Patents

Literature

66results about How to "Guarantee paste quality" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

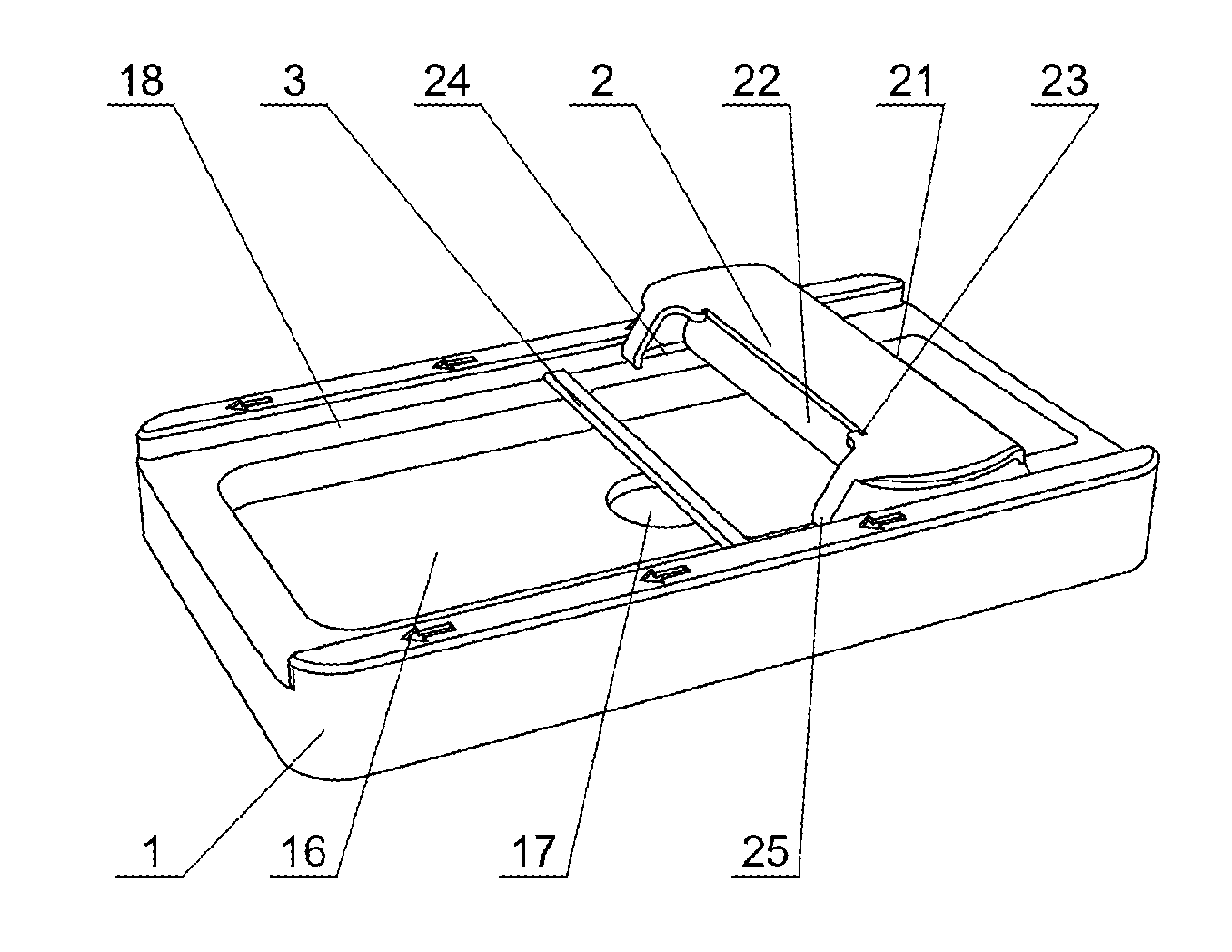

Method and device for pasting optical protection film on flat screen

InactiveUS20150000831A1Easy to optimizeLess timeLamination ancillary operationsDecorative surface effectsEngineeringMechanical engineering

