Patents

Literature

41results about How to "Strong sense of transparency" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

UV offset transparent printing ink, and preparation method

This invention relates to a method for preparing transparent ink for UV offset printing. The ink comprises: acrylate oligomer 50-70 parts, pigment 8-15 parts, dye 8-12 parts, active diluter 10-30 parts, photoinitiator 3-10 parts, and dispersant 1-5 parts. The method comprises: milling pigment and dye, mixing with part of acrylate oligomer and active diluter, milling, adding the rest acrylate oligomer and active diluter, photoinitiator and dispersant, and stirring at a high speed. The ink solves the problems of low drying speed, easy gelation, and uncontrollable viscosity faced by present transparent ink for UV offset printing. The ink has such advantages as good luster, high transparency, high adhesiveness, rapid drying, stable properties, no gelation, stable storage, and good weathering and corrosion resistance.

Owner:深圳市深赛尔股份有限公司

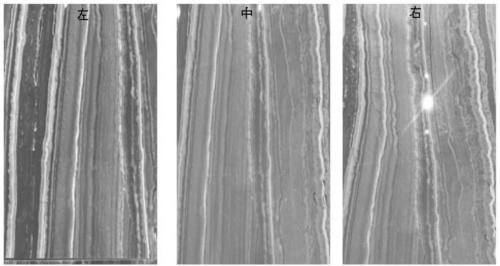

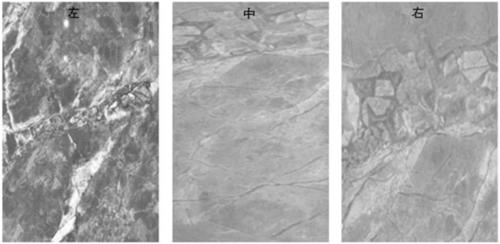

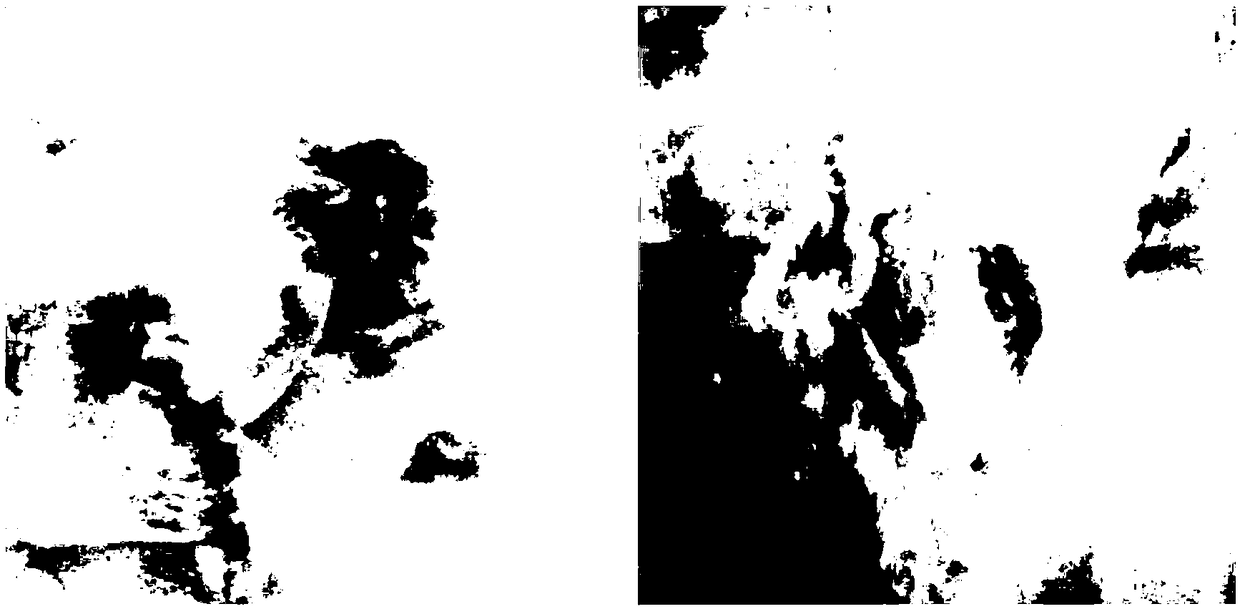

Manufacturing method for combined ceramic tile with complete pattern, spliced by plurality of ceramic tiles

InactiveCN103241049AStrong three-dimensional senseStrong sense of transparencyDecorative surface effectsClaywaresMetallurgyNatural stone

The invention relates to a manufacturing method for a combined ceramic tile with a complete pattern, which is spliced by a plurality of ceramic tiles. The method comprises the following steps of: mixing raw materials to prepare a powder material, pressing the powder material to obtain green tiles, carrying out printing and glaze spraying on the green tiles, sintering the obtained tiles to obtain the ceramic tiles, and performing seamless splicing on the plurality of ceramic tiles with different or identical figures to obtain the combined ceramic tile with the complete pattern. Compared with the prior art, the combined ceramic tile can fully display the real effect of natural stones by means of large format splicing, is strong in three-dimensional effect and rich in layering, can better adapt to current market trend, and is grand and very impressive after being paved.

Owner:SHANGHAI YUEXIN HEALTH GRP CO LTD

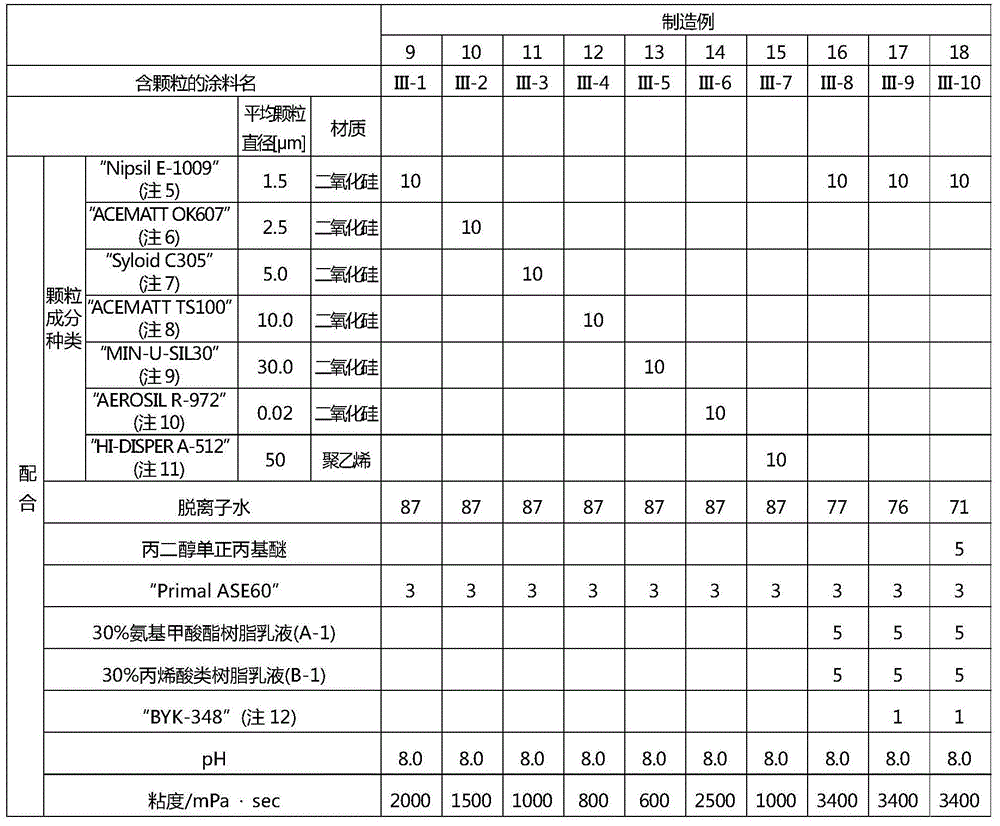

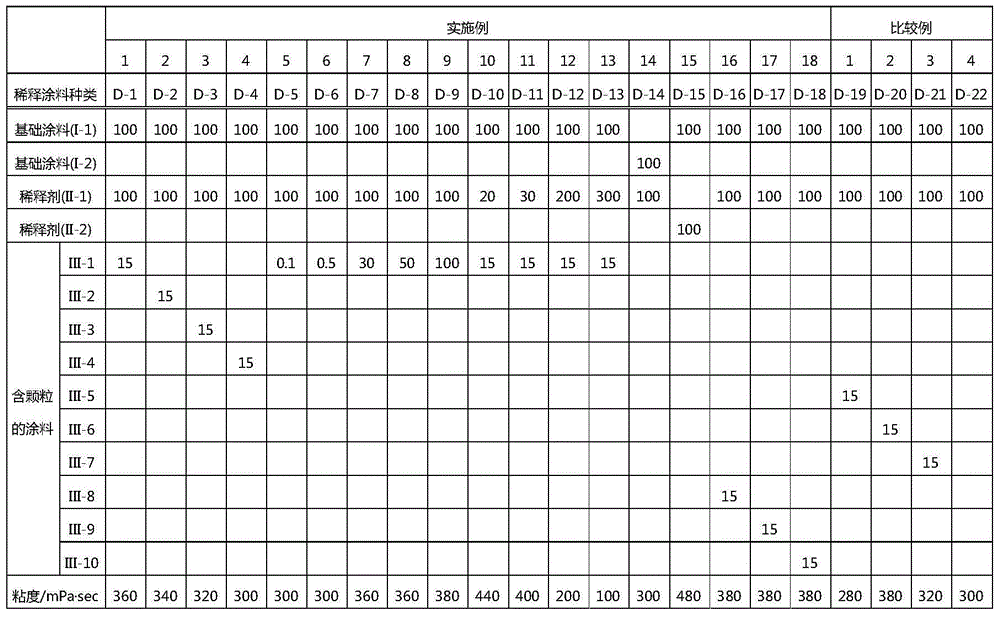

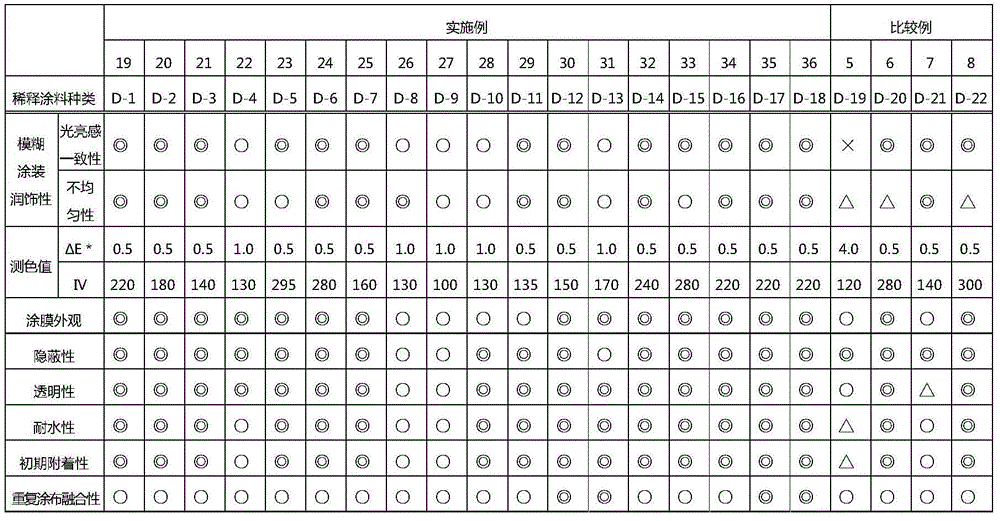

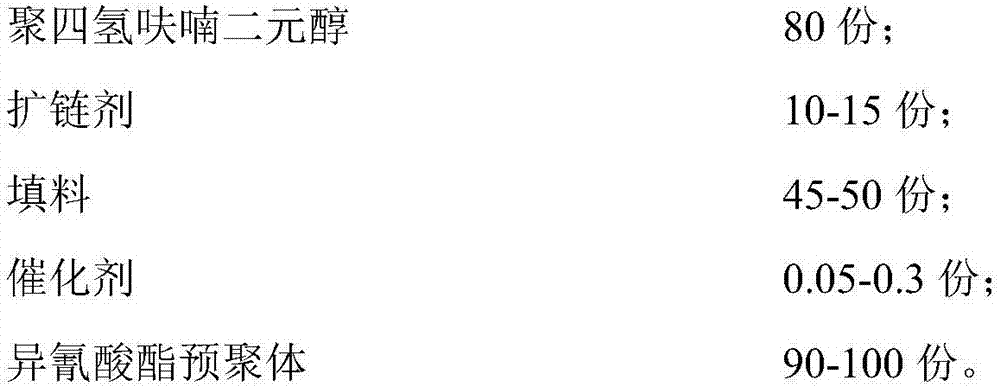

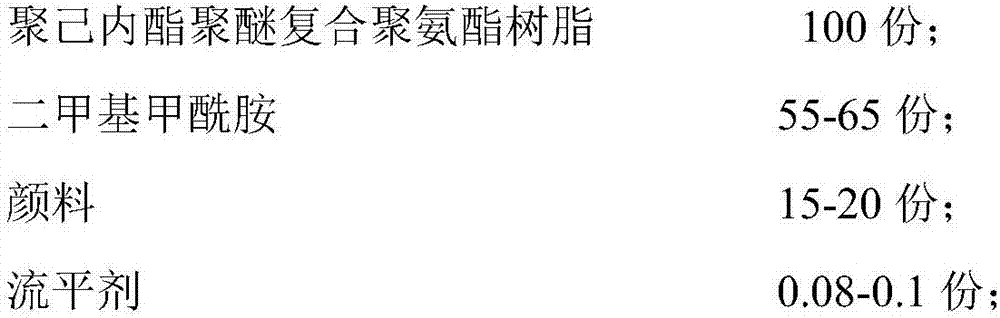

Water-based metallic basic coating composition

ActiveCN104910788AStrong sense of transparencyImprove smoothnessPolyurea/polyurethane coatingsEmulsion paintsWater basedSilica particle

The invention provides a water-based metallic basic coating composition suitable for forming a repairing coating, which totally matches with original metallic coating and used metallic coating of vehicle body. A multicomponent water-based metallic basic coating composition and a method for paint repairing employing same are provided. The water-based metallic basic coating composition is formed by combining main agent component I and diluter component II, wherein the main agent component I contains a carbamate resin emulsion A, an acrylic resin emulsion B, luminous pigment C and water, and the diluter component II contains adhesiveness adjusting agent and water. The composition contains silicon dioxide particles D, of which the average particle size ranges from 0.1 to 25.0 micrometers.

