Gear pairing for a helical gear unit or a spur gear unit and application thereof

A transmission, helical gear technology, applied in the field of gear pairs, to achieve the effect of reducing the risk of mis-engagement, low noise formation and wear, and smooth operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

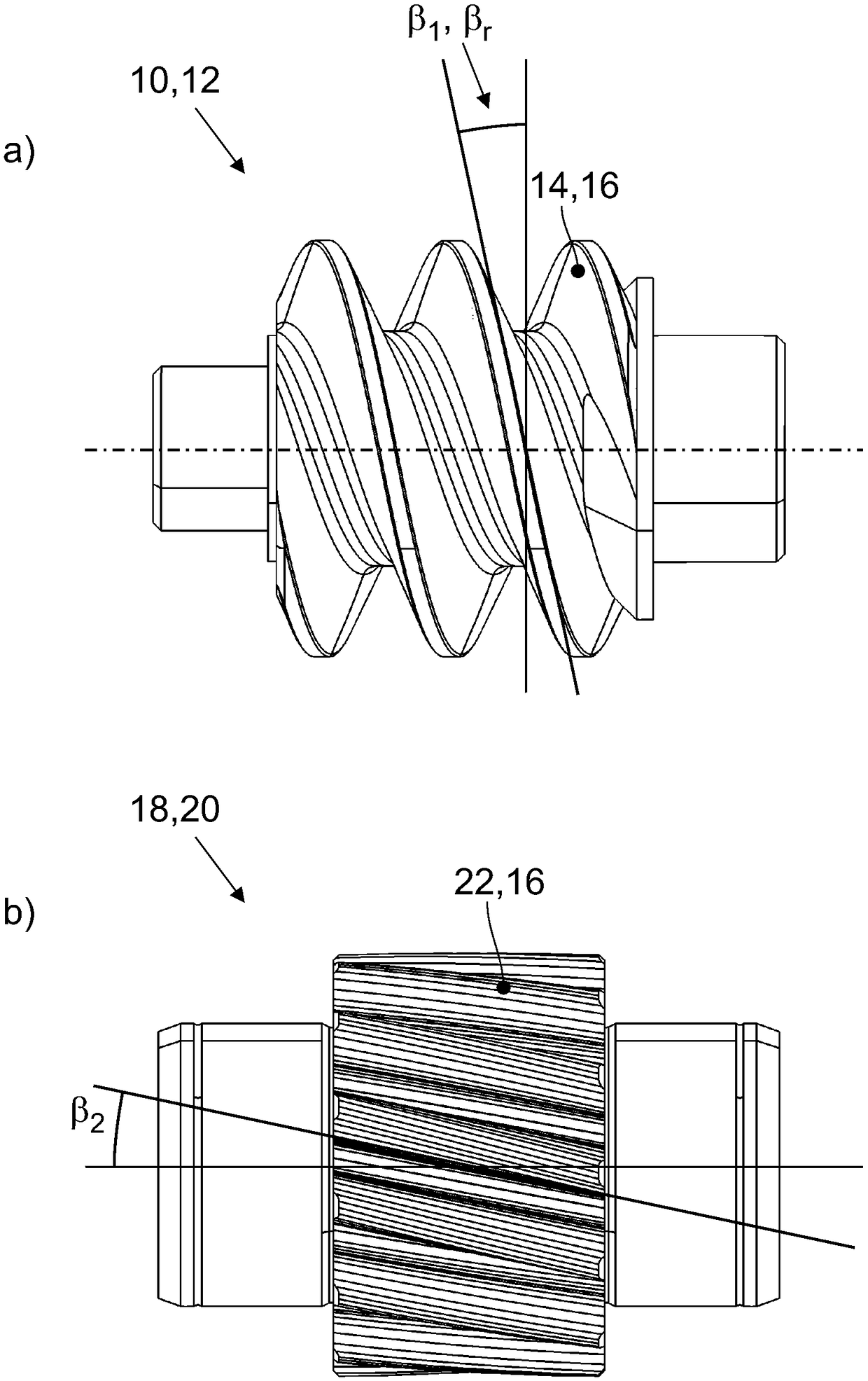

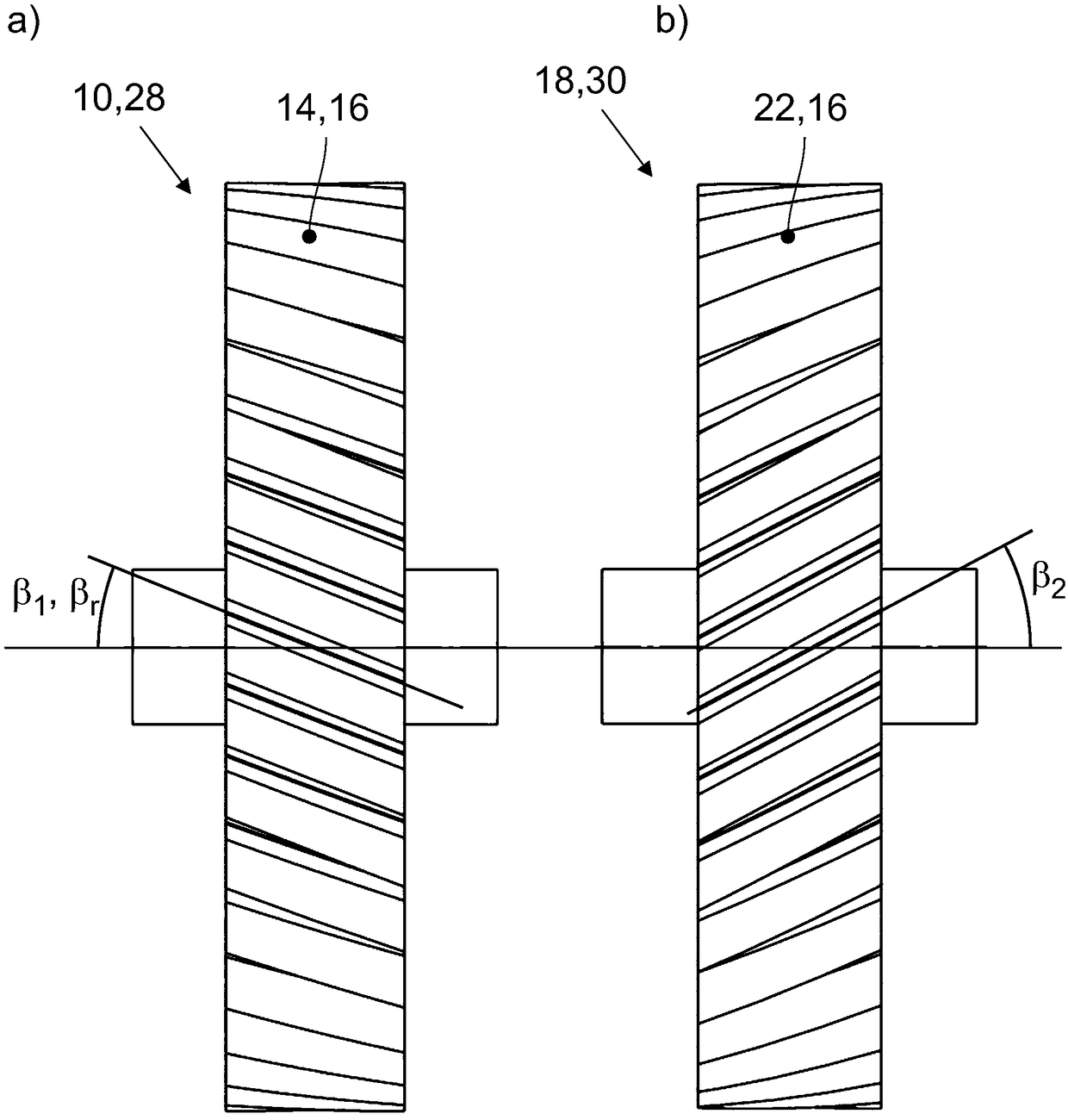

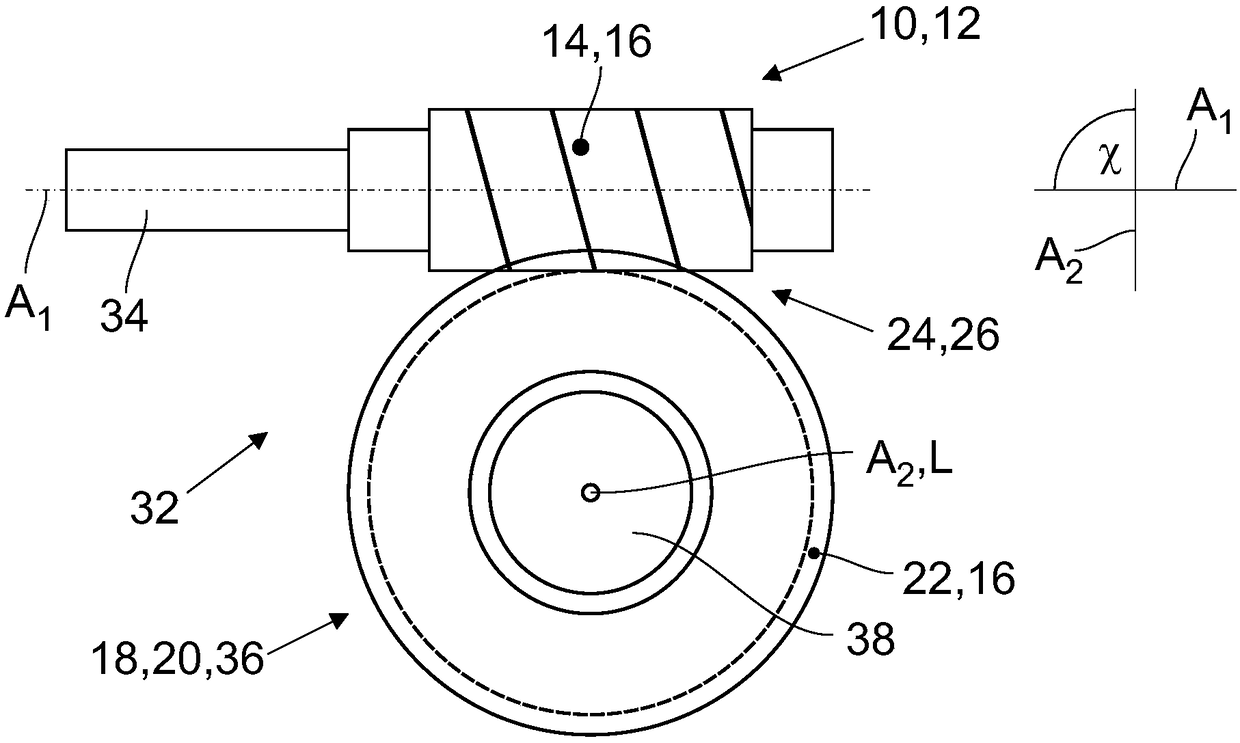

[0052] exist figure 1 In a) a first gear wheel 10 according to a first embodiment of the invention is shown, which is embodied as a worm 12 and is made entirely of plastic. The worm 12 has a first toothing section 14 in which a plurality of teeth 16 are located. The first gear tooth segment 14 has a first inclination angle β 1 .

[0053] exist figure 1 In b) the second gear wheel 18 according to the first embodiment of the invention is shown. The second gearwheel 18 is designed as a helical gearwheel 20 and is made entirely of metal. The helical gear 20 has a second toothing section 22 in which a plurality of teeth 16 are located. The second tooth segment 22 has a second inclination angle β 2 .

[0054] According to the definition, in the following, the first inclination angle β 1 should always be assigned to the plastic tooth section and the second inclination angle β 2 The assignment should always be made to a metal gear tooth segment, irrespective of whether the re...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com