Owner:SHANGHAI BOXIUTE INDAL

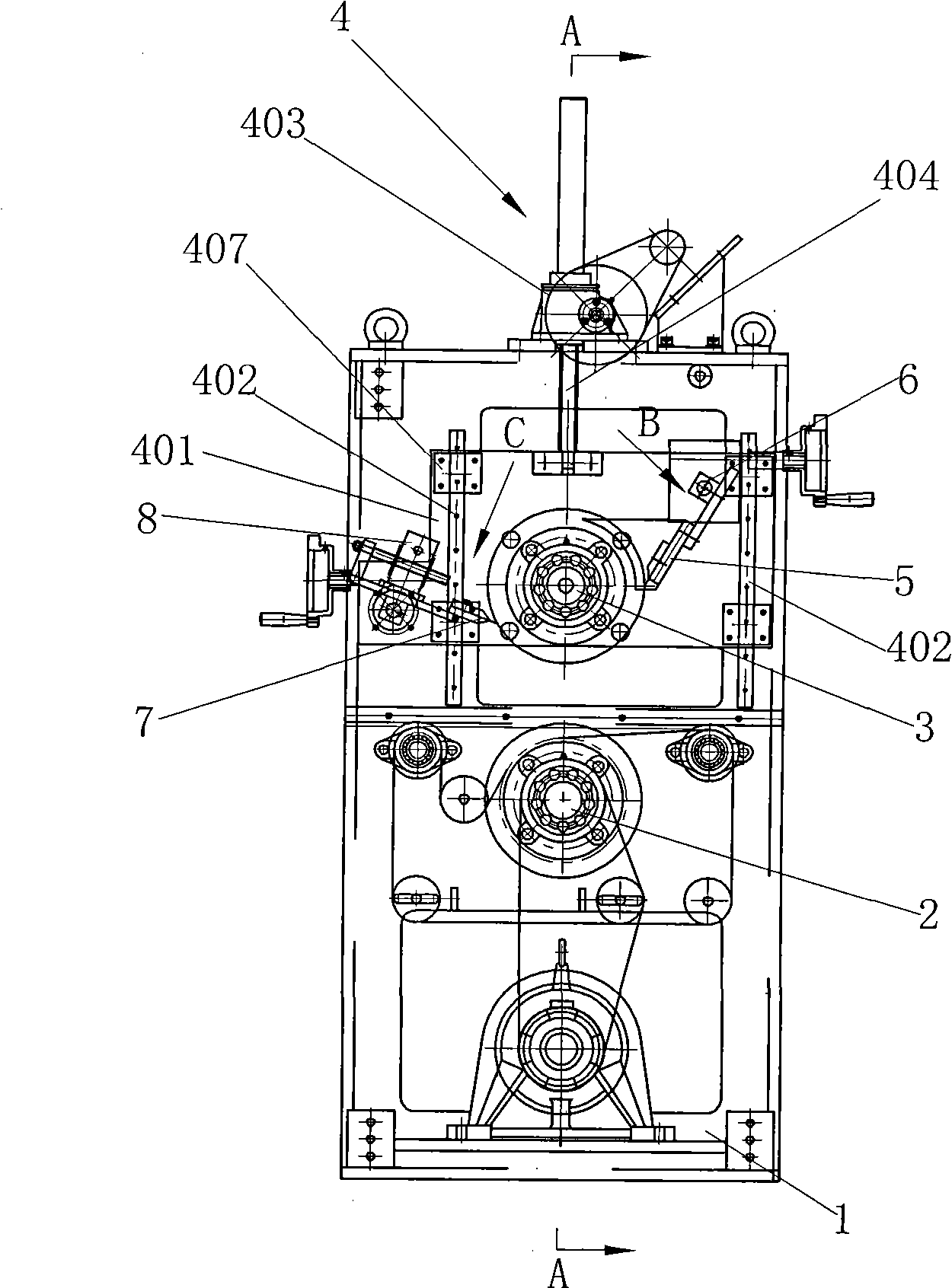

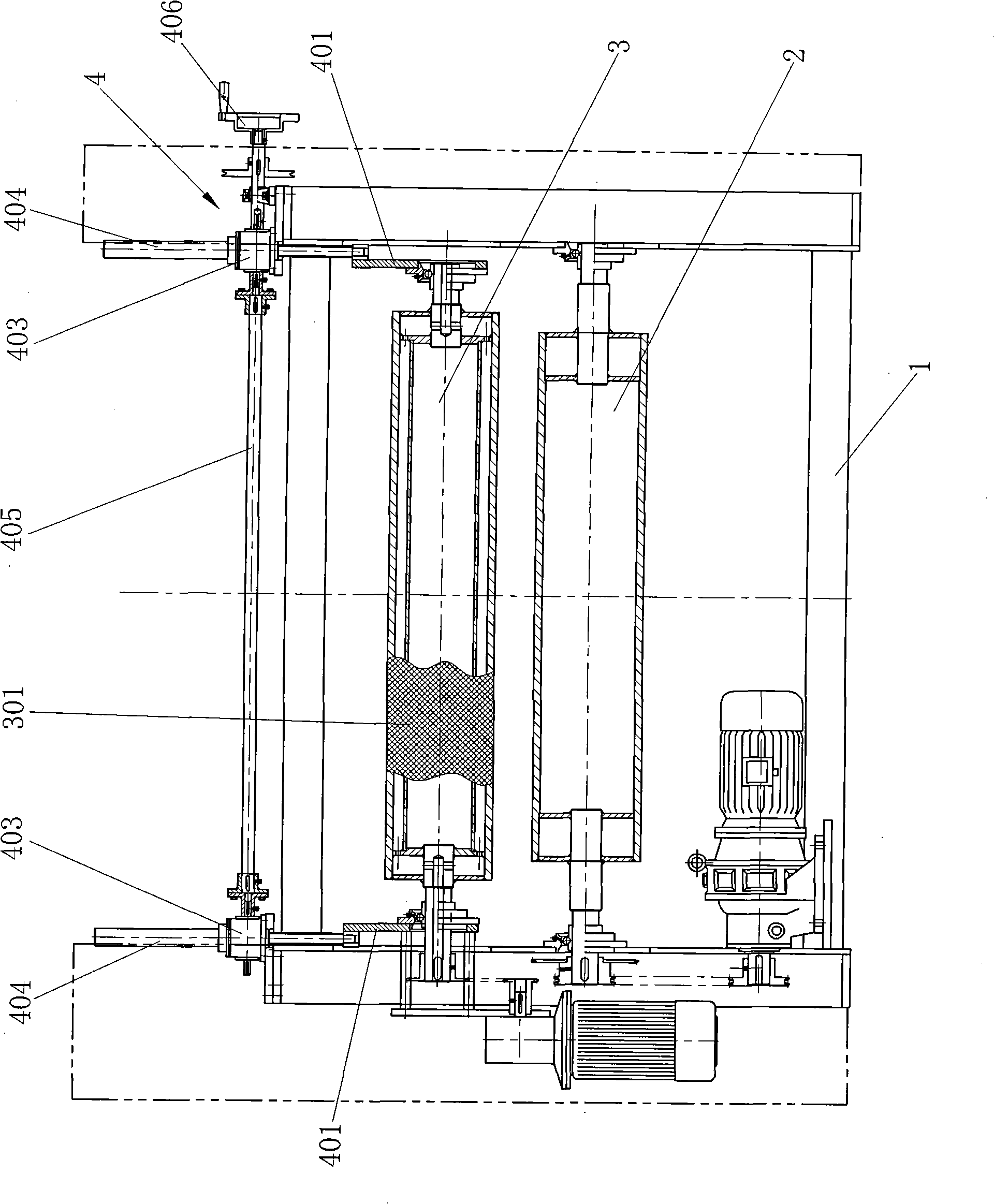

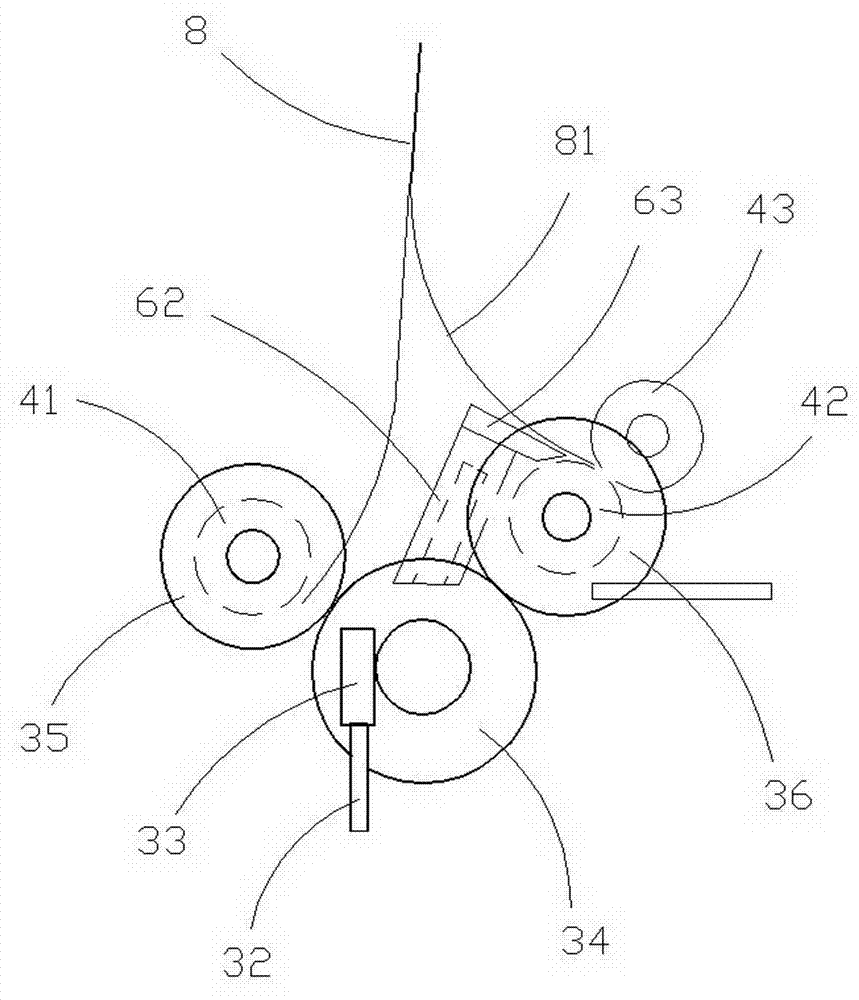

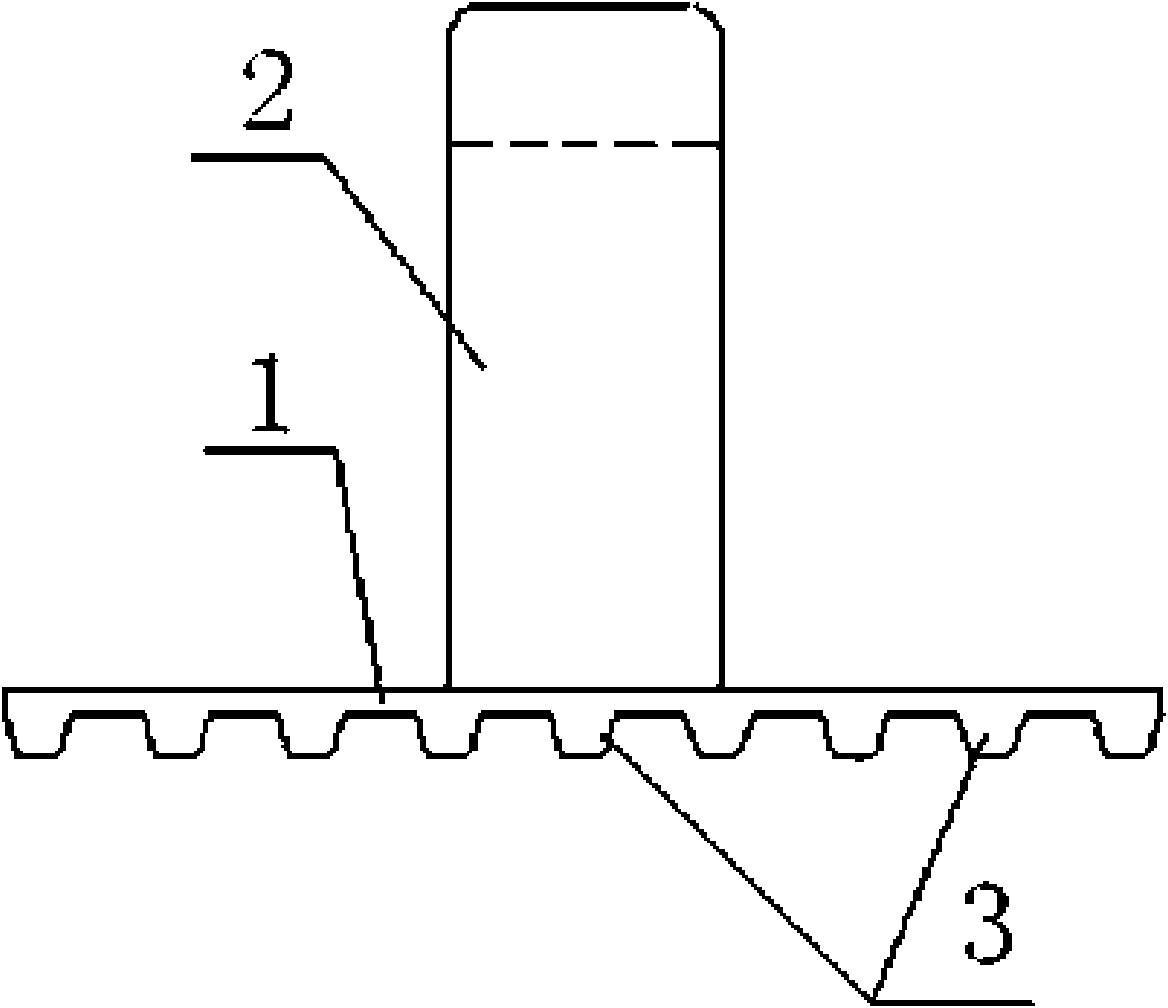

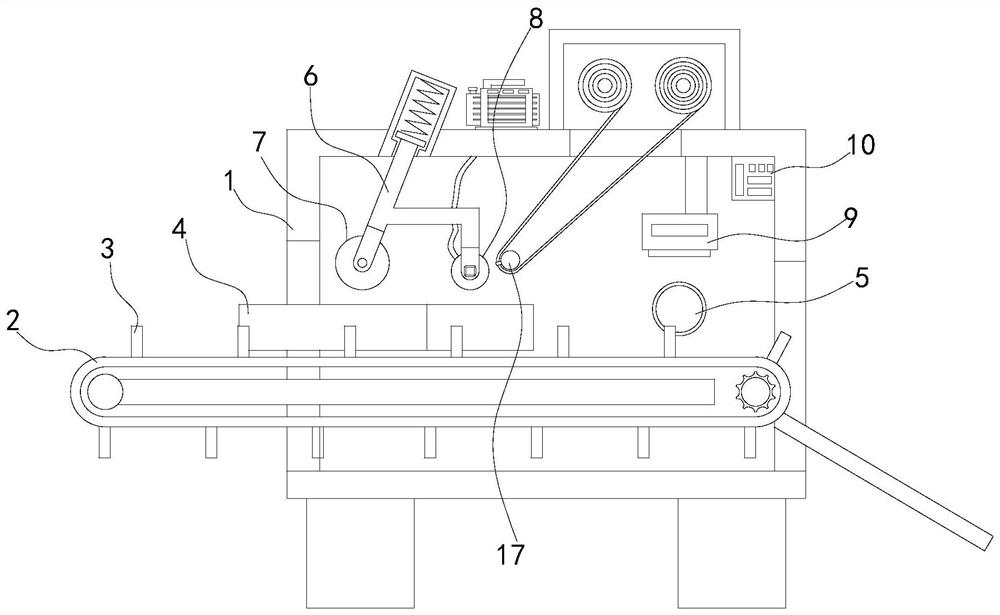

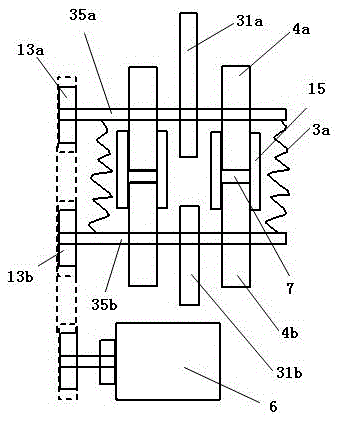

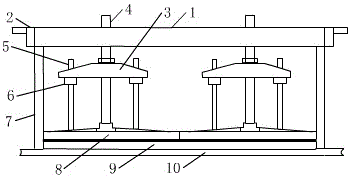

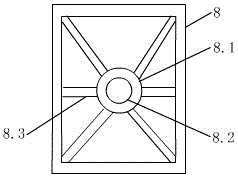

Glue spreader

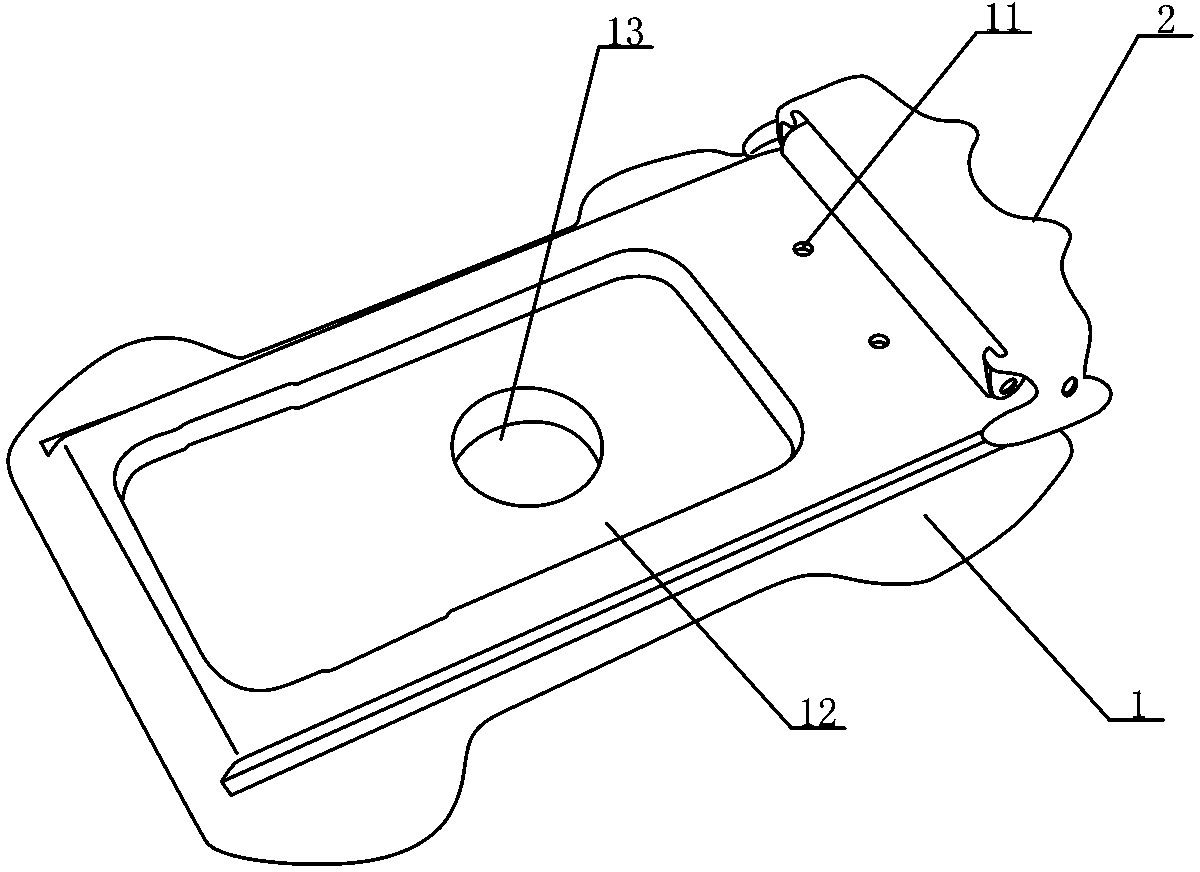

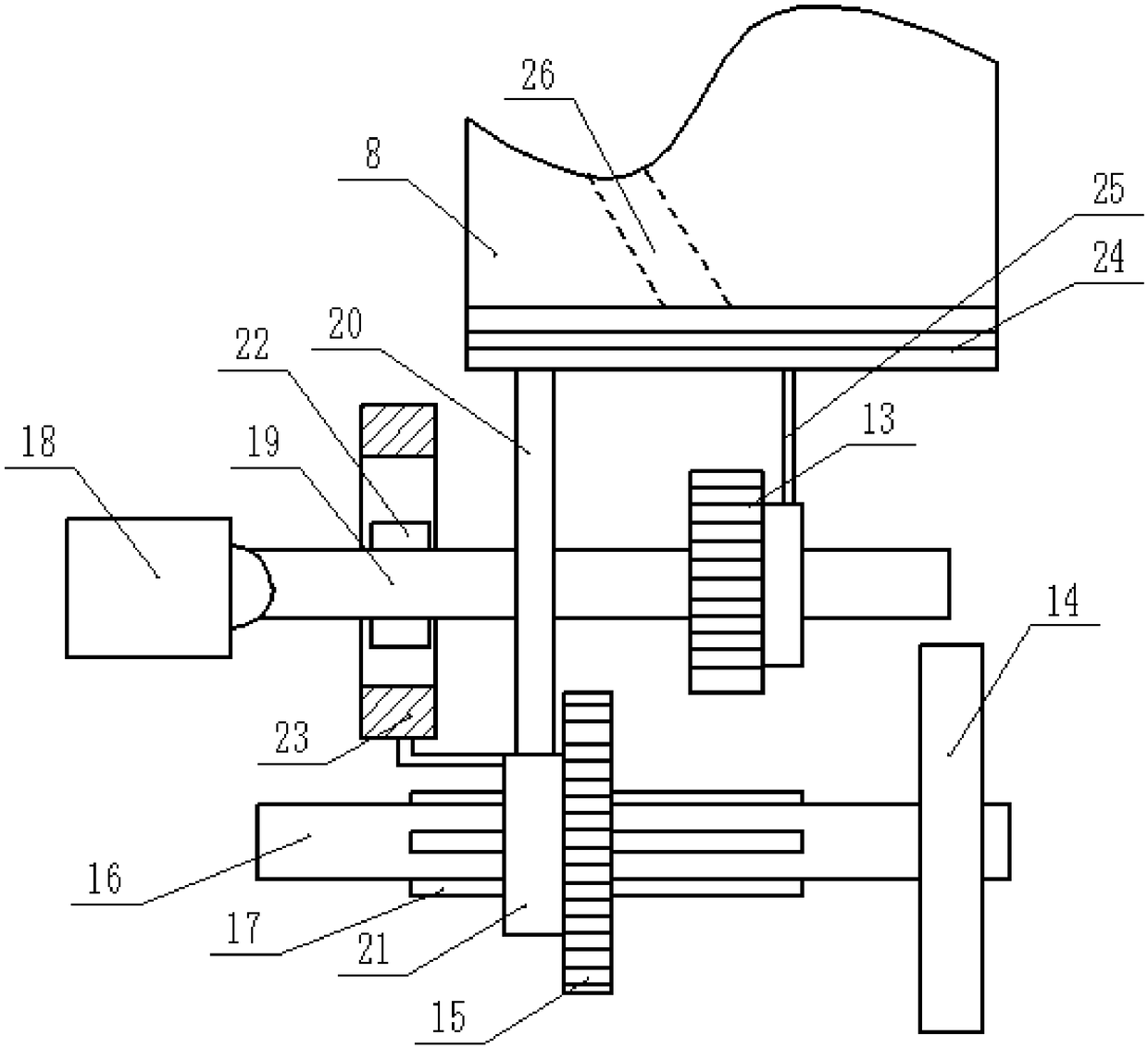

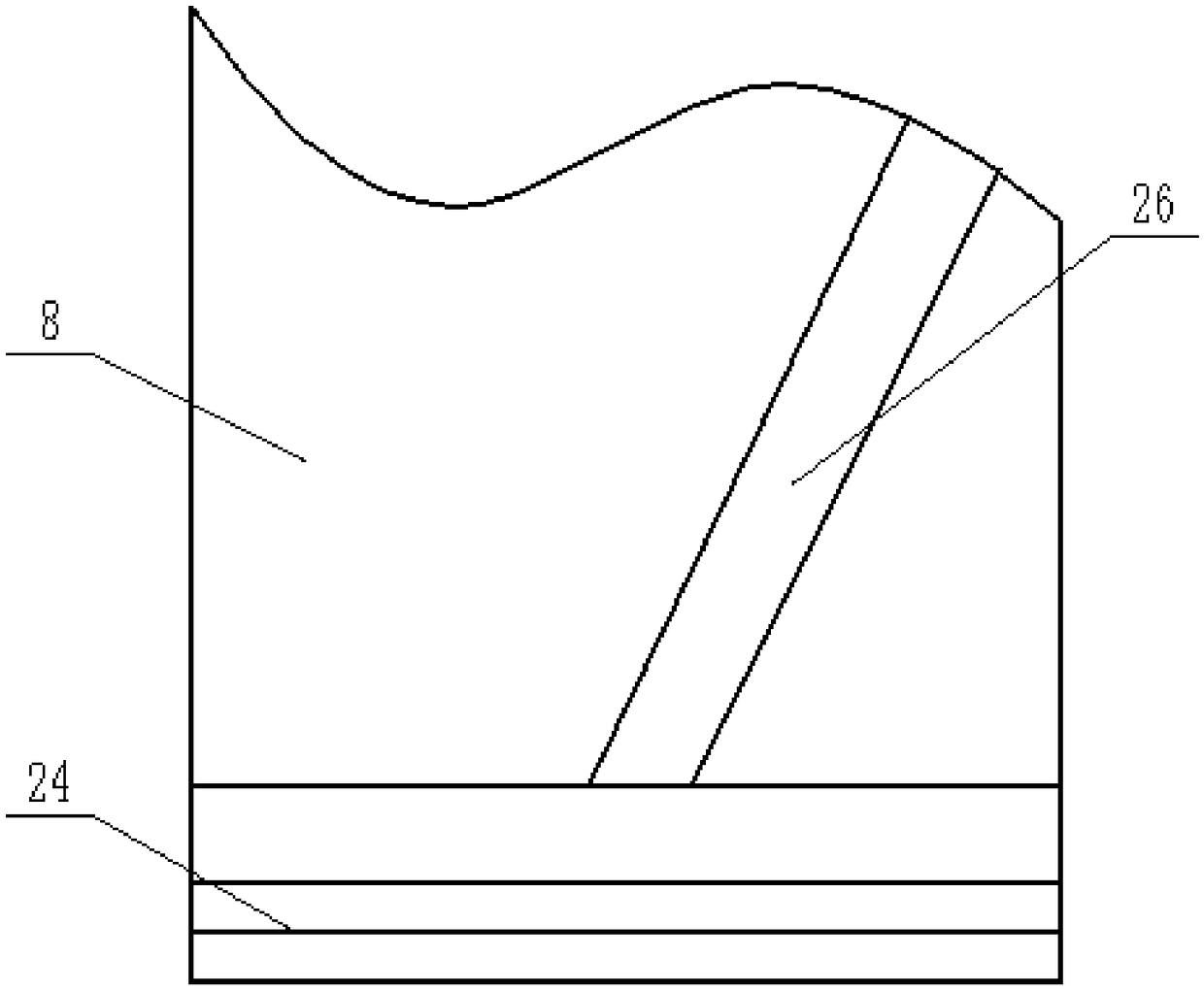

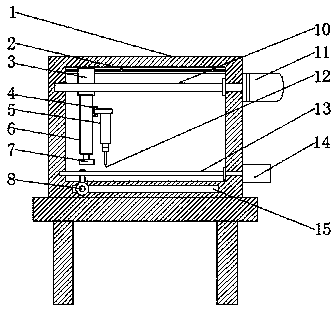

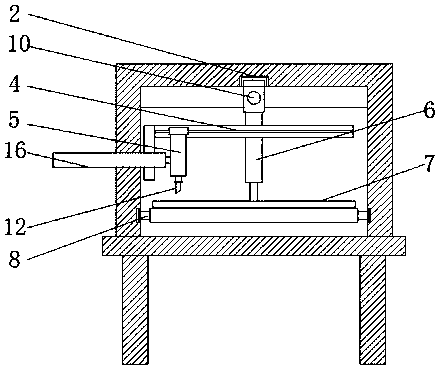

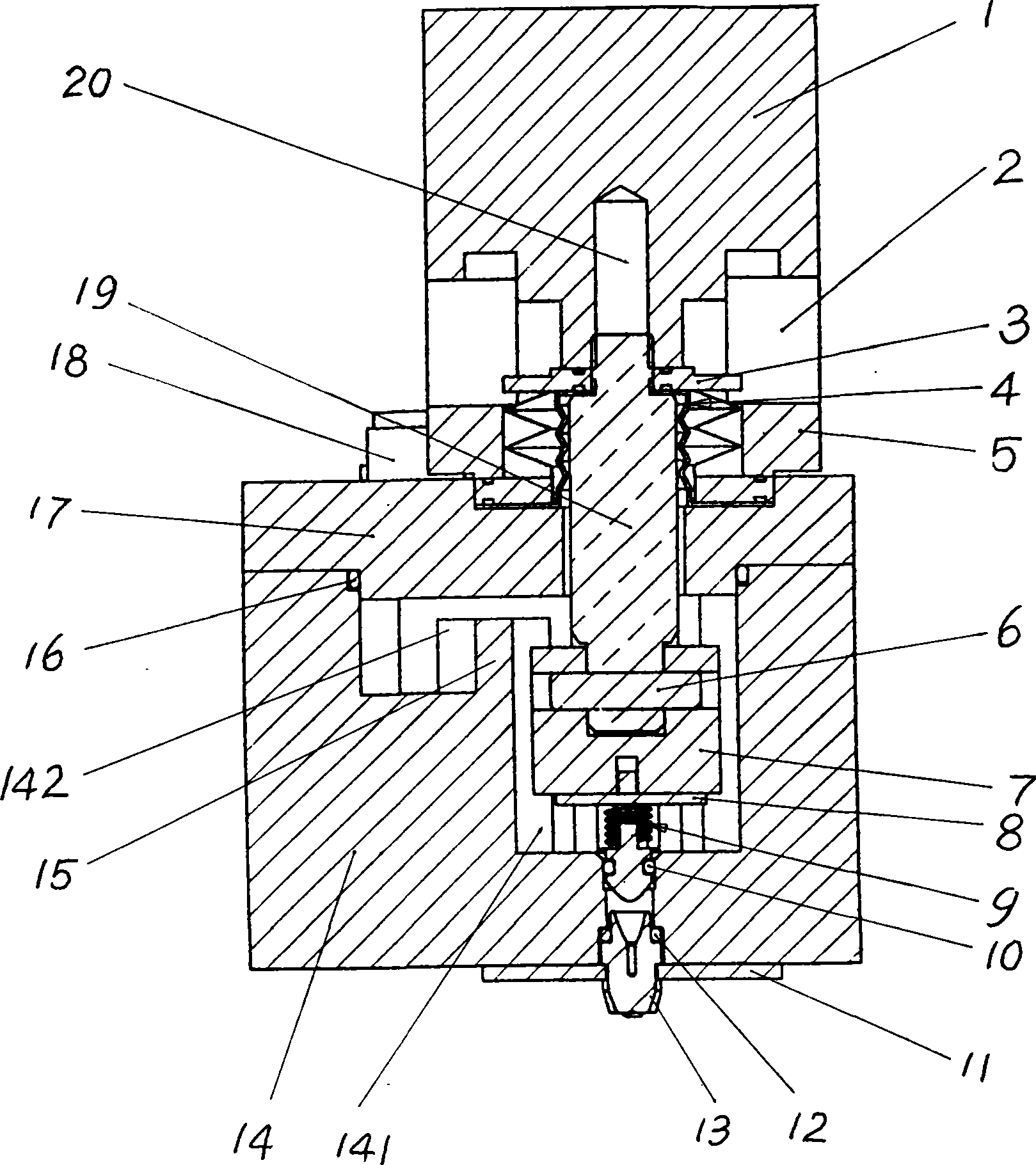

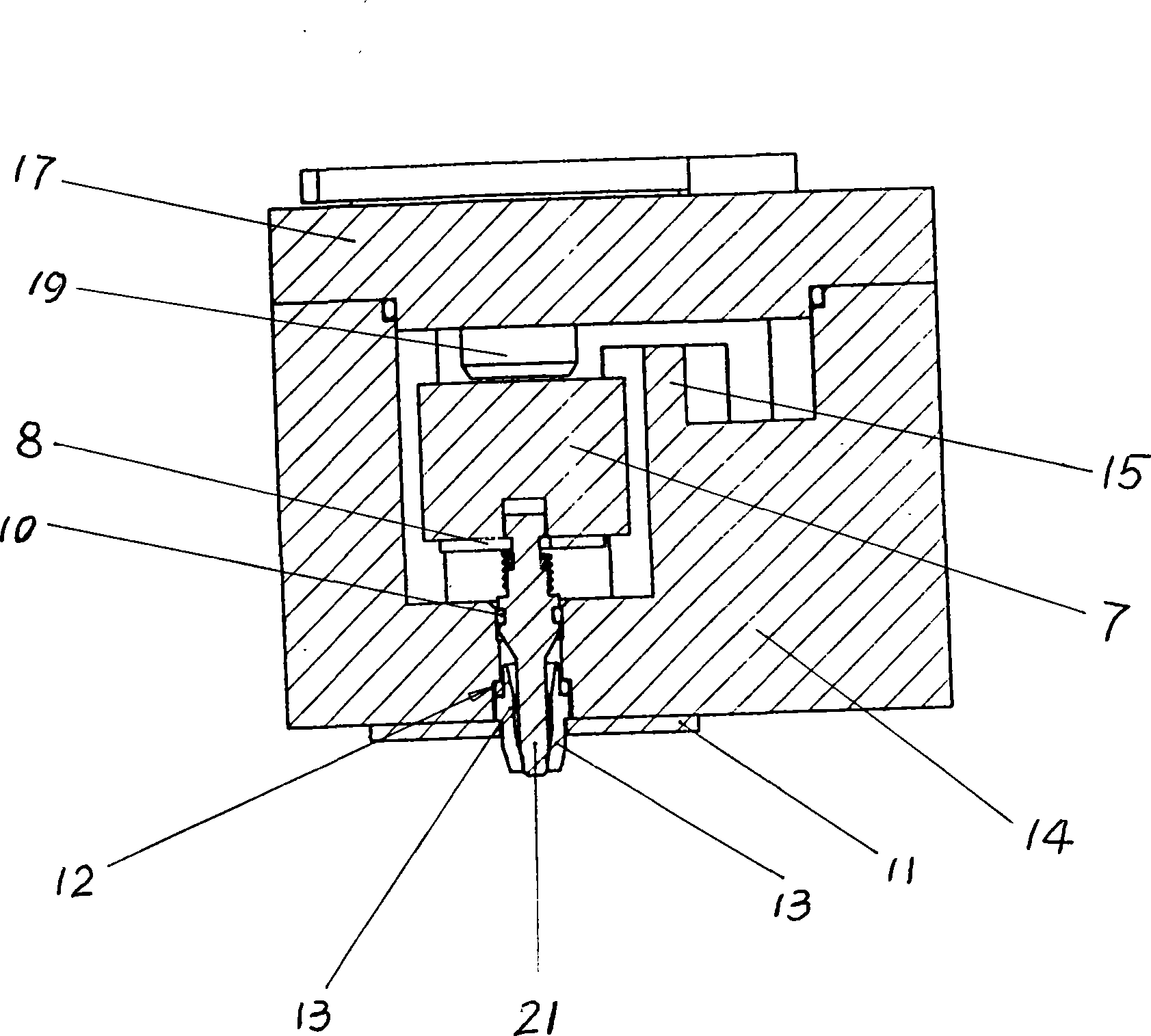

ActiveCN101862723AGuarantee paste qualityReduce the amount of glueLiquid surface applicatorsCoatingsKnurlingPulp and paper industry

The invention relates to a glue spreader, which comprises a rack. The two ends of a conveying support roller are arranged on the rack. A glue spreading roller is arranged above the conveying support roller. The conveying support roller and the glue spreading roller are respectively connected with a driving mechanism. The invention is characterized in that the two ends of the glue spreading roller are arranged on a lifting mechanism which is arranged on the rack, the surface of the glue spreading roller is provided with hatching knurling, one side of the glue spreading roller is provided with a measurement scraper which is connected with a measurement adjusting mechanism and the measurement adjusting mechanism is arranged on the lifting mechanism. The surface of the glue spreading roller is provided with the hatching knurling. Proper glue volume can be controlled and glue can be spread on the surface of base material evenly. When the surface course pasting quality is ensured, the glue usage amount and the manufacture cost are reduced.

