, for every two adjacent terminals in forward and backward directions, the guide face of the front terminal firstly guides the corresponding pin to be inserted downwards, and then the guide part of the back terminal guides the corresponding pin to move horizontally.

Owner:DEYI PRECISION ELECTRONIC IND CO LTD PANYU

Island-free lead frame structure prefilled with plastic encapsulating material, plated firstly and etched later and production method thereof

ActiveCN102324412BSimple designReduce material costsSemiconductor/solid-state device detailsSolid-state devicesLead framePhotoresist

A method for manufacturing an islandless lead frame structure (100) for semiconductor packaging includes providing a metal substrate, forming a first photoresist film on the top surface of the metal substrate, and forming a top surface plating pattern in the first photoresist film using photolithography. The metal also includes performing a plating process on the top surface and the back surface of the metal substrate to form a first metal layer (5) on the top surface and a second metal layer (6) on the back surface. Further, the method includes performing an etching process on the top surface and the back surface of the metal substrate simultaneously using a top surface etching pattern and a back surface etching pattern as the respective masks to form etched regions in the metal substrate and a plurality of leads (2), without forming any island. Further, the method includes removing the third photoresist film and the fourth photoresist film, and pre-encapsulating the etched metal substrate using a molding compound (4) to form the pre-encapsulated lead frame structure.

Owner:JCET GROUP CO LTD

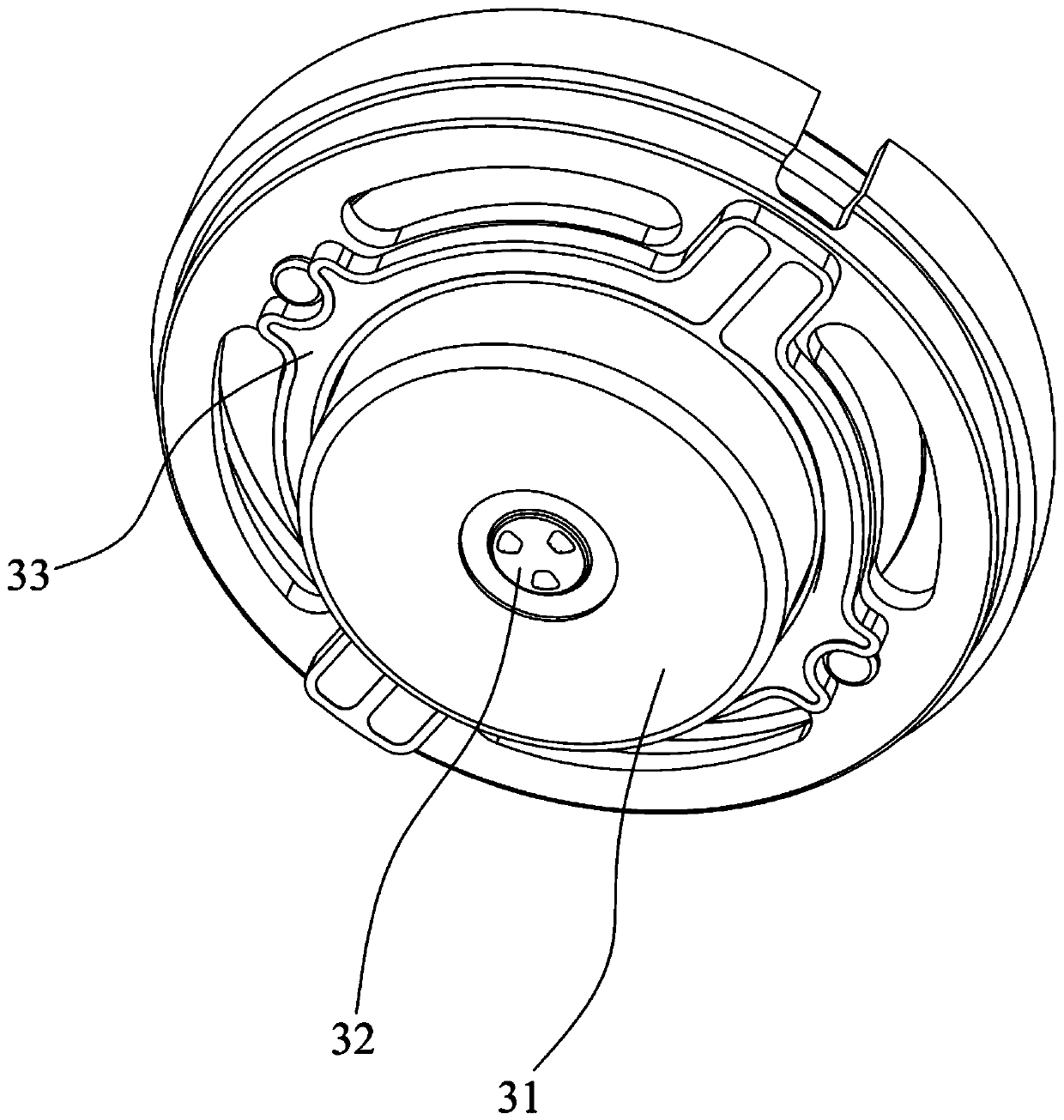

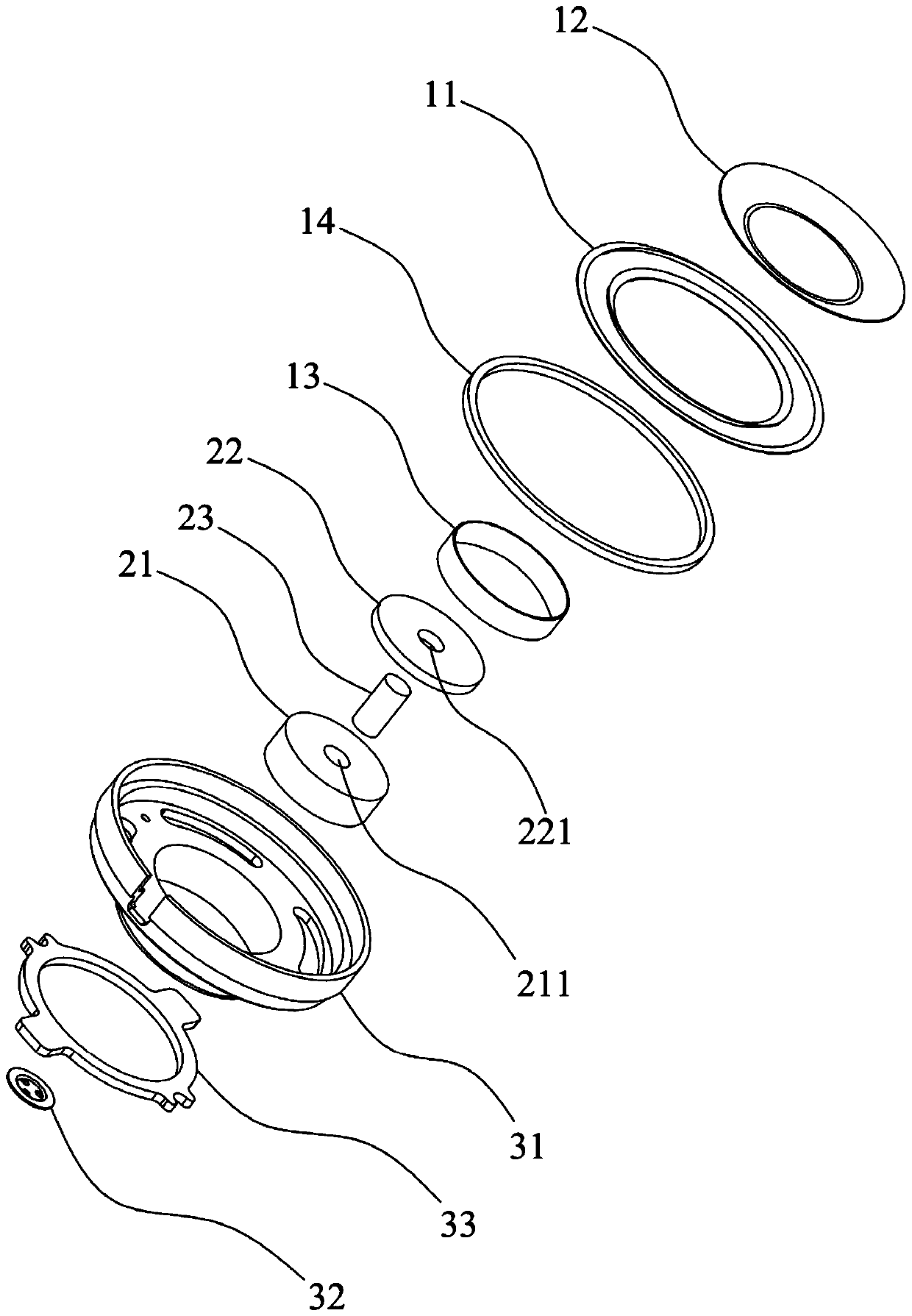

Electroacoustic device and electronic equipment adopting electroacoustic device

PendingCN111314827AResolve interferenceImprove assembly concentricityElectrical transducersSupporting systemEngineering

The invention provides an electroacoustic device and electronic equipment adopting the electroacoustic device. The electroacoustic device comprises a vibration system, a magnetic circuit system and abracket system for accommodating the vibration system and the magnetic circuit system, the vibration system comprises a vibrating diaphragm, a middle paster and a voice coil. The magnetic circuit system comprises magnetic steel, a polar plate and a middle hole positioning pin; polar plate on magnetic steel, the polar plate and the magnetic steel are cylindrical; the pole plate and the magnetic steel are coaxial, the support system comprises a support body and a rear cover, the rear cover is fixed to the bottom of the middle of the support body, a first through hole is formed in the middle of the magnetic steel, a second through hole is formed in the middle of the pole plate, the middle hole positioning pin sequentially penetrates through the second through hole and the first through hole and is fixed to the rear cover, and the middle hole positioning pin protrudes out of the pole plate. According to the invention, the problem of interference between the magnetic steel and the voice coil caused by deviation of concentricity of assembly and gluing of the magnetic steel and the bracket during vibration of the vibrating diaphragm can be solved.