Owner:KANSAI PAINT CO LTD

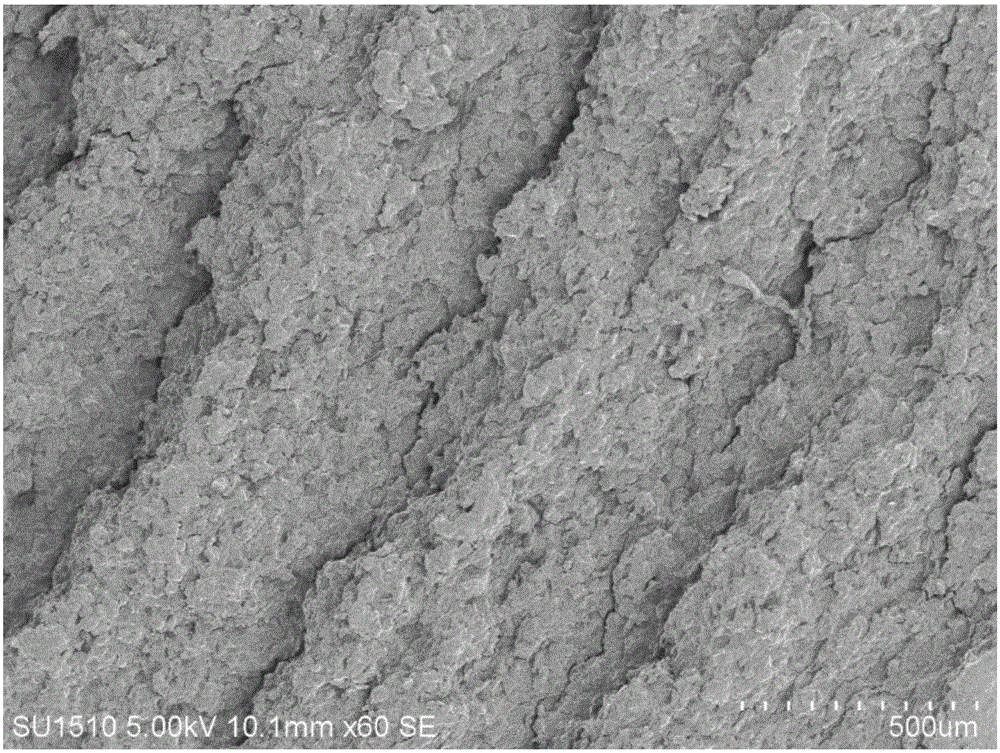

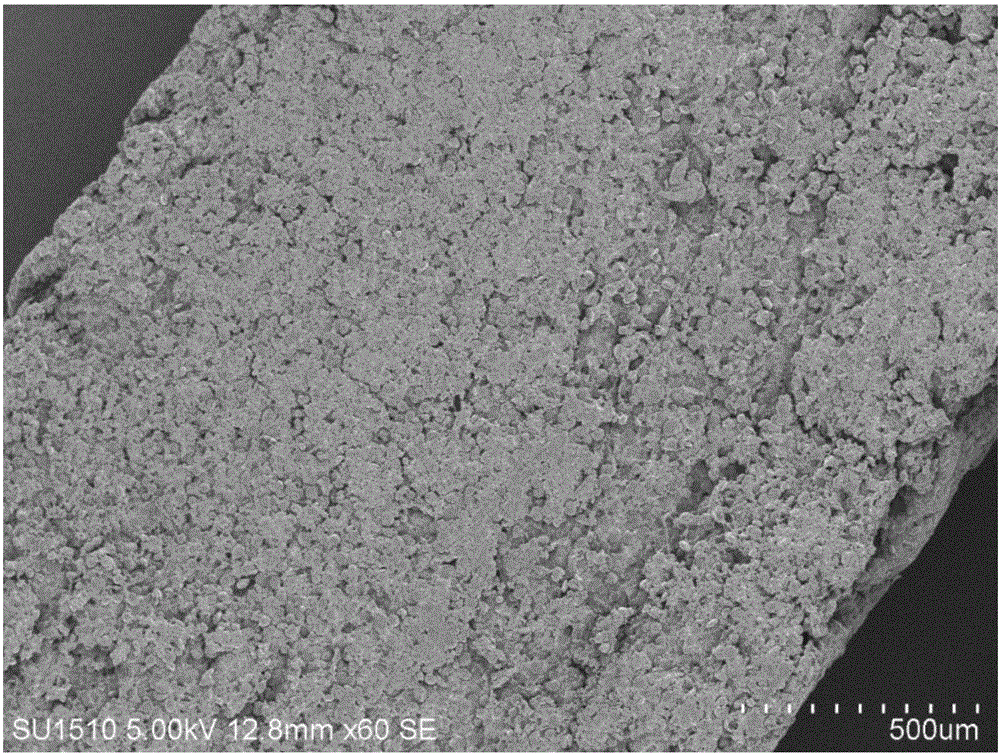

Super flat frit dry granular graze fully-polished brick and preparation method thereof

The invention relates to a super flat frit dry granular graze fully-polished brick and a preparation method thereof. The preparation method comprises the following steps: (1) laying a frit dry granular glaze on the surface of a brick blank and fixing the frit dry granular glaze; and 2) conducting firing and polishing on the brick blank obtained in the step (1).

Owner:MONALISA GRP CO LTD

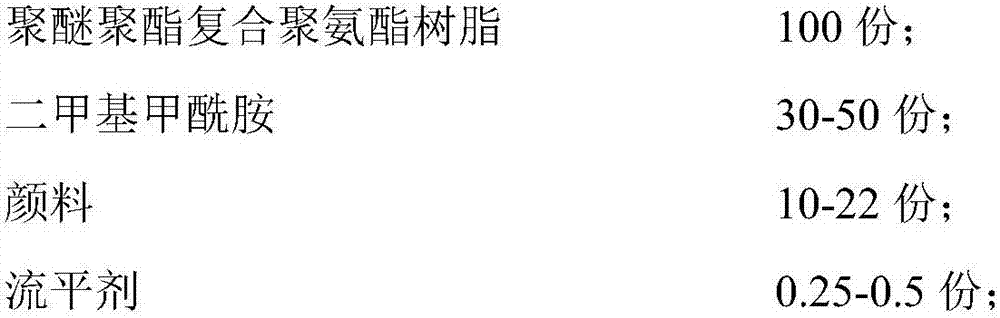

Solvent-less high-light finish ultrafine fiber polyurethane synthetic leather and preparation method thereof

The invention discloses solvent-less ultrafine fiber high-light finish polyurethane synthetic leather. The solvent-less ultrafine fiber high-light finish polyurethane synthetic leather is composed of a surface polyurethane layer, a middle polyurethane layer, a polyether type solvent-less polyurethane layer and ultrafine fiber polyurethane synthetic leather sequentially from top to bottom. The solvent-less ultrafine fiber high-light finish polyurethane synthetic leather is prepared by the following steps: coating a high-light mirror mask with surface layer polyurethane slurry, coating middle layer polyurethane slurry after baking, coating polyether type solvent-less polyurethane slurry after baking, laminating with constant-breadth ultrafine fiber polyurethane synthetic leather after pre-reaction, conducting aging, rolling together and aging again, and stripping the high-light mirror mask to obtain the finished product. The solvent-less ultrafine fiber high-light finish polyurethane synthetic leather prepared by the invention has the following superior properties: high gloss, high flatness, no crease, smooth tactility, cuts comparable to genuine leather, hydrolysis resistance, wear resistance, normal-temperature deflection resistance, freezing resistance, high efficiency, environmental protection and the like, and can be widely applied to high grade shoes, bags, suitcases and decorative materials.

Owner:ANHUI ANLI MATERIAL TECH

Novel environment-friendly paper surface glazing finishing emulsion and preparation method thereof

InactiveCN102899961AImprove stabilityNo emissionsPaper coatingCoatingsVitrificationFunctional monomer

The invention discloses a novel environment-friendly paper surface glazing finishing emulsion and a preparation method thereof. The emulsion comprises, by weight, 5 to 40% of a natural high-molecular material, 40 to 60% of a hard monomer, 30 to 50% of a soft monomer, 0.01 to 5% of a functional monomer, 0.02 to 5% of a modifier and 0.2 to 0.5% of an initiator, with the balance being deionized water. The novel environment-friendly paper surface glazing finishing emulsion provided by the invention has the advantages of capacity of film forming at room temperature, nontoxicity, no odor, striking transparency, strong adhesion, good leveling performance, no discharge of organic volatile matters (VOC) and the like, overcomes the defects of a high glass transition temperature, low dual-component resin complex formulation, utilization of an emulsifier, a film forming auxiliary agent and the like of a conventional waterborne glazing agent, regenerable resources are fully utilized, a product is sanitary and biodegradable after cyclic usage, environmental pollution is reduced, and economy and environmental protection are realized.

Owner:QINGDAO TSINGUNION HIGH TECH CO LTD

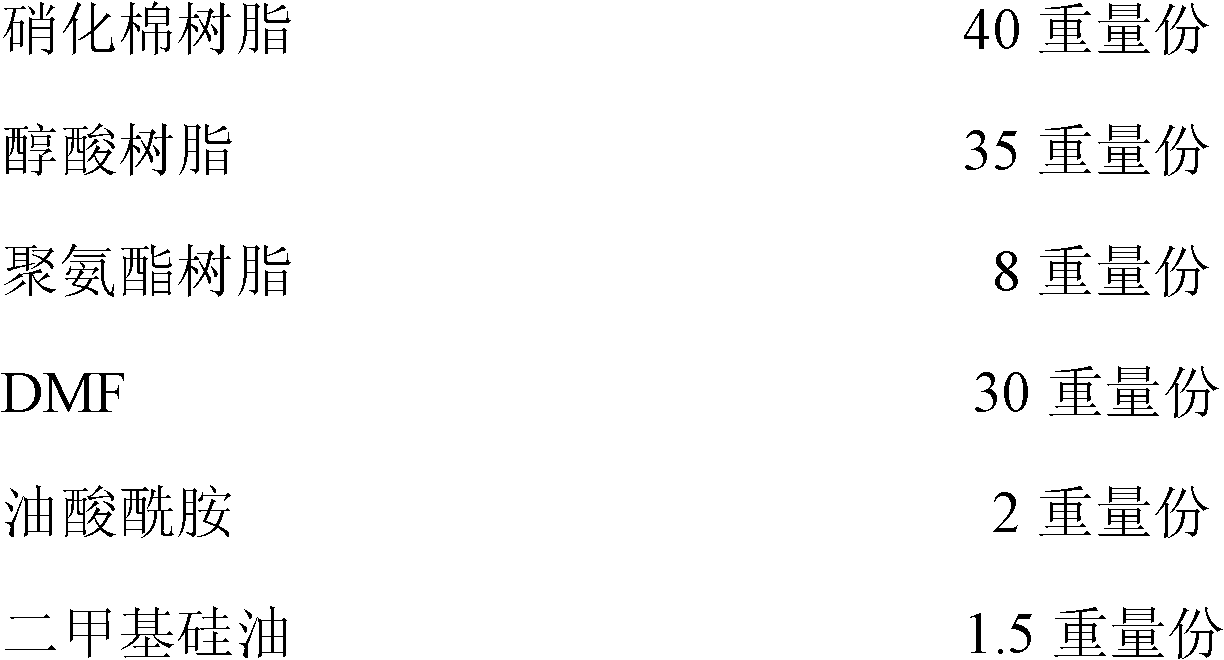

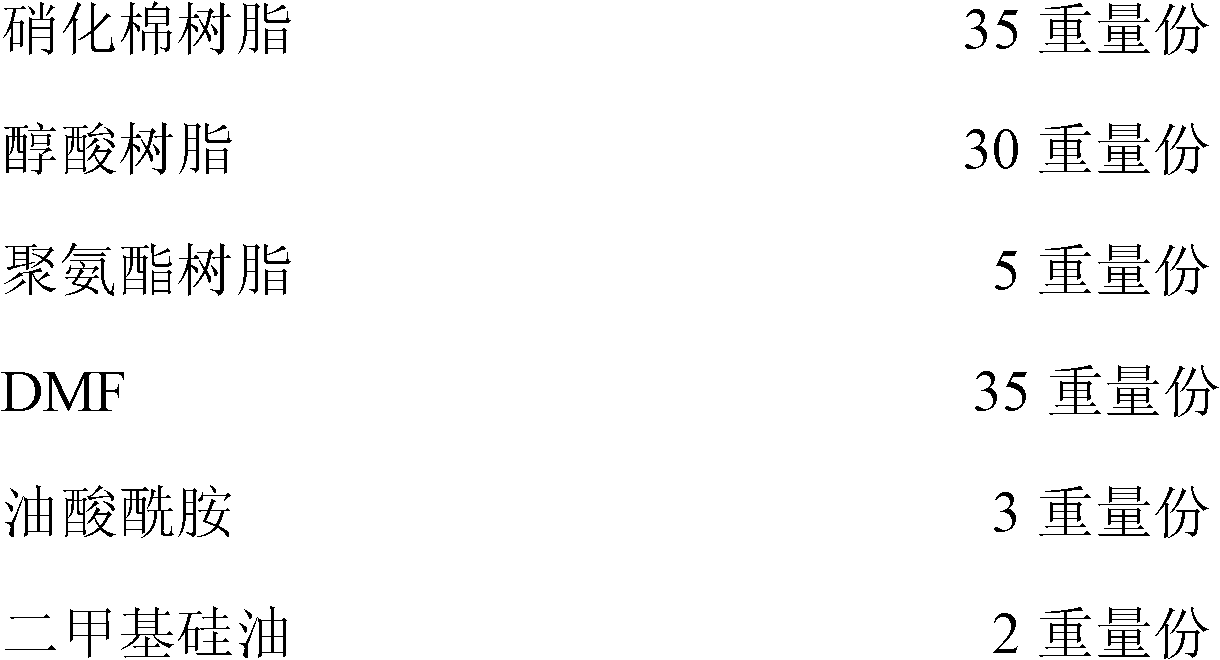

Burst resin for synthetic leather and preparation method of burst resin

The invention discloses burst resin for synthetic leather and a preparation method of burst resin. The burst resin for the synthetic leather provided by the invention consists of the following components: nitro-cotton resin, alkyd resin, urethane resin, DMF (Dimethyl Formamide), oleamide and dimethyl silicone oil. The burst resin for the synthetic leather provided by the invention is an environment-friendly material and meets an environmental protection standard of European Union; each component for constituting the burst resin for the synthetic leather has the advantages of good mud-cracking effect, glossy bright face, high transparency and unique handfeel of slippery wax; and the synthetic leather using the burst resin has a good comprehensive effect.

