Positioning system

A technology of positioning system and automatic control system, which is applied in the field of positioning system of food utensil sticking machine and marking machine, which can solve the problems of inaccurate correspondence, continuous and efficient positioning, and inability to stably send products to the glue spraying station. , to achieve the effect of increasing the success rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

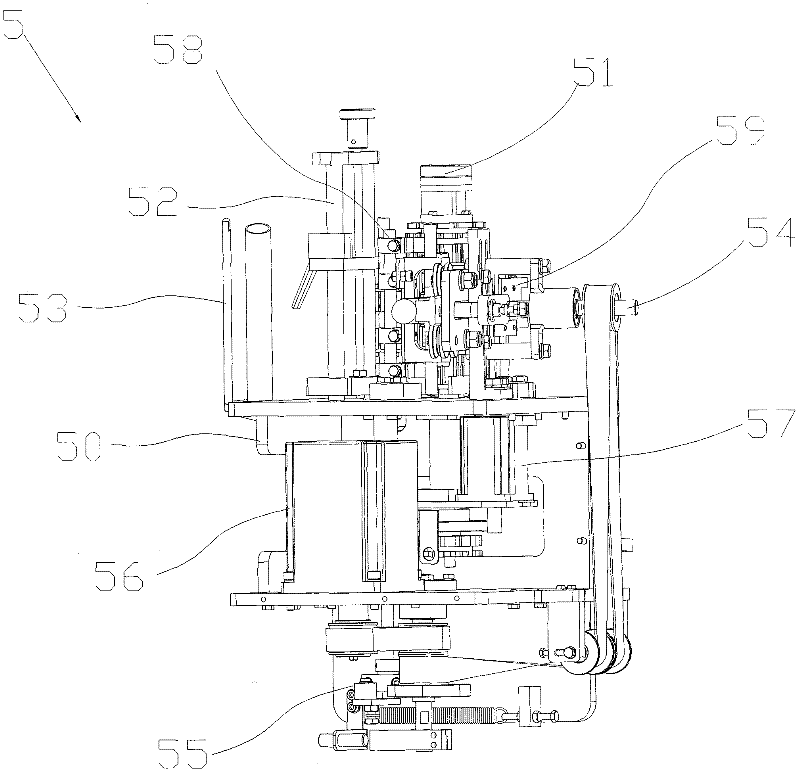

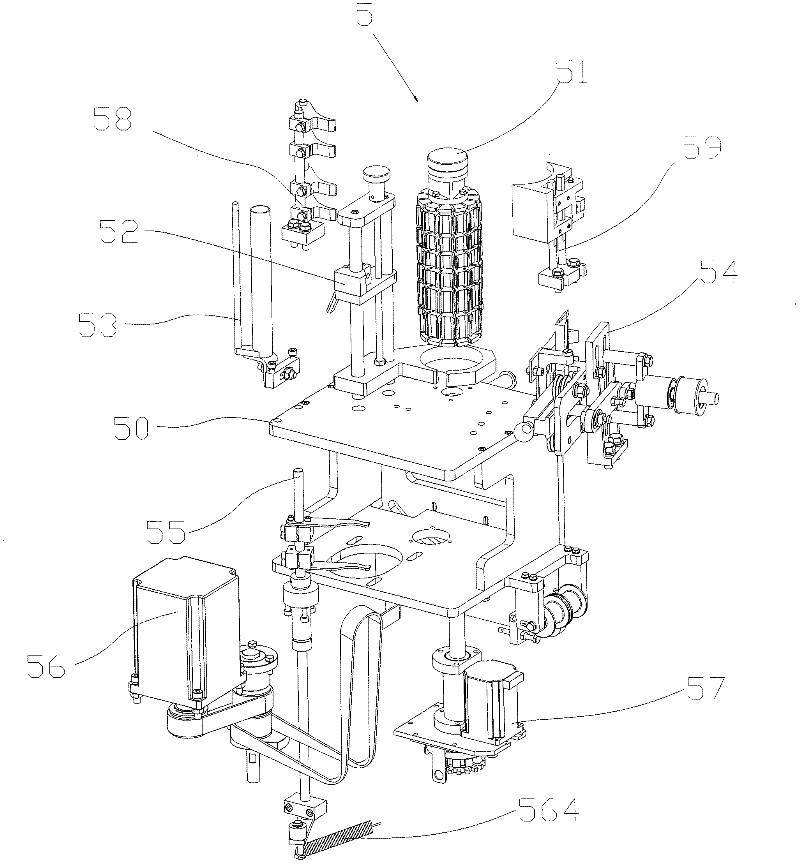

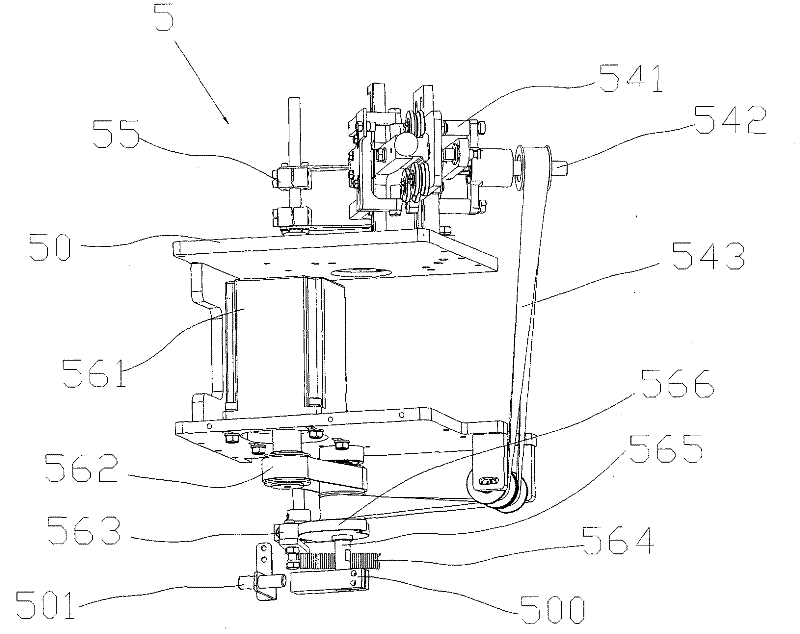

[0038] see figure 1 As shown, a positioning system includes a product input mechanism 1 for inputting a product 9, a turntable 8, and a plurality of stations along the side of the turntable 8, and a position corresponding to the station on the turntable 8 for placing the product 9. The clamping position is connected with the turntable 8 with a drive motor 81, at least one position correction mechanism 2, a product output mechanism 7, and an automatic motor that is electrically connected with the drive motor 81, the position correction mechanism 2, the product input mechanism 1, and the product output mechanism 7 respectively. Control System;

[0039] The product input mechanism 1 is arranged at the input station next to the turntable 8, which is used to input the product 9 into the clamping position, and sends an in-position signal to the automatic control system, and the automatic control system controls the drive motor 81 according to the received in-position signal Drive t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com