Patents

Literature

182results about How to "Vivid colors" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

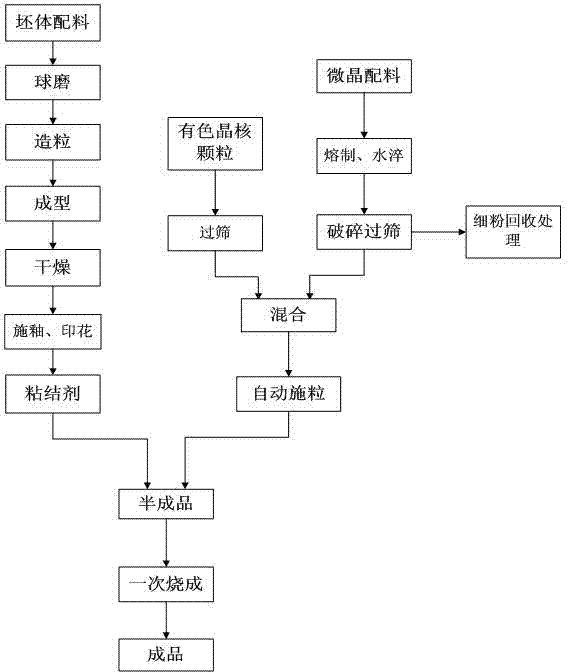

Once-firing colored crystalline glass ceramic composite brick and production method

ActiveCN103030298AImprove efficiencyReduce cost and controllable difficultyCeramic glazeEnergy consumption

The invention discloses a once-firing colored crystalline glass ceramic composite brick and a production method. The once-firing colored crystalline glass ceramic composite brick comprises a blank and a ground coat layer and a colored microcrystal layer that are arranged on the blank sequentially, wherein the colored microcrystal layer consists of a transparent microcrystal layer and colored crystal nucleus particles suspended in the transparent microcrystal layer. The production method comprises the following steps of processing the blank, applying a ground coat, conducting roller printing, applying an adhesive agent on the surface of the blank, uniformly applying transparent microcrystal dry particles and the colored crystal nucleus particles on the surface of the blank to form the colored microcrystal layer, applying a fixing agent, allowing to enter a kiln for once firing, and finishing and edging to form a finished product. The method is low in energy consumption and high in production efficiency, raw materials are saved, and the cost is lowered. The colored crystal nucleus particles suspended in the colored microcrystal layer of the once-firing colored crystalline glass ceramic composite brick are echoed by the roller printing, so that a stereo color effect is more obvious and verisimilar, and the brick has an excellent ornamental effect.

