Patents

Literature

85results about How to "Realistic texture" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

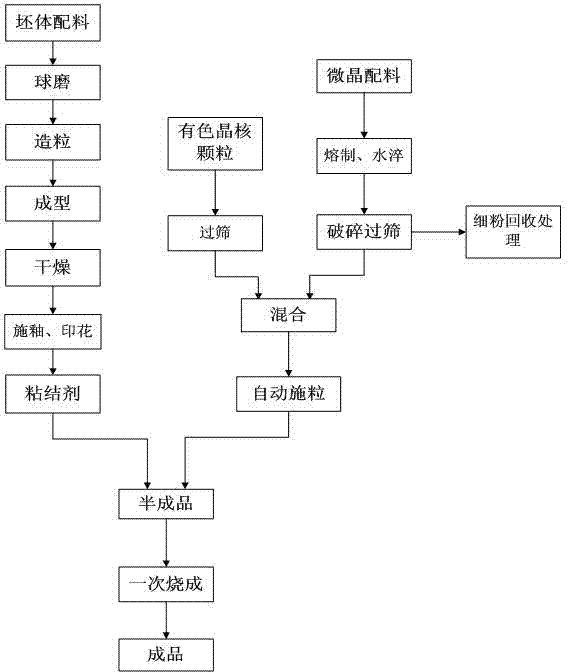

Once-firing colored crystalline glass ceramic composite brick and production method

ActiveCN103030298AImprove efficiencyReduce cost and controllable difficultyCeramic glazeEnergy consumption

The invention discloses a once-firing colored crystalline glass ceramic composite brick and a production method. The once-firing colored crystalline glass ceramic composite brick comprises a blank and a ground coat layer and a colored microcrystal layer that are arranged on the blank sequentially, wherein the colored microcrystal layer consists of a transparent microcrystal layer and colored crystal nucleus particles suspended in the transparent microcrystal layer. The production method comprises the following steps of processing the blank, applying a ground coat, conducting roller printing, applying an adhesive agent on the surface of the blank, uniformly applying transparent microcrystal dry particles and the colored crystal nucleus particles on the surface of the blank to form the colored microcrystal layer, applying a fixing agent, allowing to enter a kiln for once firing, and finishing and edging to form a finished product. The method is low in energy consumption and high in production efficiency, raw materials are saved, and the cost is lowered. The colored crystal nucleus particles suspended in the colored microcrystal layer of the once-firing colored crystalline glass ceramic composite brick are echoed by the roller printing, so that a stereo color effect is more obvious and verisimilar, and the brick has an excellent ornamental effect.

Owner:FOSHAN OCEANO CERAMICS

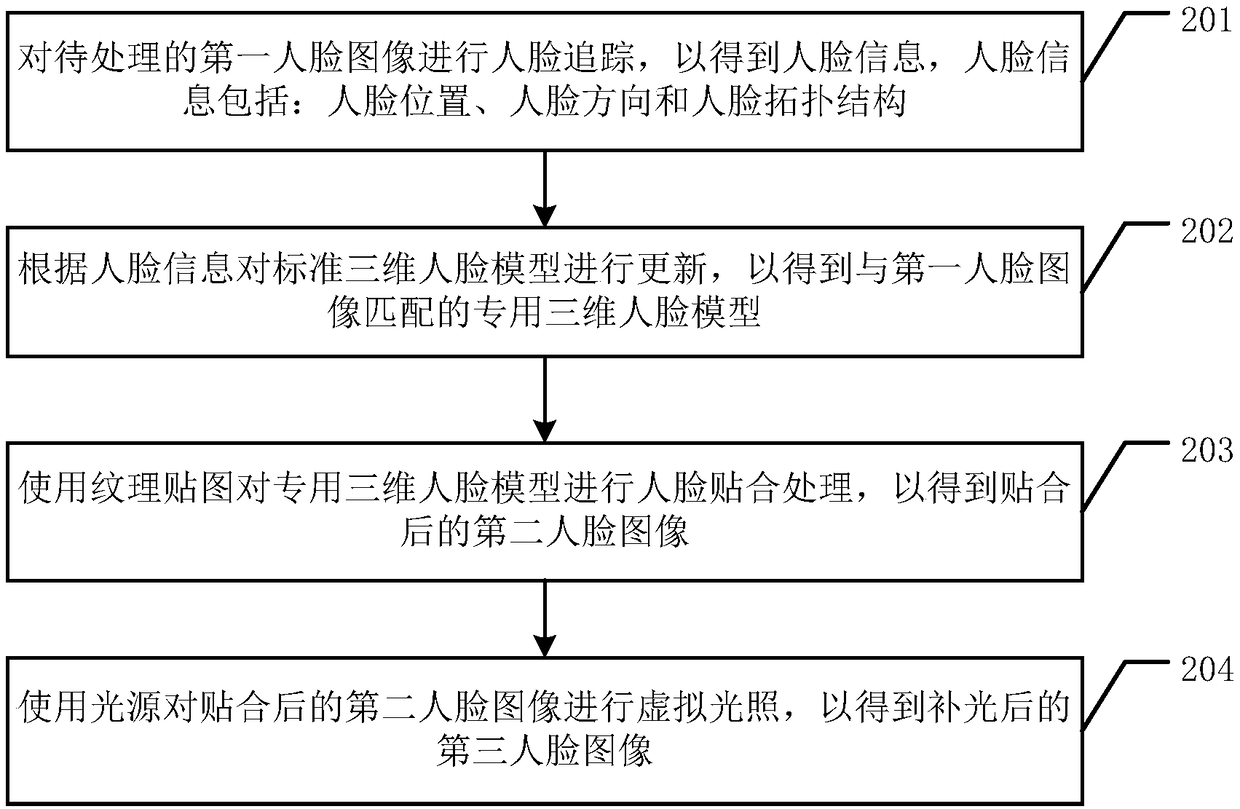

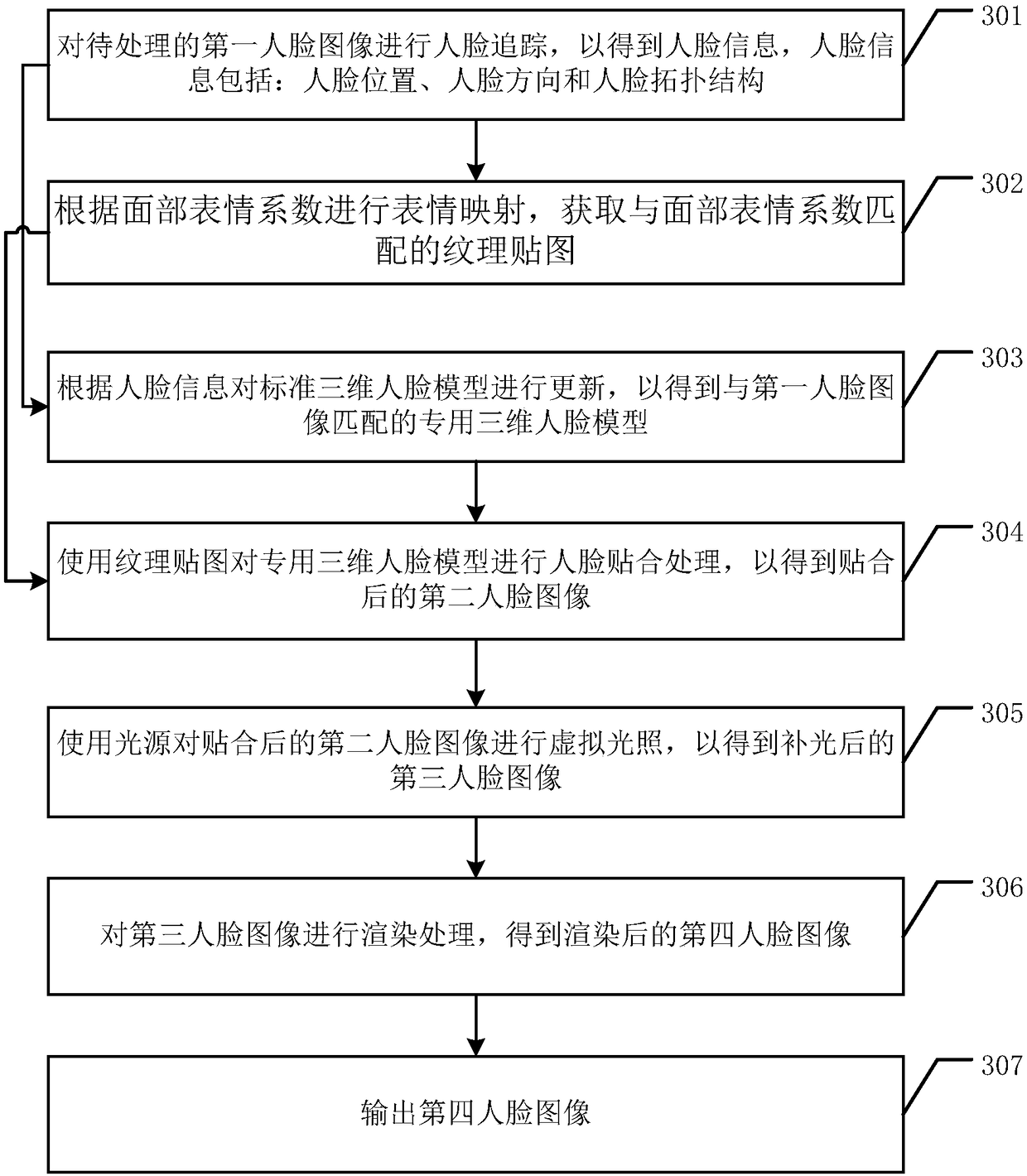

Method and device for processing face image, and computer-readable storage medium

ActiveCN108898068AImprove realismRealistic textureAcquiring/recognising facial features3D-image renderingFace modelImage matching

Embodiments of the invention disclose a method and a device for processing a face image and a computer-readable storage medium, used for improving fitting degree between a map and a face image. An embodiment of the invention provides a method for processing a face image, and the method comprises: tracking a to-be-processed first face image to obtain face information, wherein the face information comprises a human face position, a human face direction and a human face topological structure; updating a standard three-dimensional face model according to the face information to obtain a dedicatedthree-dimensional face model matched with the first face image; using a texture map to carry out face fitting processing on the dedicated three-dimensional face model to obtain a fitted second face image; using a light source to perform virtual illumination on the fitted second face image to obtain a third face image after light supplement.

Owner:TENCENT TECH (SHENZHEN) CO LTD

Non-woven embossed wallpaper

InactiveCN103215859ANot easy to fall offMeet the consumption levelSpecial visual effect coatingsSpecial paperFiberPolyvinyl chloride

The invention discloses non-woven embossed wallpaper which solves the problems that a foaming layer of the traditional wallpaper is thin easily falls off from a printing layer. The non-woven embossed wallpaper is characterized by being made by adopting a secondary foaming process, namely, a PVC (Polyvinyl Chloride) coating is coated on the surface of fiber non-woven paper to carry out primary foaming, an inhibitor is used for inhibiting, so that an area on which the inhibitor is coated cannot be foamed due to high temperature, and therefore a required wallpaper pattern is obtained; and a PVC sizing agent is used for carrying out secondary foaming, so that the product of which the foaming height can reach 0.5mm at most can be obtained. According to the non-woven embossed wallpaper, a foaming layer is thick and difficulty falls off, the stereoscopic impression is strong, the texture is soft, the sense of touch is good, the patterns are distinct, the cleaning is convenient, and non-woven embossed wallpaper can be directly scrubbed.

Owner:HUAIBEI NUOFEIYA NEW MATERIAL WALLPAPER

Manufacturing method for combined ceramic tile with complete pattern, spliced by plurality of ceramic tiles

InactiveCN103241049AStrong three-dimensional senseStrong sense of transparencyDecorative surface effectsClaywaresMetallurgyNatural stone

The invention relates to a manufacturing method for a combined ceramic tile with a complete pattern, which is spliced by a plurality of ceramic tiles. The method comprises the following steps of: mixing raw materials to prepare a powder material, pressing the powder material to obtain green tiles, carrying out printing and glaze spraying on the green tiles, sintering the obtained tiles to obtain the ceramic tiles, and performing seamless splicing on the plurality of ceramic tiles with different or identical figures to obtain the combined ceramic tile with the complete pattern. Compared with the prior art, the combined ceramic tile can fully display the real effect of natural stones by means of large format splicing, is strong in three-dimensional effect and rich in layering, can better adapt to current market trend, and is grand and very impressive after being paved.

