Artificial flowers, and preparation method

A manufacturing method and technology of artificial flowers, which are applied in the field of artificial flowers, can solve problems such as easy to break, recycling environmental pollution, poor durability, etc., and achieve effects that are not easy to change, stable in performance, and realistic in texture

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0038] Embodiment 1 (artificial simulation white lily):

[0039] According to a formula and a manufacturing method of artificial flowers of the present invention, an artificial artificial white lily is produced, measured by weight.

[0040] The ingredients included in the flower head are divided into Group A and Group B:

[0041] Group A includes 80% polyether, 3% crosslinking agent, 2% stabilizer, 1.5% catalyst, 4% water, 4.2% blowing agent, and 1.3% color paste;

[0042] Group B includes 18% isocyanate with crust material properties and 36% isocyanate with ordinary high resilience properties; wherein the weight percentage of group B is calculated on the basis of group A. This time, 20kg of ingredients are used in group A of the artificial lily flower, and 3.6kg of isocyanate for the crust material of group B, and 7.2kg of ordinary high-resilience isocyanate are used, and they are evenly mixed together.

[0043] The flower branch also includes the ingredients of group A and...

Embodiment 2

[0050] Embodiment 2: (light yellow PU artificial flowers)

[0051] Group A includes 70% polyether, 6% crosslinking agent, 4% stabilizer, 0.5% catalyst, 14% water, 4.2% blowing agent, and 1.3% color paste;

[0052] Group B includes 10% isocyanate with crust material properties and 45% isocyanate with ordinary high resilience properties; wherein the weight percentage of group B is calculated on the basis of group A.

Embodiment 3

[0053] Embodiment 3 (red PU artificial flower):

[0054] Group A includes 90% polyether, 2% crosslinking agent, 3% stabilizer, 1% catalyst, 2% water, 1.2% blowing agent, 0.8% color paste;

[0055] Group B includes 60% isocyanate of crust material property; wherein the weight percentage of Group B is calculated on the basis of Group A.