Owner:FOSHAN OCEANO CERAMICS

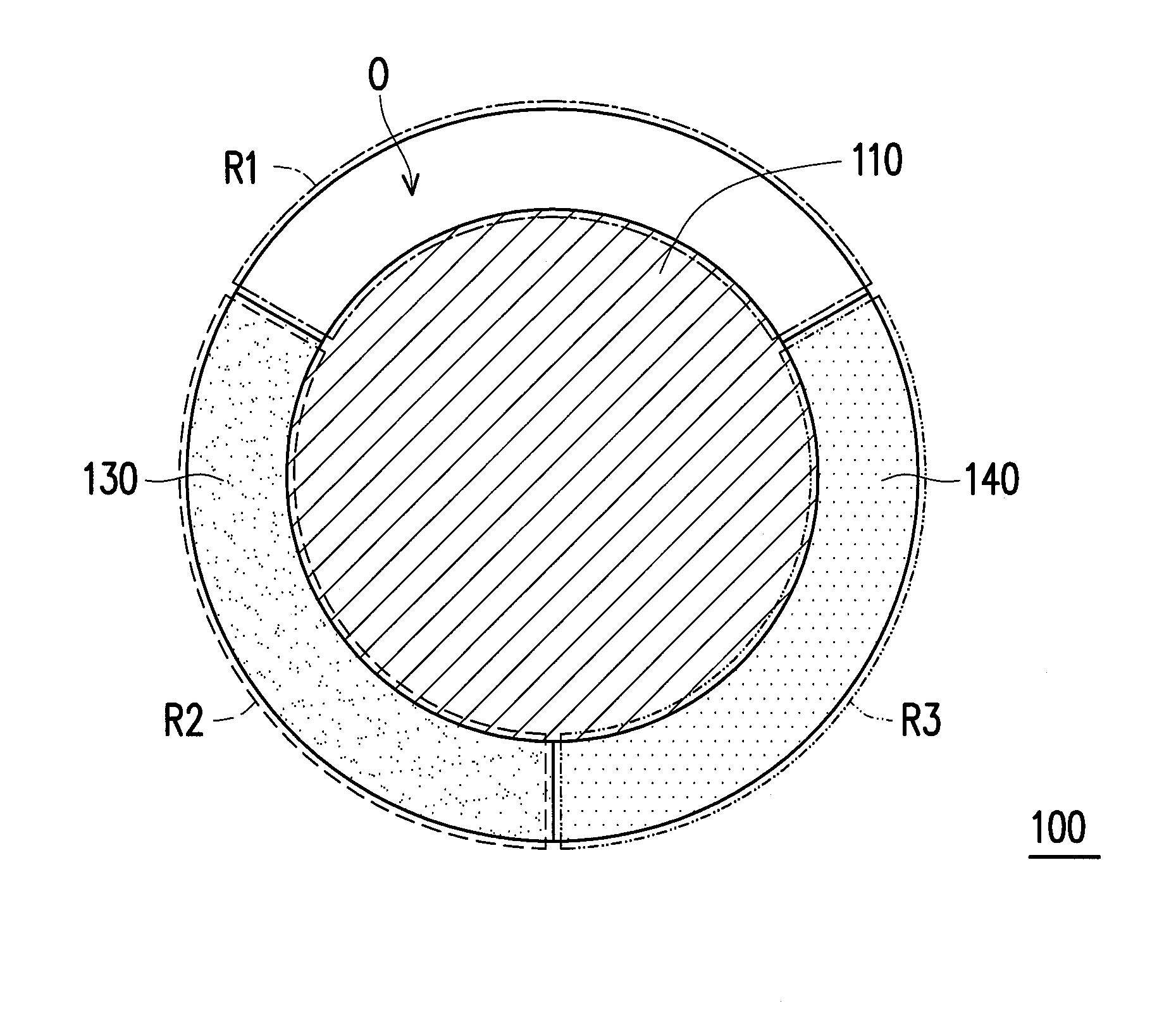

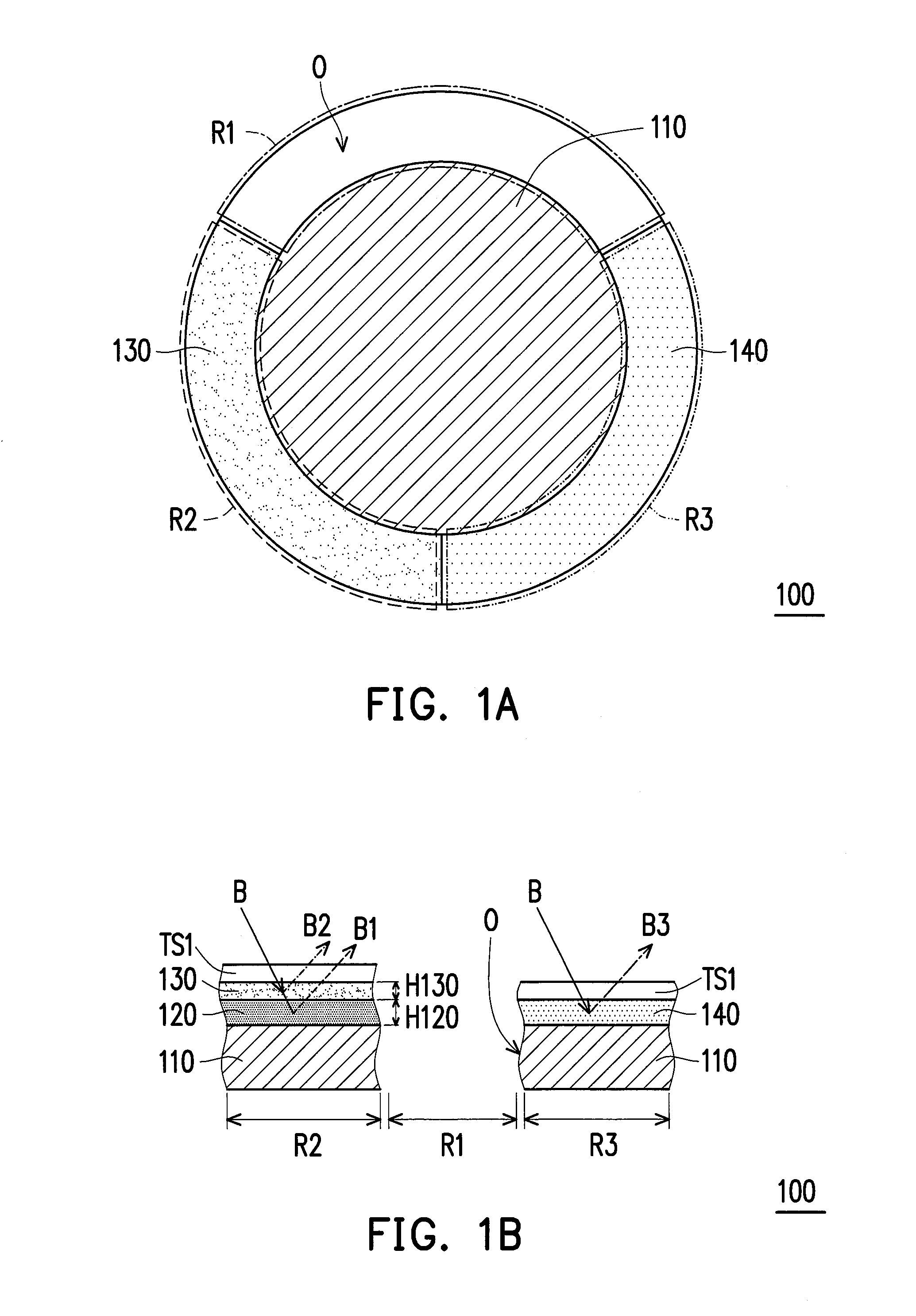

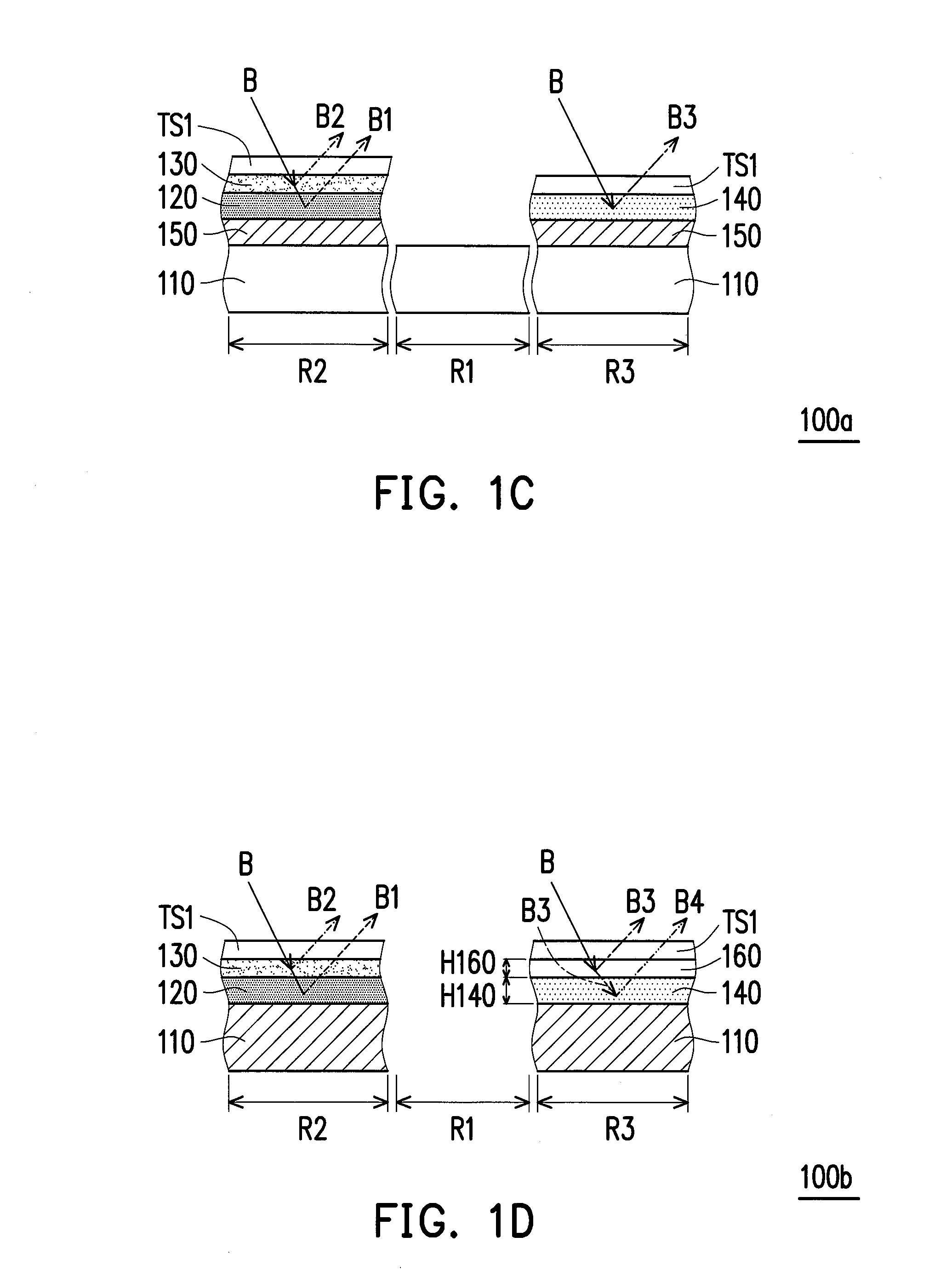

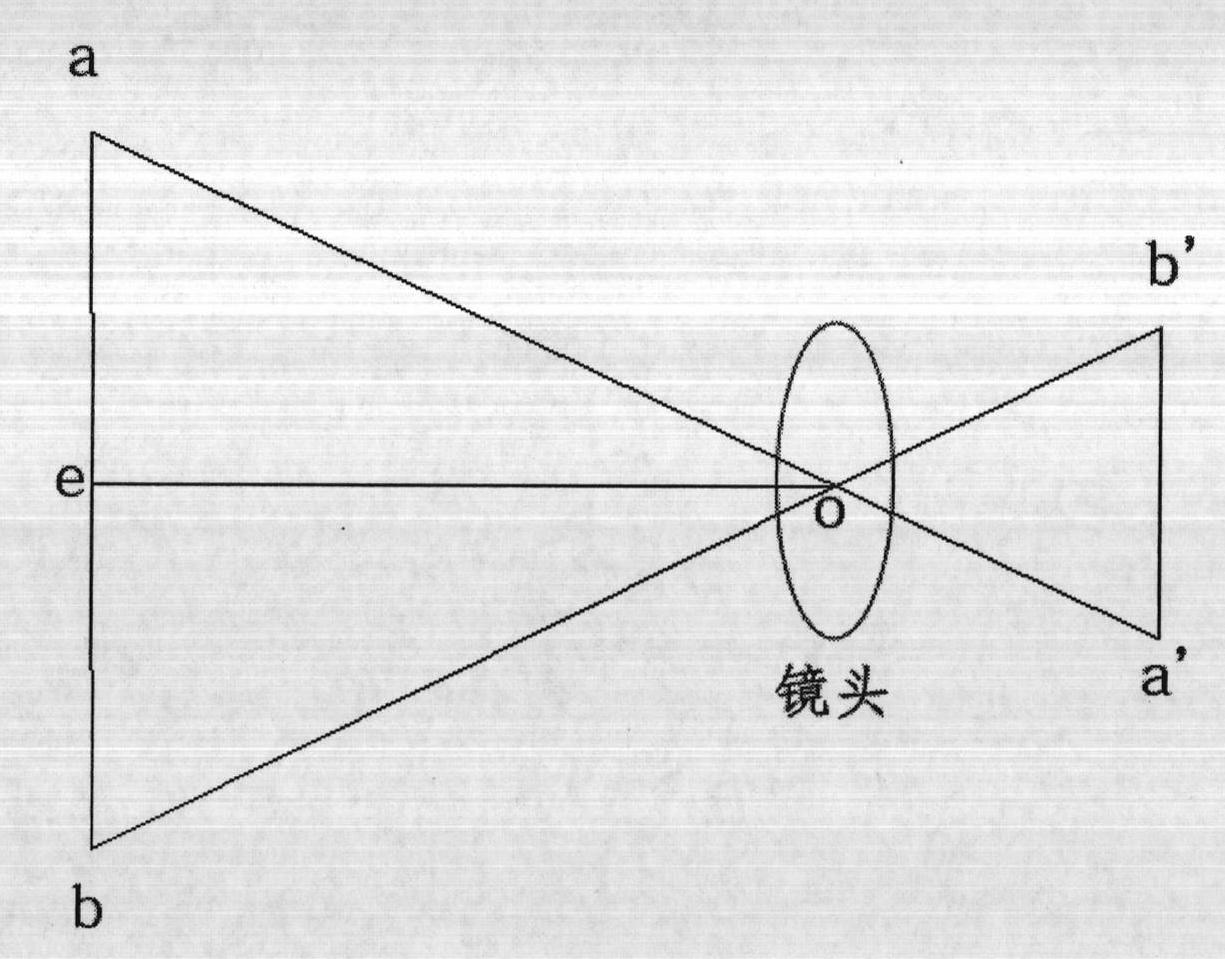

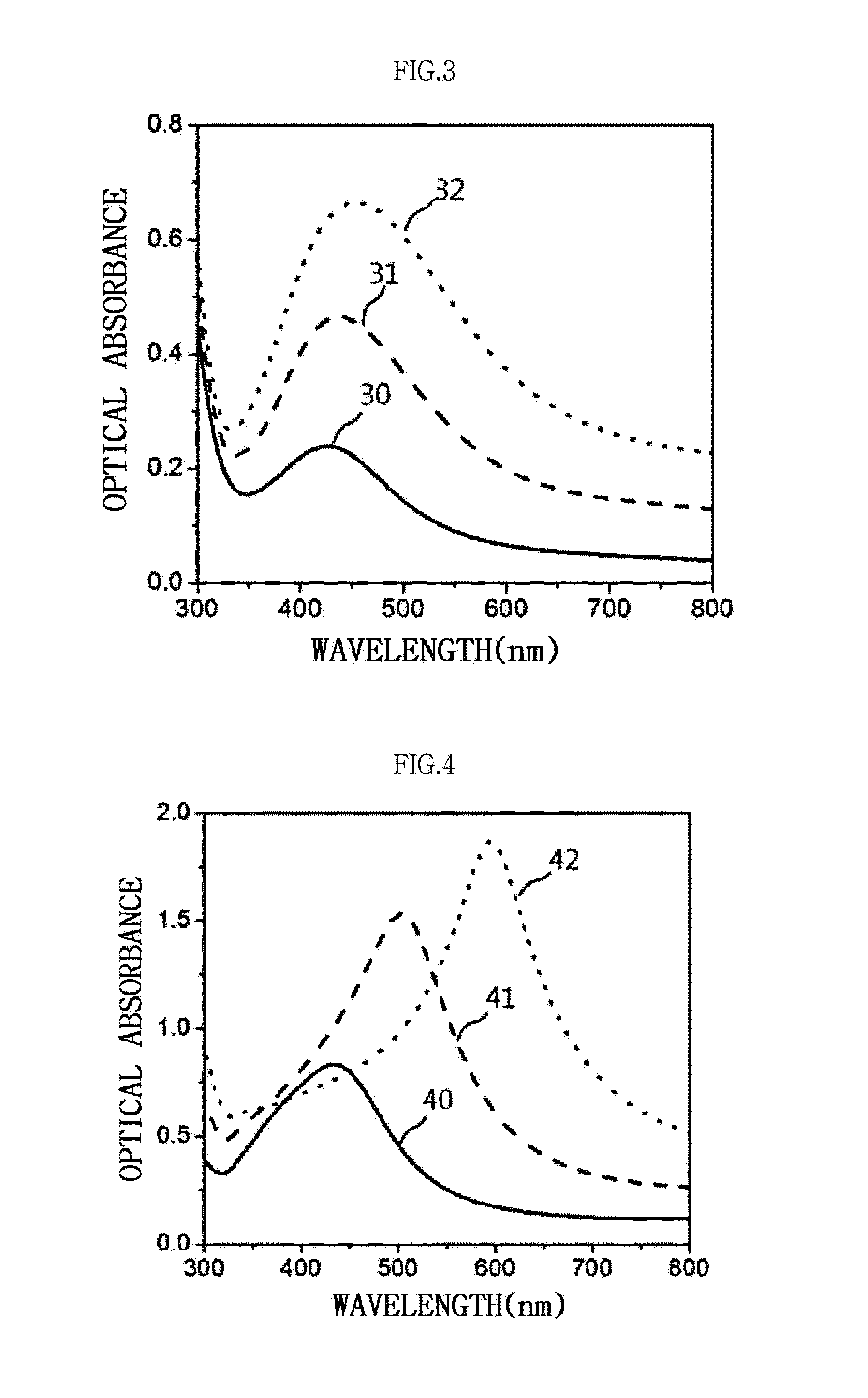

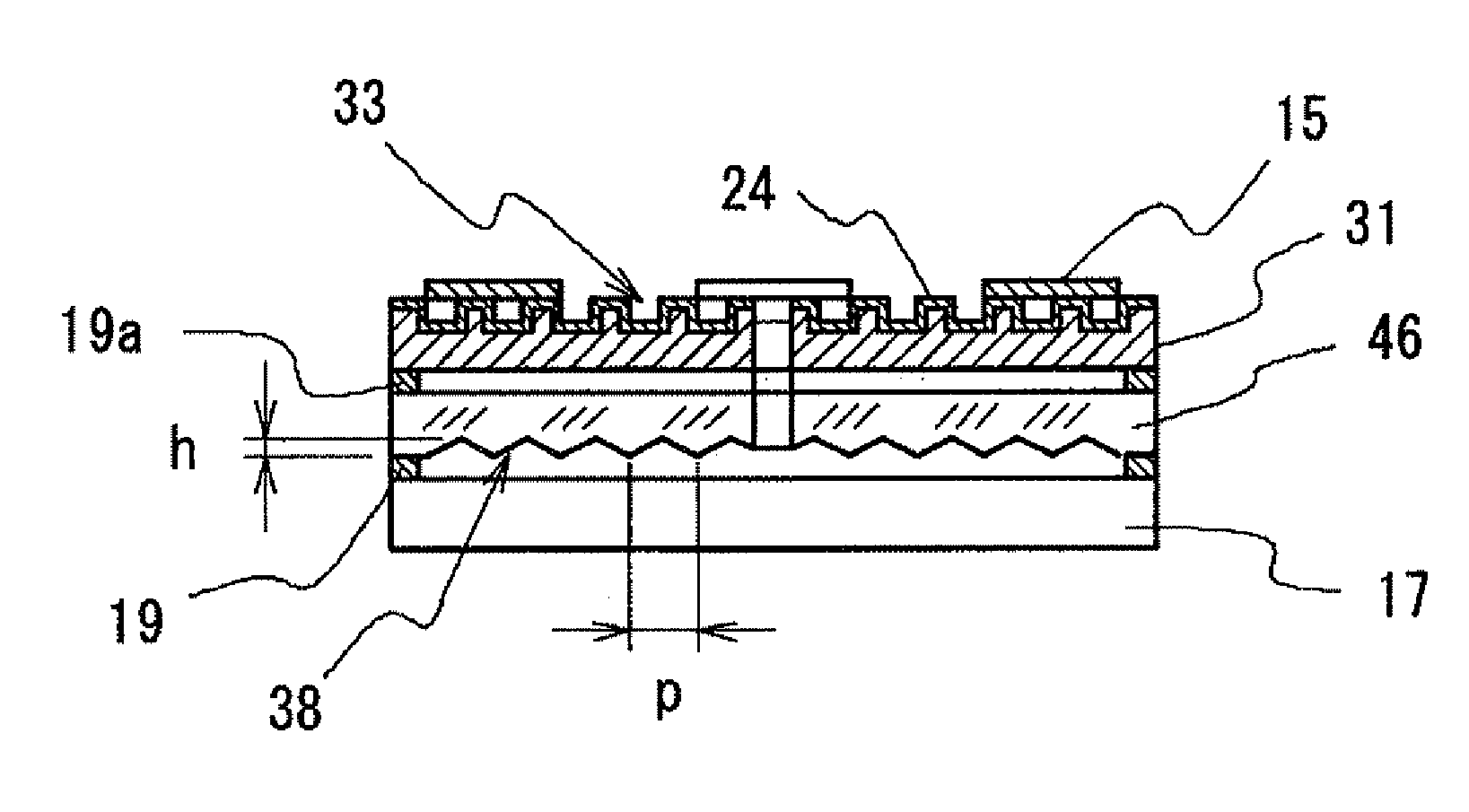

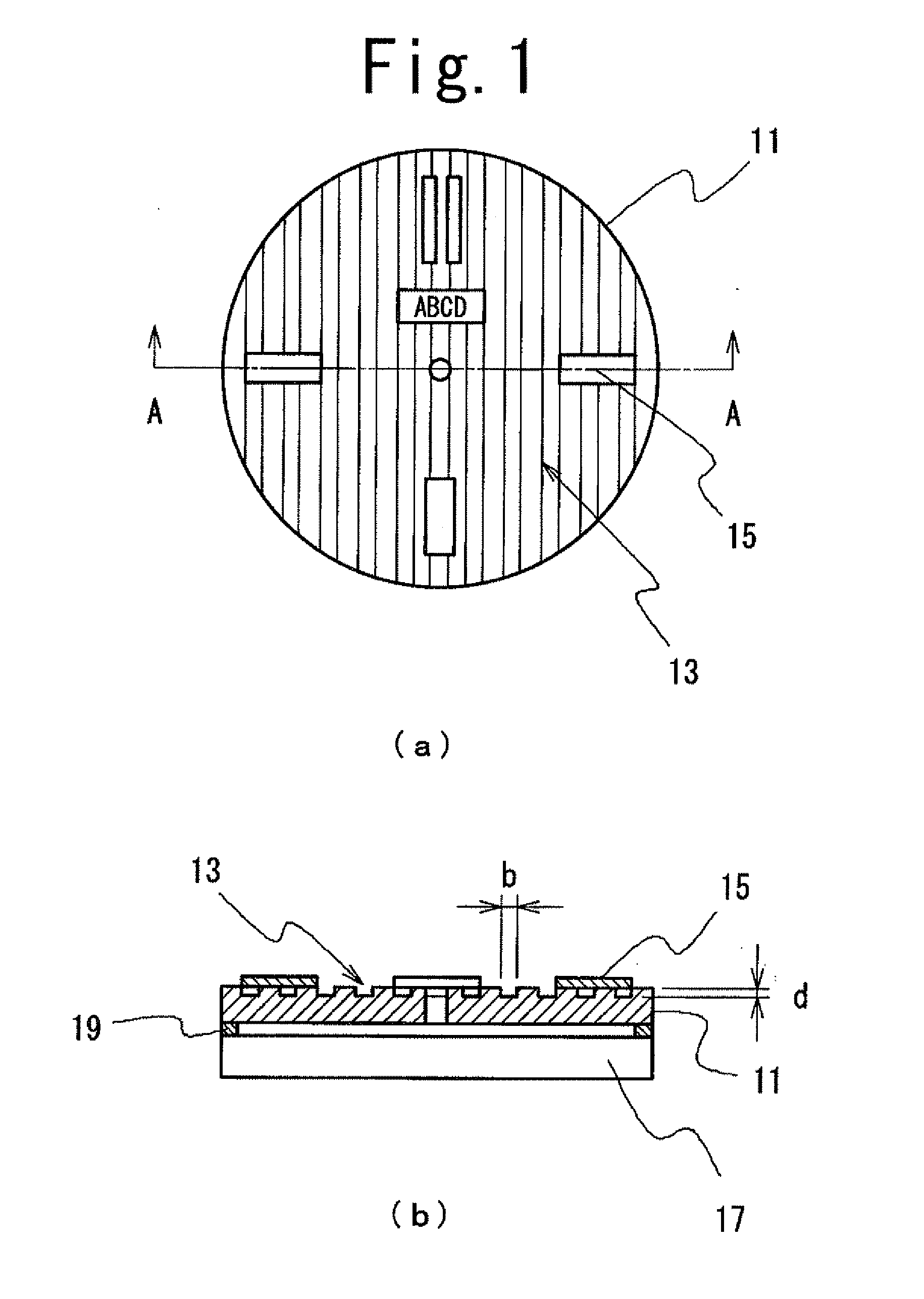

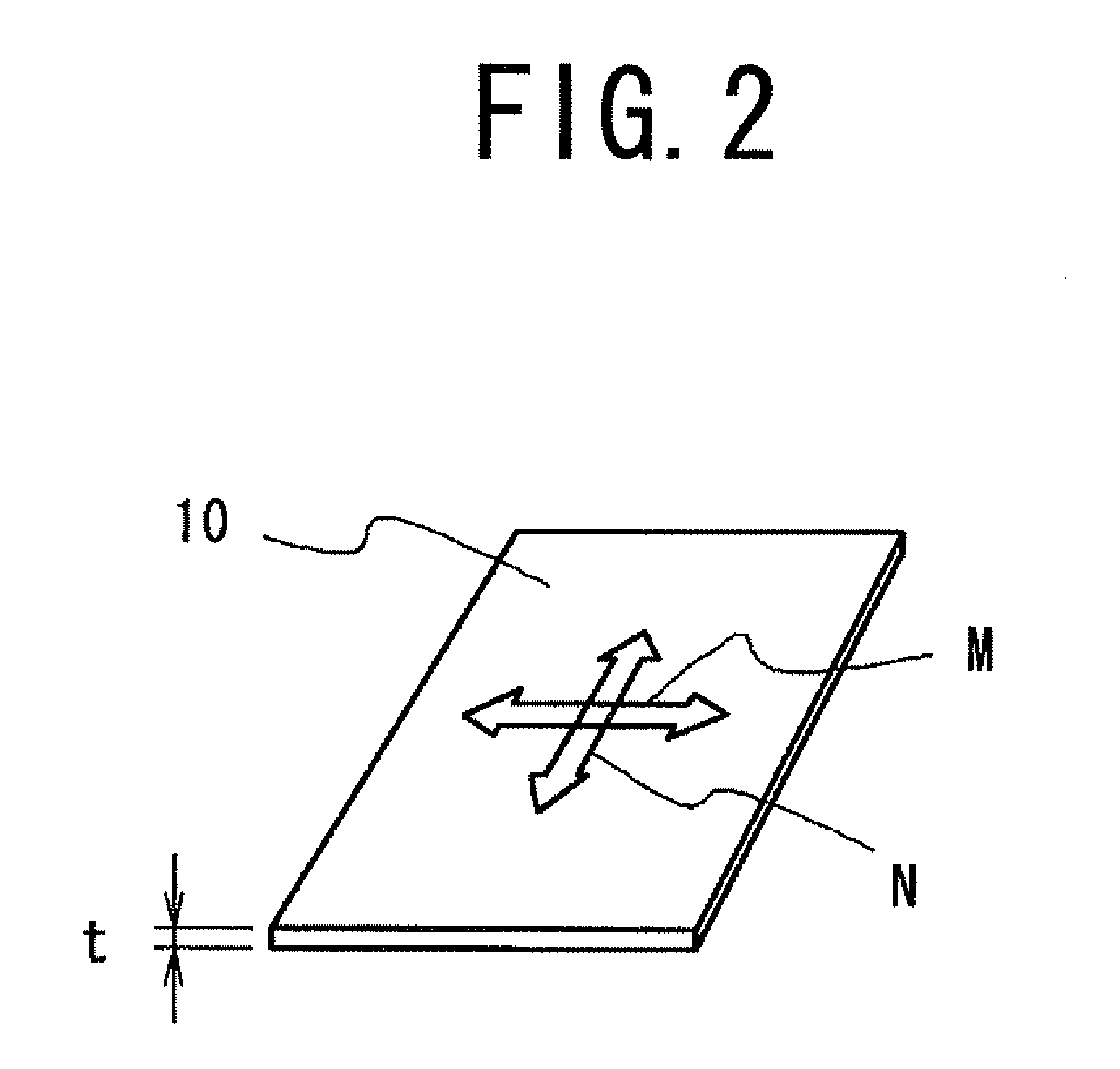

Light wavelength conversion module, illumination system, and projection apparatus

ActiveUS20150098070A1Good chromaGood color rendering/color reproduction propertyProjectorsPhotomechanical exposure apparatusLight beamLength wave

A light wavelength conversion module including a substrate, a first light wavelength conversion layer, and a first light transmissive layer is provided. The substrate has a light passing-through area and a first light wavelength conversion area. The first light wavelength conversion layer is located at the first light wavelength conversion area and between the first light transmissive layer and the substrate. The first light wavelength conversion layer is suitable for converting a coherent light beam into a first conversion light beam, wherein wavelengths of the coherent light beam and the first conversion light beam are different from each other. An illumination system and a projection apparatus are also provided.

Owner:CORETRONIC

Method for achieving oil painting three-dimensional duplication through ultraviolet-light-emitting diode (UV-LED) ink-jet printer

InactiveCN105128589ANo pollution in the processExact Stereomorphic ReplicationDecorative surface effectsDuplicating/marking methodsPrinting inkEngineering

The invention discloses a method for achieving oil painting three-dimensional duplication through an ultraviolet-light-emitting diode (UV-LED) ink-jet printer. The method comprises the following steps that (1) colored image information of an oil painting is obtained through two-dimensional non-contact scanning equipment; (2) pigment height information of the oil painting is obtained through three-dimensional scanning equipment, and a surface configuration three-dimensional model of the oil painting is established; (3) the number of layers of printing is determined according to the Z-axis height of the model, and the number of the layers is obtained by dividing the maximum value of the Z-axis by the average thickness of a single layer of white ultraviolet (UV) printing ink; (4) the cross section of each layer is extracted, and the cross sections of the layers are introduced into the UV printer to be printed after being subjected to vectorization treatment; (5) stacking printing is conducted through the white UV printing ink according to layer data, and a white three-dimensional oil painting entity is obtained; and (6) colored images are printed on the white three-dimensional oil painting entity, and a three-dimensional oil painting duplicate is formed. By means of the method, the concave-convex undulating characteristics of pigment on the surface of an oil painting original manuscript can be reproduced veritably, the three-dimensional impression of a real oil painting is achieved, the deficiency that the three-dimensional duplication of the oil painting cannot be achieved through an ordinary paint spraying and printing method is remedied, and the requirements for high-fidelity oil painting duplication can be met.

Owner:SOUTH CHINA UNIV OF TECH

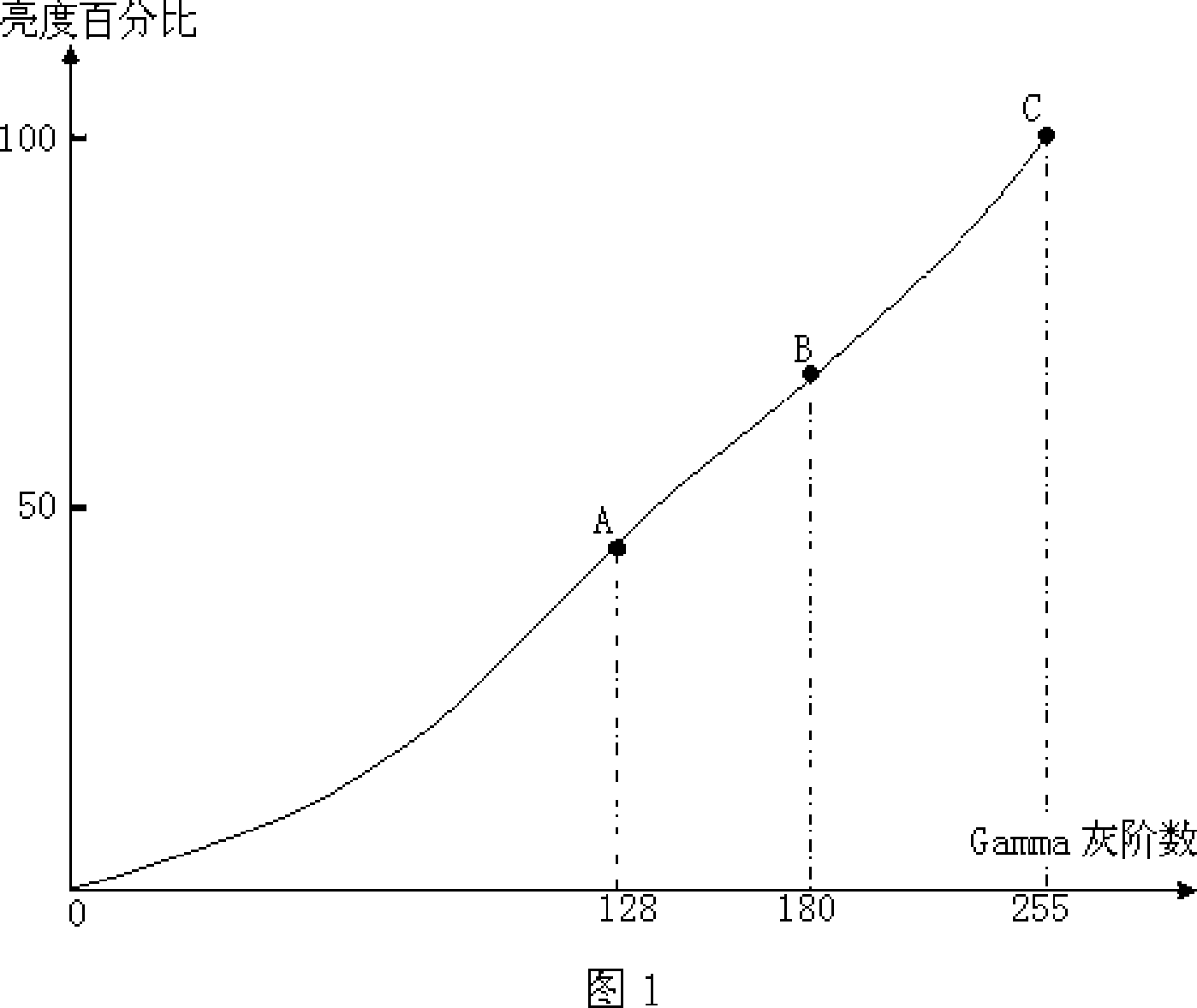

Method for correcting multi-segmented Gamma curve

ActiveCN101075428AImage color is true to lifeImage color is too uniformCathode-ray tube indicatorsCorrection methodEnvironmental geology

A method for calibrating multi-section Gamma curve includes dividing Gamma curve to be three parts of dark grey level part and intermediate part as well as bright grey level part according to different scope of grey level value, setting coefficient of Gamma curve at dark grey level part to be 2.0-2.4 and coefficient of Gamma curve at bright grey level part to be 1.5-1.9, smoothly transiting dark grey level part to be bright grey level part in linear way.