Owner:SHANGHAI YUEXIN HEALTH GRP CO LTD

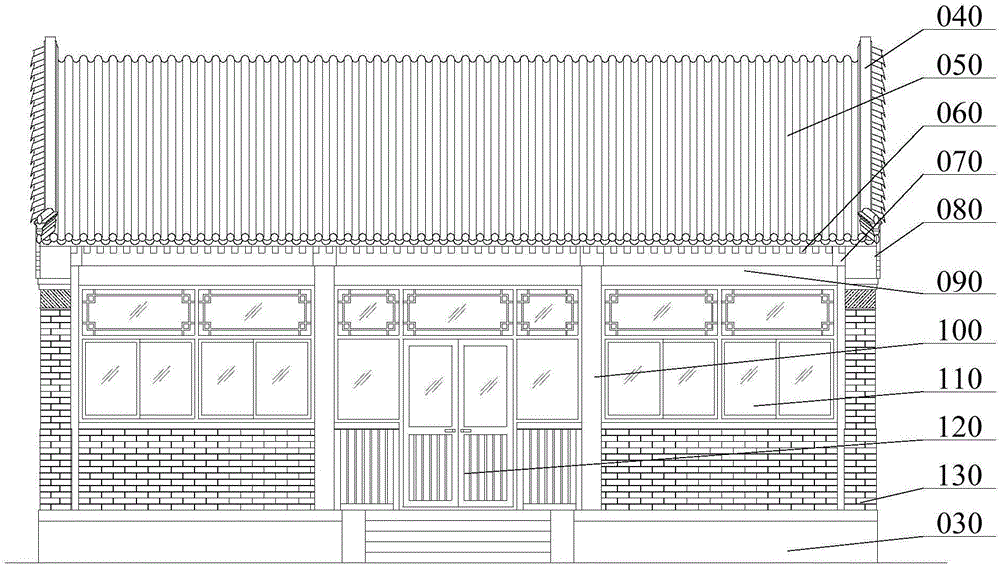

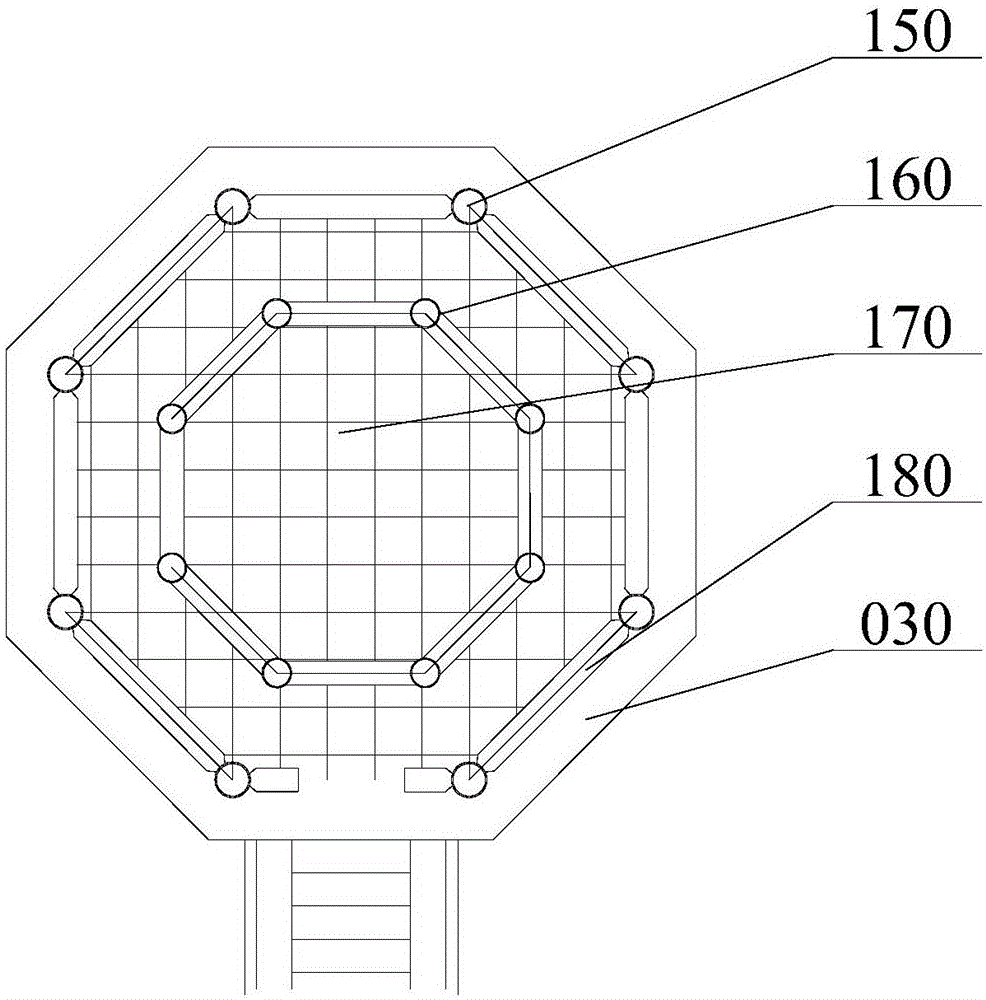

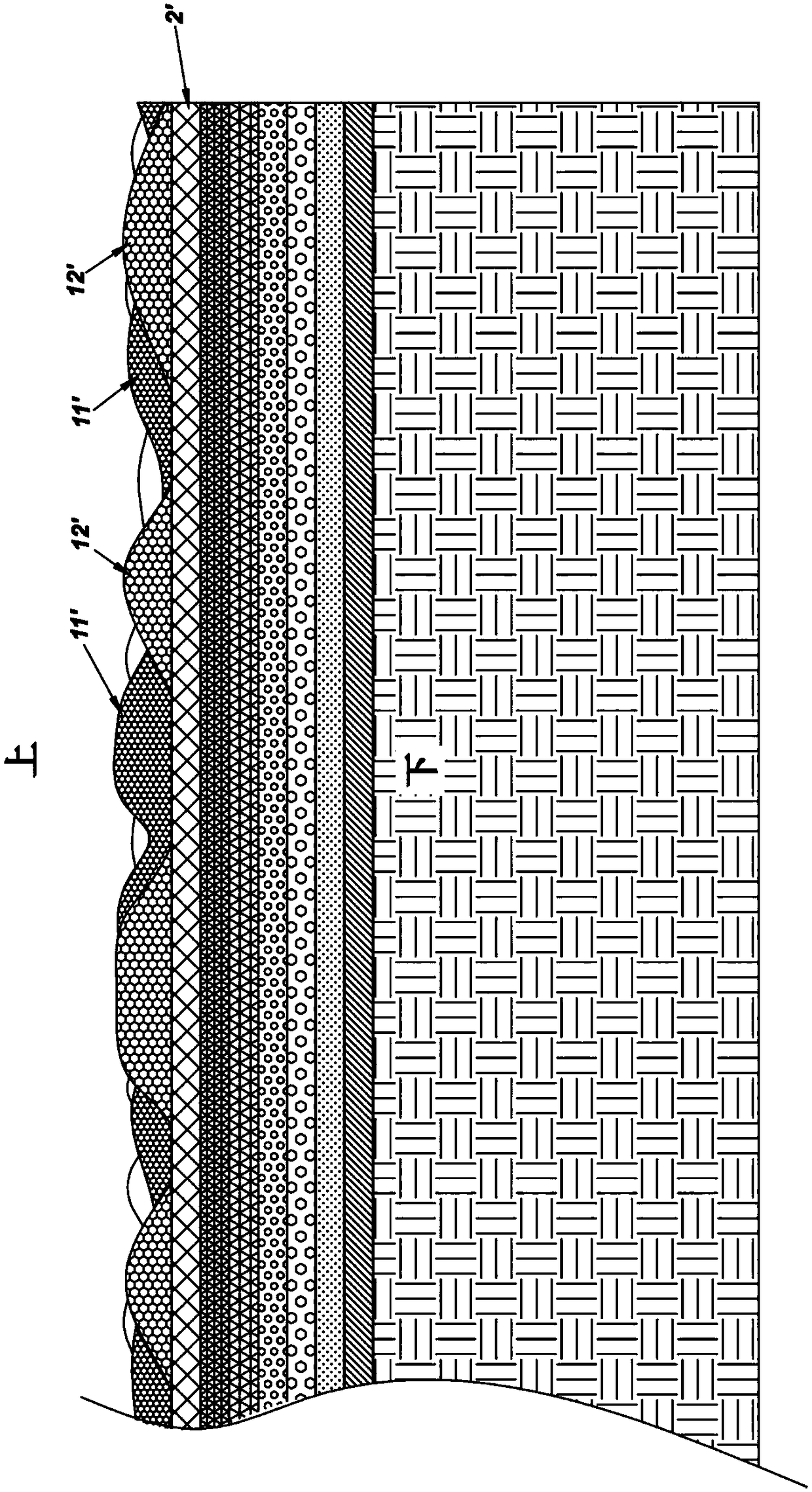

Archaistic building and manufacturing method thereof

ActiveCN106382023AConstruction rationalizationStable physical propertiesBuilding roofsRoof covering using tiles/slatesWater seepageBuilding construction

The invention provides an archaistic building and a manufacturing method thereof, relating to the technical field of manufacturing of historic buildings. The archaistic building comprises a ground foundation, a main body steel structure, archaistic upright pillars and archaistic joint tiles, wherein the archaistic joint tiles and the archaistic upright pillars are made of modified cement and are factory prefabricates with lifelike forms and excellent assembling and archaistic effects. Besides, the steps of the manufacturing method are simple, and the manufactured archaistic joint tiles are scientific in physical dimension design and reasonably butted and have the advantages that water seepage and rain leakage are avoided, the texture is real, the durability is good, and the appearance and the proportion are accordant with traditional tiles. According to the manufacturing method, the technical problems of long construction cycle and short service life in the prior art are solved, the construction of the archaistic building is relatively reasonable, and the application of the archaistic building is relatively wide.

Owner:BEIJING JUXING COMPOSITE MATERIAL TECH DEV

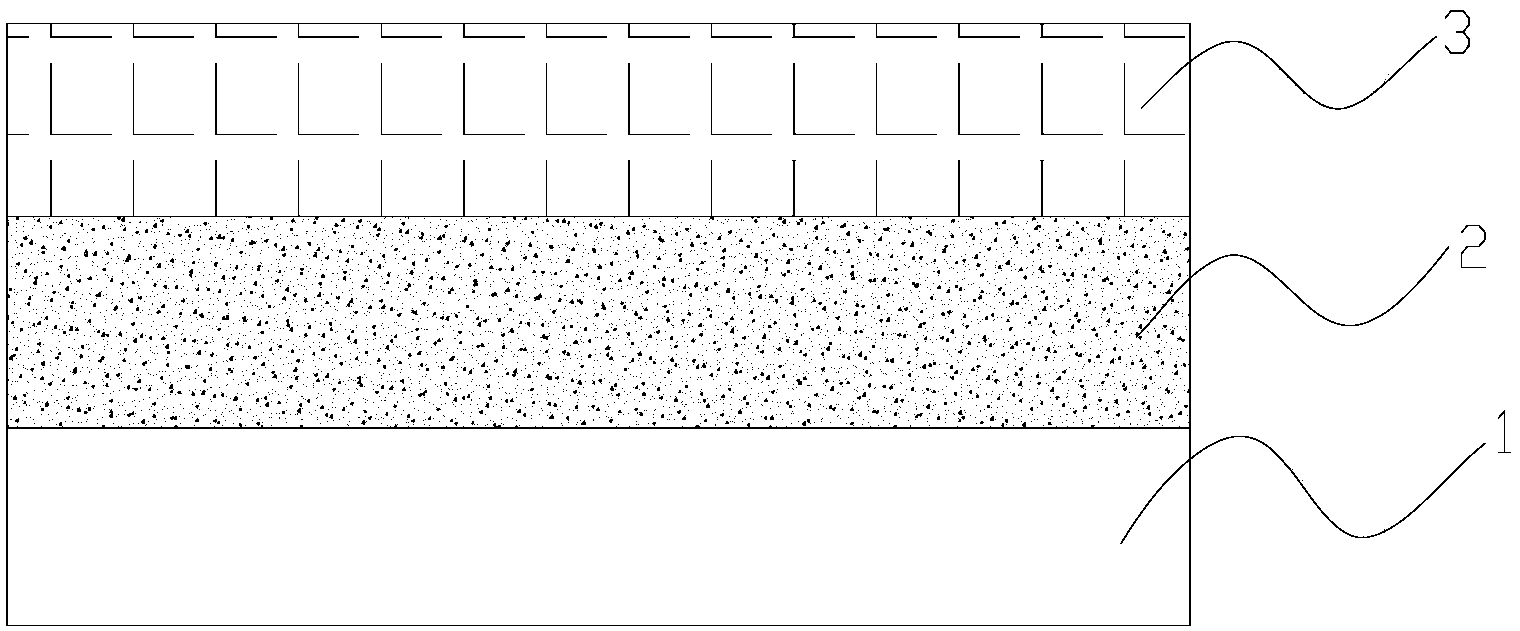

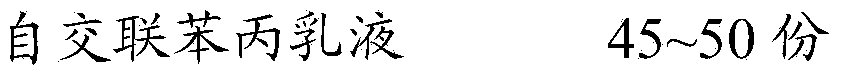

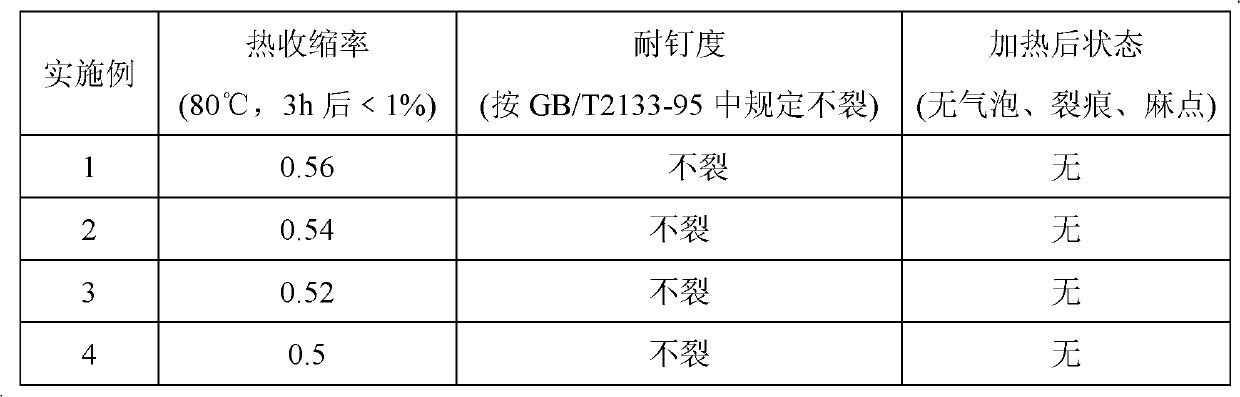

Waterborne ink and preparation method thereof as well as application of waterborne ink in PP (Polypropylene) decorative film

ActiveCN104371420ADry completelyGood reproducibilitySpecial ornamental structuresInksPolymer scienceSolvent based

The invention discloses a waterborne ink and a preparation method thereof, application of the waterborne ink in a PP (Polypropylene) decorative film and a preparation method of the PP decorative film. The preparation method of the waterborne ink comprises the following process steps: a, preparing mill base; b, grinding; and c, blending ink. The PP decorative film sequentially comprises a PP substrate layer, a waterborne ink printing layer and a varnish coating layer from bottom to top. The preparation method of the PP decorative film comprises the following process steps: 1) carrying out polarity treatment on the surface of the PP film; 2) preparing the waterborne ink; 3) printing the waterborne ink; 4) glazing and coating; and 5) embossing. By integrating the selection of materials and optimization of the process, the PP decorative film reaches the printing effect of a solvent-based ink, the printed product has no water mark, the texture is shallow and clear, natural and realistic and the PP decorative film is non-toxic and odorless and has excellent performances such as light resistance, scratch resistance, wear resistance, disinfection and sterilization; the preparation method is convenient and feasible in production processes, simple to operate and low in production cost, and is prone to industrial production.

Owner:佛山市南海天元茂新新材料有限公司

Ceramic tile frit dry granule composite process and ceramic tile

The invention discloses a ceramic tile frit dry granule composite process which is characterized by comprising the following steps: 1) selecting a tile blank; 2) spraying an overglaze; 3) throwing colorful frit dry granules to achieve effect patterns; 4) ejecting glue, and laying transparent frit dry granules; 5) sucking off excessive frit dry granules; 6) carrying out firing and polishing. By adopting the ceramic tile frit dry granule composite process disclosed by the invention, round-ball frit dry granules are used, multiple layers of frit dry granules are compounded together, more than 10meters of variable patterns can be achieved, simultaneous decoration of frit dry granules of different colors can be achieved, rich layers and vivid and natural textures can be achieved, and the graceful textures of natural and precious stone materials can be reproduced. With ejection of relief ink, a fine abrasive tool effect can be achieved, in addition, relief position effects on each pattern surface are varied naturally, natural and real relief patterns can be formed, a ceramic tile with good gray touch feelings can be manufactured, and the ceramic tile is greatly different from a conventional ceramic tile product. The invention further provides a ceramic tile.

Owner:GUANGDONG OVERLAND CERAMICS CO LTD

Preparation method of whole marble ceramic tiles

ActiveCN106187212ATrue restoration of the application effectRealistic textureSurface layerColor mixing

The invention relates to a preparation method of whole marble ceramic tiles, and belongs to the technical field of improvement of preparation of imitated-marble ceramic tiles. The preparation method of the whole marble ceramic tiles comprises the steps that green bodies are prepared by combining a dry method color mixing technology and a three-dimensional distribution technology, overglaze is applied to the surfaces of the green bodies, then, the surface layer of the overglaze is sequentially sprayed with baring ink and baring glaze, finally burning is carried out, and the whole marble ceramic tiles are obtained. The preparation method is simple, saves energy, is environmentally friendly, breaks through the bottleneck of the traditional technology and is wide in application range, and the prepared ceramic tiles really restore natural stone texture, and are integrally attractive, more vivid in space decoration effect and better in texture.

Owner:山东狮子王新材料科技有限公司

High temperature resistant release coating material for artificial synthetic leather release paper, and preparation method and application thereof

ActiveCN103740262AClear textureRealistic texturePolyurea/polyurethane coatingsTextiles and paperTripropylene glycolMethacrylate

The invention relates to a high temperature resistant release coating material for artificial synthetic leather release paper, and a preparation method and an application thereof. The release coating material is composed of modified urethane acrylate, modified epoxy acrylate, tripropylene glycol diacrylate, trimethylolpropane triacrylate ethoxylate, perfluoromethacrylate and gamma-methylacryloxypropyltrimethylsilane. A method for preparing the high temperature resistant release coating material for the artificial synthetic leather release paper comprises the steps of orderly putting all the components in a container, mixing and stirring so that the solid components are dissolved, and thus obtaining an even and approximately transparent coating. The release paper is clear and vivid in lines; due to the optimization of the formula, the release paper can be caused to be moderate in hardness, good and stable in release property, numerous in repeated use times, and excellent in solvent resistance and high-temperature resistance.