Owner:WUXI SHENGJIN MACHINERY

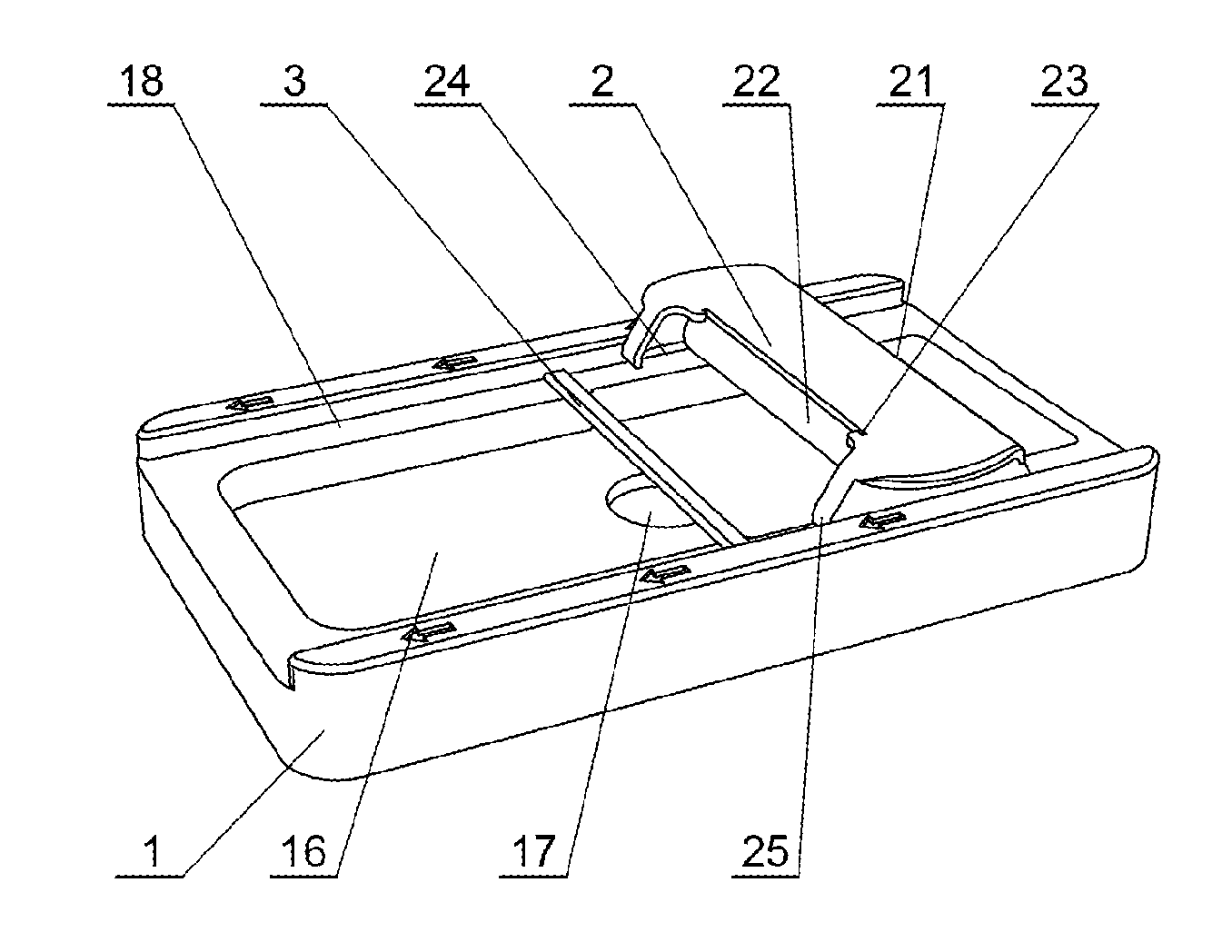

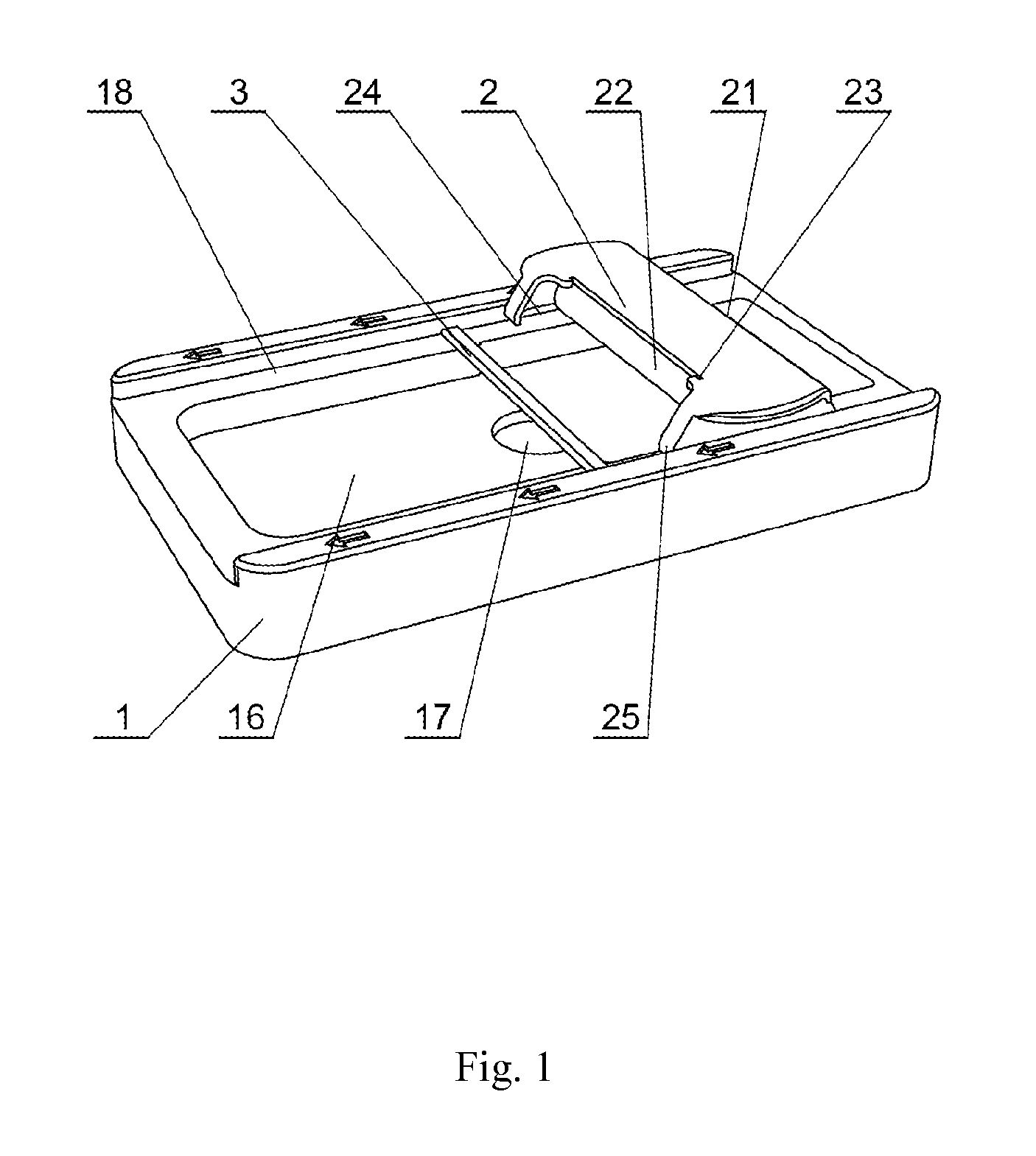

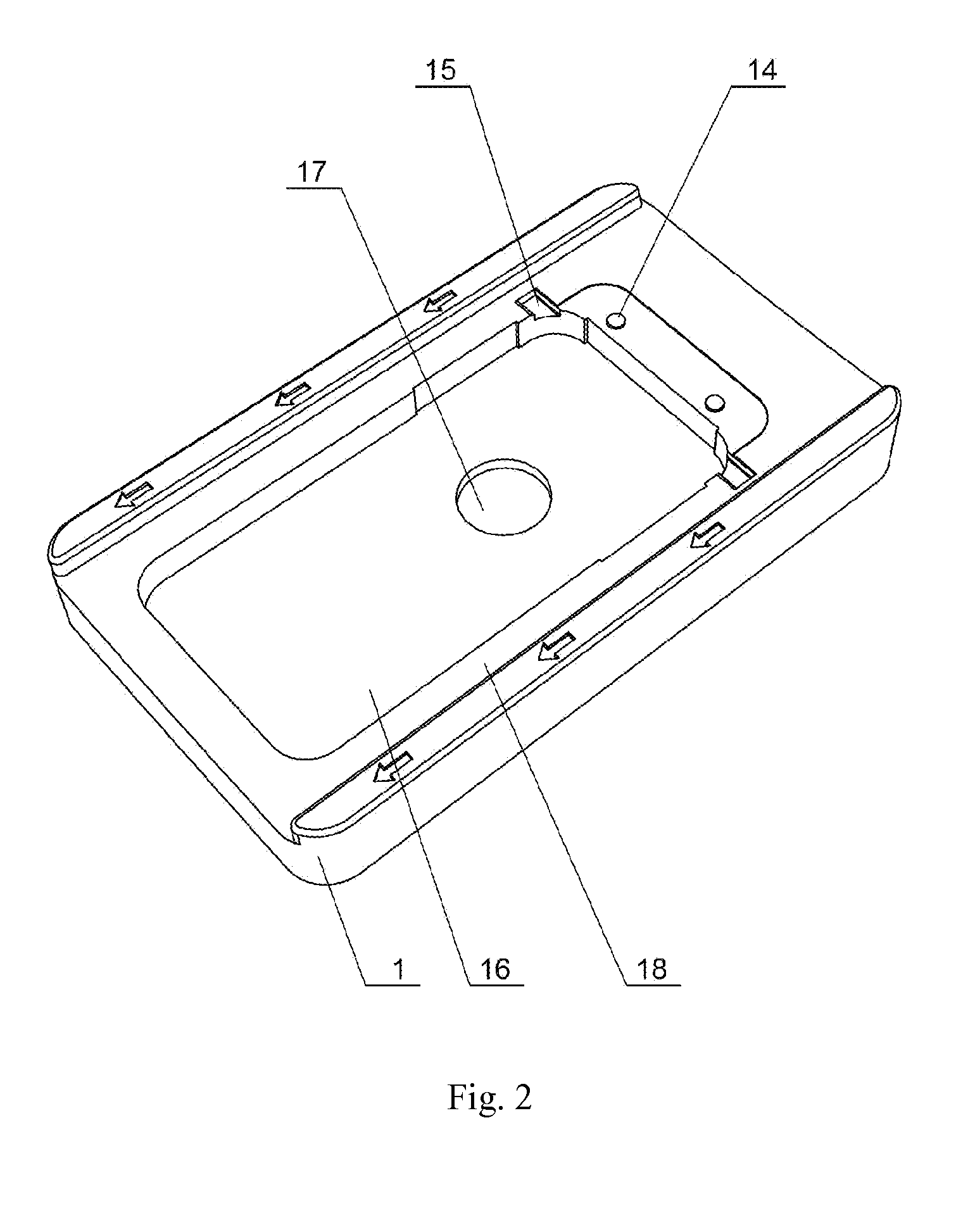

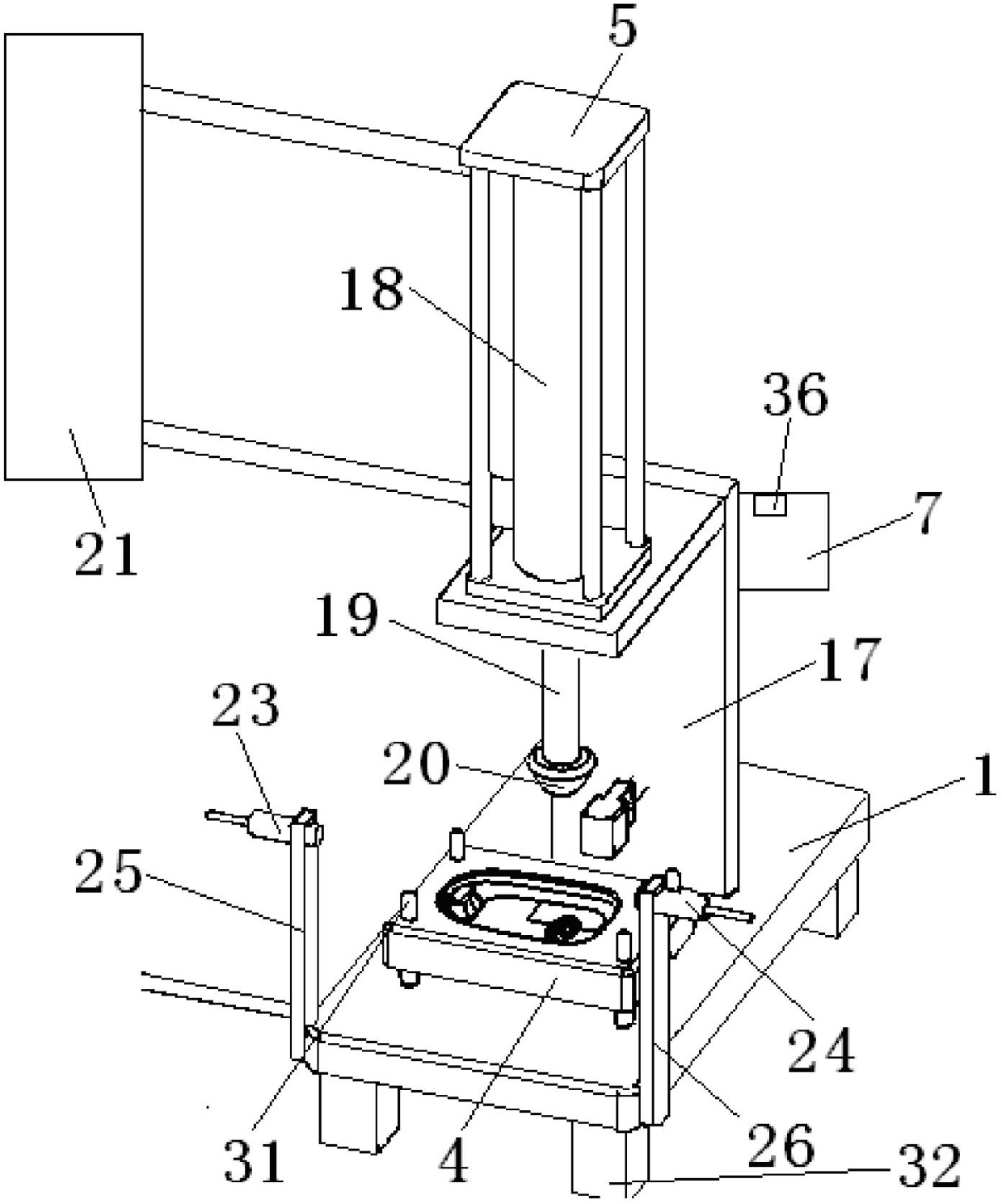

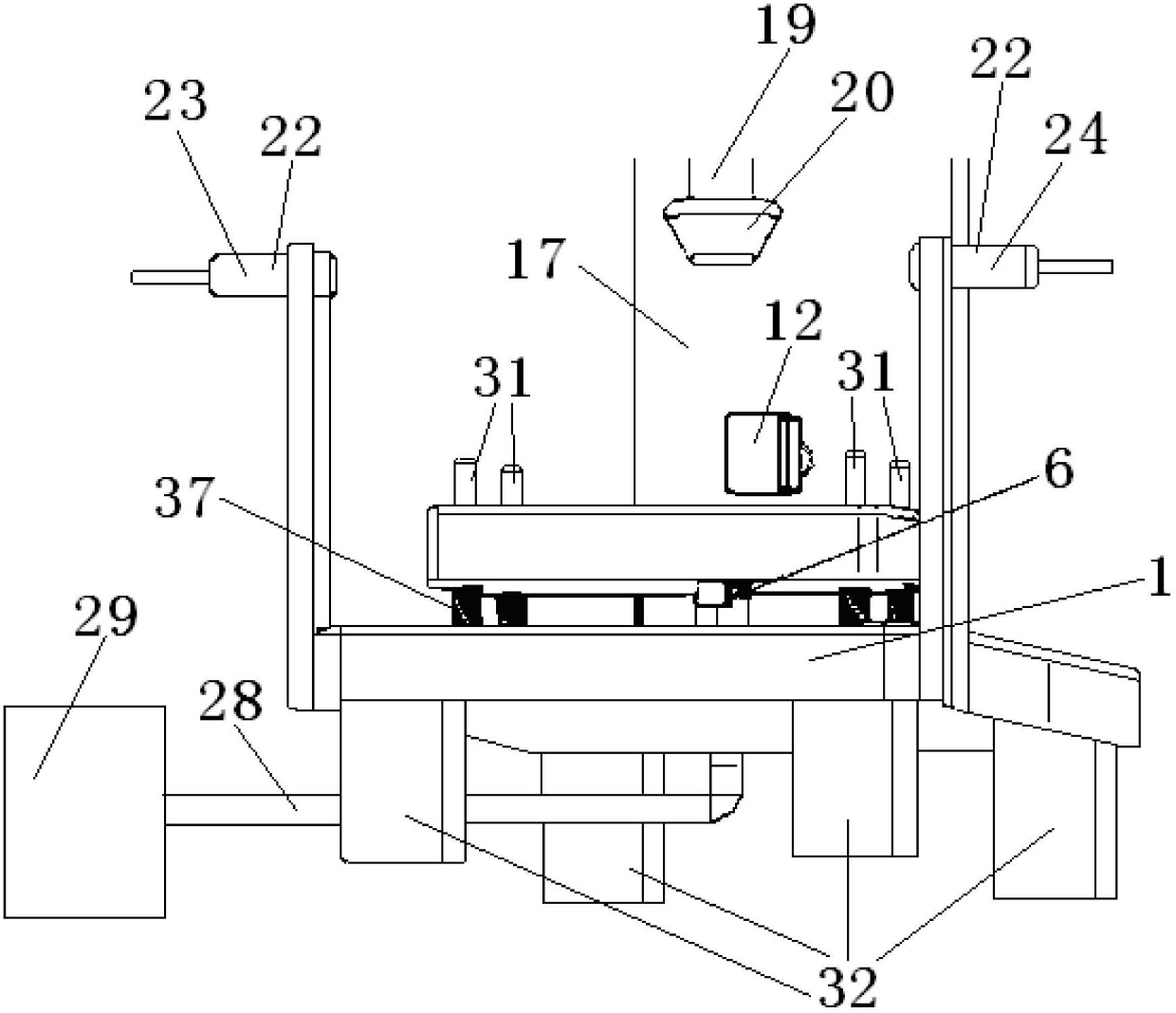

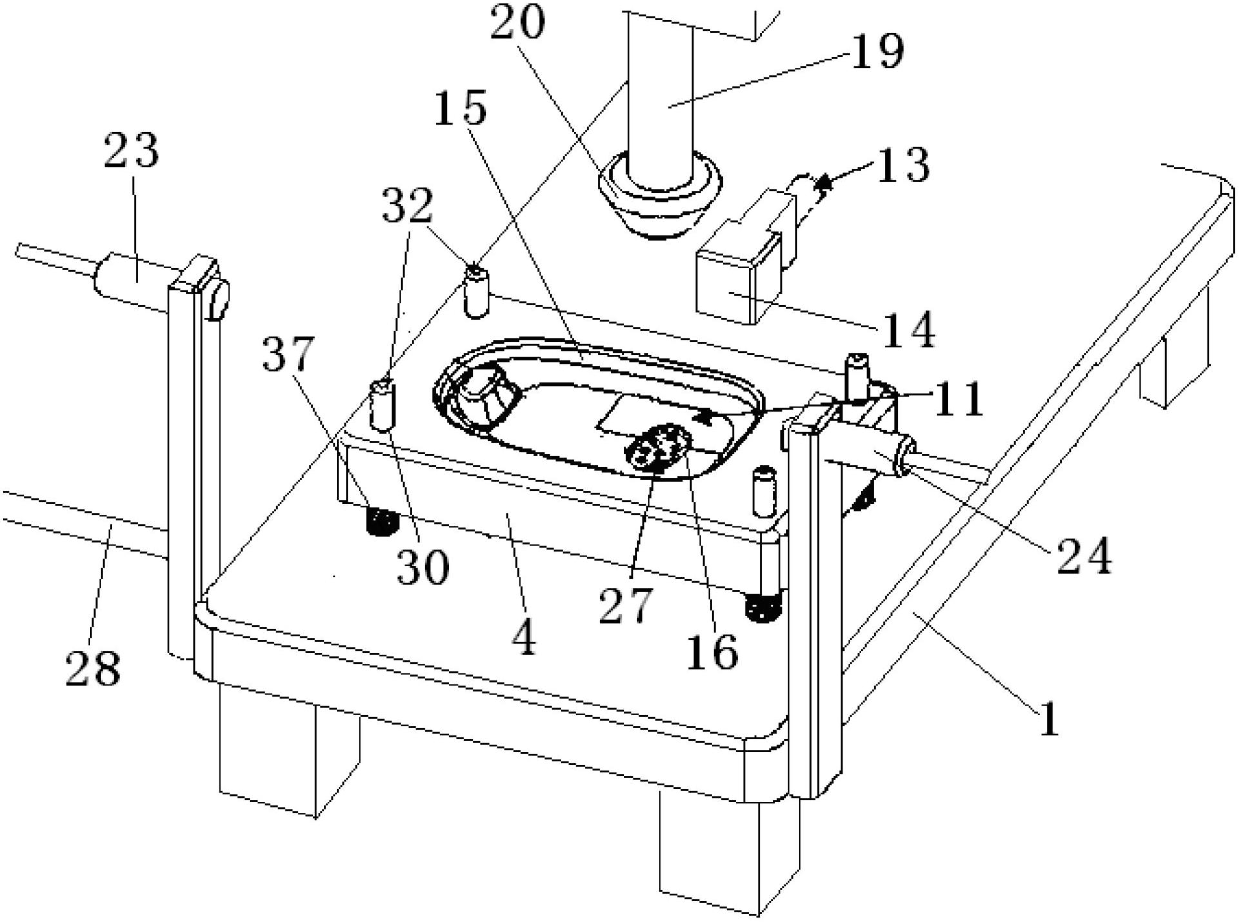

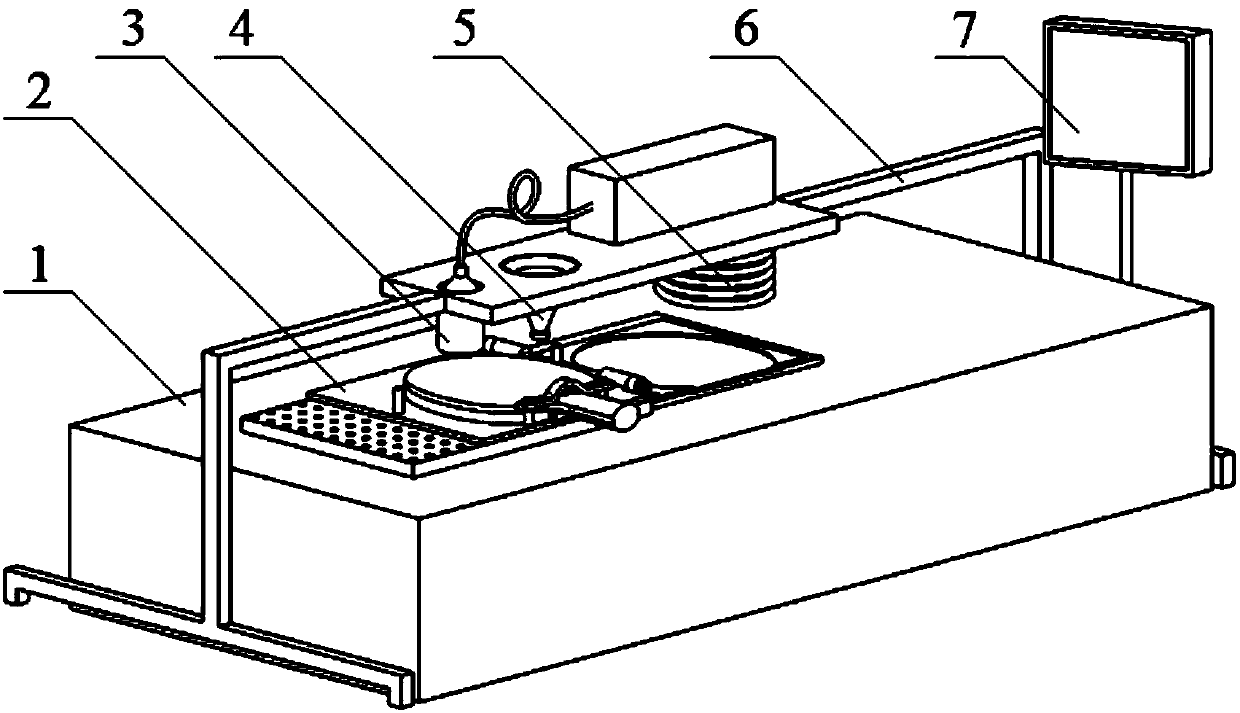

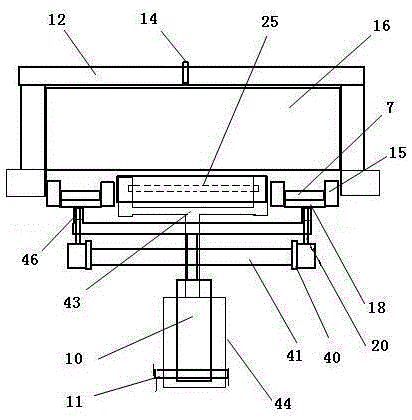

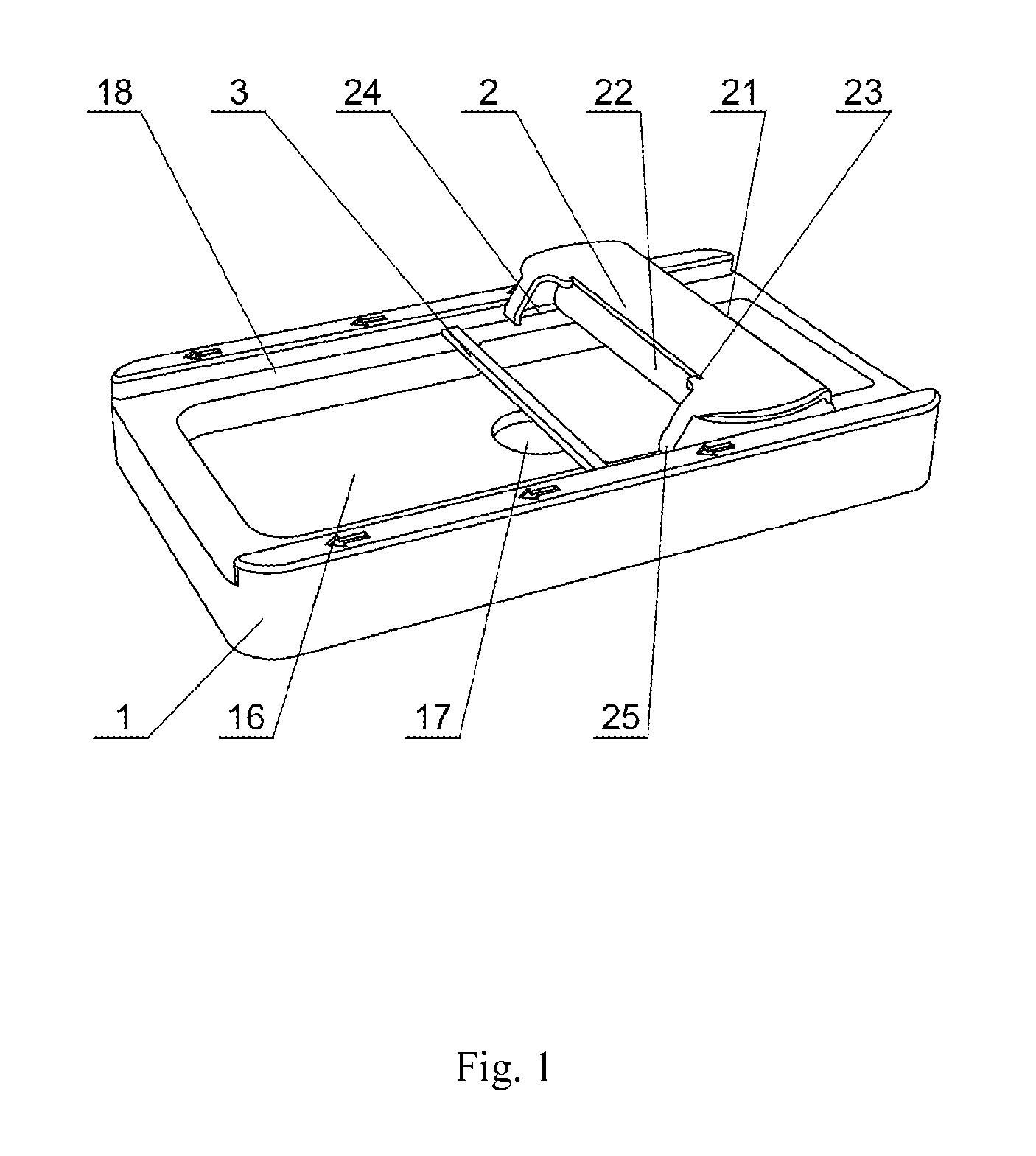

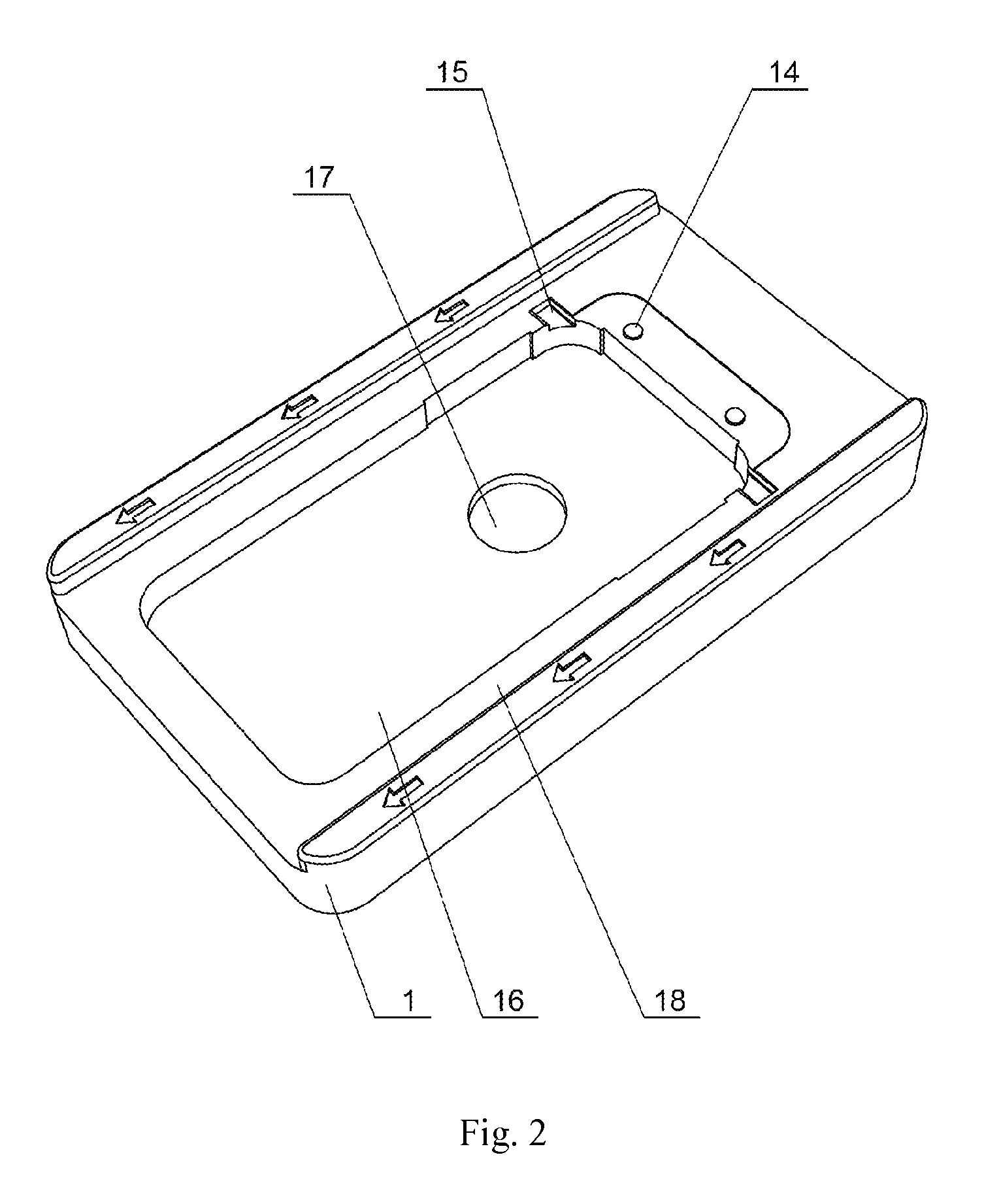

Sign pasting device and sign pasting method using same

InactiveCN102673853AGuarantee paste qualityError-proofLabelling flat rigid surfacesLabelling machinesEngineeringElectric control

The invention provides a sign pasting device applied to the technical field of sign pasting, and further relates to a sign pasting method using the sign pasting device. The pasting device comprises bases (4) for placing a plastic part (3) to be pasted with a sign, wherein the bases (4) are arranged on a supporting platform (1); a press-fit component (5) is arranged above each base (4) and has a liftable structure; a photo sensor (6) is further arranged on the base (4) and is connected with an alarm component (36); and both the photo sensor (6) and the press-fit component (5) are connected with an electric control component (7). The sign pasting device has stable pressure during sign pasting, and has an error-proofing function so as to solve the problem of omissions and errors caused by visual fatigue of an operator; and furthermore, the sign pasting device is strongly universal and can adapt to the pasting of signs of different shapes on the plastic part.