Owner:JIANGSU BAOZE POLYMER MATERIAL

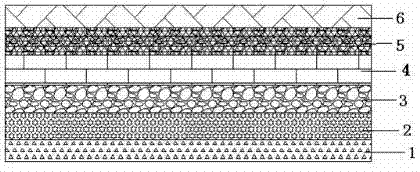

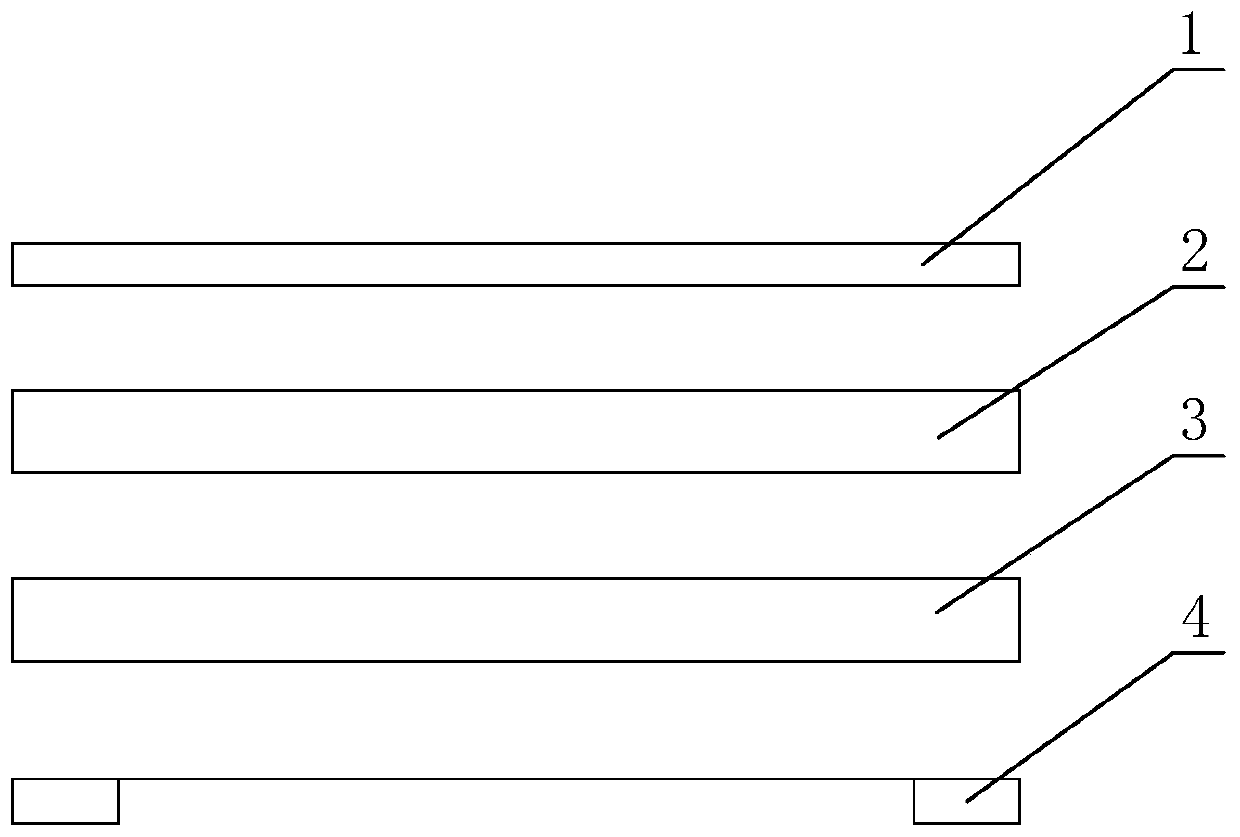

Crystal-like synthetic leather having contraction pattern

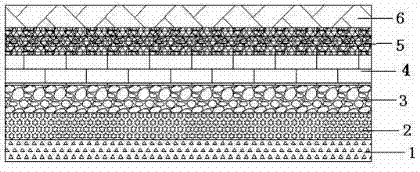

InactiveCN102407637AWith high glossStrong sense of transparencySynthetic resin layered productsSpecial ornamental structuresPolymer sciencePolyurethane adhesive

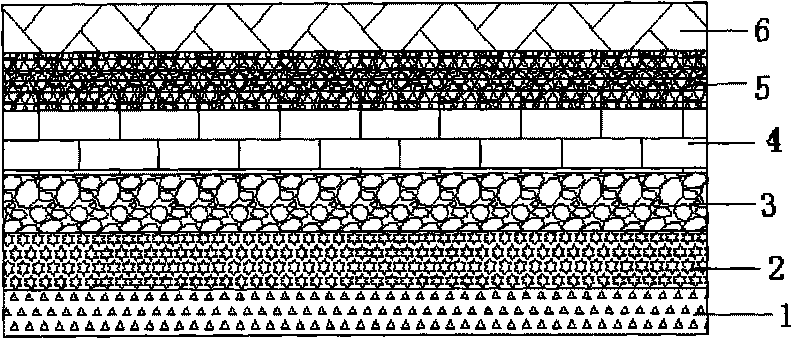

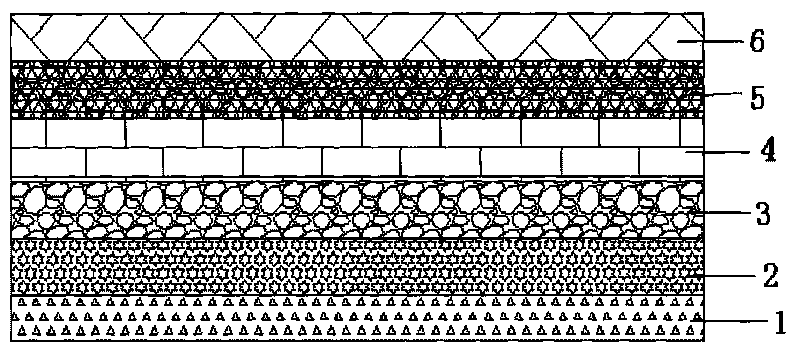

The invention discloses crystal-like synthetic leather having a contraction pattern. The synthetic leather comprises a base cloth layer (1), a modified polyurethane foaming layer (2) coated on the base cloth layer (1), a polyurethane adhesive layer (3) coated on the modified polyurethane foaming layer (2), an aqueous polyurethane resin layer (4) coated on the polyurethane adhesive layer (3), an acrylic resin layer (5) coated on the aqueous polyurethane resin layer (4) and a crystal-like resin (6) coated on the acrylic resin layer (5). Contracted lines of the synthetic leather provided in the invention can generate different patterns according to difference of lines of release paper, producing a unique visual effect; the obtained synthetic leather has the effects of high brightness and high light, a strong sense of transparency and crystal and the advantages of smoothness, a strong leather feel and the like.

Owner:WUJIANG SANHUI TEXTILE

Celadon azure secret-color glaze material

The invention discloses a celadon azure secret-color glaze material which includes a ground glaze raw material and a surface glaze raw material. The ground glaze raw material includes, by mass, 40-47% of Huangtan glaze, 5-10% of purple-golden earth, 14-22% of limestone, 10-24% of Linggen glaze, 4-6% of calcite, 5-8% of stone marrow, 2-5% of tin dioxide, 1-2% of cow bone and 4-8% of plant ash. The surface glaze raw material includes, by mass, 28-32% of the Huangtan glaze, 5-8% of purple-golden earth, 3-8% of feldspar powder, 3-6% of talcum powder, 20-24% of limestone, 25-35% of Linggen glaze, 4-6% of stone marrow, 1-2% of vanadium-zirconium blue and 1-1.5% of asbolite. In the invention, the tin dioxide, the cow bone and the plant ash are added to the ground glaze raw material and the vanadium-zirconium blue and the stone marrow are added to the surface glaze raw material, so that the azure secret-color glaze material has a mellow and bright azure color, has a fine and compact texture and is not more than 1.0% in water absorption rate.

Owner:郑峰

Nanometer emulsion composition with effect of improving skin barrier and application of nanometer emulsion composition

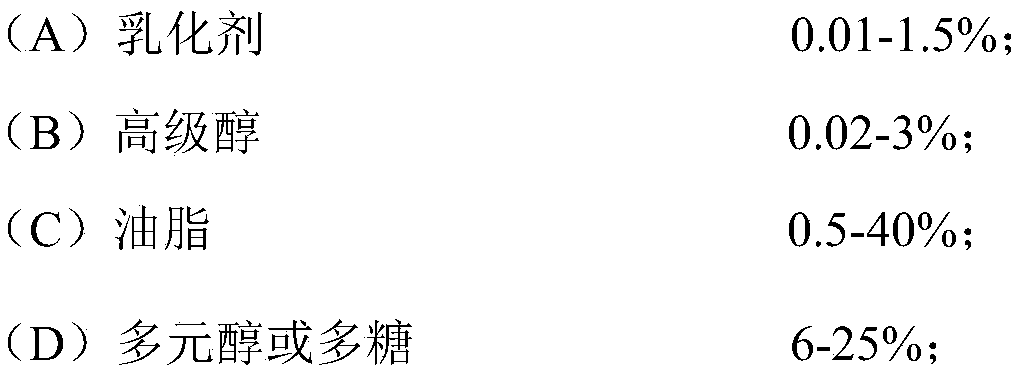

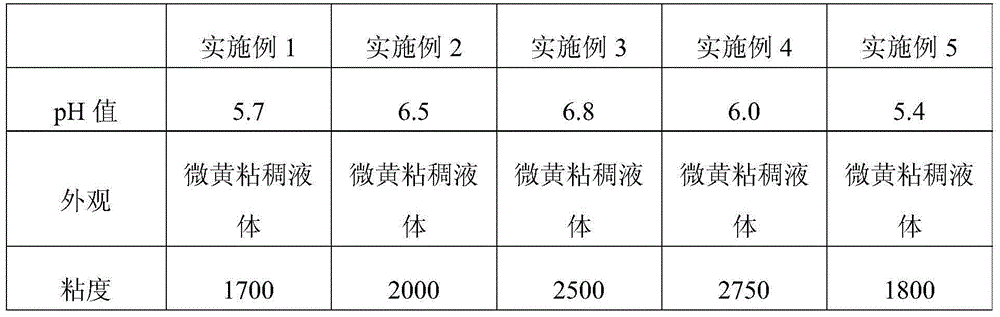

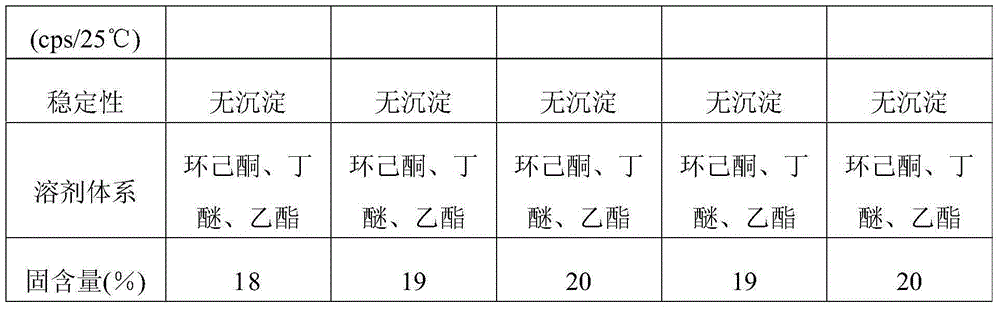

ActiveCN111568782AEasy to useLow viscosityCosmetic preparationsToilet preparationsPolymer sciencePolyol

The invention discloses a nanometer emulsion composition with an effect of improving the skin barrier and application of the nanometer emulsion composition. The nanometer emulsion composition comprises the following ingredients (A) 0.005 to 2.5 percent of an emulsifier, (B) 0.01 to 5 percent of higher alcohol, (C) 0.02 to 60 percent of grease, and (D) 3 to 30 percent of polyhydric alcohol or polysaccharide, wherein the content of the ingredient (C) is greater than or equal to the sum of the contents of the ingredient (A) and the ingredient (B). By selecting the low-content and specific-kind emulsifier to be compounded with the specific contents of the higher alcohol, the grease and the polyhydric alcohol or the polysaccharide and controlling the content of the grease to be greater than thesum of the weight of the emulsifier and the compounding weight of the emulsifier, the nanometer emulsion composition with the average particle diameter being smaller than or equal to 200 nm is prepared. The nanometer emulsion composition has low viscosity, so that a convenient use feeling is realized; the influence by different kinds of grease is avoided; the stability is high; a good transparenteffect and soft and moist skin feelings like cream are realized; the skin moisture preserving degree, the moisturizing degree, the smoothness degree and the softness can be improved; and the consumption of the emulsifier is reduced, so that the skin tolerance can be increased.