Owner:SICHUAN CHANGHONG ELECTRIC CO LTD

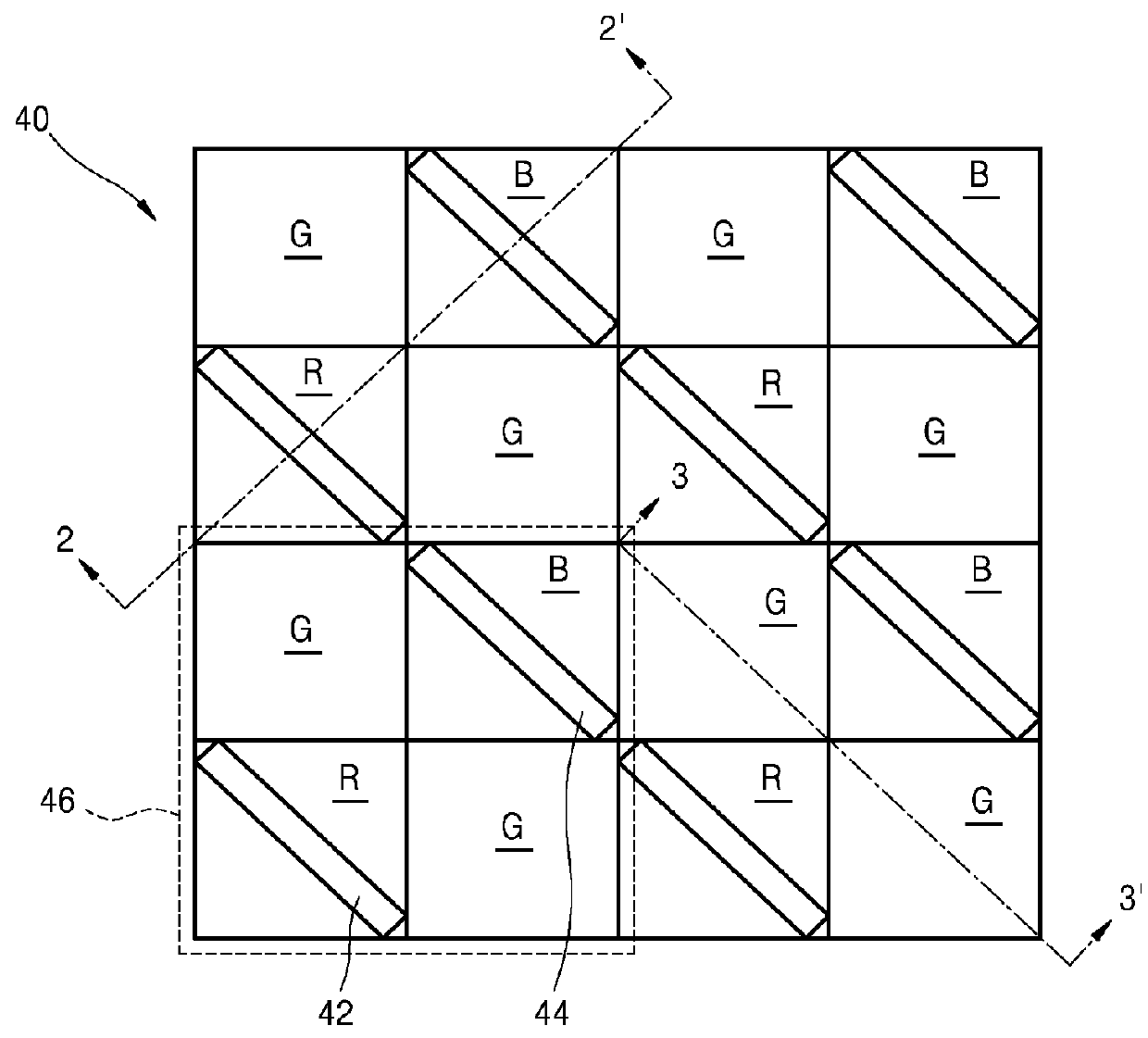

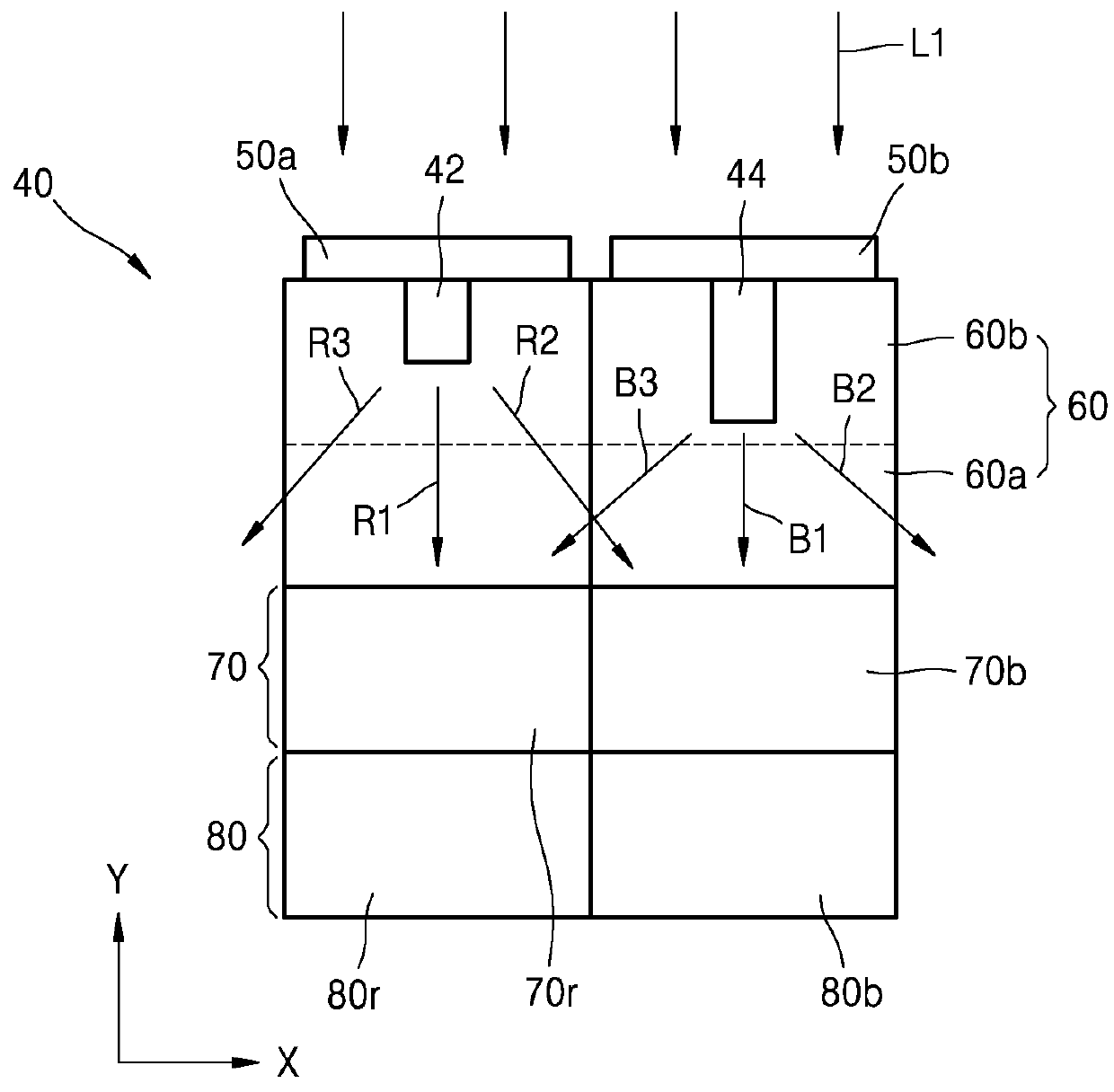

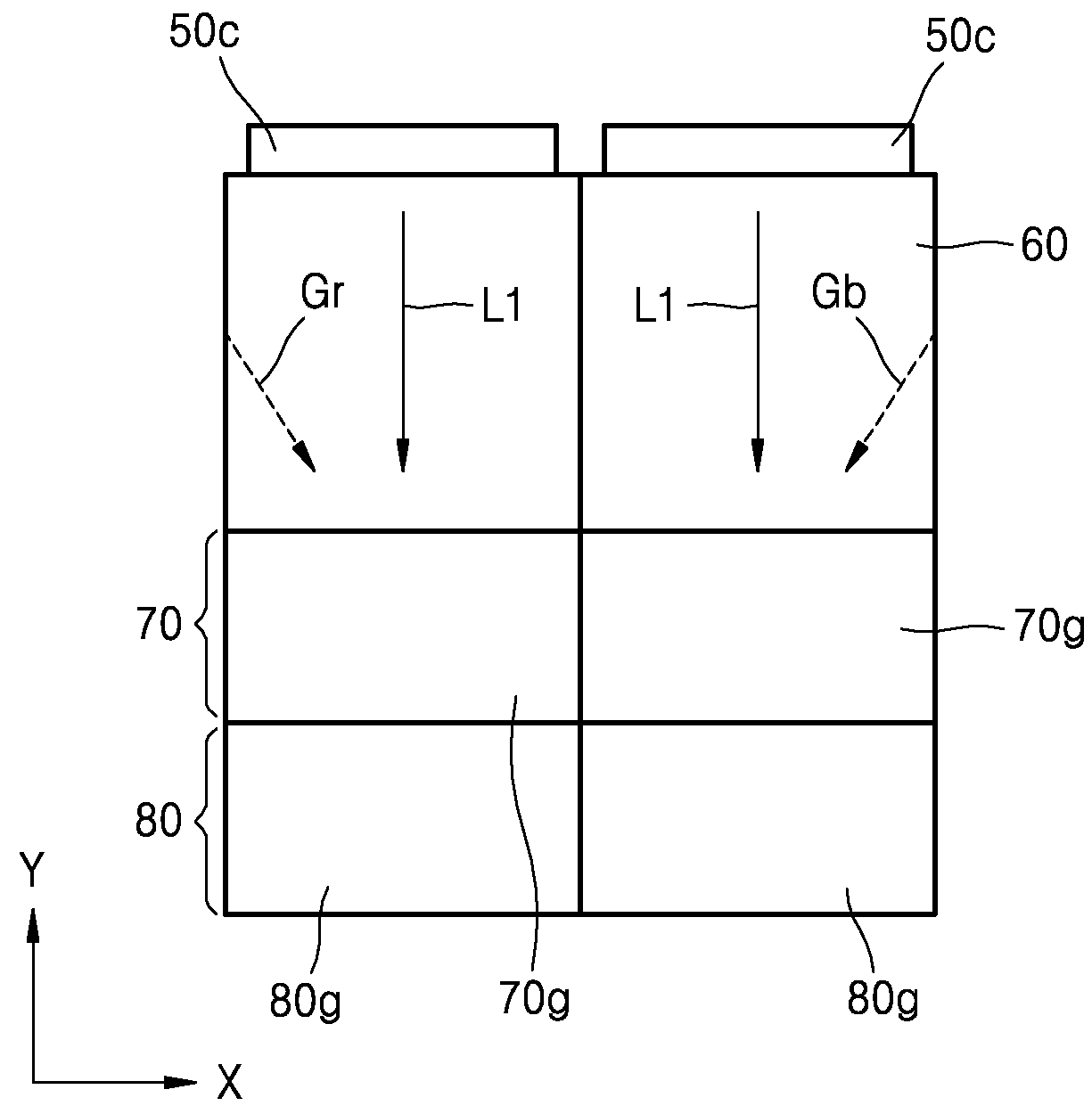

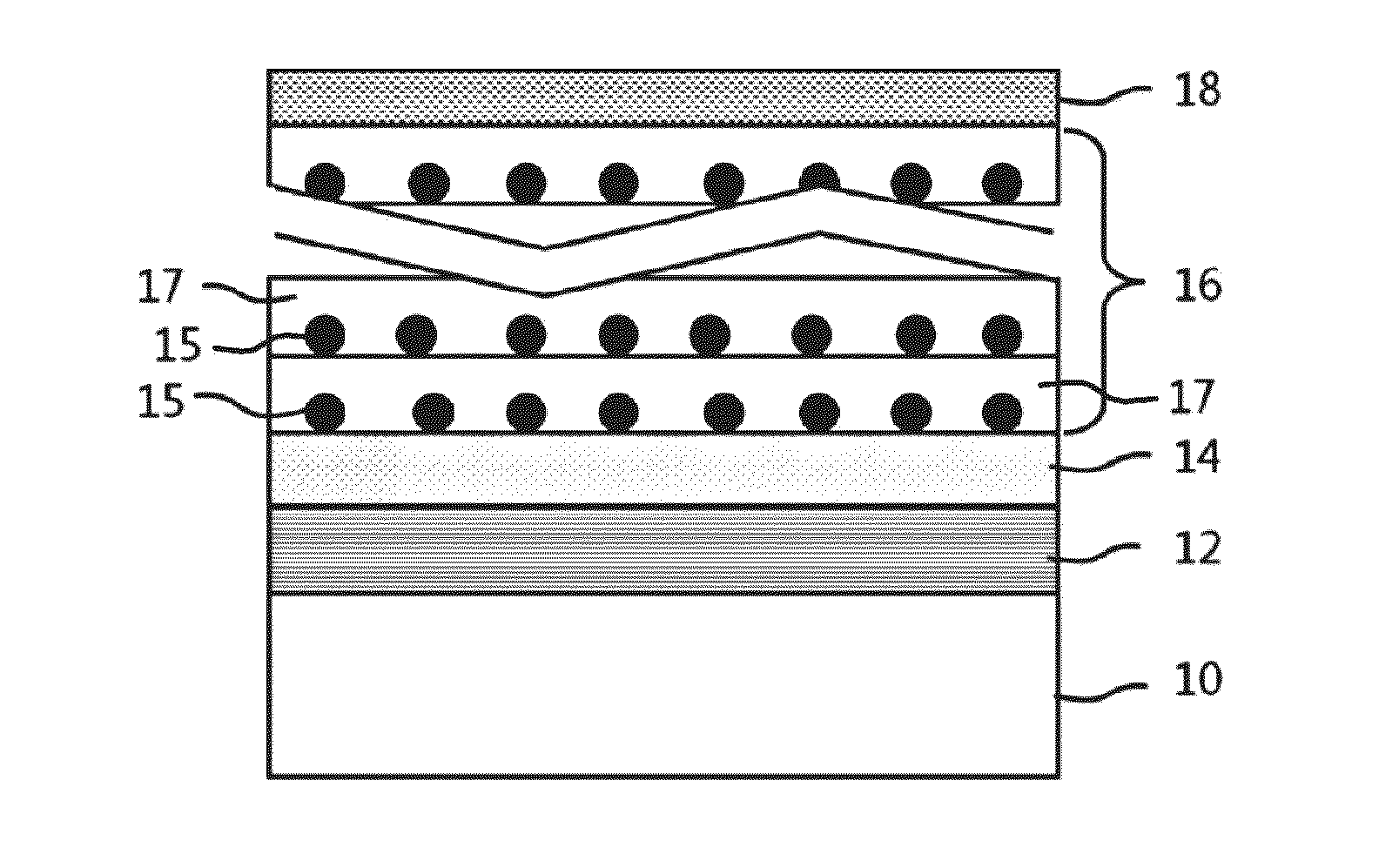

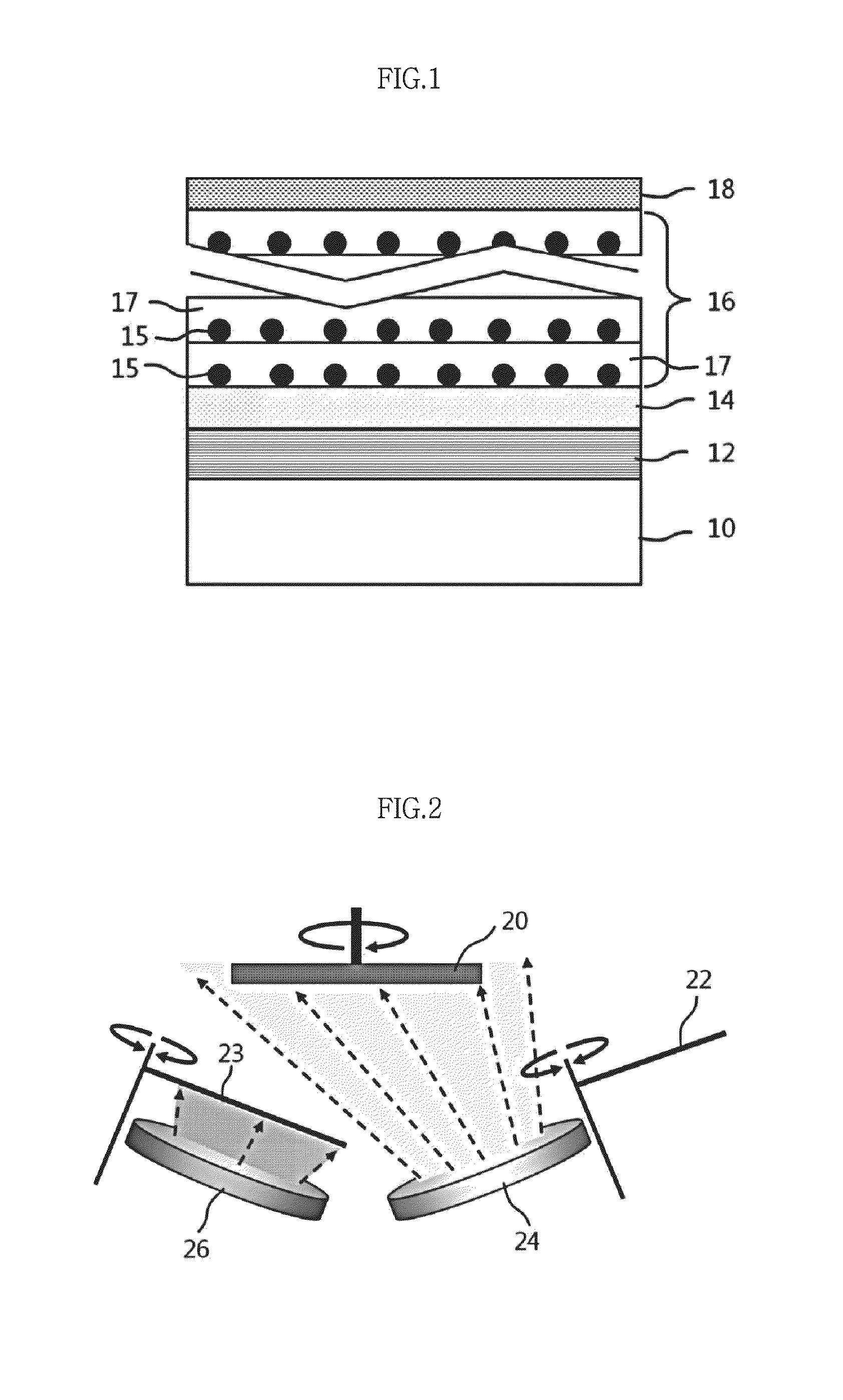

Image sensor for producing vivid colors and method of manufacturing the same

ActiveUS20160054172A1Reduce lossesImprove lighting efficiencySolid-state devicesMaterial analysis by optical meansBeam splitterRefractive index

An image sensor and a method of manufacturing the same are provided. The image sensor includes a photoelectric conversion layer; a color filter disposed on the photoelectric conversion layer; a low refractive index layer disposed on the color filter; a beam splitter disposed within the low refractive index layer; and a lens layer disposed on the low refractive index layer and covering the beam splitter. The beam splitter extends in a diagonal direction of a pixel area of the color filter, in a plan view.

Owner:SAMSUNG ELECTRONICS CO LTD

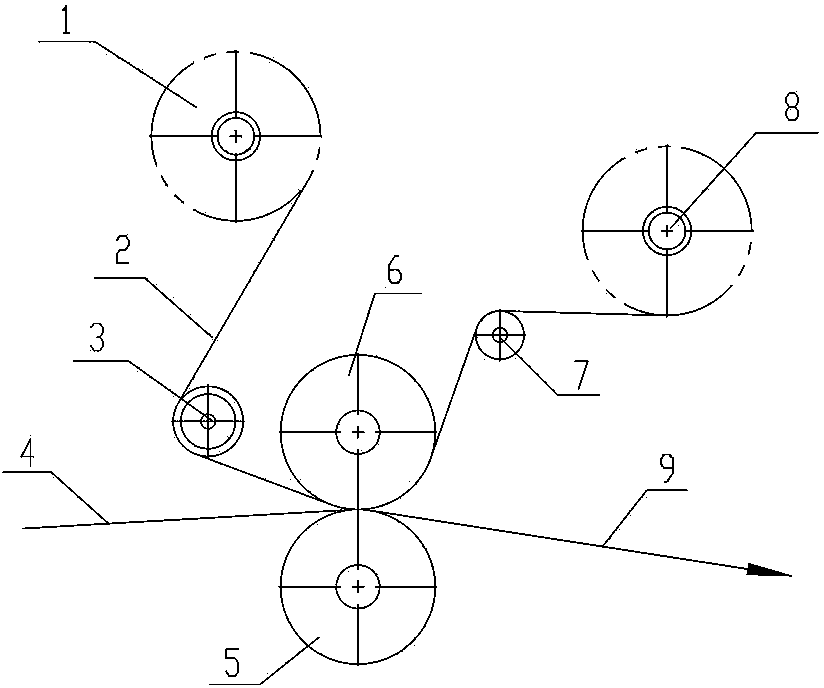

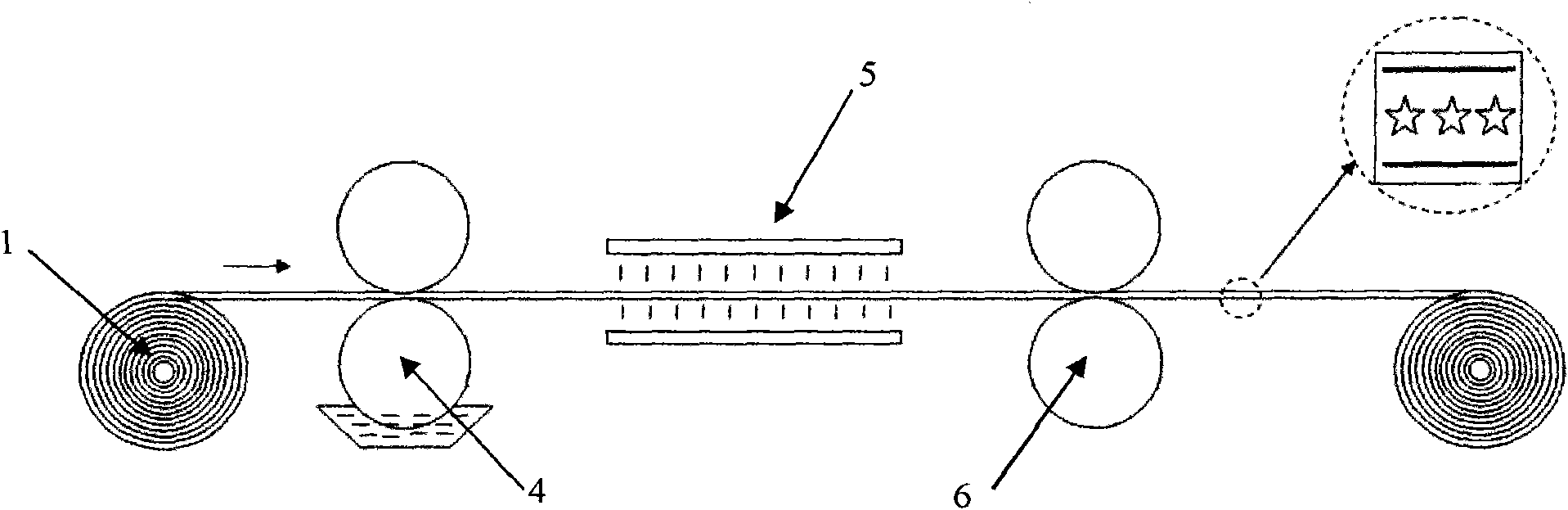

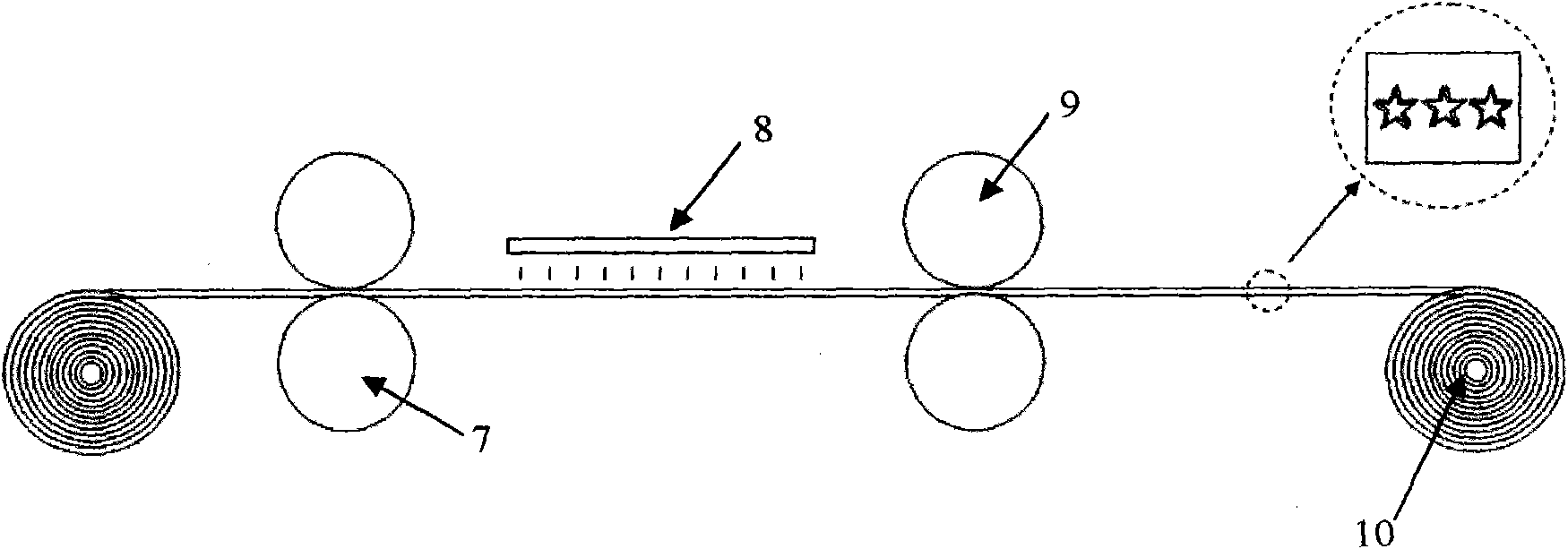

Printing technology of PVC (polyvinyl chloride) plastic coiled material floor patterns

The invention discloses a printing technology of PVC (polyvinyl chloride) plastic coiled material floor patterns. The printing technology of the PVC plastic coiled material floor patterns comprises the following steps: firstly, imprinting and coating a releasing agent on the surface of a transfer basement membrane, then printing an ink pattern layer and an adhesive according to design patterns, and drying so as to obtain a transfer membrane; conveying a coiled material floor base material and a transfer membrane together to be between a rubber roller and a mirror surface roller of a printer, and bonding the adhesive on the surface of the ink pattern layer of the transfer membrane and the surface of the coiled material floor basement material sufficiently, wherein ink patterns on the transfer membrane are bonded on the surface of the coiled material floor basement material by the adhesive; the transfer membrane is separated and coiled after changing into a transfer base membrane; the surface of the coiled material floor base material with ink patterns is pasted with a transparent membrane and then is subjected to calendering or embossing treatment so as to obtain a coiled material floor finished product. The printing technology of the PVC plastic coiled material floor patterns, which is provided by the invention, have the advantages that patterns are printed on the surface of the transfer membrane in advance, and then are transferred to the surface of the coiled material floor base material through heating and compression, thereby obtaining floor patterns which are beautiful and vivid in color and intense in layering; the grade of the PVC plastic coiled material floor patterns is improved greatly; meanwhile, the technology is simple, and the production cost is low.

Owner:ZHENGZHOU SANLIAN PLASTIC PROD

Method of manufacturing polarized spectacle lens

InactiveUS20020080488A1Vivid colorsEconomically manufacturedOptical articlesPolarising elementsPolarizerLens plate

A film of a plastic material fusible with a lens-forming material and having a high light transmissivity is bonded and laminated, with an adhesive, to a polarizing sheet having a polarization coefficient of 99.0% or higher and a light transmissivity of 40% or higher. The resultant laminate is hot-pressed into a shape similar to an aimed lens. The hot-pressed laminate is placed in a lens forming mold cavity, and a lens-forming resin which has been colored or of which light transmissivity has been adjusted to a desired transmissivity is injected into the cavity to thereby form a polarized lens.

Owner:NAKAGOSHI YASUNOBU +1

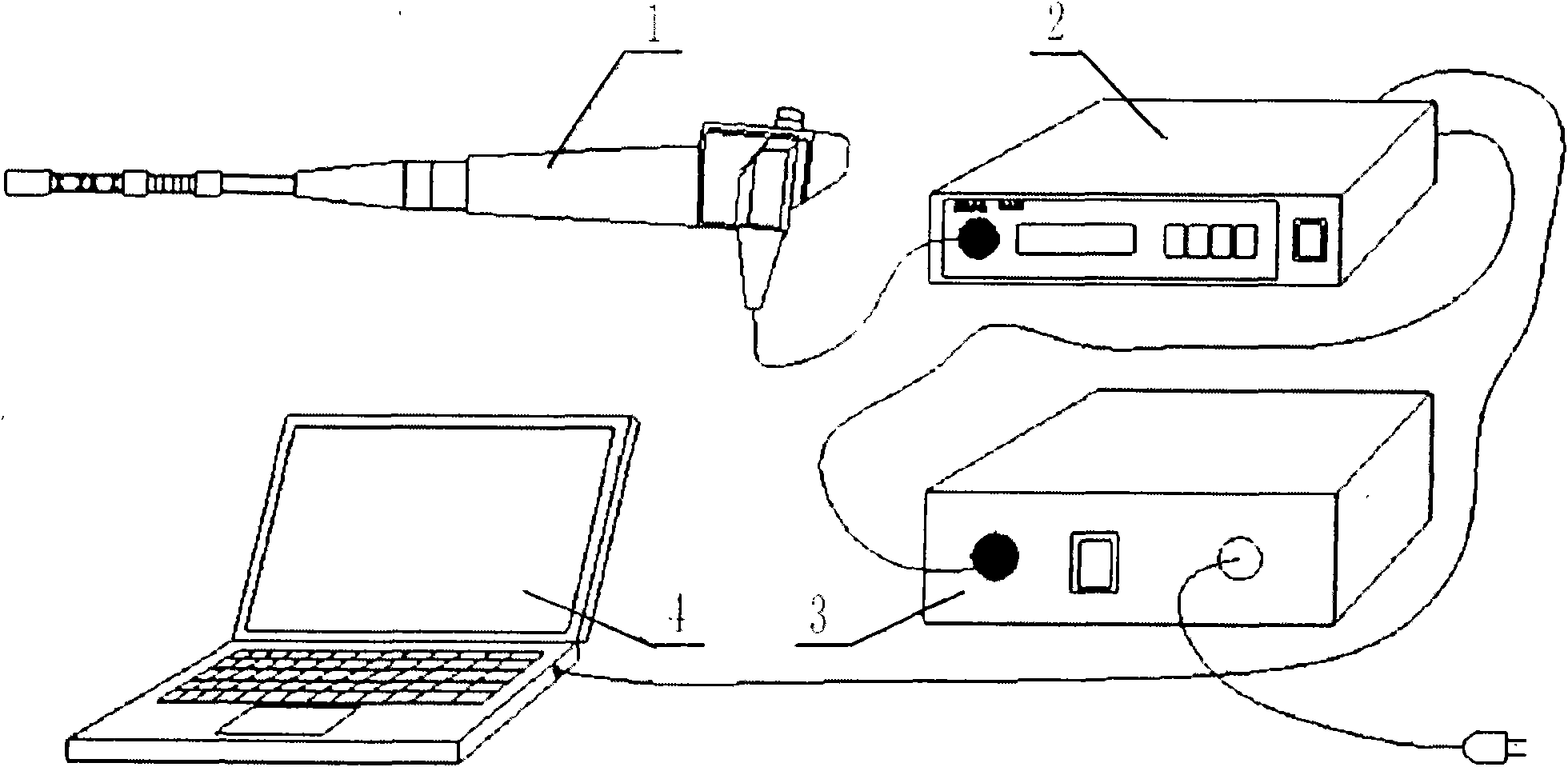

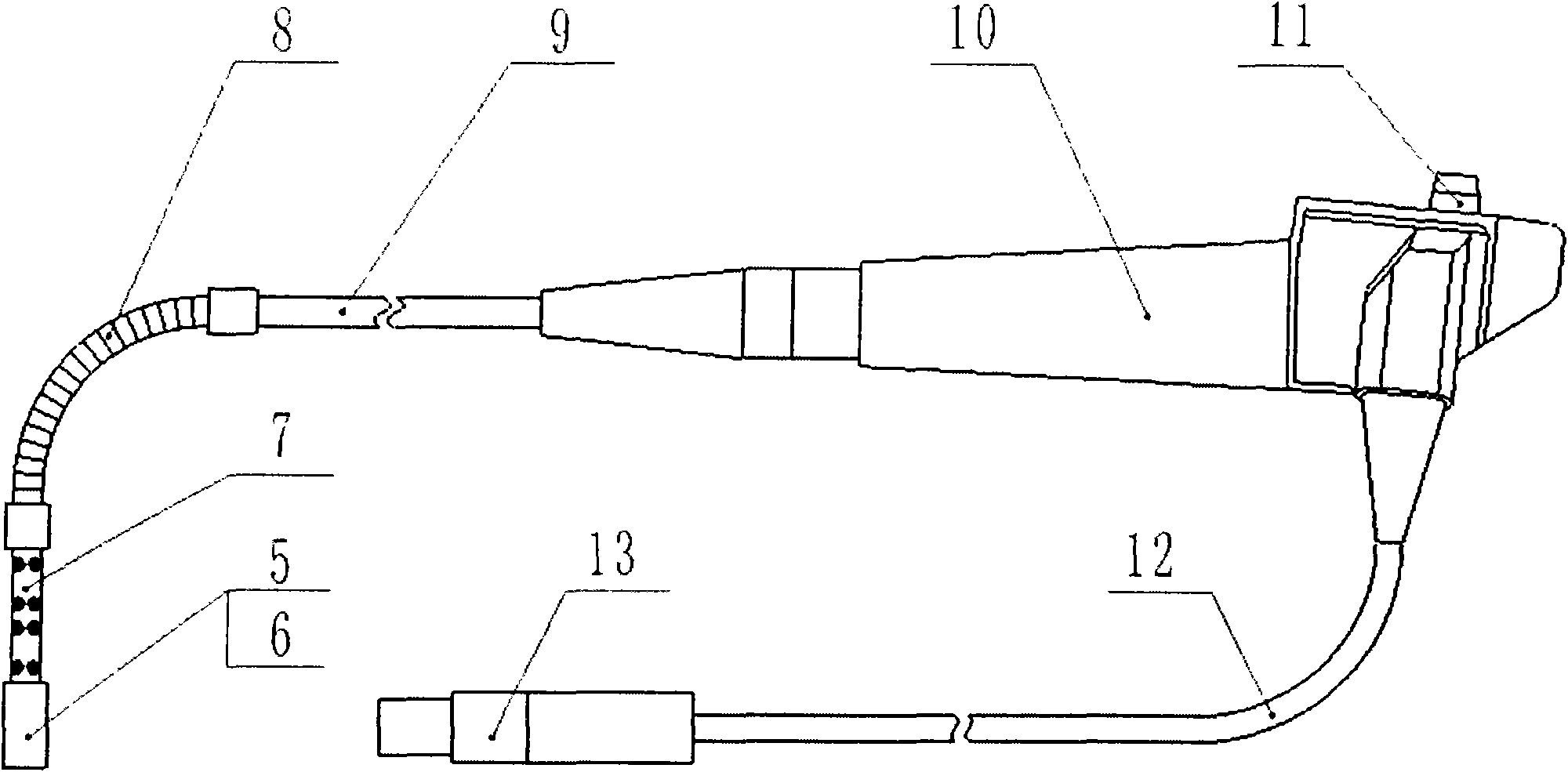

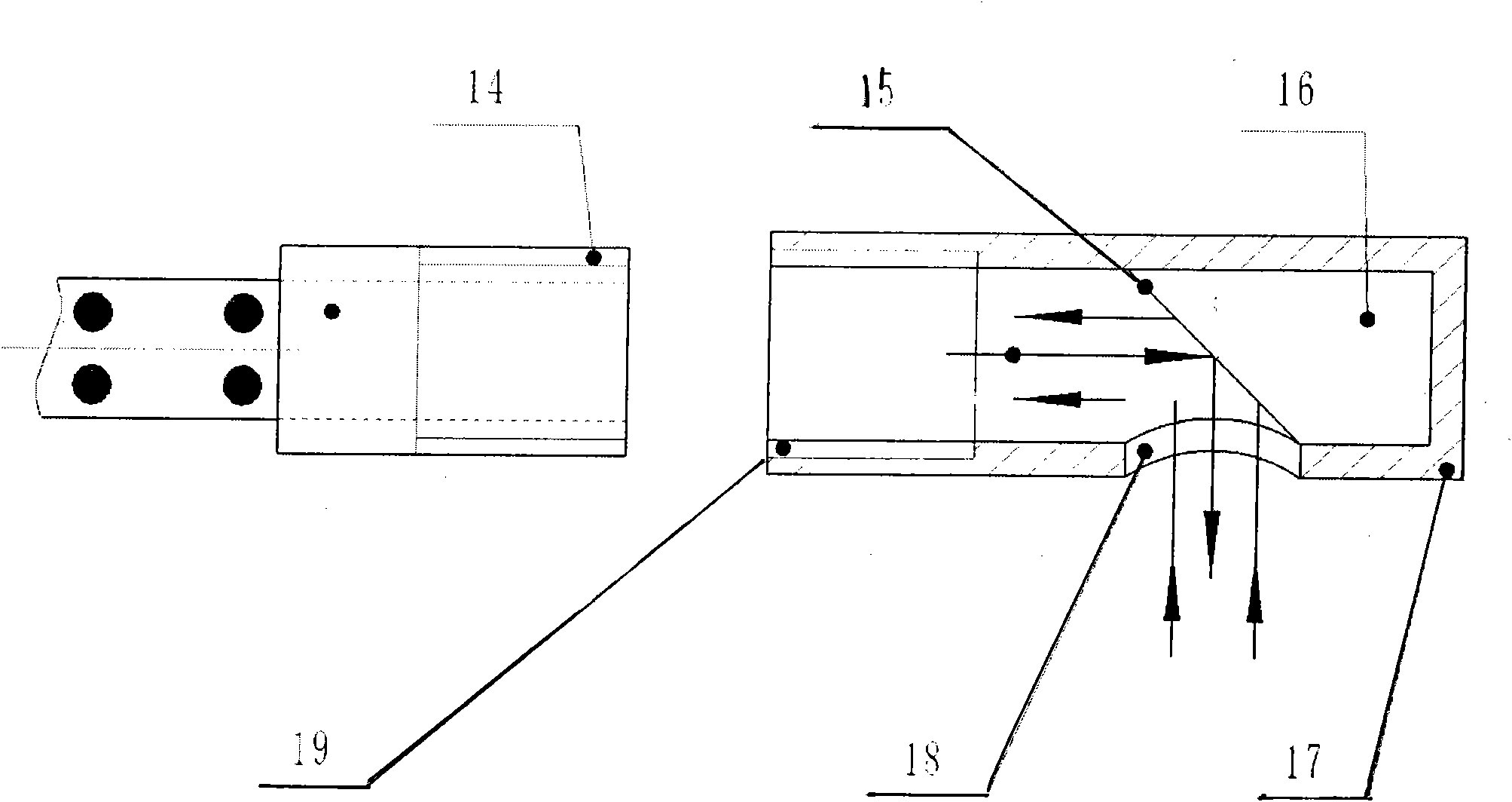

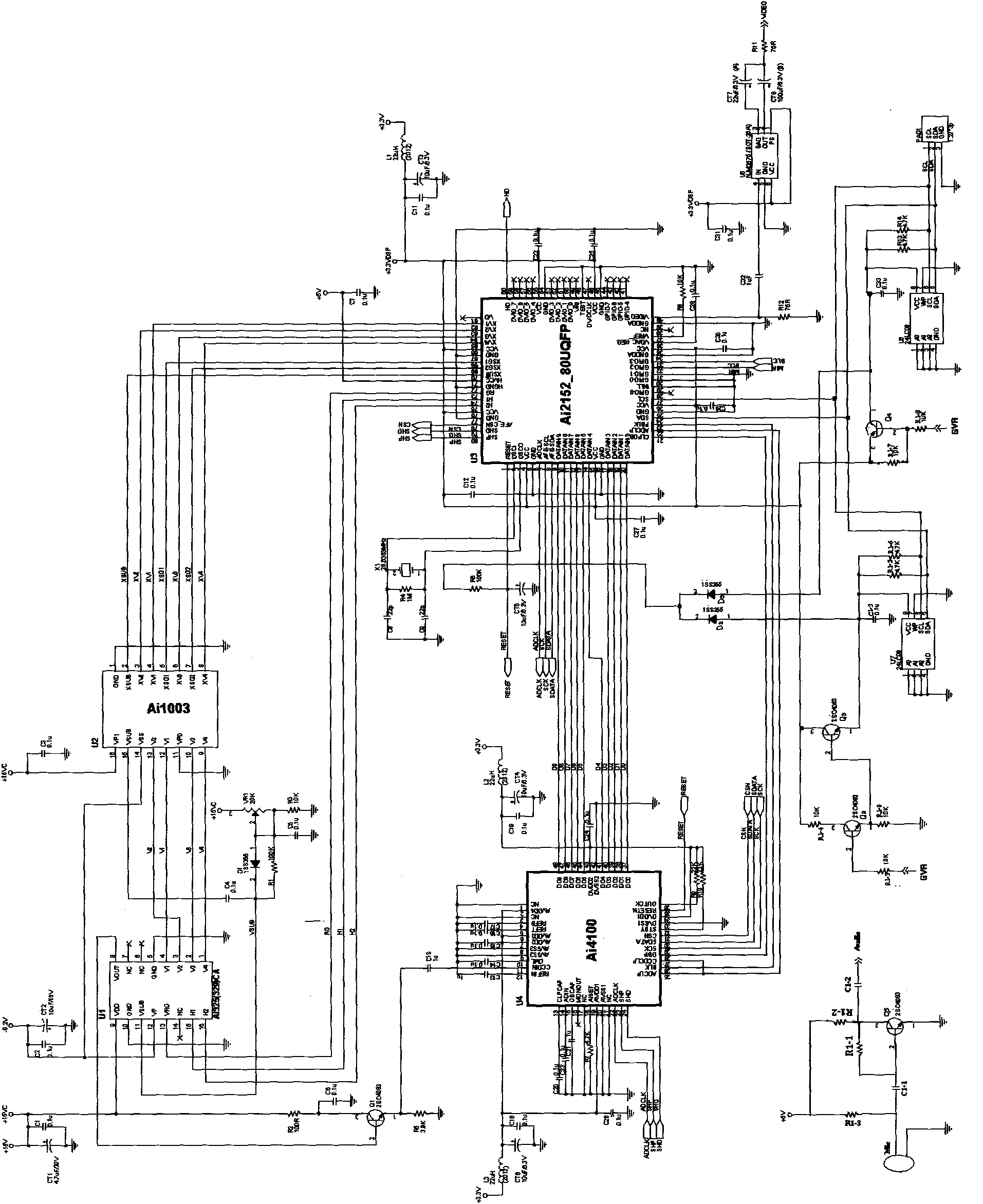

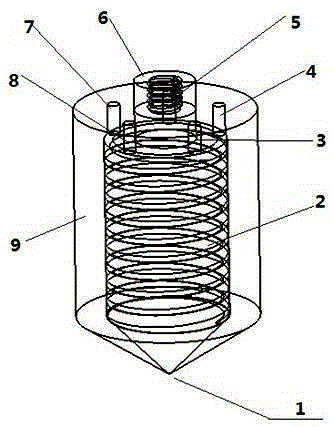

Industrial electronic endoscope

ActiveCN101551515AClear imagingVivid colorsMaterial analysis by optical meansTelescopesImaging processingImage resolution

The invention relates to a nondestructive detection apparatus, in particular a new industrial electronic endoscope for nondestructive detection. The new industrial electronic endoscope includes an endoscope probe that is connected with an image processing device through a connecting tube, wherein the endoscope probe is composed of a CCD imaging device and an LED light emitting tube; an image signal emitted from the CCD imaging device is transmitted to the image signal processing device through a transmission line disposed in the connecting tube. Compared with the industrial fibre endoscope, the advantages of the invention lie in that it has clear image, vivid colour, high resolution, large effective probing range, small volume and convenient operation and long service.

