Once-firing colored crystalline glass ceramic composite brick and production method

A technology of glass-ceramic ceramics and a production method, applied in the field of building materials, can solve the problems of poor decoration effect, high energy consumption for firing, low production efficiency, etc. Texture realistic effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

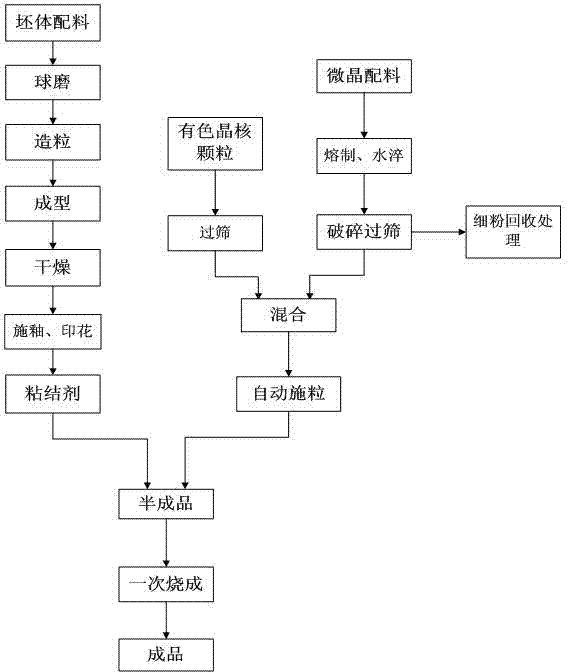

Method used

Image

Examples

Embodiment 1

[0086] The green body composition of the one-time fired colored glass-ceramic composite brick is calculated by weight percentage:

[0087] SiO 2 65%;

[0088] Al 2 O 3 19.5%;

[0089] Li 2 O 0.2%;

[0090] Na 2 O 1.8%;

[0091] K 2 O 5.6%;

[0092] MgO 6.7%;

[0093] CaO 0.4%;

[0094] ZrO 2 0.5%;

[0095] Fe 2 O 3 0.2%;

[0096] TiO 2 0.1%;

[0097] The composition of the base glaze of the one-time fired colored glass-ceramic composite brick is calculated by weight percentage:

[0098] SiO 2 55.0%;

[0099] Al 2 O 3 17.4%;

[0100] CaO 10.4%;

[0101] Na 2 O 2.6%;

[0102] K 2 O 1.4%;

[0103] MgO 3.2%;

[0104] ZrO 2 10%.

[0105] The transparent microcrystalline dry particle composition of the one-time fired colored glass-ceramics composite brick is calculated by weight percentage:

[0106] SiO 2 59%;

[0107] Al 2 O 3 12.5%;

[0108] CaO 8.2%;

...

Embodiment 2

[0129] The green body composition of the one-time fired colored glass-ceramic composite brick is calculated by weight percentage:

[0130] SiO 2 61.6%;

[0131] Al 2 O 3 20.5%;

[0132] Li 2 O 0.5%;

[0133] Na 2 O 1.4%;

[0134] K 2 O 4.3%;

[0135] MgO 7%;

[0136] CaO 3%;

[0137] ZrO 2 0.7%;

[0138] Fe 2 O 3 0.5%;

[0139] TiO 2 0.5%.

[0140] The composition of the base glaze of the one-time fired colored glass-ceramic composite brick is calculated by weight percentage:

[0141] SiO 2 54.5%;

[0142] Al 2 O 3 16.2%;

[0143] CaO 11.3%;

[0144] Na 2 O 3.1%;

[0145] K 2 O 2.5%;

[0146] MgO 2.4%;

[0147] ZrO 2 10%.

[0148] The glass-ceramic components of the one-time-fired colored glass-ceramics composite brick are calculated by weight percentage:

[0149] SiO 2 53%;

[0150] Al 2 O 3 14.2%;

[0151] CaO 9.7%;

[0152] MgO 5.6%;

[0153] Na 2 O...

Embodiment 3

[0172] The green body composition of the one-time fired colored glass-ceramic composite brick is calculated by weight percentage:

[0173] SiO 2 63%;

[0174] Al 2 O 3 twenty one%;

[0175] Li 2 O 0.5%;

[0176] Na 2 O 0.5%;

[0177] K 2 O 2%;

[0178] MgO 6.7%;

[0179] CaO 5%;

[0180] ZrO 2 1%;

[0181] Fe 2 O 3 0.2%;

[0182] TiO 2 0.1%;

[0183] The composition of the base glaze of the one-time-fired colored glass-ceramic composite brick is calculated by weight percentage:

[0184] SiO 2 55.5%;

[0185] Al 2 O 3 17.5%;

[0186] CaO 16.4%;

[0187] Na 2 O 2.6%;

[0188] K 2 O 1.6%;

[0189] MgO 1.0%;

[0190] ZrO 2 5.4.

[0191] The glass-ceramic components of the one-time-fired colored glass-ceramics composite brick are calculated by weight percentage:

[0192] SiO 2 59%;

[0193] Al 2 O 3 12.5%;

[0194] CaO 8.2%;

[0195] MgO 6.3%;

[0196...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com