Built-in touch control substrate, driving method thereof and display panel

An embedded, substrate technology, used in static indicators, optics, instruments, etc., can solve the problem of uneven display and achieve the effect of uniform display

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

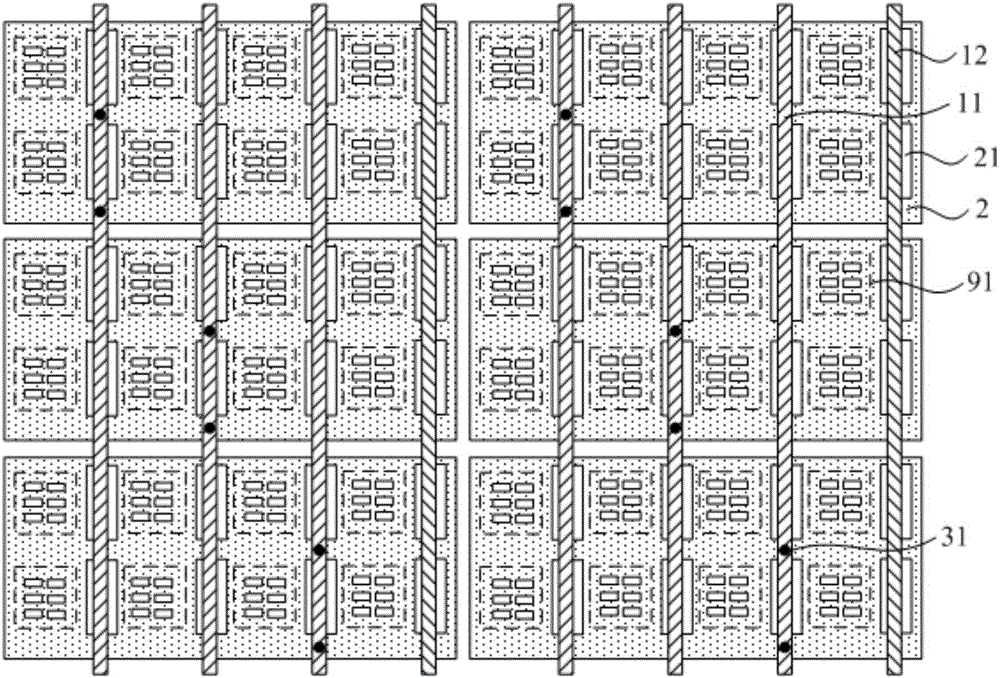

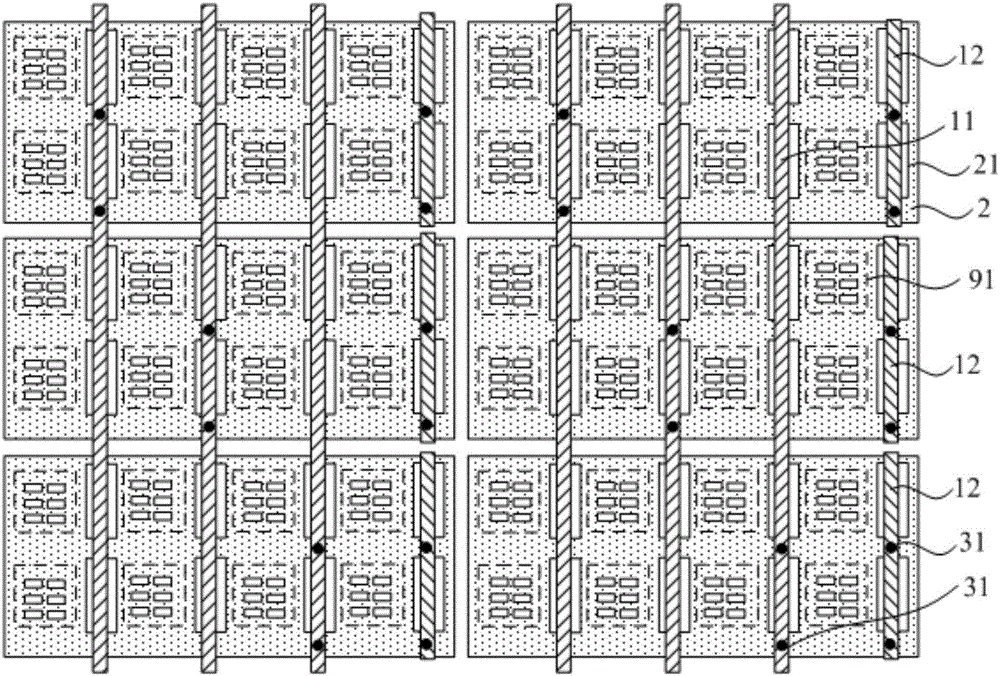

[0035] Such as Figure 2 to Figure 4 As shown, this embodiment provides an in-cell touch substrate.

[0036] The in-cell touch substrate is a substrate in the display panel, but it can also realize the touch function.

[0037] Preferably, the in-cell touch substrate is an array substrate of a liquid crystal display, and thus includes structures such as pixel electrodes, data lines, gate lines, thin film transistors, and gate insulating layers, which will not be described in detail here. Of course, the in-cell touch substrate may also be in other forms such as a color filter substrate.

[0038] Specifically, the above embedded touch substrate includes:

[0039] A plurality of common electrodes, the common electrodes are time-division multiplexed as touch electrodes 2;

[0040] Multiple touch signal lines 11;

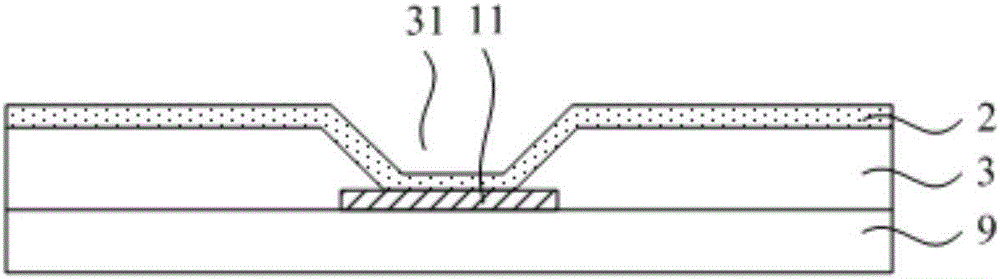

[0041] An insulating layer 3 is provided between the touch electrodes 2 and the touch signal lines 11, and each touch electrode 2 is overlapped with a plurality of to...

Embodiment 2

[0062] This embodiment provides a display panel, which includes:

[0063] The above-mentioned in-cell touch substrate.

[0064] The display panel of this embodiment includes the above-mentioned in-cell touch substrate, so that it has the function of touch control, and the problem of uneven display will not occur.

[0065] Specifically, the in-cell touch substrate can be an array substrate, a color filter substrate, and the like.

[0066] Specifically, the display panel of this embodiment can be any product or component with a display function such as a liquid crystal display panel, an OLED panel, an electronic paper, a mobile phone, a tablet computer, a television set, a monitor, a notebook computer, a digital photo frame, and a navigator.

Embodiment 3

[0068] This embodiment provides a method for driving the above-mentioned in-cell touch substrate, wherein,

[0069] In the display stage, the common electrode signal is applied to the above-mentioned touch signal line to perform display; in the touch stage, the touch signal is applied to the above-mentioned touch signal line to perform touch.

[0070] In this embodiment, since each redundant line is connected to the touch electrode, and the touch electrode is further connected to the touch signal line, when a signal is applied to the touch signal line, the redundant line is also applied through the touch electrode. The same signal, so there is no need to set additional signal sources for the redundant lines, so as not to increase the number of touch chips (that is, not to increase the cost), and to ensure that the signals of the redundant lines are synchronized with the signals of the touch signal lines, thereby playing a role Make the display uniform.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com