Owner:JIANGXI LIANCHUANG HONGSHENG ELECTRONICS

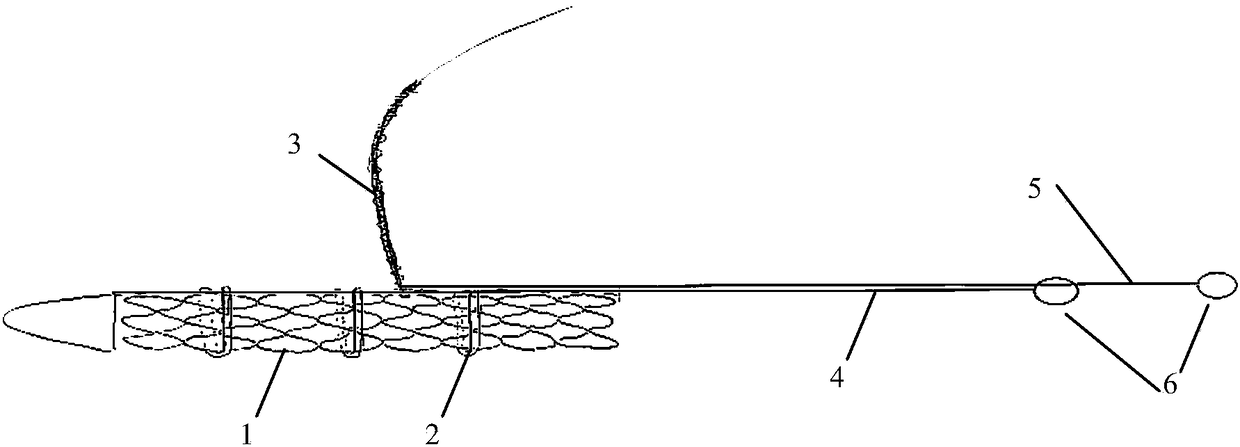

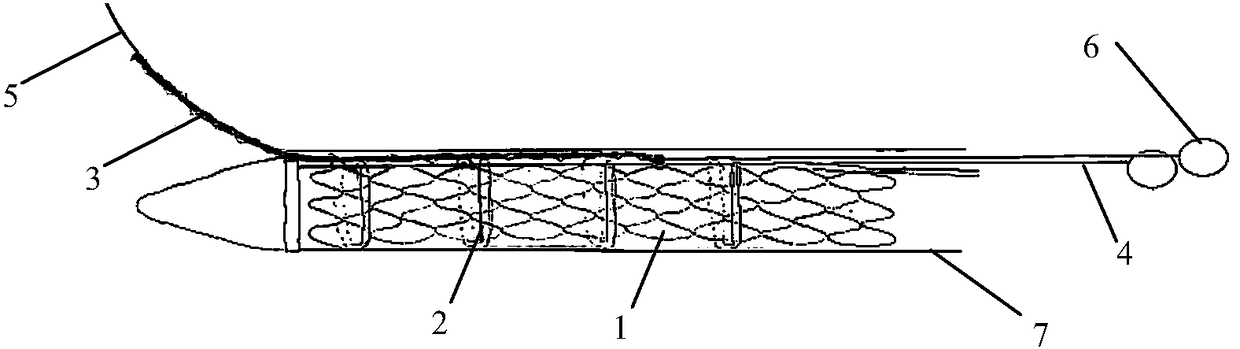

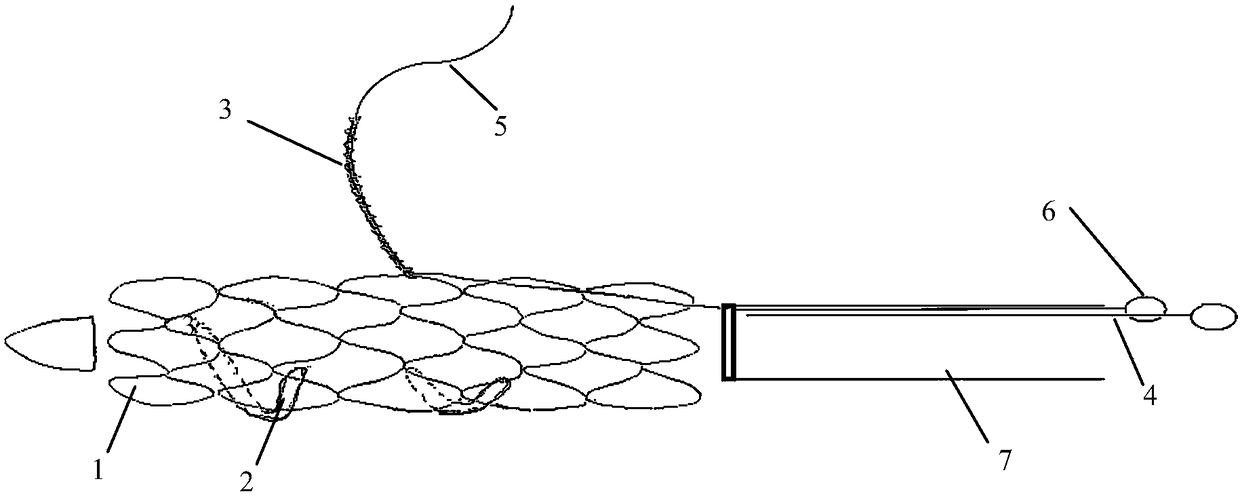

Integrated releasing controlling device for spring ring and bare stent

The invention discloses an integrated releasing controlling device for a spring ring and a bare stent. The integrated releasing controlling device comprises the spring ring and the bare stent, whereinone end of the spring ring is anchored on the outer surface of the bare stent; the integrated releasing controlling device also comprises a plurality of flexible binding pieces, a first guide wire and a second guide wire, the binding pieces are bent to be in a C shape and used for transversely binding the bare stent on the periphery at intervals, and the two ends of all the binding pieces are sequentially strung through the first guide wire; the second guide wire penetrates through the spring ring in the axial direction of the spring ring and is bound through a fine line. According to the integrated releasing controlling device for the spring ring and the bare stent, it can be effectively avoided that the spring ring and the bare stent are wound in a conveying pin and the positioning releasing process, positioning releasing can be controlled in a multistage mode, and the accuracy is improved; the released spring ring can be wound and shrunk on the periphery of an anchoring area, gapsare accurately blocked off, and the blocking effect of the spring ring is greatly improved.

Owner:SHANGHAI CHANGHAI HOSPITAL

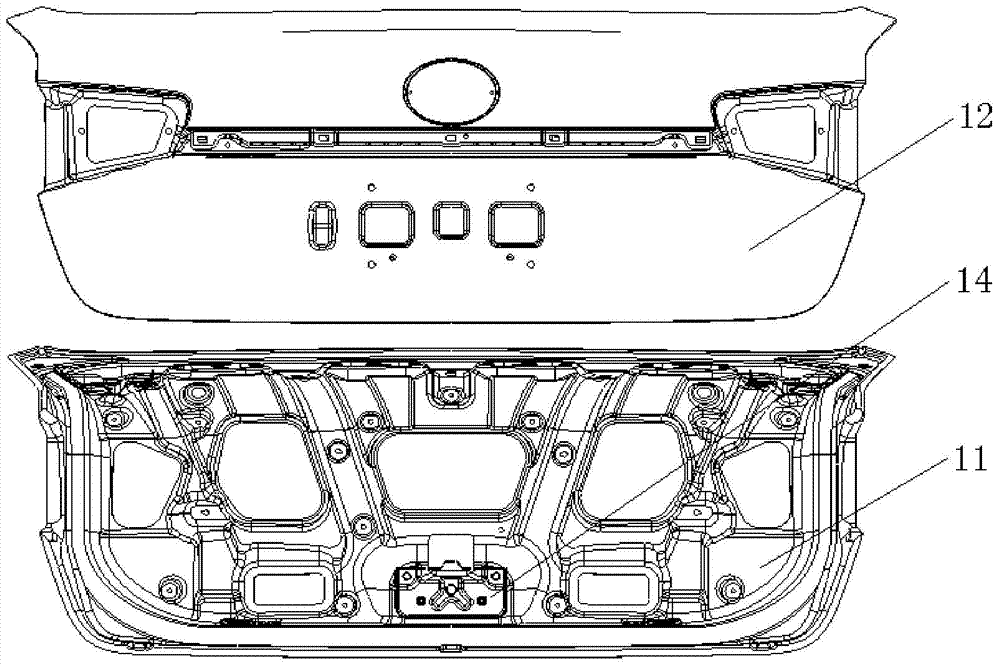

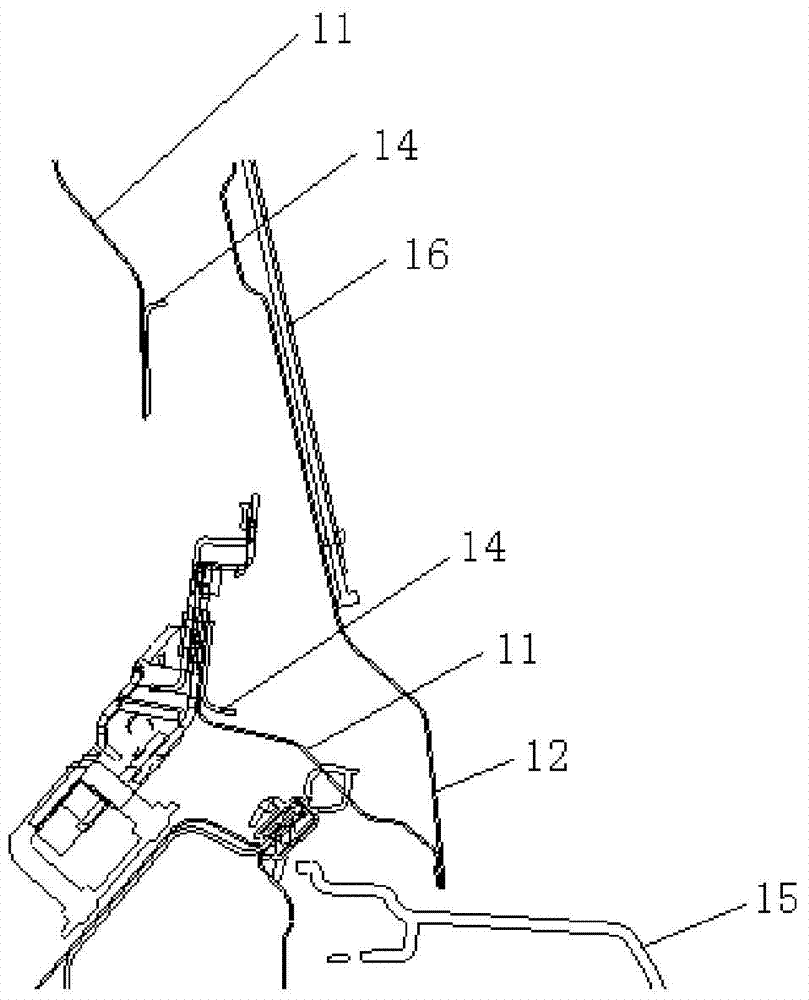

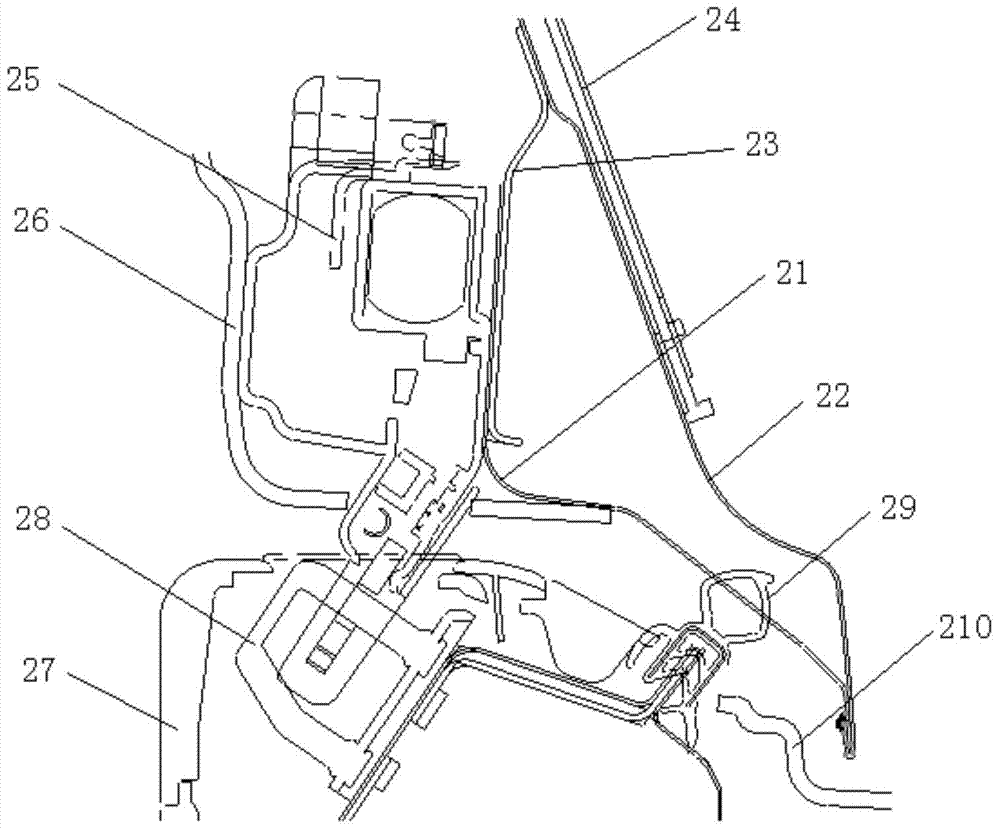

Hatchback vehicle and rear cover assembly thereof

The invention discloses a hatchback vehicle and a rear cover assembly thereof. The rear cover assembly comprises an inner plate, an outer plate and a cover lock mounting plate, wherein the edges of the inner plate and the outer plate are provided with edge covering structures, and the inner plate and the outer plate are fixedly adhered at the edge covering structures through sealing stripes; the cover lock mounting plate comprises a main body unit and an extension unit, the main body unit is welded to the inner plate, and the extension unit is welded to the outer plate. Therefore, besides the traditional edge covering and adhering structures, the rear cover assembly also obtains the welding structures on the cover lock mounting plate; the cover lock mounting plate achieves indirect connection between the inner plate and the outer plate and improves the connecting structure between the inner plate and the outer plate, thereby reducing the risk of displacement between the inner plate and the outer plate, enhancing the strength of the rear cover assembly and further ensuring the traveling safety of a vehicle.

