Mechanism used for maintaining pressure of L-shaped part

A technology of parts and translation mechanism, which is applied in the field of mechanisms for maintaining pressure on L-shaped parts, can solve problems such as parts dislocation, and achieve the effect of avoiding dislocation and improving quality.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

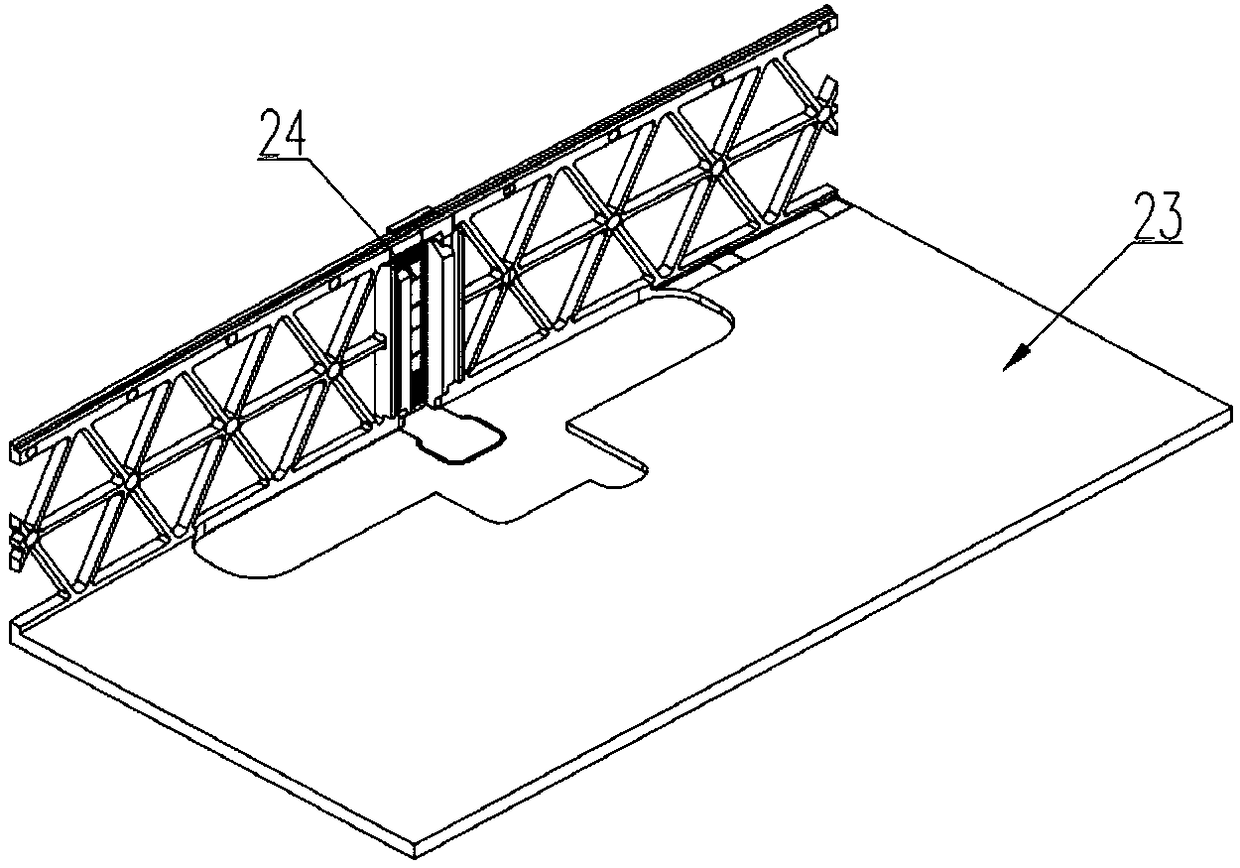

[0046] Such as Figure 1 to Figure 6 As shown, it is embodiment 1 provided by the present invention, and this embodiment provides a pressure maintaining device for maintaining pressure on two L-shaped parts.