Owner:HUAANTANG BIOTECH GRP CO LTD

Scraping-resistant polishing treating agent for synthetic leather and preparing method thereof

InactiveCN105220466AStrong sense of transparencyUnique feelFibre treatmentProduction lineCyclohexanone

The invention relates to a scraping-resistant polishing treating agent for synthetic leather. The scraping-resistant polishing treating agent is used for the later-stage printing technology for the synthetic leather. The scraping-resistant polishing treating agent is prepared from polyurethane resin, nitrocotton, ethyl ester, cyclohexanone, butyl ether, silicon dioxide matting agents, methyl-phenyl silicone oil, organic silicone oil and dispersing agents. The invention further relates to a preparing method of the scraping-resistant polishing treating agent for the synthetic leather. The components of the scraping-resistant polishing treating agent for the synthetic leather are coordinated and carry out combined action, the polished surface of the leather is high in lucent feeling and unique in hand feeling, the leather treated with the treating agent is natural in luster and clear in color, the polished surface of the leather is quite good in scraping resistance, and the comprehensive effect is good; the scraping-resistant polishing treating agent is a novel material for later-stage printing and can be used for an existing synthetic leather production line, the technology is simple, production devices do not need to be changed, production cost can not be increased, and the scraping-resistant polishing treating agent can also be used for pretreatment and is wide in application range.

Owner:JIANGSU BAOZE POLYMER MATERIAL

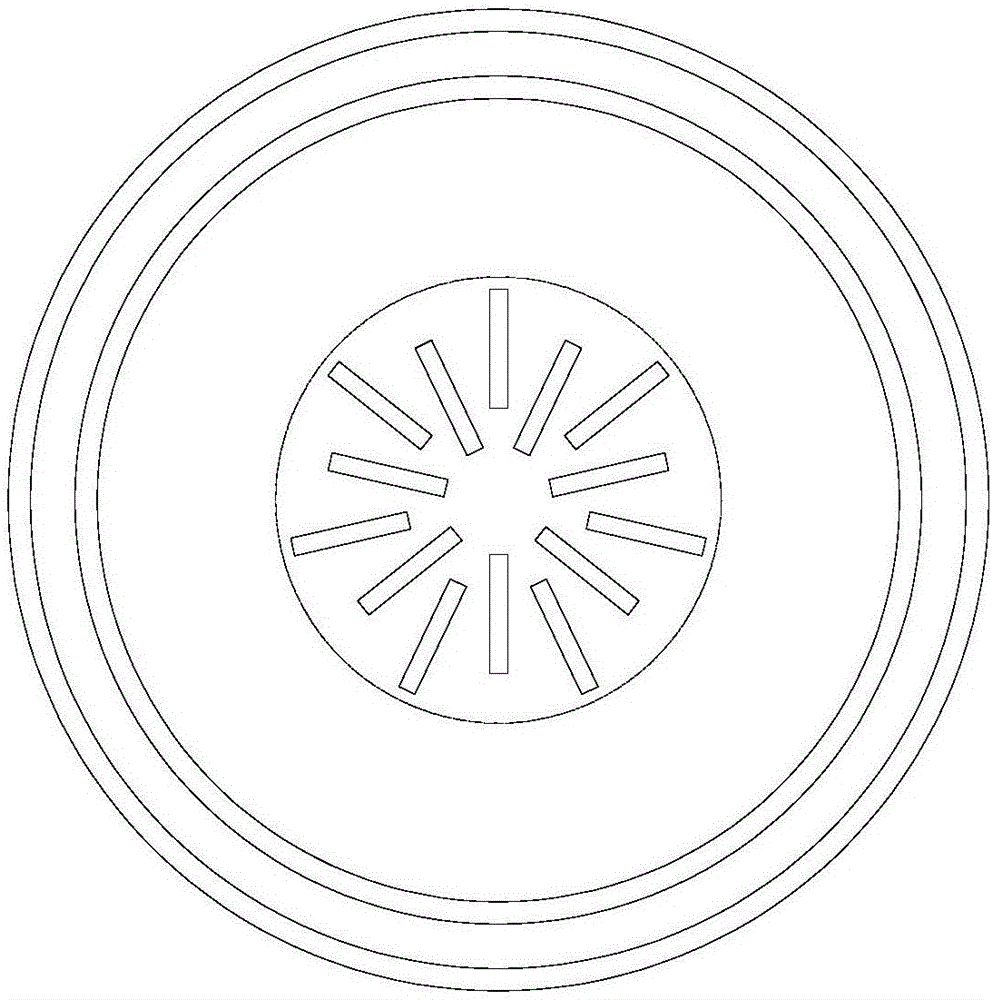

Preparation process for solving problem of polishing yellow edges of grey glazed bricks

ActiveCN110978221AGood sphericityFlat surfacePolishing machinesCeramic shaping apparatusBrickPolishing

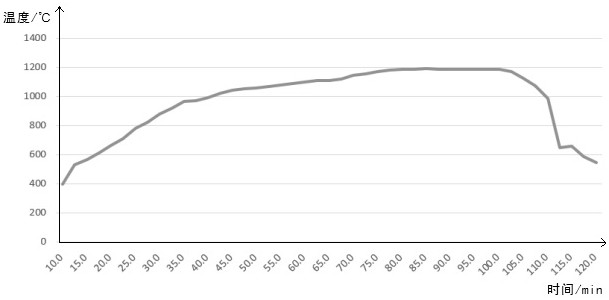

The invention relates to a preparation process for solving the problem of polishing yellow edges of grey glazed bricks. The method comprises the following steps: (1) powder is prepared: the ball discharge slurry moisture is 34-36%, the fineness 325-mesh screen residue is 1.5-2.0%, the flow rate is 50-80S, the pressed powder moisture is 6.0-6.5%, and the volume weight of the powder is 0.95-1.0; (2)the powder is aged for 24 hours, pressed, molded and dried at the temperature of 210 DEG C for 2 hours, and is discharged from a kiln at the temperature of 70-90 DEG C; (3) grinding and polishing ofthe green body are carried out; (4) ground coat is sprayed on the surface of the green body; (5) ink-jet decoration is carried out: ink sorts: blue, brown, brown, bright red, orange, golden yellow, black, black and gray; (6) transparent glaze is sprayed on the surface of a brick body; (7) firing in a roller kiln at the temperature of 1168-1185 DEG C for 75-82 minutes is carried out; and (8) polishing is carried out, wherein polishing parameters comprise 20 groups of rough polishing grinding heads, 16 groups of medium polishing grinding heads and 20 groups of fine polishing grinding heads.

Owner:JIANGXI HEMEI CERAMICS +3

Synthetic leather with crystal feeling contracted patterns

InactiveCN101694068AStrong sense of transparencyStrong crystal senseSynthetic resin layered productsTextiles and paperPolyurethane adhesiveChemistry

The invention discloses synthetic leather with crystal feeling contracted patterns, which comprises a substrate cloth layer, a polyurethane foaming layer (2) coated on the substrate close layer (1), a polyurethane adhesive layer (3) coated on the polyurethane foaming layer (2), acrylic resin (4) coated on the polyurethane adhesive layer (3), modified polyurethane resin (5) coated on the acrylic resin (4) and crystal feeling resin (6) coated on the modified polyurethane resin (5). In the synthetic leather, the acrylic resin layer and the modified polyurethane resin layer which are combined to use can generate unique contracted pattern effect, contracted texture of the acrylic resin layer and the modified polyurethane resin layer can generate different patterns according to different texture of release paper, the modified polyurethane resin layer is further coated with the crystal feeling resin layer, and then the synthetic leather has high-gloss and high-brightness effect, and has strong vision sense and crystal feeling.

Owner:JIANGSU BAOZE POLYMER MATERIAL

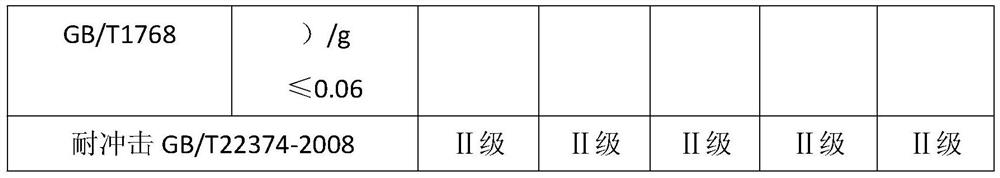

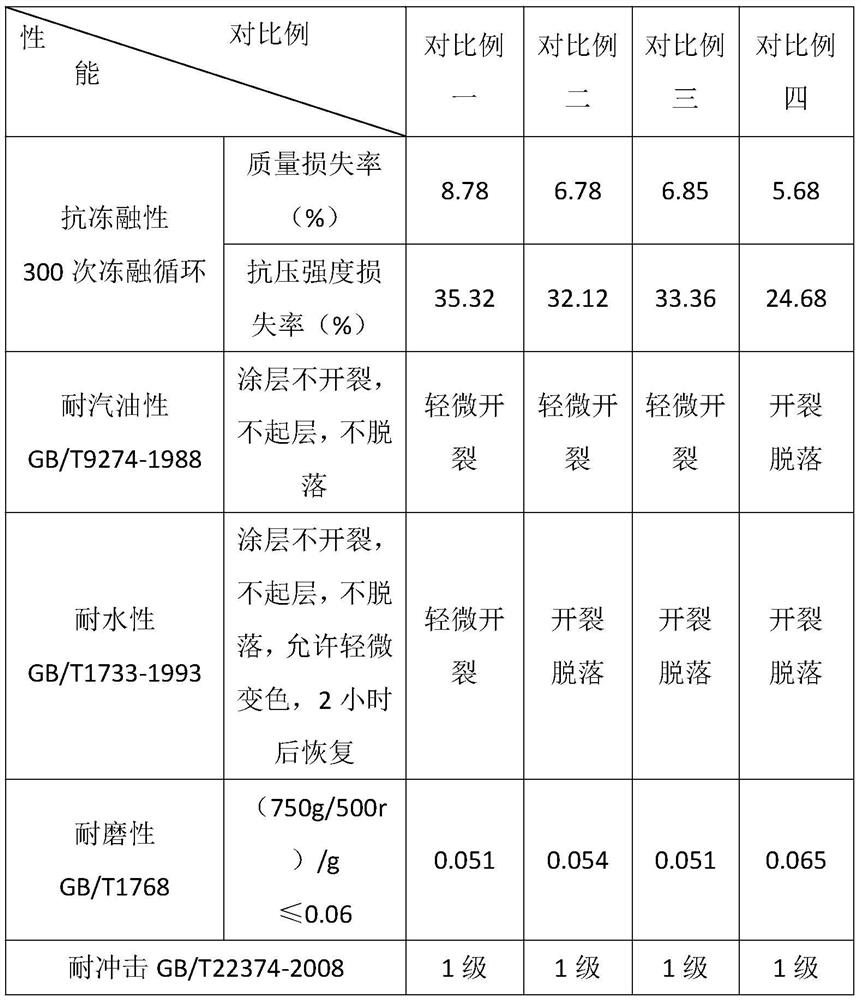

Anti-freeze-thaw water-based terrace and construction method thereof

InactiveCN111635696AStrong sense of transparencyLow costCellulose coatingsPaints with free metalsFreeze thawingCarbon fibers

The invention discloses an anti-freeze-thaw water-based terrace and a construction method thereof. According to the technical key points, the anti-freeze-thaw water-based terrace comprises a concreteterrace base layer and an anti-freeze-thaw layer arranged on the concrete terrace base layer, the anti-freeze-thaw layer comprises the following raw materials by weight: 57-85 parts of siloxane, 36-48parts of modified silane, 60-78 parts of water-based varnish, 20-35 parts of polypropylene glycol diglycidyl ether, 18-33 parts of o-tolyl glycidyl ether, 25-36 parts of calcium oxide, 19-36 parts ofvolcanic ash, 28-45 parts of carbon fiber, 25-36 parts of ramie fiber, 18-35 parts of filler and 23-35 parts of an antioxidant. The anti-freeze-thaw layer paint prepared by the preparation method disclosed by the invention has low moisture, compact texture and strong shrinkage stress bearing capacity, so that the terrace has excellent anti-freeze-thaw performance, and the preparation and construction processes are very simple and convenient.

Owner:黄永华

3D infiltrated crystallization glaze and application thereof

The invention discloses a 3D infiltrated crystallization glaze and application thereof. The glaze comprises a ground glaze and a cover glaze, wherein the cover glaze comprises the following raw materials: potassium feldspar, soda feldspar, quartz, kaolin, calained talc and a dyeing assistant agent. The glaze formula can really achieve a 3D in-glaze decoration effect and realize the unification ofthe surface decoration effect, the abrasive resistance and the hardness; in addition, the glaze is low in raw material cost, stable in performance, high in transparency, strong in transparent feeling,bright in color, and clear in pattern texture, is favorably compared with raw gemstone basically, and completely subverts the decoration effect of existing infiltrated glaze. By adopting the 3D infiltrated crystallization glaze provided by the invention, the consumption of infiltrated ink can be reduced by 35% relative to that of common infiltrated glaze, meanwhile, the consumption of the dyeingassistant agent can be reduced by 30% relative to that of the common infiltrated glaze, so that the production cost is reduced, the market popularization is benefited, the competitiveness is improved,and the reduction of the consumption of the dyeing assistant agent can reduce the tendency of crazing of ink jet infiltrated product glaze, so that the defects of finished products are reduced, and the rate of finished products is improved by 1%-3%.