Owner:ANHUI JIANGHUAI AUTOMOBILE GRP CORP LTD

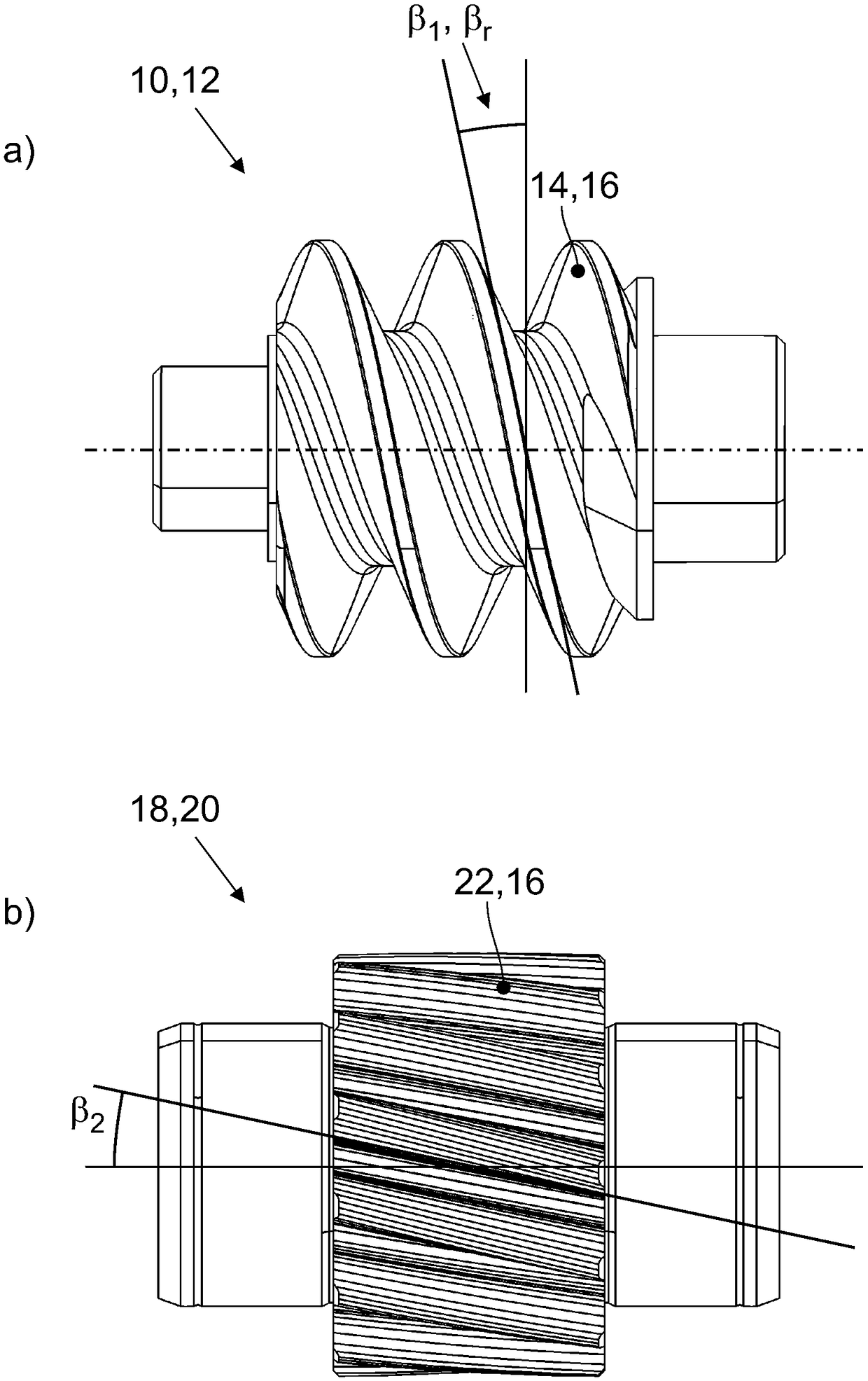

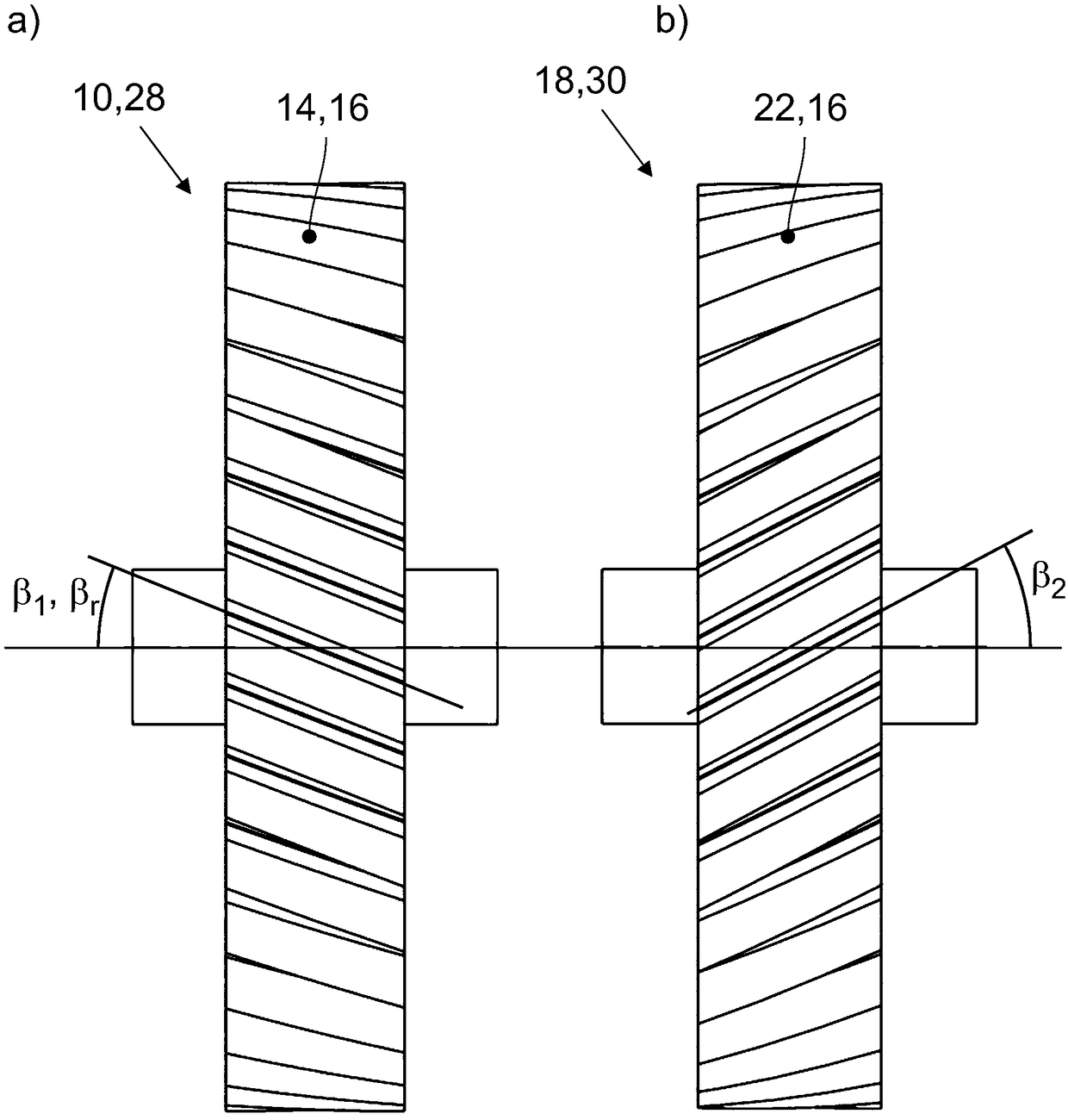

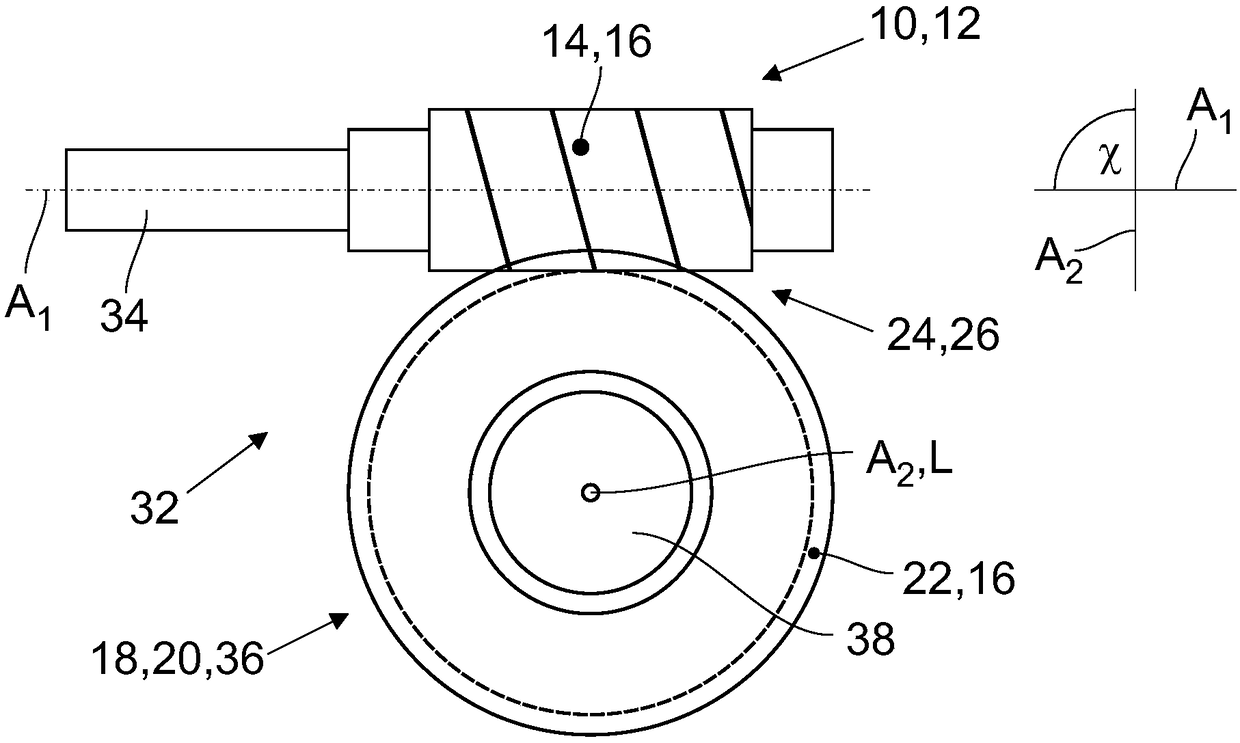

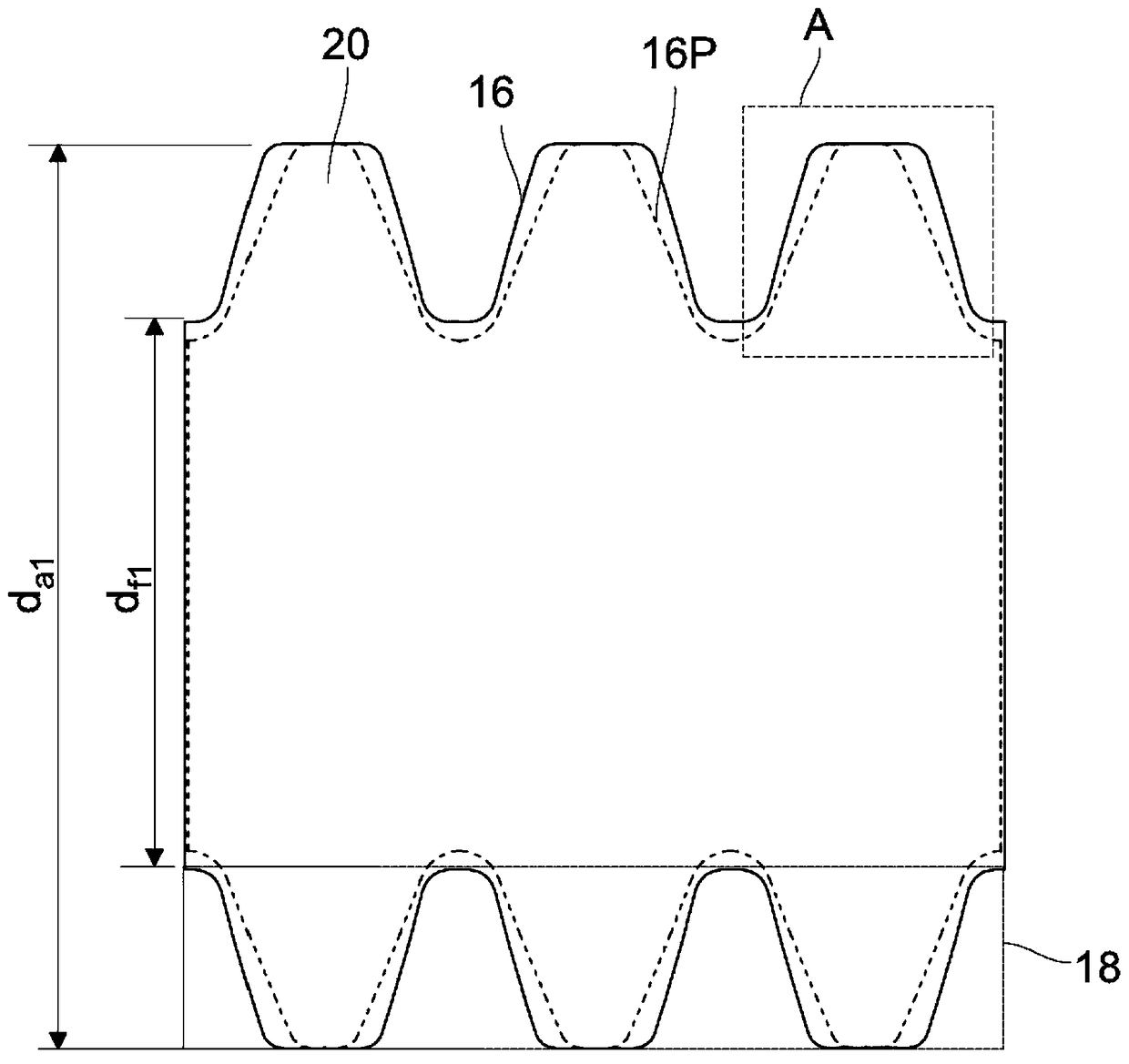

Gear pairing for a helical gear unit or a spur gear unit and application thereof

ActiveCN108953496AReduced risk of misalignmentReduce noiseVehicle seatsPortable liftingGear wheelEngineering

The present application relates to a gear pairing for a helical gear unit or a spur gear unit, comprising a first gear with a first toothing portion, and a second gear with a second toothing portion,wherein the first gear has a first axis and the second gear has a second axis, which enclose a shaft angle, which is between 0 and 90 degrees, the first toothing portion and the second toothing portion can be brought into meshing engagement and, when engaged, form an involute toothing, the materials of the first and second toothing portions are chosen so that, when engaged, a material pairing metal / plastic results, and the toothing portion made of plastic has a first helix angle and the toothing portion made of metal has a second helix angle. The formula is as shown in the description.

Owner:IMS GEAR SE & CO KGAA

Mechanism used for maintaining pressure of L-shaped part

PendingCN109236820AAvoid Misplaced SituationsImprove qualityMaterial gluingEngineeringMechanical engineering

The invention provides a mechanism used for maintaining pressure of an L-shaped part, and belongs to the technical field of pressure maintaining. The mechanism comprises a base, a positioning part, afirst frame, a first pressing fit part, a second pressing fit part and a second frame. When the mechanism is used for maintaining the pressure of the L-shaped part, part dislocation can be effectivelyavoided, the quality of the whole product is kept, and meanwhile the mechanism has the advantage that commissioning is convenient.

