Manufacturing method of veneer open paint sheet material

A production method and technology of open paint, applied to the device for coating liquid on the surface, pretreatment surface, coating, etc., can solve the problems of long time involved and large energy consumption, and achieve short time involved in the process and low energy consumption , good economic benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

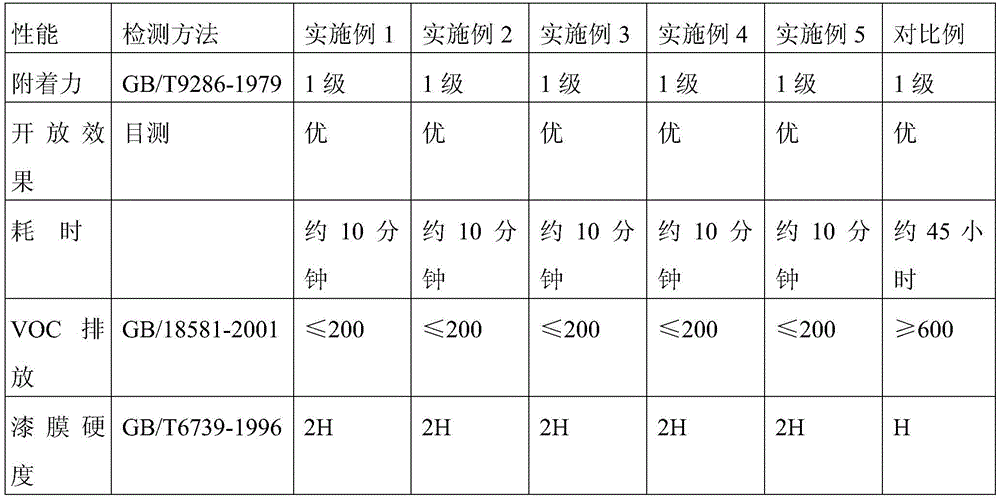

Examples

Embodiment 1

[0039] This embodiment provides a method for making a veneer open paint board, comprising the following steps:

[0040] (1) Use high-density fiberboard base material, fill the uneven surface of the base material with transparent putty ash roll coating, use 320# paper abrasive belt to smooth the surface, remove dust, and stick natural veneer on one side by hot pressing; hot pressing The temperature of pasting was 110° C., and the pressure was 150 kPa. The veneer is thin oak planks. After the veneer is veneered, the cracked and uneven parts of the veneer surface are filled with transparent putty or colored putty, and then the surface of the board with natural veneer is polished and sanded with 320# and 400# automatic sanding equipment;

[0041] (2) Polish the surface of the veneer with a paper abrasive belt to remove dust;

[0042] (3) Do coloring treatment on the veneer, roll coat UV transparent primer, and control the coating amount of transparent primer at 28g / m 2 .

[00...

Embodiment 2

[0049] This embodiment provides a method for making a veneer open paint board, comprising the following steps:

[0050] (1) Use high-density fiberboard or plywood base material, fill the uneven surface of the base material with transparent putty ash, polish the surface with 320# paper abrasive belt, remove dust, and paste natural veneer with double-sided hot pressing; The temperature for pressing and pasting is 100°C and the pressure is 180kPa; the veneer is ash board; after the veneer is veneered, the cracked and uneven parts of the veneer surface are filled with transparent putty or colored putty, and the surface of the board with natural veneer is applied again , using 320#, 400# automatic sanding equipment for sanding;

[0051] (2) Polish the surface of the veneer with a paper abrasive belt to remove dust;

[0052] (3) Do coloring treatment on the veneer, roll coat UV transparent primer, and control the coating amount of transparent primer at 25g / m 2 .

[0053] (4) Afte...

Embodiment 3

[0059] This embodiment provides a method for making a veneer open paint board, comprising the following steps:

[0060] (1) Use high-density fiberboard or plywood base material, fill the uneven surface of the base material with transparent putty ash, polish the surface with 320# paper abrasive belt, remove dust, and paste natural veneer with double-sided hot pressing; The temperature for pressing and pasting is 120°C and the pressure is 120kPa. The veneer is a thin elm board. After the veneer is veneered, the cracked and uneven parts of the veneer surface are filled with transparent putty or colored putty. Use 320#, 400# automatic sanding equipment for sanding;

[0061] (2) Polish the surface of the veneer with a paper abrasive belt to remove dust;

[0062](3) Do coloring treatment on the veneer, roll coat UV transparent primer, and control the coating amount of transparent primer at 30g / m 2 .

[0063] (4) After ultraviolet baking, polish it with 400# paper abrasive belt an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com