Owner:震宇(芜湖)实业有限公司

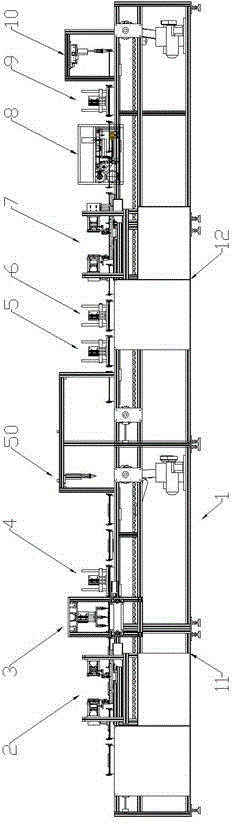

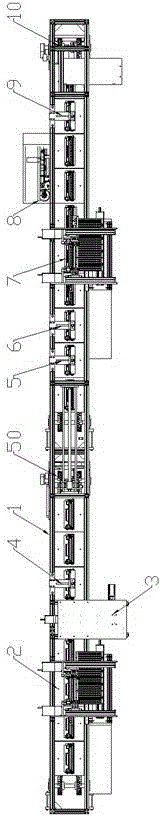

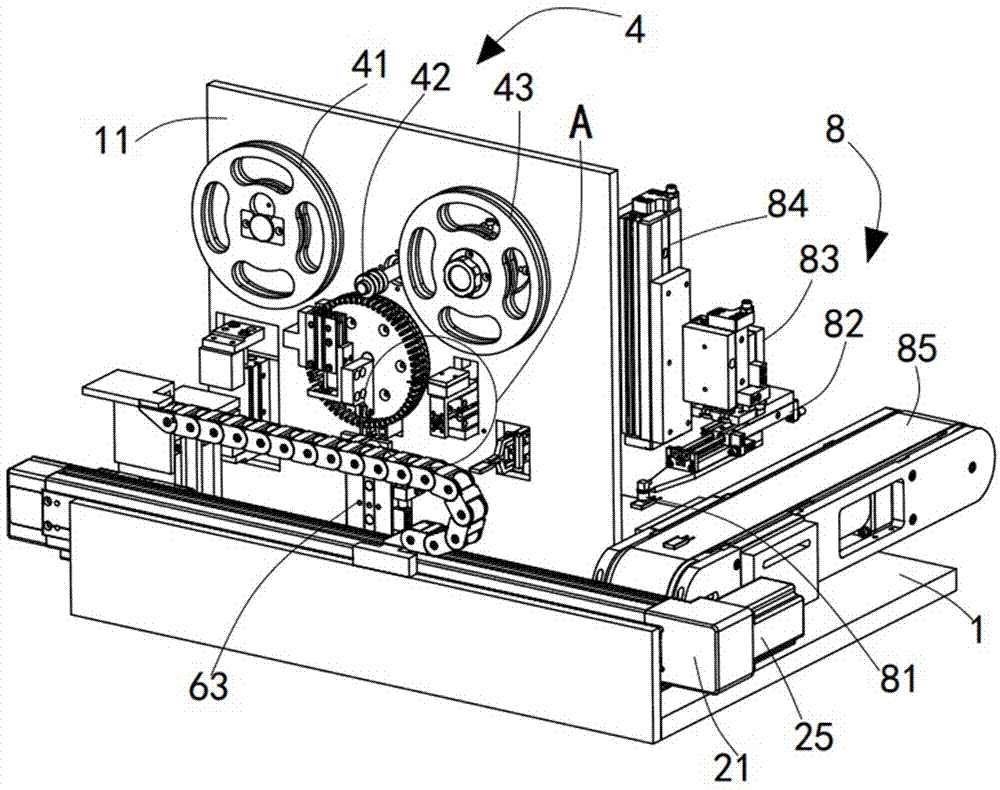

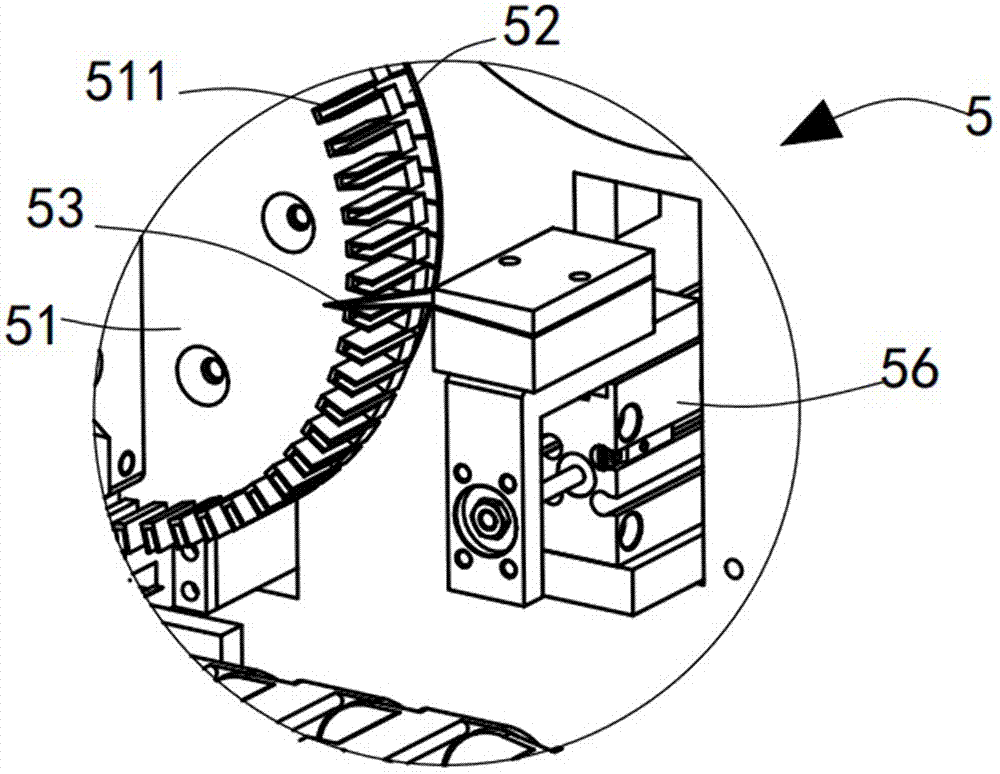

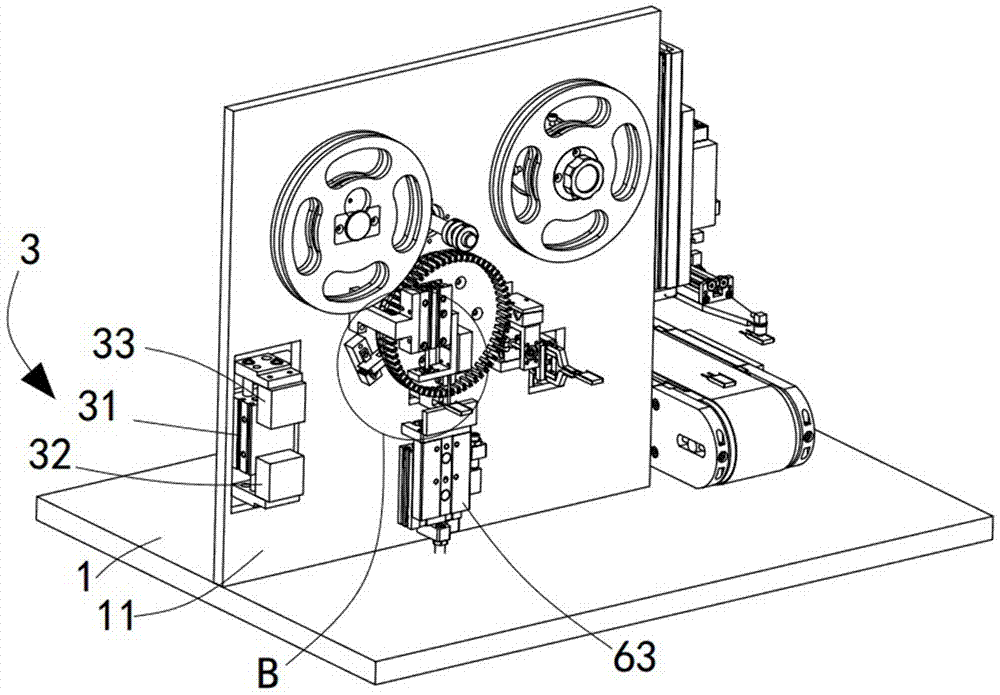

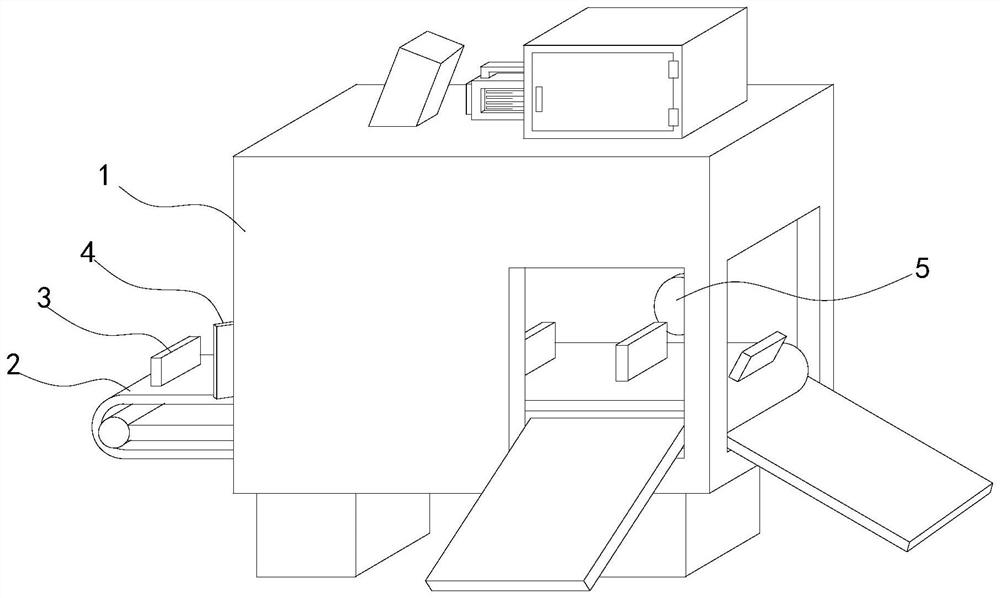

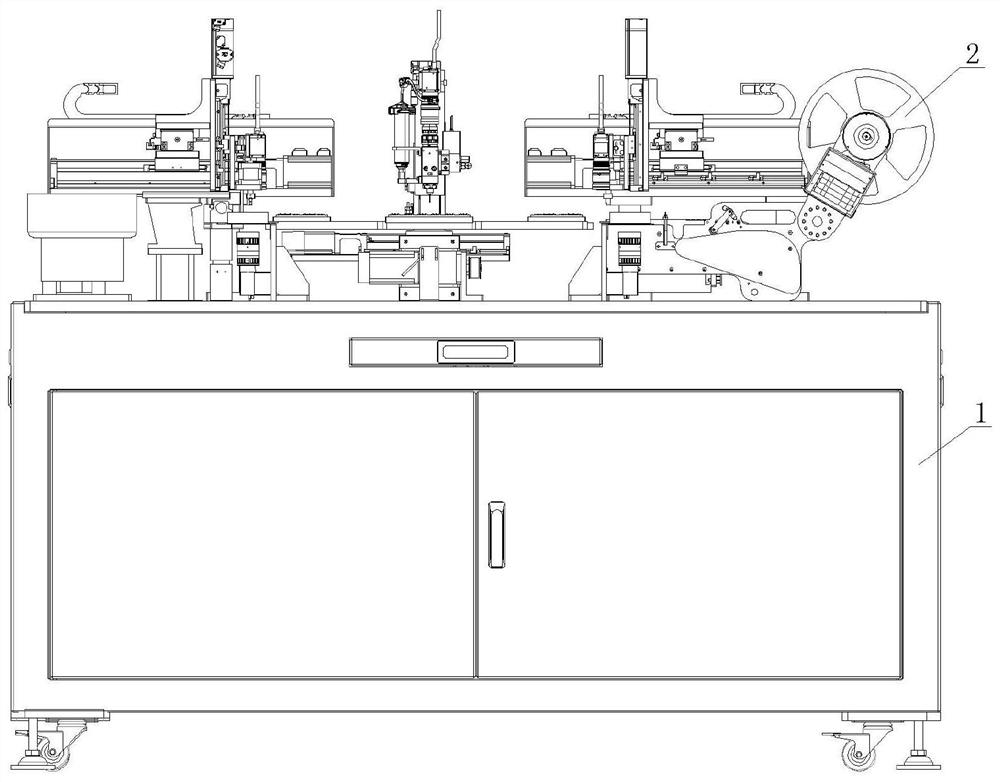

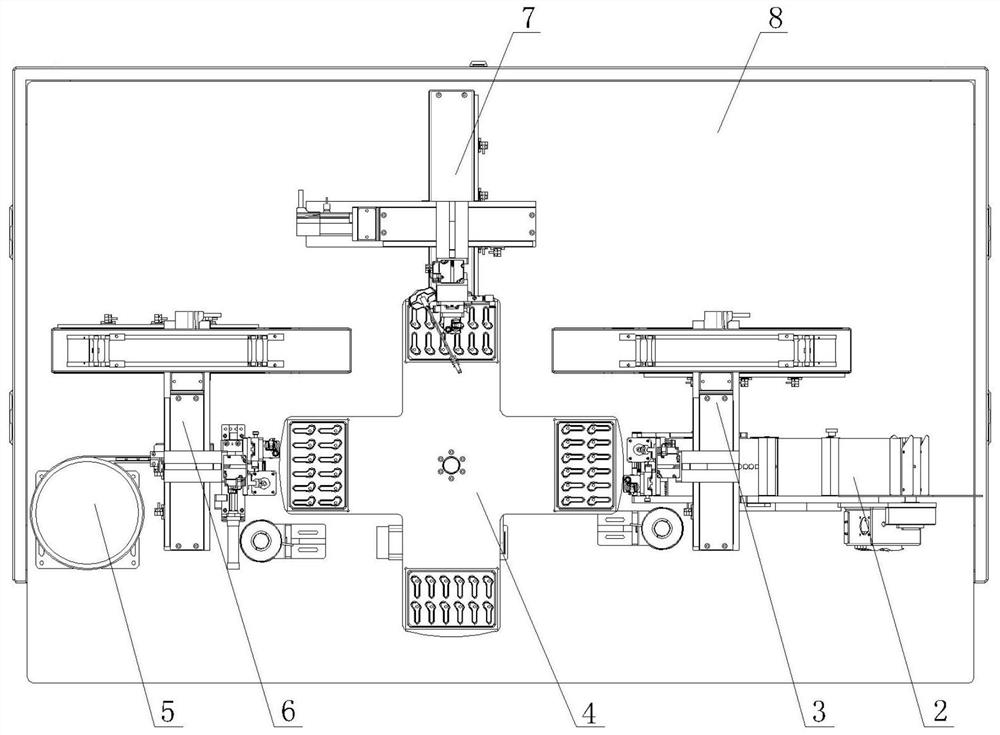

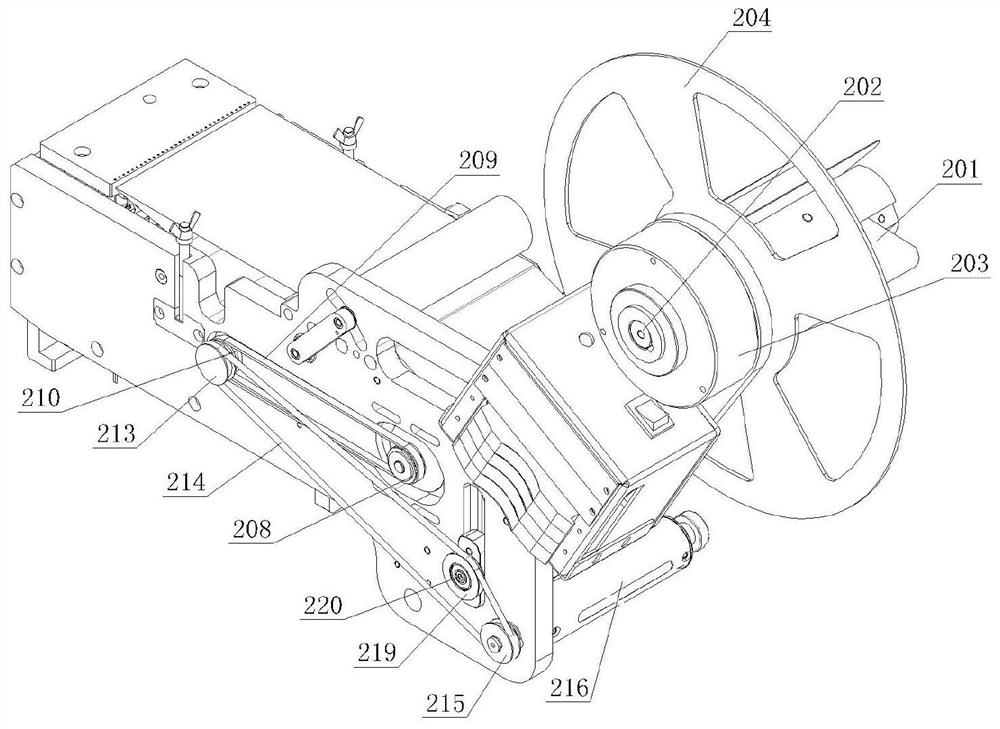

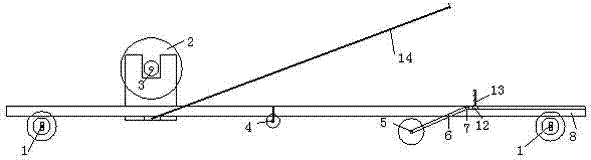

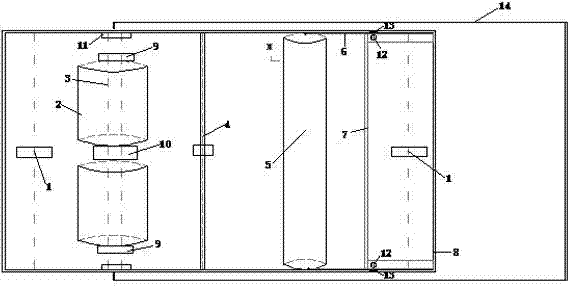

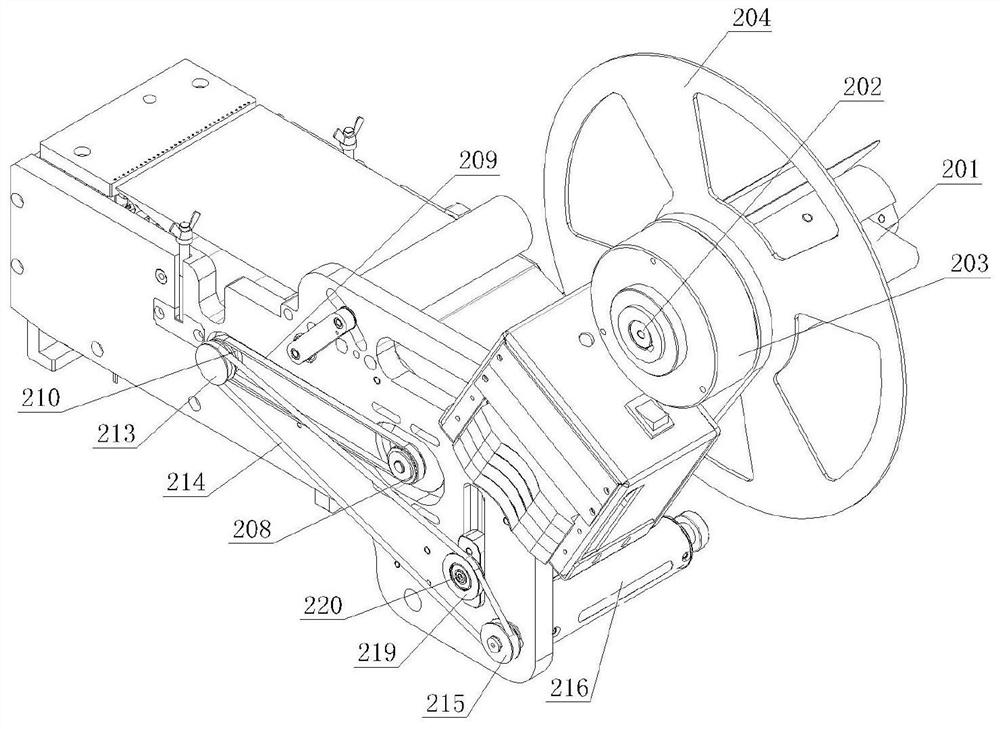

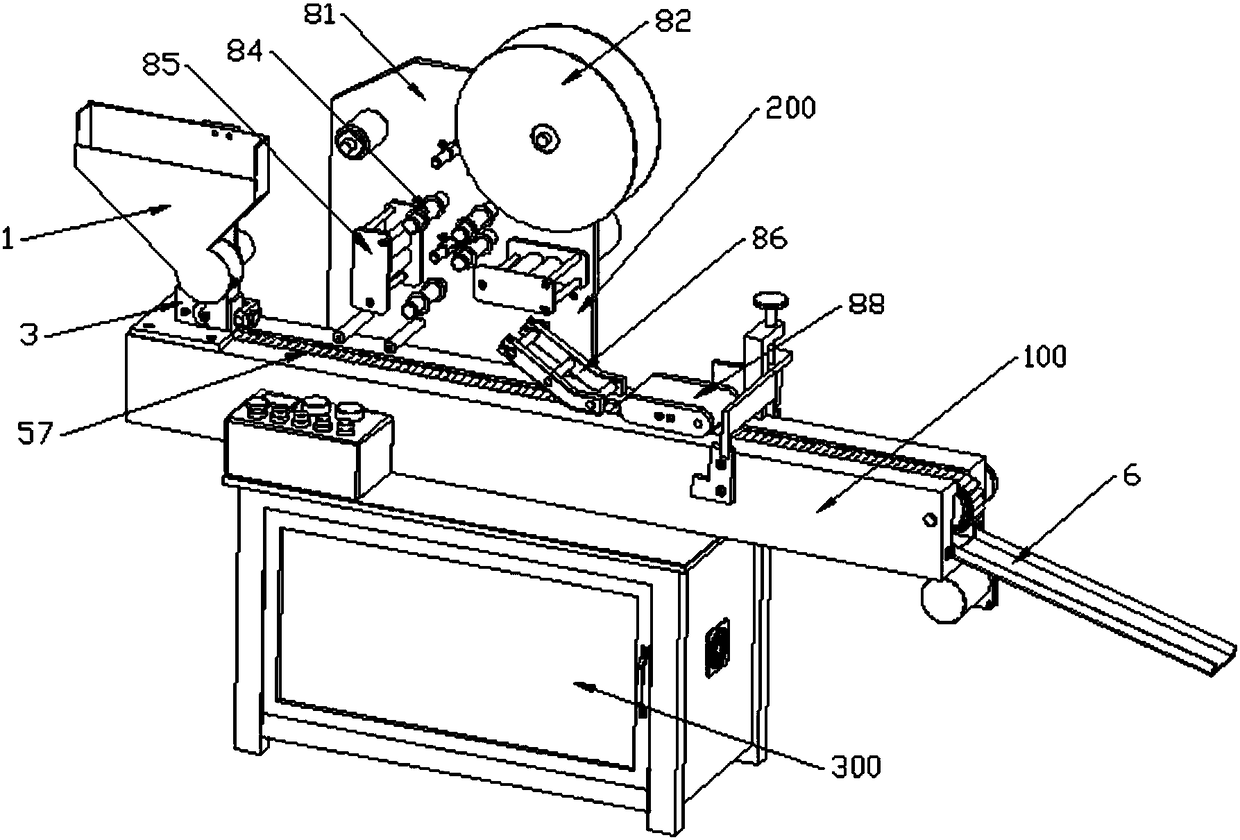

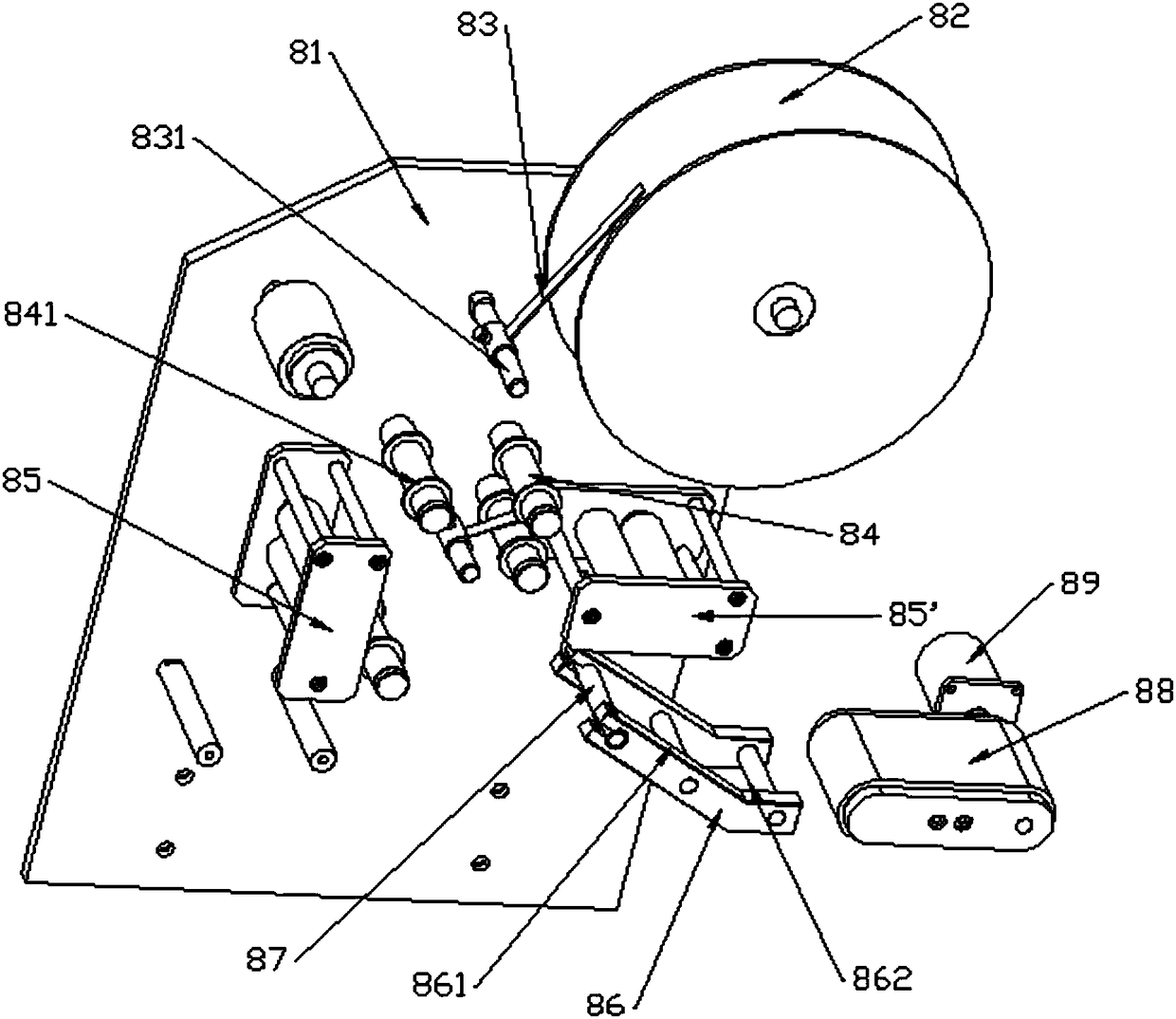

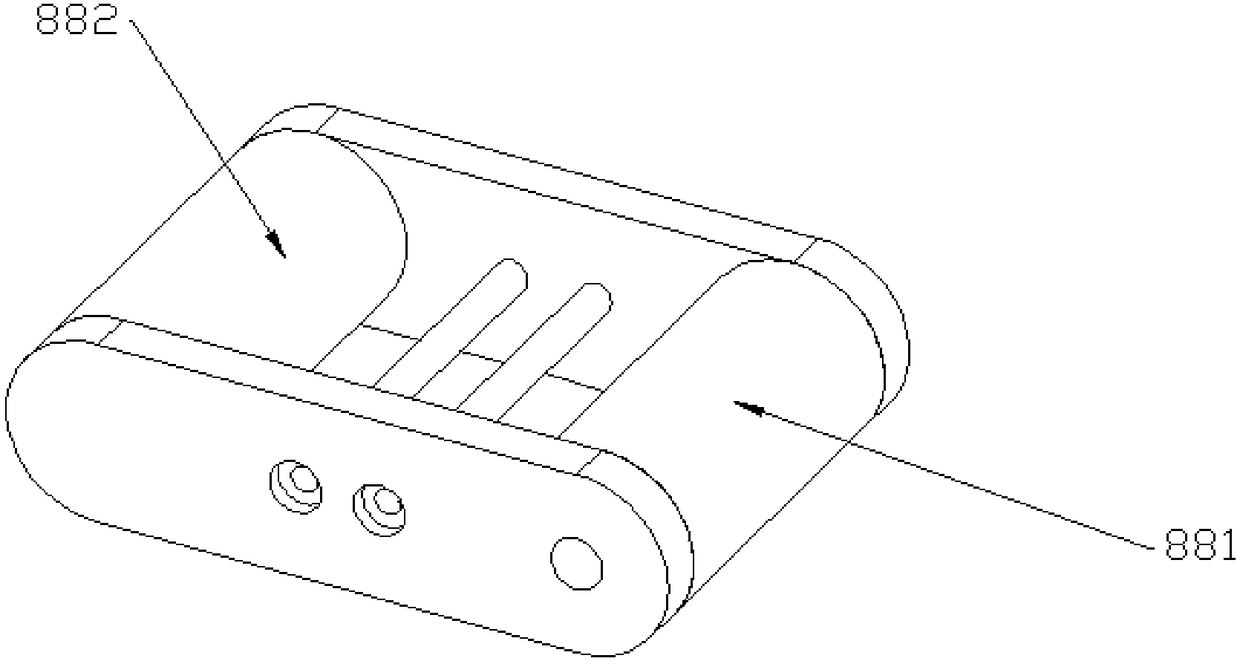

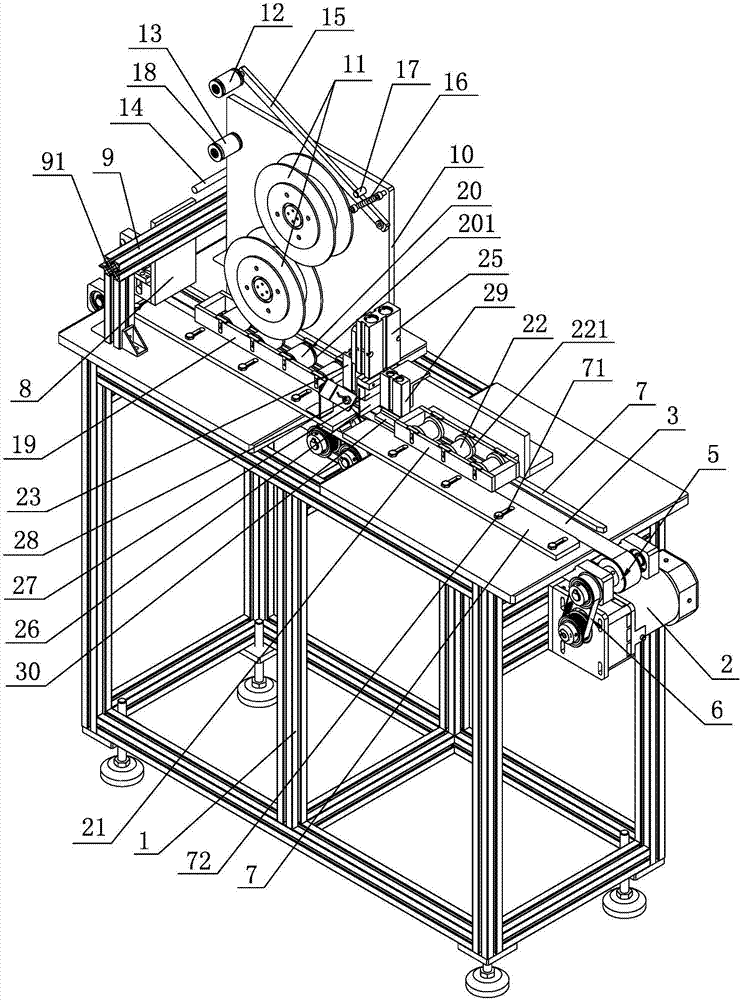

Automatic pasting production line for scrapers, sponges and felts

The invention discloses a production line used for automatically pasting scrapers, sponges and felts, and aims at providing an automatic pasting production line for the scrapers, the sponges and the felts. The automatic pasting production line is high in production efficiency, low in labor cost and good in pasting effect. The automatic pasting production line comprises a main base (1), a controller, a transmission belt arranged on the main base (1) and a motor, and the motor is in transmission connection with the transmission belt and is electrically connected with the controller. A short sponge pasting mechanism (2), a long sponge pasting mechanism (3), a long sponge pressing mechanism (4), a short sponge pressing mechanism (5), a first gluing mechanism (6), a felt pasting mechanism (7), a scraper pasting mechanism (8), a second gluing mechanism (9) and a discharging mechanism (10) are sequentially arranged on the base body (1) in the conveying direction of the transmission belt. The production line is applied to the technical field of automatic pasting production of the scrapers, the sponges and the felts of toner cartridges.

Owner:PROSPECT IMAGE PROD LIMITED OF ZHUHAI

Method and device for adhering film on screen by shearing protective film in staggered mode

InactiveCN103448943APhenomenon that will not be strippedPrecise positioningPackagingStructural engineeringProtection layer

The invention discloses a method and device for adhering a film on a screen by shearing a protective film in a staggered mode. The device comprises a base, a rolling wheel seat and a stripping roller. The method comprises the following steps: shearing the screen protective film in a staggered mode; adhering an adhering sheet and a positioning sheet on an adhering layer; and adhering the stripping roller on a release layer. An equipment positioning cavity, a sliding rail and a positioning hole are arranged on the front surface of the base of the device; the rolling wheel seat consists of a rolling wheel shell and a roller; a roller shaft seat and a sliding rail are arranged on the rolling wheel shell; the roller is arranged in the roller shaft seat; and the rolling wheel seat spans on the base and moves on the sliding rail. The method and the device have the advantages that in the link of adhering the protective film to the screen, when the stripping roller turns over a stripping layer and a product layer, the phenomenon that the product layer is stripped is avoided and operation is simple, convenient and quick; the device is accurate in positioning; adhesion is time-saving and labor-saving; and operation error is avoided even for a green hand, so the adhesion quality is guaranteed.