Owner:广东道氏陶瓷材料有限公司

Jun porcelain overglaze painting process

ActiveCN113773118AImprove adhesionLow firing temperatureCeramic materials productionClaywaresGlazeColourant

The invention discloses a Jun porcelain overglaze painting process which comprises the following steps: wiping a Jun porcelain glaze blank, dipping colored drawing pigment by using a line drawing pen to draw a pattern on colored glaze of the glaze blank, then dipping diluted pigment by using a coloring pen to color on the colored glaze of the glaze blank, and then smearing color blocks in a part of a colored area by using a sweeping pen to ensure that the coloring is uniform and natural; and finally, putting the colored Jun porcelain glaze blank into a kiln at 720-760 DEG C, firing for 100-120 minutes, and naturally cooling for 6 hours to obtain the product. The color and glaze fusion effect is good, the color forming effect is good, the surface smoothness and brightness of the jun porcelain are good, operation is easy and convenient, and the production efficiency can be improved.

Owner:禹州市天禧钧窑文化传播有限公司

Oil-wax polishing treatment agent for synthetic leather and preparation method thereof

The invention relates to an oil-wax polishing treatment agent for synthetic leather. The oil-wax polishing treatment agent for the synthetic leather is applied to a posterior printing technology of the synthetic leather and comprises the following components: nitrocotton, butyl ester, butyl ether, silicon dioxide extinction powder, methyl phenyl silicone oil, organic silicone oil and a dispersing agent. The invention also relates to a preparation method of the oil-wax polishing treatment agent for the synthetic leather. The oil-wax polishing treatment agent for the synthetic leather has the advantages that all the components are mutually coordinated and act jointly, crystalistic sense of polished leather surface is strong, handfeel is unique, and the leather obtained by virtue of the oil-wax polishing treatment agent is strong in oil-wax feel, clear in colour and lustre and excellent in comprehensive effect; meanwhile, the oil-wax polishing treatment agent for the synthetic leather is a novel material applied to posterior printing and can be applied to an existing synthetic leather production line, technology is simple, production equipment does not need to be changed, and production cost can not be increased.

Owner:JIANGSU BAOZE POLYMER MATERIAL

Environment-friendly oil polish

The invention discloses an environment-friendly oil polish which is composed of the following components in parts by weight: 20-25 parts of acrylic resin, 30-34 parts of acrylic acid emulsion, 10-15 parts of ethanol, 2-3 parts of defoaming agent, 2-3 parts of surfactant, 1-2 parts of coating reinforcer and 20-24 parts of water. The oil polish is environment-friendly, non-toxic and smellless, and has the advantages of high transparency, no organic volatile matters, favorable use effect, favorable glossiness, favorable folding endurance, favorable wear resistance, favorable chemical resistance and wide application range.

Owner:ANHUI ZHONGCAI PRINTING

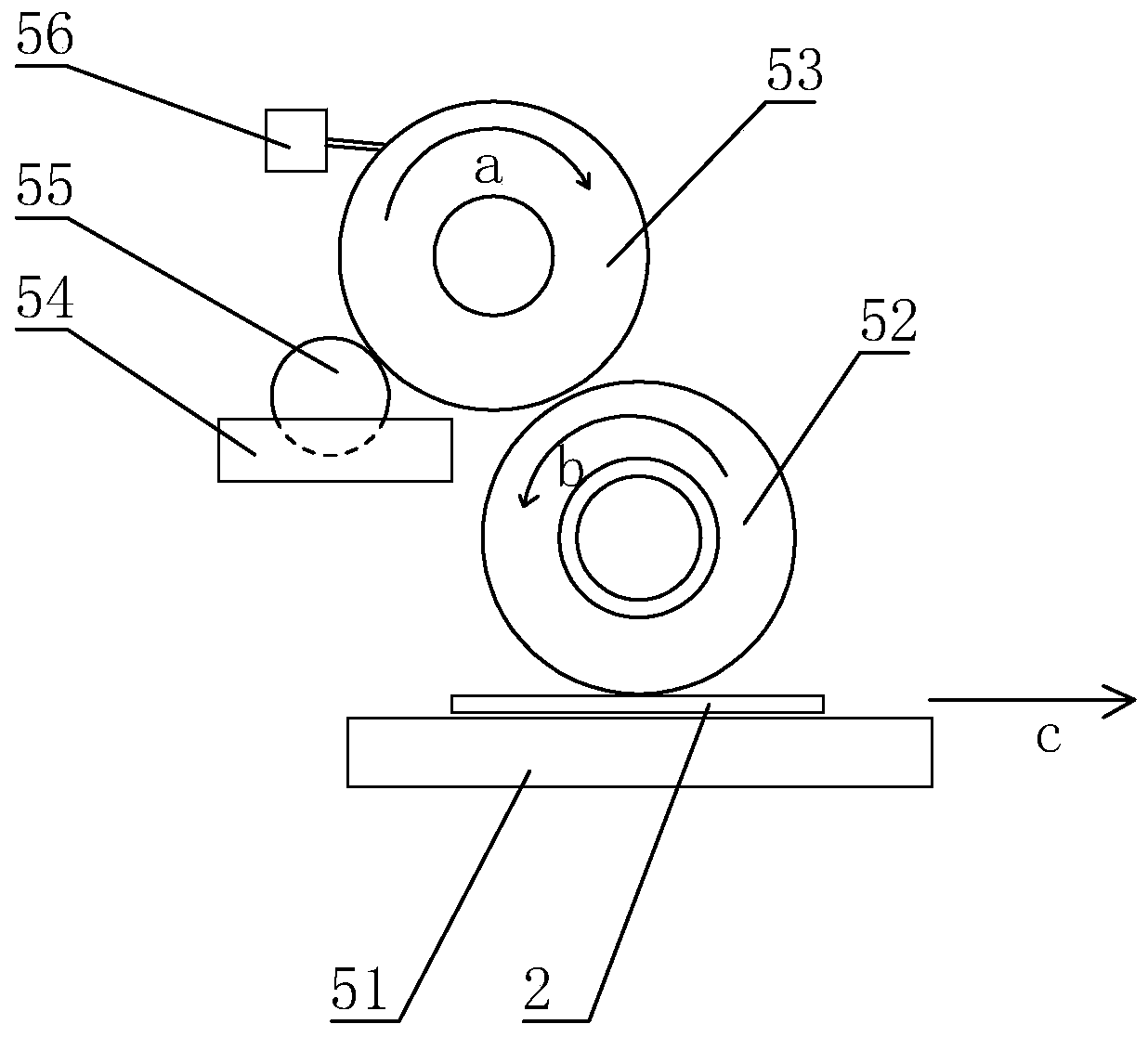

Orientation degree controllable extruded quick-cooked noodles and preparation method thereof

ActiveCN106071781ASimple preparation processReduce wasteFood ingredientsFood shapingEnzymeMonoglyceride

The present invention provides orientation degree controllable extruded quick-cooked noodles. The noodles are prepared from the following raw materials: 100 parts of flour, 1.2-30 parts of hydrophilic colloids, 0.02-0.1 part of an enzyme preparation, 0.2-0.4 part of dietary alkali, 0.5-2.5 parts of edible salt, 0-4 parts of monoglycerides and 0-15 parts of food ingredients. The preparation method comprises the steps of material mixing, blending, and extruding and shaping. In the blending process, the enzyme preparation is added. In the extruding process, a special shaping die device is used. With the help of the new extruding die device and using the enzyme adding and extruding technology, the orientation degrees and quick-cooking performances are controlled from the aspects of flour raw material selecting, hydrophilic colloid compounding, enzyme preparation controlling, food ingredient matching, extrusion operation parameter arranging, etc., so that the edible quality and product performance of the noodles are significantly better than those of the traditional noodles. Besides, the production operations are simple and feasible, and the orientation degree controllable extruded quick-cooked noodles are of great significances for the industrial development.

Owner:JIANGNAN UNIV

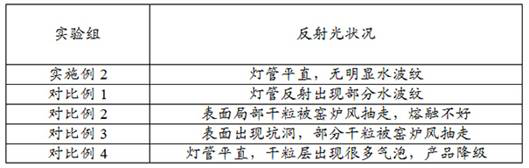

A kind of super-flat frit dry grain glaze full-throwing brick and its preparation method

The invention relates to an ultra-flat frit dry-grain glaze full-polished brick and a preparation method thereof. The preparation method comprises the following steps: (1) distributing the frit dry-grain glaze on the surface of the brick blank and fixing the frit dry-grain glaze; ( 2) The adobe obtained in step (1) is fired and polished.

Owner:MONALISA GRP CO LTD

Ultrathin glass protective cover plate structure for folding display screen mobile phone

PendingCN110266839AStrong sense of transparencyPerfect transparency and touchTelephone set constructionsIdentification meansDislocationDuctility

The invention discloses an ultrathin glass protection cover plate structure for a folding display screen mobile phone. The structure comprises ultrathin glass, an explosion-proof ink layer is arranged below the ultrathin glass, and an ink frame is arranged on the lower surface of the explosion-proof ink layer. The ultrathin glass protective cover plate is high in transparency, the OLED display screen can be protected and folded in all directions, the explosion-proof ink has certain ductility, and the explosion-proof ink is prevented from being separated to cause dislocation and crease when the ultrathin glass protective cover plate is bent; and even if the protective glass of the display screen is broken, the protective glass cannot fly away, so that the use safety of the foldable mobile phone is ensured.

Owner:安徽繁盛显示科技有限公司

Luminous bamboo floor machining technology

InactiveCN107901170AImprove performanceIncrease profitCane mechanical workingReed/straw treatmentCompression moldingFiber

The invention discloses a luminous bamboo floor machining technology and belongs to the field of floor machining. The luminous bamboo floor machining technology sequentially includes the following several steps of bamboo sawing, piece breaking, slicing, filament pressing, bleaching, glue dipping, drying, die pressing, forming, paint applying, drying, sanding and finish paint applying. During die pressing, bamboo fiber powder and bamboo charcoal powder which are obtained after glue dipping are mixed; luminous primer paint, elastic primer paint, wear-resisting primer paint and hardened primer paint are sequentially applied in the step of paint applying; and finish paint is applied for 2 times to 5 times. By means of the luminous bamboo floor machining technology, the problems that bamboo chips and bamboo fibers are treated improperly in a traditional machining technology, and consequently, the environment is polluted, the decoration effect is single, and the attractiveness is poor are solved.