Owner:SHANGHAI MUNICIPAL ELECTRIC POWER CO +1

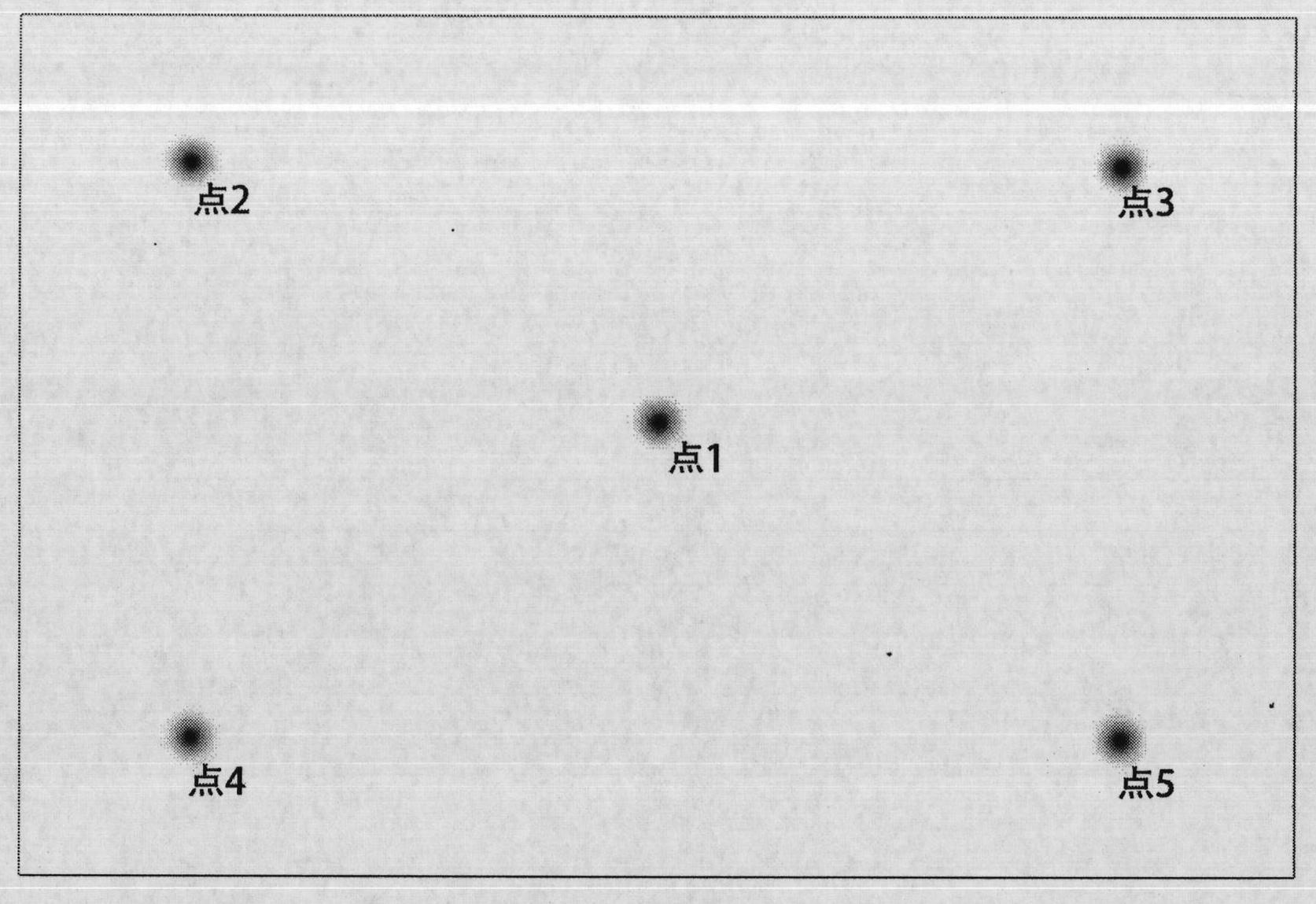

Digital high-fidelity image collecting and processing method of stone cave temple wall paintings

InactiveCN102609924AHigh resolutionImprove fidelityImage enhancementTelevision system detailsFull scaleParallel translation

The invention discloses a digital high-fidelity image collecting and processing method of stone cave temple wall paintings. The method is characterized in that through photography collection, image treatment and image storage, by utilizing a cavalier perspective and parallel translation principle and adopting an autonomously designed photography collecting system and a unique cross-shaped skeleton image splicing processing method, the data is stored safely, normalized stone cave cultural relic wall painting digitalization is carried out, thousands and even more original images photographed for the same wall surface can be spliced and fused into a traceless and perfect high-fidelity full-scale integral imaging picture, and the purposes that the precious cultural heritage can be stored permanently and used sustainably for human beings are achieved.

Owner:DUNHUANG ACAD +1

Plasmonic nano-color coating layer and method for fabricating the same

ActiveUS20150116856A1High chromaLittle changeOptical filtersVacuum evaporation coatingNanometreMaterials science

A plasmonic nano-color coating layer includes a composite layer including a plurality of metal particle layers and a plurality of matrix layers and having a periodic multilayer structure in which the metal particle layers and the matrix layers are alternately arranged, a dielectric buffer layer located below the composite layer, and a mirror layer located below the dielectric buffer layer, wherein the color of the plasmonic nano-color coating layer is determined based on a nominal thickness of the metal particle layer and a separation between the metal particle layers.

Owner:KOREA INST OF SCI & TECH

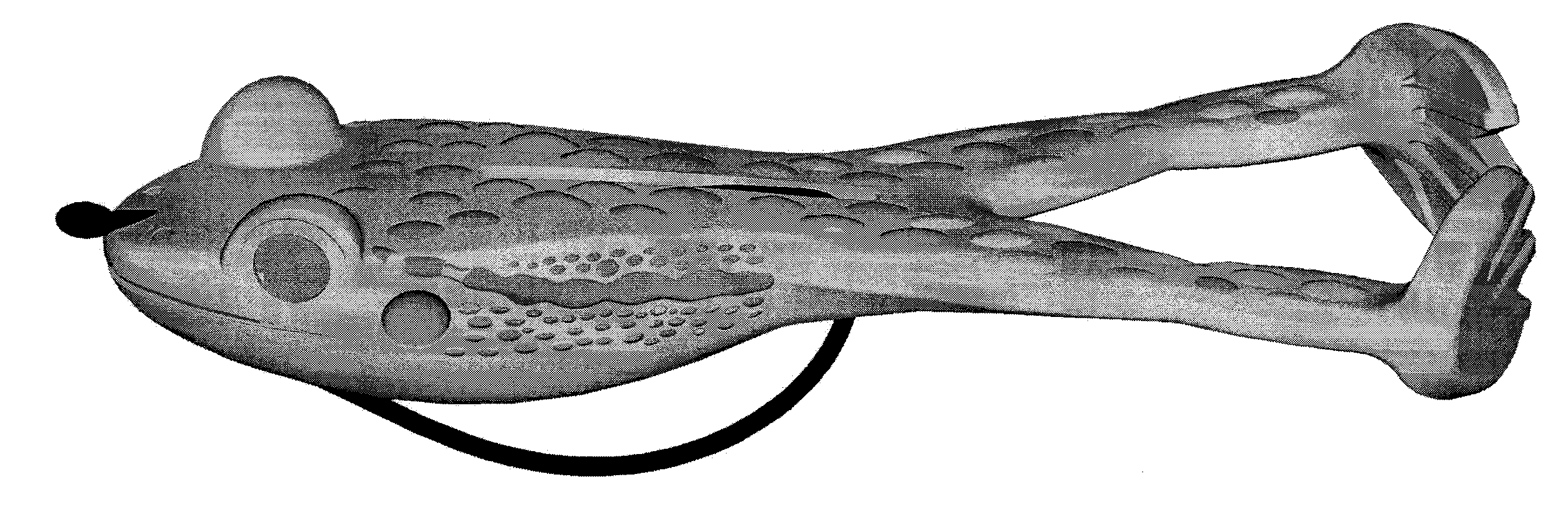

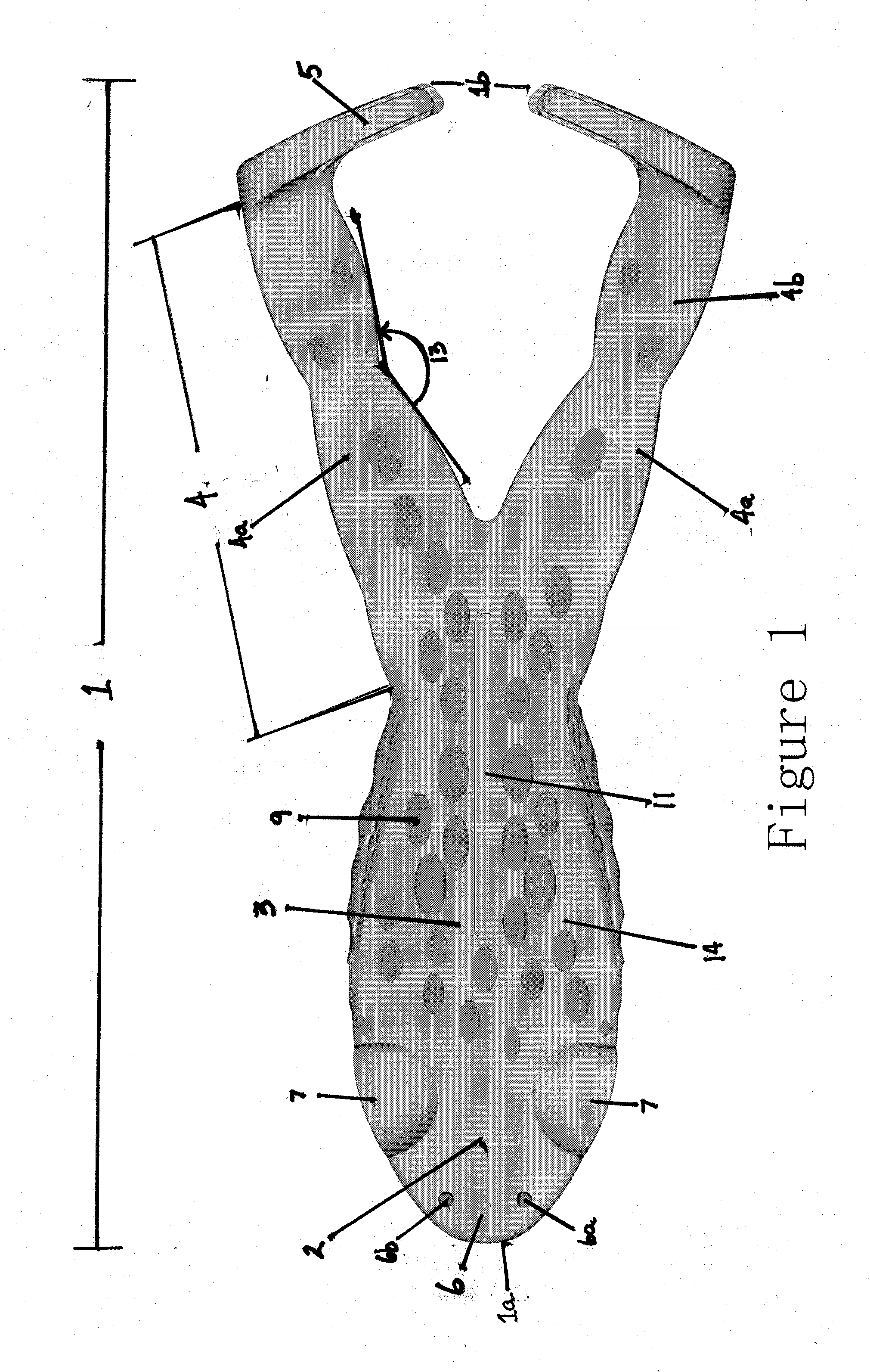

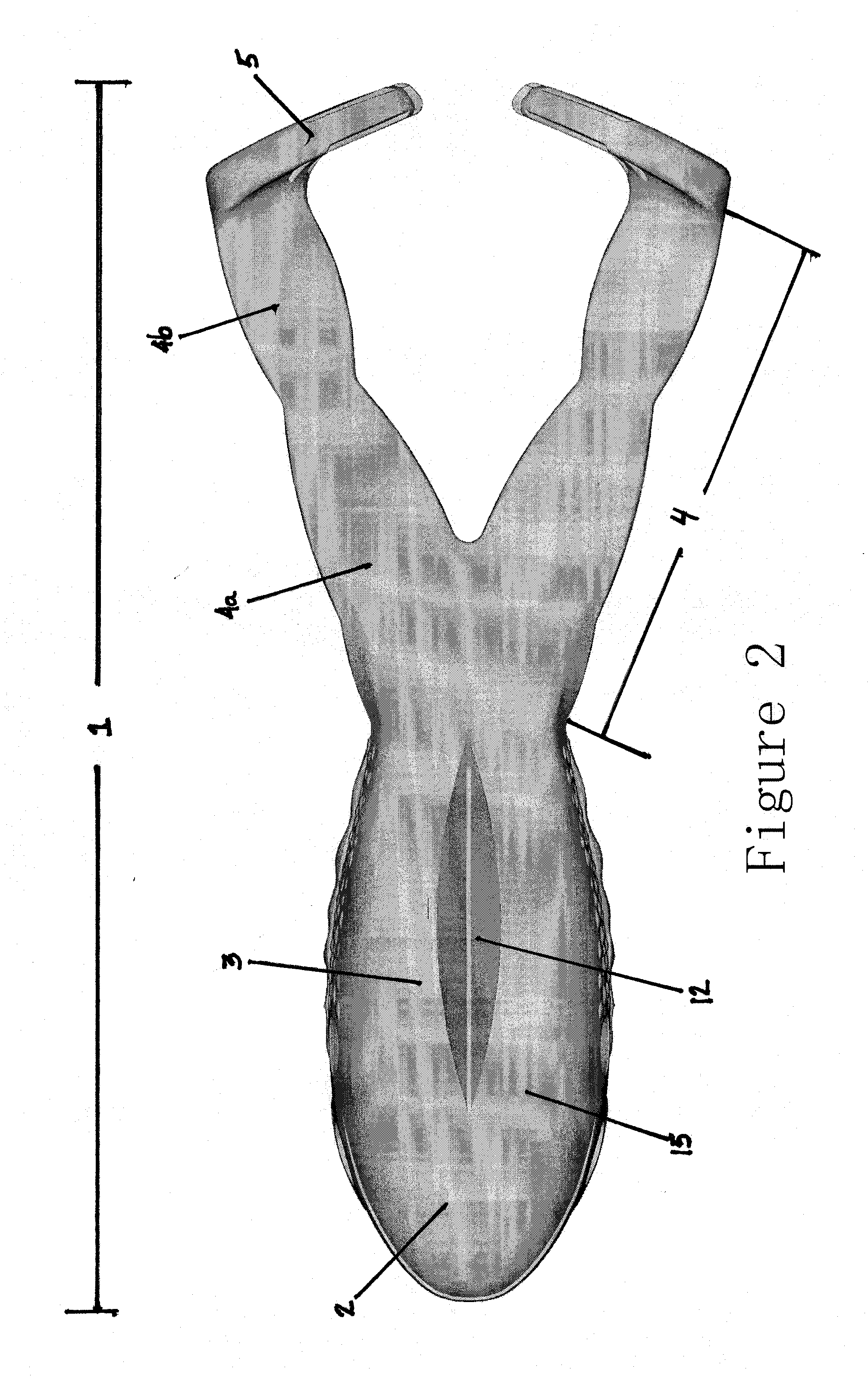

Frog Fishing Lure and Method of Use

A realistic, solid-bodied, plastic frog fishing lure with hind legs and webbed feet for providing vibration for attracting fish, the frog fishing lure capable of correcting itself underwater so that the lure runs in an upright position at all times when being fished.

Owner:TUSCARORAN PRO LURES

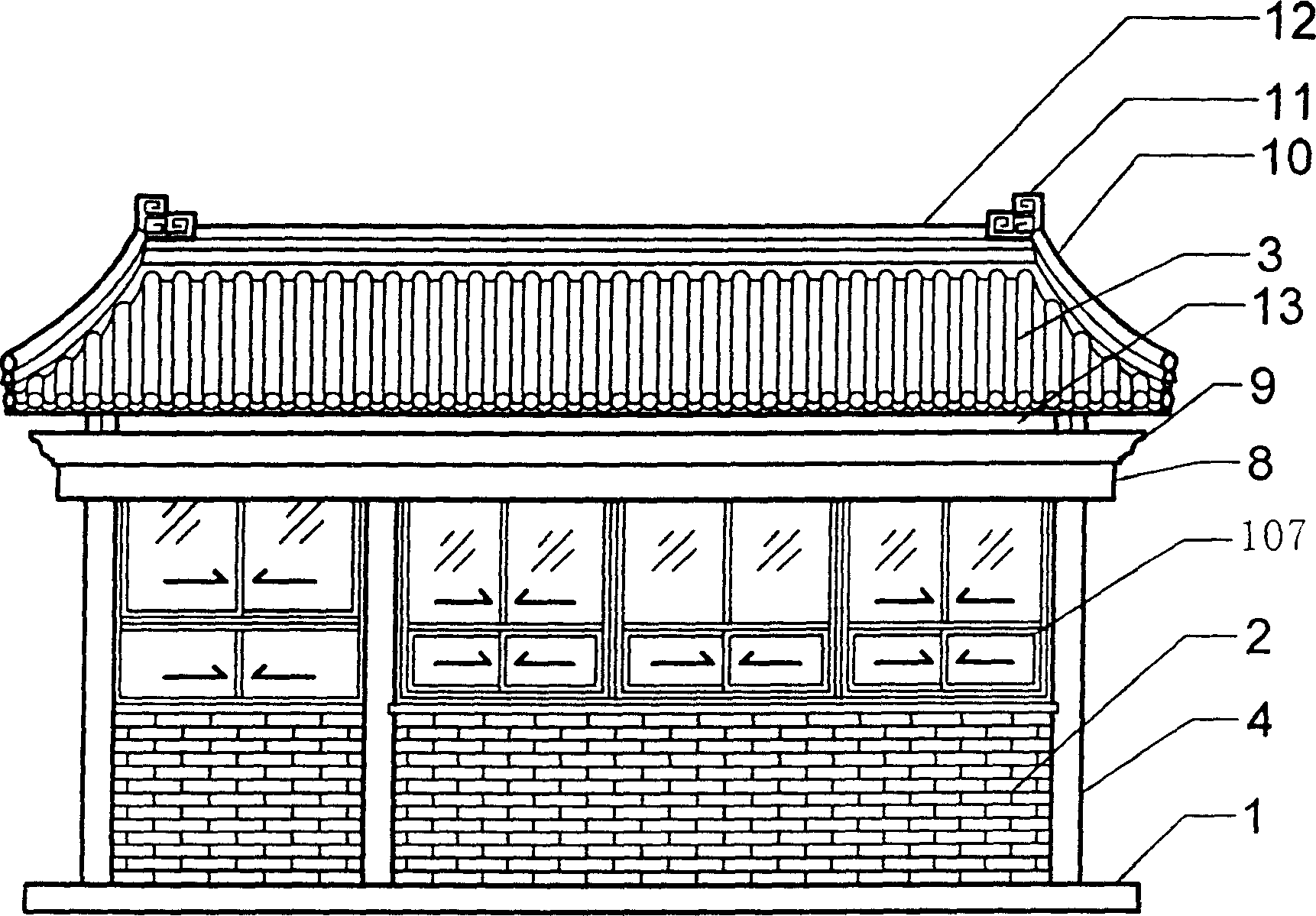

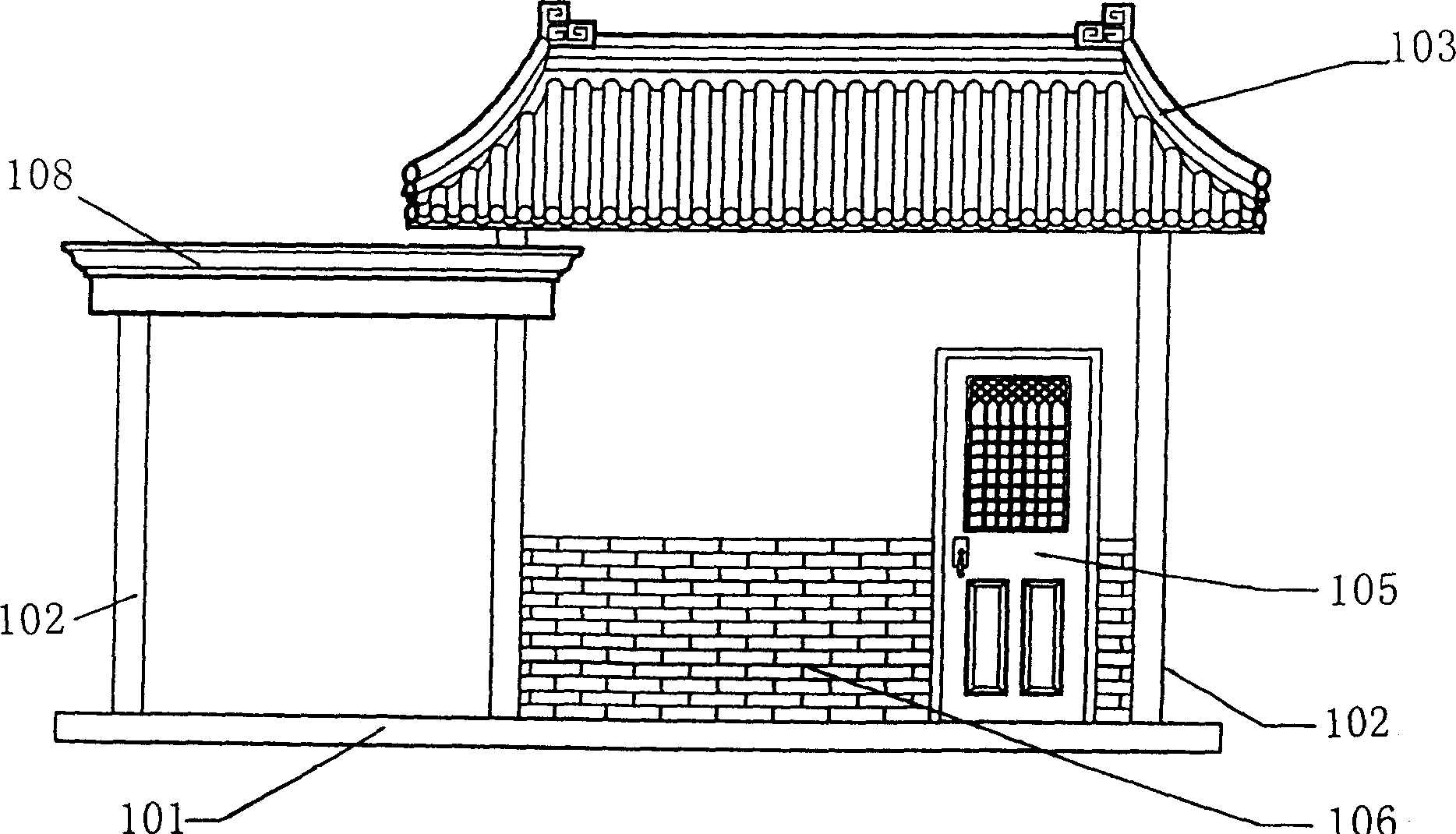

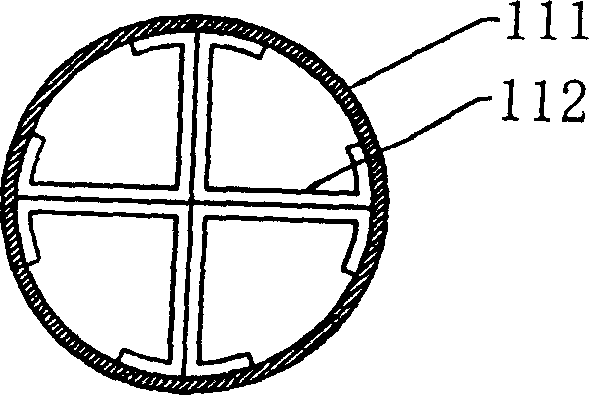

Light archaized architecture production method and product

ActiveCN1884731ALifelike shapeVivid colorsCeramic shaping apparatusBuilding constructionsPulp and paper industryEngineering

The invention relates to a method for producing light pseudo-classic building, which comprises: (1), using steel plate or iron steel as foundation; (2), mounting upright post on it; (3), using metallic support to install the roof truss support and mounting roof truss support on the upright post; (4), mounting wall, door, and window between iron plate or steel plate, and roof truss support and upright post; (5), using magnesite composite pulp with yellow, green or black color to produce the pseudo-classic roof truss; (6) mounting pseudo-classis roof on the roof truss support, to obtains final building. The invention has simple process, high reality, and better pseudo-classis effect.