Owner:王旭辉

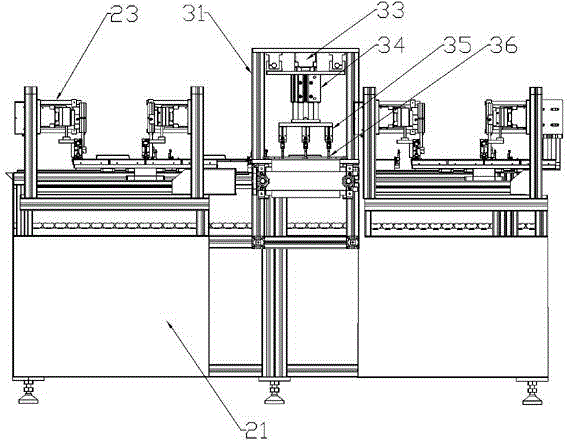

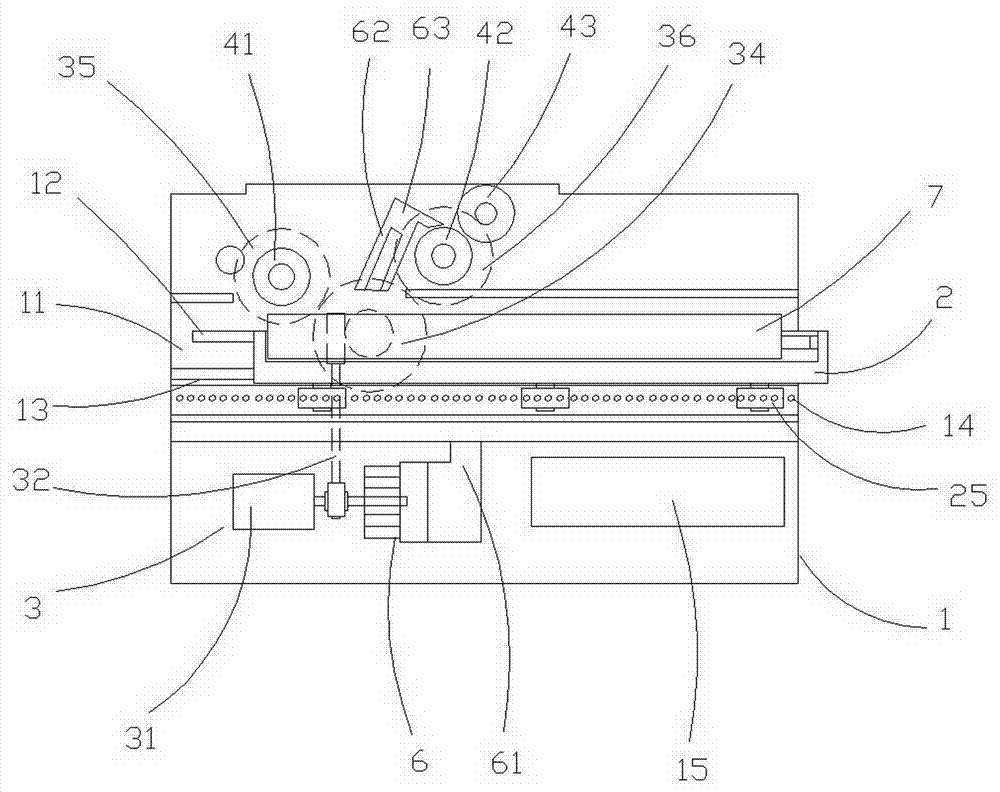

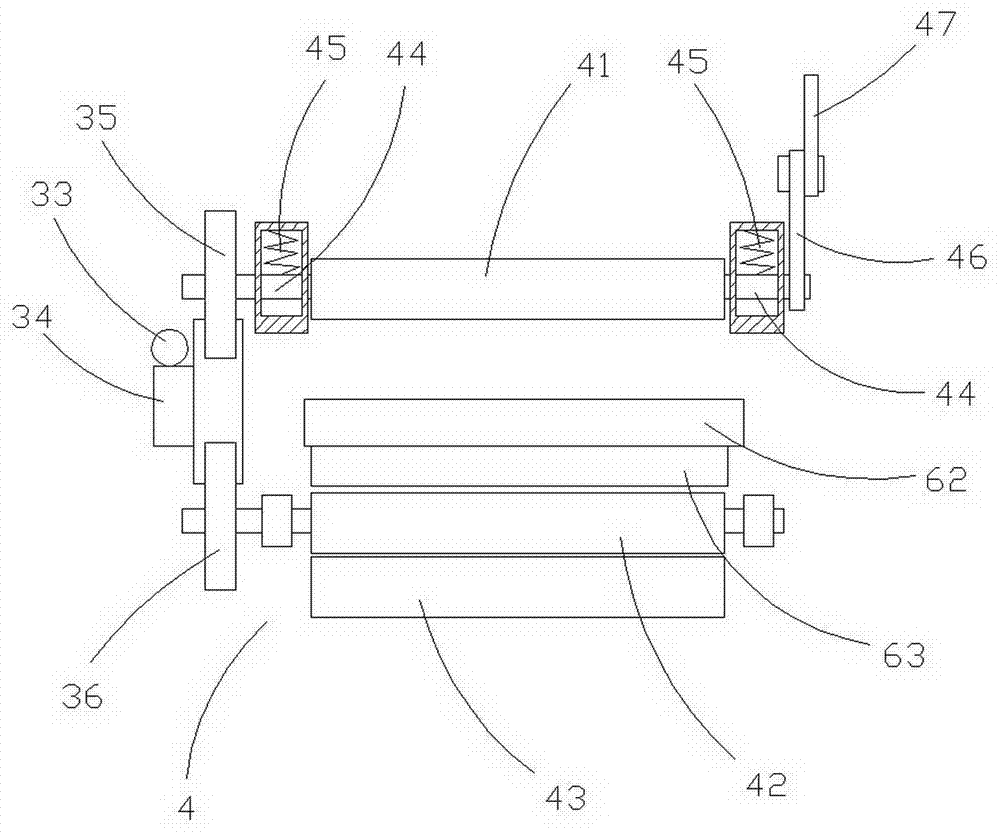

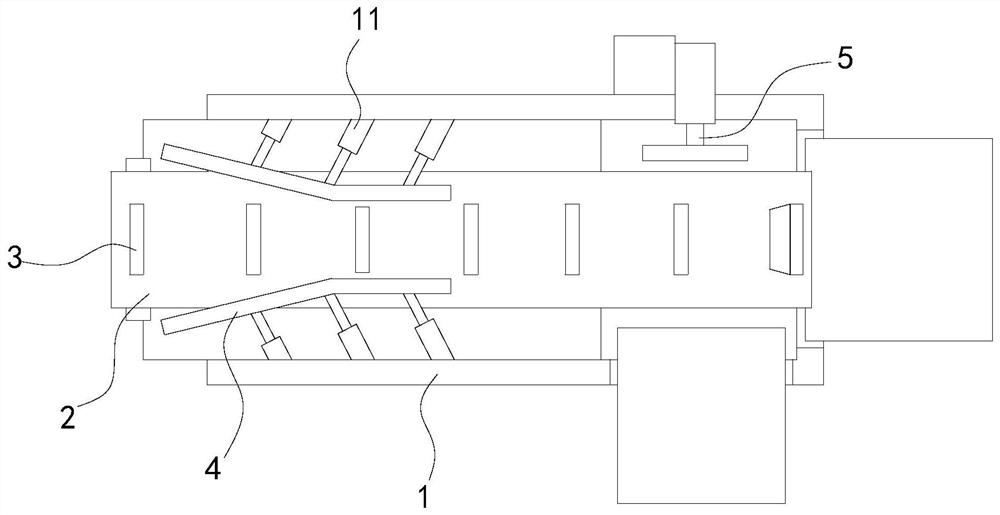

Adhesive tape pasting and folding all-in-one machine for battery lugs

PendingCN107994263AFor precise cuttingEnsure consistencyFinal product manufactureElectrolyte accumulators manufactureAutomation

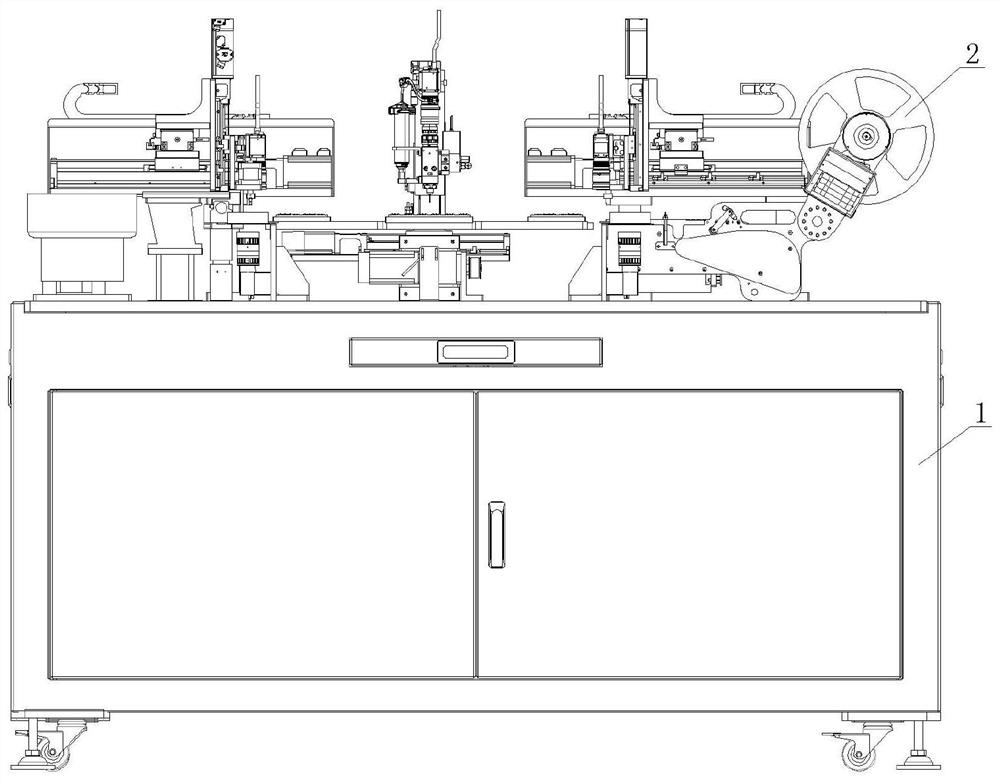

The invention relates to an adhesive tape pasting and folding all-in-one machine for battery lugs. The machine comprises a machine base, a support plate arranged on the machine base, a clamping and moving mechanism arranged on the machine base for clamping and moving batteries, a pressing assembly arranged on the support plate for flattening the lugs, a feeding mechanism arranged on the support plate for providing adhesive paper, an adhesive paper cutting mechanism arranged on the support plate for cutting adhesive paper, an adhesive tape pasting mechanism matched with the adhesive paper cutting mechanism for pasting the adhesive paper on the battery lugs, a folding mechanism for folding the battery lugs and a discharging mechanism for transferring batteries. According to the machine, a plurality of mechanisms such as the feeding mechanism, the adhesive paper cutting mechanism, the adhesive tape pasting mechanism, the discharging mechanism and the like are arranged, automation is realized from flattening of the battery lugs, cutting and pasting of the adhesive paper, folding of the lugs and final discharging, workers are only required to place products in the working process, so that production efficiency is improved, the production cost is reduced, and consistency of processing quality is ensured.

Owner:HUIZHOU HENGTAI TECH

Automatic film pasting device

ActiveCN104118600APrecise positioningMake sure it is pasted flatPackagingEngineeringMechanical engineering

The invention discloses an automatic film pasting device. The automatic film pasting device is composed of an outer shell, a transmission device and a film pasting mechanism. A sliding accommodating disk for containing a mobile phone is arranged in a cavity of the outer shell. The transmission device drives a film pressing shaft and a film output shaft of the film pasting mechanism to rotate. A dust suction pipe of a dust collector is transversely arranged at an inlet portion between the film pressing shaft and the film output shaft to conduct micronic dust processing on the mobile phone. In the rotating process of the film pressing shaft and the film output shaft, the accommodating disk is forcibly driven to move forward, the film pressing shaft rolls a protective film onto the mobile phone, the film output shaft drives a roll shaft to rotate correspondingly to roll a clamped attachment film out of a cover body from a recovery port portion, and then pasting of the protective film and separation of the attachment film from the protective film are achieved synchronously.

Owner:广州美枫电子科技有限公司

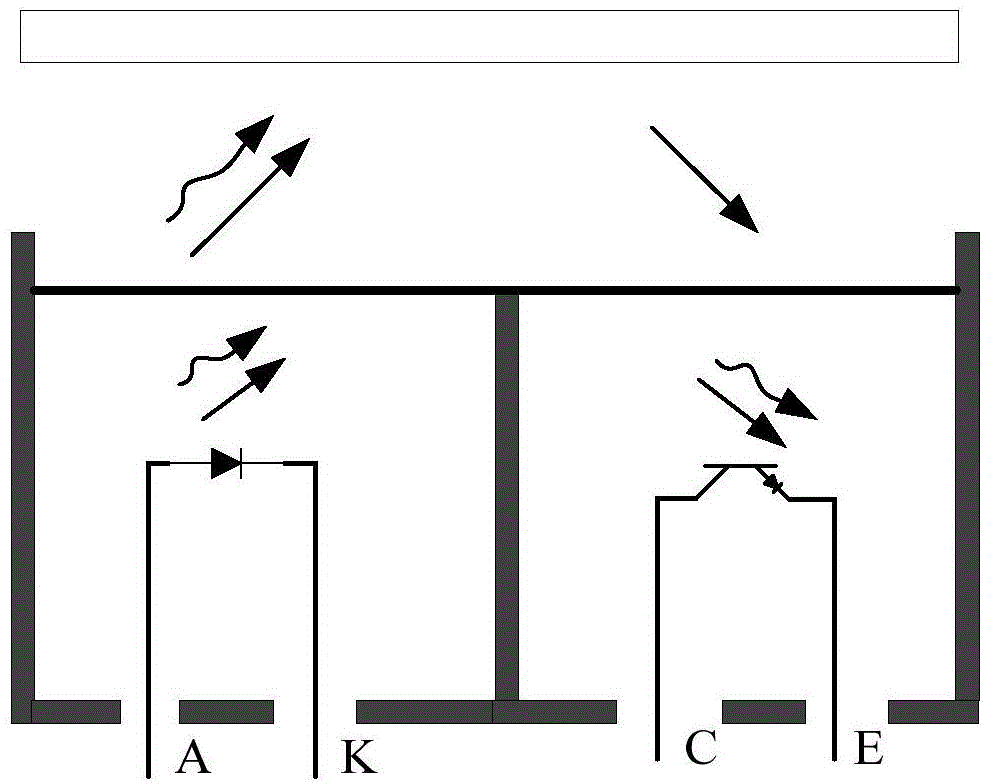

Labelling head with label detection function and applicable to electric energy meter labelling machine

InactiveCN104890966AGuarantee paste qualityImprove test efficiencyLabelling machinesInlet channelCylinder block

Disclosed is a labelling head with a label detection function and applicable to an electric energy meter labelling machine. The labelling head comprises a labelling head installation plate, a label suction disc, a labelling head locating block, guide shafts, a linear cylinder and a linear cylinder stroke adjusting block. The labelling head locating block is fixed to the labelling head installation plate. A cylinder body of the linear cylinder is fixed to the labelling head locating block, and a piston rod and the linear cylinder stroke adjusting block are in transmission connection. One end of each guide shaft is fixedly connected with the linear cylinder stroke adjusting block, and the other end of each guide shaft penetrates through the labelling head locating block and is connected with the label suction disc. A plurality of screening holes are uniformly distributed in the label suction disc and communicated with a gas outlet channel and a gas inlet channel through a gas channel adjusting valve. A color mark sensor is further arranged on the labelling head installation plate and connected with an alarm through signals. The labelling head is compact in structure and flexible to control. When labels are pasted in an inclined mode, or missed or folded, an alarm signal can be timely outputted, the label adhesion quality is guaranteed, and the working efficiency of the electric energy meter labelling machine is improved.

Owner:STATE GRID CORP OF CHINA +2

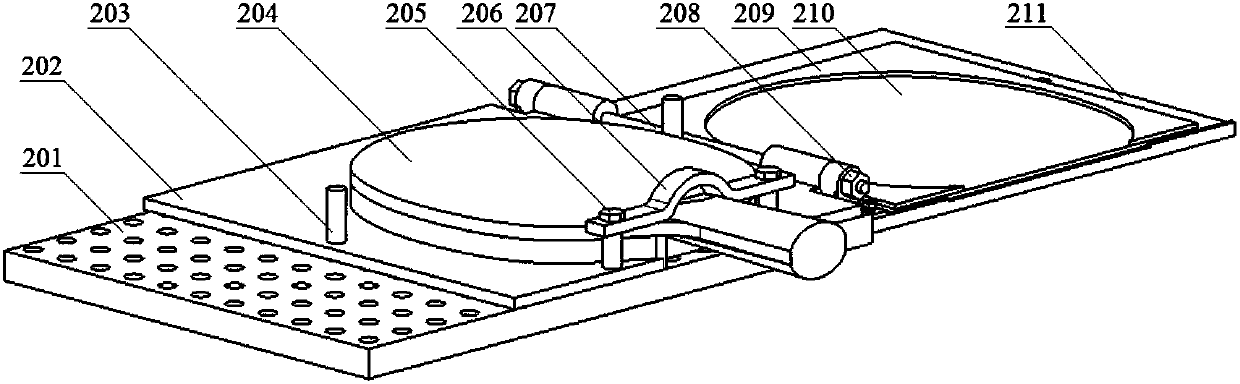

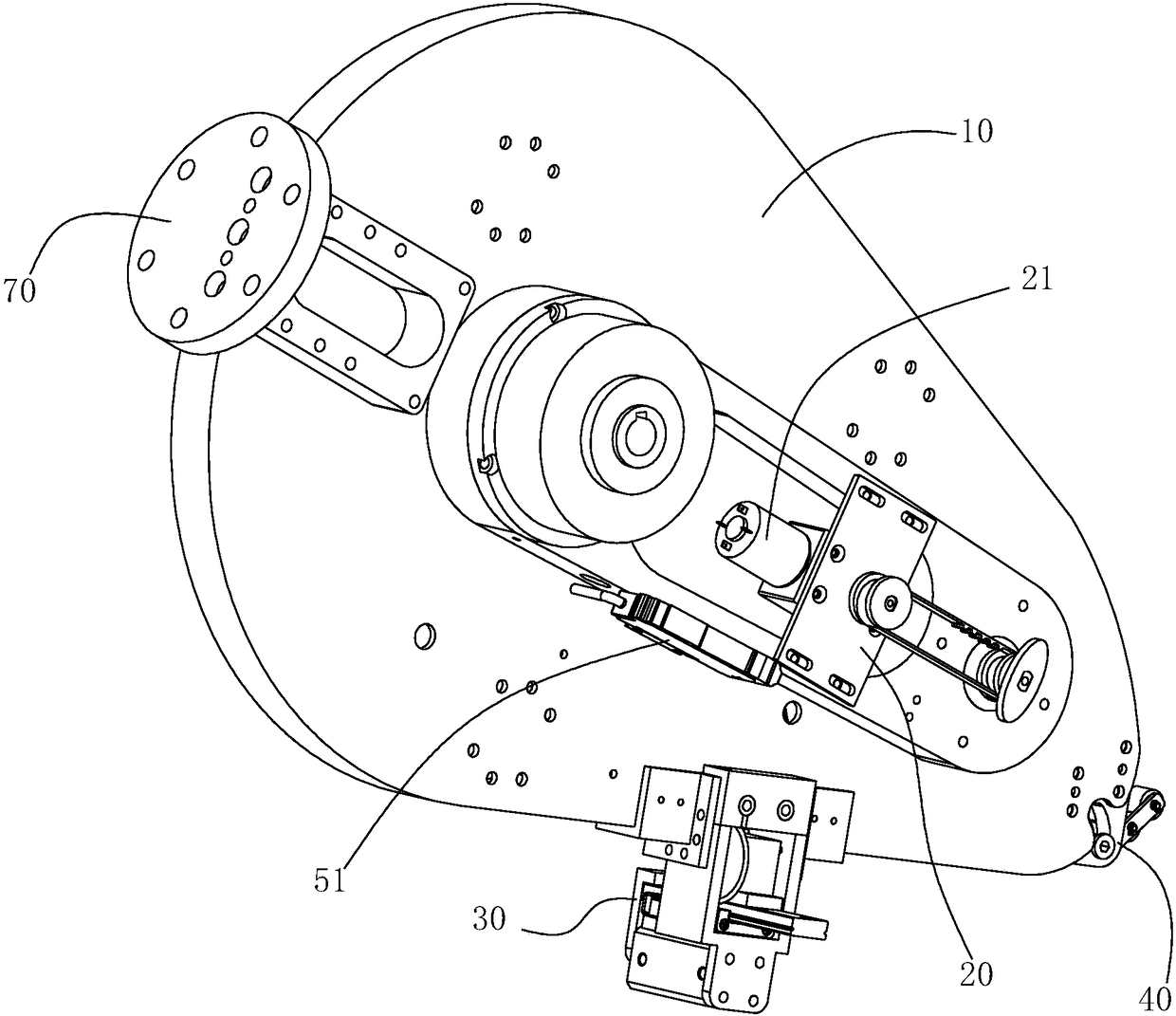

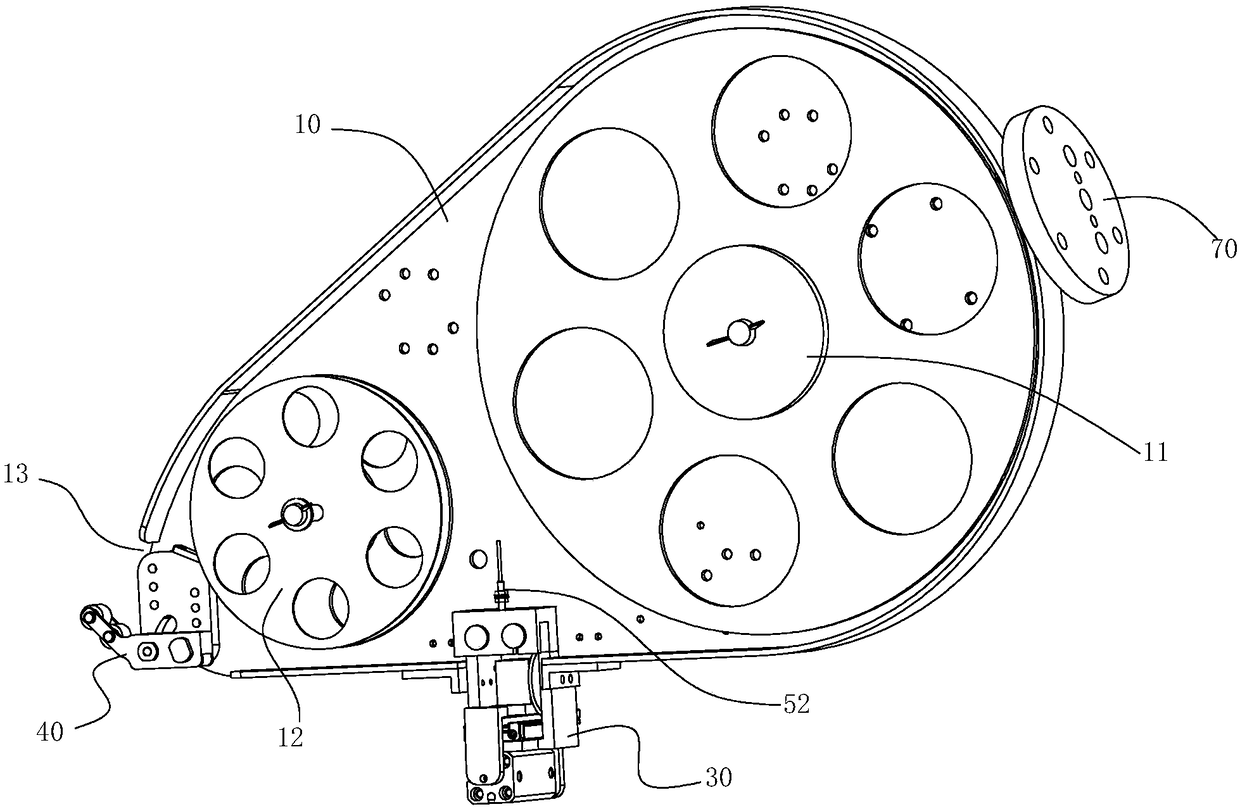

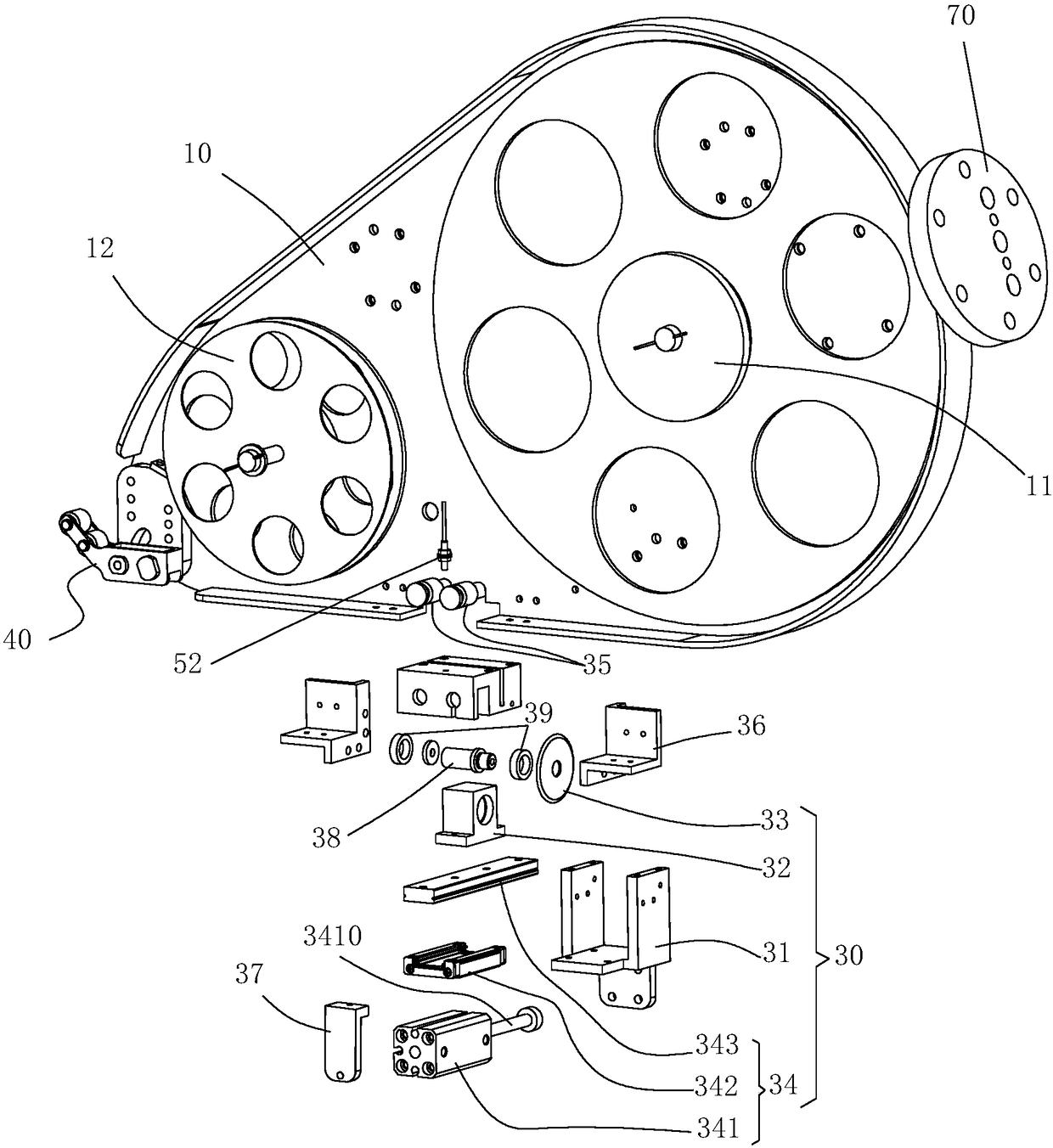

Automatic laser cutting and pasting device for table tennis racket rubber

PendingCN107694057AImprove uniformityAdjustable thicknessLaser beam welding apparatusRacket sportsLaser cuttingEngineering

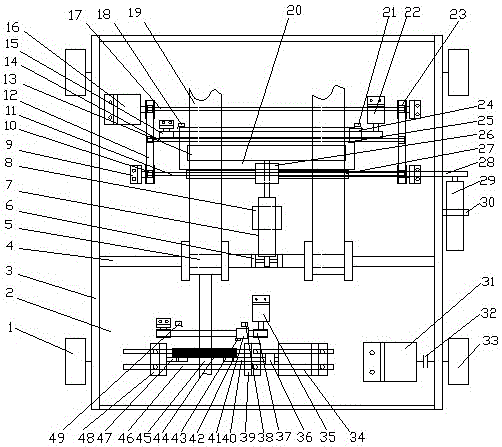

The invention discloses an automatic laser cutting and pasting device for table tennis racket rubber. The problems that when the table tennis racket rubber is manually cut and pasted, the efficiency is low and the quality cannot be ensured are solved, and by means of the automatic laser cutting and pasting device, the pasting quality and efficiency of the table tennis racket rubber can be effectively improved, so that the technical requirements for operators and the work load are greatly reduced. According to the technical scheme, the automatic laser cutting and pasting device comprises a three-dimensional moving platform, a workbench is fixedly arranged on the three-dimensional moving platform, a racket bottom plate fixing device and a rubber fixing device are arranged on the workbench and rotationally connected, and the rubber fixing device can be overturned to be matched with the racket bottom plate fixing device in an overlapping mode; a laser cutting device, an adhesive coating device and a pressing device are correspondingly arranged above the workbench, the three-dimensional moving platform drives the workbench to move, so that the racket rubber is subjected to adhesive coating, pressing and extra rubber cutting with laser in sequence, and the racket rubber pasting process is completed.

