Display screen calibration method, display screen calibration system and computer readable storage medium

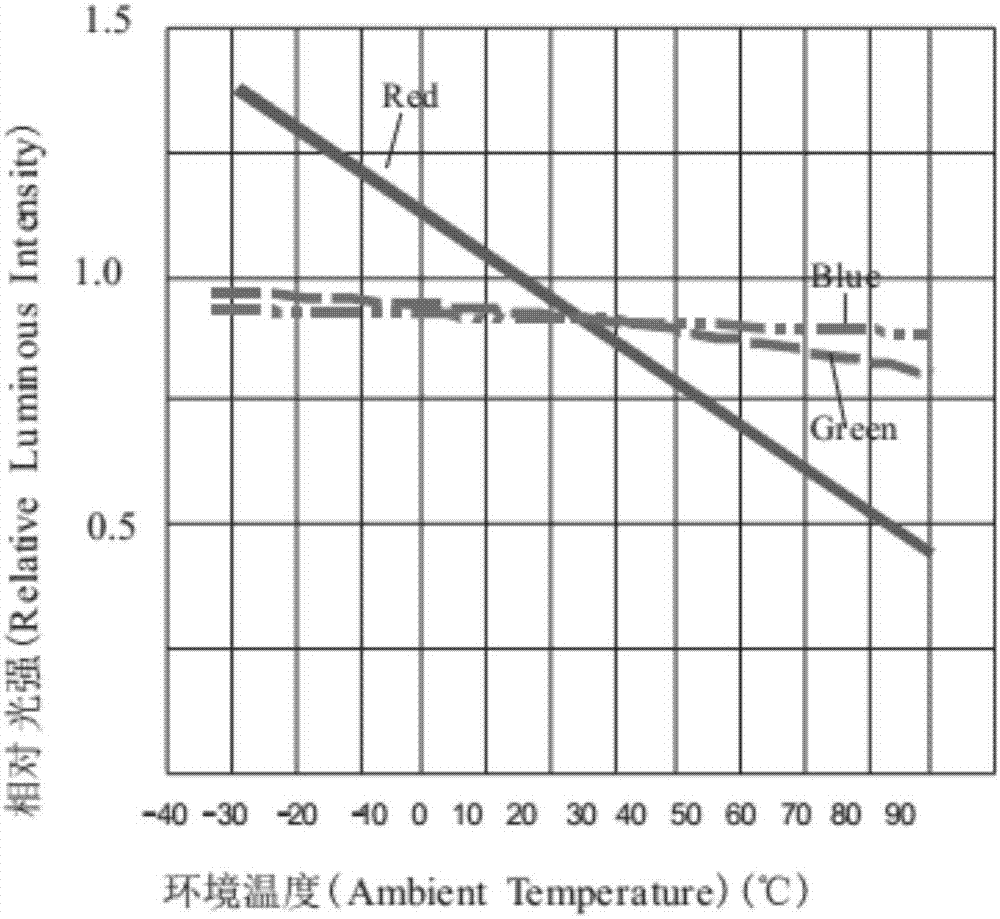

A correction method and correction system technology, applied in the field of display screens, can solve the problems of inability to accurately restore images, inconsistent three-color attenuation, color cast, etc., and achieve excellent visual viewing effects, excellent display effects, and accurate image restoration effects.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