Owner:ZHEJIANG KAREN SPECIALTY MATERIALS

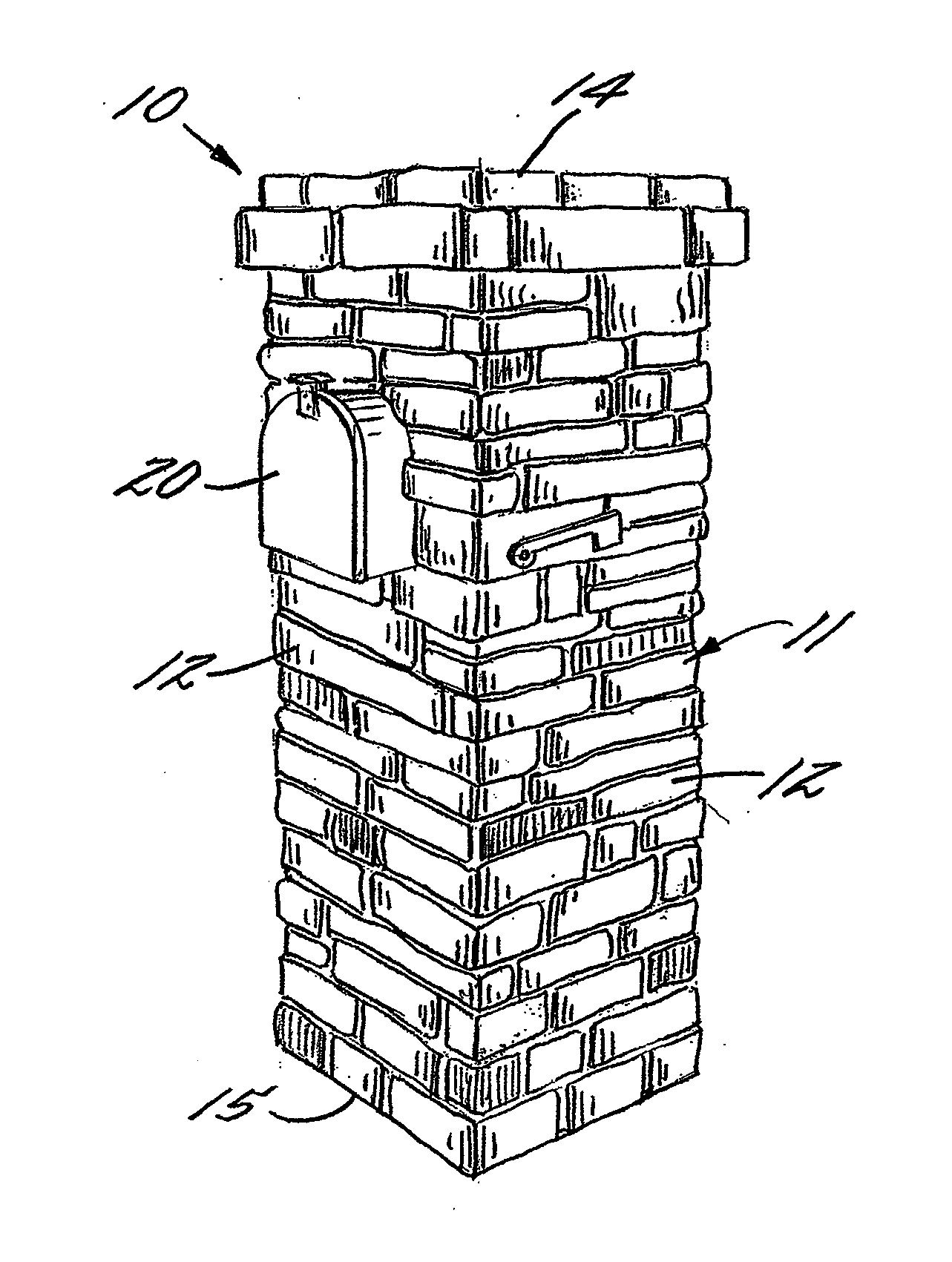

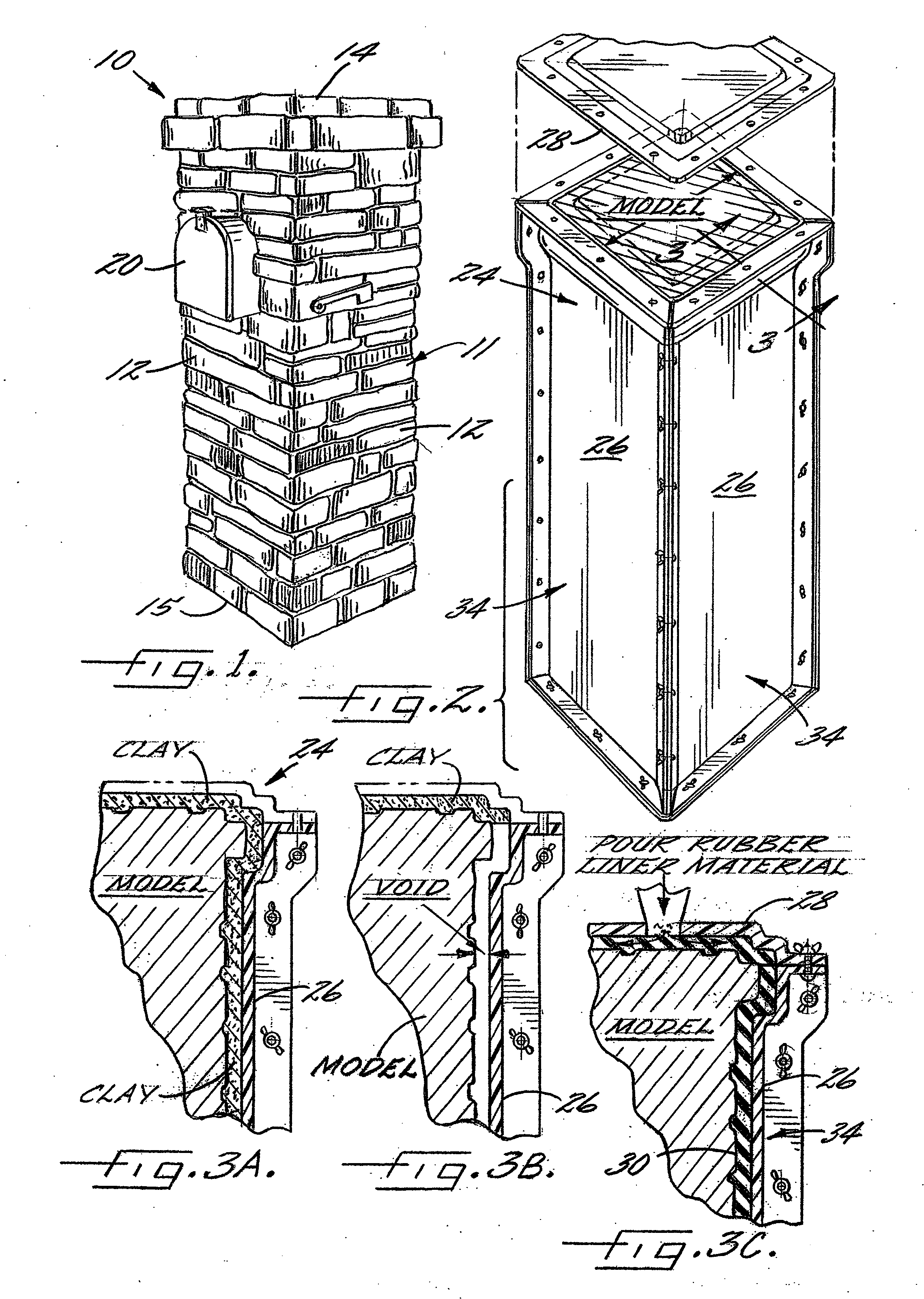

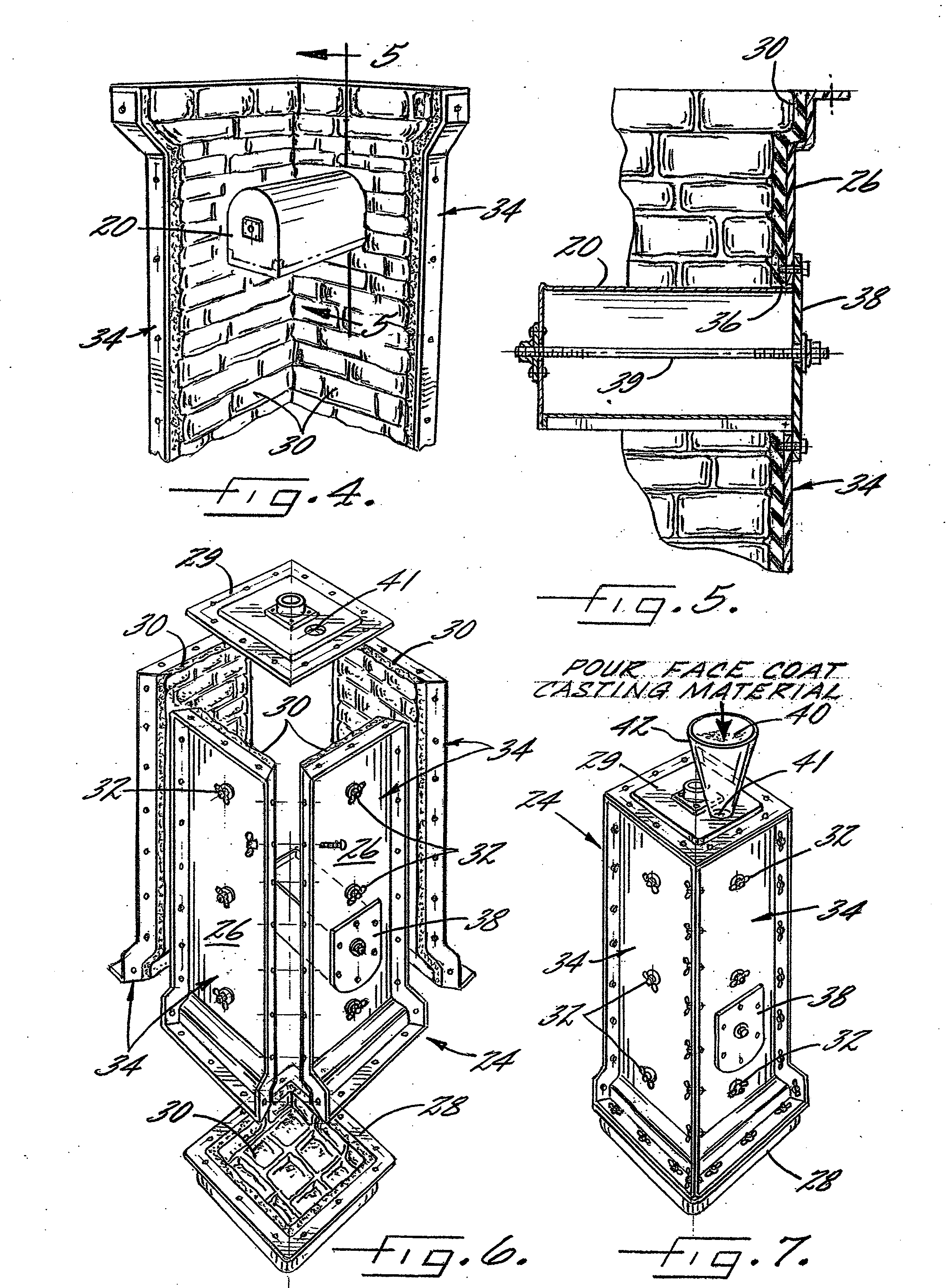

Simulated Stone or Brick Column and Method of Fabricating Same

InactiveUS20110030292A1Easy to installHigh tensile strengthSolid waste managementSpecial ornamental structuresBrickMaterials science

A simulated stone or brick column is fabricated by a method that involves providing a hollow closed mold that has an inner face in the form of a reverse image of the desired stone or brick surface. A liquid casting material is introduced into the mold and in the mold is rotated about two perpendicular axes so that the casting material coats the inner face of the mold and results in the formation of a hollow column having the external appearance of the desired stone or brick surface. The casting material forms a molded column that has a texture and contour that simulate a stone or brick surface. A mailbox and newspaper tube can be installed in the column.

Owner:ARC TECH

Simulated wood board and production method thereof

InactiveCN102535813AStable materialNo pollution in the processCovering/liningsDecorative surface effectsPublic placeEngineering

The invention relates to a wood board, in particular to an artificial simulated wood board and a production method thereof. The simulated wood board aims to overcome shortcomings of natural wood, is waterproof, moisture-proof, insect-proof, mothproof, anti-crack, harmless and pollution-free, does not deform, and can replace the natural wood. The simulated wood board comprises a base material layer, and a primer layer, a pattern layer made of marble and a finish layer are successively arranged at the front of the base material layer from bottom to top. The invention further provides the production method of the simulated wood board. The production method comprises following steps: selecting a base material; cutting the selected base material into a base material with the required dimension; arranging tenon fasteners on the cut base material; coating primer on the front of the base material; printing textures of natural wood on the surface of the base material coated with the primer; and coating finish on the surface of the base material printed with the textures of the natural wood. The simulated wood board can be paved on floors of various humid environments and public places, and completely overcomes shortcomings that various wood floors are expanded when wetted and are contracted when dried.

Owner:GUANGZHOU GUANGYANG FU BULGARI HOME MATERIAL

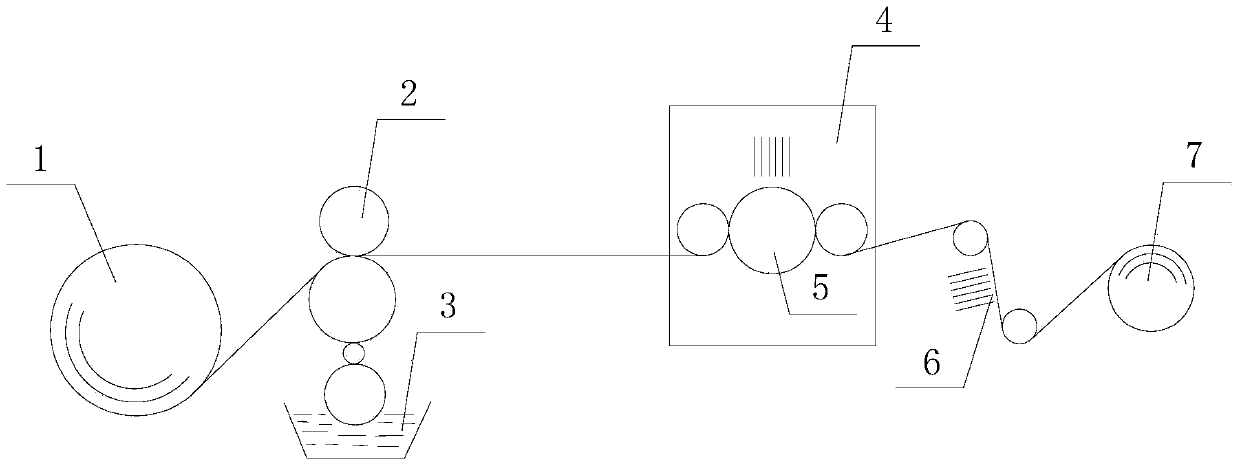

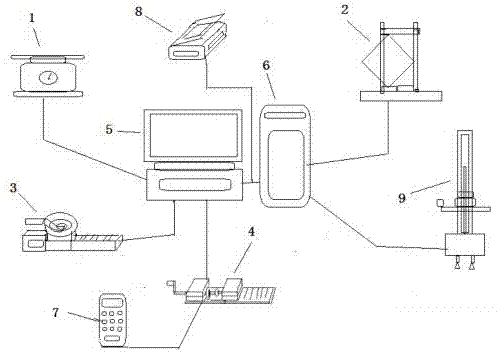

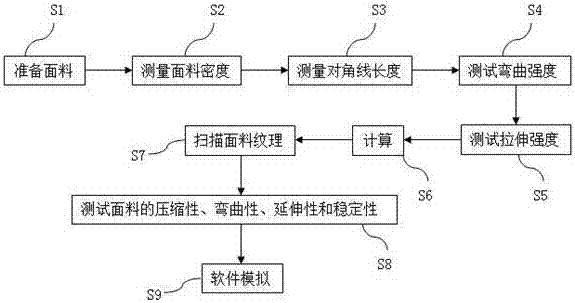

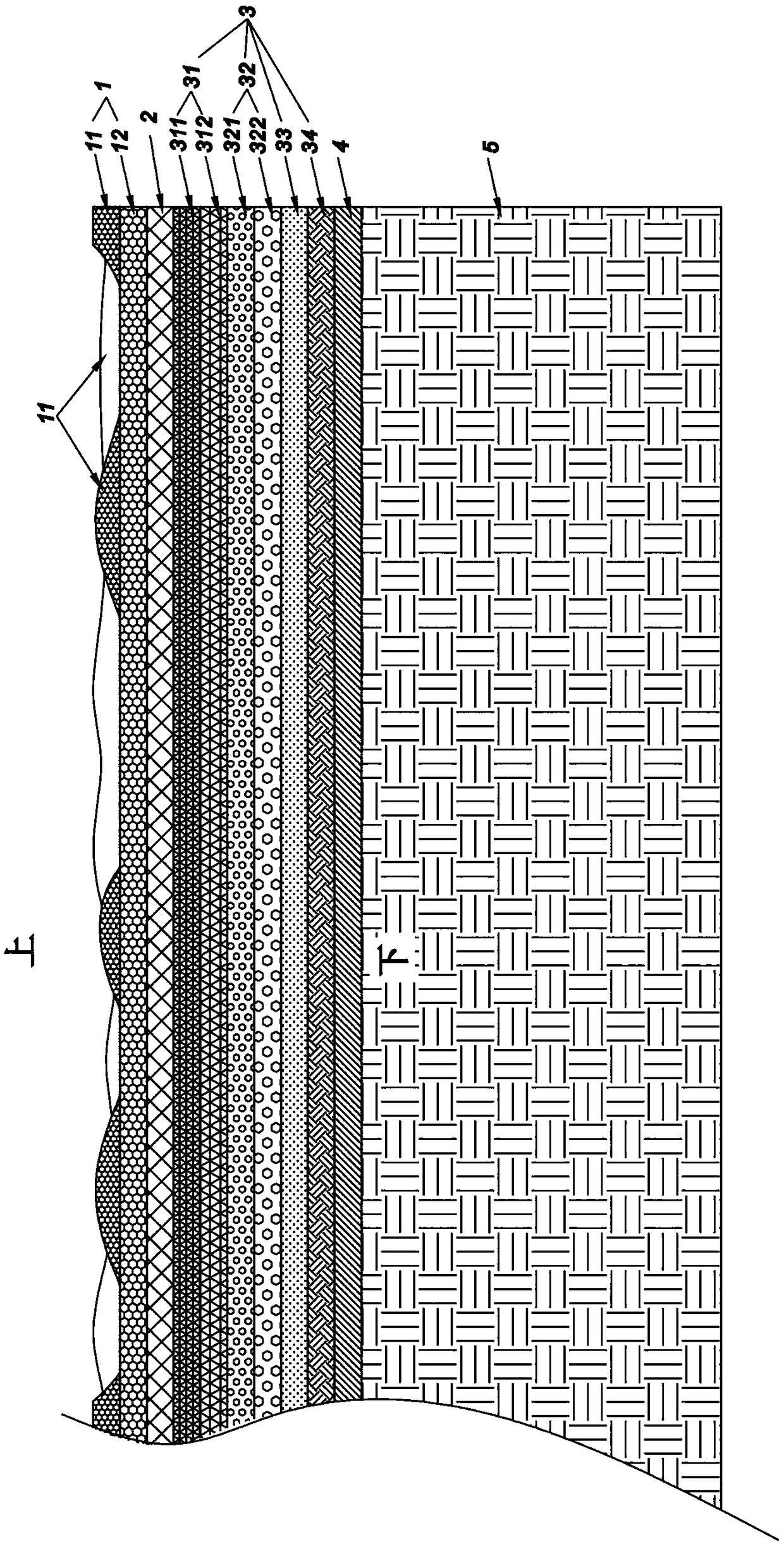

Simulation system for physical properties and digital attributes of textile fabric and measurement method

PendingCN106909763AEnhanced fabric simulationThe calculation process is simpleTextile testingDesign optimisation/simulationMeasurement deviceComputerized system

The invention discloses a simulation system for physical properties and digital attributes of a textile fabric and a measurement method. The simulation system comprises a computer system, fabric simulation software, a fabric physical property measurement device and a fabric scanning system, wherein the fabric simulation software is arranged in the computer system; the fabric physical property measurement device and the fabric scanning system are connected with the computer system separately; the computer system is provided with a data output port; and various physical data during fabric measurement and data during fabric scanning are subjected to operation work through the computer system. The real visual effect of the physical attributes of the garment fabric can be quickly and virtually shown, the technical problems of distortion and deficiency of various physical attributes of the garment fabric simulated by three-dimensional garment simulation software in the market at present are successfully solved, and the realistic design effects of various dresses, work clothes, underwear, three-dimensional embroideries and the like can be shown.