Owner:QINGDAO TECHNOLOGICAL UNIVERSITY

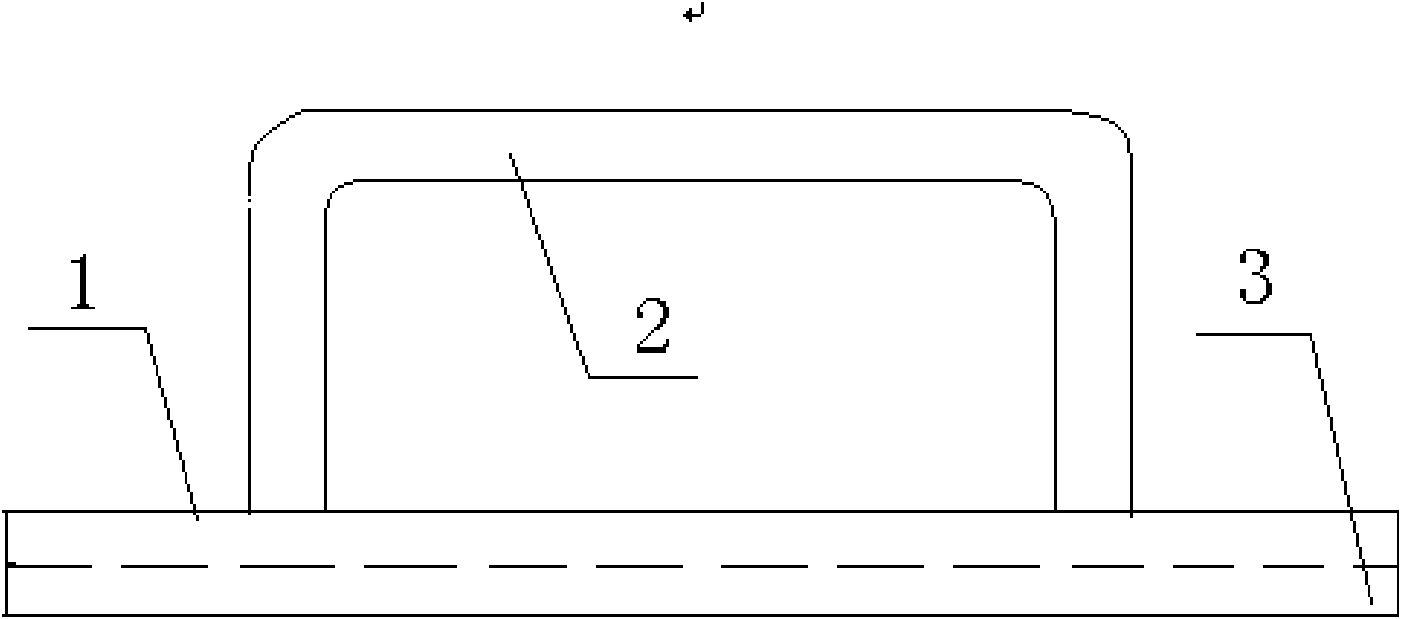

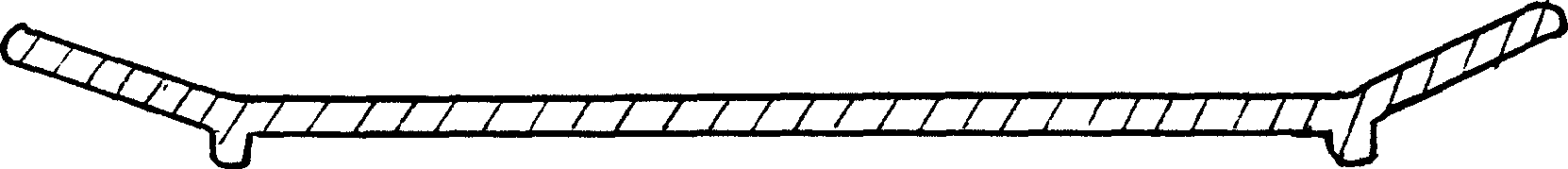

Plastering and trough-pulling construction method of face brick wall surface and pull trough plate

InactiveCN101666144AImprove adhesionGuarantee paste qualityCovering/liningsBrickExpanded clay aggregate

The invention discloses a plastering and trough-pulling construction method of a face brick wall surface and a pull trough plate. For the wall surface with the basecourse being concrete pavement or ceramic hollow bricks, the wall surface needing to be adhered with face bricks is processed according to the following method: 1) foundation treatment; 2) treatments of hanging a perpendicular line, ensuring all the inside and outside corners to be 90 degrees, and screed; (3) plastering treatment; (4) trough-pulling treatment, namely using the pull trough plate to draw grooves which are arranged horizontally, vertically or obliquely with the angles with the horizontal line being smaller than 90 degrees on the plastering layer during prehardening of the plastering layer, thus increasing the adhesive property between the plastering surface and the wall tiles and further ensuring the adhesive quality of the face bricks; and (5) curing treatment; and the face bricks can be adhered by a conventional method after the curing treatment is finished. The invention not only has the advantages of avoiding hollowness, falling and other phenomena after the face bricks are adhered, but also has the advantages of higher construction quality, easy construction, lower requirements on the technological capability of the constructors and the like.

Owner:CCFED THE FIGTH CONSTR & ENG

Labeling device for corrugated carton production and label detection mechanism thereof

InactiveCN112591248AImprove labeling efficiencyAvoid affecting the efficiency of subsequent processingLabelling machinesSuction forceClassical mechanics

The invention relates to the field of corrugated carton production, in particular to a labeling device for corrugated carton production and a label detection mechanism thereof. The labeling device comprises a device body, a limiting device is movably installed on the left side in the device body, a conveying belt is movably installed at the lower end in the device body, a movable frame is movablyinstalled on the left side of the upper end in the device body, a guiding device is movably installed at the lower end of the movable frame, a labeling device is movably installed on the right side ofthe movable frame, an air extractor at the upper end of the exterior of the device body is connected with the interior of an air suction cavity through a pipeline, an air suction channel on the labeling device can generate inward suction force, and therefore the non-sticky side of a label scraped off by a guiding roller is sucked, when the labeling device drives the label to rotate, the label canmake contact with a corrugated carton on the conveying belt, the automatic labeling effect is achieved, the outer end of the air suction channel is obliquely arranged towards the two sides, the contact area of suction force in the air suction channel and the label can be increased, and therefore the stability when the label is driven to move is improved.

Owner:浙江骏驰纸制品有限公司

Carton sealing device

The invention relates to a carton sealing device. The device comprises a cutting mechanism and a conveying belt; the conveying belt comprises a driving wheel and a belt face, a clamping groove is formed in the belt face, a rubber roll, a feeding roller and a discharging roller are arranged above the belt face, adhesive tape is wound in the rubber roll, a first transverse shaft is connected to thedriving wheel, a driven gear is arranged on the first transverse shaft in a sleeving manner, a rotation part is rotatably connected to the end face of the driven gear, two magnetic blocks with opposite magnetic properties are connected to the rotating part, a second transverse shaft is arranged on the outer side of the first transverse shaft, a drive mechanism is connected to the second transverseshaft, a metal bar is connected to the second transverse shaft, a driving gear is connected to the second transverse shaft, the cutting mechanism comprises an air cylinder and a cutting knife, the cutting knife is fixedly connected to the air cylinder, the bottom of the cutting knife is provided with an electric heating wire electrically connected with the metal bar, an inclined groove is formedin the cutting knife, the high end of the groove is away from the driving gear, a push rod rotatably connected with the rotating part is in sliding connection into the groove, and the two side portions of the cutting knife are rotatably connected with rollers through connecting rods. Automatic sealing of a carton is achieved.

Owner:重庆市琦缘包装有限公司

Cutting device for explosion-proof film

InactiveCN109940675AGuarantee paste qualityPrecise control of cutting positionMetal working apparatusEngineeringConductor Coil

The invention discloses a cutting device for an explosion-proof film. The cutting device comprises a support, a first guide rail, a moving block, a second guide rail, a first hydraulic cylinder, an explosion-proof film winding roller, a first motor, a cutter, a second screw rod, a second motor, a third guide rail and a third hydraulic cylinder. A second hydraulic cylinder is utilized for controlling a pressing plate to fall off to fix the pasted explosion-proof film, the first motor is utilized for driving the first screw rod to rotate, thus the pressing plate is controlled to press the explosion-proof film, thus the explosion-proof film is pasted closely and neatly, the second motor is utilized for driving the second screw rod to rotate, thus a connecting block is controlled to drive theexplosion-proof film winding roller to move, the third guide rail and a pulley are utilized for enabling the explosion-proof film winding roller to move stably, the third hydraulic cylinder is utilized for controlling the first hydraulic cylinder to move on the second guide rail, the first hydraulic cylinder is utilized for controlling the cutter to fall to cut the explosion-proof film, the devicecan fix the pasted explosion-proof film, the pasting quality of the explosion-proof film is ensured, and the cutting position can be controlled precisely.

Owner:江敏

Rotary table type automatic pasting equipment

Owner:XIAMEN YOUXIN INFORMATION TECH CO LTD

Automatic sticking equipment for adhesive tape

PendingCN108313804AImprove processing productivityGuaranteed accuracyArticle deliveryDrive motorEngineering

The invention provides automatic sticking equipment for adhesive tape. The automatic sticking equipment for the adhesive tape comprises an adhesive tape loading mounting plate, an adhesive tape take-up and pay-off driving assembly, an adhesive tape cutting-off structure, an adhesive tape attaching head structure and a controller. The adhesive tape loading mounting plate is provided with an adhesive tape storage part, an adhesive tape waste recovery part and an adhesive tape outlet. The adhesive tape take-up and pay-off driving assembly comprises a driving motor. The adhesive tape cutting-off structure comprises a mounting cutter rest, a cutter mounting base, a cutting blade and a slippage assembly. The mounting cutter rest is provided with an adhesive tape passing groove and a cutter containing space. The slippage assembly can drive the cutter mounting base to linearly slip in a reciprocating mode in the direction perpendicular to the extension direction of the adhesive tape passing groove. The adhesive tape attaching head structure comprises an attaching mechanical arm and attaching rolling wheels. The controller is both electrically connected with the driving motor and the slippage assembly. By applying the technical scheme, the problems that the processing production efficiency in double-faced non-setting adhesive tape attaching is low and adhesive tape attaching productionquality of products is poor in the prior art can be solved.

Owner:深圳市世椿机器人有限公司

Multi-valve linkage glue-spraying device

ActiveCN101480642AKeep healthyReduce pollutionLiquid surface applicatorsSpray nozzlesMulti-valveEngineering

The invention relates to a multi-valve linking glue spraying device which comprises a shell, a glue spraying mechanism, an upper cover and a driving mechanism, wherein the upper cover is provided with a glue inlet, the driving mechanism is arranged on the upper cover, and the bottom of the shell is provided with at least two holes; the glue spraying mechanism comprises more than one connecting bar, ball-head pin valve and nozzle, the number of the ball-head pin valves is matched with the that of the nozzles, the nozzles are arranged in the holes arranged on the bottom of the shell, and the number of the nozzles is equal to the number of the holes arranged on the bottom of the shell; the connecting bar is provided with at least two ball-head pin valves, one ball-head pin valve corresponds to one nozzle, and the connecting bar is connected with the driving mechanism and is driven by the driving mechanism so as to cause the connecting bar to drive the ball-head pin valves to move along a perpendicular direction. In addition, when the connecting bar upwards moves, all the nozzles are simultaneously opened to cause glue solution to outflow from the nozzles, and the glue spraying is realized; when the connecting bar downwards moves, all the ball-head pin valves simultaneously close the nozzles, thereby the invention can achieve the purpose of synchronous and uniform glue outflow and synchronous closing.

Owner:DALIAN HUAGONG INNOVATION TECH

Method for making ceramic art utensils

InactiveCN1603281ARealistic imitation glaze pattern effectVivid colorsDecorative surface effectsLacquerPulp and paper industry

The invention relates to a method to make artwork ceramics vessel. First, making ceramics raw body of tumbling body and printing the image on the surface of the vessel to chrome paper; second, cutting the chrome paper and sticking the chrome paper cut from chrome paper onto the corresponding area of the raw body and covering the surface of chrome paper with light transmission lacquer, covering the surface that need not stick chrome paper with lacquer. The invention slickly adopts chrome paper and light transmission lacquer to adorn the surface of ceramics to make it have realistically imitating enamel painting effect, but sharply decreasing the cost.

Owner:广东强盛陶瓷玻璃有限公司

Surface mounting electronic component device for PCB

ActiveCN112333998AImprove stripping efficiencyImprove placement productivityPrinted circuit assemblingElectrical componentsSurface mountingEngineering

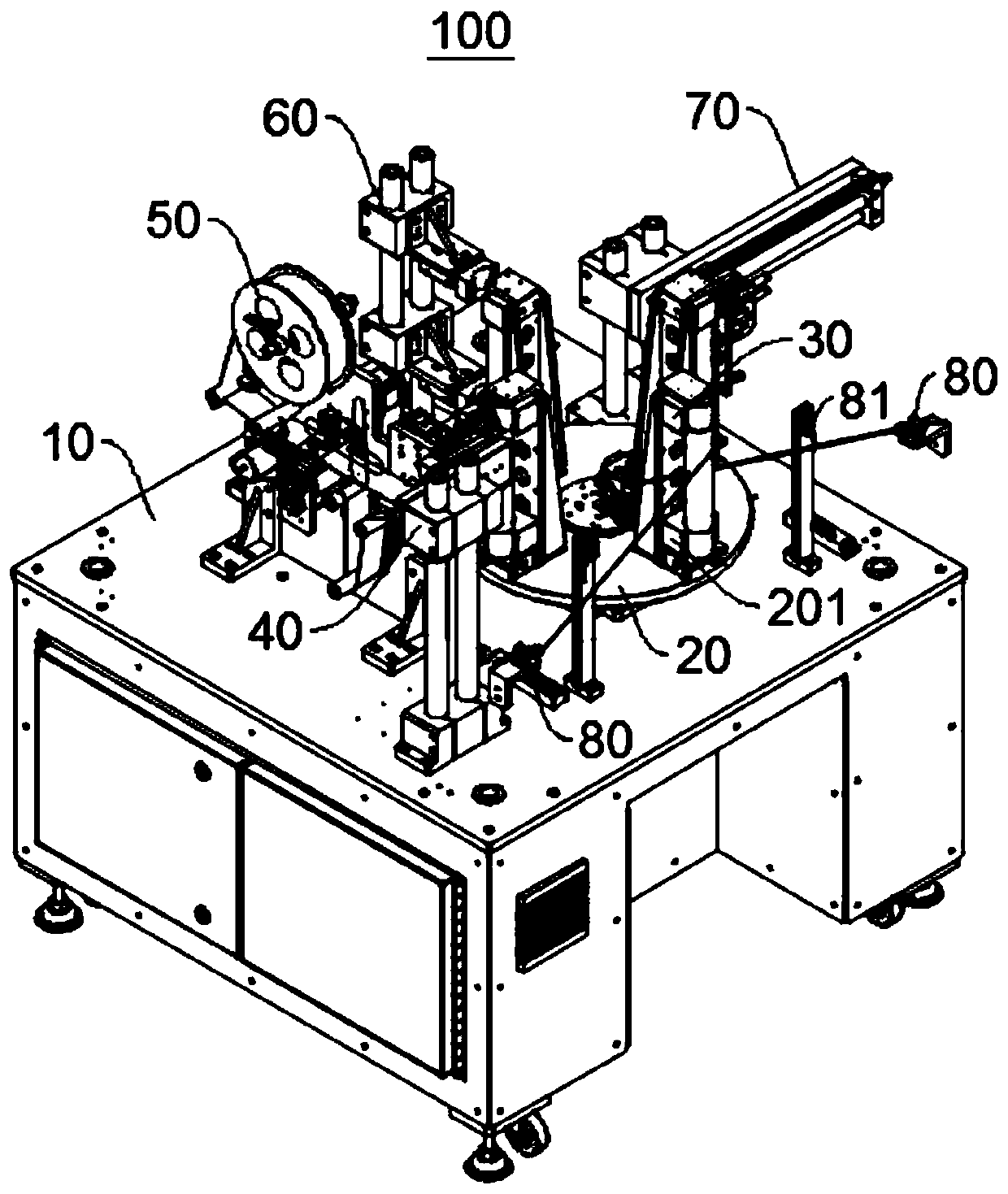

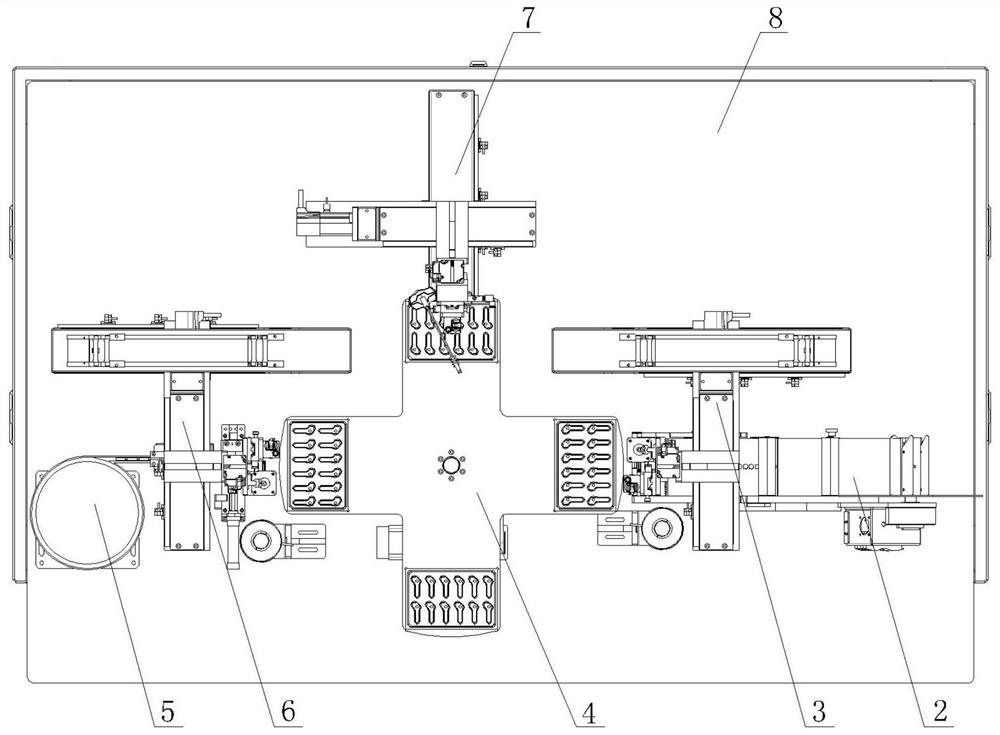

The invention relates to a surface mounting electronic component device for a PCB, which mainly solves the problem that electronic components on a carrier tape need to be stripped when the existing electronic components are mounted. According to the technical scheme, the surface mounting electronic component device for the PCB comprises a rack, an electronic component conveying mechanism, an electronic component mounting mechanism, a rotary disc rotating mechanism, a PCB conveying mechanism, a PCB carrying mechanism, a dispensing mechanism and a PLC; wherein a workbench is arranged at the topof the rack, the rotary disc rotating mechanism is arranged in the middle of the workbench, and the dispensing mechanism is arranged on the rotary disc rotating mechanism; the electronic component conveying mechanism, the PCB conveying mechanism and the dispensing mechanism are sequentially arranged around the turntable rotating mechanism in a surrounding manner, and an electronic component pasting mechanism is arranged between the turntable rotating mechanism and the electronic component conveying mechanism. According to the technical scheme, the problem is better solved, and the automatic assembling machine can be used for assembling electronic components.

Owner:佛山市雅昕电子有限公司

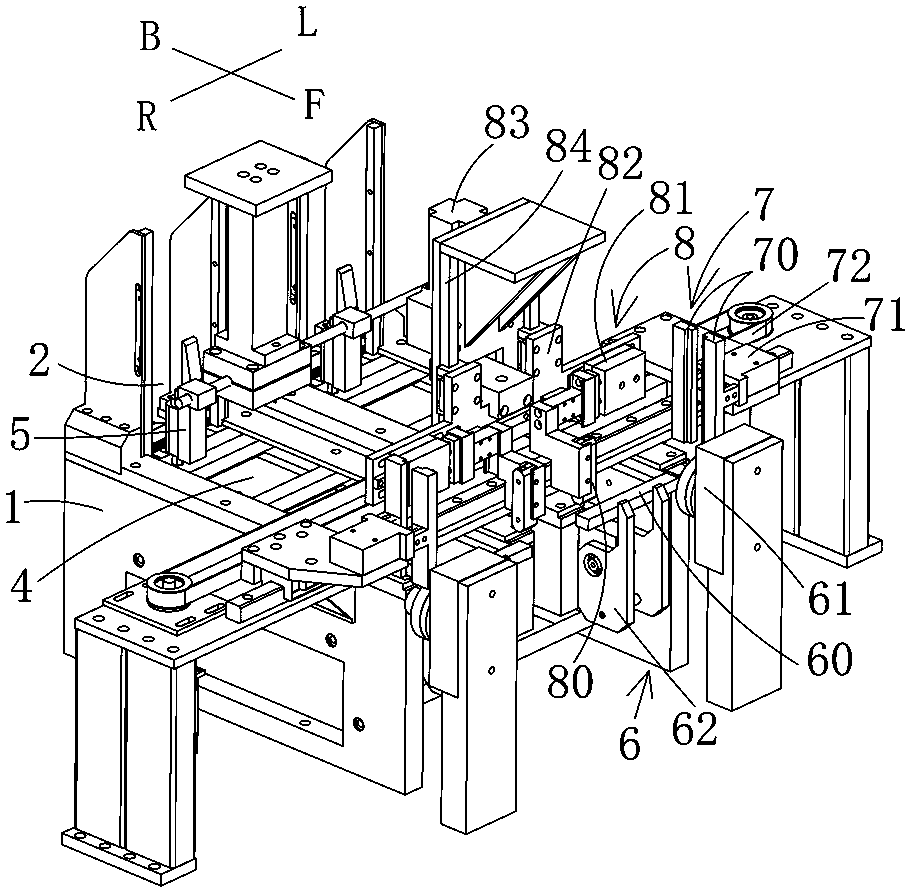

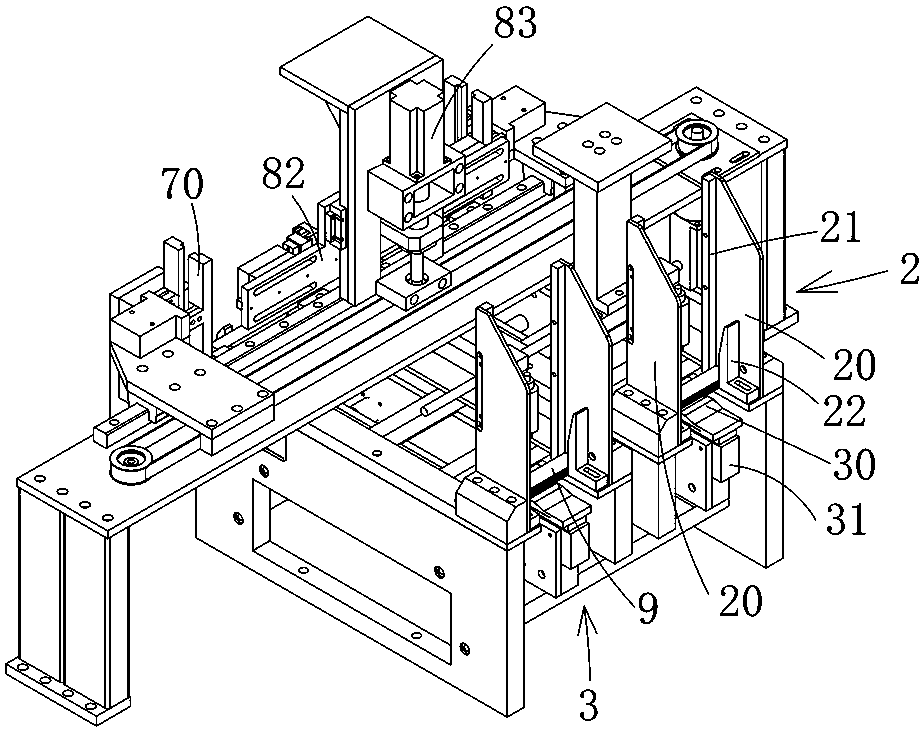

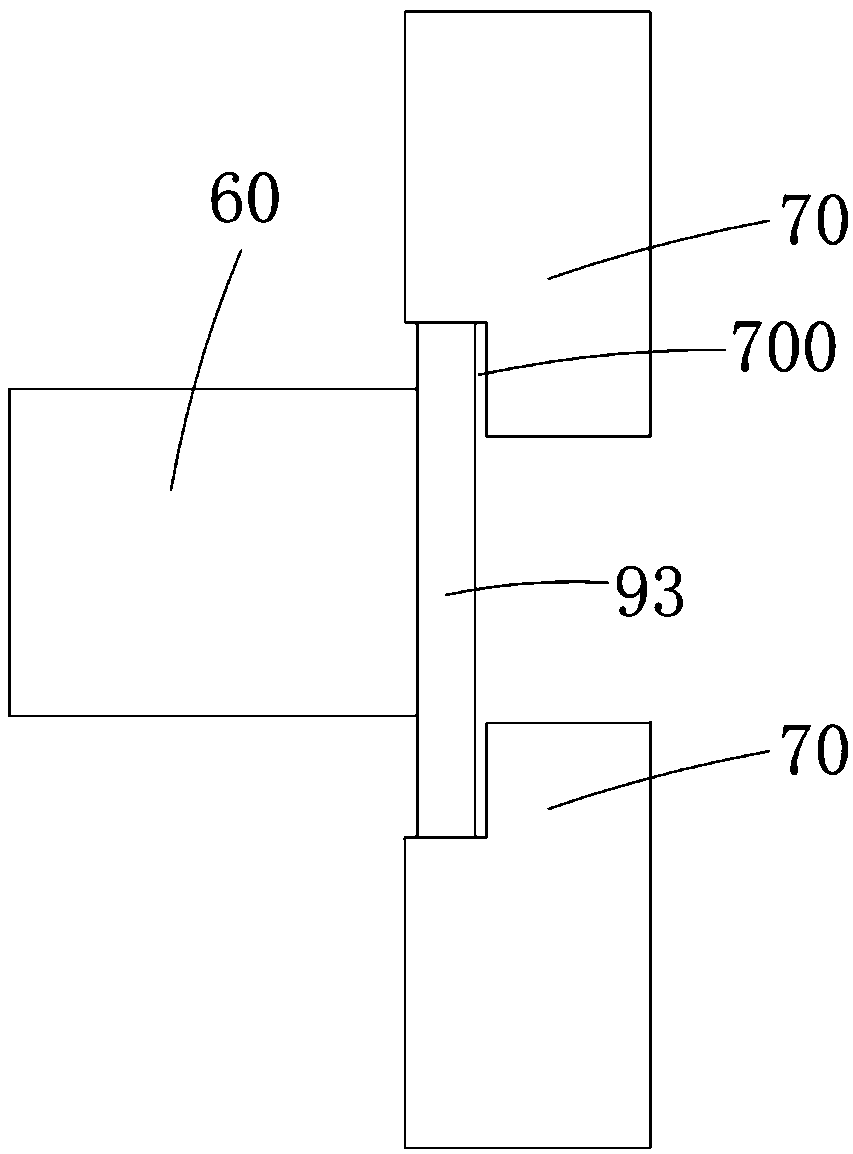

Enveloping strip sticking device of wine box automatic assembly machine

ActiveCN109664548AImprove production efficiencyGuarantee paste qualityBox making operationsPaper-makingEngineeringAssembly machine

