Industrial electronic endoscope

An electronic endoscope and endoscope technology, applied in telescopes, optics, instruments, etc., can solve the problems of fiber-optic industrial endoscopes, such as the use distance and life limit, the heavy weight of the probe part, and the image clarity of broken wires. Achieve the effect of long service life, convenient operation and high resolution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] Below in conjunction with the accompanying drawings, the features of the present invention and other related features will be described in further detail by embodiments, so as to facilitate the understanding of those skilled in the same industry:

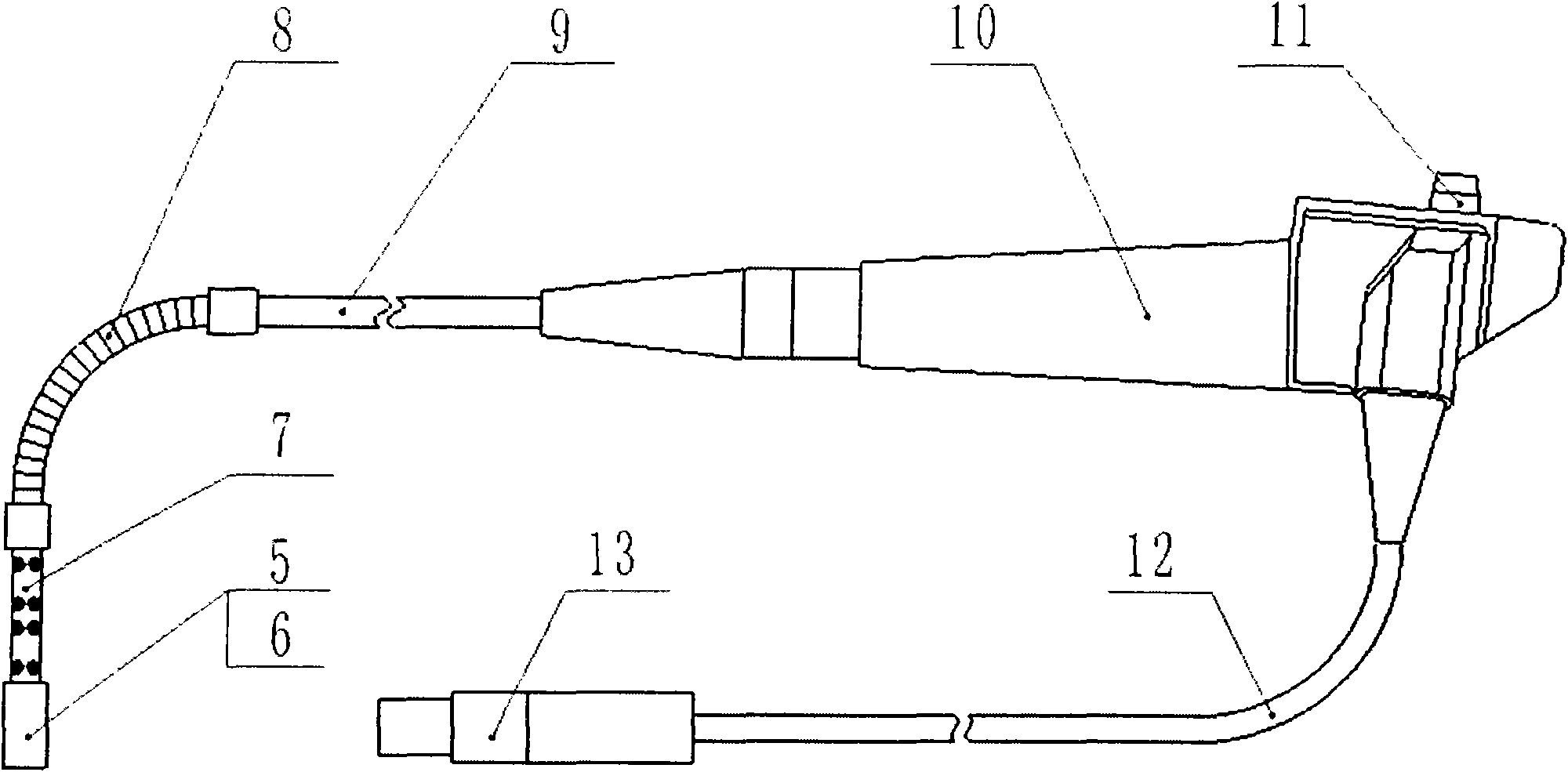

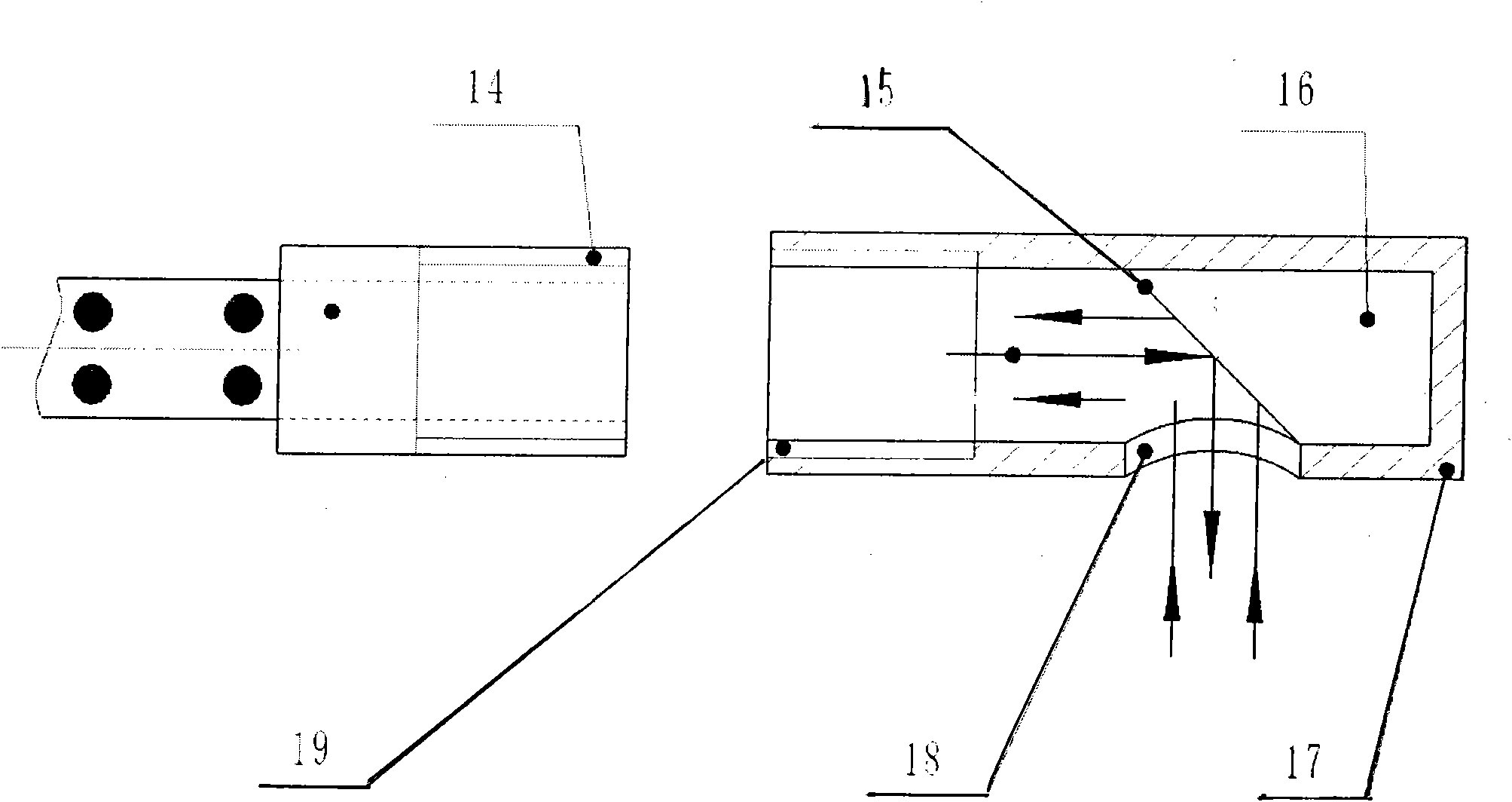

[0016] like Figure 1-3 As shown, numerals 1-19 respectively represent: endoscope probe 1, image signal conversion processing device 2, power supply 3, computer 4, CCD imaging device 5, LED light-emitting tube 6, operable hose 7, metal snake skin tube 8 , metal straight pipe 9, handle 10, operating mechanism 11, signal transmission line 12, connecting plug 13, external thread 14, coating layer 15, cylinder 16, side view corner mirror housing 17, lighting observation hole 18, internal thread 19 .