Owner:广西大海服装科技有限公司

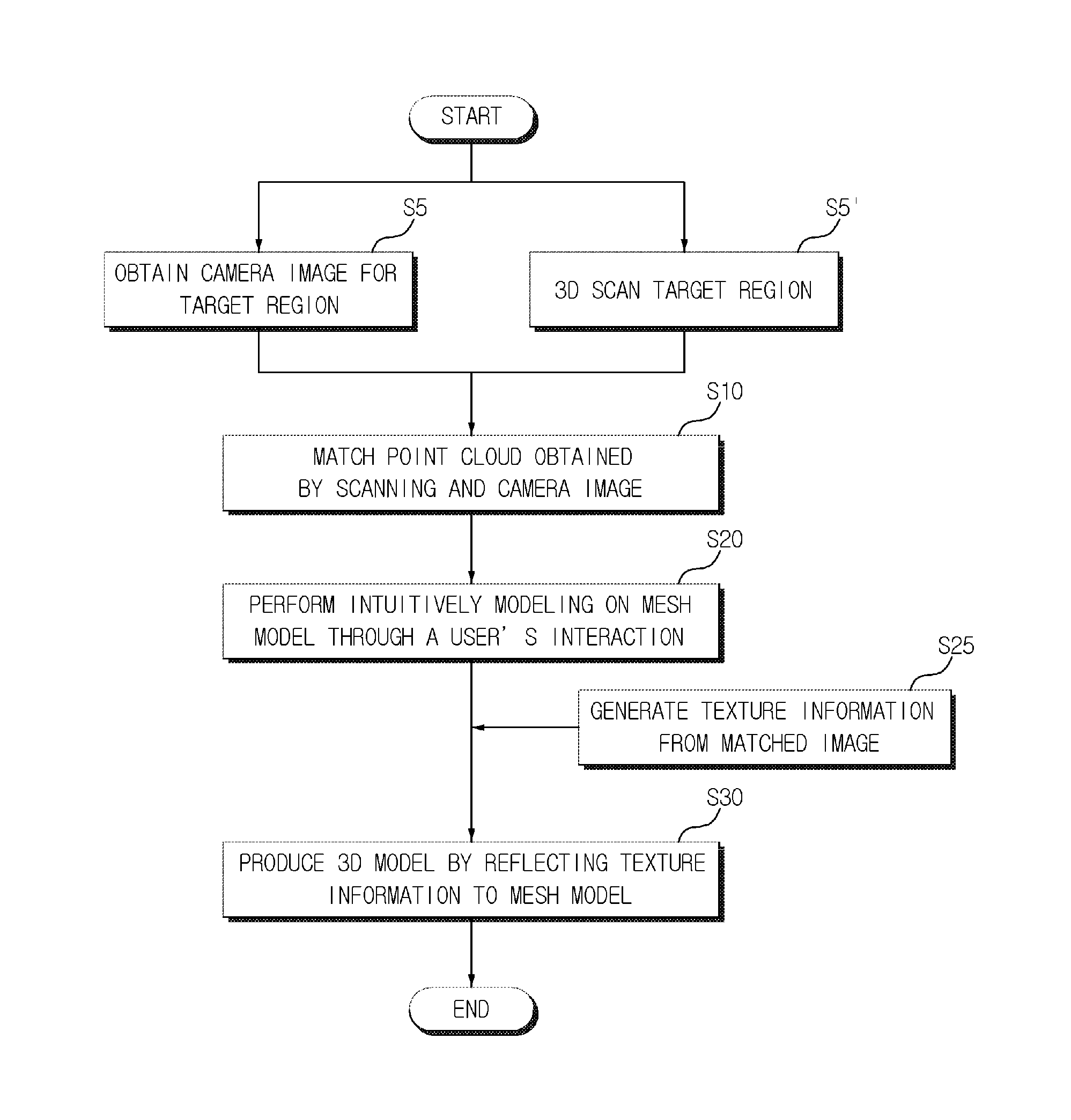

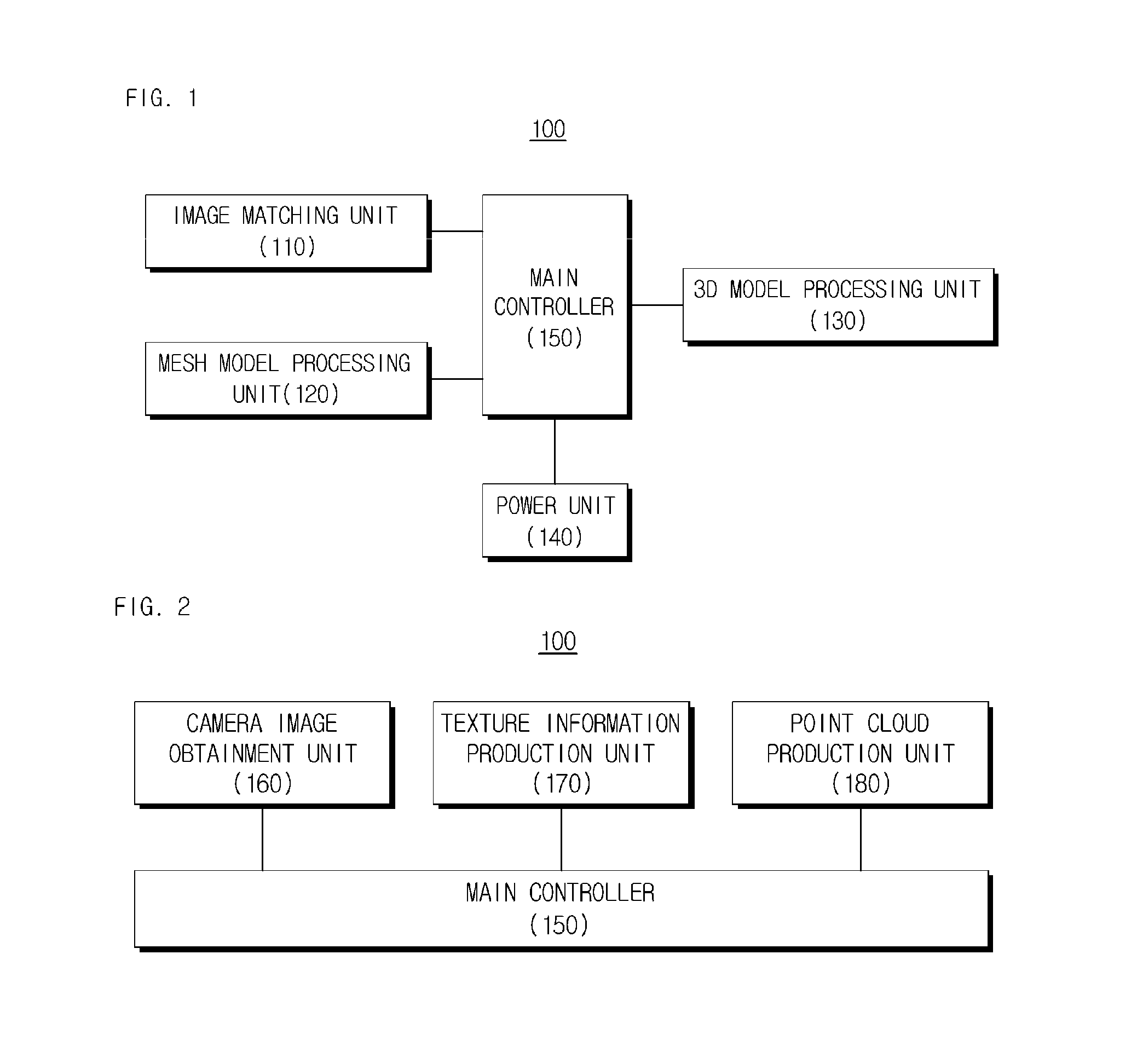

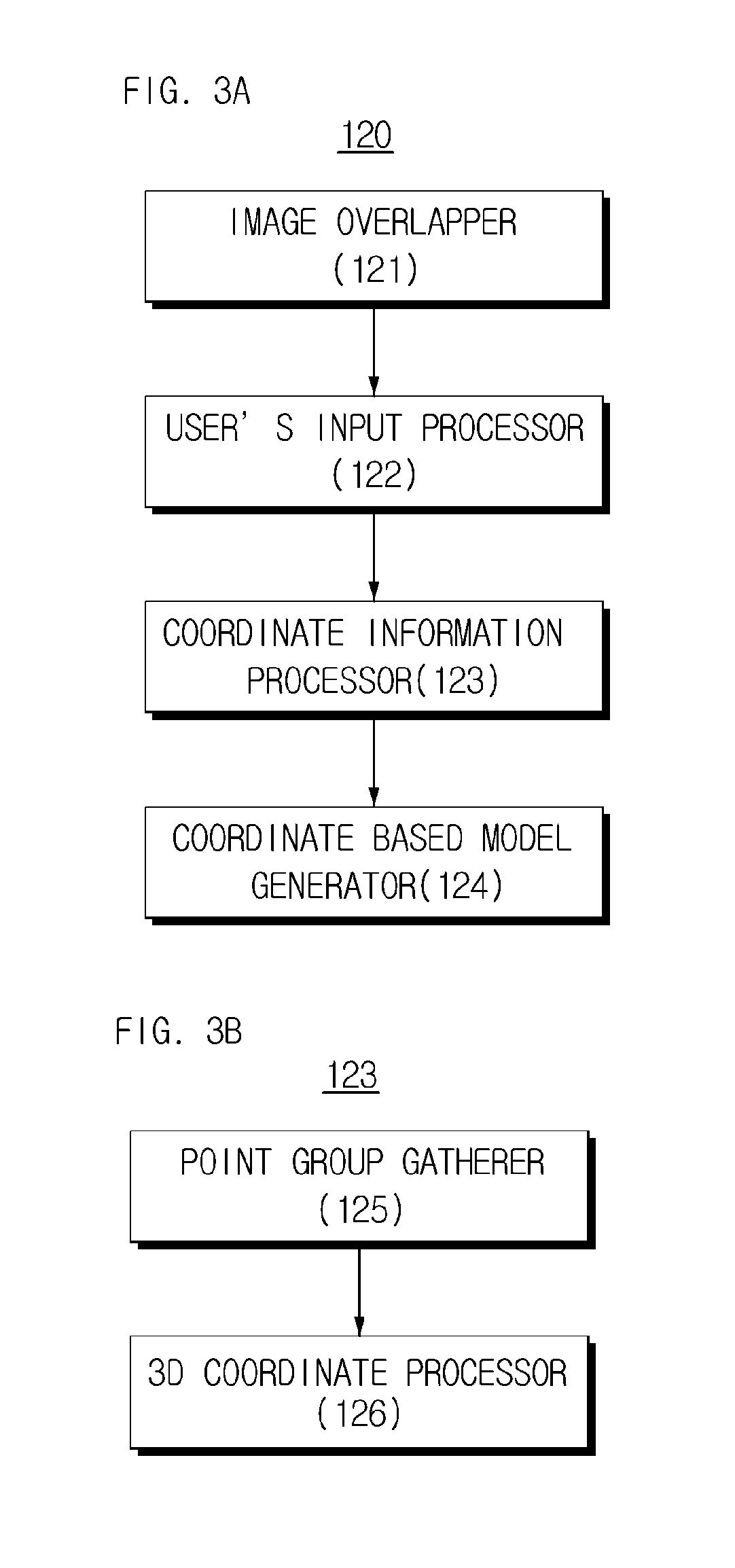

Apparatus and method of producing 3D model

ActiveUS9208607B2Easy to produceRealistic textureImage generation3D-image renderingCamera imagePoint cloud

Disclosed are an apparatus and a method of producing a 3D model in which a 3D model having a static background is produced using a point cloud and an image obtained through 3D scanning. The apparatus includes an image matching unit for producing a matched image by matching a point cloud obtained by scanning a predetermined region to a camera image obtained by photographing the predetermined region; a mesh model processing unit for producing an object positioned in the region as a mesh model; and a 3D model processing unit for producing a 3D model for the object by reflecting texture information obtained from the matched image to the mesh model. The disclosed may be used for a 3D map service.

Owner:ELECTRONICS & TELECOMM RES INST

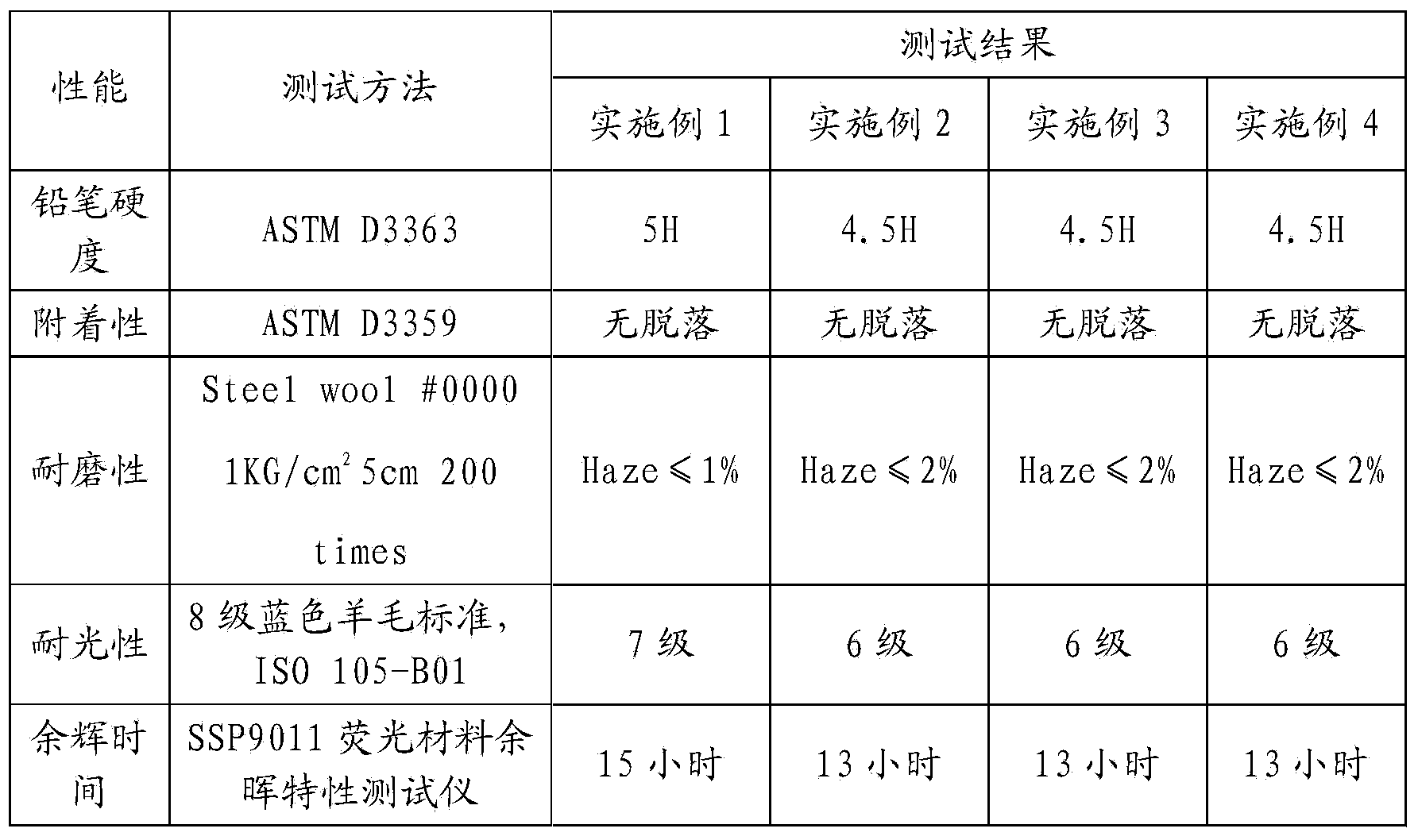

Preparation method of luminous decorative plate

The invention discloses a preparation method of a luminous decorative plate. The preparation method comprises the following steps: 1) preparing material: water-based luminous ink is prepared by the following raw materials in percentage by weight: a material A composed of 5-20% of water-based acrylic resin, 8-20% of luminous powder, 0.5-2% of a dispersant, 0.2-0.5% of a defoaming agent and 15-20% of tap water, a material B composed of 10-20% of a casein solution, 0.3-0.5% of a defoaming agent, 0.5-2% of an anti-settling agent, 5-10% of ethanol, 2-5% of propylene glycol, 20-40% of tap water and 1-2% of a leveling wetting agent and a material C composed of 0.5-2% of a thickening agent and 0.5-1% of a pH value regulator; 2) printing; 3) dipping; 4) pressing, so as to obtain the luminous decorative plate. The luminous decorative plate prepared through the method provided by the invention has the effect of environmental protection and a long-term luminous function, and further has the characteristics of light fastness, scratch resistance, wear resistance, and natural and vivid texture.

Owner:CHANGZHOU WEIXING DECORATIVE MATERIALS

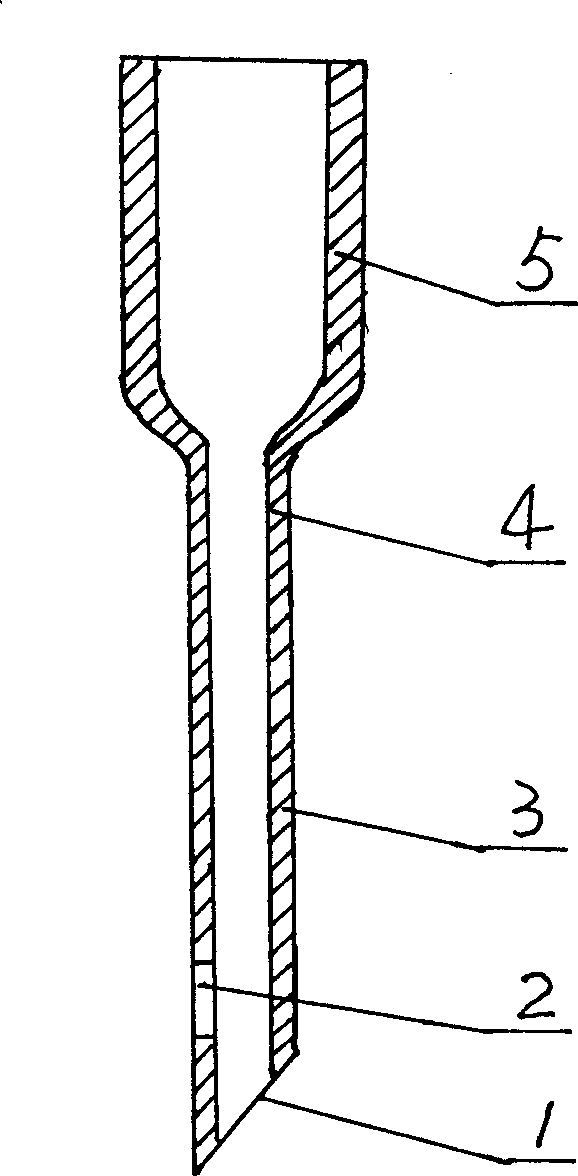

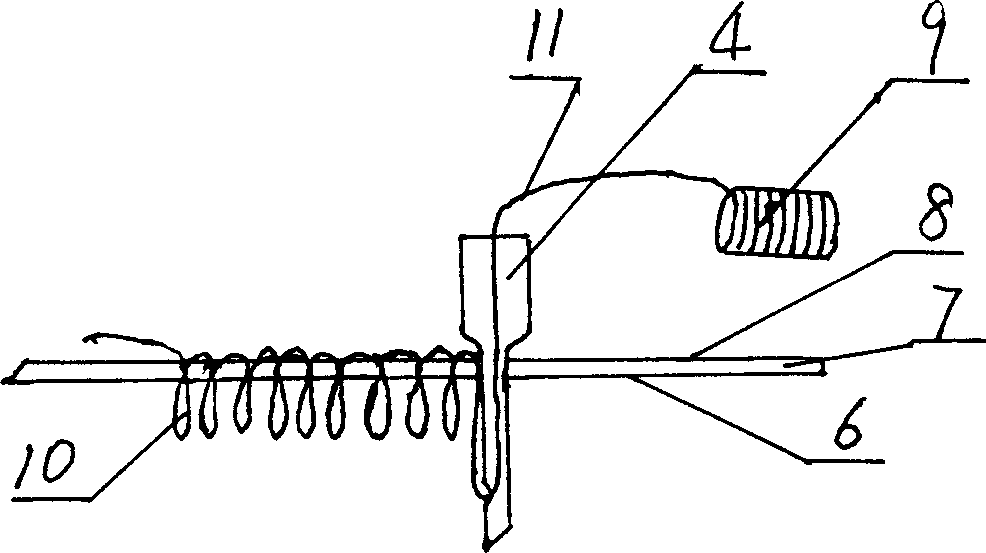

Insertion type embroidering method and insertion embroidering needle

The invention discloses a plug-type embroidery method and special plug-embroidery needle, which is characterized by the following : the plug-embroidery needle consists of hollow needle body and back hollow crank with a small outlet hole next to one needle-point side end of the needle front; inserting the plug-embroidery needle into the cloth from back and extracting along the same hole to form a small stitch; inserting along the back pattern continually to form many small dependent stitches strictly, which generates the preset embroidery pattern; adapting single color embroidery thread different from the pattern color to embroider the entire pattern as substrate around the pattern or within the blank of pattern; daubing the dilute paste on the back uniformly and dry in air; cementing the back needle hole and embroidery thread together entirely. This plug-type embroidery method can finish embroidering the needing one color thread pattern with the stub of entire thread bobbin plugging in the embroidery needle only once, which saves time and labor to accelerate the embroidery speed. The embroidery pattern is smooth and soft, which is abrasion-proof, durable with fine and natural vein.