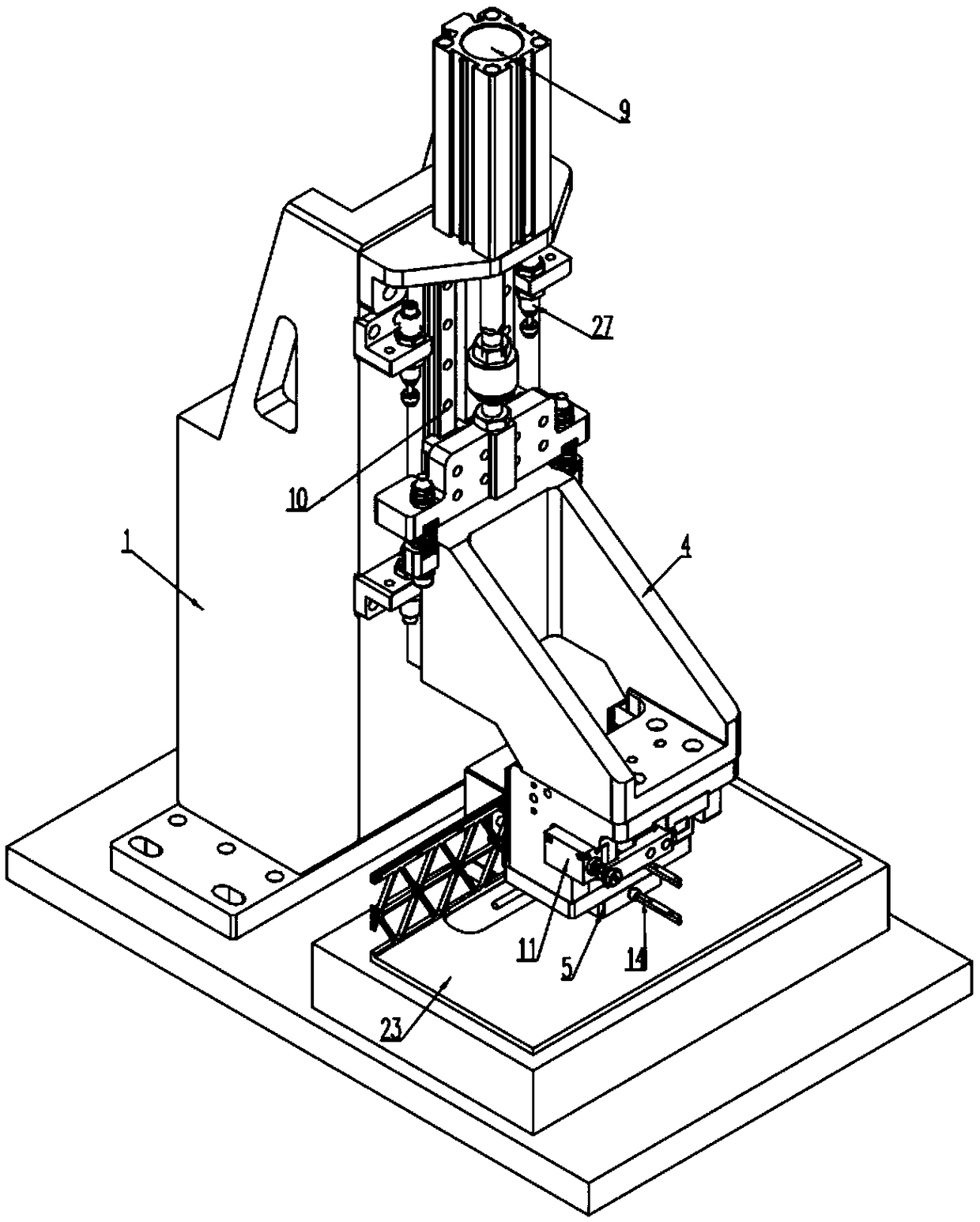

[0047] This embodiment includes a seat body 1, a positioning member 2, a first frame body 4, a first pressing member 5 and a second pressing member 6, the positioning member 2 is installed on the seat body 1, and has an L-shaped positioning surface. The L-shaped positioning surface 3 is suitable for positioning the outside of the L-shaped part; the first frame body 4 is vertically arranged on the seat body 1, and is suitable for moving up and down driven by the lifting mechanism; the first pressing part 5 It is arranged at the lower end of the first frame body 4 and is suitable for moving up and down under the drive of the first frame body 4. The first pressing member 5 is suitable for moving the L-shaped parts vertically to the lower end. The horizontal section is pres...