Owner:SUZHOU RS TECH

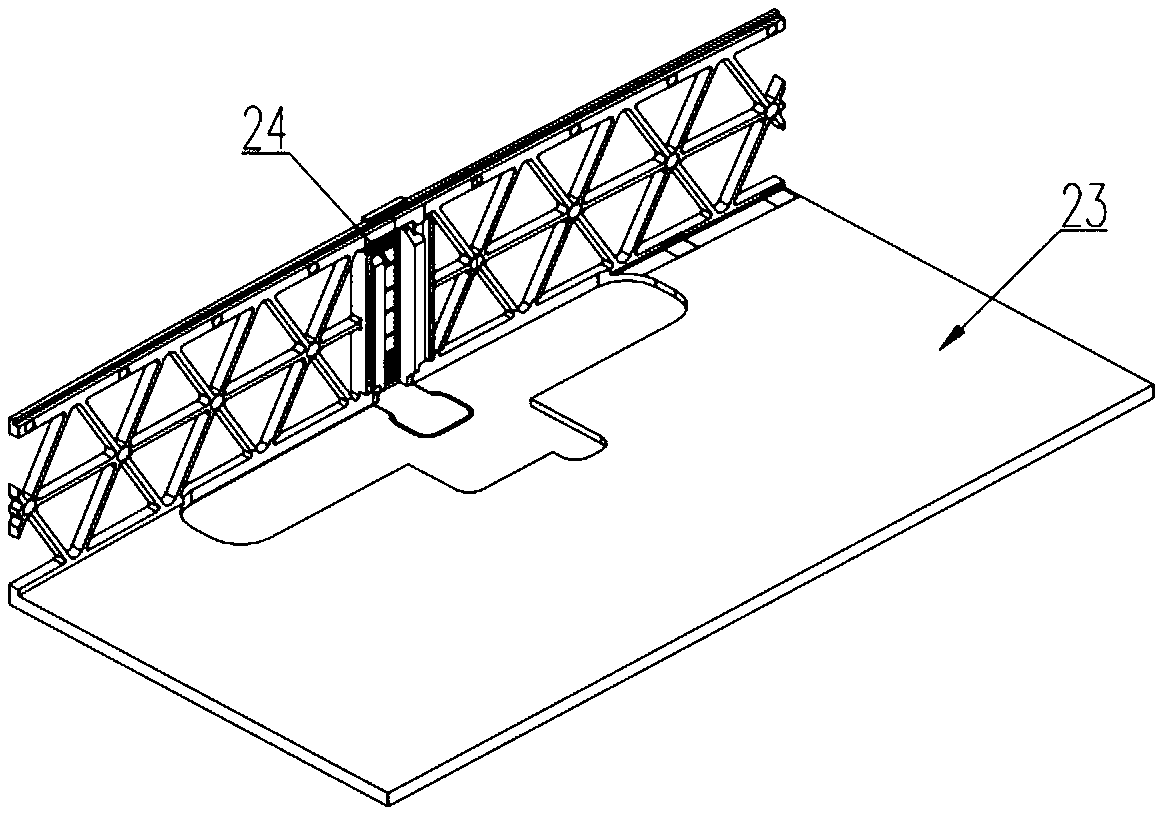

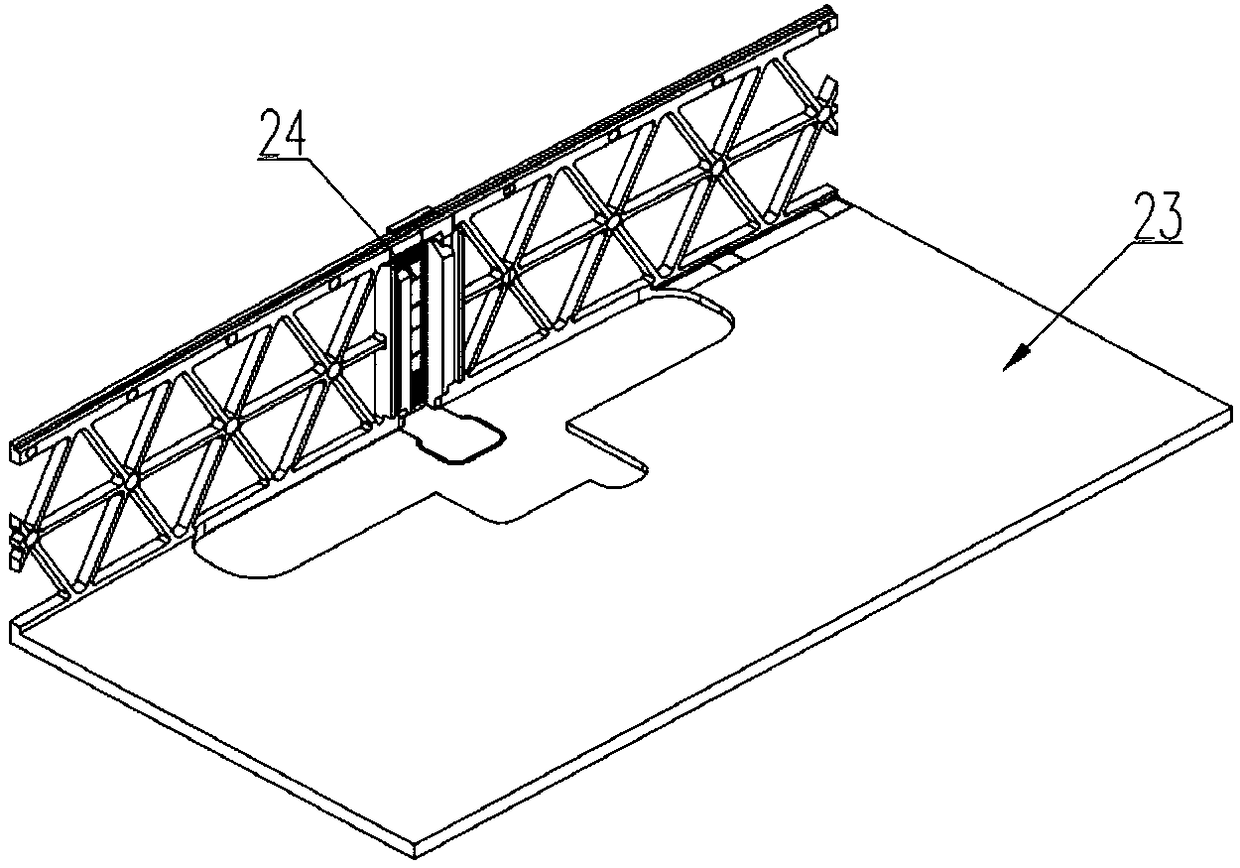

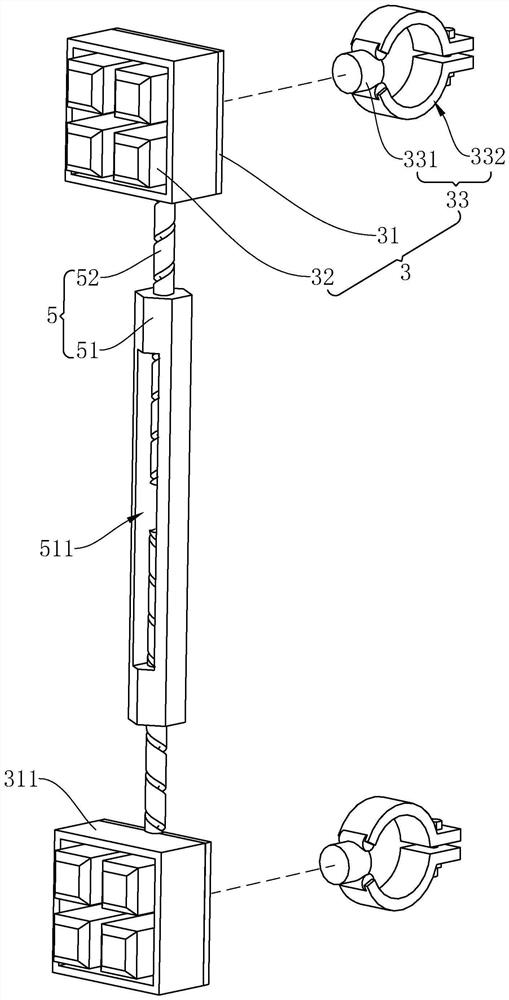

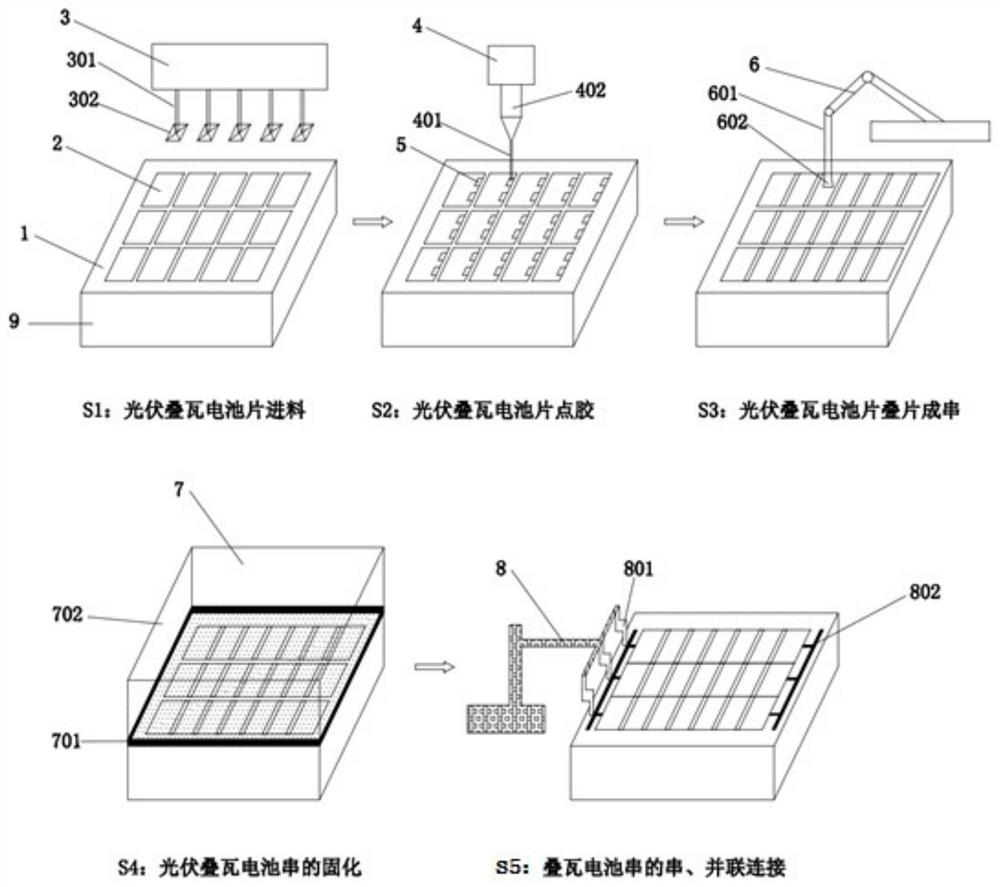

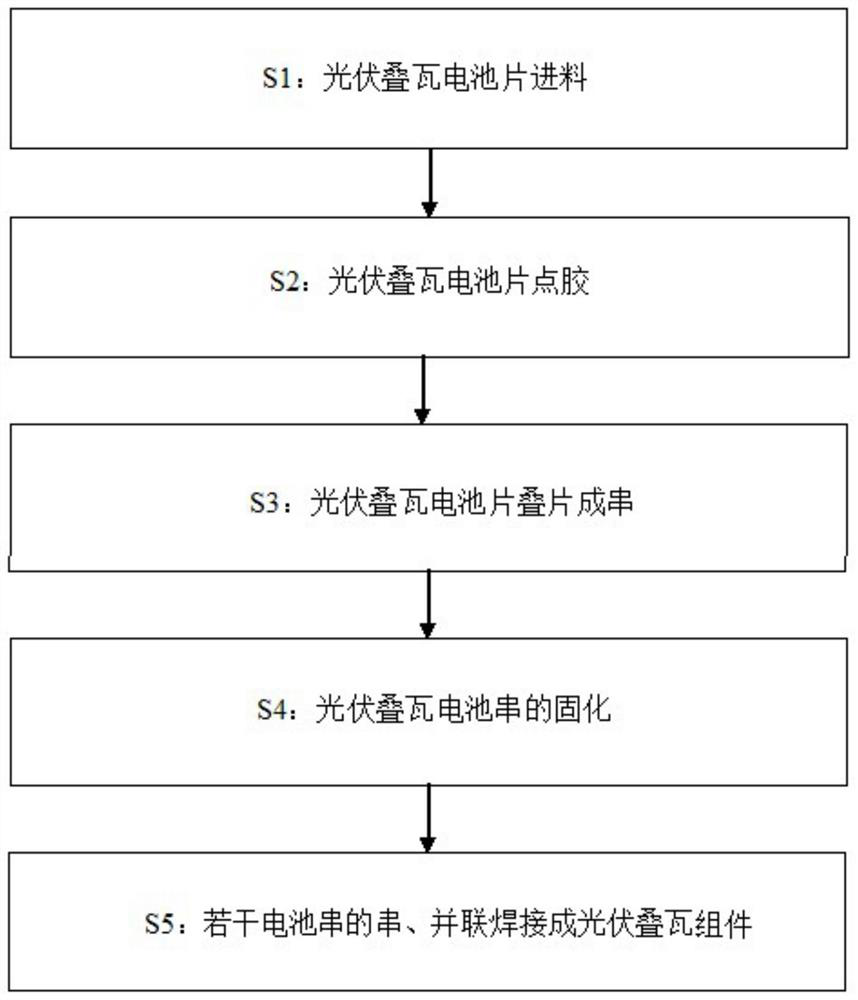

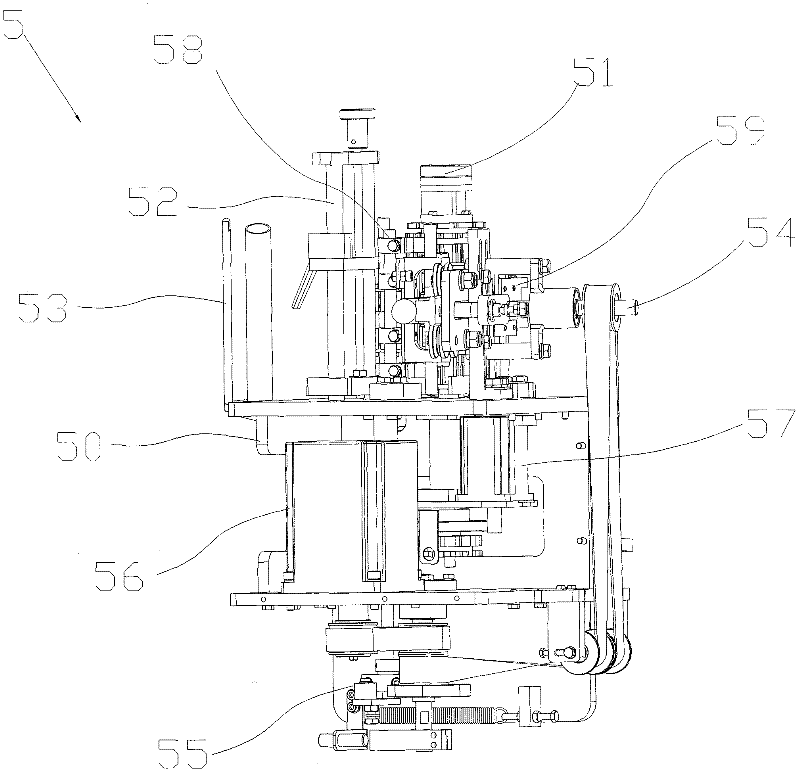

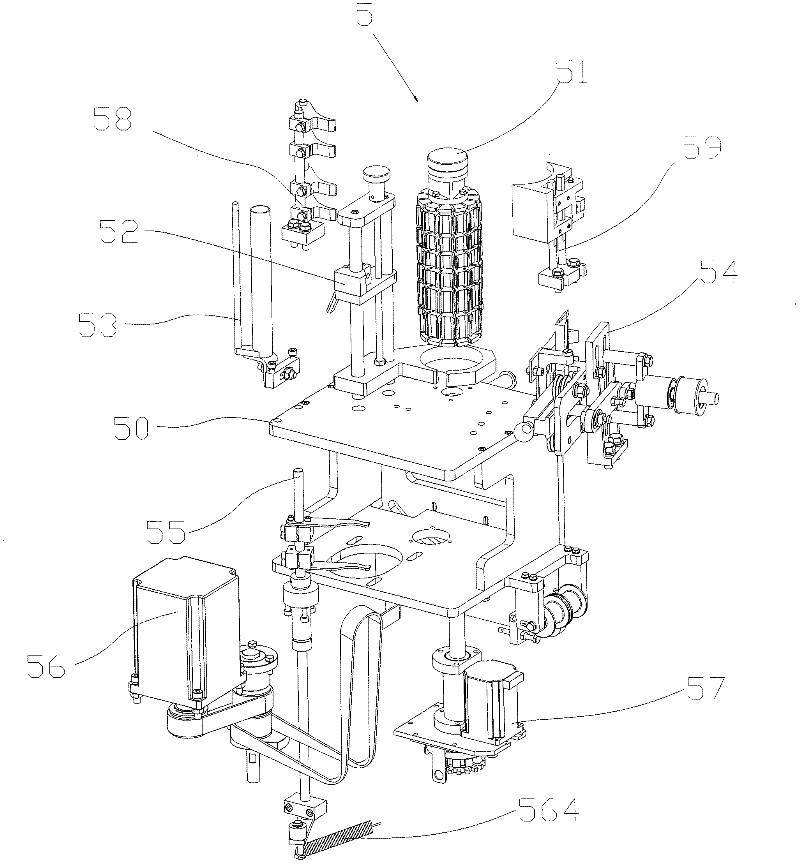

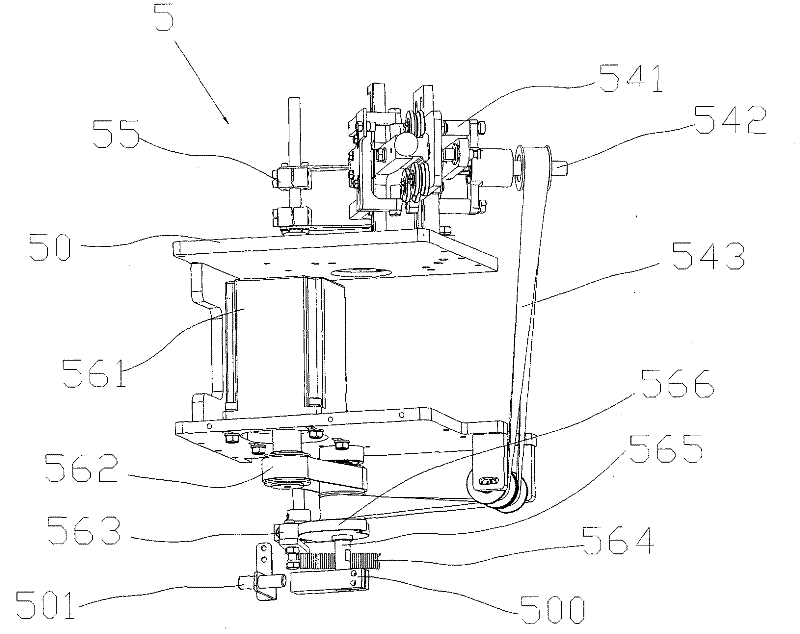

Lithium-ion battery zigzag lamination equipment and process thereof

ActiveCN109244554BReduced risk of misalignmentFinal product manufactureElectrolyte accumulators manufactureStructural engineeringLithium-ion battery

The invention discloses a lithium ion battery zigzag stacking equipment and its technology. The lithium ion battery zigzag stacking equipment includes: a diaphragm, a plurality of negative electrode plates are arranged on the upper surface of the diaphragm at regular intervals, and a plurality of negative electrode plates are arranged on the lower surface of the diaphragm. A positive electrode sheet; a hot-press composite device; a separator cutting device; a lamination mechanism, and the zigzag lamination process of a lithium-ion battery includes the following steps: (1) die-cut or cut the positive roll and the negative roll first, and then place them on the diaphragm The upper surface and the lower