Owner:辛美霞

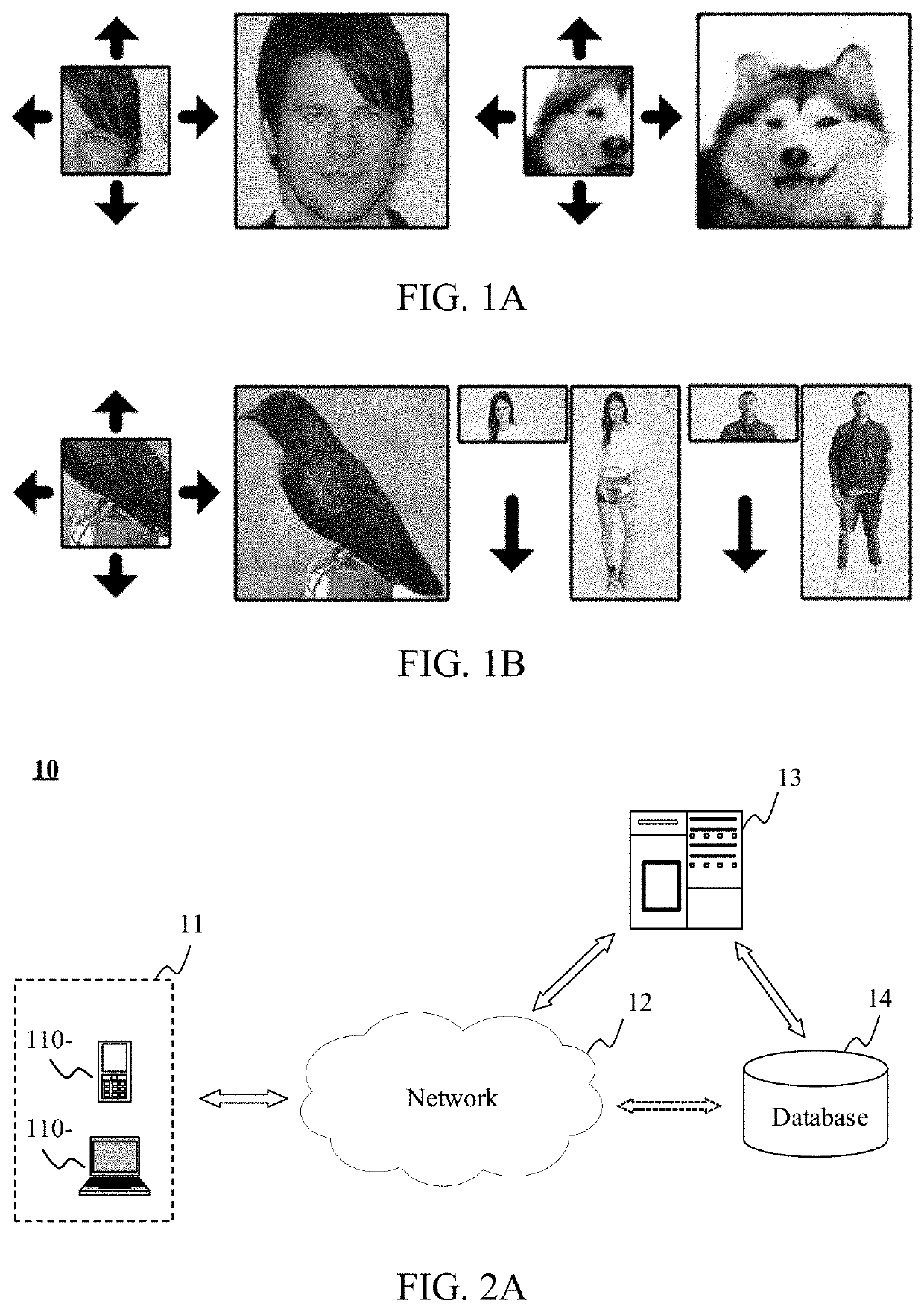

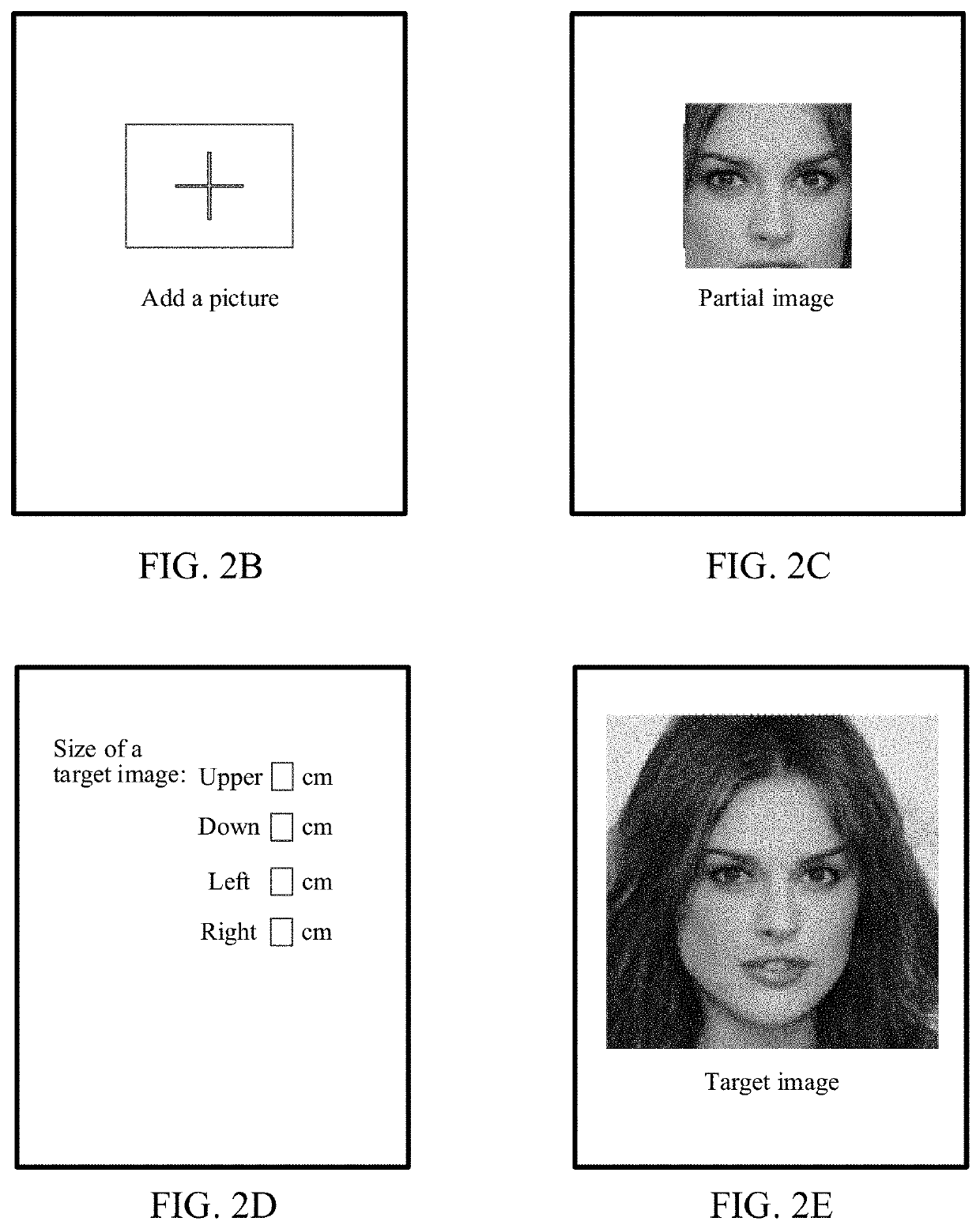

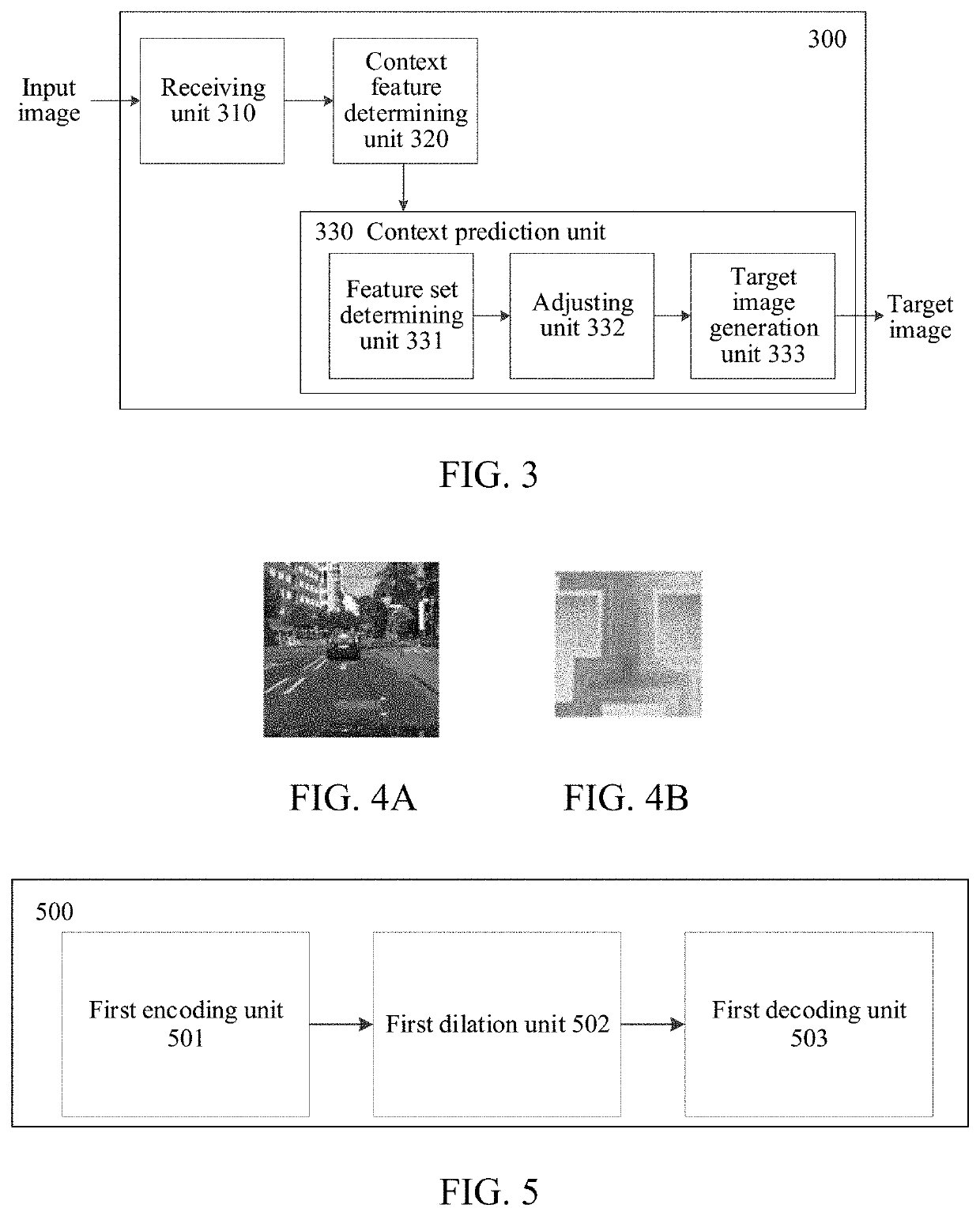

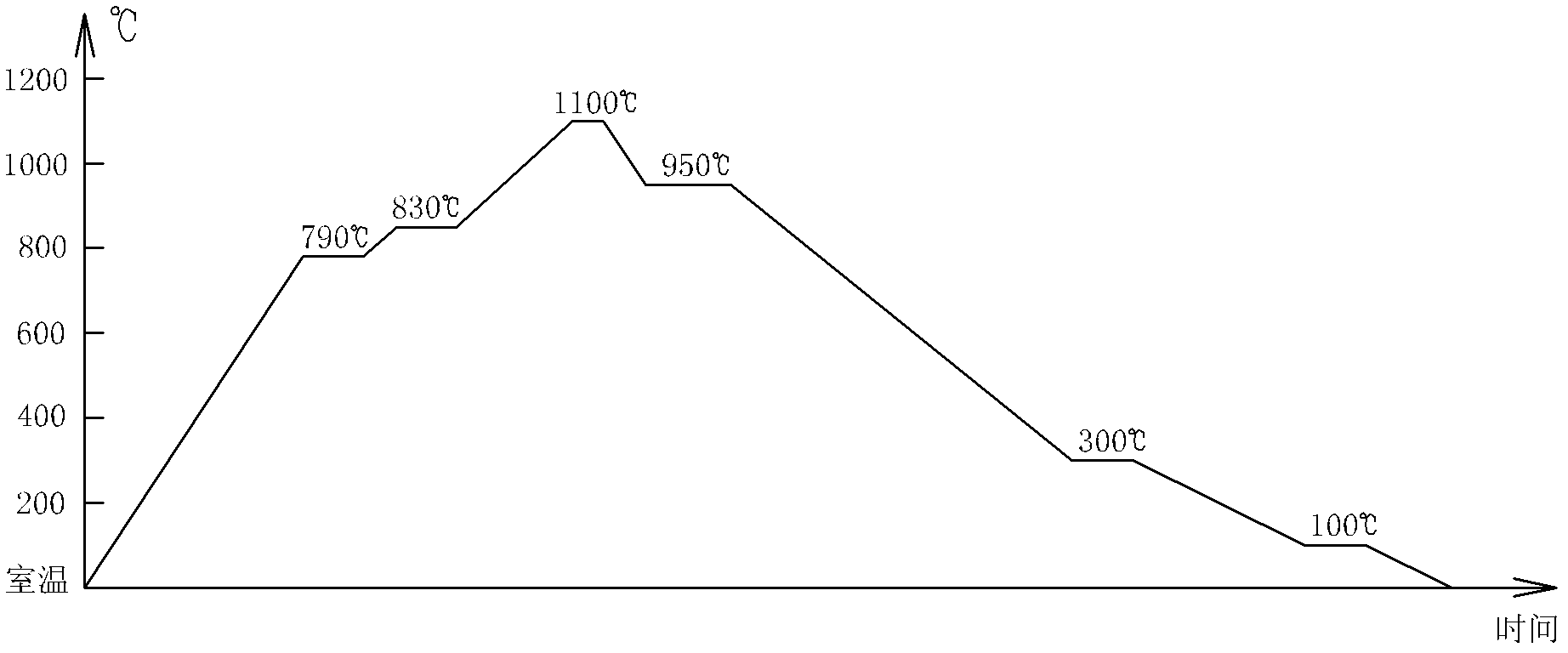

Image processing method and apparatus, device, and storage medium

PendingUS20210334942A1Color/texture consistencyImprove consistencyImage enhancementImage analysisImaging processingFeature set

This application discloses an image processing method, device, and apparatus, and a storage medium. The method is performed by a computing device, the method including: receiving an input image; determining a context feature of the input image; determining a first feature set and a second feature set according to the context feature and based on a size of a target image and a location of the input image in the target image; adjusting the second feature set according to a first feature statistic of the first feature set, to obtain an adjusted second feature set; and generating the target image based on the adjusted second feature set and the first feature set.

Owner:TENCENT TECH (SHENZHEN) CO LTD

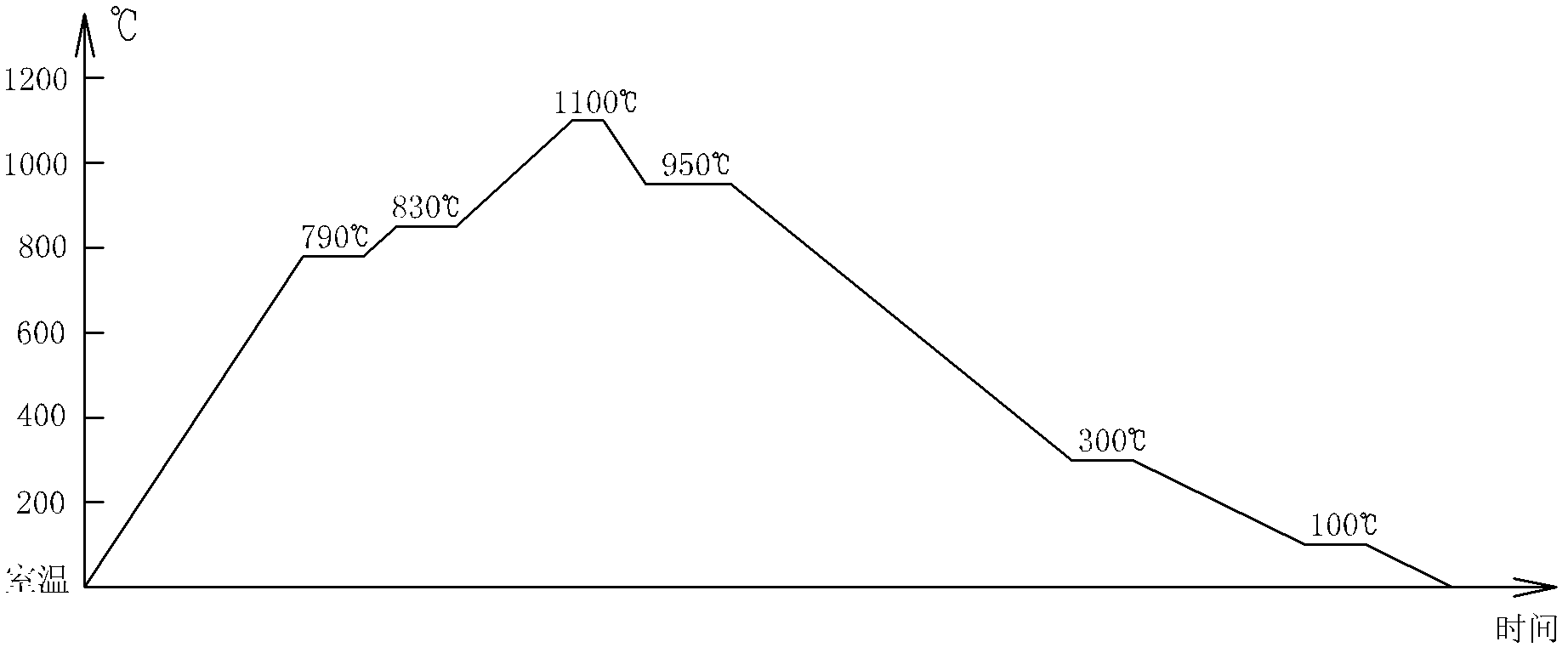

Hot-melting glass with bowlder effect and manufacturing method of hot-melting glass

ActiveCN102583971ATake advantage ofJade works wellGlass shaping apparatusRoom temperaturePre treatment

The invention relates to a piece of hot-melting glass with a bowlder effect and a manufacturing method of the hot-melting glass. The manufacturing method comprises a pre-treating step: breaking the whole piece of hot-melting glass into fragments; a sintering step: placing the fragments into a mould box coated with a releasing agent and placing the mould box into a sintering furnace for sintering, wherein the sintering process comprises a heating stage, a cooling stage, a constant-temperature sintering stage and an annealing cooling stage in turn, specifically: increasing the temperature from the room temperature to the highest temperature 100-150 DEG C higher than the preset sintering temperature in a laddered heating manner, keeping the temperature for 5-10 minutes, and then reducing the highest temperature to the preset sintering temperature at 920-950 DEG C, keeping the sintering temperature for 30-40 minutes and fully sintering, and then cooling the temperature to be the room temperature in a laddered annealing cooling manner; and a post-processing step: carrying out post-processing on a sintered product, thereby obtaining the end product. The manufacturing method provided by the invention is simple and easy in process, the corner wastes of glass are fully utilized, the cost is lower, the hot-melting glass is suitable for mass popularization and application, the manufactured end product has excellent bowlder effect, the texture is vivid and the appearance is beautiful.