The invention relates to an enveloping strip sticking device of a wine box automatic assembly machine. The enveloping strip sticking device can implement mechanical automated enveloping strip stickingon wine boxes. The enveloping strip sticking device of the wine box automatic assembly machine comprises a rack, and is characterized in that the rack is provided with an enveloping strip bin, a enveloping strip table top and an enveloping strip pushing mechanism used for pushing enveloping strips in the enveloping strip bin; a glue spraying mechanism used for spraying glue to the enveloping strips is arranged above the enveloping strip table top; An enveloping strip rotating mechanism is arranged in front of the enveloping strip table top; the enveloping strip rotating mechanism comprises arotary block capable of carrying an enveloping strip and a rotary power source used for driving the rotary block to rotate. The enveloping strip sticking device of the wine box automatic assembly machine realizes mechanical automated full-automatic stacking on the enveloping strips, greatly improves the manufacturing efficiency of the wine boxes, reduces the labor cost and also ensures the sticking quality of the enveloping strips.

Owner:瑞安市正创机械有限公司

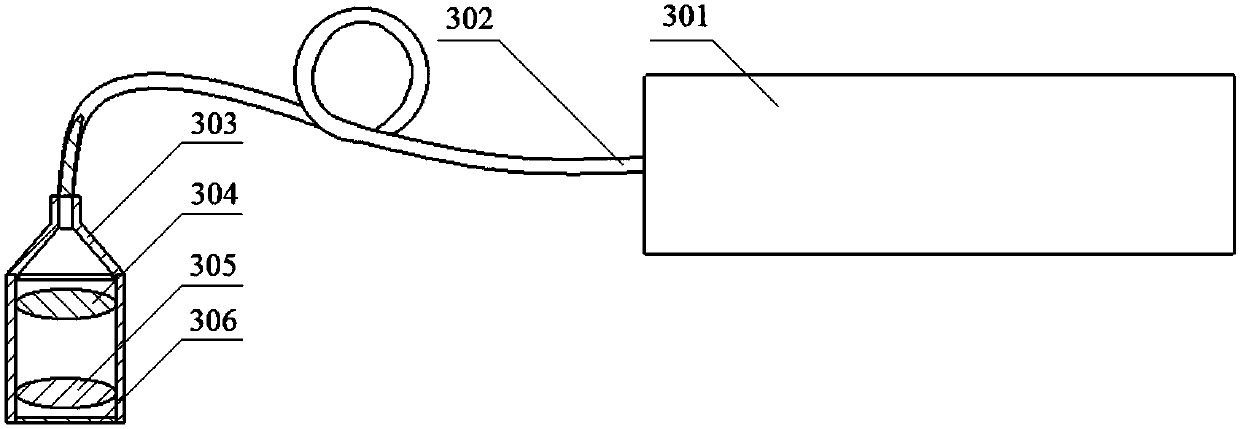

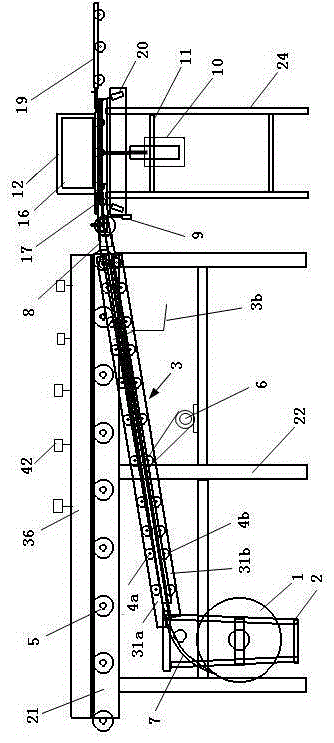

Pasting equipment and pasting method of double-sided adhesive sticker tapes for toilet paper pack

The invention discloses pasting equipment and a pasting method of double-sided adhesive sticker tapes for a toilet paper pack, and belongs to the field of paper-making packaging equipment. The production equipment comprises an adhesive sticker tape roll rack used for arranging double-sided adhesive sticker tape rolls, an expanding device for expanding the double-sided adhesive sticker tape rolls, a shearing device for cutting off the double-sided adhesive sticker tape rolls, a pasting device for pasting adhesive sticker tapes to the bottom surface and the side surfaces of the toilet paper pack and a transport unit for transporting the toilet paper pack; the pasting equipment is equipment capable of pasting one or more rows of adhesive sticker tapes to the outer surface of the toilet paper pack; a controller is arranged on the pasting equipment; and the pasting equipment can be utilized to eliminate a great deal of operation inconvenience in an adhesive sticker pasting process, so that the pasting efficiency is guaranteed to be matched with a toilet paper pack production line, and the adhesive sticker pasting efficiency is improved.

Owner:嘉兴芸诗娇电子商务有限公司

Concrete joint glue pouring and adhesive tape sticking device and using method thereof

InactiveCN104843535APaste firmlyGuarantee paste qualityArticle deliveryEngineeringFront and back ends

The invention discloses a concrete joint glue pouring and adhesive tape sticking device and a using method thereof. The concrete joint glue pouring and adhesive tape sticking device is used for the construction of sticking an adhesive tape after filling glue to a channel concrete joint and the sticking of the adhesive tape after grouting glue to the concrete joint required to grout glue. The device comprises a chassis, guide wheels and an adhesive tape; the guide wheel, an adhesive tape installing shaft, an adhesive tape separating shaft and a grinding cylinder are installed on the chassis; the adhesive tape installing shaft is installed at the front part of the chassis, and two rolls of adhesive tapes are mounted on the adhesive tape installing shaft; the grinding cylinder is fixed on a grinding cylinder lifting frame through a connecting rod, and the adhesive tape separating shaft is mounted between the adhesive tape installing shaft and the grinding cylinder; guide wheels are mounted at front and back ends of the chassis, and handrails are fixed at both side s of the chassis. An operator holds the handle and forwards pushes the adhesive tape device, so that the adhesive tapes are bonded at both sides of the concrete joint after being grinded by the grinding cylinder. The device is light and flexible in use and convenient to operate; the space between the adhesive tapes bonded at both sides of the concrete joint is consistent; thus the concrete joint glue pouring and adhesive tape sticking device prevents the sealing glue in the concrete joint from polluting a non-grouting zone. Moreover, the device reduces the manual investment, greatly improves the adhesive tape sticking speed and quality, and improves the economical benefit.

Owner:中石化胜利建设工程有限公司

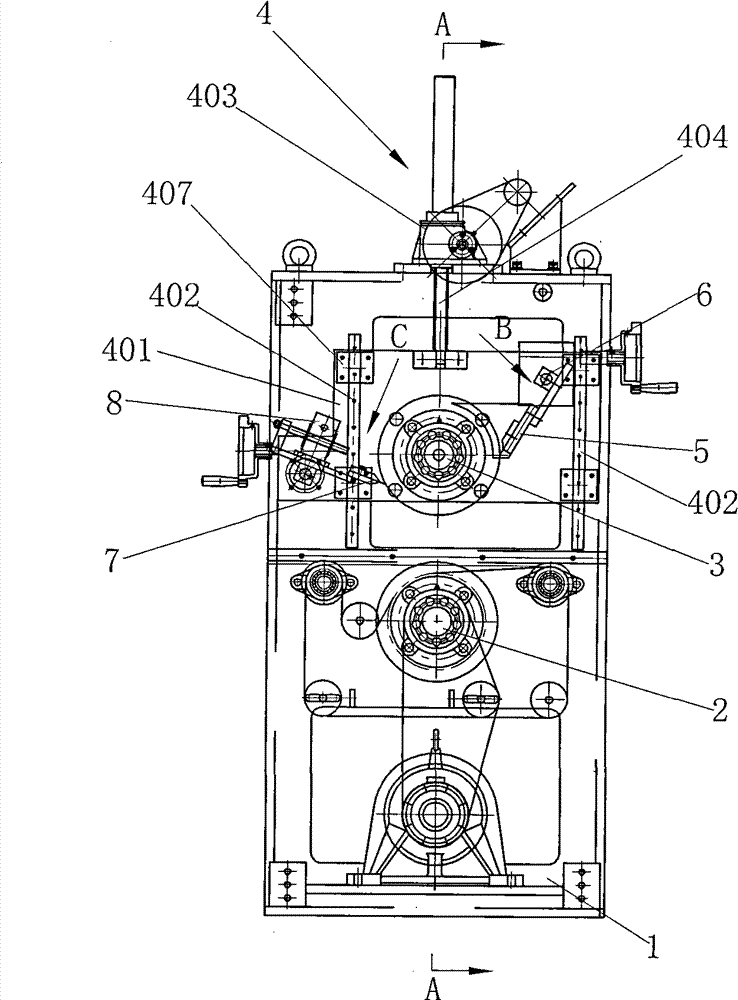

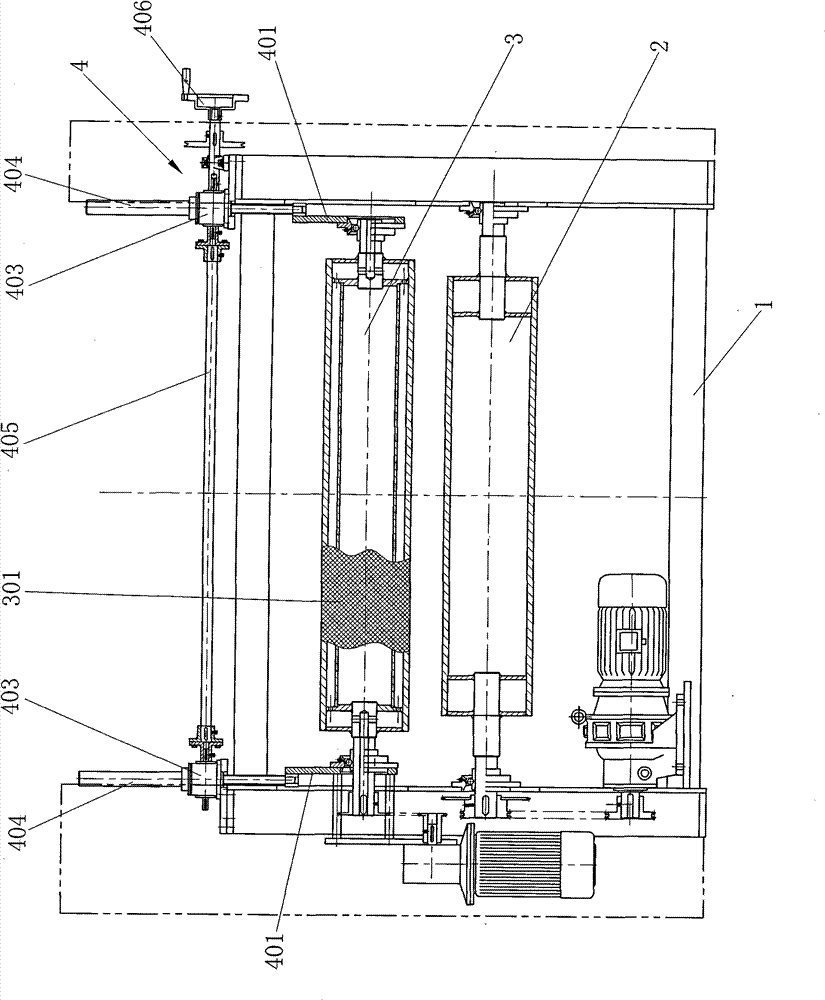

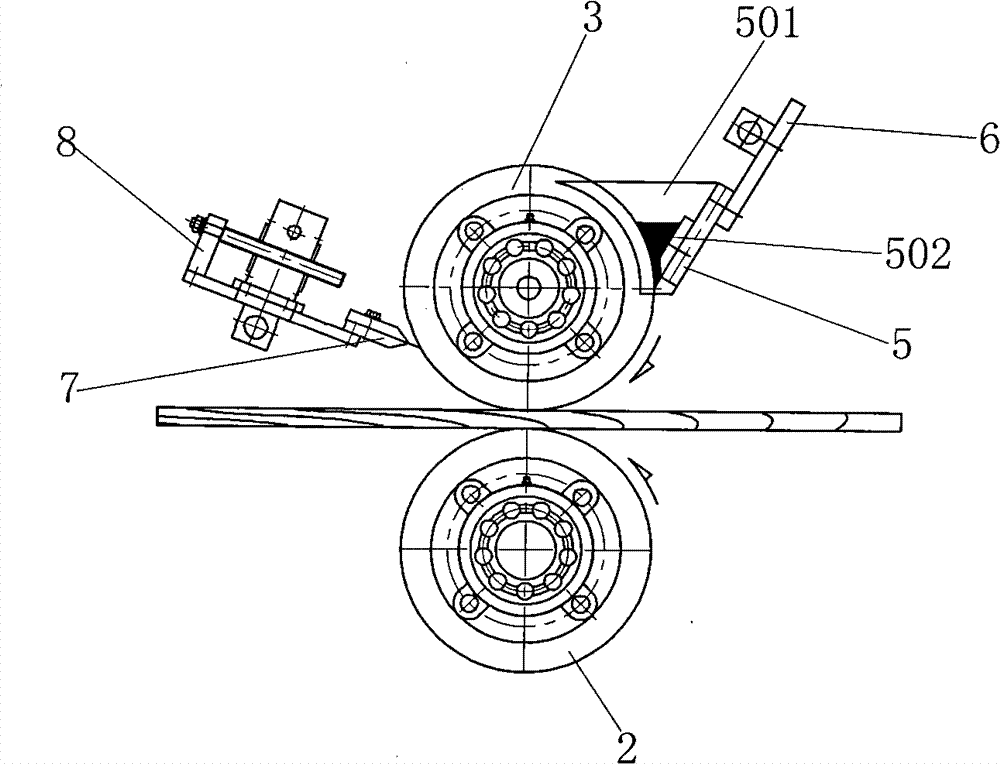

Glue spreader

ActiveCN101862723BGuarantee paste qualityReduce the amount of glueLiquid surface applicatorsCoatingsKnurlingPulp and paper industry

The invention relates to a glue spreader, which comprises a rack. The two ends of a conveying support roller are arranged on the rack. A glue spreading roller is arranged above the conveying support roller. The conveying support roller and the glue spreading roller are respectively connected with a driving mechanism. The invention is characterized in that the two ends of the glue spreading rollerare arranged on a lifting mechanism which is arranged on the rack, the surface of the glue spreading roller is provided with hatching knurling, one side of the glue spreading roller is provided with a measurement scraper which is connected with a measurement adjusting mechanism and the measurement adjusting mechanism is arranged on the lifting mechanism. The surface of the glue spreading roller is provided with the hatching knurling. Proper glue volume can be controlled and glue can be spread on the surface of base material evenly. When the surface course pasting quality is ensured, the glue usage amount and the manufacture cost are reduced.