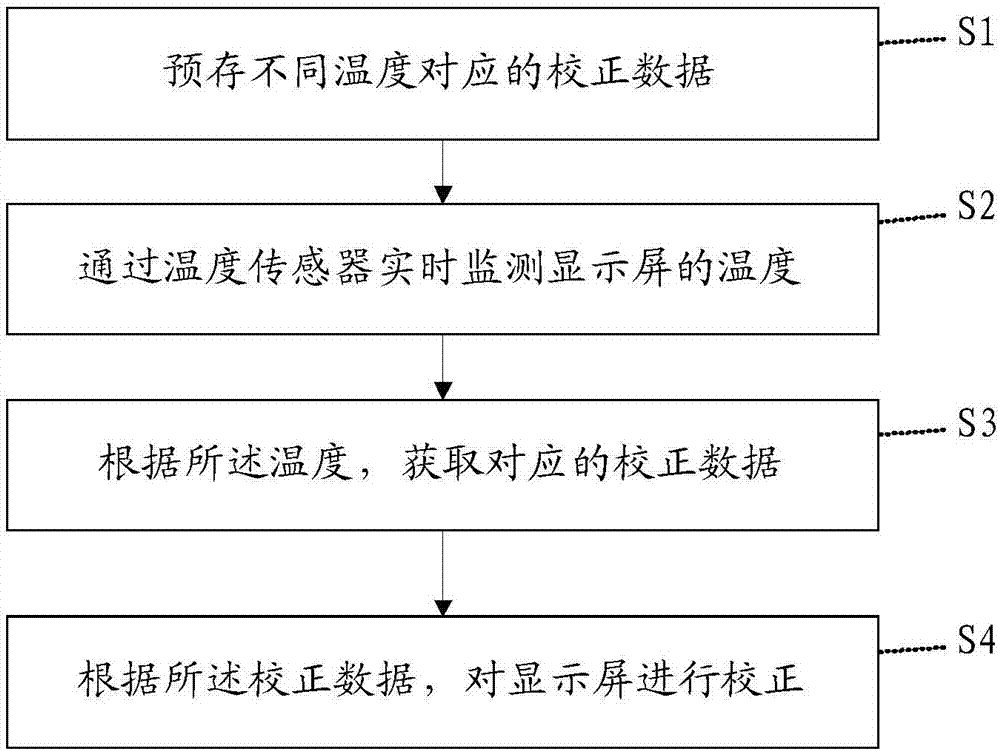

[0064] Please refer to figure 2 , Embodiment 1 of the present invention is: a display screen correction method, which can be applied to LED display screens, and the method includes the following steps:

[0065] S1: pre-store calibration data corresponding to different temperatures;

[0066] S2: Monitor the temperature of the display screen in real time through a temperature sensor; the display screen can be an LED display screen, and the temperature of the display screen can be the temperature of the LED display screen module or the temperature of the LED display screen box.

[0067] S3: Obtain corresponding calibration data according to the temperature;

[0068] S4: Calibrate the display screen according to the calibration data.

[0069]Furthermore, before leaving the factory, the LED display can decide whether to perform correction according to the effect of the screen body and customer requirements, and can mark whether to perform correction through the preset correction...

Embodiment 2

[0077] This embodiment is a specific application scenario of Embodiment 1.

[0078] The LED display screen in the present embodiment is provided with temperature sensor, single-chip microcomputer and Flash memory chip; The correlation table, the microcontroller can extract the corresponding correction data at different temperatures.

[0079] When the cabinet or module reaches a certain temperature, the single-chip microcomputer can extract the correction data of the cabinet or module in the Flash memory chip when the temperature is at this temperature, and the correction coefficient [R ij 〕 T , [G ij 〕 T , [B ij 〕 T Send it to the LED display, and the LED display can be calibrated. Among them, [R ij 〕 T Represents the red LED light R in row i, column j ij Correction coefficient when the box or module is at temperature T, [G ij 〕 T Indicates the green LED light G in row i, column j ij Correction coefficient when the box or module is at temperature T, [B ij 〕 T Rep...

Embodiment 3

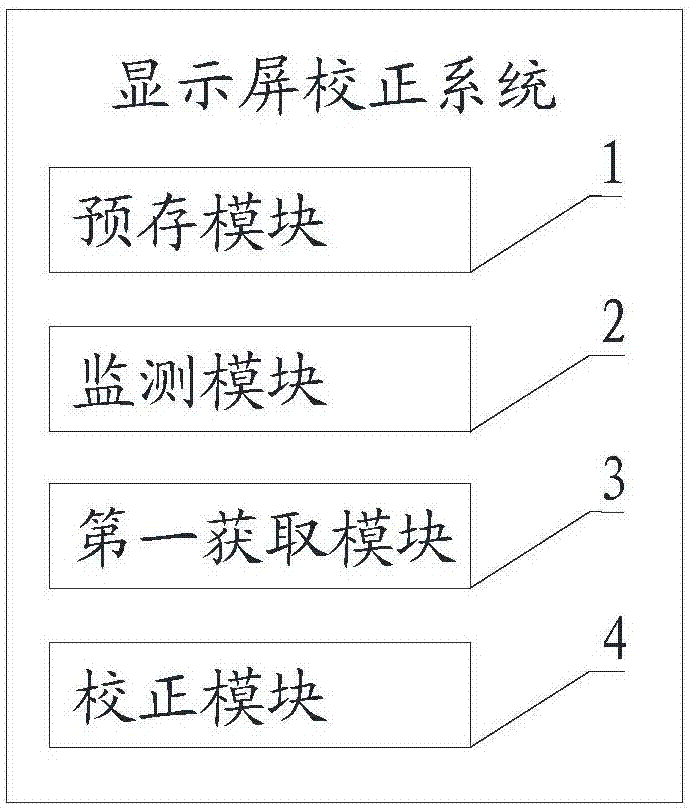

[0082] Please refer to Figure 4 , this embodiment is a display calibration system corresponding to the above embodiments, including:

[0083] Pre-storage module 1, used for pre-storing calibration data corresponding to different temperatures;

[0084] The monitoring module 2 is used to monitor the temperature of the display screen in real time through a temperature sensor;

[0085] The first acquisition module 3 is configured to acquire corresponding correction data according to the temperature;

[0086] The calibration module 4 is configured to calibrate the display screen according to the calibration data.

[0087] Further, the temperature of the display screen includes the temperature of the display screen module and / or the temperature of the display screen box.

[0088] Further, it also includes:

[0089] A judging module 5, configured to judge whether correction is required according to a preset correction coefficient;

[0090] The execution module 6 is configured t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com