Plastic decorative sheet material and preparation method thereof and special wale hot-pressing roller

A technology of decorative sheets and transparent plastic sheets, which is applied in the field of embossed hot pressing rollers, to achieve the effects of rich aesthetic feeling and ornamental value, obvious embossed three-dimensional effect, and reducing alignment errors

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment A

[0019] Such as Figure 4 The structure of the embossed hot pressing roller group shown includes embossed hot rollers 12 and flat rollers 13 of the embossed hot rollers. Airtight cams 14 are provided at both ends of the embossed hot rollers around the roller body.

Embodiment 1

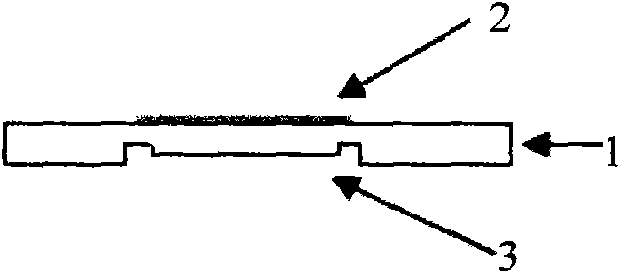

[0021] Such as figure 1 The plastic decorative sheet shown includes a transparent plastic sheet substrate 1, a color print pattern 2 is provided on the front of the substrate, and a concave-convex embossed pattern structure 3 with a line outline corresponding to the front print pattern is provided on the back of the substrate.

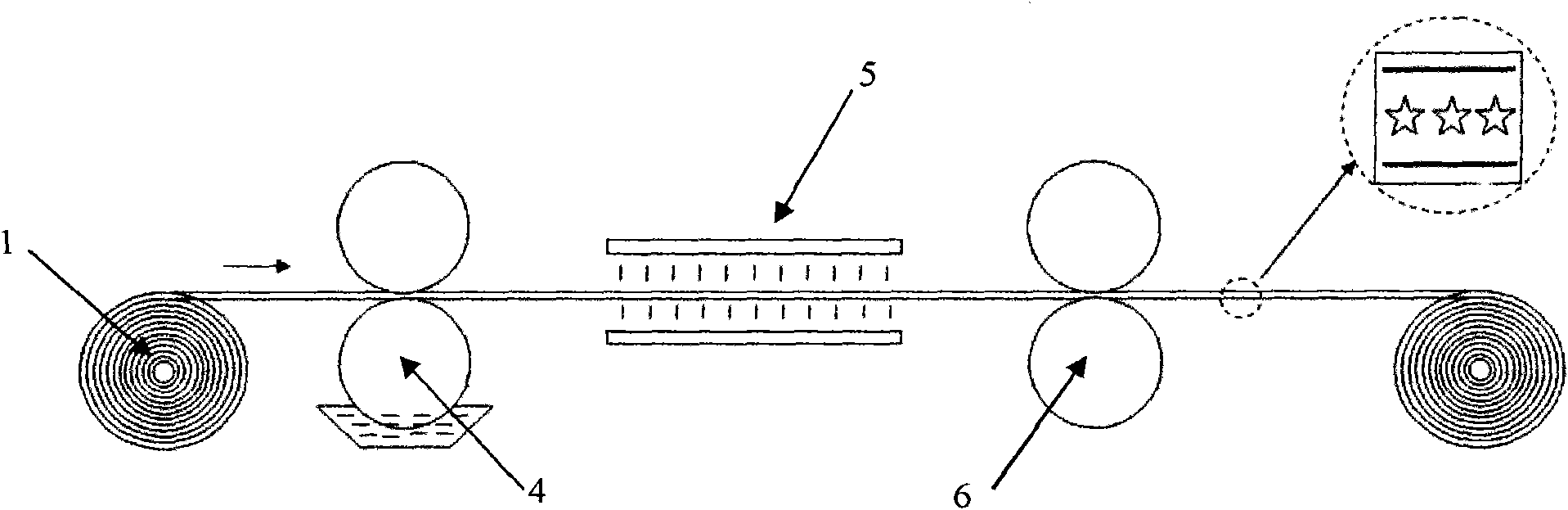

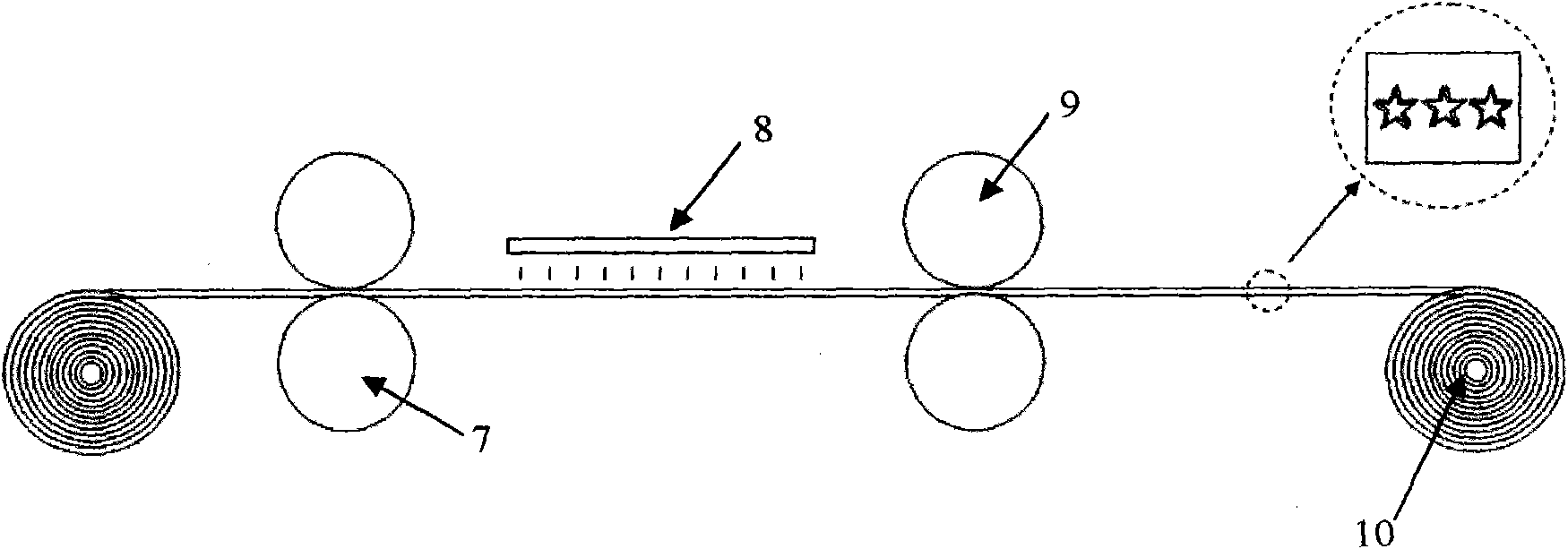

[0022] The following examples are based on figure 2 and image 3 Based on:

Embodiment 2

[0024] Such as figure 2 and image 3 As shown, a polyvinyl chloride sheet with a thickness of 0.8 mm is gravure-printed by an embossing roller 4, dried by a drying device 5, and then hot-pressed by a hot-pressing groove 6 to obtain a polyvinyl chloride printing sheet with a registration groove. sheet reprocessing image 3 After being pressed by the alignment roller 7 shown, it is preheated by the preheating device 8, then embossed by the hot pressing roller 9, then trimmed, and finally wound up by the winding shaft 10 to obtain a decorative embossed PVC sheet. The alignment accuracy is less than 0.1mm.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com