Owner:徐日宏

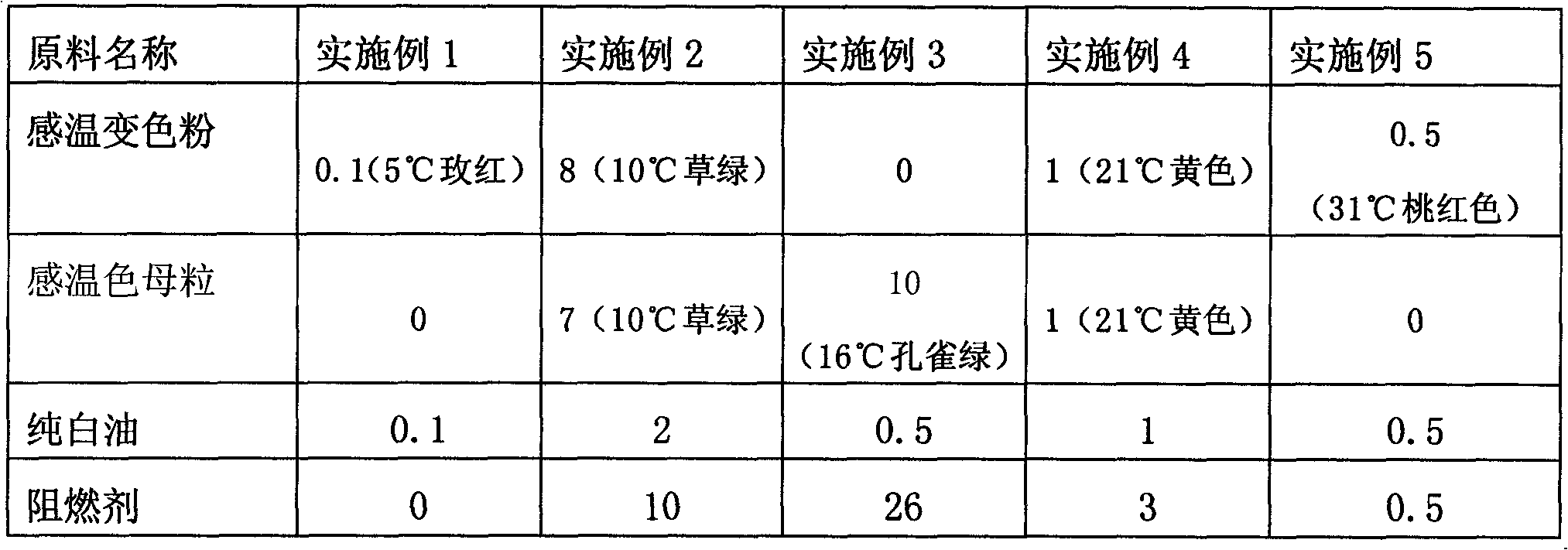

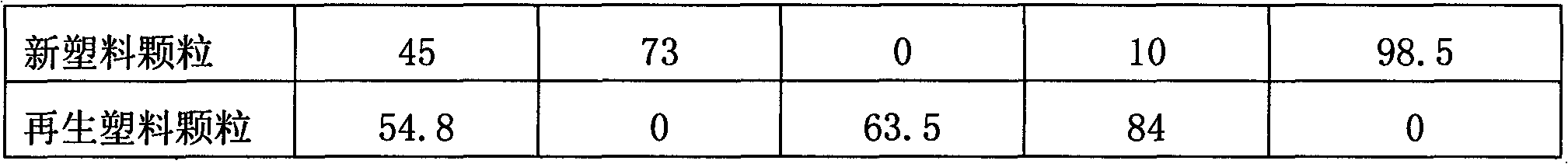

Temperature-sensitive color-changing artificial pebbles and manufacturing method thereof

The invention discloses a temperature-sensitive color-changing artificial cobblestone and a manufacturing method thereof, aiming to provide a low-cost, conveniently produced, natural and realistic artificial cobblestone that can be mass-produced and can change color when exposed to sunlight or when the temperature rises or falls and methods of manufacture thereof. It is a temperature-sensitive color-changing material containing temperature-sensitive color-changing powder or / and temperature-sensitive color masterbatch in the raw materials for making artificial pebbles. The production process of temperature-sensitive artificial pebbles is as follows: batching, mixing, injection molding, demoulding, cooling, polishing, cleaning, inspection, packaging and storage. The temperature-sensitive color-changing artificial pebbles produced according to the above formula and process can change color at different temperatures because the temperature-sensitive color-changing artificial pebbles contain temperature-sensitive color-changing powder. It can be widely used in gardens, paths, stairs, gardens, rockeries, swimming pools, fish tanks, aquariums, and indoor and outdoor decorations. It not only has the decorative purpose of ordinary pebbles, but also has a more beautiful effect of temperature-sensitive discoloration.

Owner:嘉善天路达工贸有限公司

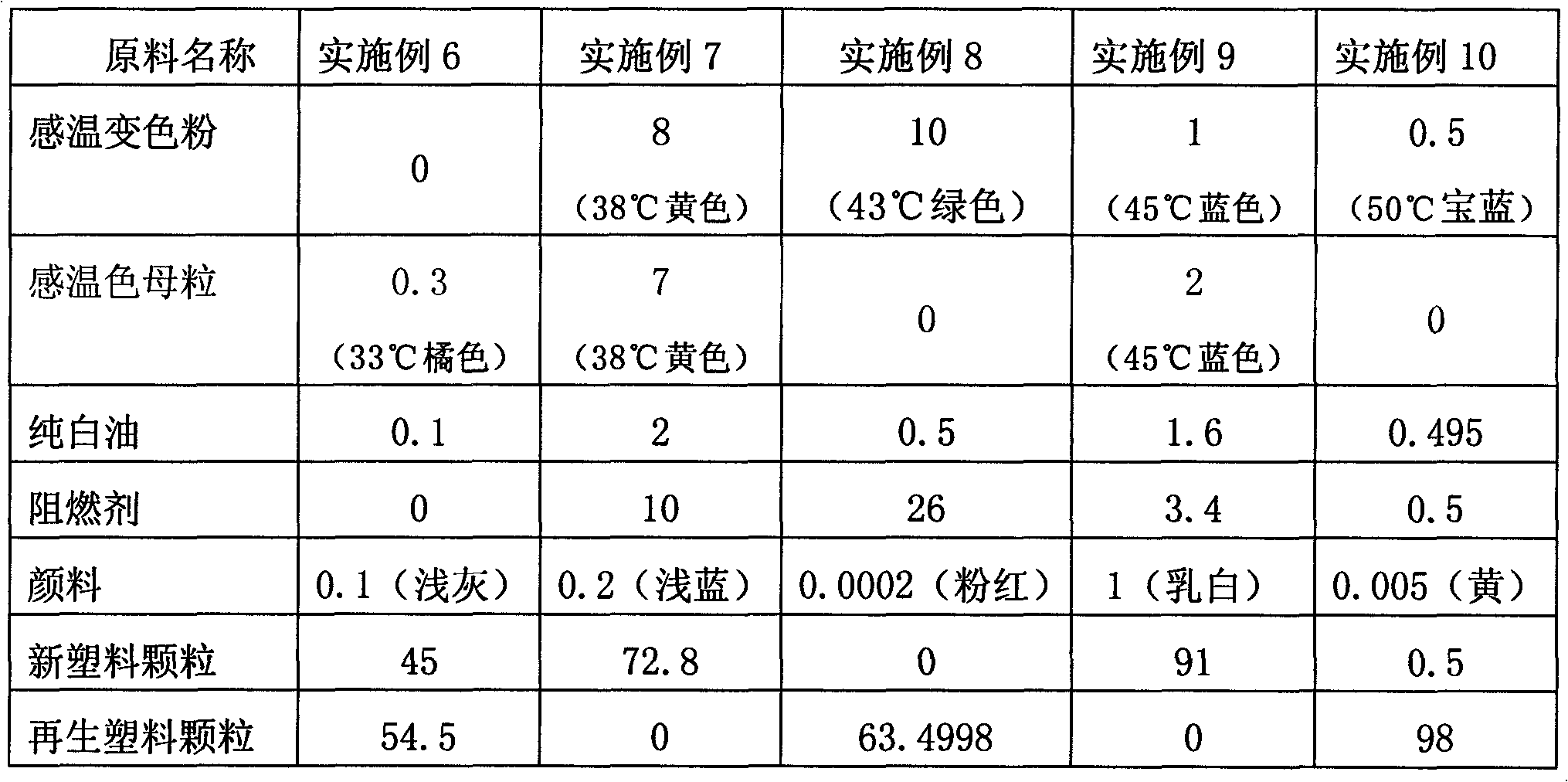

Ceramic brick with negative ion function and production method thereof

InactiveCN106747667AWith negative ion functionNegative ion function is goodEdge grinding machinesPolishing machinesBrickMetallurgy

The invention discloses a ceramic brick with a negative ion function and a production method thereof. The ceramic brick is characterized in that a negative ion additive is added into a ceramic layer. The production method comprises the following steps of (1) preparing a ceramic brick blank; (2) preparing a ceramic material with high-temperature ceramic forming property; (3) applying the ceramic material onto the surface of the blank, forming a ceramic layer, and drying; (4) printing, decorating, forming a printing and decorating layer, and drying; (e) firing; (f) grinding edges. The ceramic brick and the production method have the beneficial effects that the problems of low releasing concentration of negative ions and consumption of a large amount of negative ion powder for increasing releasing concentration of negative ions in the prior art are solved, and the economic and environment-friendly production method of the ceramic brick with the negative ion health function is provided.

Owner:HANGZHOU NABEL CERAMIC

Luminescent artificial cobble stone and production method thereof

The invention discloses a luminescent artificial cobble stone and a production method thereof, aiming at providing a luminescent artificial cobble stone, which has the characteristics of low cost, convenient production, naturality and vividness, and can be produced in large scale and luminescent at night and a production method thereof. The artificial cobble stone is prepared from materials containing luminescent powder. The production process of the artificial cobble stone comprises the following steps of: preparing the materials, mixing the materials, molding by injection, demolding, cooling, polishing, cleaning, inspecting, packaging and loading into a warehouse. The luminescent artificial cobble stone produced by the formulation and the process can emit light at night because the artificial cobble stone contains the luminescent powder, and can be widely applied to parks, footpaths, ladders, gardens, rockeries, swimming pools, fish tanks, aquariums, interior and exterior decorations and the like. The artificial cobble stone not only has the decoration function of common stones, but also sparkles at night, has the effects of safety and beautifulness, and plays the role of safety instruction under the condition of sudden power failure.

Owner:俞善锋

Novel celluloid paint for lacquer painting

The invention provides a novel celluloid paint for lacquer painting. The celluloid paint comprises nitrocellulose, resin, a plasticizer, a strong solvent and a diluent, wherein the ratio of the contents of resin and part of plasticizer to the content of nitrocellulose is 1.5: 1; and under such condition, the celluloid paint can overcome the shortcoming that a white primer film is yellowed after long-time use, has the work effect entirely different from the colored work effect of the traditional lacquer painting, is bright in color and brings a vivid sense.