Owner:刘薇

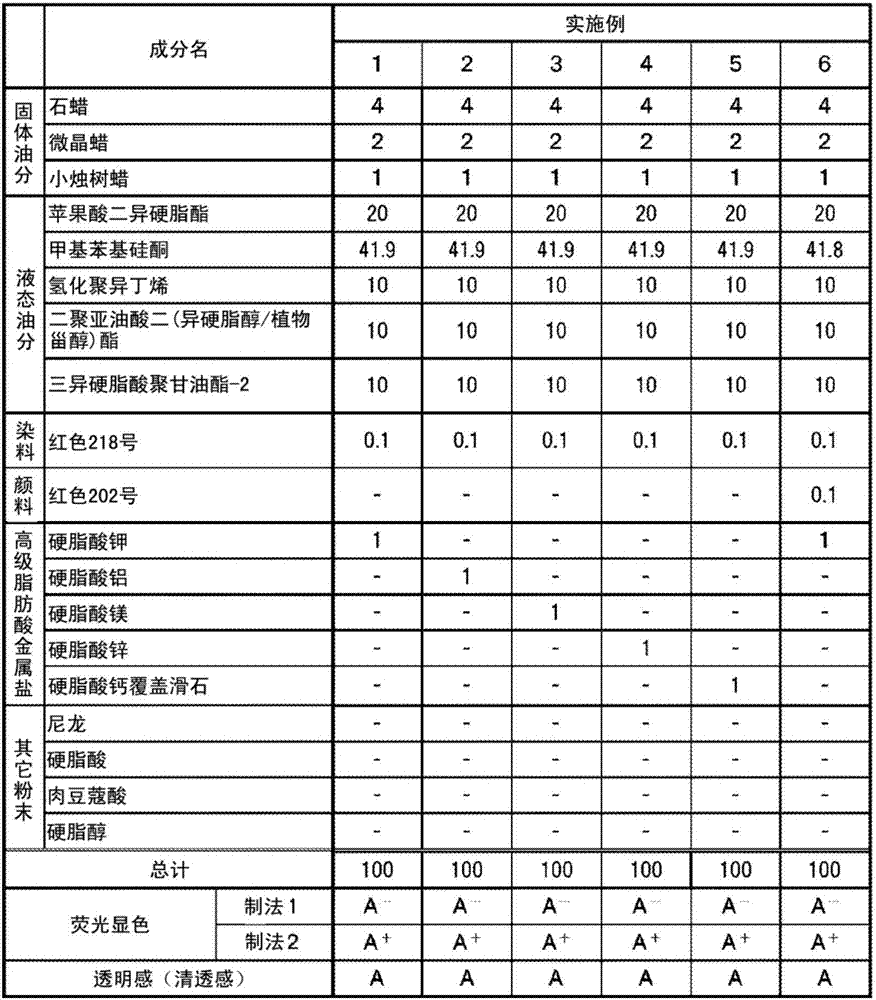

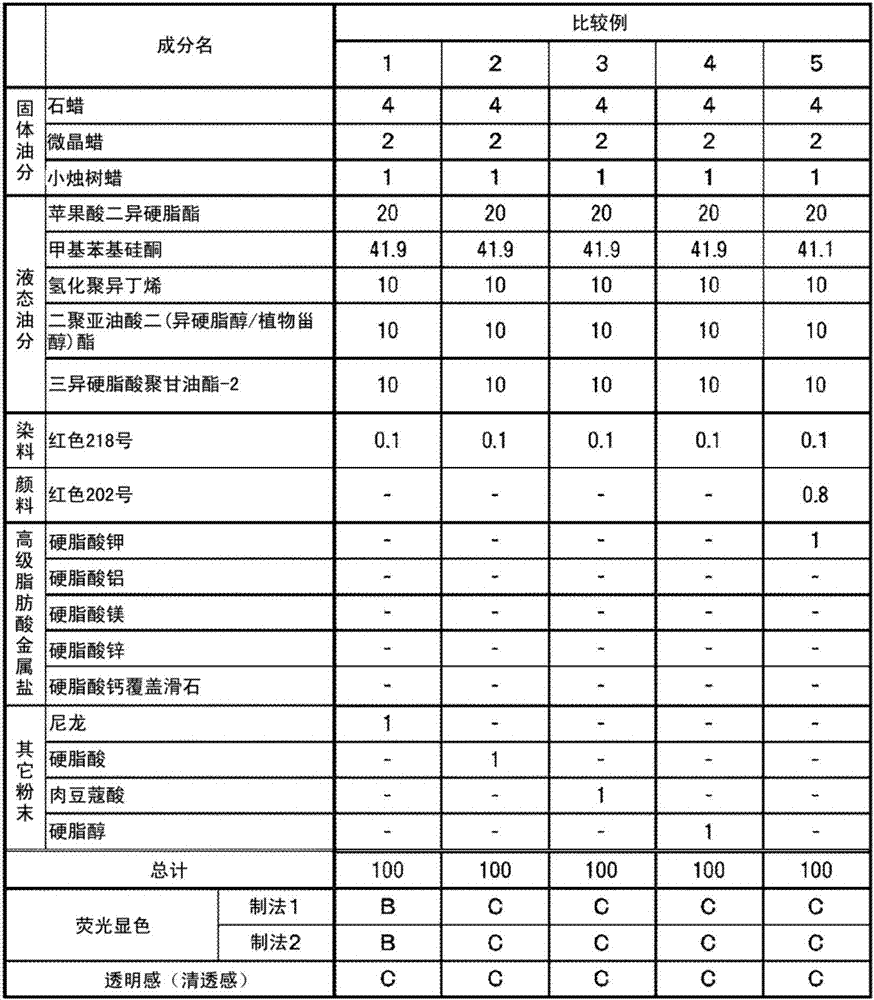

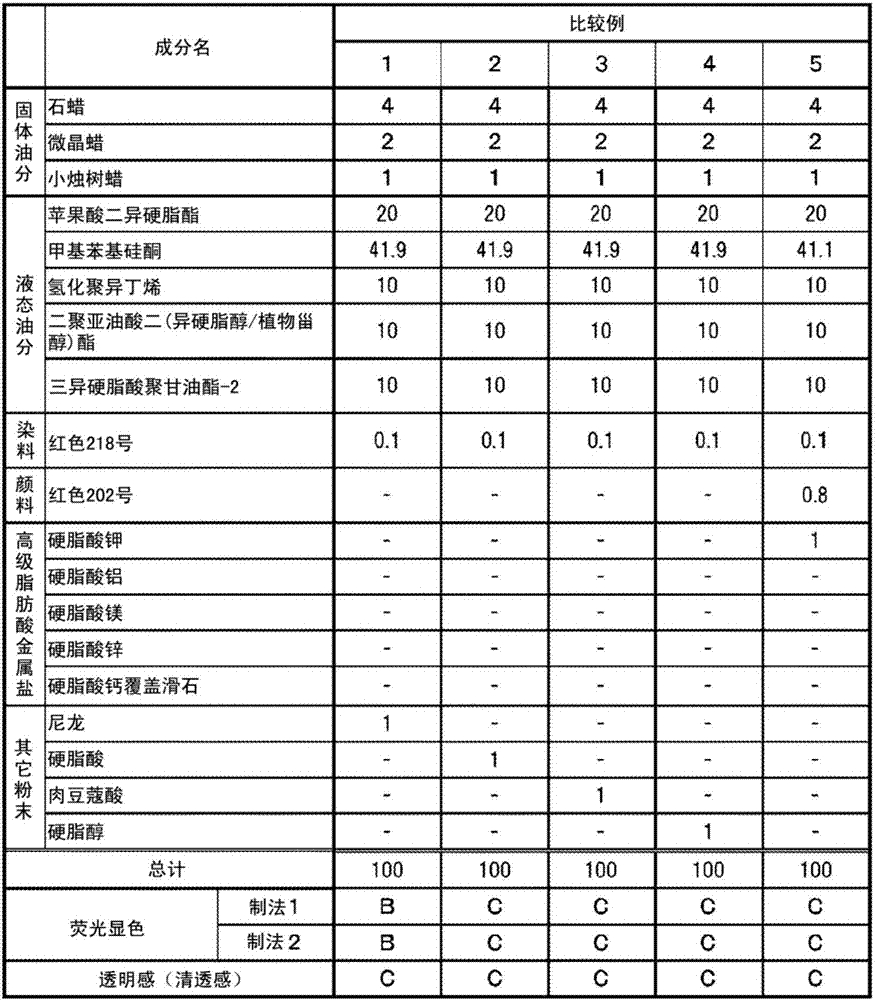

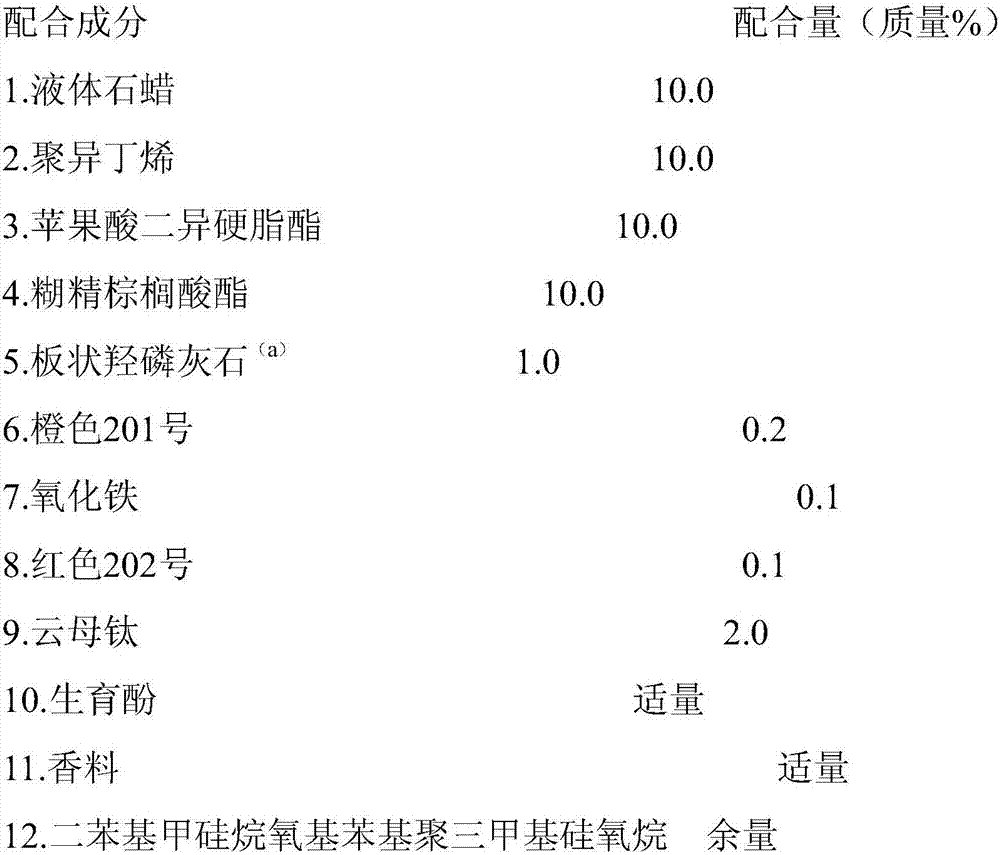

Makeup cosmetic

ActiveCN107205905ABright fluorescent colorStrong sense of transparencyCosmetic preparationsMake-upShadow eyeFluorescence

Provided are a makeup cosmetic which can have bright fluorescent coloring whilst still having excellent transparency (being clear), and a novel cosmetic coloring material that is suitable for the cosmetic. The present invention provides a makeup cosmetic comprising (A) at least one kind of oil-soluble dye selected from the group consisting of red no. 218, red no. 223 and orange no. 201, (B) a higher fatty acid metal salt, and (C) oil, wherein the blending amount of pigment is not greater than 0.5 mass%, and the oil-soluble dye is dissolved or dispersed in the oil. The makeup cosmetic, according to the present invention, can achieve high luminance fluorescent coloring whilst also having excellent transparency, and can be used as a lip cosmetic, blusher or eye shadow.

Owner:SHISEIDO CO LTD

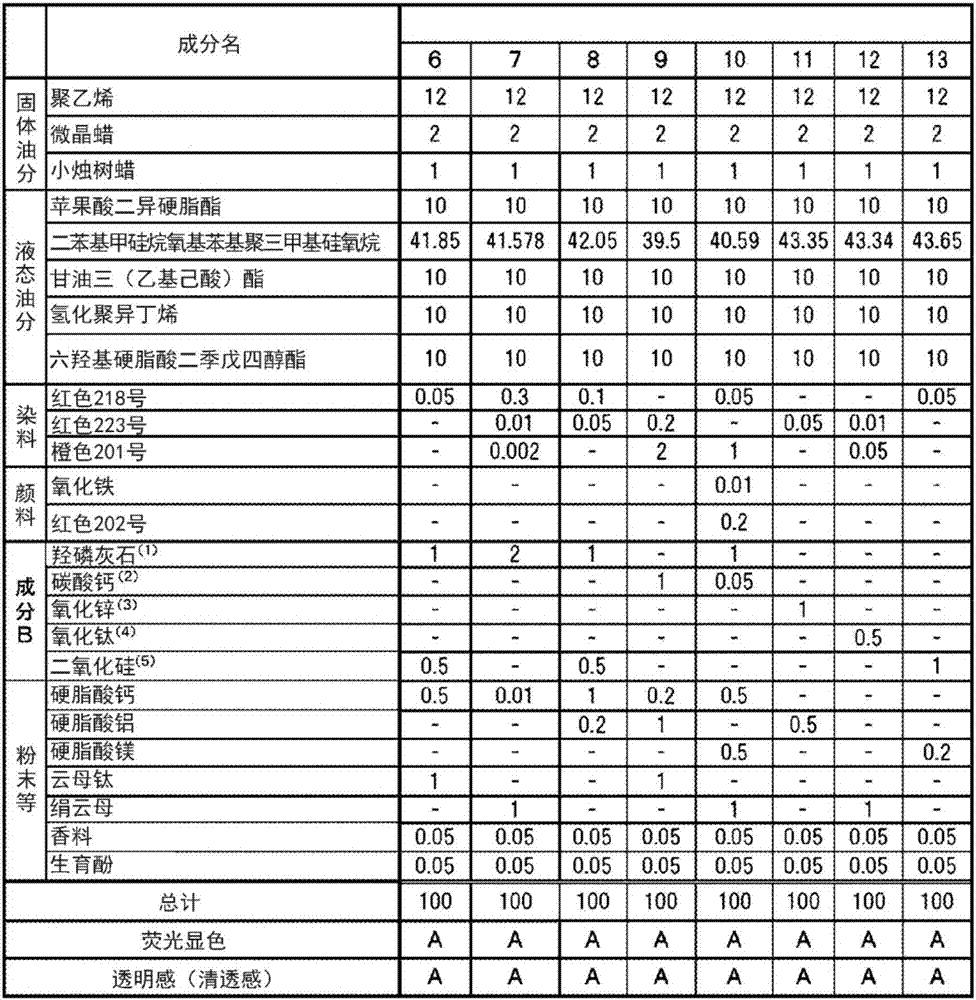

Makeup cosmetic

ActiveCN107205906ABright fluorescent colorStrong sense of transparencyCosmetic preparationsMake-upFluorescenceSilicon dioxide

Provided are a makeup cosmetic which can have bright fluorescent colouring whilst still having excellent transparency (being clear), and a novel cosmetic colouring material that is suitable for the cosmetic. The present invention provides a makeup cosmetic comprising (A) at least one kind of oil-soluble dye selected from the group consisting of red no. 218, red no. 223 and orange no. 201, (B) particles of a specific material selected from hydroxyapatite, calcium carbonate, a metal oxide (other than ferric oxide) and silica, and (C) oil, wherein the blending amount of pigment is not greater than 0.5 mass%, and the blending amount of water is less than 1.5 mass%. The makeup cosmetic, according to the present invention, can achieve high luminance fluorescent colouring whilst also having excellent transparency, and can be used as a lip cosmetic, blusher or eye shadow.