Owner:BEIJING JUXING COMPOSITE MATERIAL TECH DEV

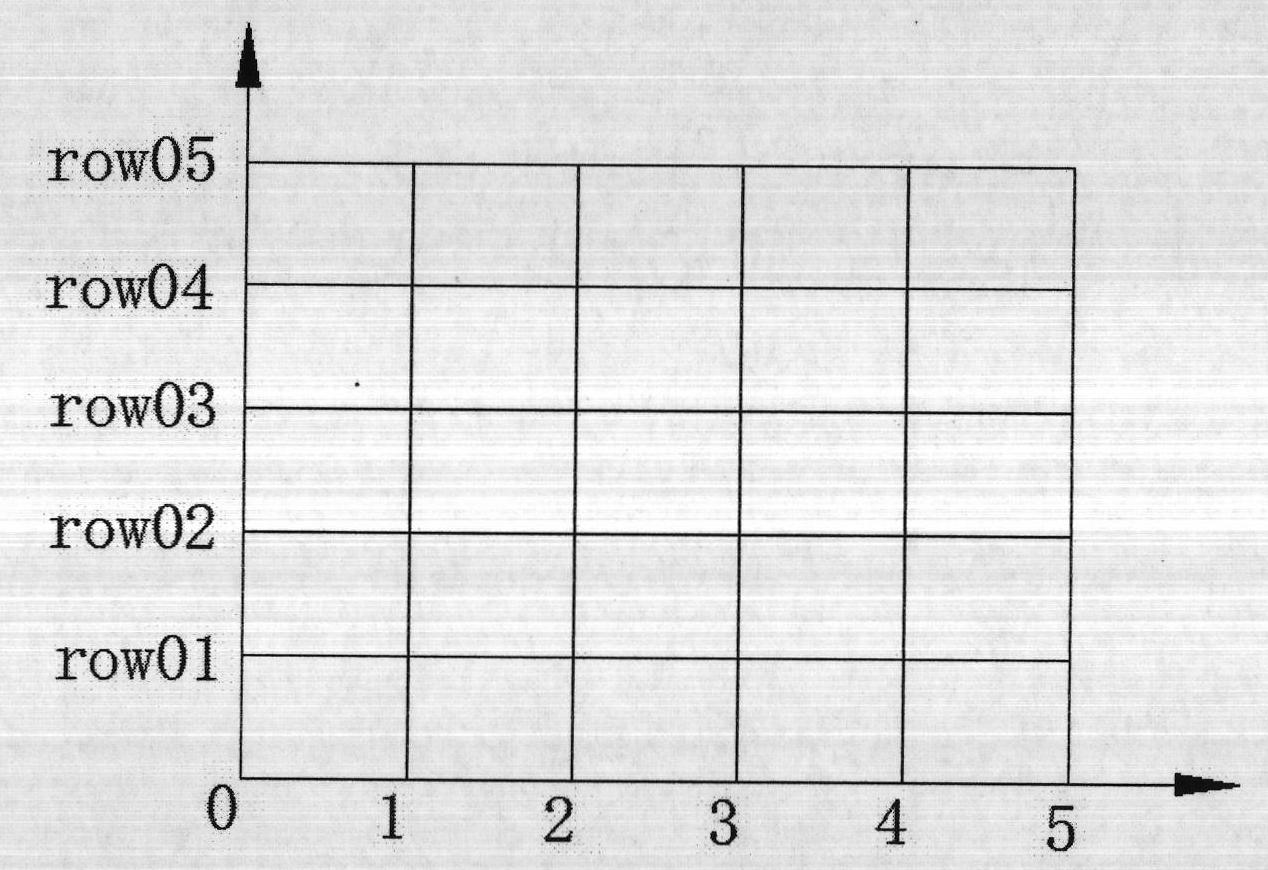

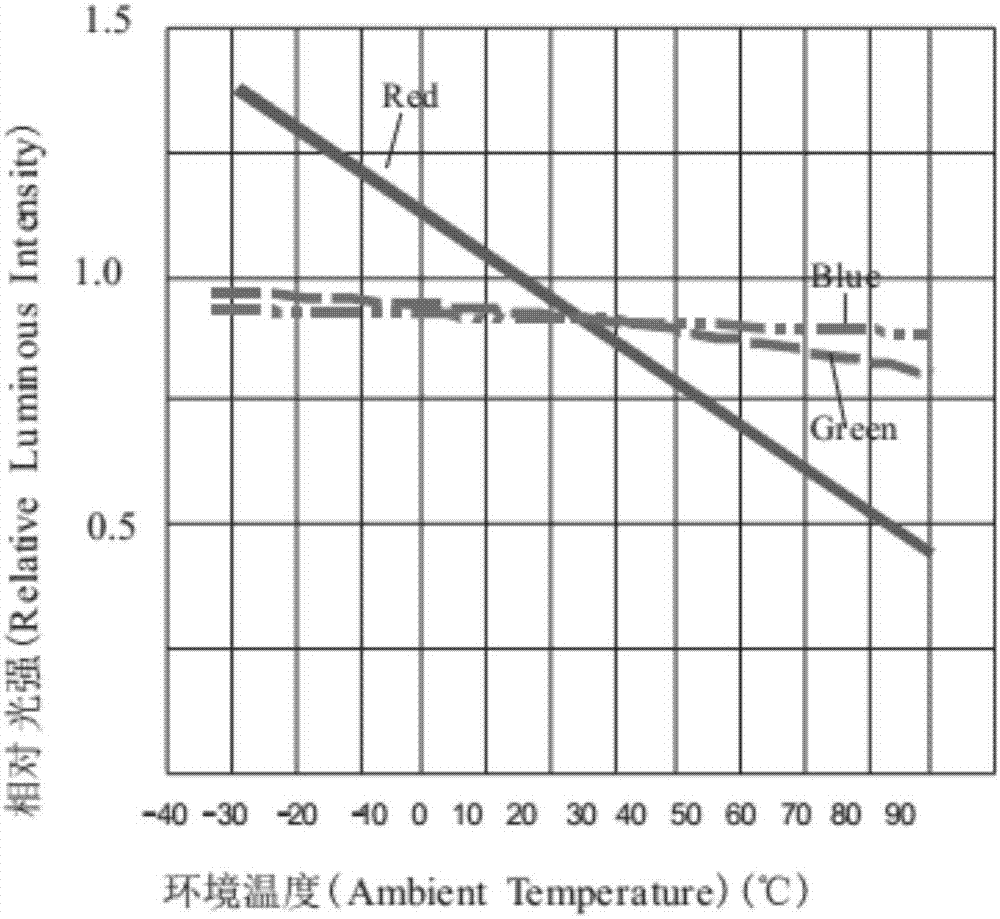

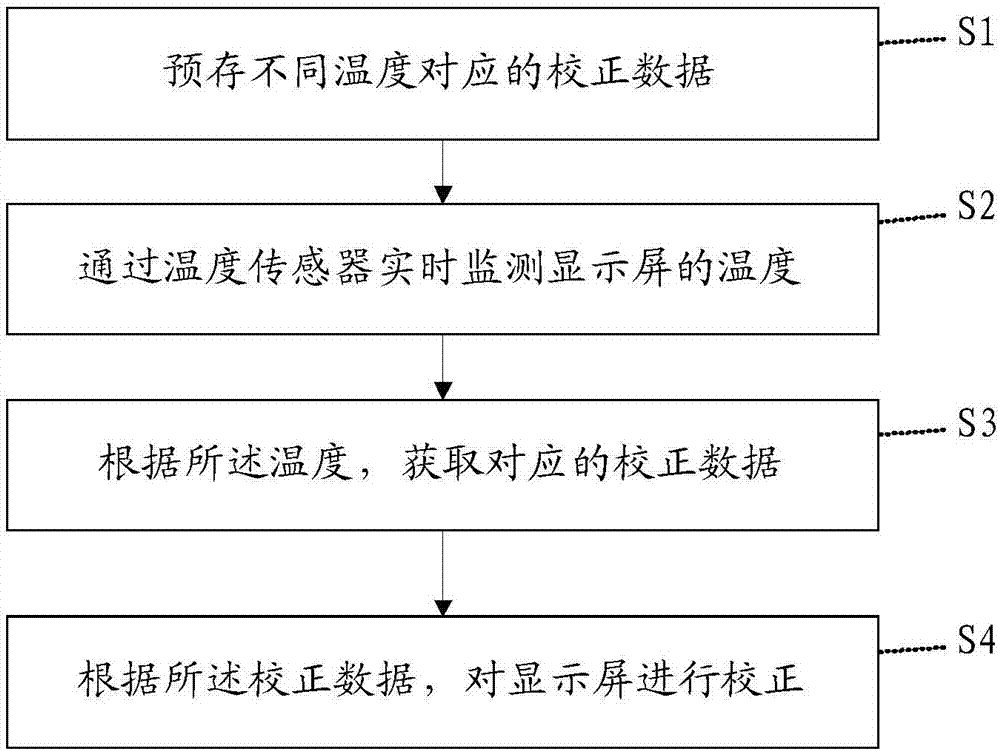

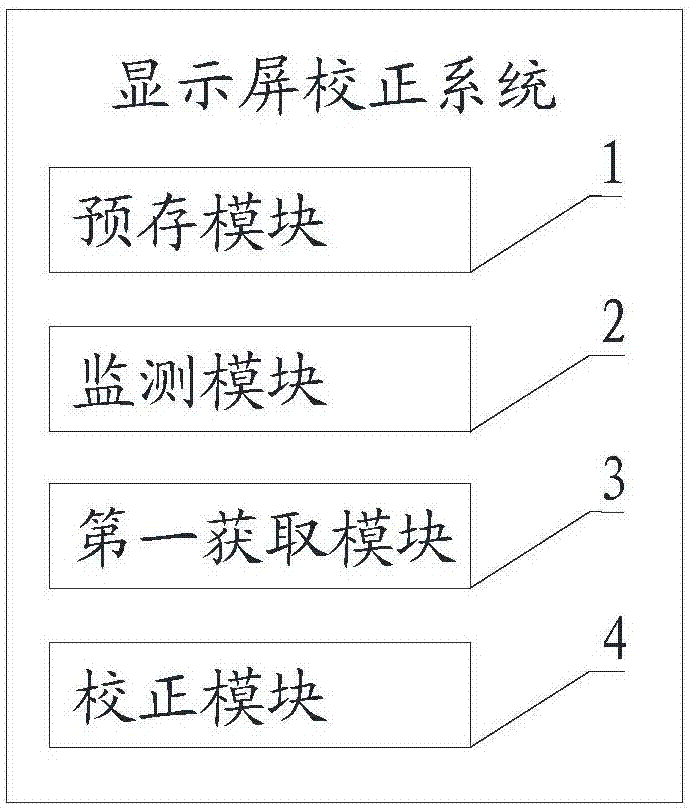

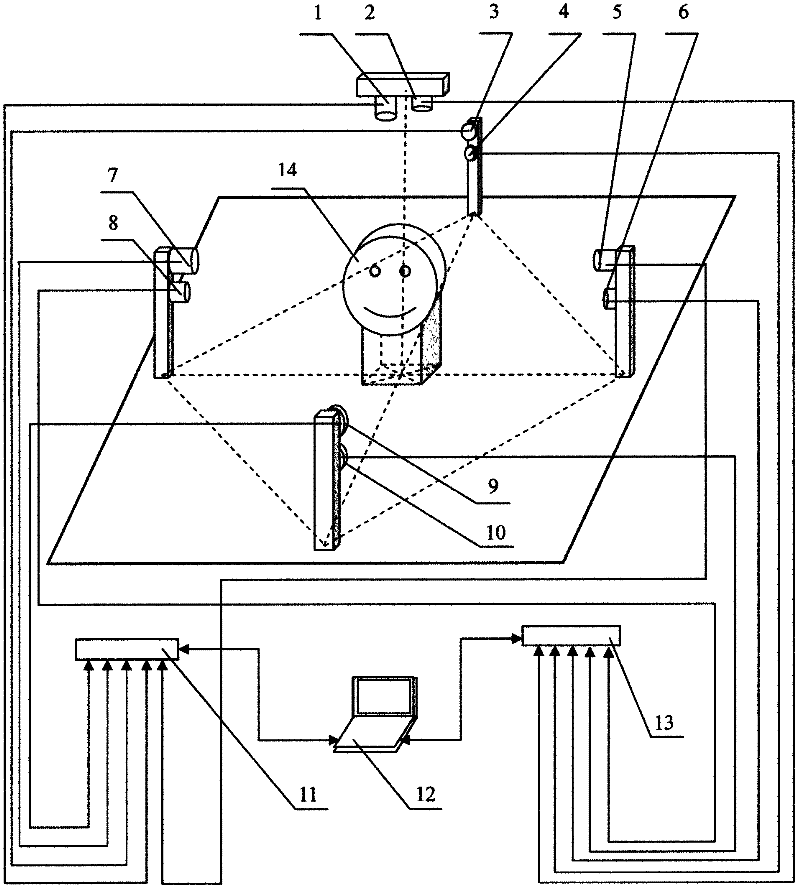

Display screen calibration method, display screen calibration system and computer readable storage medium

InactiveCN107146572AShow uniformImprove color cast more and more serious problemStatic indicating devicesLED displayComputer graphics (images)

The invention discloses a display screen calibration method, a display screen calibration system and a computer readable storage medium. The display screen calibration method comprises the steps of pre-storing calibration data corresponding to different temperatures; monitoring the temperature of a display screen in real time through a temperature sensor; acquiring the corresponding calibration data according to the temperature; and performing calibration on the display screen according to the calibration data. According to the invention, the LED display screen can be ensured to display uniformly at different temperatures, so that a problem that the LED display screen is increasingly severe in color cast along with the rise in temperature is improved, the white balance is kept to be accurate, the color is true to life, the image is accurately restored, the LED display screen is enabled to continuously keep the excellent display effect, and good visual appreciation effect of customers is ensured.

Owner:UNILUMIN GRP

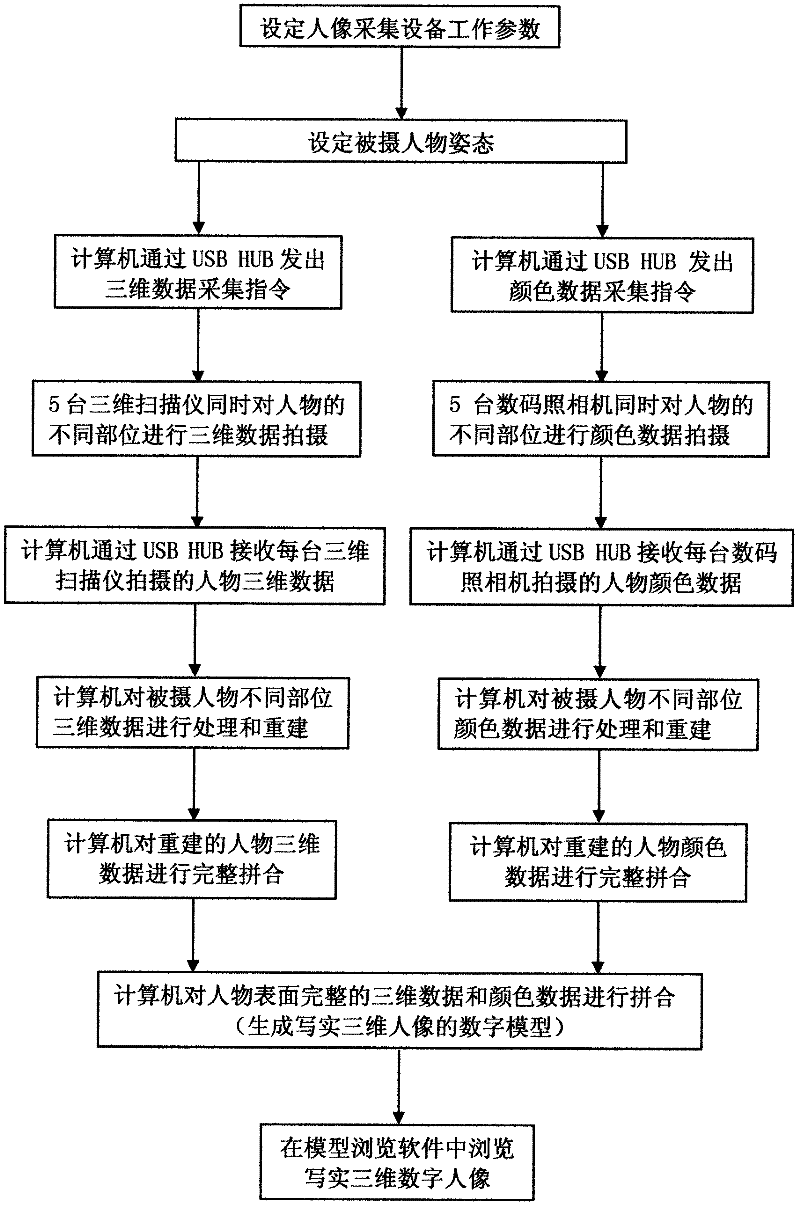

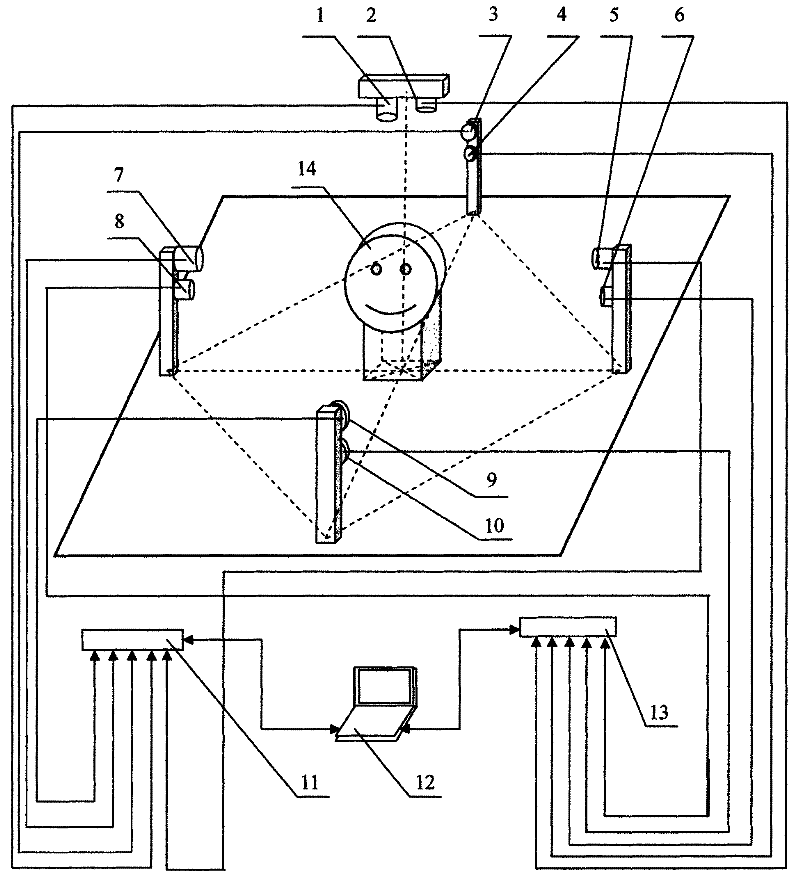

A realization method of realistic 3D digital portrait

InactiveCN102298789AShort acquisition timePortrait data is complete3D-image rendering3D modellingThree dimensional dataSoftware

The invention relates to a method for realizing a realistic three-dimensional digital portrait. In the method, multiple portrait data acquisition devices surrounding the subject are simultaneously photographed in all directions at multiple points and angles, and all three-dimensional data on the surface of the subject at a specific moment are captured at one time. and color data, process and reconstruct the captured 3D data and color data by computer to obtain the complete 3D model data and color data of the character, and finally combine the complete 3D model data and color data The spatial position and color information are accurately synthesized to generate a color digital model of a realistic 3D digital portrait, and the color digital model is imported into the model browsing software, and the realistic 3D digital portrait is rotated, zoomed in, and zoomed out.

Owner:DALIAN HENGYI INFORMATION TECH

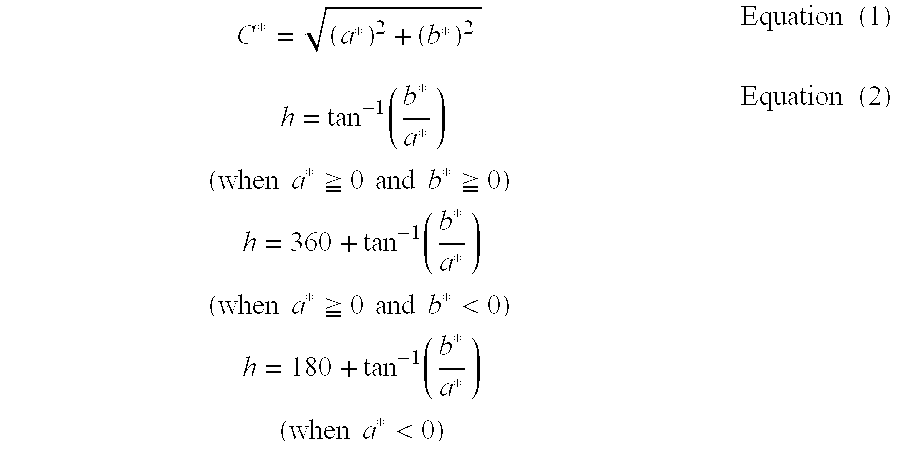

Water-based ink set for ink-jet recording and ink-jet recording method

InactiveUS20070046749A1Excellent gas resistanceGas resistance can be improvedMeasurement apparatus componentsDuplicating/marking methodsWater basedHigh density

A water-based ink set for ink-jet recording is provided which is capable of: reducing graininess in a low-density printed part in a cyan direction without reducing the color reproduction range in the cyan direction in a high-density printed part; extending the color reproduction range in a blue direction and / or a green direction; and improving gas resistance and the vividness in the blue direction and / or the green direction. The water-based ink set for ink-jet recording includes a cyan dye ink employing dye as a coloring agent and a blue pigment ink employing pigment as a coloring agent and / or a green pigment ink employing pigment as a coloring agent. The cyan dye ink is a light cyan dye ink having a lightness (L*) of about 60 or more in the L*a*b* colorimetric system.

Owner:BROTHER KOGYO KK

Display Panel and Apparatus Provided with the Same

ActiveUS20100053752A1Inhibit coloringImprove the decorative effectVisual indicationPolarising elementsEngineeringSolar cell

A display panel is provided with a solar cell, a light transmitting substrate arranged on a side of the solar cell to be seen, and a reflective polarizing plate. An uneven pattern is arranged on at least one surface of the reflective polarizing plate.

Owner:CITIZEN WATCH CO LTD

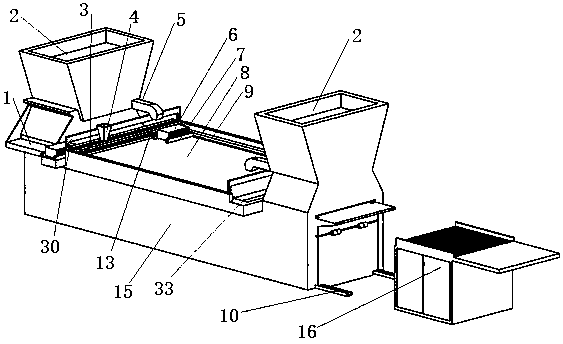

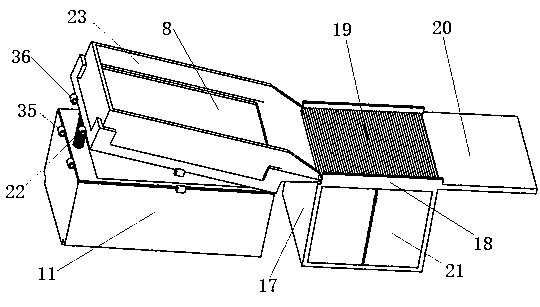

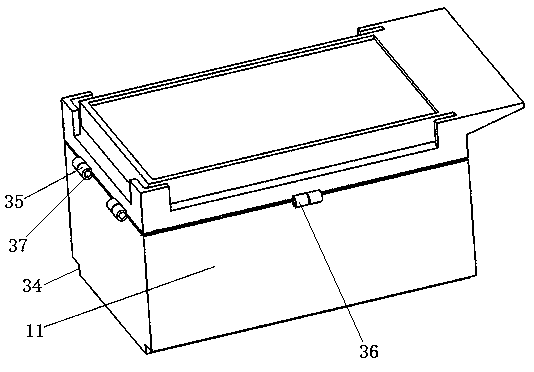

Rapid dual-way material paving full-color 3D printing machine

PendingCN109176824AShort pauseShorten the timeAdditive manufacturing apparatusCeramic shaping apparatus3d printerFull color

The invention discloses a rapid dual-way material paving full-color 3D printing machine. The rapid dual-way material paving full-color 3D printing machine comprises a shell, a control platform and a material paving mechanism; printing assemblies are arranged on the two sides of the material paving mechanism, and adopt photocuring full-color inkjet print heads, UV photocuring lamp tubes are arranged on the two sides of the bottoms of the photocuring full-color inkjet print heads, material boxes are arranged on the two ends of the shell, quantitative discharging devices are arranged at the lowerends of the material boxes, a forming cylinder body is arranged in the shell, the forming cylinder body can slide along guide rails on the two sides of the bottom in the shell, a forming cylinder upper rend powder bed is arranged on the top of the forming cylinder body, a discharging opening is formed in one end of the shell, and a sand removal device is arranged on the outer side of the discharging opening. Dual-way material paving of a material paving mechanism is achieved, in the back and forth process of the material paving mechanism, the dwell time is short, the work efficiency is greatly improved, sand removal and material taking are integrated, the automation degree is high, manpower and time are greatly saved, the sand removal efficiency is improved, the raw material use rate is high, and cost is greatly saved.