surface are respectively bonded with die-cut or cut negative electrode sheets and positive electrode sheets, and the positive electrode sheets and negative electrode sheets are alternately distributed; (2) Then the separator is thermally pressed and composited with each negative electrode sheet and positive electrode sheet; (3 ) and finally carry out zigzag folding and cut the diaphragm. The invention realizes seamless docking between die-cutting or cutting and zigzag laminations, saves the pole piece transfer device and facilities, and fixes the pole piece by hot-compression composite method, which reduces the dislocation of the pole piece during the transfer process of the bare cell risks of.

Owner:江苏卡耐新能源有限公司 +4

Batch marking equipment for triangular marks of oil casing screwed joints

ActiveCN112248661AOvercoming the problem of root-by-root markingImprove work efficiencyTypewritersCamScrew joint

The invention discloses batch marking equipment for triangular marks of oil casing pipe screwed joints. The equipment comprises two supporting legs and a transverse rod fixed between the two supporting legs; a plurality of L-shaped pieces are connected onto the transverse rod; one end of each L-shaped piece is in sliding fit with the side surface of the transverse rod, the other end is located above the transverse rod and strides over the transverse rod; the L-shaped pieces can slide along the axis of the transverse rod; the equipment further comprises clamping pieces in sliding fit with the L-shaped pieces; the clamping pieces can slide in the longitudinal direction; the clamping pieces are located below the transverse rod and stride across the transverse rod; cams are arranged below theclamping pieces; the cams are driven by a driving mechanism to rotate; the end, located above the transverse rod, of each L-shaped piece is further provided with a marking assembly. According to the batch marking equipment for the triangular marks of the oil casing pipe screwed joints, the technical problem of low efficiency due to the fact that casing pipes are required to be marked one by one inthe prior art is solved, and the purpose that the triangular marks are printed on a row of laid casing pipes in batches at the same time is achieved.

Owner:熊勇

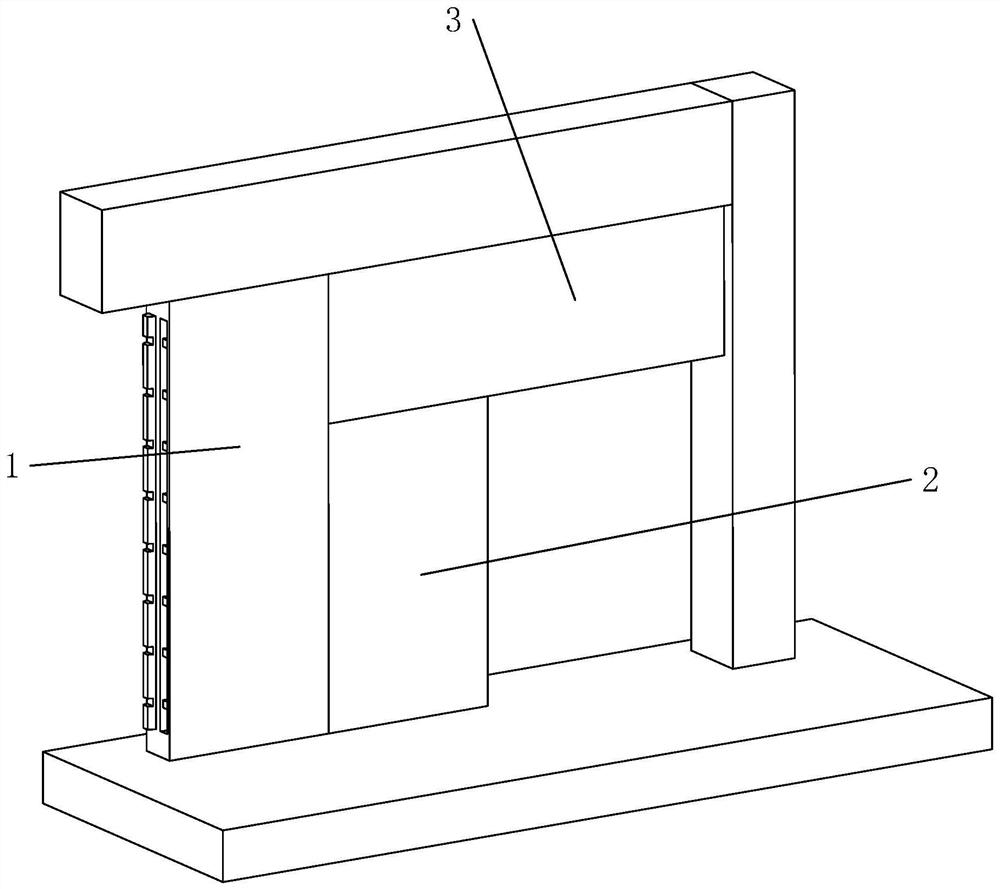

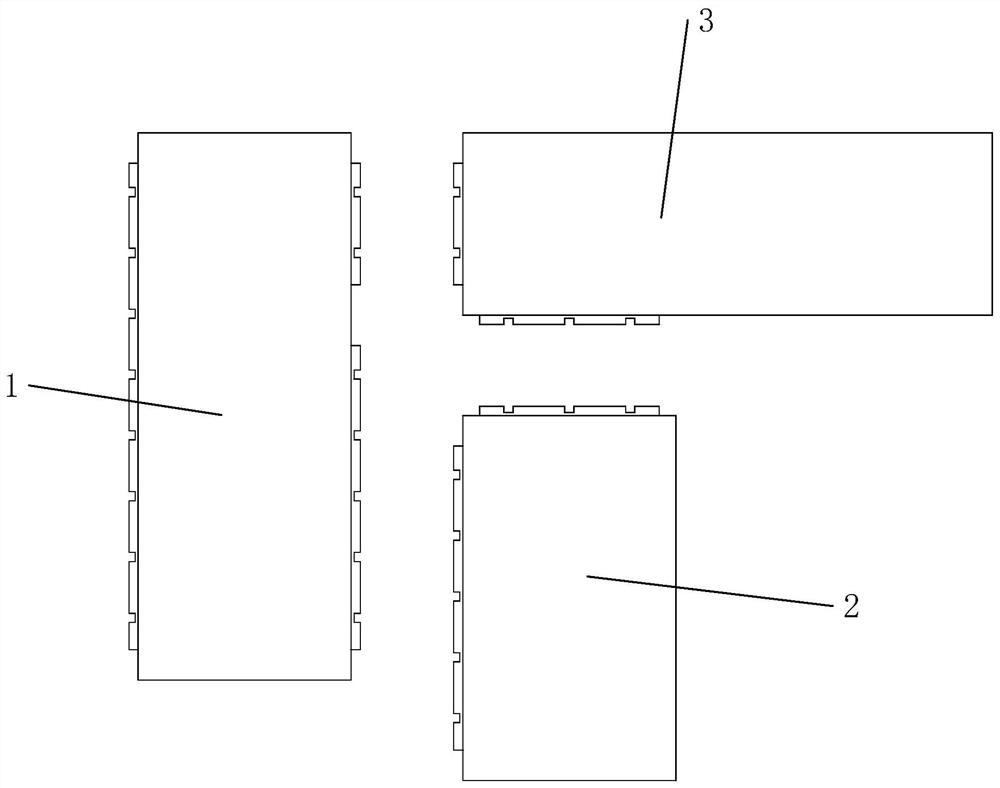

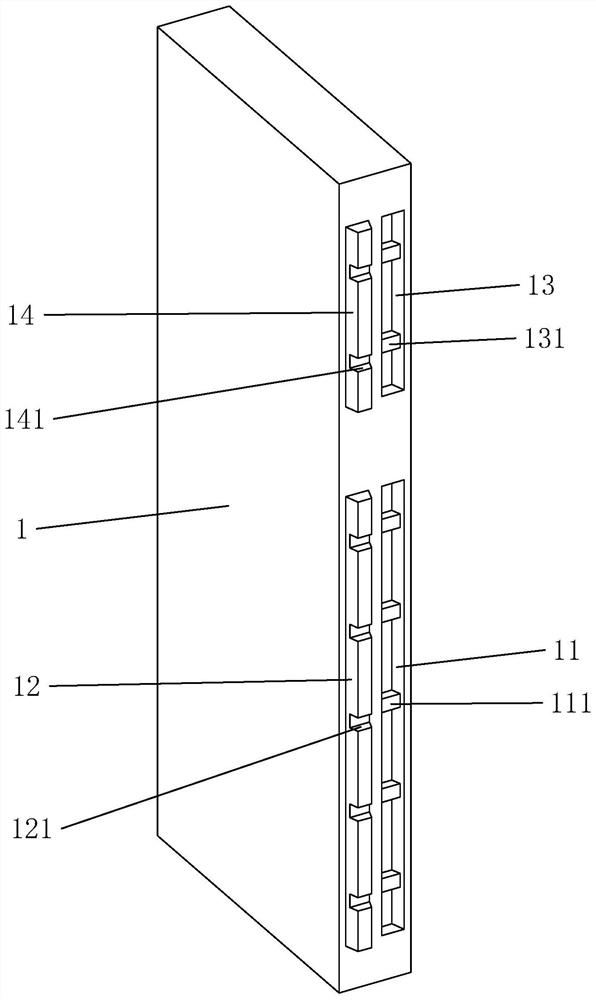

Fabricated building wall and fabricated building thereof

InactiveCN113136985AImprove stabilityReduced risk of misalignmentWallsArchitectural engineeringEngineering