Embodiment approach

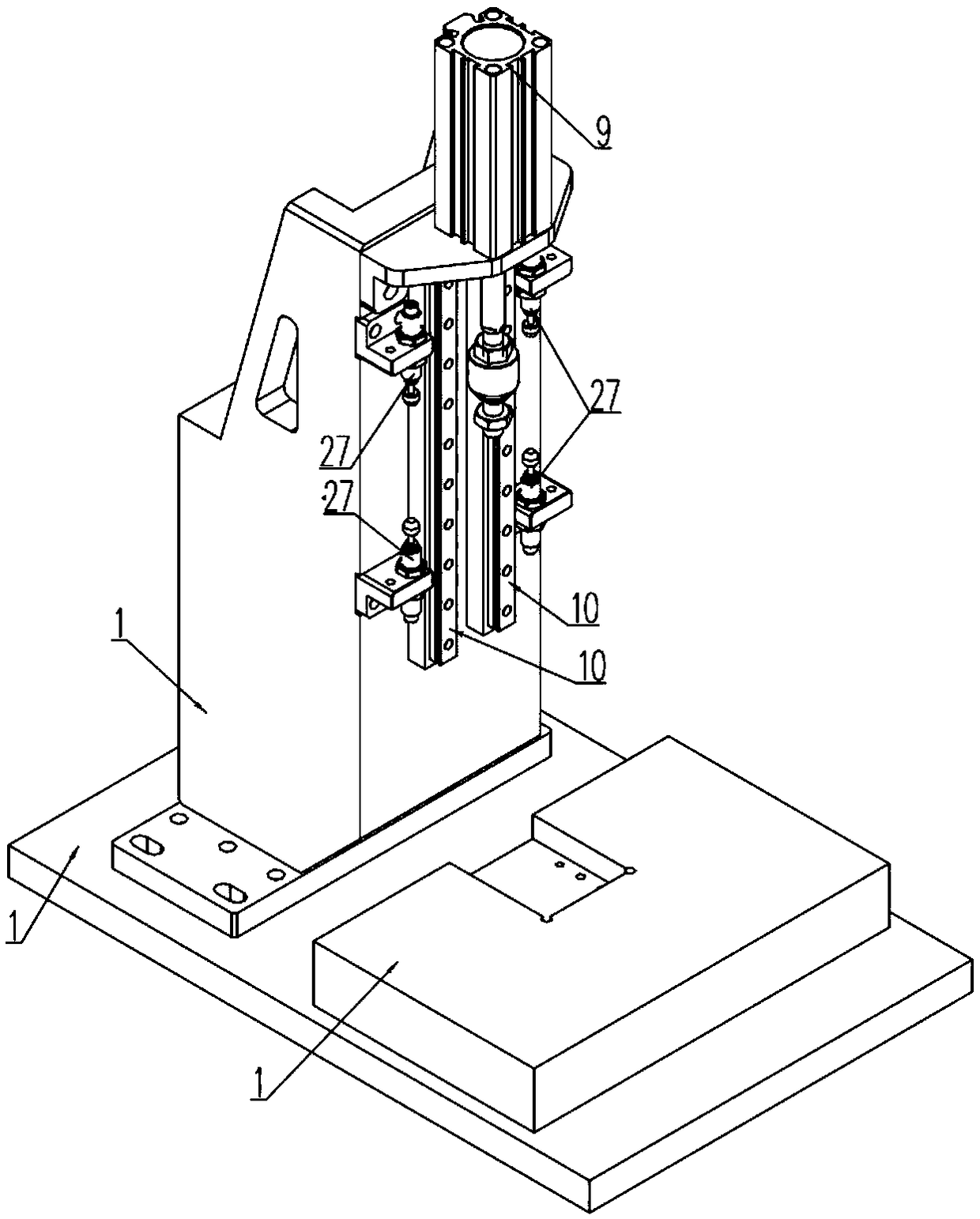

[0051] As a specific implementation of the lifting mechanism, the lifting mechanism includes a first power element 9 and a first slide rail 10, the first power element 9 is fixedly installed on the base body 1; the first slide rail 10 is vertically installed on the base body 1 Above; the first frame body 4 is slidably installed on the first slide rail 10 and is suitable for vertical movement along the first slide rail 10 driven by the power element. In this embodiment, the first power element 9 is specifically a telescopic cylinder.

specific Embodiment approach

[0052] As a specific implementation of the translation mechanism, the translation mechanism includes a second power element 11 and a second slide rail 12, the second power element 11 is fixedly installed on the first frame body 4; the second slide rail 12 is horizontally installed on On the first frame body 4; in this embodiment, the second power element 11 is specifically a telescopic cylinder. The second pressing member 6 is slidably installed on the second slide rail 12 and is suitable for sliding along the second slide rail 12 driven by the second power element 11 .

[0053] As a more optimal embodiment of this equipment, between the first frame body 4 and the seat body 1, between the first power element 9 and the first pressing part 5, between the second pressing part Buffer components are installed between 6 and the second power element 11. By installing a buffer member between the above structures, on the one hand, it can provide pressure for components that require pr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com