Owner:甘肃顺域新材料科技有限公司 +2

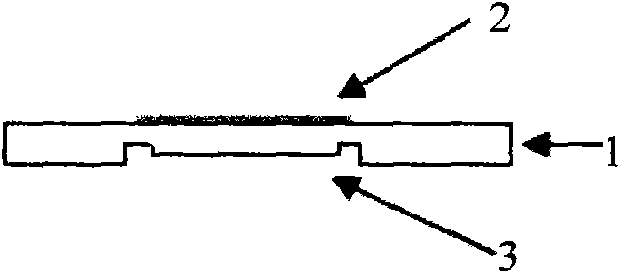

Plastic decorative sheet material and preparation method thereof and special wale hot-pressing roller

ActiveCN102101411AAccurateReduce alignment errorsSpecial ornamental structuresOther printing apparatusColor printingEngineering

The invention relates to a plastic decorative sheet material and a preparation method thereof, and a special wale hot-pressing roller. The sheet material is characterized in that the substrate is a transparent plastic sheet, wherein a color printing pattern is printed on the right side of the sheet; an accidented embossing pattern is hot-pressed on the reverse side with a line profile corresponding to the printing pattern on the right side; and the printing pattern and the embossing pattern at a corresponding position are offset by less than 1 mm. Because of the special light refraction effect of the accidented embossing on the color printing pattern, the plastic decorative sheet material has a vivid color and a strong stereo perception, exhibits a more beautiful visual effect than common planar printed plastic decorative sheet materials and common embossing plastic decorative sheet materials, and is especially suitable to manufacture daily-use decorative products such as tablecloth, dinner pad, table pad, etc.

Owner:DONGGUAN IUIU HOUSEHOLD PROD

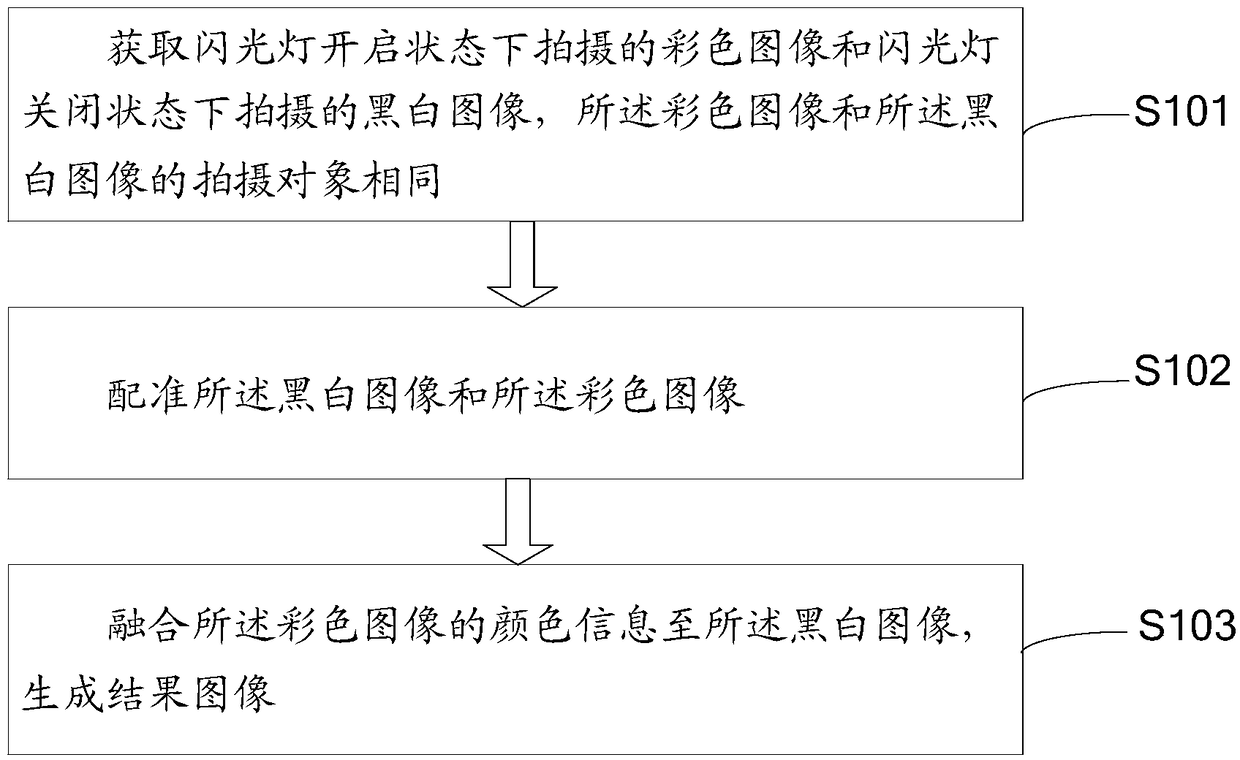

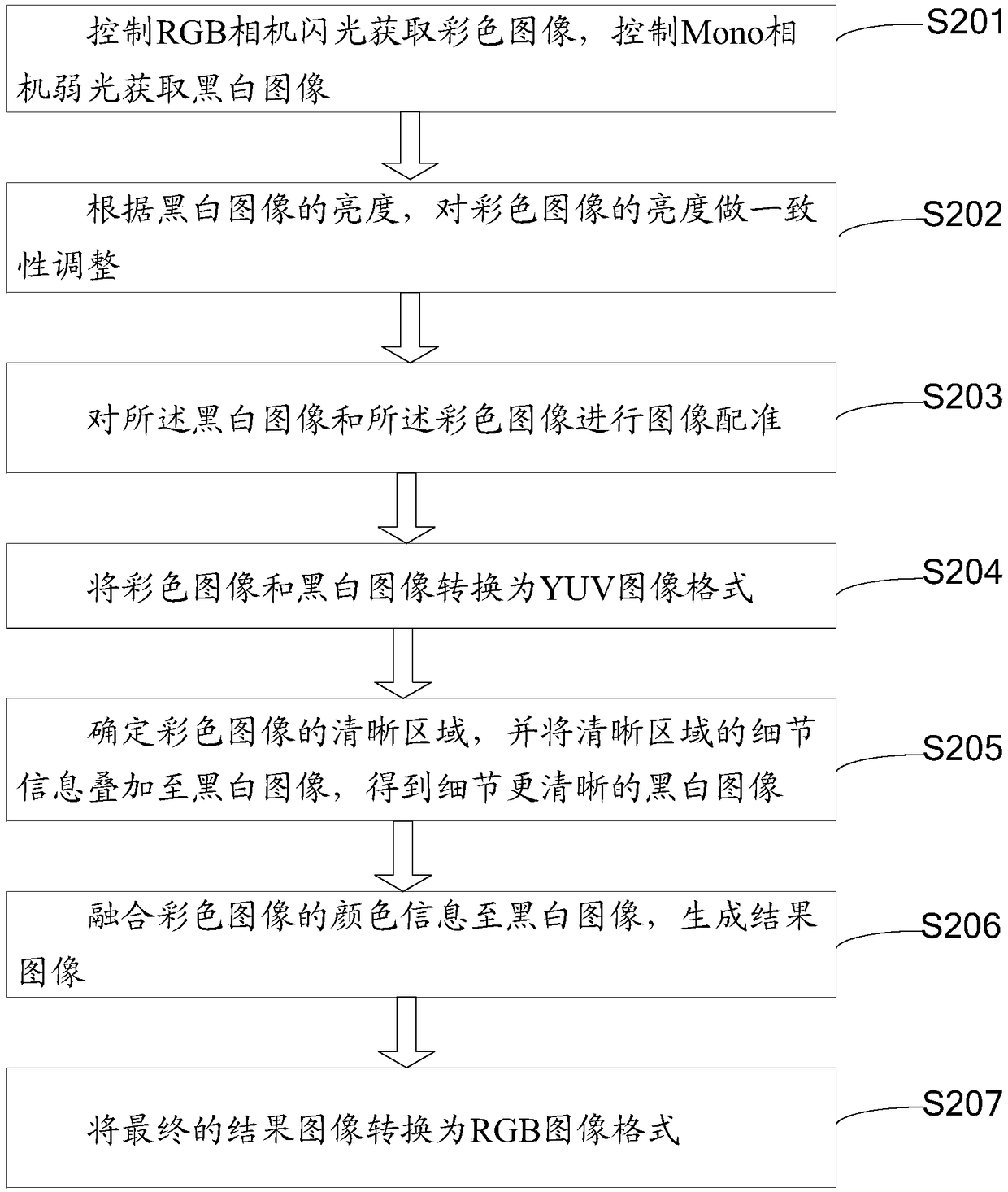

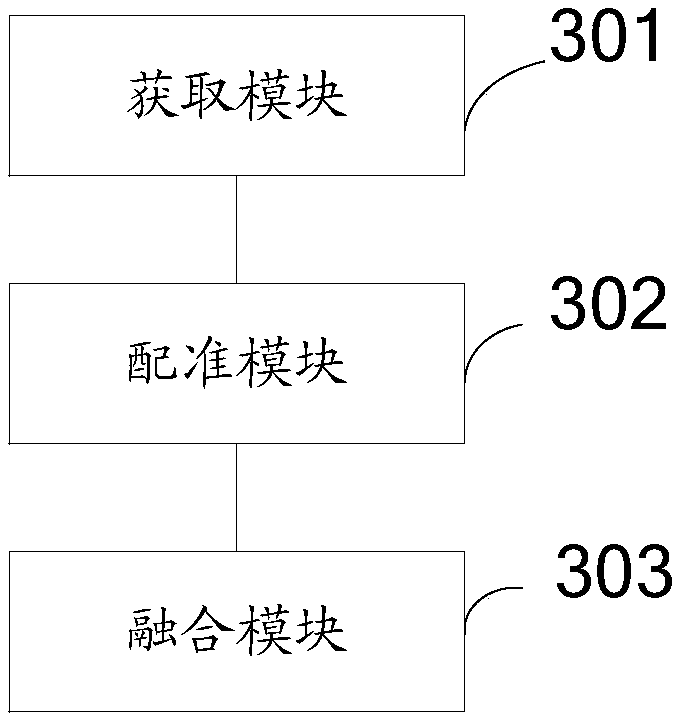

Image fusion method and device, electronic equipment and medium

ActiveCN108717691AAvoid overexposureVivid colorsImage enhancementImage analysisColor imagePoor Quality Image

The invention discloses an image fusion method and device, electronic equipment and a medium. The method comprises the steps of obtaining a color image photographed in a flash lamp turn-on state and ablack and white image photographed in a flash lamp turn-off state, wherein a photographing object of the color image is the same as the photographing object of the black and white image; carrying outregistration on the black and white image and the color image; and fusing color information of the color image to the black and white image, and generating a result image. According to the method, the device, the electronic equipment and the medium provided by the invention, the problem that in the prior art, the image quality is low due to the fact that an image generated through fusion of double cameras: a color camera and a black and white camera is limited by the color image is solved, and the technical effect of improving the image quality is improved.

Owner:CHENGDU CK TECH

Production technology for 3D high-definition printing UV interior wall decorative sheet

ActiveCN105544910AThree-dimensional product patternVivid colorsCovering/liningsSpecial ornamental structuresSmooth surfaceHigh definition

The invention relates to a production technology for 3D high-definition printing UV interior wall decorative sheets, and belongs to the field of decorative sheet processing. The technology comprises: sanding and dedusting a calcium silicate board; pre-heating; coating anti-seepage paint in a rolling manner; coating on the back; coating putty, base coat, glue, and colored paint in a rolling manner; performing 3D scanning on overcoating patterns; performing 3D printing; performing smooth surface processing; performing UV photocuring; and laminating films and packaging. The UV interior wall decorative sheet is stereo in patterns, lifelike in colors, and high in surface flatness, and is good in waterproofness, resistant in scraping, simple in manufacturing process, wide in material selection range, low in cost, and fast in forming speed.

Owner:WUXI JIEYANG ENERGY SAVING TECH

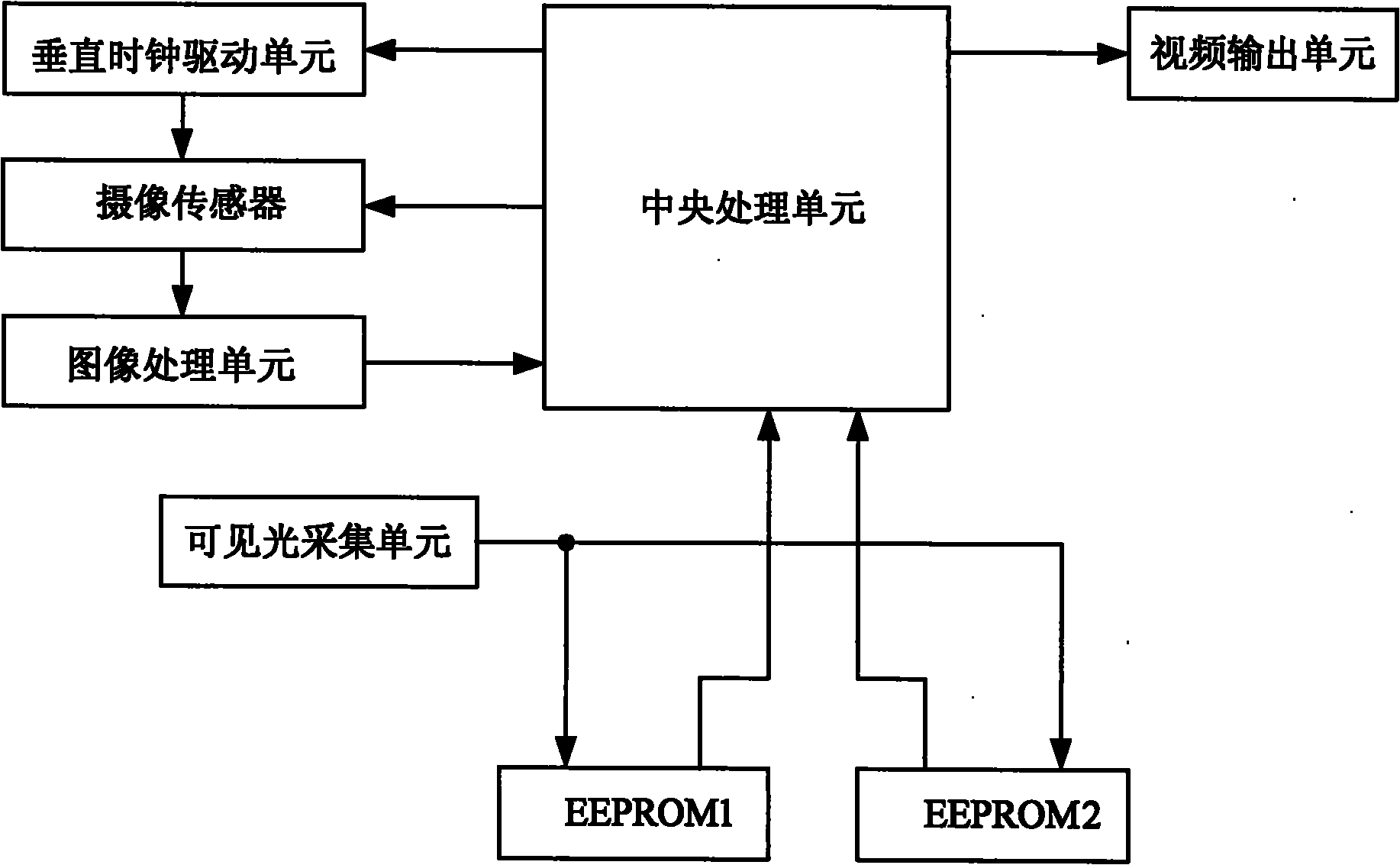

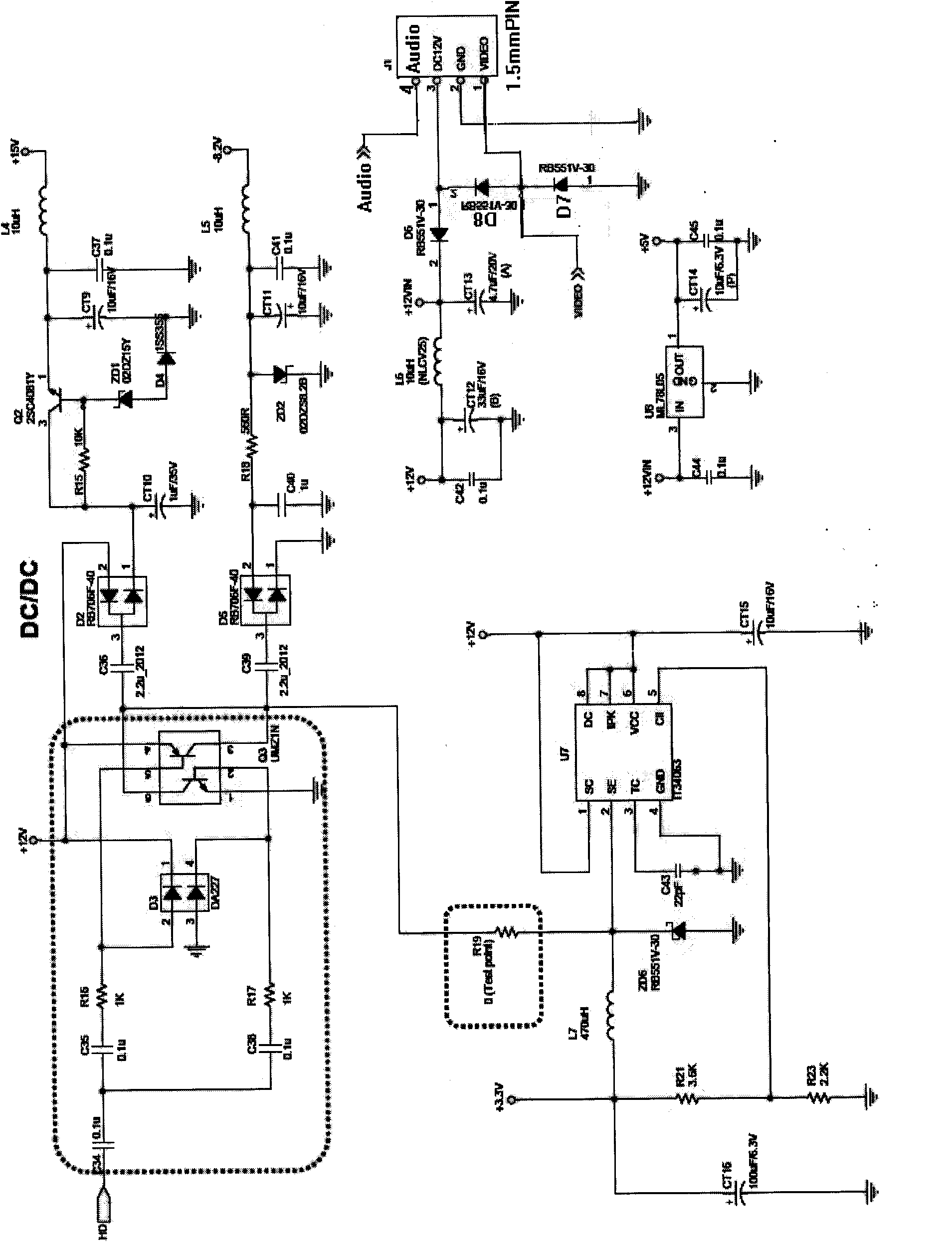

Day and night high-definition and dual-mode camera and image processing method thereof

InactiveCN102137224AVivid colorsTelevision system detailsColor television detailsInfraredColor image

The invention provides a novel day and night high-definition and dual-mode camera and an image processing method thereof. The principle that an image sensor can sense both visible light and infrared is utilized. Different image effect adjustment procedures under different light intensities in a central processing unit are stored in different storage units respectively. A visible light acquisition unit acquires the external visible light, and then the central processing unit is connected to the different storage units according to the intensity of the visible light, i.e., different image effect adjustment-procedures are called, and then the image signals acquired by the image sensor are processed differently, i.e., color image shooting is performed in the daytime and infrared shooting is performed at night, and the acquired video signals are adjusted to be in a black and white state so that more clear and bright images can be obtained no matter in the night or daytime.