Owner:SHISEIDO CO LTD

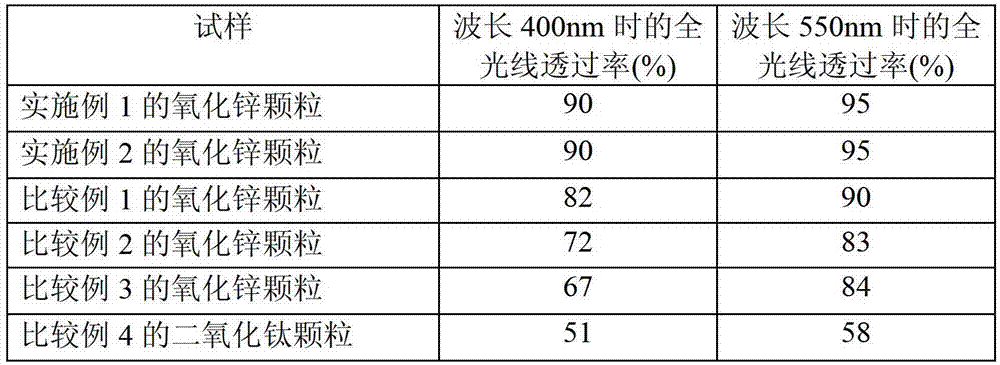

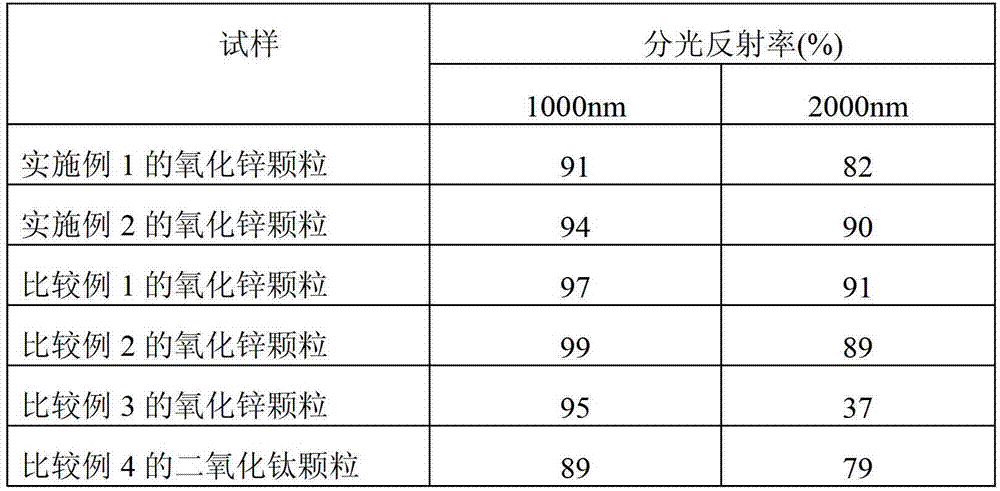

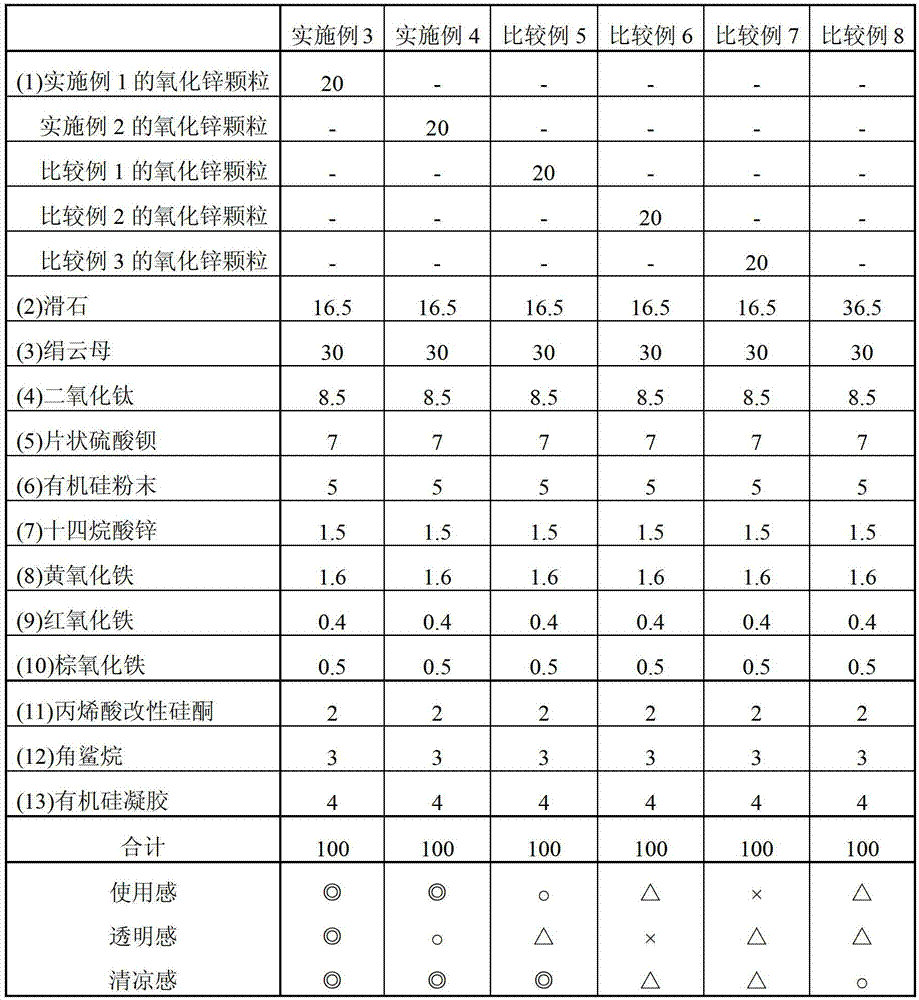

Zinc oxide particles and cosmetic material

ActiveCN103118982AEasy to useStrong sense of transparencyCosmetic preparationsBody powdersTransmittanceZinc

The invention aims to obtain large zinc oxide particles which have excellent transparency and capabilities such as infrared reflection and do not have a negative effect on texture when added to a cosmetic product, and to obtain a cosmetic material in which the zinc oxide particles are mixed. [Solution] Zinc oxide particles characterized in that the average particle size is 3 to 20 [mu]m, the average friction coefficient is 3 or less, the total visible light transmittance is 85% or greater, and the near infrared reflectivity is 80% or greater.

Owner:SAKAI CHEM IND CO LTD

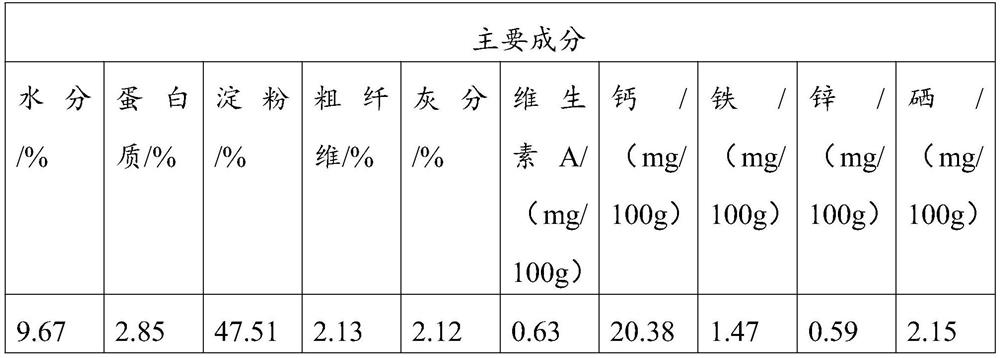

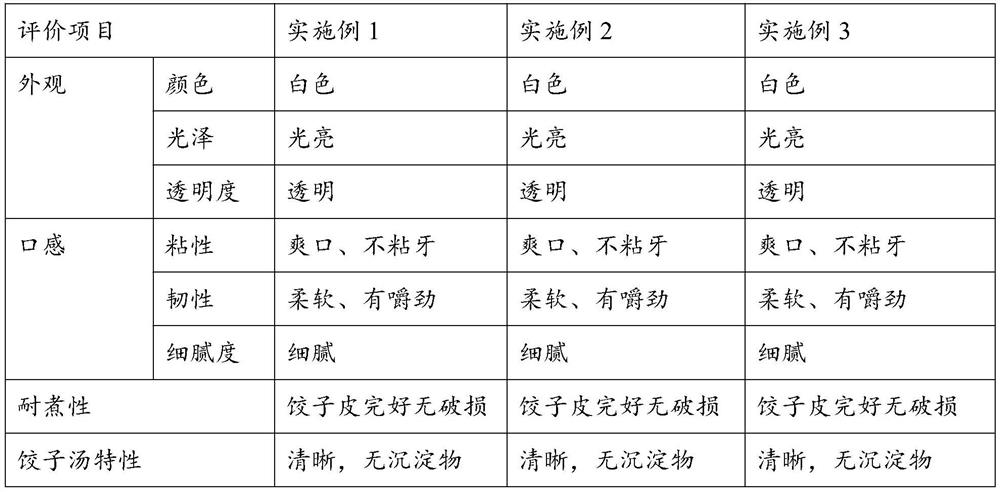

Sweet potato dumpling flour and preparation method thereof

PendingCN112806545AMalleableBoiling resistantClimate change adaptationFood dryingBiotechnologyNutritive values

The invention relates to the technical field of food, in particular to sweet potato dumpling flour and a preparation method thereof. According to the sweet potato dumpling flour, the defect that wheat dumpling flour does not have gluten protein is overcome, the sweet potato dumpling flour is produced by processing carefully selected sweet potatoes through a wet method, and the nutritional value of the sweet potato dumpling flour is greatly increased. The sweet potato dumpling flour is prepared by the following steps of selecting raw material sweet potatoes (careful selection), hydraulically conveying, cleaning and removing stones, cleaning by a roller, crushing, finely crushing, separating, de-sanding, spray-drying and packaging to obtain a finished product. On one hand, the fineness and whiteness of the sweet potato whole flour are solved, the transparency and boiling fastness are enhanced, and on the other hand, the defects that dumplings are easy to age, crack, case ascites and worse in taste during frozen storage are overcome.