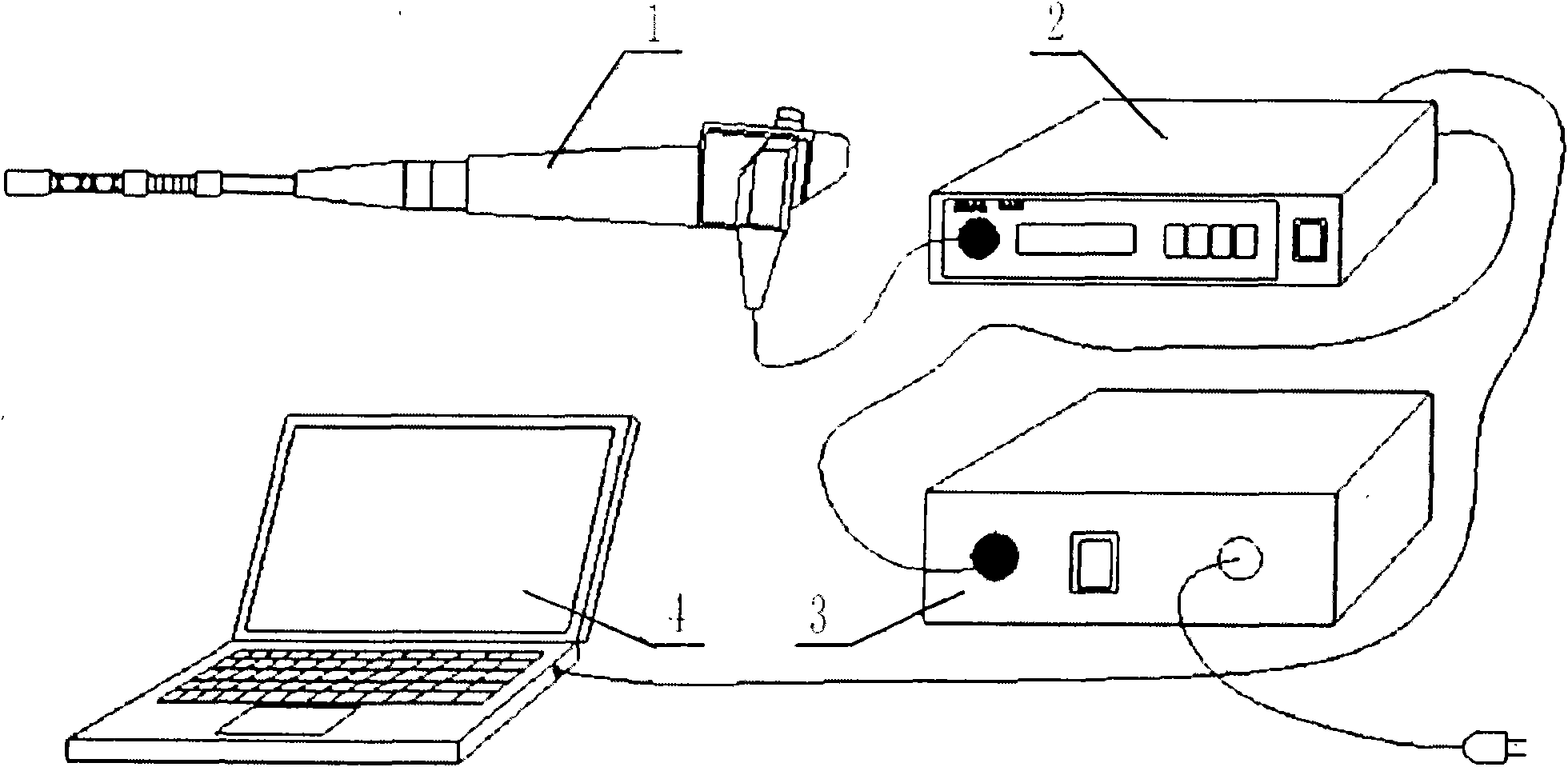

[0017] like figure 1 As shown, the industrial electronic endoscope device is composed of an endoscope probe 1 , an image signal conversion processing device 2 , a power supply 3 , and a computer 4 . The endoscopic probe 1 shoots ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com