Owner:平遥恒隆泰漆艺有限公司

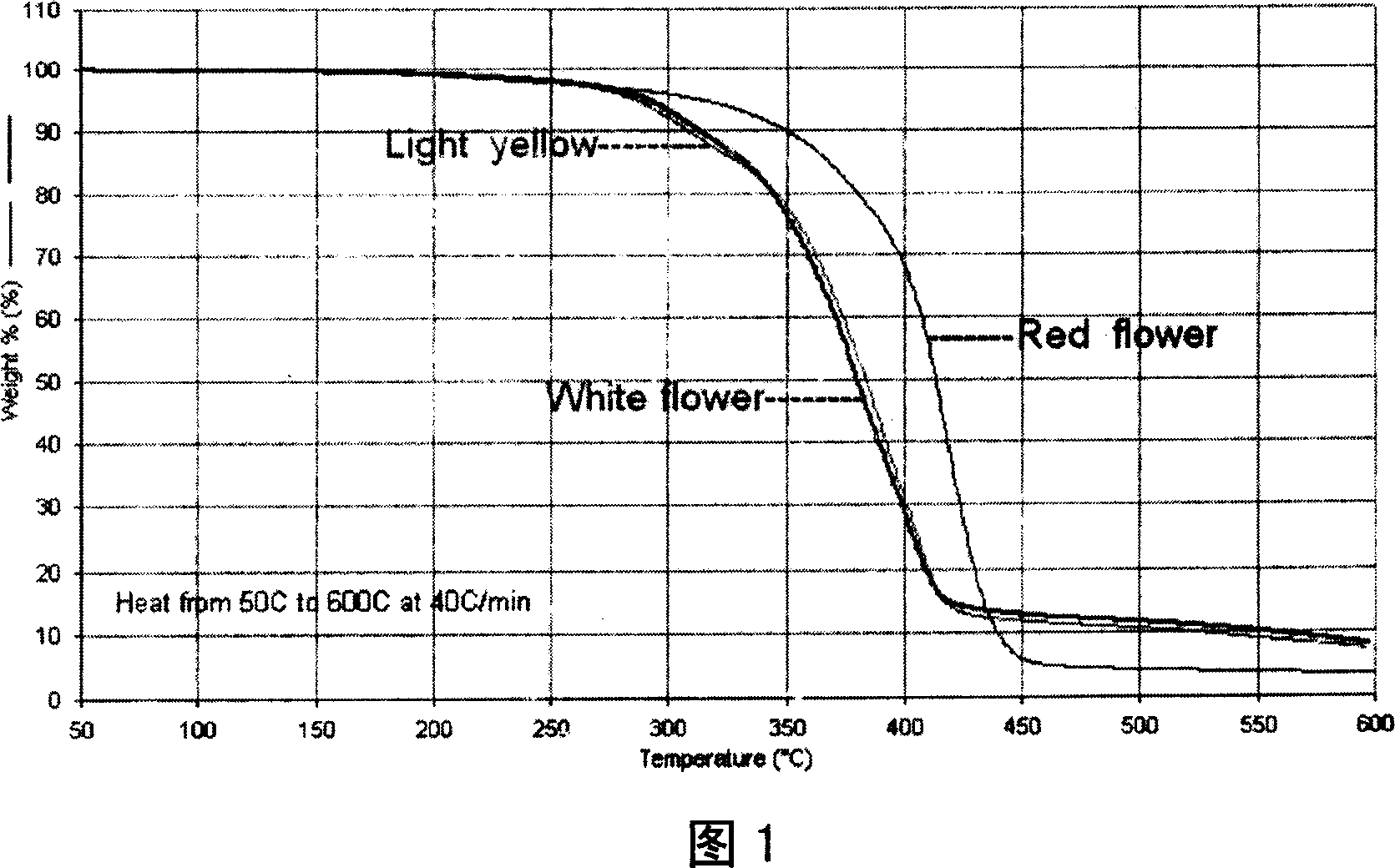

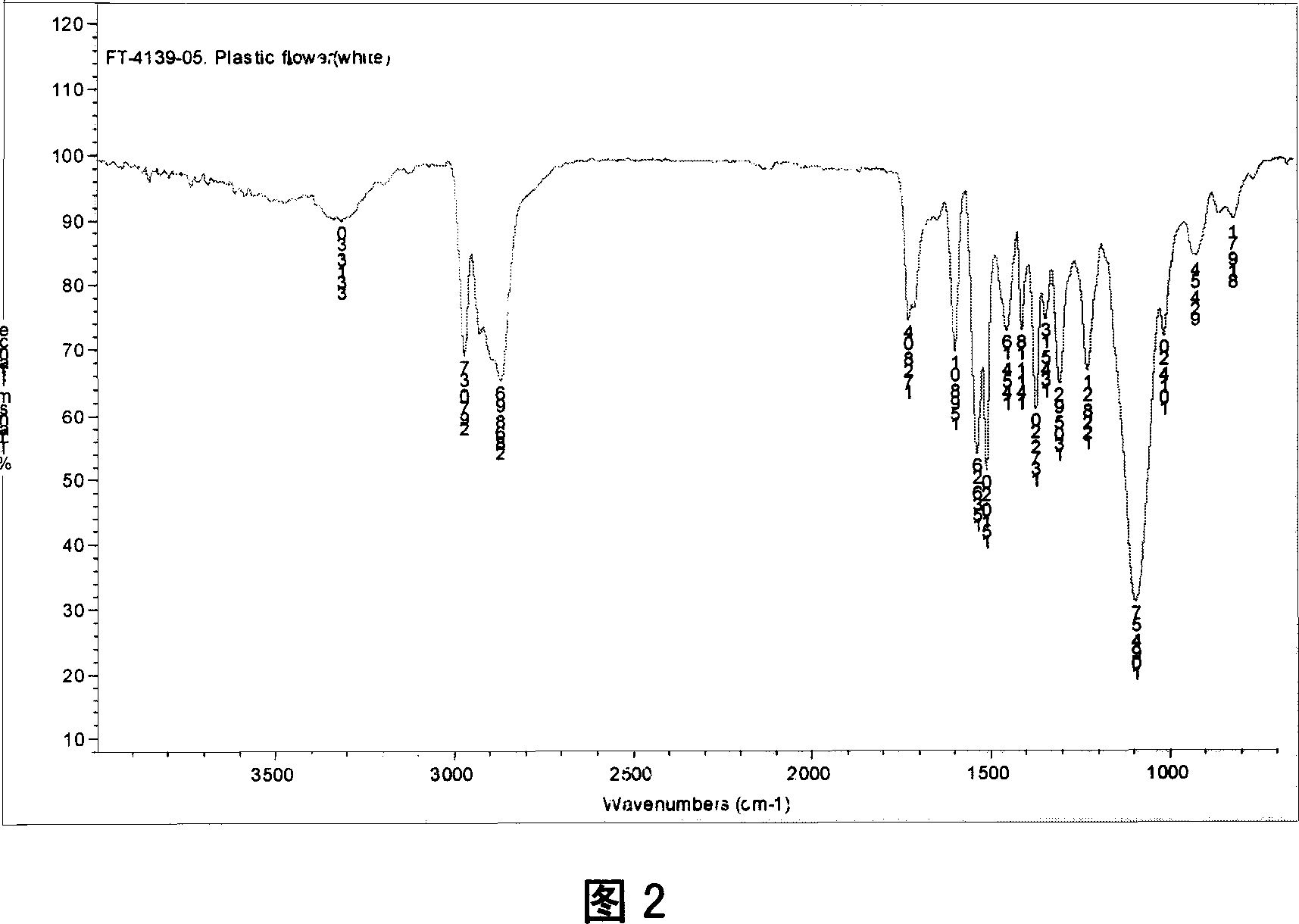

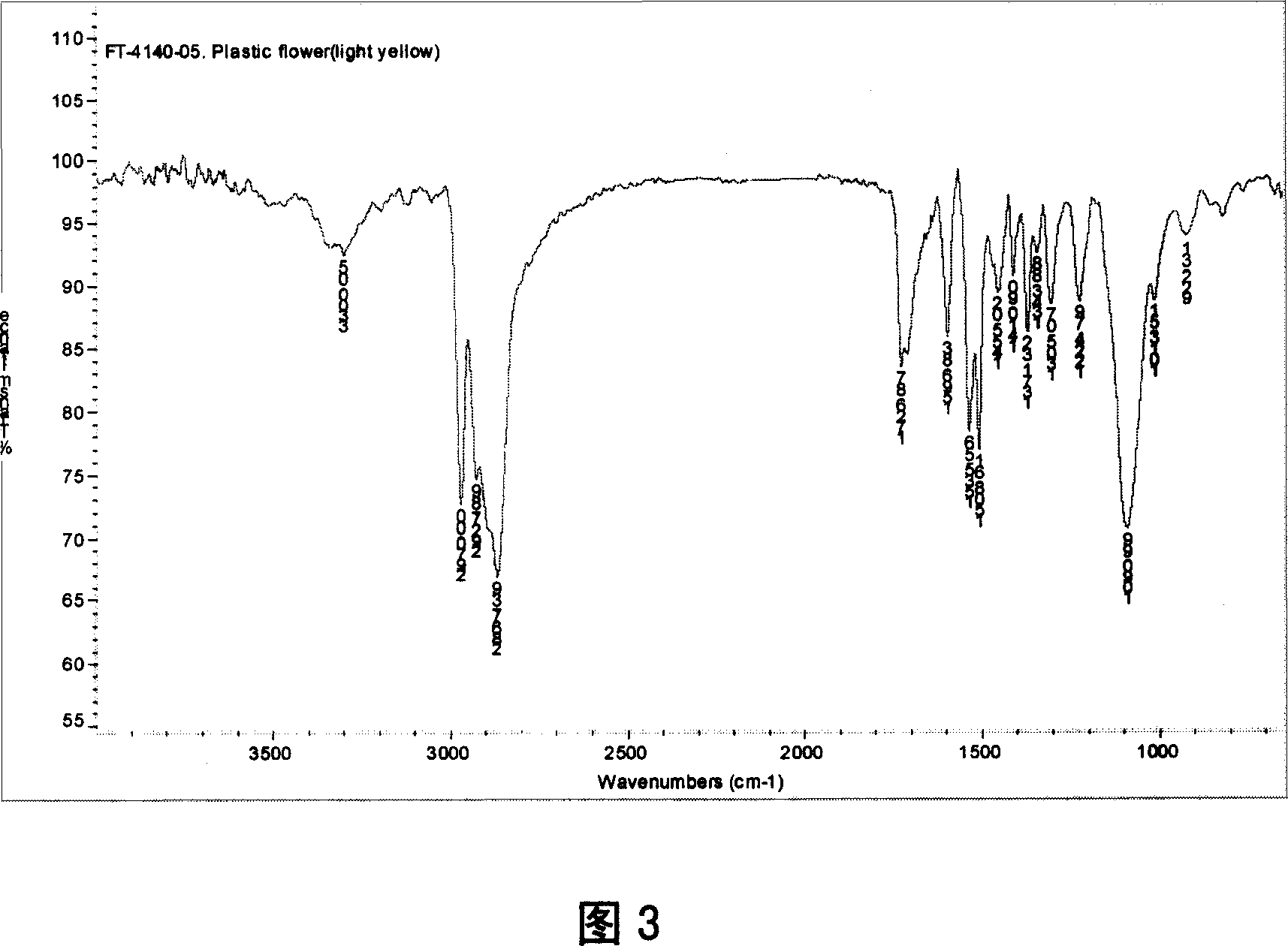

Artificial flowers, and preparation method

InactiveCN1957787AImprove performanceRealistic textureArtificial flowers and garlandsChemistryArtificial flower

An artificial flower is made of foamed polyether polyurethane, which is prepared from the material group A including polyether, cross-linking agent, stabilizer, foaming agent and pigment and the material group B including isocyanate through proportional mixing and fusing.

Owner:威森工艺品(东莞)有限公司

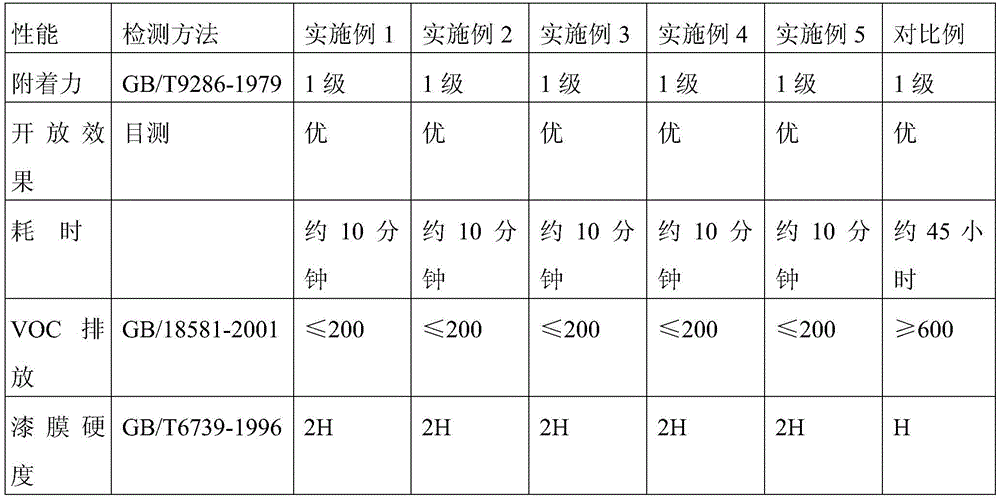

Manufacturing method of veneer open paint sheet material

The invention discloses a manufacturing method of a veneer open paint sheet material, and belongs to the technical field of the preparation of paint sheet materials. The manufacturing method of the veneer open paint sheet material comprises the following steps of adopting a high-density fiberboard or plywood base material, filling unlevel places on the surfaces of the base material by using transparent putty in a roller coating manner, grinding the surfaces to be level by using a 320# abrasive paper belt, removing dust, and adhering natural veneers to double surfaces in a hot pressing manner; grinding the surfaces of the veneers to be level by using the abrasive paper belt, and removing dust; carrying out tinting processing on the veneers, and coating UV (Ultraviolet) transparent primer on the veneers in the roller coating manner; after veneers are subjected to ultraviolet baking, grinding the veneers to be level by using a 400# abrasive paper belt, and removing dust; coating gloss oil for color modulation on the veneers in the roller coating manner; grinding the veneers to be level by using the 400# abrasive paper belt, removing dust, and coating a varnish top-coat on the veneers; subjecting the veneers to the ultraviolet baking. According to the manufacturing method of the veneer open paint sheet material, the UV transparent primer is coated on the veneers in the roller coating manner, and the veneers are good in adhesive force; paint films are natural, and are good in plumpness and real in texture; the manufacturing method of the veneer open paint sheet material can be used for completely replacing a conventional manual banking varnish spray coating process, and can be used for generally realizing the production and the manufacturing in an automatic batch mode of a coating process.

Owner:SHANDONG DONGYU HONGXIANG CABINET MATERIAL CO LTD

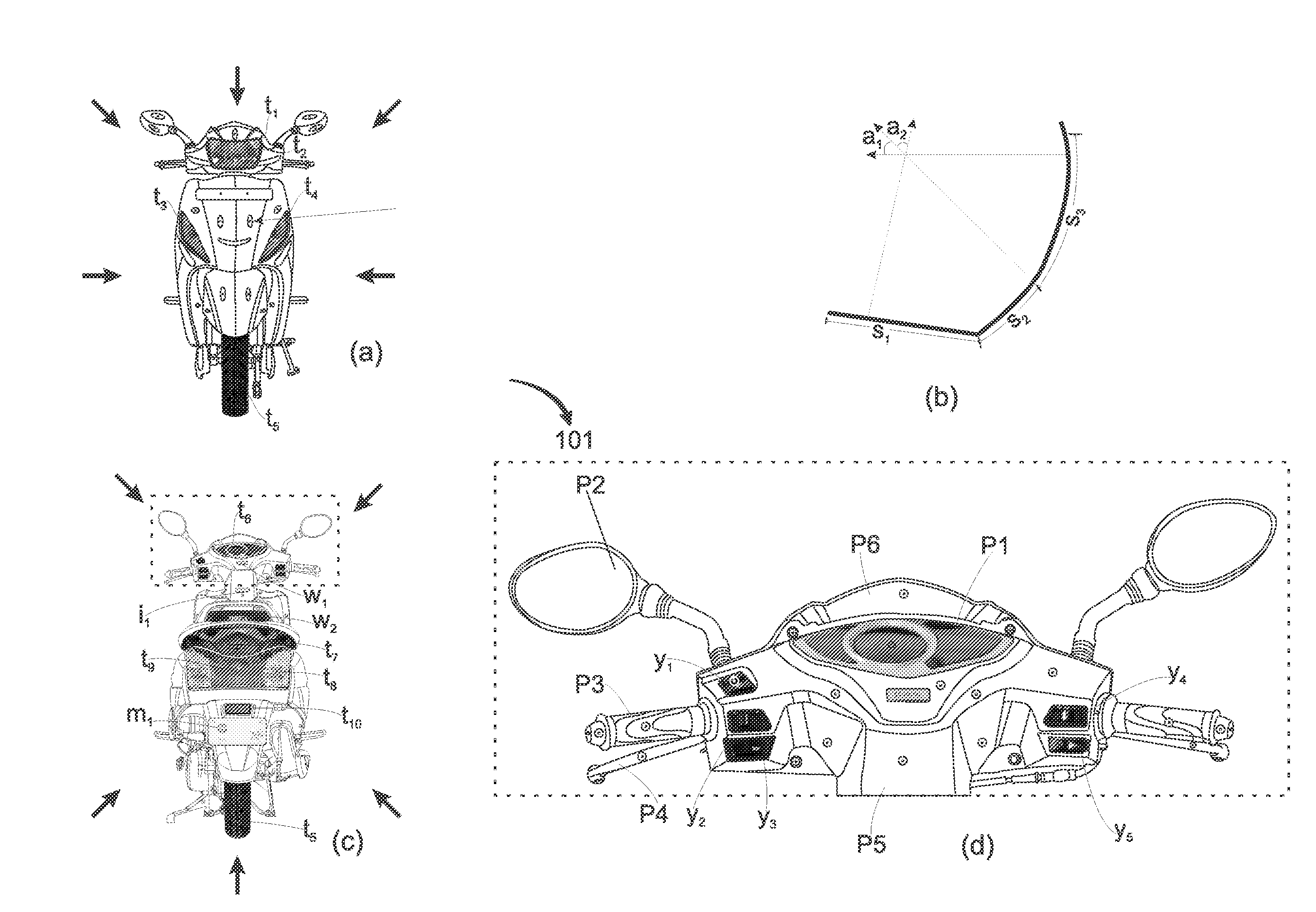

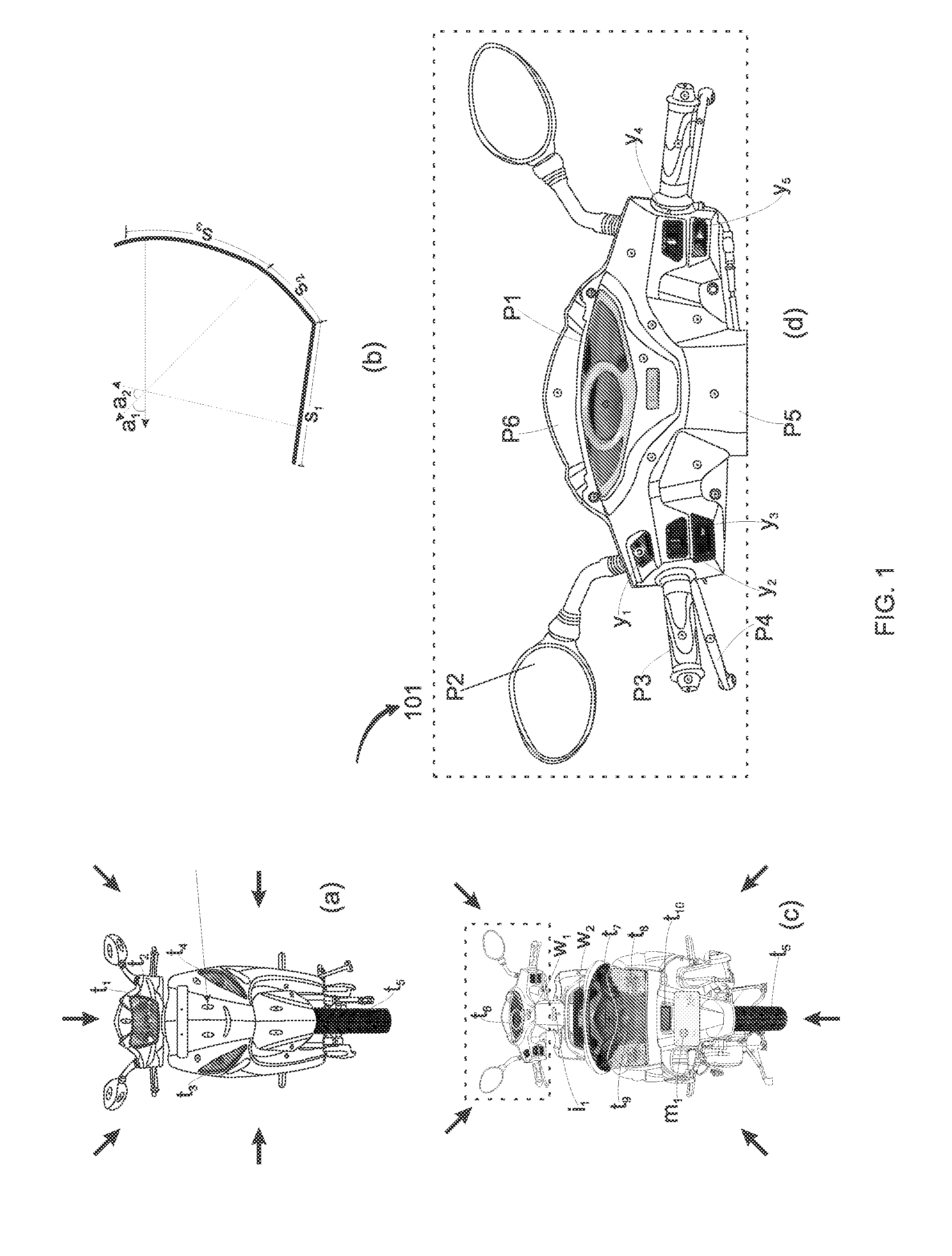

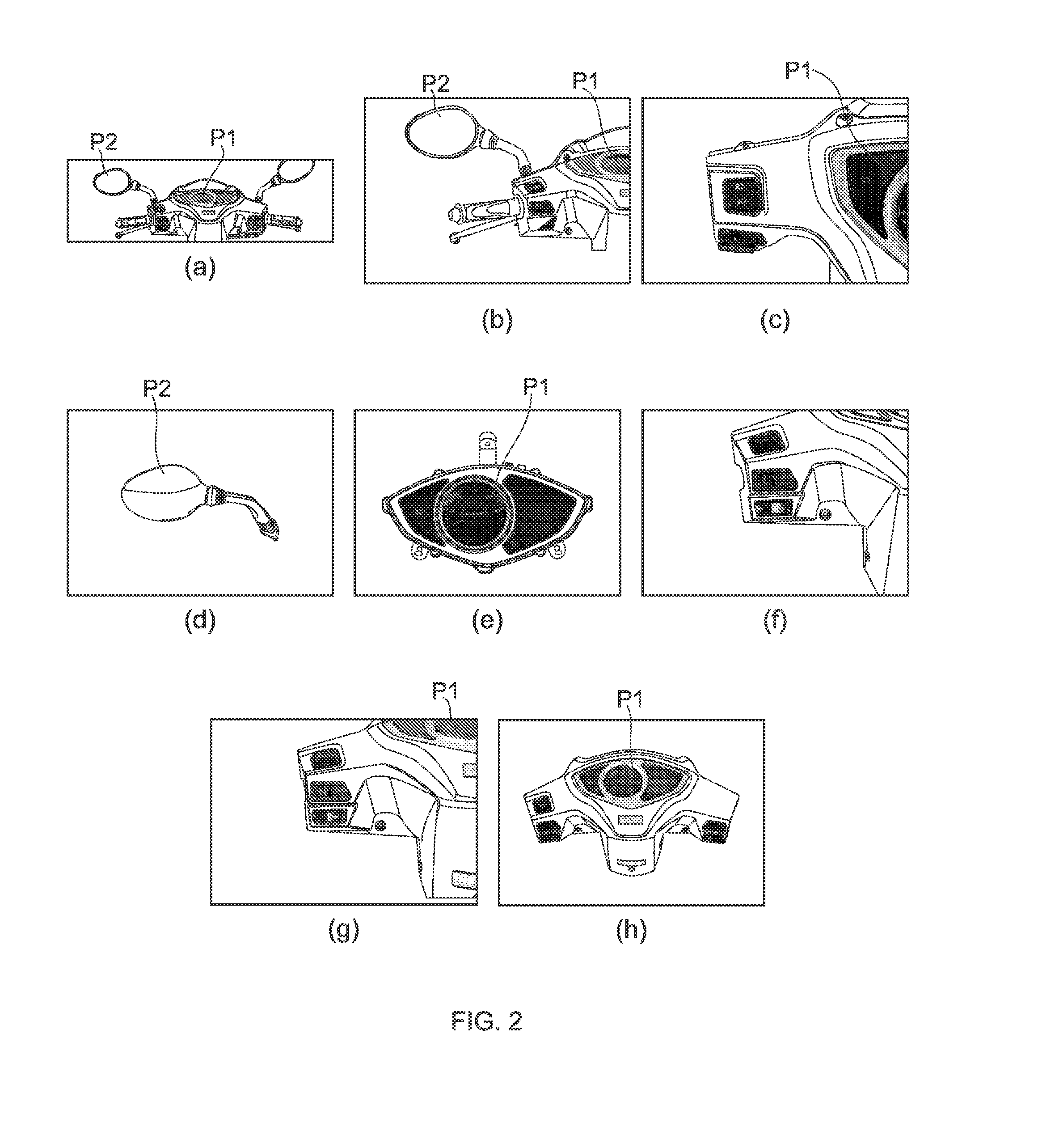

Texturing of 3d-models using photographs and/or video for use in user-controlled interactions implementation

ActiveUS20160307357A1Precise detailingSmall file sizeImage rendering3D-image rendering3D computer graphicsLight emitting device

Texturing of external and / or internal surfaces, or on internal parts of 3D models representing real objects, for providing extremely real-like, vivid and detailed view on and / or within the 3D-model, is made possible using a plurality of real photographs and / or video of the real objects. The 3D models are 3D computer graphics models used in user-controlled interactions implementation purpose. The view of texture on the 3D-model that is textured using real photographs and / or video replicates view of texture as on the real 3D object. Displaying realistic texture on 3D-model surface applying video as texture is made possible replicating real view of light blinking from a physical light emitting device of real object such as head light or rear light of an automotive vehicle.