Owner:HENAN UNIVERSITY OF TECHNOLOGY

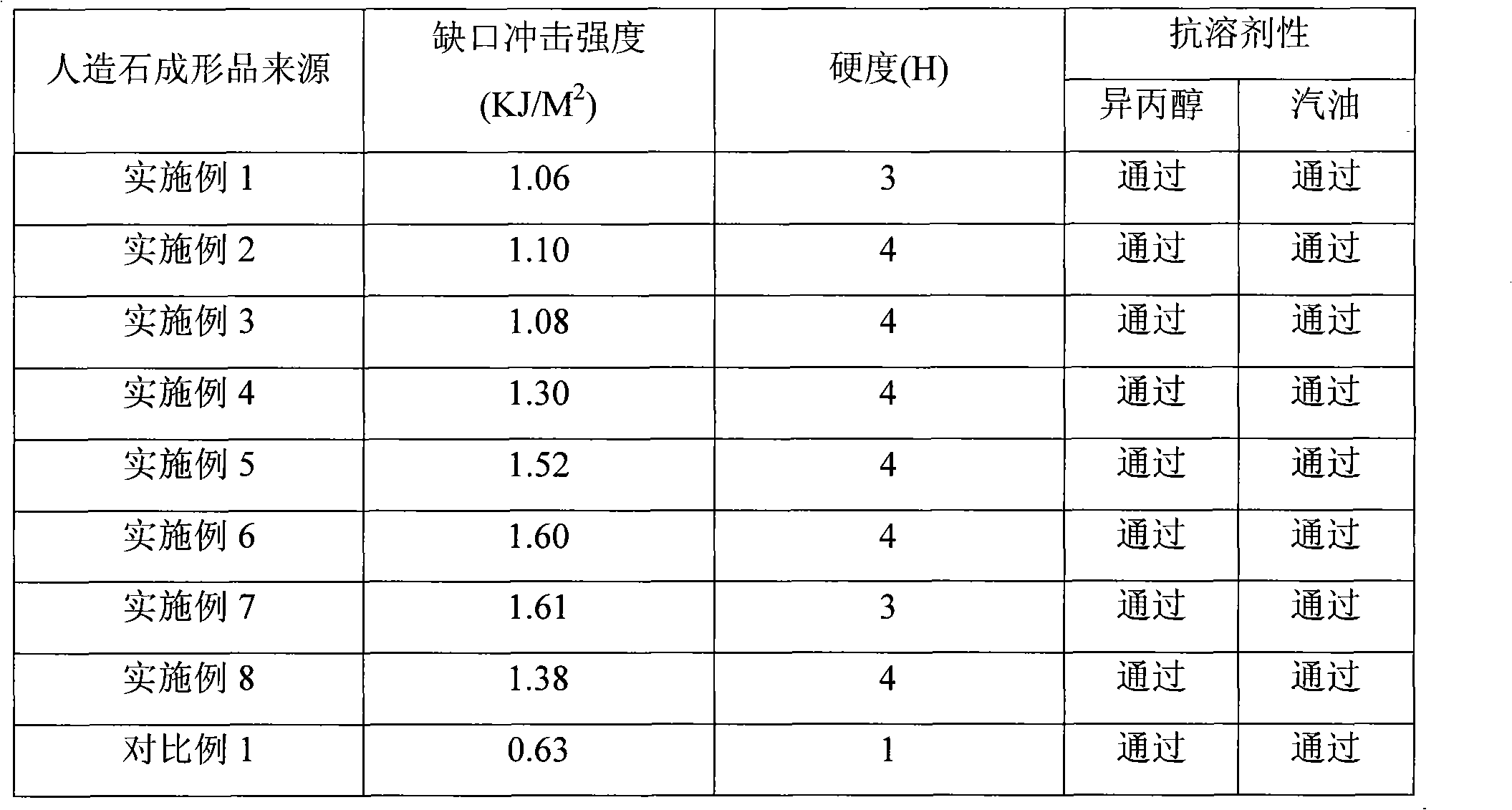

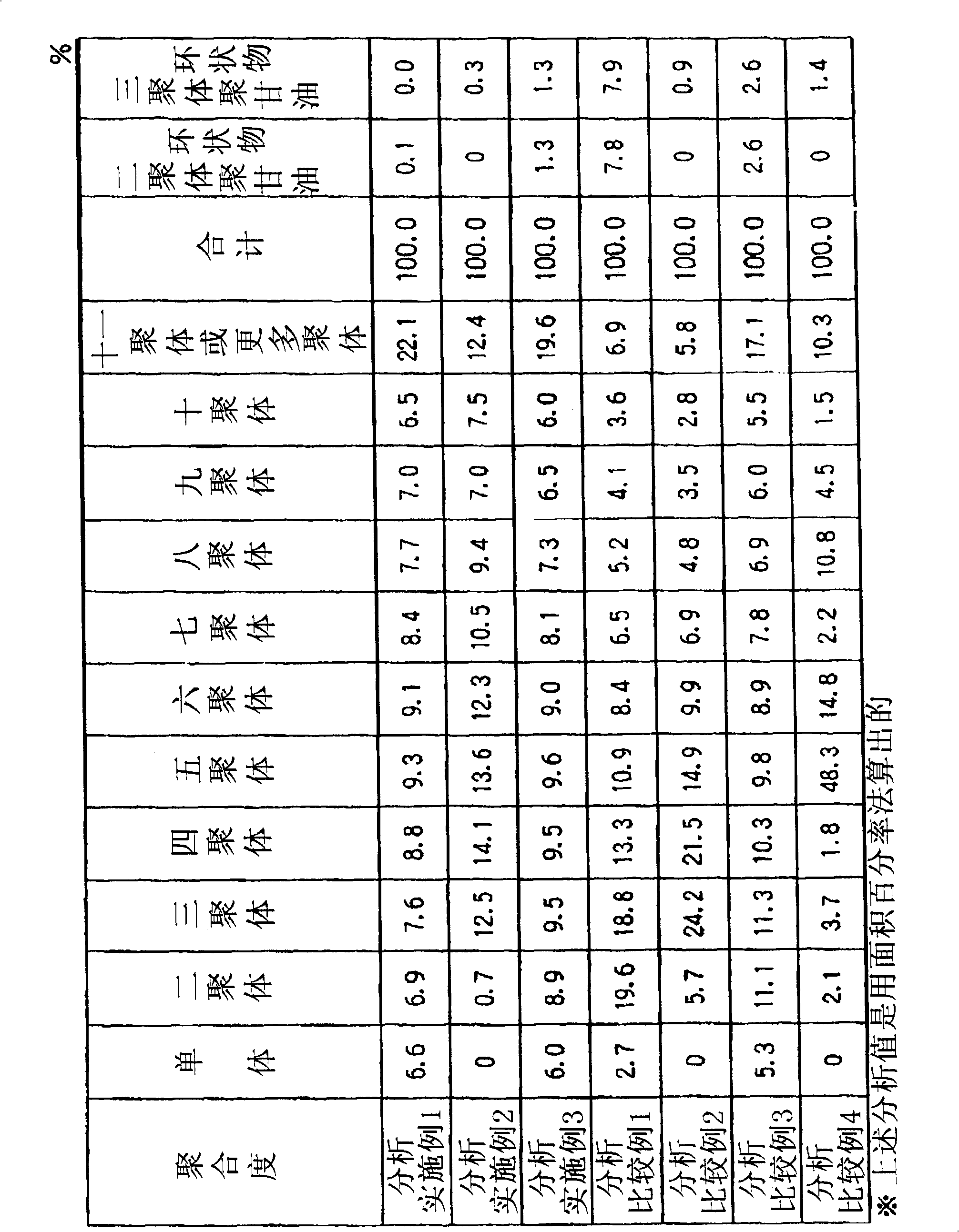

Artificial stone composition, manufacturing method thereof, artificial stone and method for preparing molding

The invention relates to an artificial stone composition, wherein, the composition contains a monomer, a filler, a curing agent and a defoamer, the monomer is (methyl) acrylic ester, compared with 100 parts by weight of the monomer, the content of the filler is 75 to 350 parts by weight, the content of the curing agent is 0.1 to 15 parts by weight, and the content of the defoamer is 0.1 to 25 parts by weight. The artificial stone which is obtained by the invention has natural texture, beautiful patterns, good transparency and high material strength, thereby having very high added values.

Owner:BYD CO LTD

Non-toxic brightening oil for glazing technique

The invention discloses a non-toxic brightening oil for a glazing technique, which is composed of the following components in parts by weight: 26-28 parts of acrylic resin, 20-24 parts of acrylic acid emulsion, 2-4 parts of photoinitiator, 4-6 parts of matting oil, 12-14 parts of ethanol, 2-4 parts of defoaming agent, 2-3 parts of surfactant, 1-2 parts of coating reinforcer and 25-28 parts of water. The brightening oil is environment-friendly, non-toxic and smellless, and has the advantages of high transparency, no organic volatile matters, favorable use effect, favorable glossiness, favorable folding endurance, favorable wear resistance, favorable chemical resistance and wide application range.

Owner:ANHUI ZHONGCAI PRINTING

Oil-in-water-type emulsified cosmetic preparation and process for producing the same

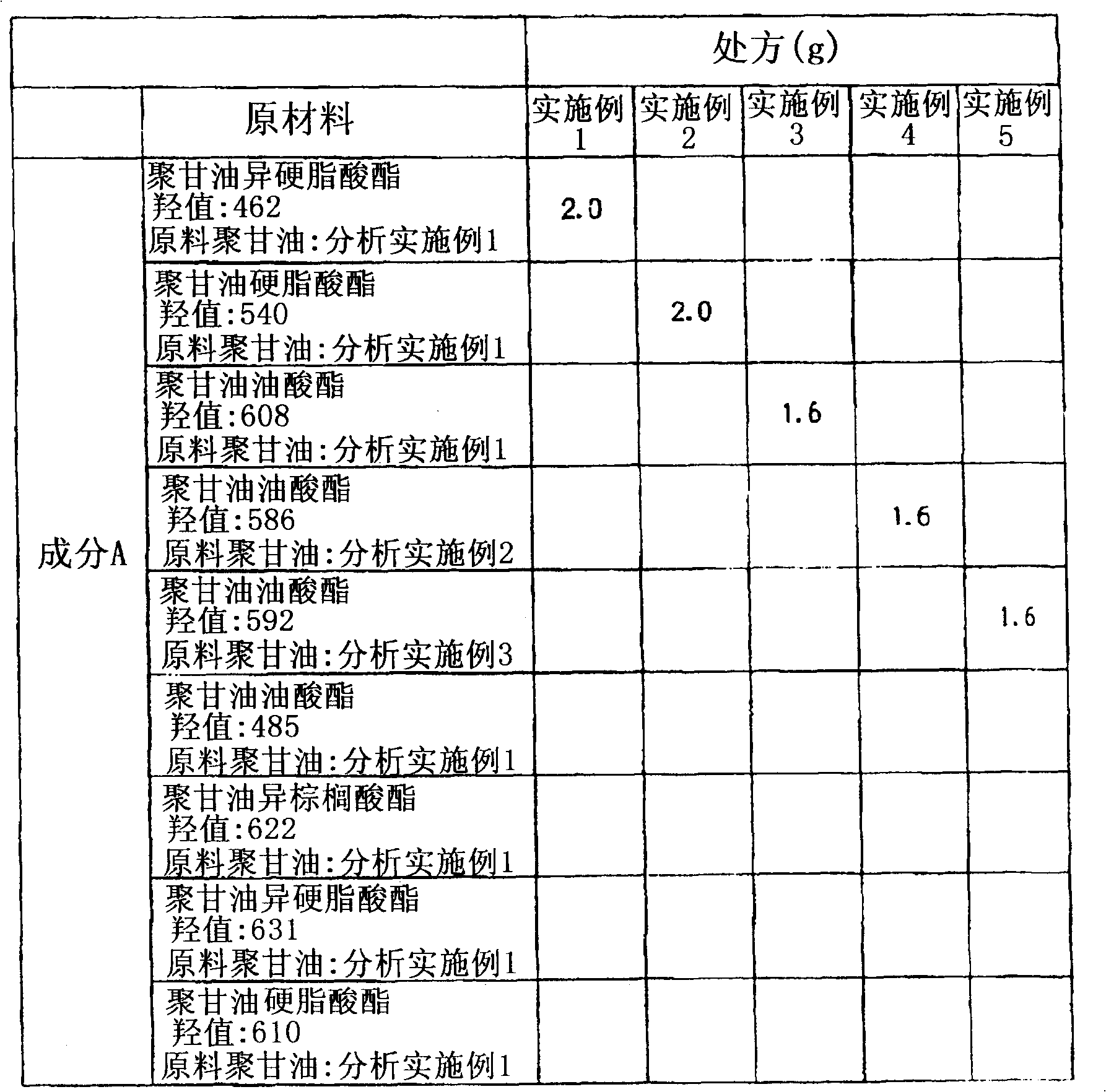

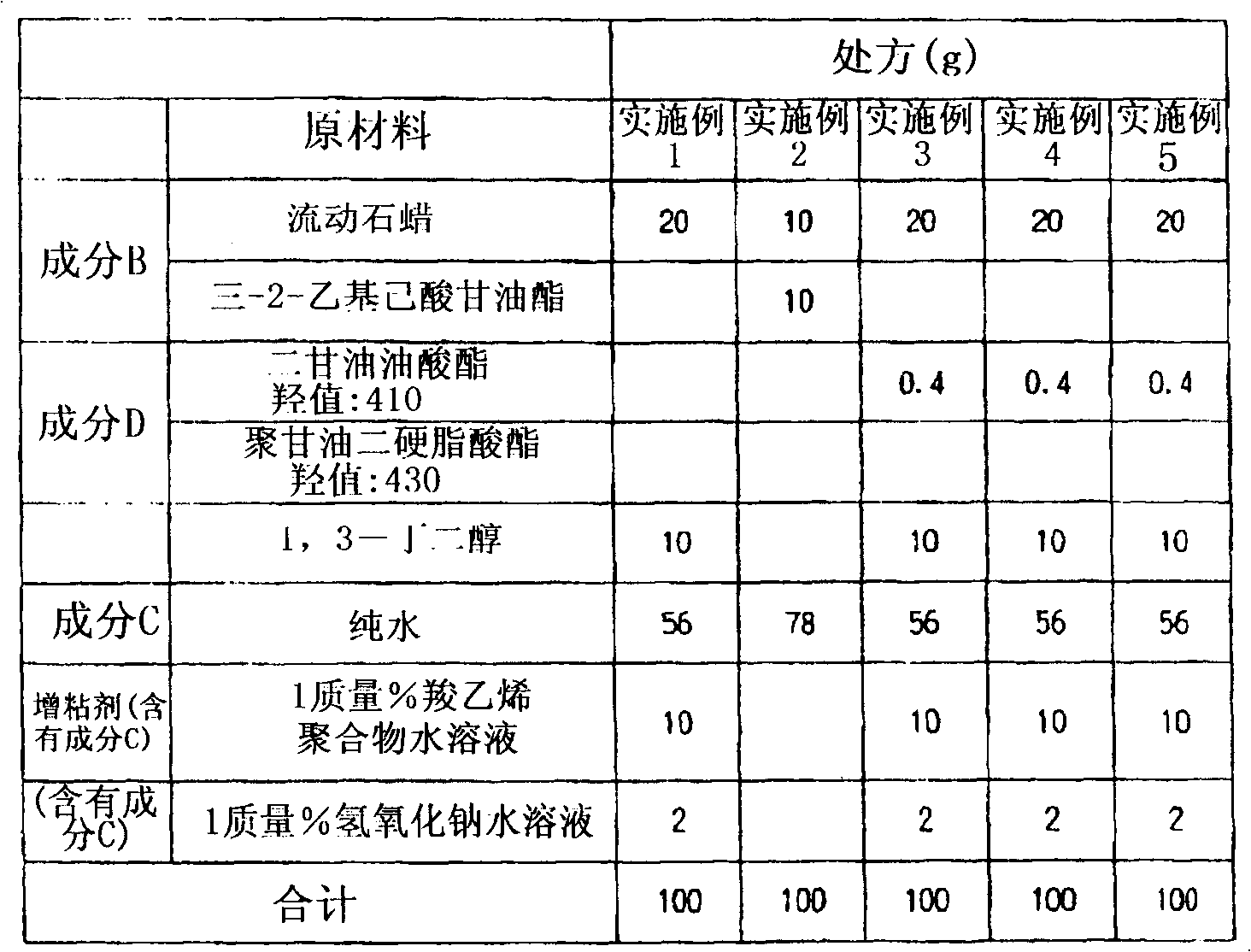

ActiveCN100435773CImprove emulsion stabilityExcellent temperature change stabilityCosmetic preparationsHair cosmeticsGlycerolHydroxyl value

An oil-in-water-type emulsified cosmetic preparation containing a polyglycerol / fatty acid ester as a surfactant. It has high stability to temperature fluctuations and gives an excellent use feeling. The oil-in-water-type emulsified cosmetic preparation comprises 1) a surfactant comprising a polyglycerol / fatty acid ester which has a hydroxy value of 450 to 700 and in which 50 to 100% by mass of all constituent fatty acid residues are accounted for by a C16-18 fatty acid residue and the polyglycerol has a specific polymerization degree distribution, 2) an oily matter, and 3) water.

Owner:THE NISSHIN OILLIO GRP LTD

Preparation method of mirror surface dry grain polished ceramic plate

The invention relates to the technical field of architectural ceramics, and specifically discloses a method for preparing a mirror-surface dry-grain-polished ceramic plate, which is characterized by comprising the following steps: S1. Auxiliary glaze with a sense of transparency, get glue mixture A, apply glue mixture A on the tile body with the surface glaze; S3. Dry cloth; S4. Mix glue and fluxing glaze to obtain glue mixture B , the glue mixture B is applied on the brick blanks with dry particles; S5. drying; S6. firing; the fluxing glaze described in step S4 comprises the following components in parts by weight: wollastonite 40-50 weight 10 to 15 parts by weight of calcined kaolin; 3 to 5 parts by weight of alumina; 15 to 20 parts by weight of reclaimed dry particles; 25 to 35 parts by weight of potassium feldspar. The invention effectively improves the flatness of the surface of the mirror-surface dry-grain-polished ceramic plate, the mirror effect, the transparency and the expressive power of the product are stronger, and the decorative effect of the product is effectively improved.

Owner:广东兴辉陶瓷集团有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com