Owner:WUXI SHENGJIN MACHINERY

Ship body pasting plate pressing device

Owner:葫芦岛渤船工贸管件公司

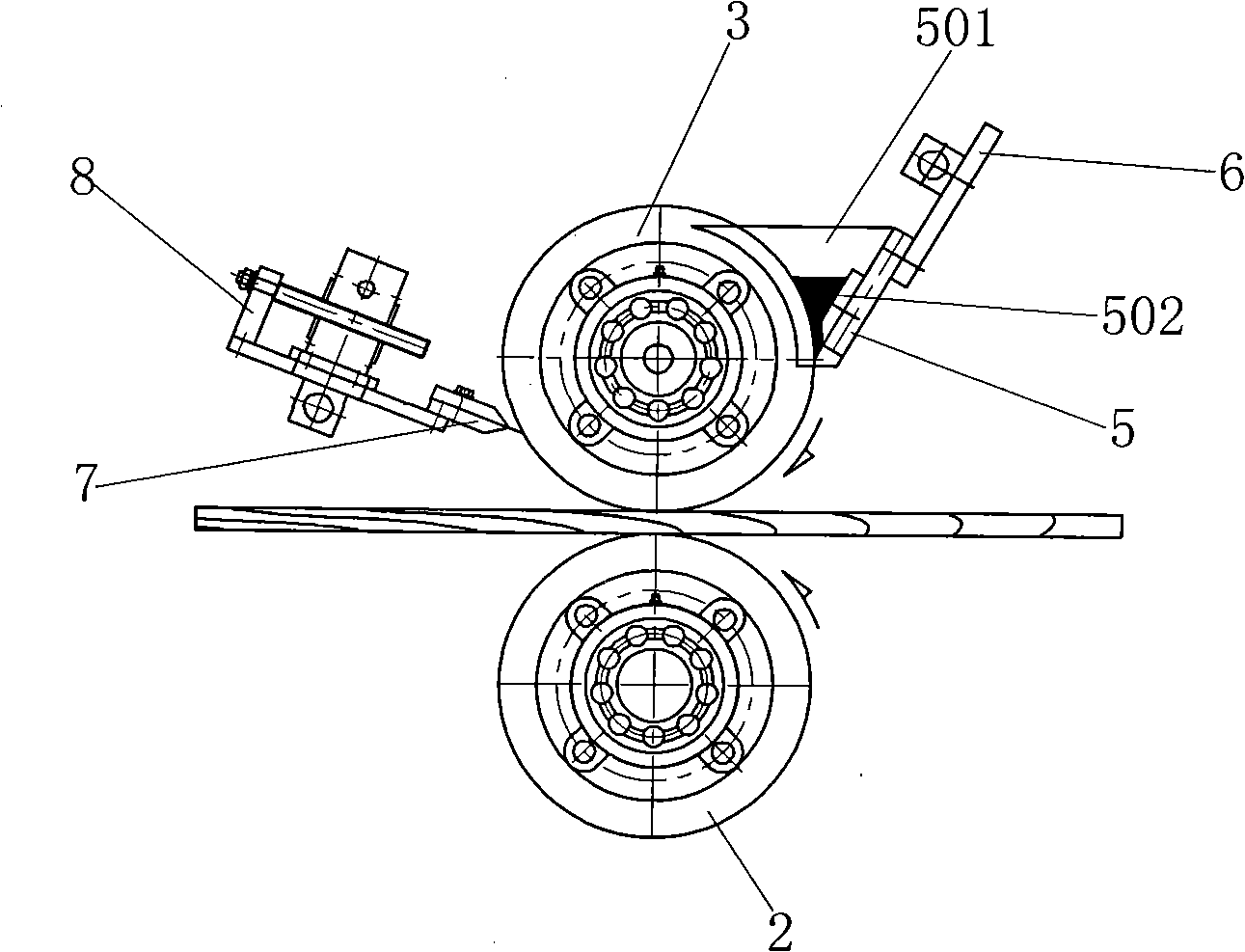

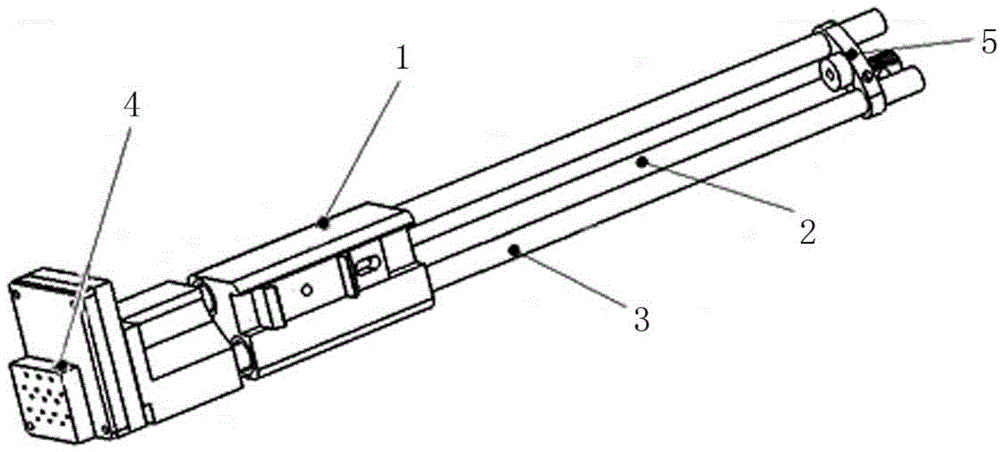

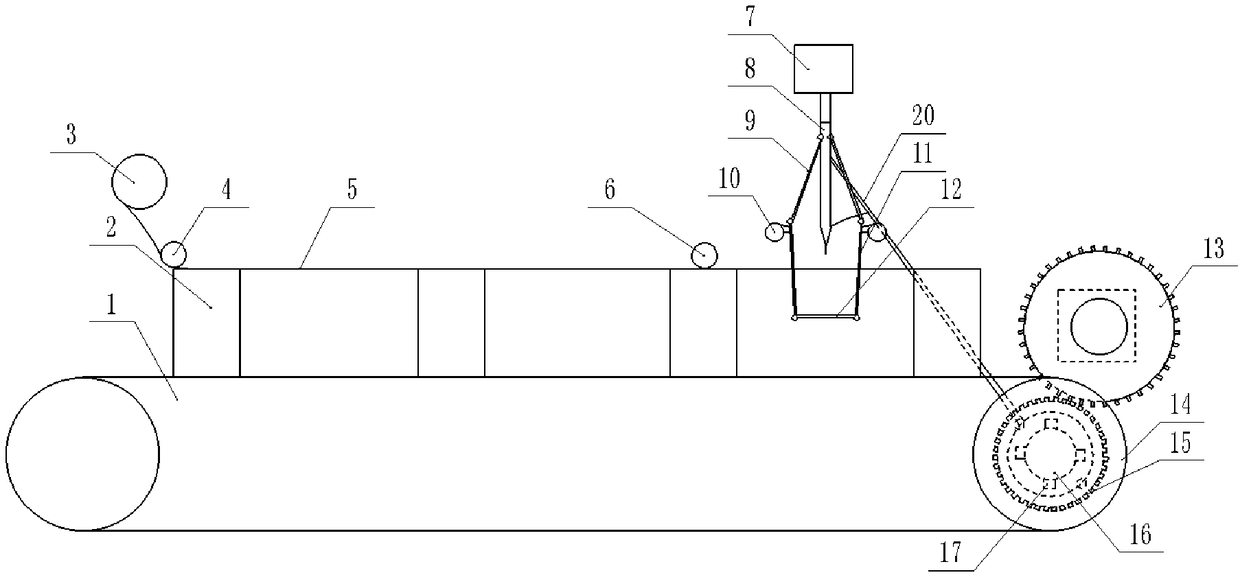

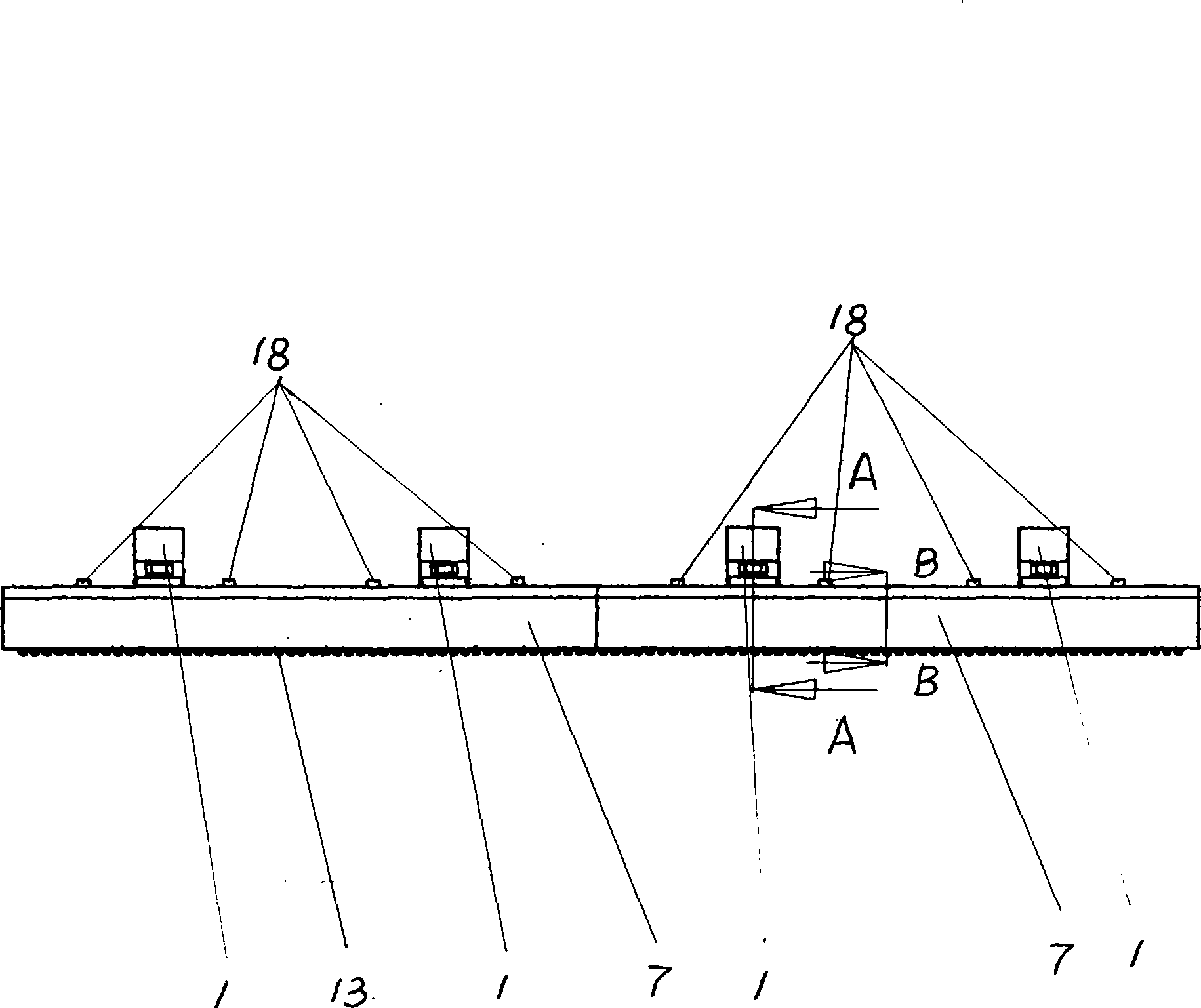

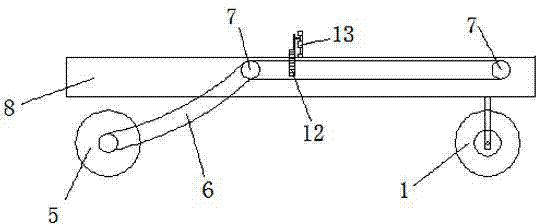

Multi-functional adhesive tape automatic pasting and cutting machine

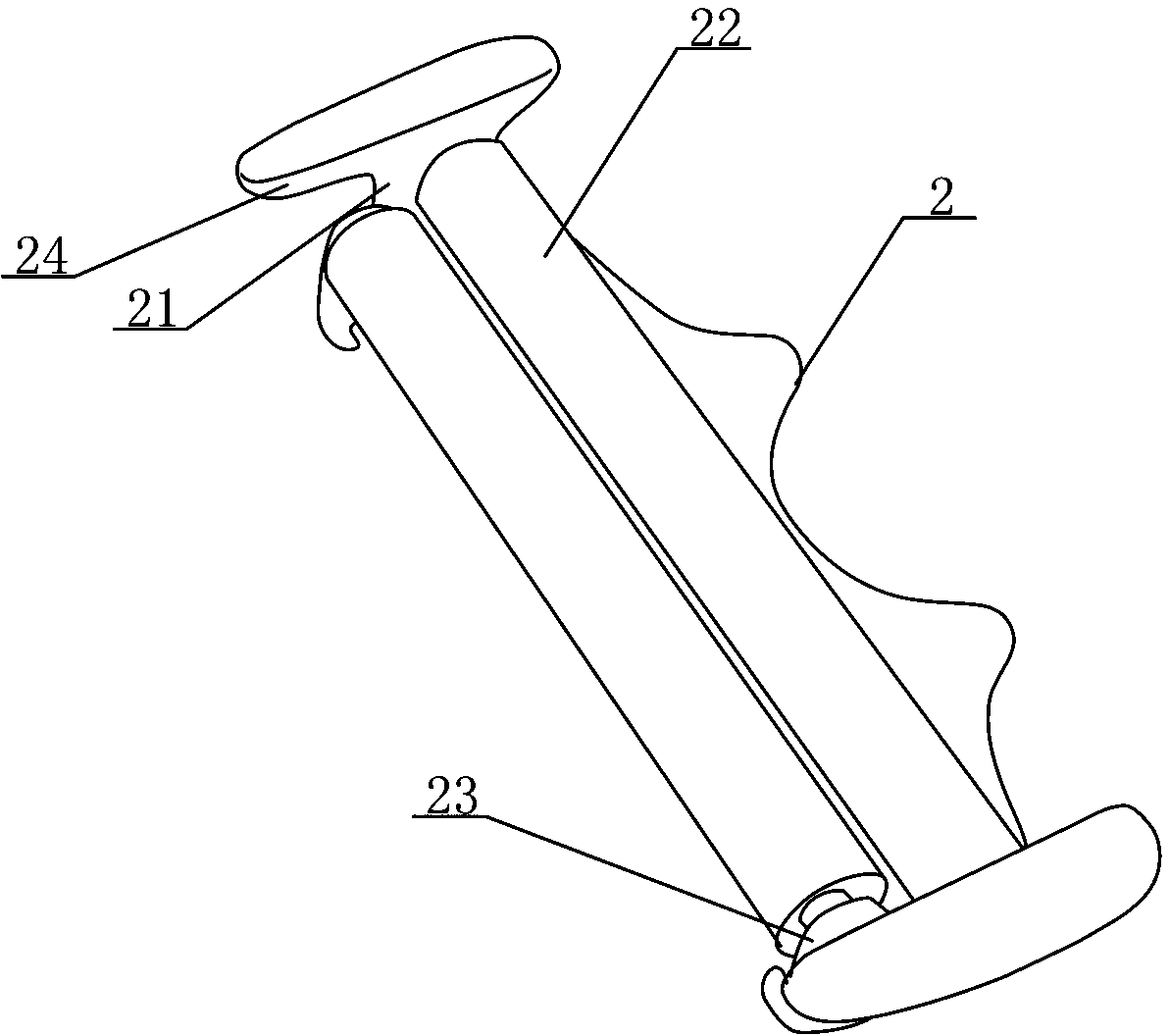

ActiveCN106218979ARealize continuous pastingWide adaptabilityWrapper twisting/gatheringDrive wheelCoupling

The invention discloses a multi-functional adhesive tape automatic pasting and cutting machine. The multi-functional adhesive tape automatic pasting and cutting machine comprises three assisting wheels (1), a base plate (2), four side plates (3) and a driving wheel (33) which are connected to form a frame; the driving wheel (33) is connected with a moving motor (31) on the base plate (2) to from a moving frame through a coupler (33), and the moving frame is provided with a adhesive tape flat pasting cutting machine and a adhesive tape roll pasting cutting machine to form the adhesive tape automatic pasting and cutting machine. The multi-functional adhesive tape automatic pasting and cutting machine can conduct adhesive tape automatic flat pasting on packing boxes and printed circuit boards, can conduct adhesive tape continuous and recycling pasting, and can conduct adhesive tape rotating wrapping and pasting on cables and data cables; pasting and cutting of the adhesive tape are completed at one time; one machine has two uses; working efficiency is high, pasting quality is good, automation degree is high, pasting speed is easy to control, automatic and continuous pasting is achieved, and applicable range is wide.

Owner:JIANGSU VOCATION & TECHNICAL COLLEGE OF FINANCE & ECONOMICS

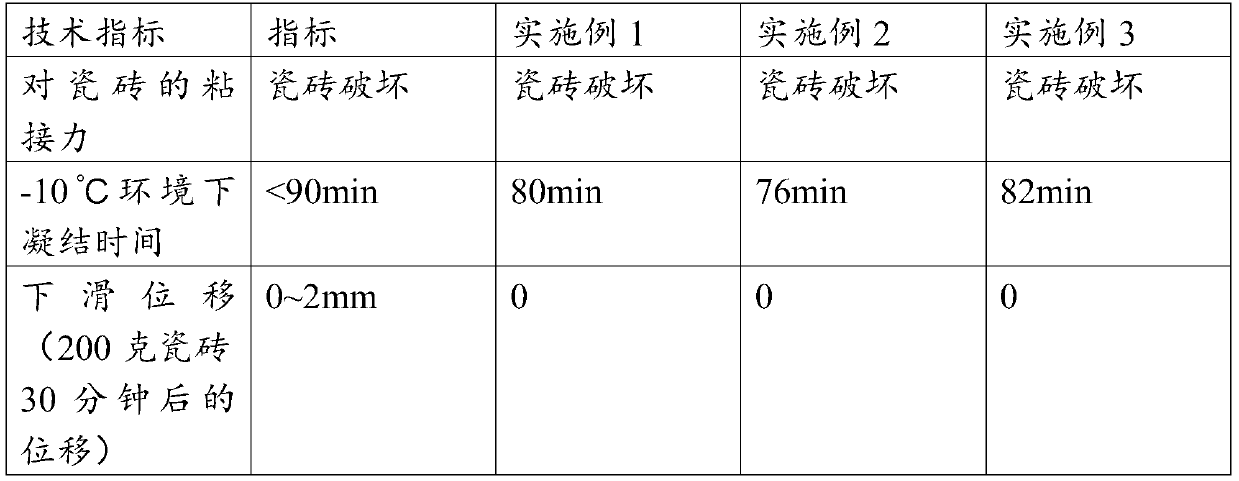

Quick-drying type adhesive for ceramic tiles

The invention discloses a quick-drying type adhesive for ceramic tiles. The adhesive comprises the following components, in parts by weight: 60-65 parts of river sand, 32-38 parts of cement, 0.5-0.8 part of polymer rubber powder, 0.8-1.2 parts of silica fume, 0.5-0.8 parts of calcium formate, and 0.2-0.3 part of cellulose ether. According to the adhesive provided by the invention, the silica fumeand the calcium formate are added, so that the quick-drying type adhesive for the ceramic tiles has quick-drying performance; and at the same time, the polymer rubber powder and other components are added, so that the adhesive for the ceramic tiles has good bonding property, and the adhesive for the ceramic tiles can be tightly bonded with the ceramic tiles when used, effectively avoids a phenomenon of displacement of the ceramic tiles, ensures the bonding quality of the ceramic tiles, and improves the bonding efficiency of the ceramic tiles.

Owner:佛山市卓仕高新型材料有限公司

Assembly method based on PCB surface mounting electronic component device

PendingCN114449881AImprove stripping efficiencyImprove placement productivityElectrical componentsSurface mountingElectronic component

The invention relates to an assembly method based on a surface mounting electronic component device for a PCB (Printed Circuit Board), and mainly solves the problem that an electronic component on a carrier tape needs to be stripped when the existing electronic component is mounted. The surface mounting electronic component device for the PCB comprises a rack, an electronic component conveying mechanism, an electronic component mounting mechanism, a rotary table rotating mechanism, a PCB conveying mechanism, a PCB carrying mechanism, a dispensing mechanism and a PLC, a workbench is arranged at the top of the rack, the rotary table rotating mechanism is arranged in the middle of the workbench, the PCB conveying mechanism is arranged on the rotary table rotating mechanism, and the PCB conveying mechanism is arranged on the rotary table rotating mechanism. According to the technical scheme, the electronic component conveying mechanism, the PCB conveying mechanism and the dispensing mechanism are sequentially arranged around the rotary disc rotating mechanism in a surrounding mode, and the electronic component pasting mechanism is arranged between the rotary disc rotating mechanism and the electronic component conveying mechanism, the problem is well solved, and the automatic assembling machine can be used for assembling electronic components.

Owner:肖世涛

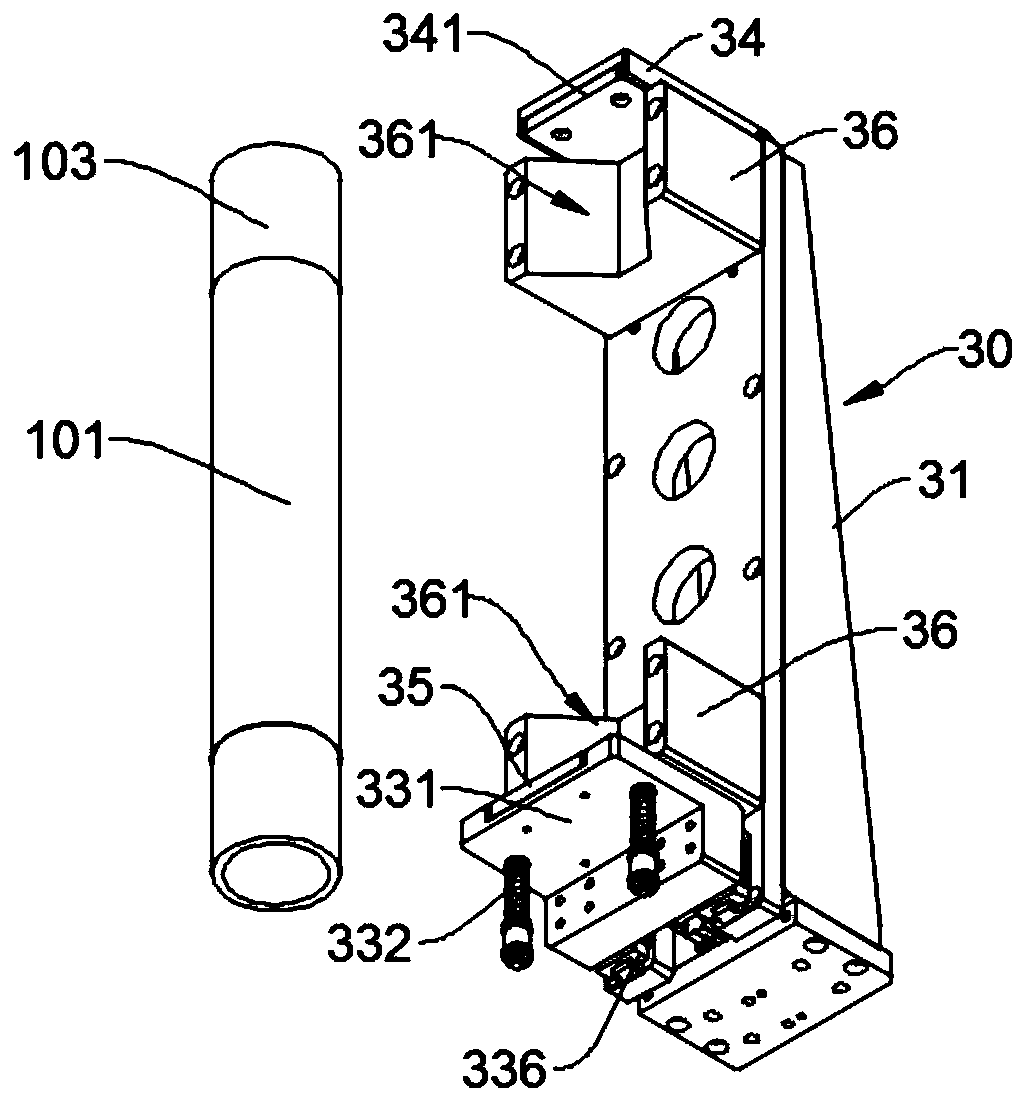

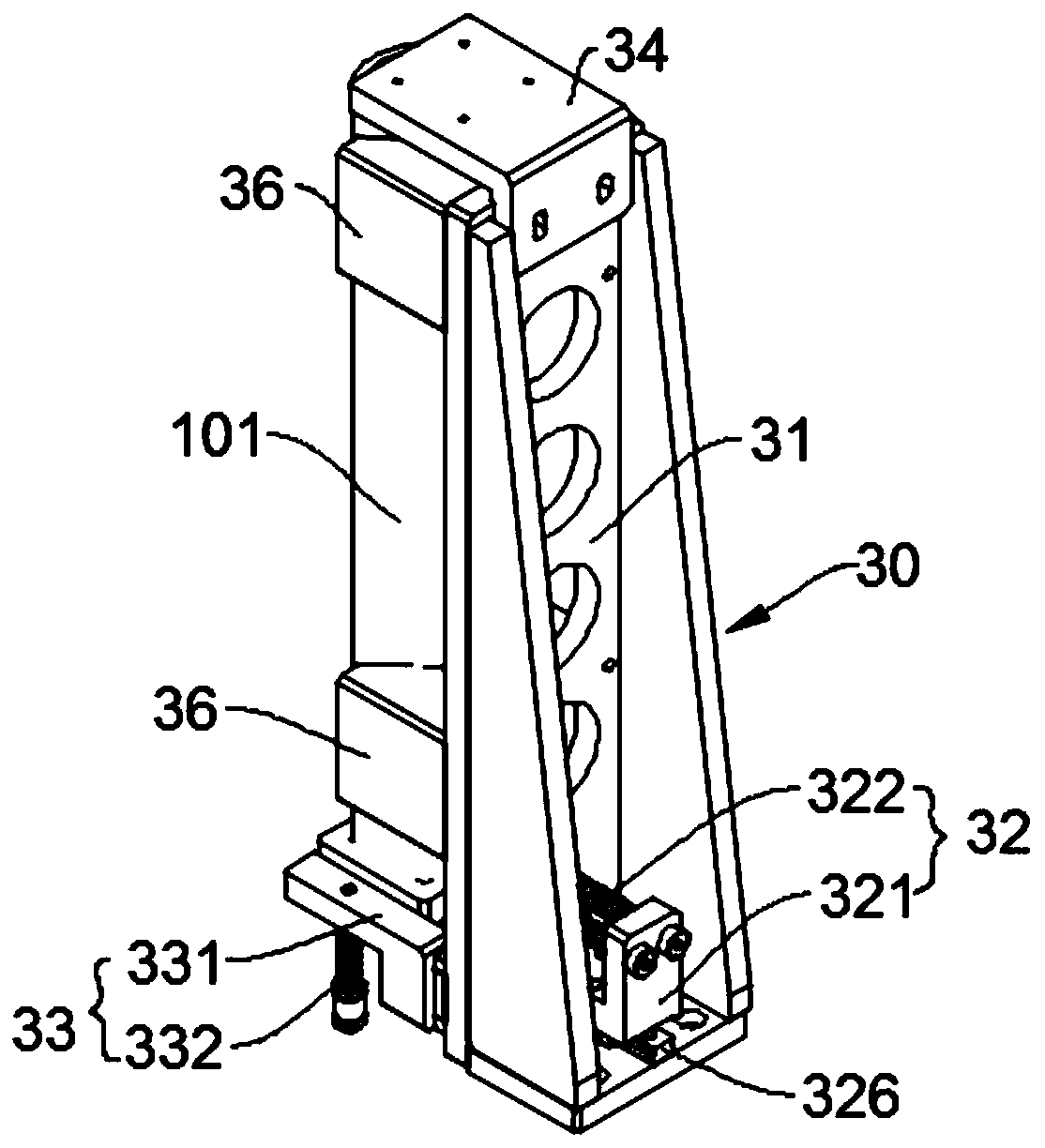

Rod part labeling device

InactiveCN108146758APrevent movementPositioning accuracyLabelling machinesEngineeringSpeed reduction

The invention provides a rod part labeling device and belongs to the field of labeling equipment. The rod part labeling device comprises a feeding assembly, a press-covering assembly and a working table. The feeding assembly is arranged above the working table. The press-covering assembly is arranged on one side of the working table. The feeding assembly comprises a discharge chute, a discharge wheel, a guide block and a conveying assembly. The width of the discharge chute is greater than the length of one battery and less than the length of the two batteries. The discharge chute comprises a feed area located at the upper end and a transition area located at the lower end. The transition area is circular. The discharge wheel is arranged in the transition area and is rotatably connected tothe transition area. A plurality of locating grooves are uniformly formed in the discharge wheel. The axes of the locating grooves are perpendicular to the width direction of the discharge chute. Theguide block is arranged at the lower end of the transition area. A speed reduction groove communicating with the transition area is formed in the guide block. A transmission assembly arranged horizontally is arranged at the lower end of the speed reduction groove. The longitudinal center line of the transmission assembly is parallel to the center lines of the locating grooves. The rod part labeling device is accurate in feeding, capable of achieving rapid labeling of a label on the outer surface of a rod part and high in efficiency.

Owner:新昌县小毅家电子商务有限公司

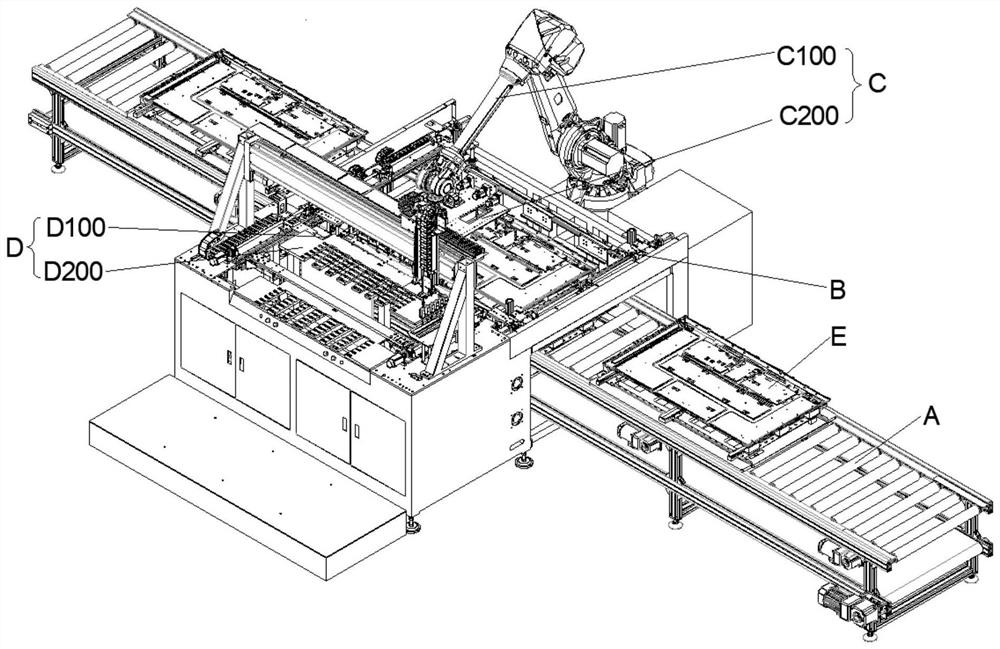

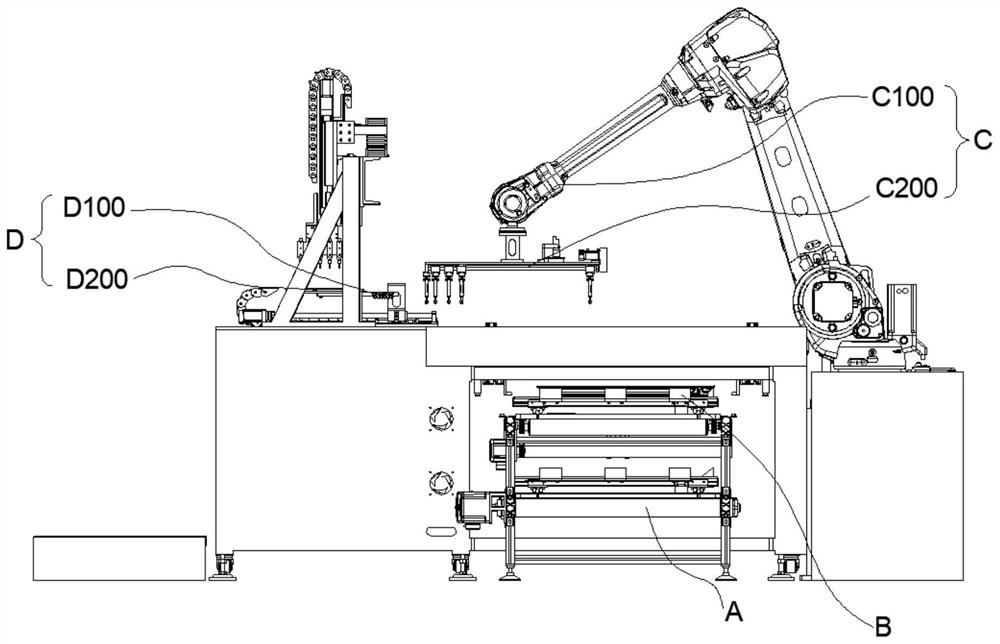

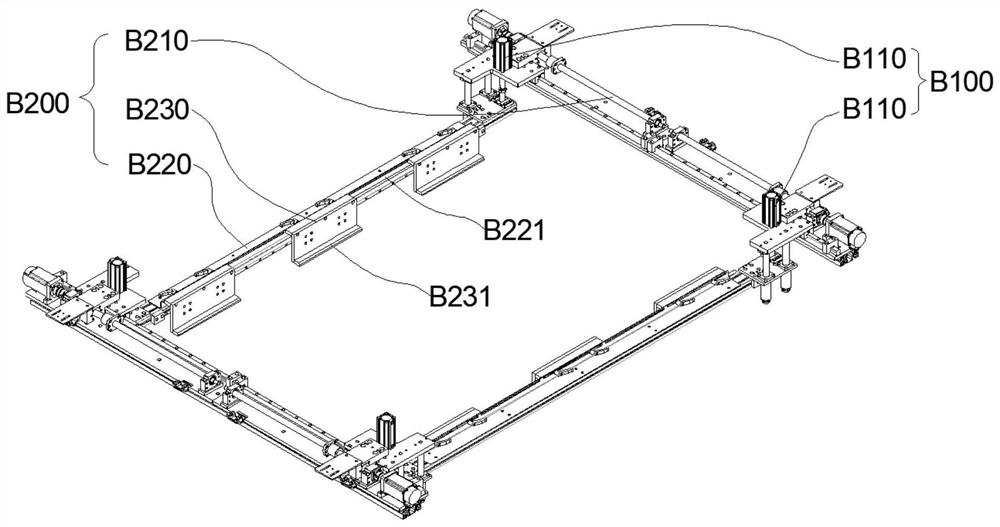

Light bar attaching equipment

ActiveCN112230460AImprove bonding qualityIncrease productivityNon-linear opticsDisplay deviceEngineering

The invention discloses light bar attaching equipment, relates to the technical field of display devices, and aims to solve the problems that the efficiency is low, the labor cost is high, and the quality problem is easily caused by misoperation when a light bar is manually adhered to a back plate. The light bar attaching equipment comprises a conveying line, a holding and clamping device and a light bar transferring device used for transferring a dispensing light bar to a back plate. The conveying line is used for conveying the back plate. The conveying line is provided with an attaching station. The holding and clamping device is located on the attaching station. The holding and clamping device comprises a jacking mechanism and a clamping mechanism arranged on the jacking mechanism. Theclamping mechanism is used for horizontally clamping the back plate at the attaching station. The jacking mechanism is used for adjusting the horizontal height of the clamping mechanism. The light barattaching equipment provided by the invention is used for attaching the light bar to the backlight module.

Owner:广东长虹智能制造技术有限公司 +1

Method and device for pasting optical protection film on flat screen

InactiveUS9481159B2Easy to optimizeLess timeLamination ancillary operationsLaminationTectorial membraneEngineering

Owner:SHANGHAI BOXIUTE INDAL

An automatic pasting device for double-sided adhesive tape on cardboard strips

ActiveCN106185439BGuarantee paste qualityAutomatic paste implementationConveyorsArticle deliveryControl systemCoupling

Owner:CRE8 DIRECT NINGBO CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com