Owner:福建榕鸿建设有限公司

Liquid crystal light alignment circuit and liquid crystal panel

ActiveCN105549270BReduced risk of misalignmentImprove yieldNon-linear opticsLiquid-crystal displayEngineering

The invention discloses a liquid crystal light alignment circuit which comprises a first liquid crystal display panel, a second liquid crystal display panel, a first public electrode, a second public electrode, a third public electrode, a fourth public electrode, a first field effect transistor and a first welding disc, wherein the first public electrode and the second public electrode are connected together and are both connected with the first liquid crystal display panel; the third public electrode and the fourth public electrode are connected together and are both connected with the second liquid crystal display panel; the source area of the first field effect transistor is connected with the second public electrode; the drain area of the first field effect transistor is connected with the third public electrode; the first welding disc is connected with the grid area of the first field effect transistor; when the first public electrode and the first liquid crystal display panel or the fourth public electrode and the second liquid crystal display panel are abnormally connected, the first welding disc can be electrified to communicate the second public electrode with the third public electrode. By adopting the liquid crystal light alignment circuit, normal liquid crystal light alignment voltage can be provided. The invention further discloses a liquid crystal panel.

Owner:TCL CHINA STAR OPTOELECTRONICS TECH CO LTD

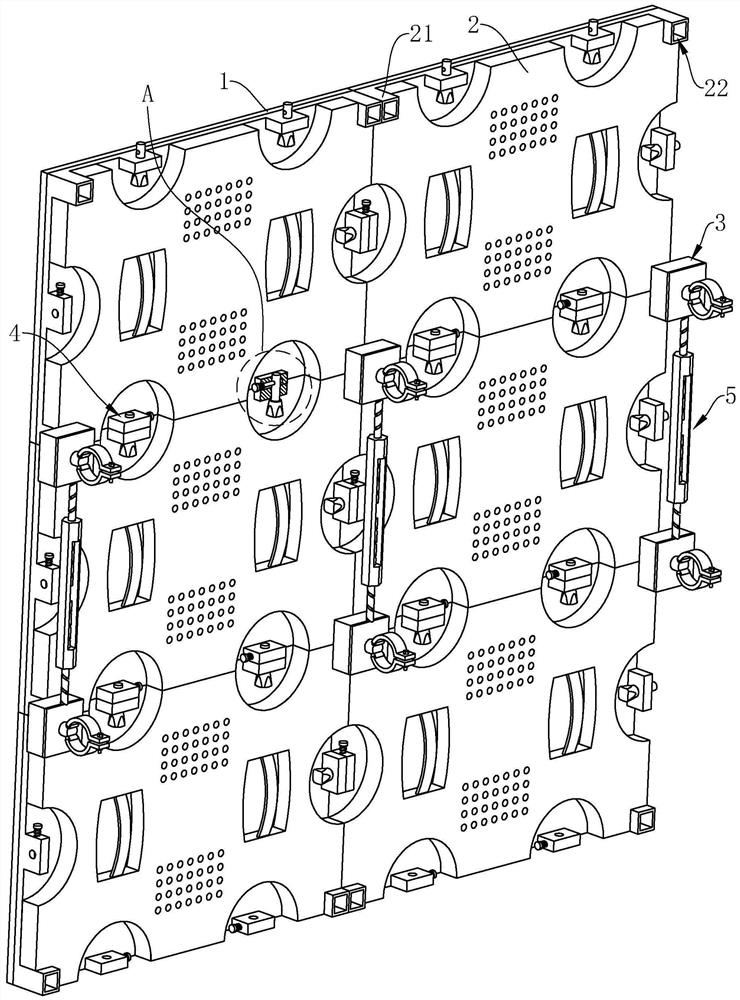

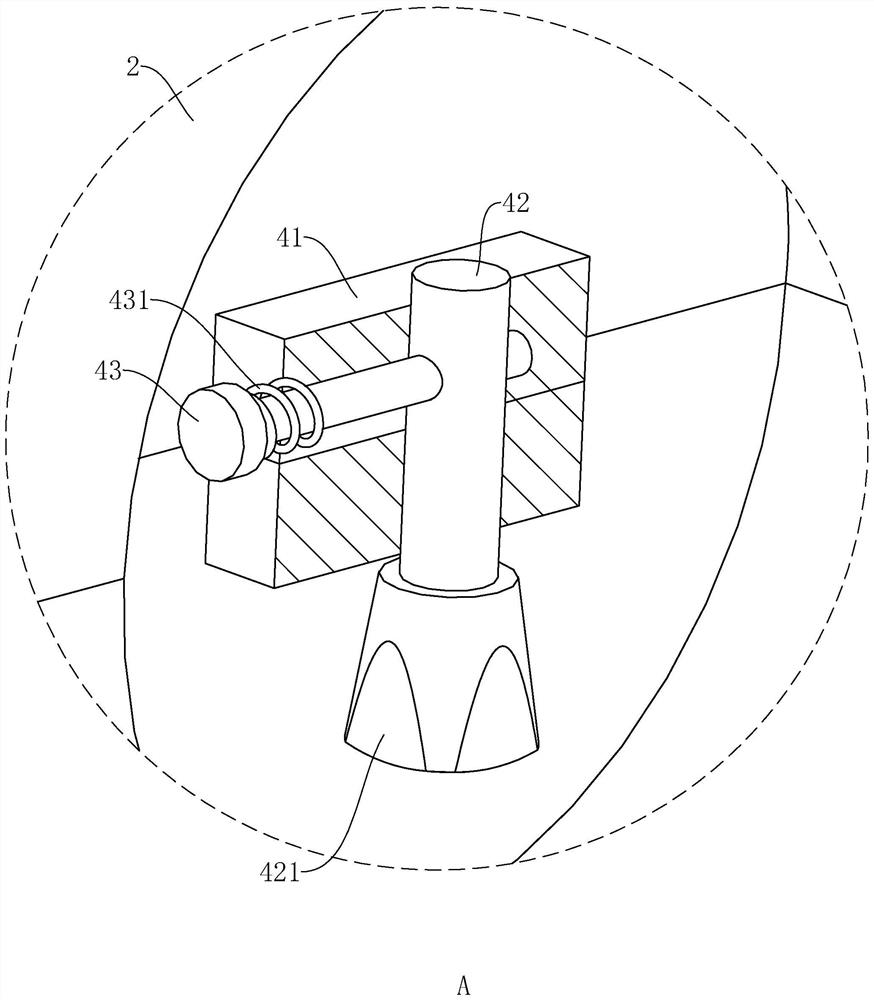

Spliced display screen capable of preventing image deformation

PendingCN114263830AImprove splicing firmnessReduced risk of misalignmentStands/trestlesIdentification meansImage deformationEngineering

The invention relates to the technical field of display screens, in particular to an image-deformation-preventing spliced display screen which comprises a display screen body, display screen bases are fixedly connected to the back face of the display screen body, fixing bases are fixedly arranged at the corners of the display screen bases, and fastening connecting mechanisms are connected to the fixing bases of the adjacent display screen bases. The fastening connection mechanism is used for fixedly connecting at least two fixing seats of the display screen bases; according to the display screen module panel, the splicing firmness of the adjacent display screen module panels can be improved, the dislocation risk of the display screen module panels can be reduced, and the display screen can normally display images.

Owner:深圳市荣国星光电科技有限公司

A kind of liquid metal conductive glue and its application

ActiveCN109679552BLow costImprove conductivityPhotovoltaic energy generationEpoxy resin adhesivesPolymer scienceLiquid metal

The invention relates to a liquid metal conductive glue and its application. The liquid metal conductive adhesive is composed of liquid metal, silver powder and matrix resin, wherein the liquid metal accounts for 25%-81% of the total mass of the conductive adhesive, and the silver powder accounts for 5%-45% of the total mass of the conductive adhesive. The amount is base resin. The liquid metal conductive adhesive has the characteristics of low cost, high conductivity, and high bonding strength, and has good wettability to the battery sheets. As a connecting material for shingled components, it can significantly reduce production costs and the contact between shingled battery sheets. Contact resistance; at the same time, due to the low curing temperature of the liquid metal conductive adhesive, the risk of hidden cracks and fragments of the battery sheet caused by high temperature can be reduced; the cured conductive adhesive has good flexibility, which can absorb the thermal stress of the battery sheet and improve Reliability of shingled components. In addition, the use of the conductive adhesive of the present invention can simplify the connection process of the existing shingling technology, and improve the production efficiency and yield of shingling components.

Owner:YUNNAN KEWEI LIQUID METAL VALLEY R & D CO LTD

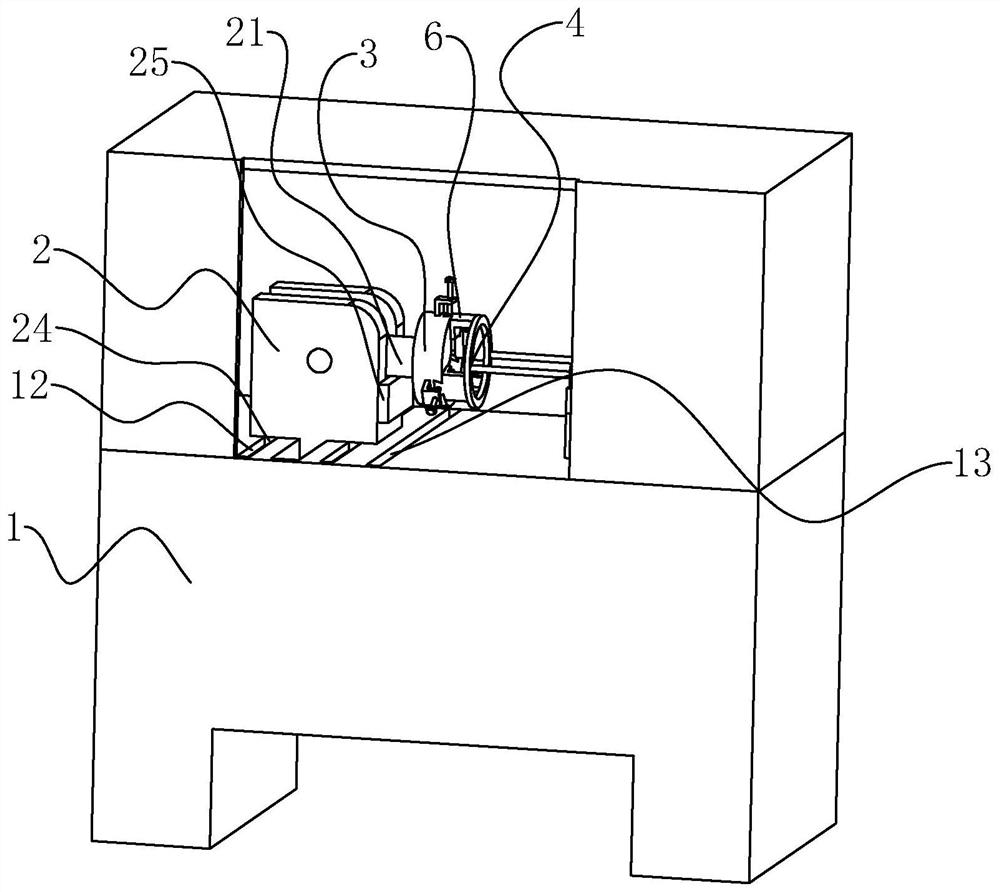

A jig for machining a gear shaft

ActiveCN111730377BAchieve a fixed purposeReduce the chance of turningPositioning apparatusMetal-working holdersGear wheelEngineering

The present application relates to a gear shaft processing fixture, which relates to the field of gear processing equipment, which includes a workbench and a chuck arranged on the workbench, the chuck is provided with at least two clamping mechanisms, and the The clamping mechanism includes a clamping block, a positioning rod and a stopper for limiting the position of the clamping block, the clamping block and the chuck are slidably connected, the positioning rod and the clamping block connected, the chuck is provided with a positioning hole, the distance between the adjacent clamping blocks is equal, the clamping block is arc-shaped and concentric with the positioning hole, and the The positioning rod faces the axis of the positioning hole. The present application has the effect of reducing the probability of the gear shaft turning during machining.