Owner:SHENZHEN HUASHI LIANFA ELECTRONICS TECH

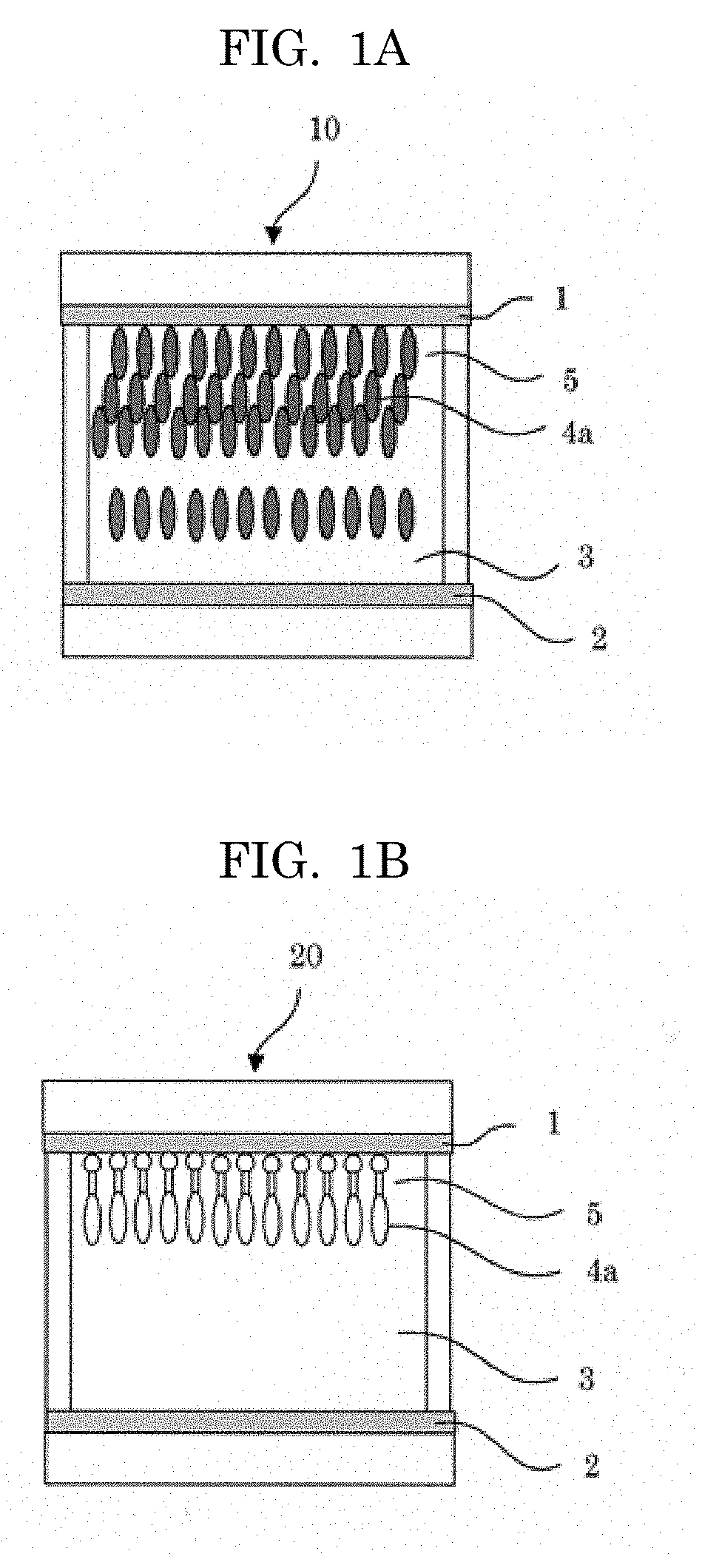

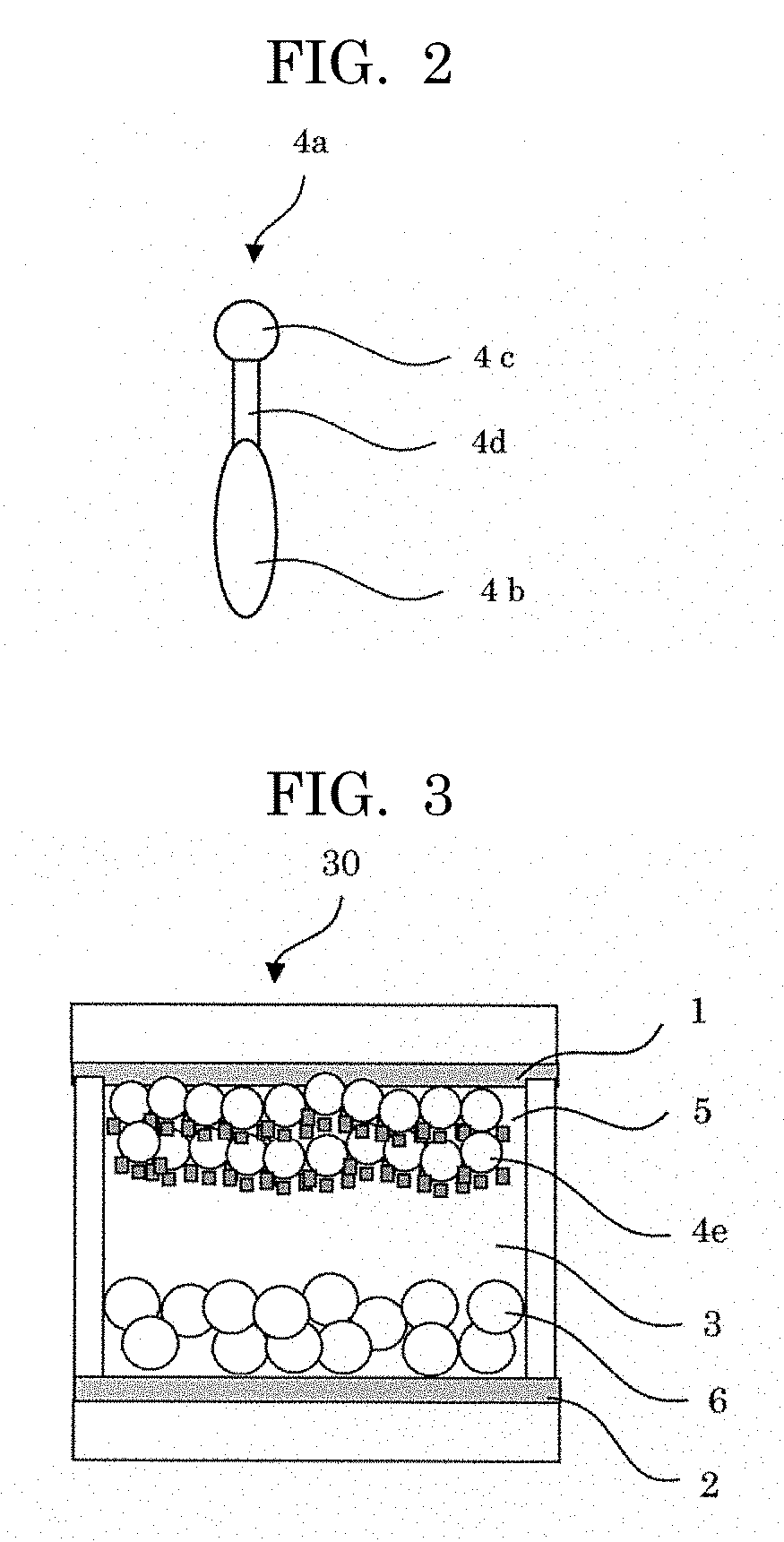

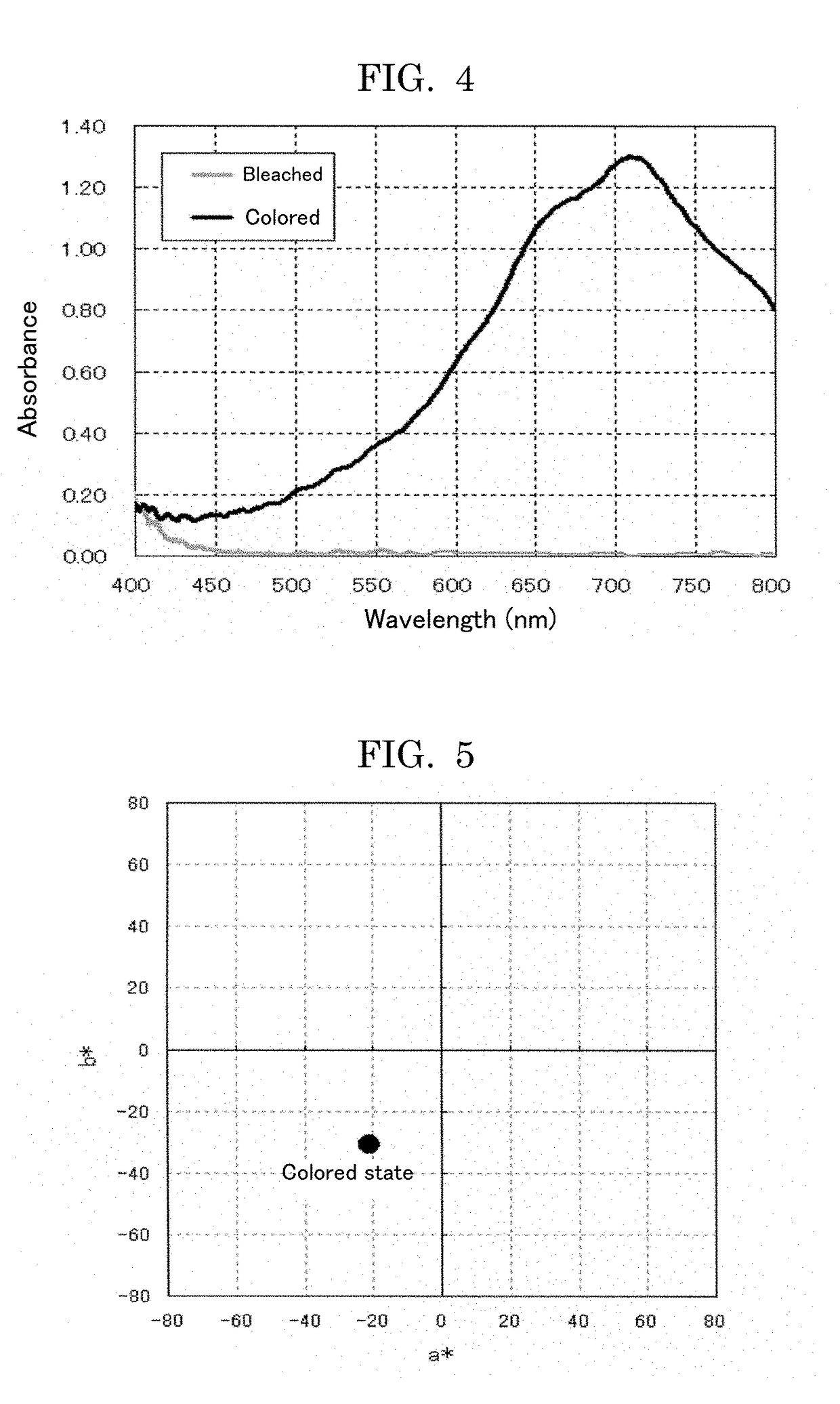

Electrochromic compound, electrochromic composition, and display element

ActiveUS20190031694A1Sharp light absorption spectrum characteristicLess remained colorSilicon organic compoundsConductive materialCrystallographyHydrogen atom

To provide an electrochromic compound, represented by the following general formulawhere X1, X2, X3, X4, X5, X6, X7 and X8 are each independently a hydrogen atom or a monovalent substituent; R1 and R2 are each independently a monovalent substituent; A− and B− are each independently a monovalent anion; and Y is represented by the following general formula (II) or (III):where X9, X10, X11, X12, X13, X14, X15, X16, X17, and X18 are each independently a hydrogen atom or a monovalent substituent.

Owner:RICOH KK

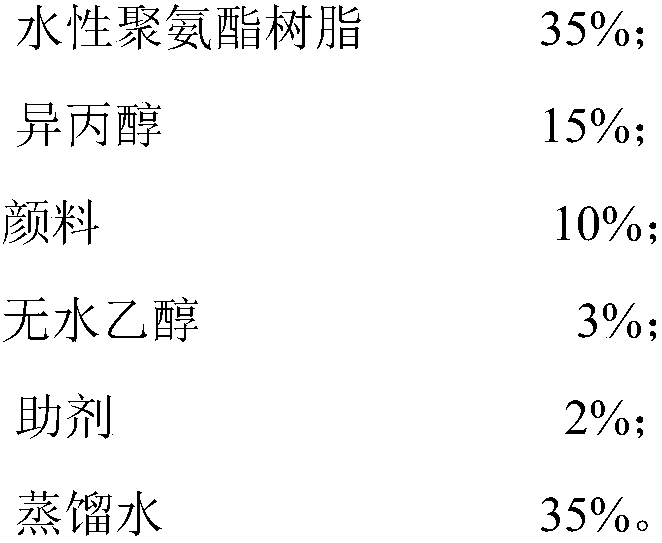

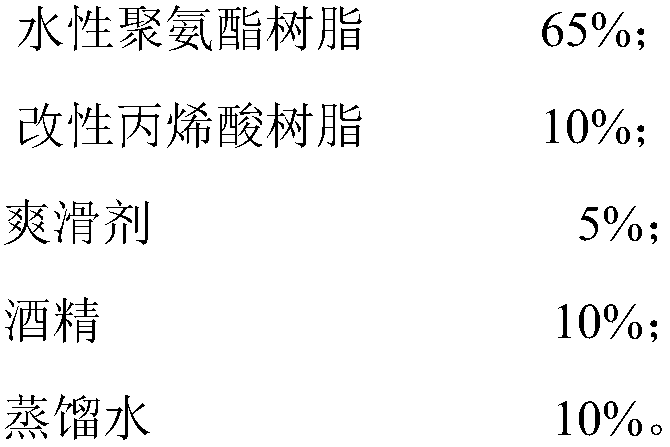

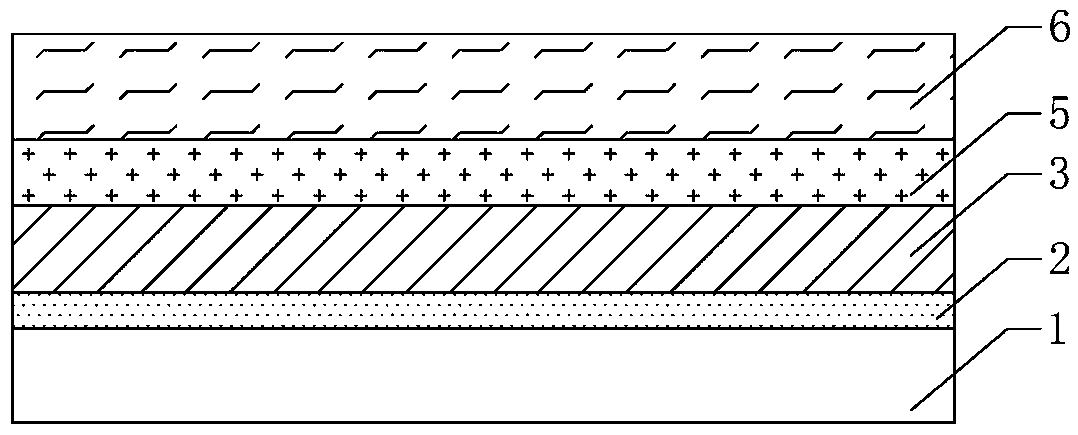

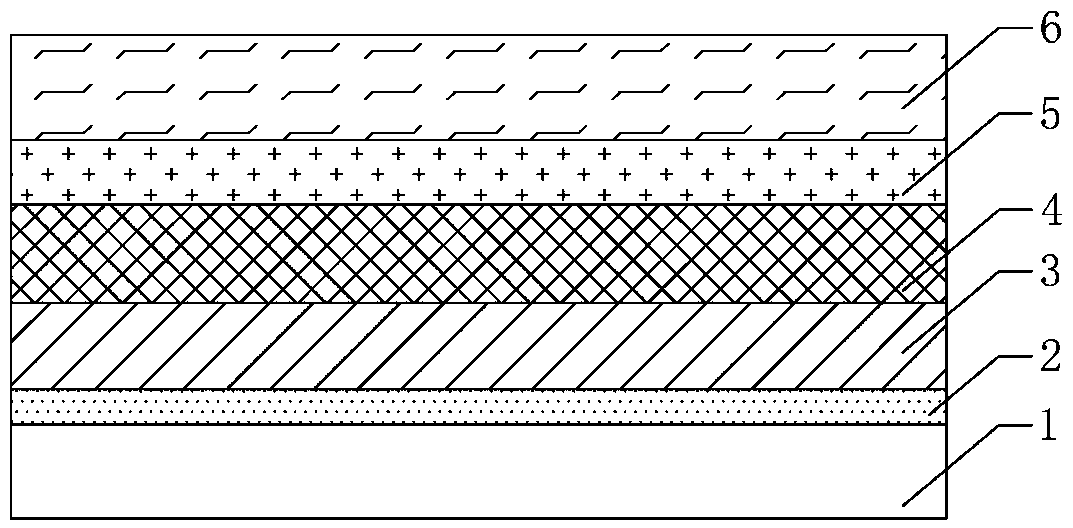

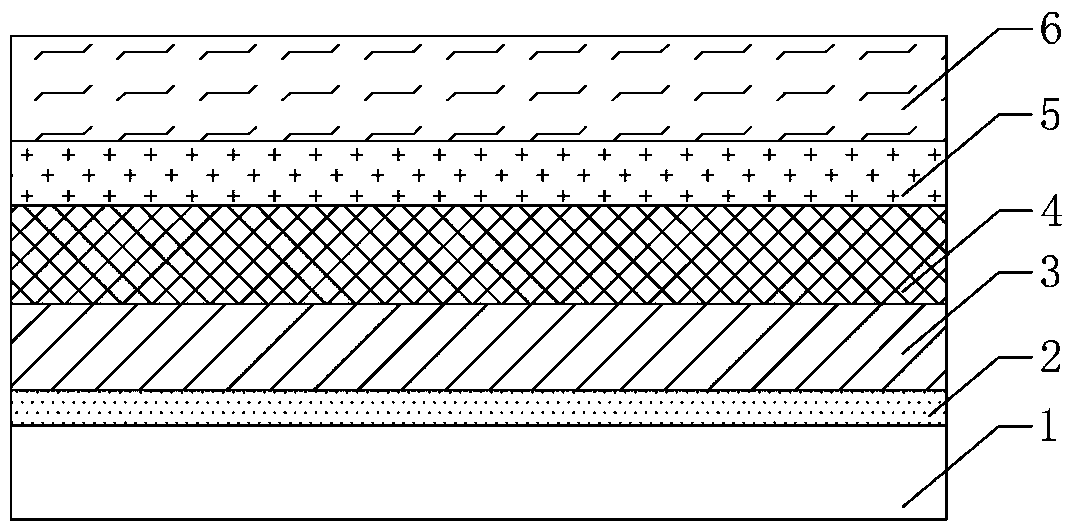

Environment-friendly decorative paper and preparing method thereof

The invention discloses environment-friendly decorative paper. The environment-friendly decorative paper comprises an environment-friendly substrate layer, a substrate function layer, a water-based ink decorative layer and a water-based protective layer from bottom to top in sequence. The environment-friendly decorative paper is poisonless and tasteless, can replace a traditional PVC decorative material to be applied to planar compounding, edge covering and covering and plasticizing of various irregular profiles and shapes and also has superior comprehensive performance. The invention furtherdiscloses a preparing method of the environment-friendly decorative paper. The environment-friendly decorative paper is low in raw material cost, the preparing process is high in controllability, andthe environment-friendly decorative paper is also environmentally friendly and poisonless and applicable to large-scale industrialized production.

Owner:GUANGDONG T&H NEW MATERIALS CO LTD

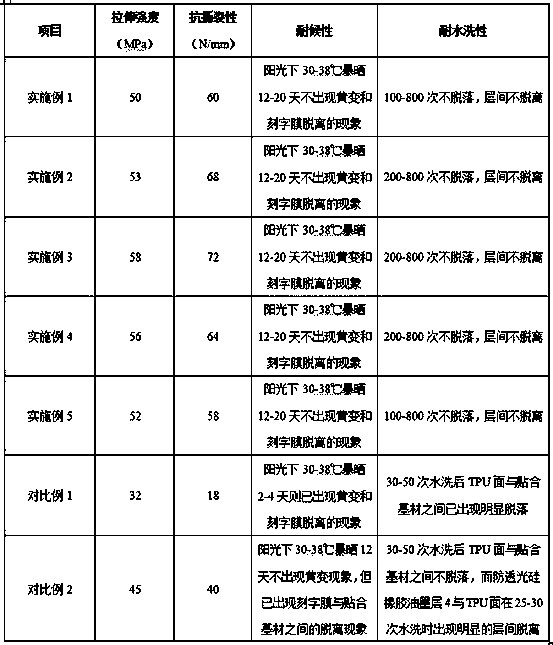

High elasticity silicone rubber heat transfer film and preparation method thereof

ActiveCN108690515AImprove water resistanceImprove processing efficiencyNon-macromolecular adhesive additivesFilm/foil adhesivesPolymer scienceSurface layer

The invention relates to the technical field of heat transfer films, and specifically relates to a high elasticity silicone rubber heat transfer film and a preparation method thereof. The high elasticity silicone rubber heat transfer film comprises following components from bottom to top: a bearing base material, a release layer, a silicone rubber surface layer, an interface bonding agent layer, and a TPU hot melt adhesive membrane; wherein the interface bonding agent layer is prepared an interface bonding agent, which comprises two resin components. The provided heat transfer film has the advantages of silicone rubber and TPU, such as excellent elasticity, high tearing resistant strength, weatherability, yellowing resistance, washing resistance, and the like. Layering is difficult to happen. Even if the heat transfer film is exposed under the sun, color change or fading is difficult to happen. The water washing fading rate is not more than 0.5%. When the color transfer film is washedwith materials with other colors, other materials will not be dyed easily. The stability is high. The heat transfer film can be easily adhered on multiple materials, the bonding strength is strong, the heat transfer film is not easy to peel off, the stability is good, the hand feeling is fine, the appearance is good, and the service life is long.

Owner:卢汉军

Method for manufacturing home decoration stickers

InactiveCN101537762AVivid colorsAvoid it happening againSpecial ornamental structuresDwelling equipmentUltravioletPrinting ink

The invention provides a method for manufacturing home decoration stickers, which comprises two main steps of coating the back of a base material with light-adhesive static pressure-sensitive adhesive and adopting silk-leaking printing for the surface printing of the base material. The step of adopting silk-leaking printing for the surface printing of the base material is divided into the following: a step of manufacturing a silk-leaking plate, which is to adopt Japanese Sefar silk net and Italian Saati silk net with 40 to 420 meshes and adopt German KIWO photosensitive adhesive; a step of coating a silk net with the photosensitive adhesive, which is to coat the front and back of the silk net three times respectively and expose the silk net coated with the photosensitive adhesive for 55 seconds; a step of printing the base material, which is to adopt luminescent ink and colorless transparent printing ink in the proportion of 40 percent to uniformly print, print four-color pasty printing ink on 460-mesh silk net, use a four-color plate to print respectively and then adopt two 3000 ultraviolet lamps for irradiation; and a step of cutting-shaping, which is to emboss and shape patterns. The home decoration stickers have the advantages of no glue on sticking surfaces, no marks left after the stickers are taken off, double-side effect, reusability, vivid color and stereoscopic impression.

Owner:TIANJIN JIUSHUN PRINTING

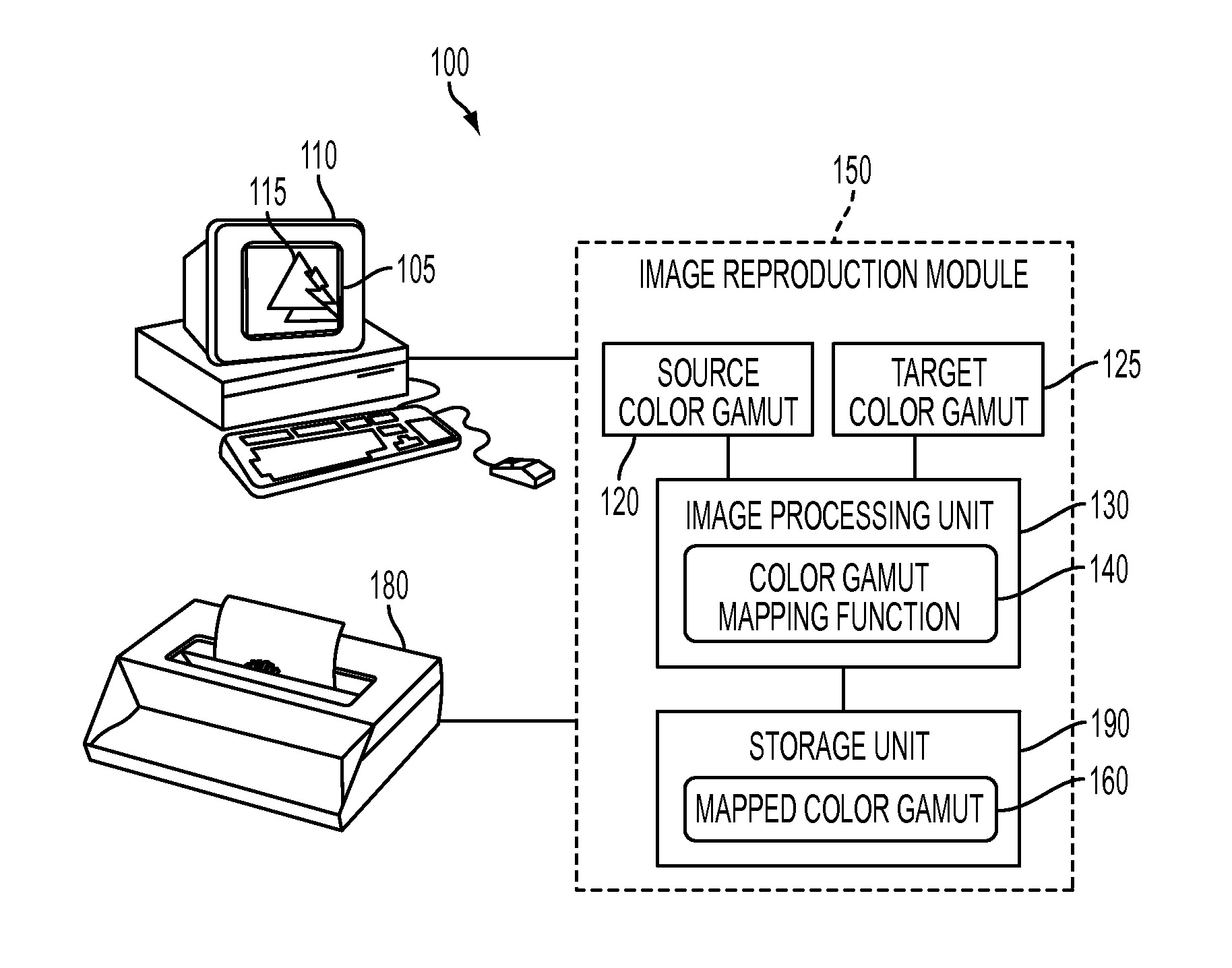

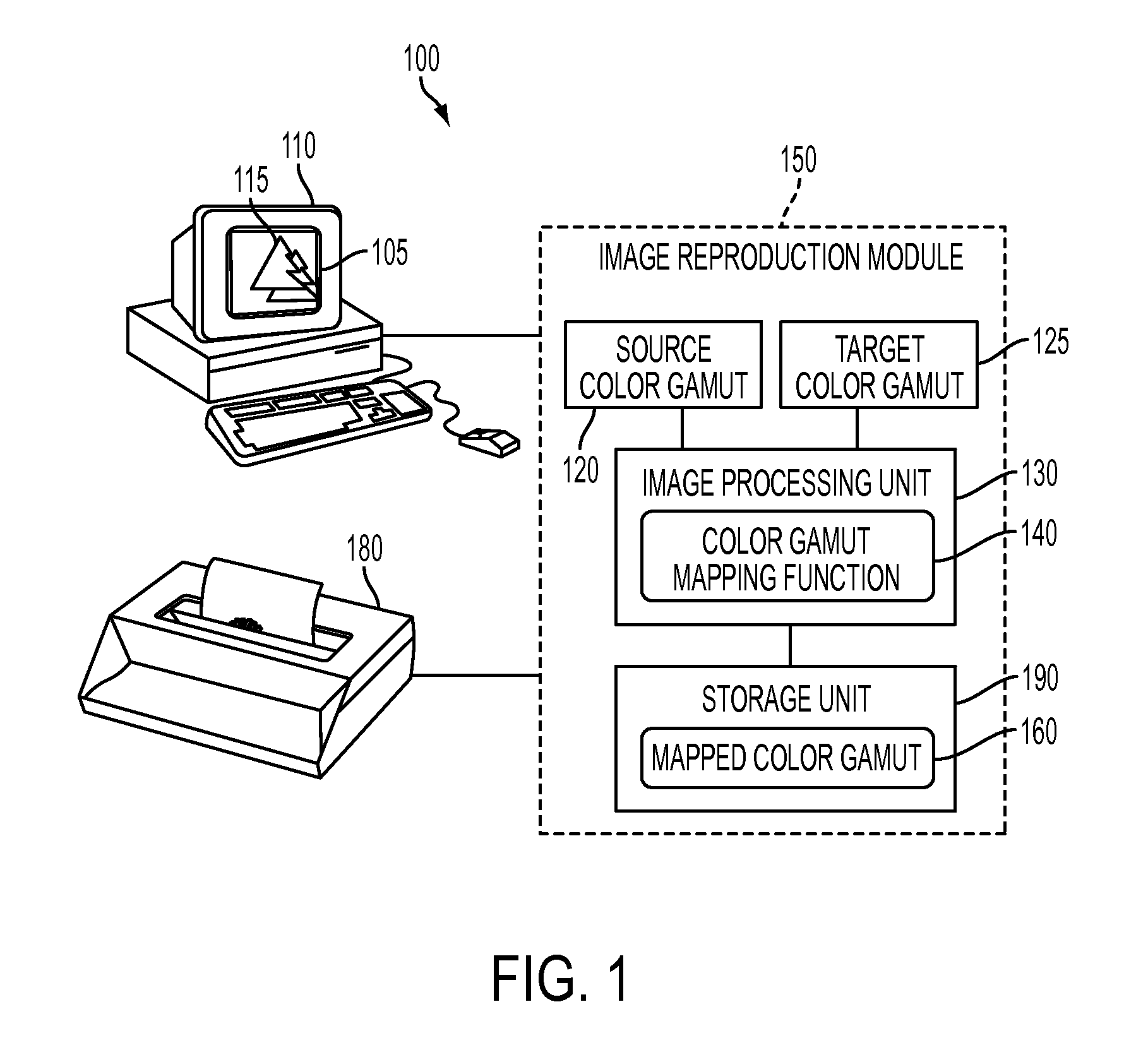

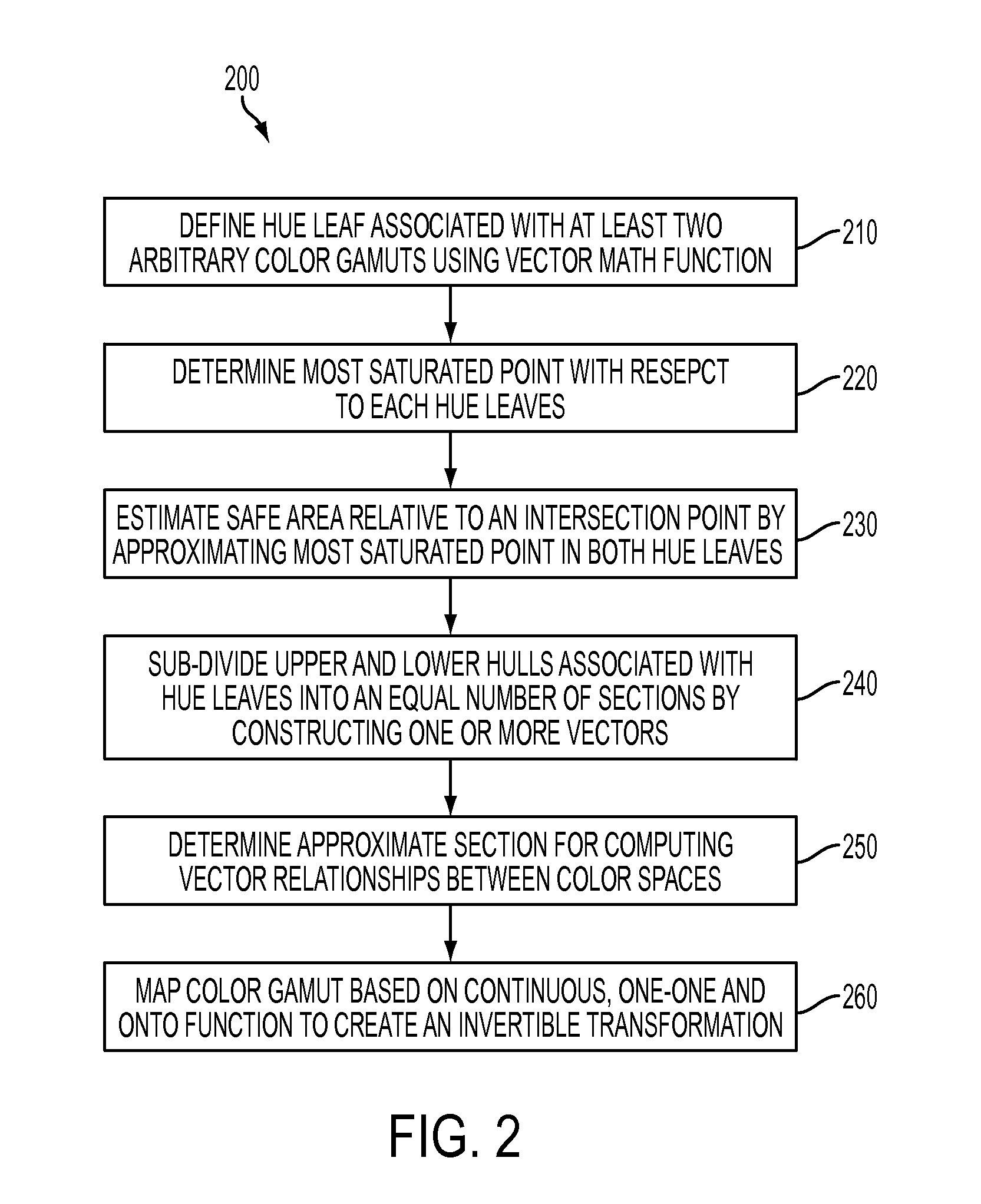

Method and system for partitioning and mapping color gamuts based on one-one and onto mapping function

InactiveUS20120007877A1Preserve hue angle, saturation, and lightnessPreserving hueDigitally marking record carriersDigital computer detailsGamutHue

A method and system for mapping color gamuts based on one-one and onto mapping function in order to create an invertible transform is disclosed. A hue leaf associated with at least two arbitrary color gamuts can be defined utilizing a vector math function and a most saturated point with respect to each hue leaves can be determined. A safe area relative to an intersection point can be estimated by approximating the most saturated point in both hue leaves. An upper hull and a lower hull associated with the hue leaves can be continuously sub-divided with an equal number of sections by constructing one or more vectors. An appropriate section for computing a vector relationship in the color gamut can be determined in order to map the color gamuts based on the continuous, one-one and onto function thereby creating an invertible transformation.