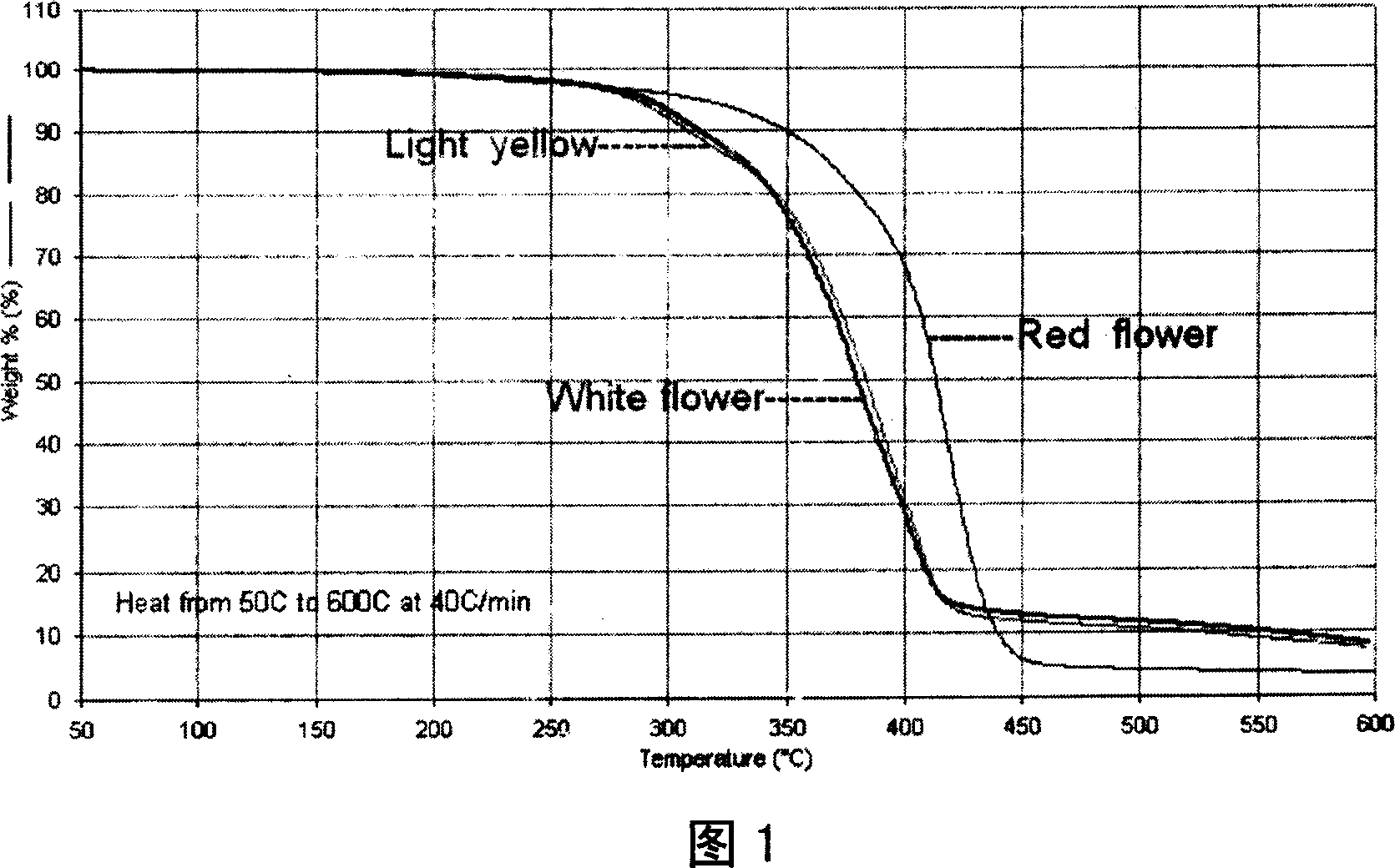

[0056] The above three different flowers, artificial artificial white lilies, light yellow PU artificial flowers and red PU artificial flowers, have been tested by the American Society for Testing and Materials, and the results are as follows:

[0057] 1) Qualitative testing of materials

[0058] Sample name: artificial flower, 1) white; 2) light yellow; 3) red, one for each