Owner:浙江三欢齿轮有限公司

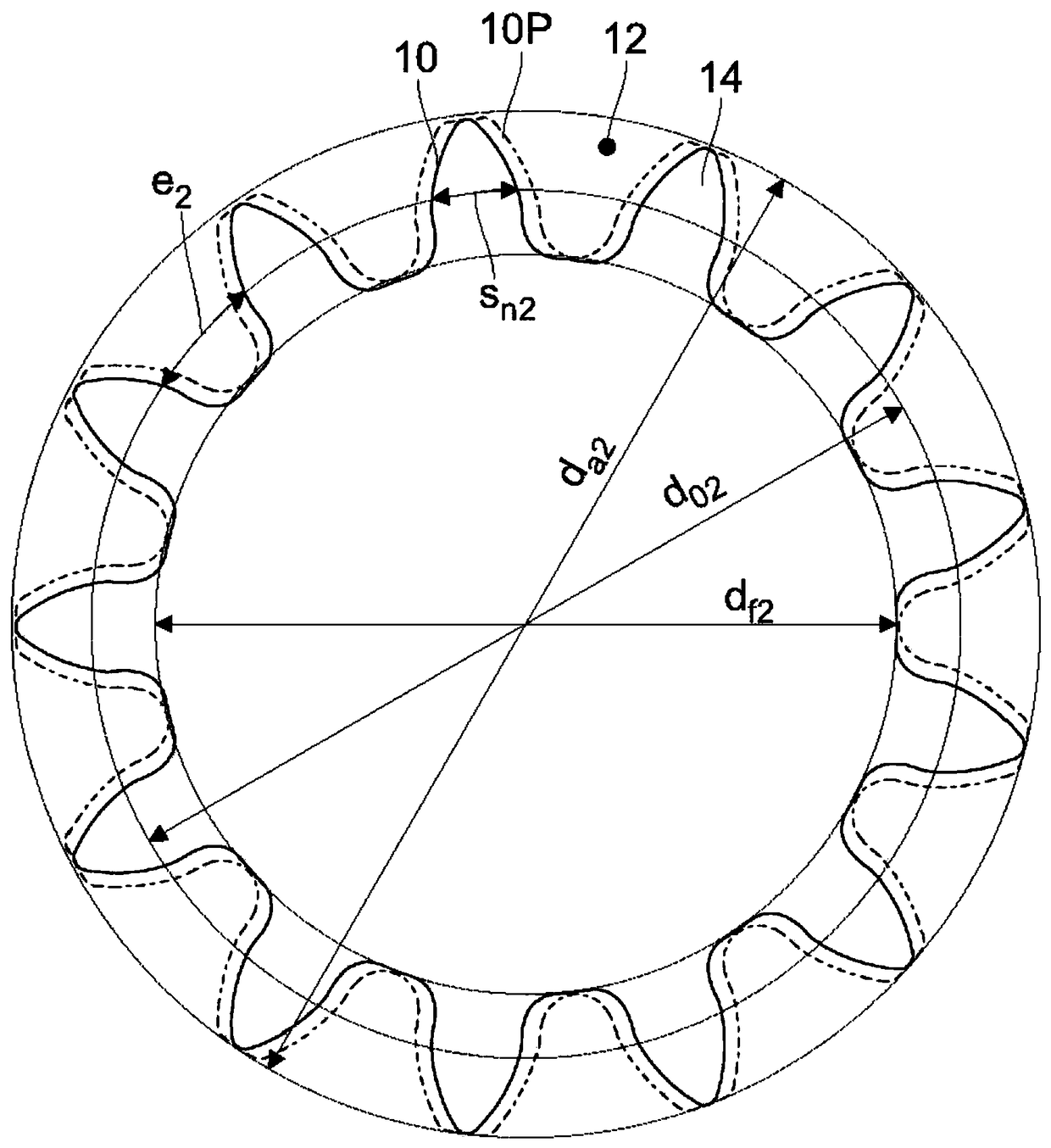

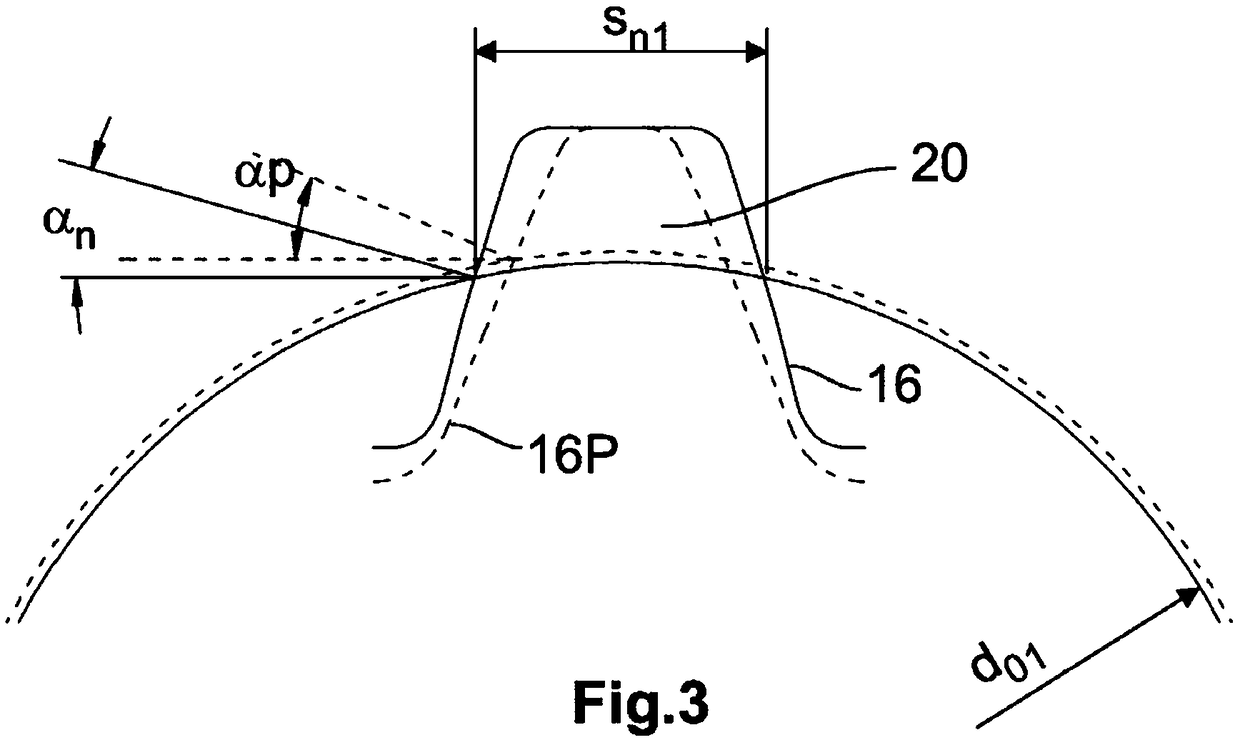

Gear pair for a helical gear transmission, helical gear transmission with such a gear pairing and use of such a gear pair in spur gear transmissions

ActiveCN108953495AReduced risk of mis-engagementReduce noiseVehicle seatsToothed gearingsGear wheelNormal teeth

A gear pair for a helical gear transmission (22), comprising a helical gear (10) with a first toothing segment (12), and a worm (16) with a second toothing segment (18), wherein the first toothing segment (12) and the second toothing segment (18) can be brought into intermeshing and form an involute toothing (26) when intermeshed, the materials of the first and the second toothing segments (12, 18) are chosen such that when intermeshed there results a plastic-metal material pairing, and the toothing segments (12, 18) made of plastic has a first normal tooth thickness (sn1) and the toothing segments (12, 18) made of metal has a second normal tooth thickness (sn2), wherein the ratio of the first normal tooth thickness (sn1) to the second normal tooth thickness is increased by 10 to 200% withrespect to a reference profile.

Owner:IMS GEAR SE & CO KGAA

Sequentially etched and plated lead frame structure without island prepacked plastic sealed material and producing method thereof

ActiveCN102324415BSimple designReduce material costsSemiconductor/solid-state device detailsSolid-state devicesEngineeringLead frame

A method for manufacturing an islandless lead frame structure (100) for semiconductor packaging includes providing a metal substrate, and performing an etching process on the top surface and the back surface of the metal substrate simultaneously using a top surface etching pattern and a back surface etching pattern as the respective masks to form etched regions in the metal substrate and a plurality of leads (2), without forming an island. Further, the method includes placing the etched metal substrate in a mold, and encapsulating the etched metal substrate using the mold such that a molding compound (4) is filled in the etched regions and areas between the plurality of leads (2), while exposing top surfaces and back surfaces of the plurality of leads (2). The method also includes performing a plating process on the encapsulated metal substrate to form a first metal layer (5) on the exposed top surfaces of the plurality of leads (2), and a second metal layer (6) on the exposed back surfaces of the plurality of leads (2).

Owner:JCET GROUP CO LTD

Positioning system

ActiveCN102050244BIncrease success rateEffective clamping and fixingPackagingConveyor partsAutomatic controlControl system

The invention discloses a positioning system which comprises a product input mechanism, a turntable, a plurality of stations, block positions, a driving motor, at least one position correcting mechanism, a product output mechanism and an automatic control system, wherein the product input mechanism is used for inputting products; the plurality of stations are arranged aside the turntable; the block positions used for placing products are arranged at positions, which are corresponding to the stations, on the turntable; the driving motor is connected to the turntable; the automatic control system is electrically connected to the driving motor, the position correcting mechanism, the product input mechanism and the product output mechanism; the product input mechanism is arranged at an input position aside the turntable and is used for inputting the products into the block positions, and simultaneously, the automatic control system controls the driving motor to drive the turntable to rotate along the radial direction so as to move the products to the next station; the position correcting mechanism is arranged at a correcting position; when marks at preset positions on the surfaces of the products are detected, signals are sent to the automatic control system, and then according to the received signals, the automatic control system controls the driving motor to drive the turntable to rotate along the radial direction so as to move the products to the next station; a holding mechanism which is used for holding or releasing products in the block positions at different stations isarranged on the turntable; and the product output mechanism is arranged at an output position aside the turntable and is used for moving the products in the block positions out of the turntable and outputting the products.

Owner:广州市铭慧机械股份有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com