Owner:XEROX CORP

FDM type 3D printing spraying nozzle and FDM type 3D printing method capable of achieving gradual color changing

InactiveCN106541576AAchieve full color printingRealize full color 3D printing3D object support structuresApplying layer meansSpray nozzleEngineering

The present invention discloses a FDM type 3D printing spraying nozzle capable of achieving gradual color changing. The FDM type 3D printing spraying nozzle comprises a mixing melting chamber, wherein a spraying nozzle is arranged on the lower end of the mixing melting chamber, the upper end of the mixing melting chamber is provided with a raw material inlet and is further uniformly provided with a plurality of colored color master batch wire inlets for communicating the cavity of the mixing melting chamber at intervals, an extrusion screw rod for extruding a material from the spraying nozzle is arranged in the mixing melting chamber, and the upper end of the extrusion screw rod is provided with a connection device for connecting a screw rod motor. The invention further discloses a FDM type 3D printing method capable of achieving gradual color changing. According to the present invention, with the printing method, the real full-color printing can be achieved, wherein the free color matching for the model can be achieved by matching the position information and the color information and timely melting the color master batches according to the ratio, the advantages of one-time molding, simple structure, convenient operation and color fidelity are provided, and the real full-color 3D printing can be achieved.

Owner:SOUTH CHINA UNIV OF TECH

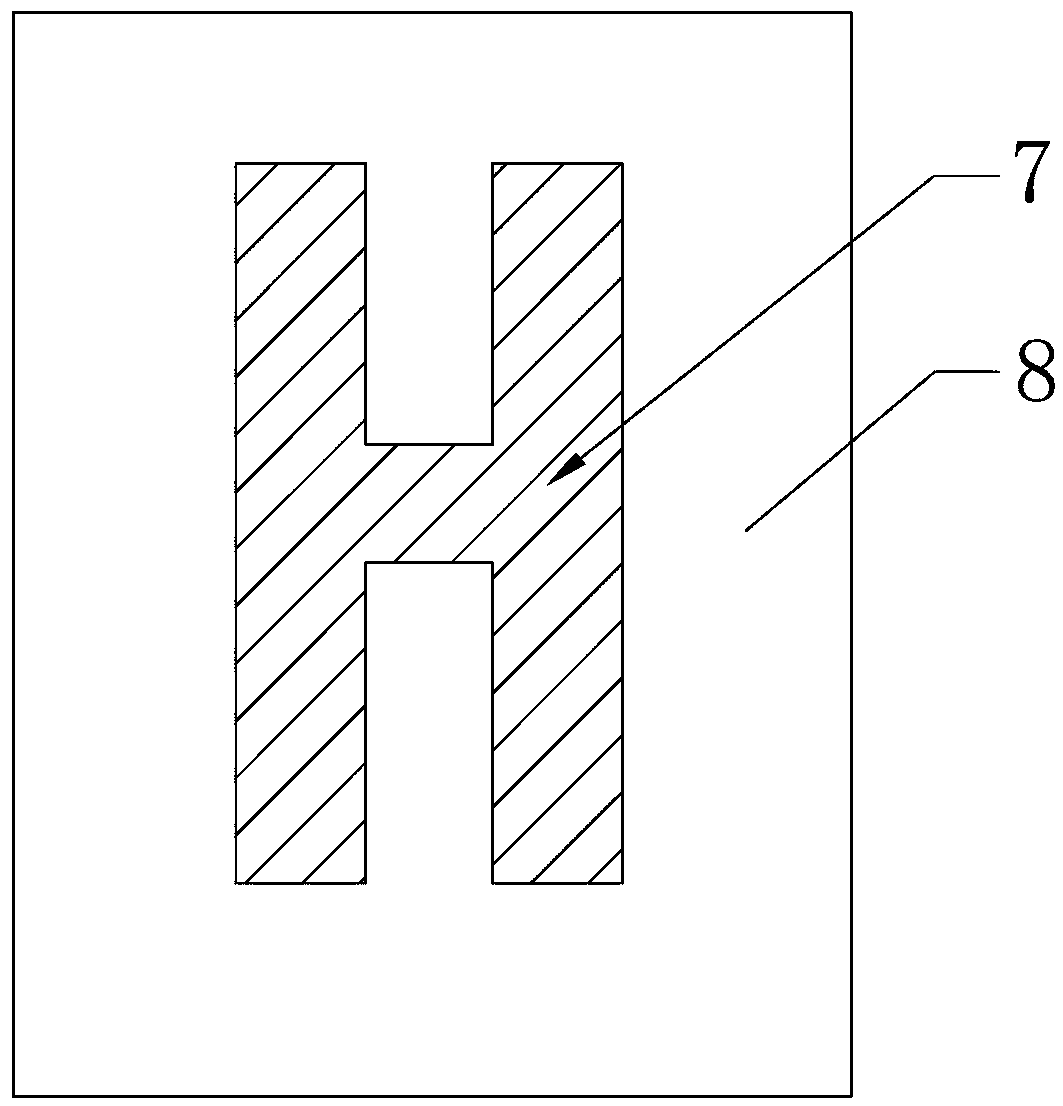

High-elasticity silicone rubber lettering film and preparation method and application method thereof

ActiveCN108610997AIncrease elasticityAvoid deformationPolyureas/polyurethane adhesivesInksRubber materialPolymer science

The invention relates to the technical field of thermal transfer printing lettering film, and in particular, relates to a high-elasticity silicone rubber lettering film and a preparation method and anapplication method thereof. The high-elasticity silicone rubber lettering film comprises a load-bearing substrate, a release layer, a surface layer silicone rubber ink layer, an anti-photopermeable silicone rubber ink layer, an adhesive interfacial agent layer and a TPU hot melt adhesive film which are connected from bottom to top successively; the adhesive interfacial agent layer is prepared from an adhesive interfacial agent, and the adhesive interfacial agent is an adhesive interfacial agent containing dual-resin components. The silicone rubber lettering film has the advantages of both thesilicone rubber material and the TPU material, has good elasticity, tearing strength, weatherability, yellowing resistance, water washing resistance and other comprehensive properties, has layers noteasy to separate, is not easy to discolor or fade by sunlight exposure, and has the water-washing fading rate not less than 0.5%, is not easy to dye when being mixed and washed with materials with other colors, and is high in stability, easy to bond with a variety of materials, high in bonding strength, not easy to peel off, good in stability, delicate in hand feeling, good in aesthetic degree, and long in service life.

Owner:卢汉军

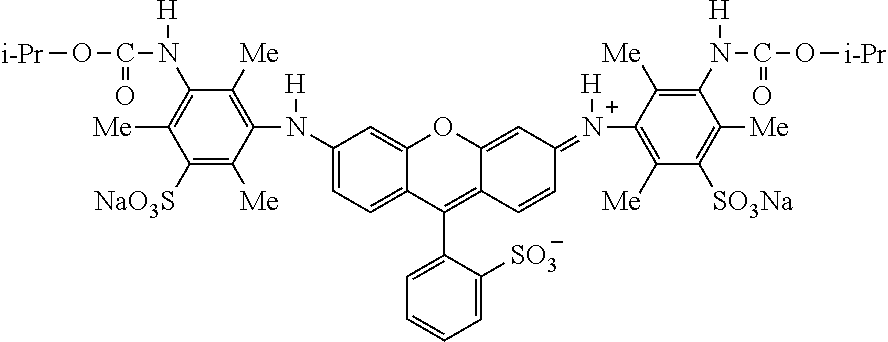

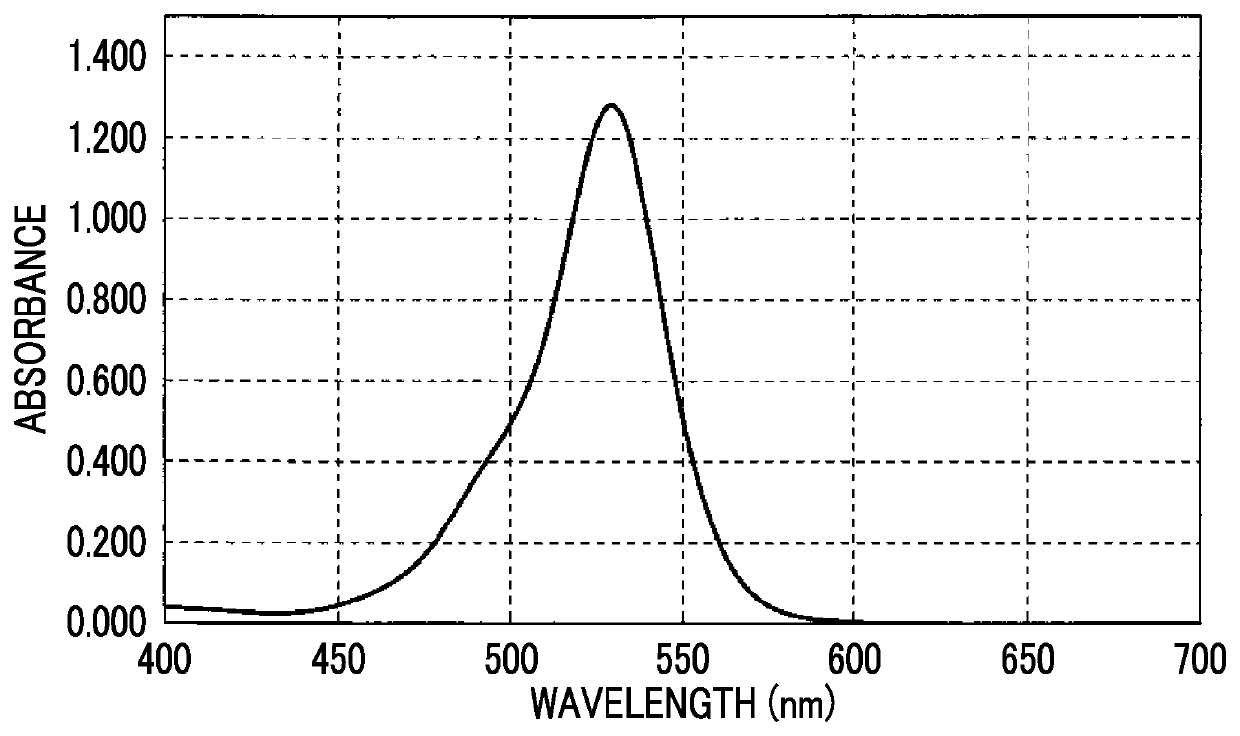

Coloring composition for dyeing or textile printing, ink for ink jet textile printing, method of printing on fabric, and dyed or printed fabric

InactiveUS20170101534A1Good colorHigh color optical densityInksDyeing processTextile printerPolymer science

Provided are a coloring composition for dyeing or textile printing including a compound having the following structure, an ink for ink jet textile printing including the above-described coloring composition for dyeing or textile printing, a method of printing on fabric, and a dyed or printed fabric. As a result, the color is excellent, the color optical density is high, the fixing properties are excellent, bleeding is reduced, and light fastness is excellent.

Owner:FUJIFILM CORP

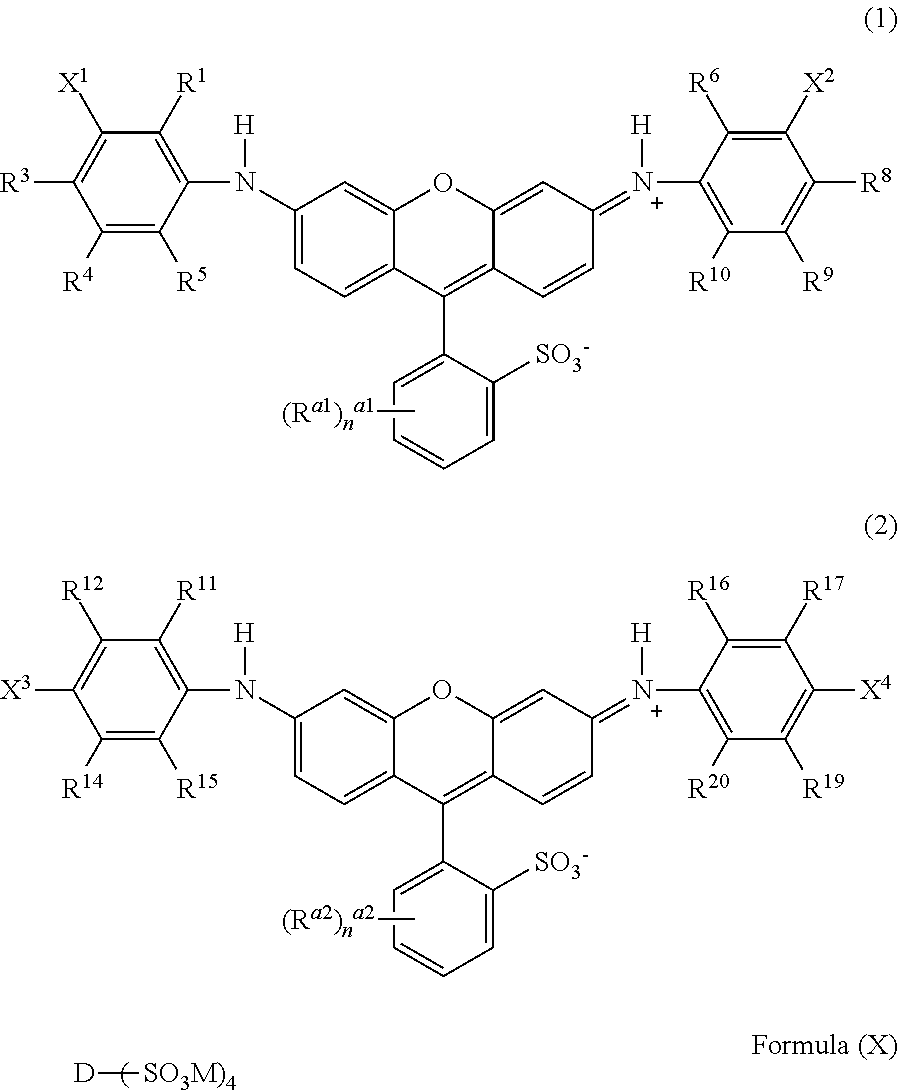

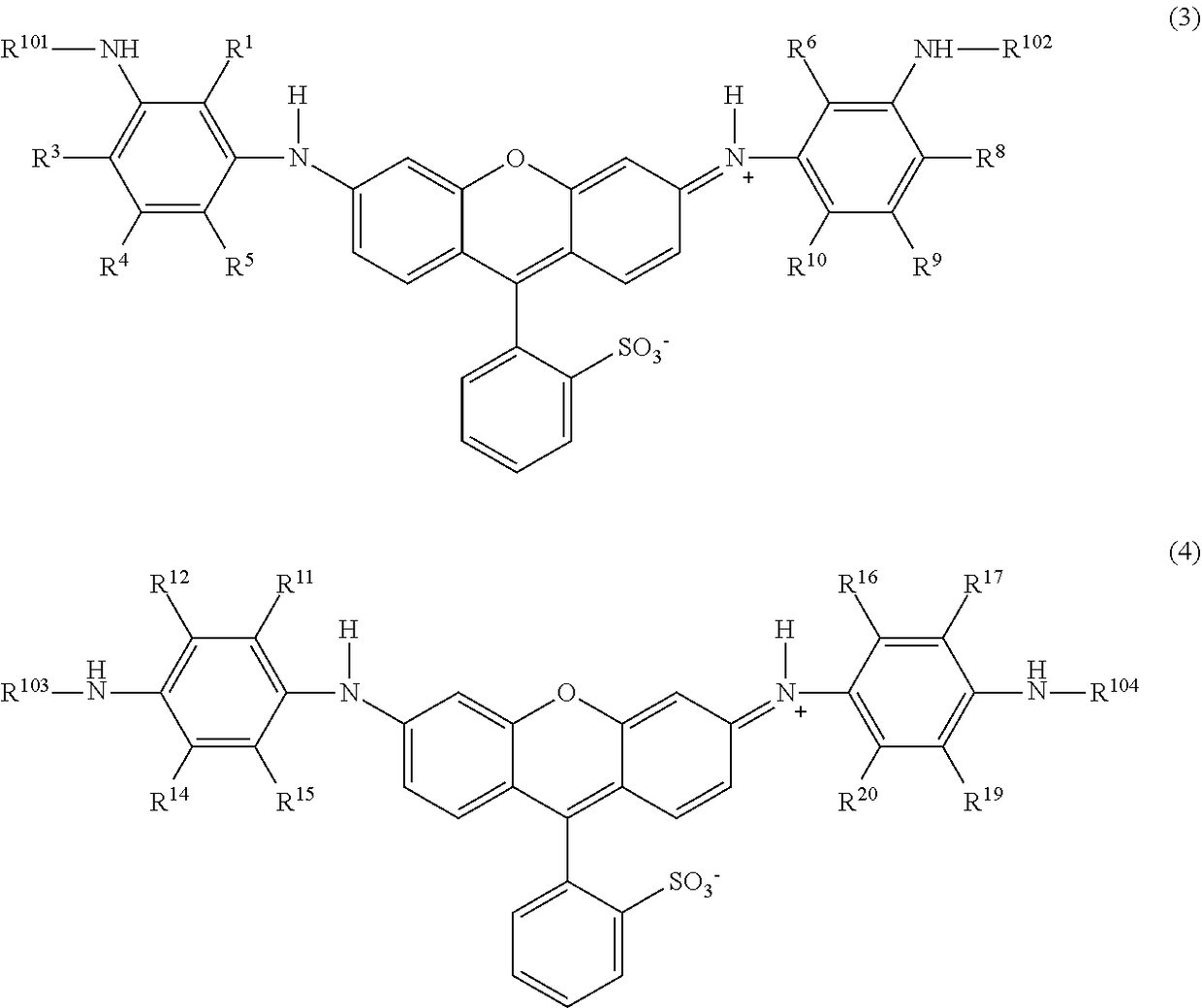

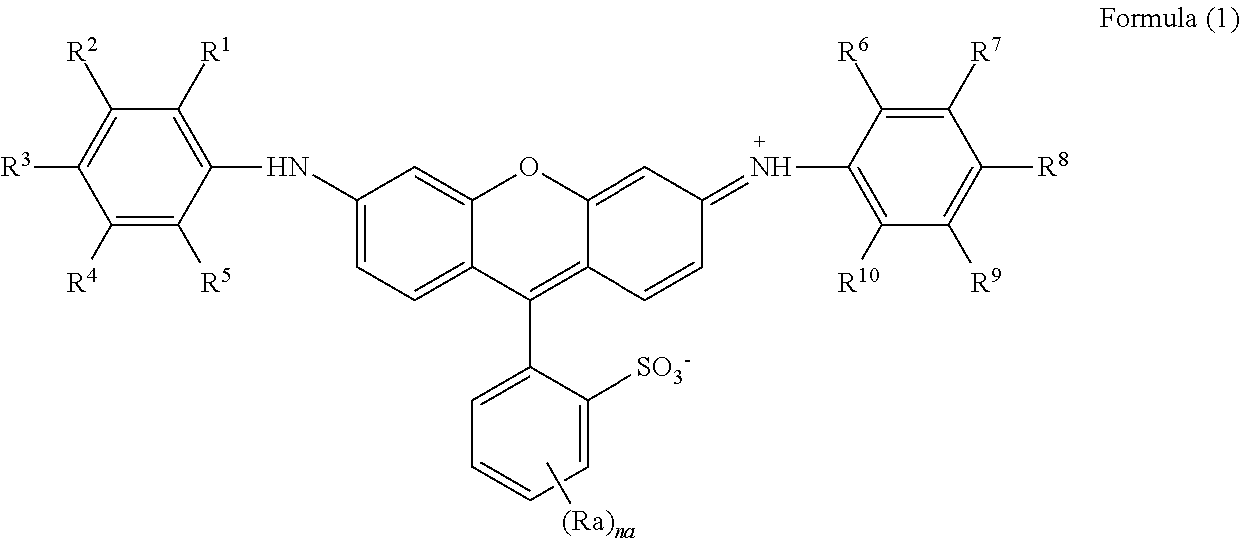

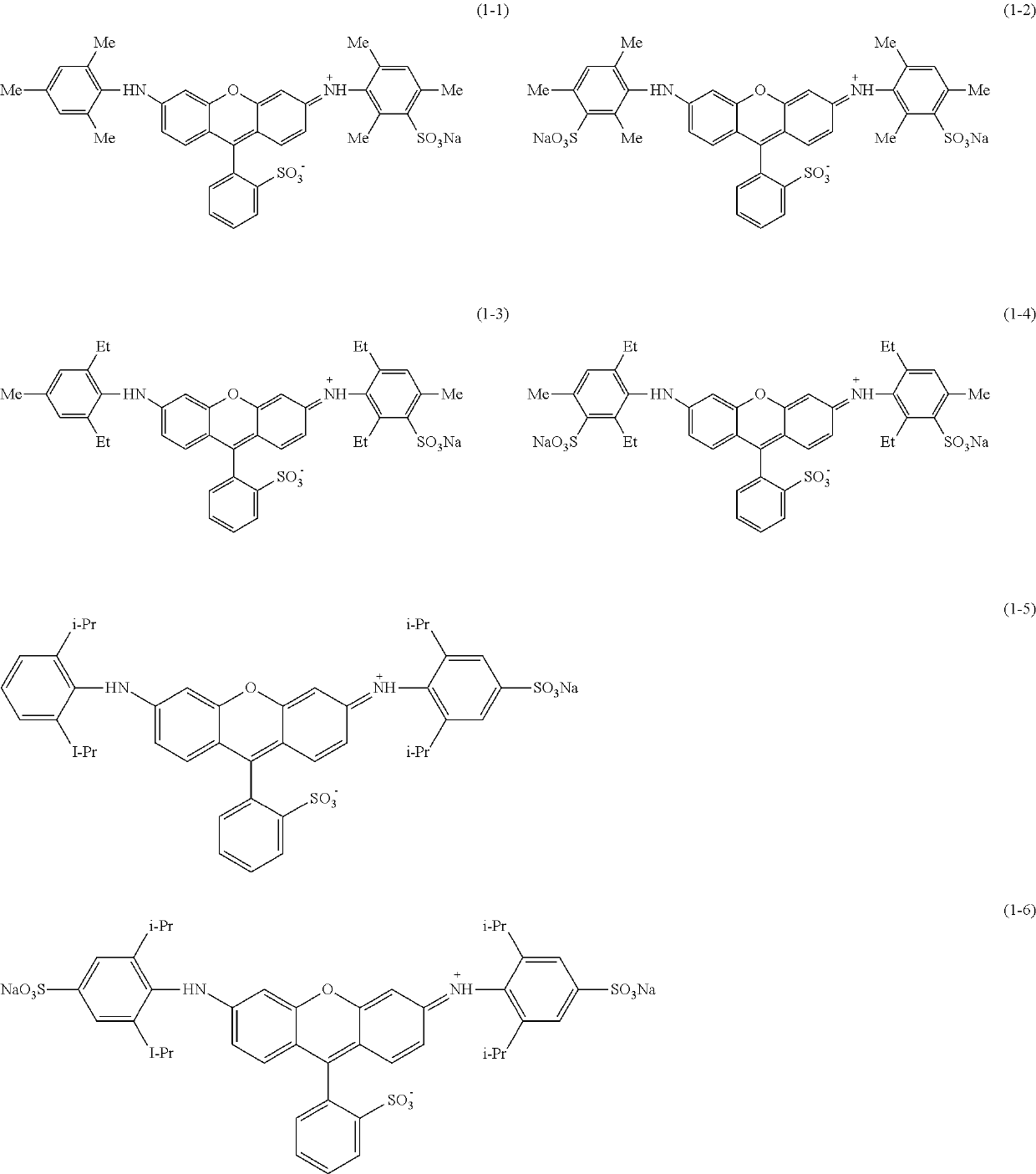

Coloring composition for textile printing, textile printing method, ink for ink jet textile printing, and dyed fabric

ActiveUS10487210B2Fast formingGood effectPyronine/xanthon/thioxanthon/selenoxanthan/telluroxanthan dyesDuplicating/marking methodsTextile printerPolymer chemistry

Provided are: a coloring composition for dyeing including a compound represented by Formula (1) shown in this specification or a salt thereof; a coloring composition for textile printing in which the coloring composition for dyeing is used for textile printing; a compound which is preferable as a material of the coloring compositions; a textile printing method in which the above-described coloring composition for textile printing is used; an ink for ink jet textile printing including the above-described coloring composition for textile printing; and a dyed fabric.

Owner:FUJIFILM CORP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com