Owner:VATS NITIN +1

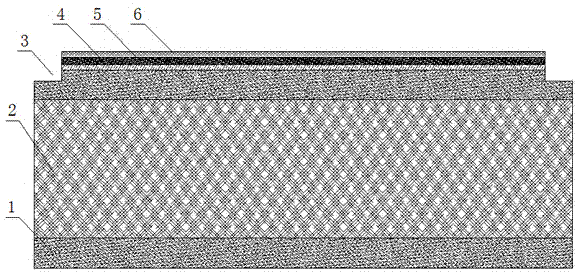

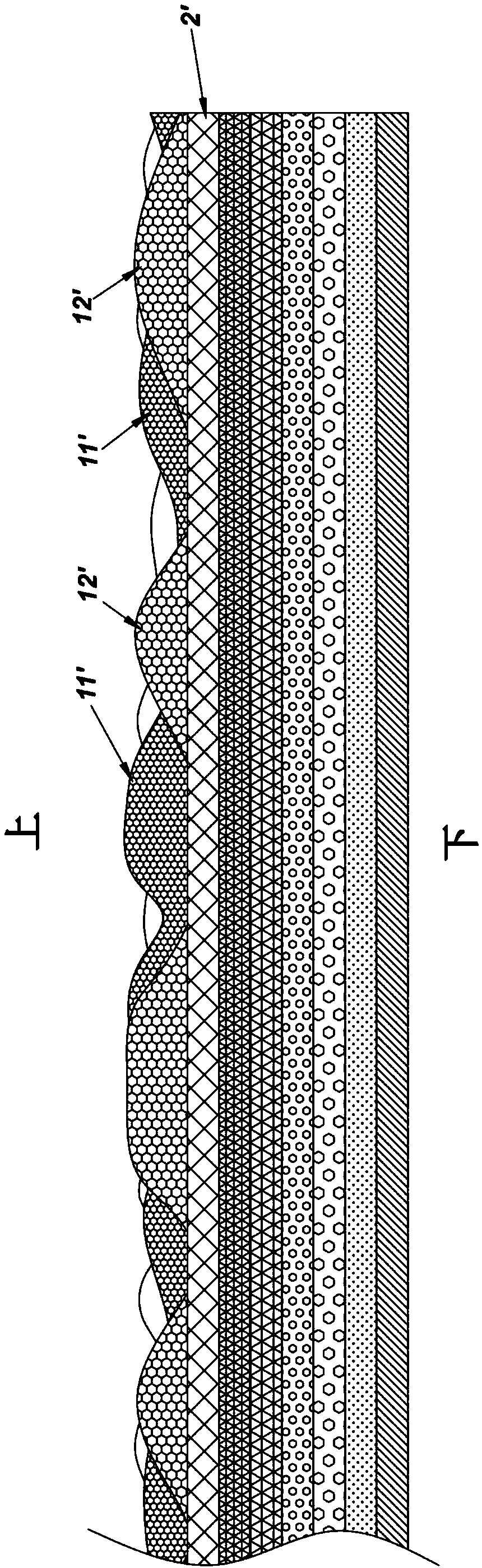

Multifunctional and environment-friendly wood-like decorative board and production method thereof

ActiveCN109203821ARealistic textureLong-lasting functionNatural patternsOrnamental structuresSolid woodPulp and paper industry

The invention provides a multifunctional and environment-friendly wood-like decorative board, and further provides a production method of the multifunctional and environment-friendly wood-like decorative board. The multifunctional and environment-friendly wood-like decorative board can simultaneously have the look and texture of solid wood with additional functions. The multifunctional and environment-friendly wood-like decorative board comprises a wood-like decorative film and a plate body, and the wood-like decorative film specifically comprises a texture functional layer, a base film layer,a visual effect layer and an adhesive layer from top to bottom. The texture functional layer is divided into a hard functional part and a soft functional par. The hard functional part and the soft functional part are simultaneously exposed on the front side of the wood-like decorative film. The soft functional part contains soft particles and microcapsules; the hard functional part contains hardparticles and microcapsules; and the microcapsules of the soft functional part and the microcapsules of the hard functional part both contain functional substances. The multifunctional and environment-friendly wood-like decorative board and the production method thereof have the following advantages that the texture and the look of the wood grain are very realistic, and the decorative board can beprovided with various functions which are easy to customize as needed.

Owner:佛山市顺德区四方板业科技有限公司

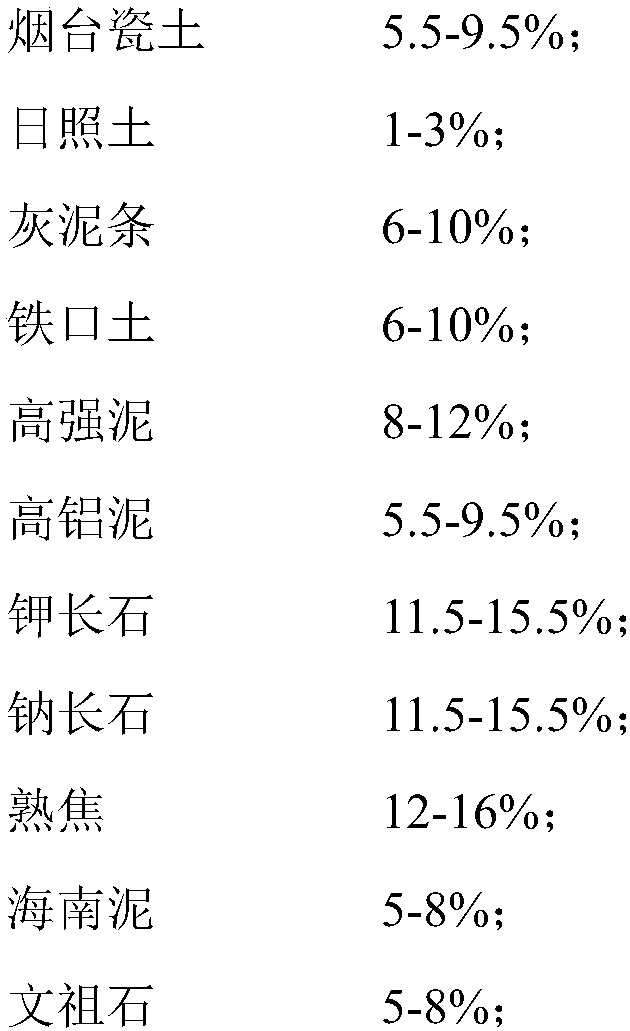

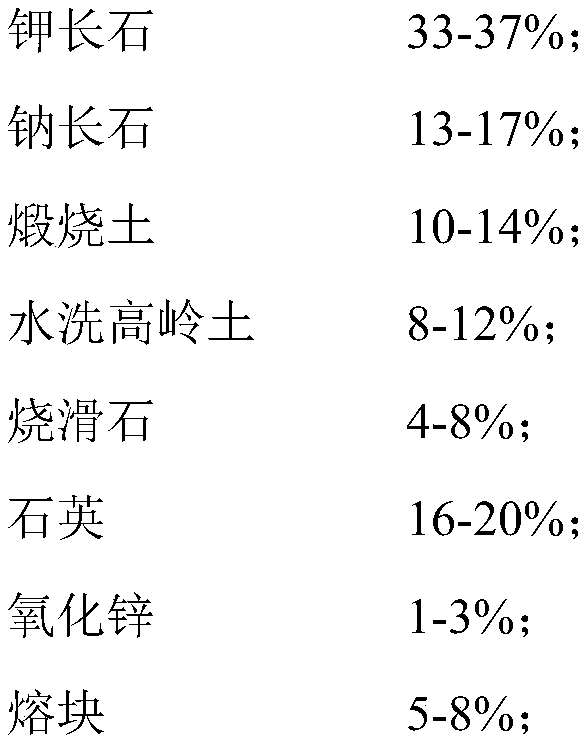

Imitation raw gemstone ceramic tile and preparation method thereof

The invention belongs to the technical field of architectural ceramics, and particularly relates to an imitation raw gemstone ceramic tile and a preparation method thereof. The ceramic tile comprisesa green body material layer, a bottom glaze layer and a color-forming glaze layer, wherein the green body material layer is prepared from the following raw materials: Yantai porcelain clay, Rizhao clay, plaster strips, high-strength clay, high-aluminum clay, potassium feldspar, sodium feldspar, cooked coke, Hainan clay, Wenzu stone and pyrophyllite, the bottom glaze layer is prepared from the following raw materials: potassium feldspar, sodium feldspar, calcined clay, washed kaolin, calcined talc, quartz, zinc oxide, frit and zirconium silicate, and the color-forming glaze layer is prepared from the following raw materials: potassium feldspar, dolomite, corundum, zinc oxide, washed kaolin, barium carbonate, frit and whisker materials. The ceramic tile has the advantages that the hand feeling of the ceramic tile is close to that of raw gemstone, and the texture and the color are vivid; and the fire resistance is high, the frost resistance is high, the surface hardness can reach 5 levels, the skid resistance can reach R9 or above, the anti-fouling and anti-corrosion effects are achieved, and in addition, negative ions can be released. The preparation method has the advantages of being scientific, reasonable, simple and feasible.

Owner:淄博新金亿陶瓷科技有限公司

Inorganic rock-wool thermal insulation decorating plate with leveling natural stone paint surface

ActiveCN104775584ASimple structureImprove sealingCovering/liningsCoatingsCalcium silicateInsulation layer

The invention discloses an inorganic rock-wool thermal insulation decorating plate with a leveling natural stone paint surface. The decorating plate comprises a heat insulation layer made of inorganic rock-wool; calcium silicate boards which are taken as reinforced layers are respectively arranged at the upper surface and the lower surface of the heat insulation layer; the outer side surface of the calcium silicate board arranged at one side of the heat insulation layer is coated with a leveling natural stone paint finish coat; the finish coat comprises a prime coat, a natural stone paint layer and a finish paint layer; mounting sides are respectively arranged at the peripheries of the finish coat and the calcium silicate board connected with the finish coat. The inorganic rock-wool thermal insulation decorating plate integrates the functions of heat insulation, heat preservation and surface decoration, and is simple in structure, easy to install, light in self weight, high in strength and good in safety; the finish coat has the characteristics of having the true color of natural stone, being natural in color, vivid in texture, colorfast, environment-friendly, flat, smooth, high in accuracy, high in self-cleaning ability, weather-proof, cracking-resistant, anti-drop and the like; the finish coat adopts a three-layer structure including the prime coat, the natural stone paint layer and the finish paint layer, so that the decorating plate is stable and firm and does not lose paint and fade, and the product quality is guaranteed.

Owner:信阳新天意绿色建材有限公司

Reflection heat insulation and preservation veneer integrated external wall panel sectional material

InactiveCN104594586ASuppresses radiant heatGood energy saving effectCovering/liningsWater-setting substance layered productFiberEmulsion

The invention relates to a reflection heat insulation and preservation veneer integrated external wall panel sectional material which is composed of a heat preservation layer and a veneer layer, wherein the heat preservation layer and the veneer layer are pressed to form a whole. The heat preservation layer is an existing external wall external heat preservation sectional material product made of inorganic mineral materials in the market. The veneer layer is formed by preparing ten raw materials of waste stone detrital materials, hollow glass micro-beads, vitrified micro-beads, rare-earth oxides, rutile, waterborne emulsion, inorganic adhesives, wood fiber, polypropylene short fiber and film formation auxiliaries and water. An overall composed, pressed and formed structure of the heat preservation layer and the veneer layer is adopted for the sectional material, the structure is used for an external wall body, safety is high, solar radiant heat absorbed by a building can be reduced, temperature rising caused by solar radiation absorbed by the surface of the building is prevented, heat transmitted into a room is reduced, the heat preservation and insulation requirement of the building outer wall body is met, and the purposes of providing comfortable indoor and outdoor environments, saving energy and lowering consumption are achieved.

Owner:信阳天意节能技术股份有限公司

Fully plastic wood-imitation material and preparation method thereof

InactiveCN102336977BHigh mechanical strengthLow coefficient of linear expansionFilling materialsMixed materials

The invention discloses a fully plastic wood-imitation material and a preparation method thereof and relates to a wood-imitation material and a preparation method thereof. The fully plastic wood-imitation material comprises the following components in parts by weight: 100 parts of polystyrene, 20-40 parts of high impact polystyrene, 10-15 parts of resin, 2-5 parts of inorganic filling material, 0.5-2 parts of colorant and 1.5-3 parts of addition agent. The addition agent is mixed with the colorant to obtain a mixed material A; the resin and the inorganic filling material are dried; the polystyrene, the high impact polystyrene, the resin, the mixed A and the inorganic filling material are mixed to obtain a mixed material B; and the mixed material B is granulated, and then the obtained granules are molded to obtain the fully plastic wood-imitation material. Compared with the conventional wood-imitation material, the fully plastic wood-imitation material contains no wood component and no heavy metal, is waterproof, moistureproof, insect-resistant, anticorrosive and environment-friendly and contains low carbon. By injection or extrusion molding, the fully plastic wood-imitation material can be used without polishing, and products can be recovered by 100% and recycled.

Owner:XIAMEN UNIV +1

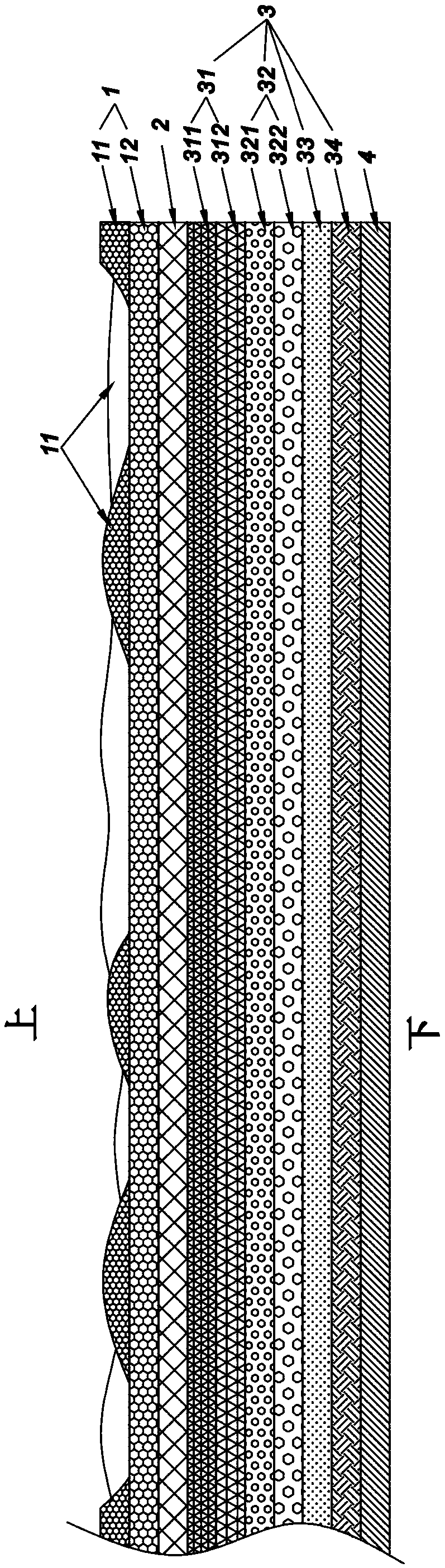

Multifunctional and environment-friendly imitated wood decorative film and production method thereof

ActiveCN109181562ARealistic textureAntifouling/underwater paintsFilm/foil adhesivesSolid woodMaterials science

The invention provides a multifunctional and environment-friendly imitated wood decorative film with appearance and texture of solid wood and additional functions. The multifunctional and environment-friendly imitated wood decorative film comprises a texture functional layer, a base film layer, a visual effect layer and an adhesive layer from top to bottom in turn; the texture functional layer isdivided into a hard functional part and a soft functional part; the hard functional part and the soft functional part are exposed on the front side of the imitated wood decorative film; the soft functional part contains soft grains and microcapsules; the hard functional part contains hard grains and microcapsules; functional materials are contained in the microcapsules of both the soft functionalpart and hard functional part. The invention also provides a production method for the imitated wood decorative film. The multifunctional and environment-friendly imitated wood decorative film and theproduction method thereof provided by the invention have the advantages that the appearance and texture of wood grains are vivid, the decorative film can be endowed with various easily customized functions according to requirement and the decorative film is suitable for adhesion and coating of different materials.

Owner:佛山市顺德区宝丽马彩膜板业科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com