[0059] piece

[0060] Test environment: temperature (T): 23±3℃, relative humidity (RH): 50±5%

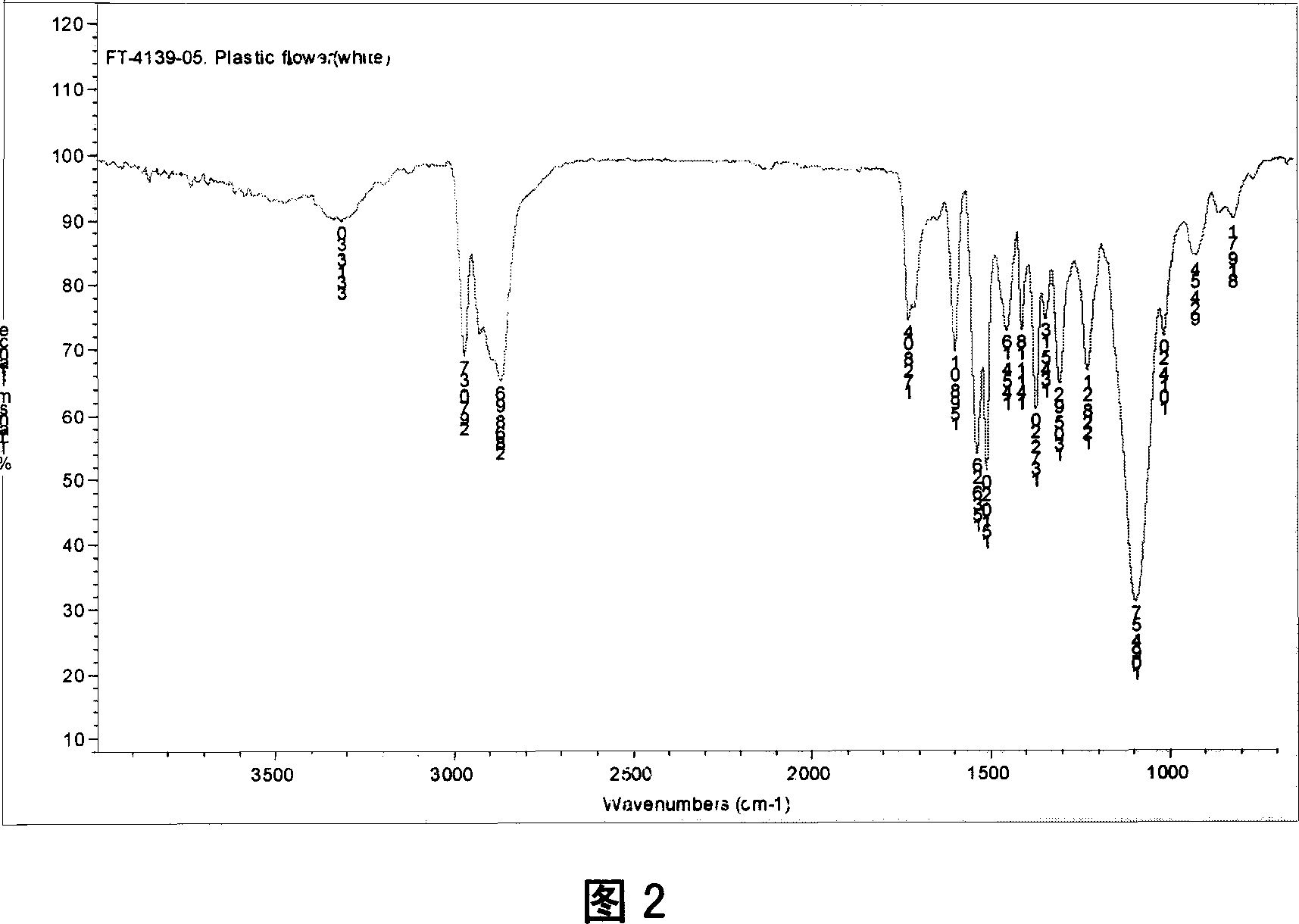

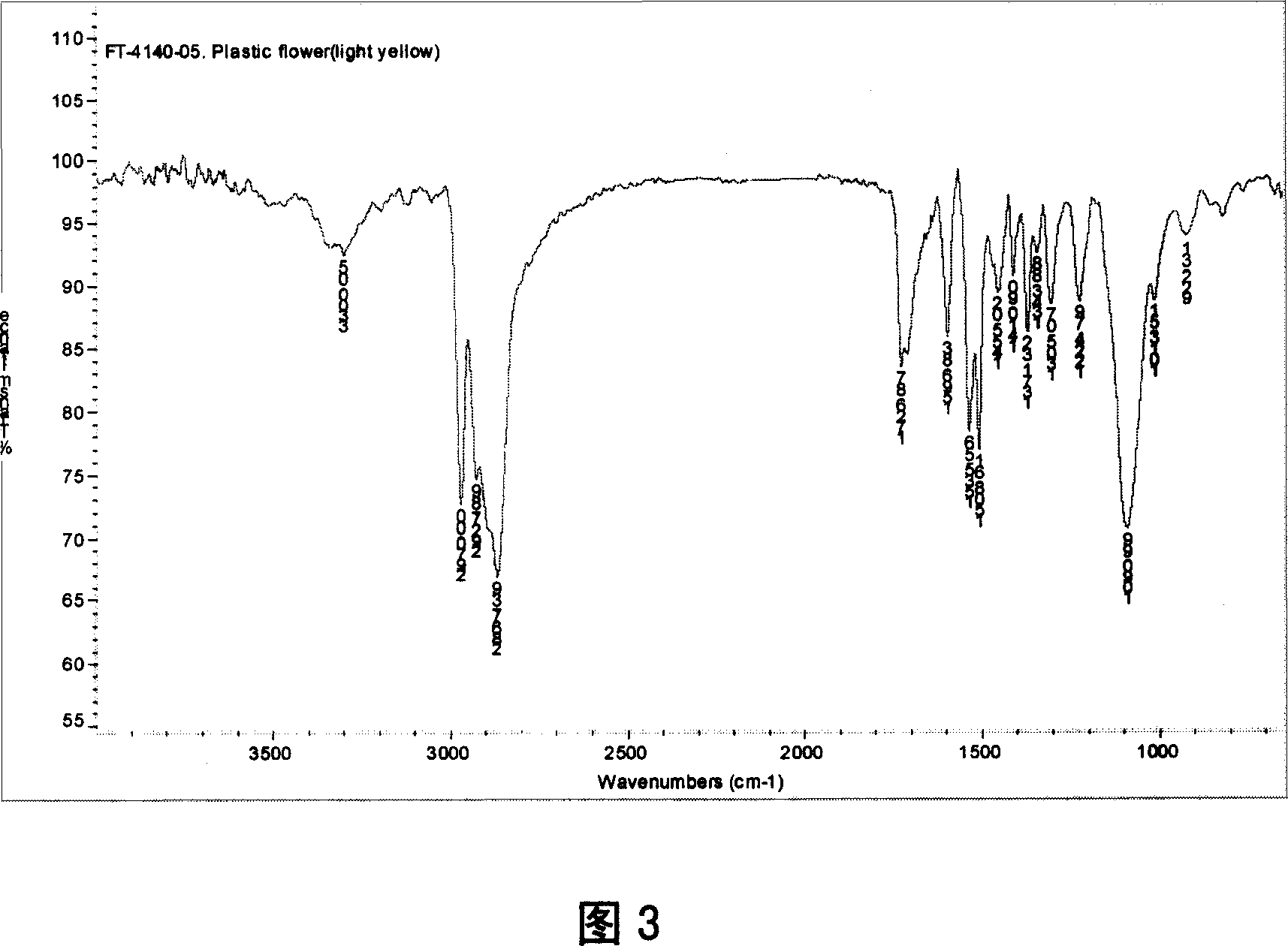

[0061] Test purpose: Qualitative analysis of components by infrared spectroscopy

[0062] ASTM E 1252-98, Standard Practice for General

[0063] Test ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com