Preparation method of mirror surface dry grain polished ceramic plate

A technology of dry granules and slabs, applied in the field of architectural ceramics, which can solve problems such as unsatisfactory surface flatness, poor mirror effect and transparency, and imperfect matching of dry granules on the surface, so as to achieve transparency and strong expressiveness , reduce the melting temperature, and increase the effect of particle gradation range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0038] A kind of preparation method of mirror surface dry granule polishing ceramic plate, comprises the following steps:

[0039] S1. The adobe is pressed and formed, and after drying, a top glaze is applied to the adobe; then, patterns are printed on the adobe with the glaze applied by an inkjet printer;

[0040] S2. mixing glue and auxiliary glazes for improving exhaust and enhancing transparency to obtain glue mixture A, and applying glue mixture A to the glazed brick;

[0041] S3. Use dry grain machine cloth 0.8kg / m 2 Dry particles, the dry particle size is 300~700μm;

[0042] S4. mixing glue and fluxing glaze to obtain glue mixture B, and applying glue mixture B to the brick adobe with dry particles;

[0043] S5. drying;

[0044] S6. Burning;

[0045] S7. The fired ceramic plate is polished to obtain a finished product.

[0046] The fluxing glaze described in step S4 comprises the following components by weight:

[0047] 40-50 parts by weight of wollastonite; 10-15...

Embodiment 2

[0049] A kind of preparation method of mirror surface dry granule polishing ceramic plate, comprises the following steps:

[0050] S1. The adobe is pressed and formed, and after drying, a top glaze is applied to the adobe; then, patterns are printed on the adobe with the glaze applied by an inkjet printer;

[0051] S2. Mix the glue and the auxiliary glaze used to improve air exhaust and enhance the sense of transparency to obtain the glue mixture A, apply the glue mixture A to the glazed brick, the density of the auxiliary glaze in the glue is 1.08~1.12g / ml;

[0052] S3. Use dry grain machine cloth 0.8kg / m 2 Dry particles, the dry particle size is 300~700μm;

[0053] S4. Mix glue and fluxing glaze to obtain glue mixture B, apply glue mixture B on the brick adobe with dry particles; the density of fluxing glaze in glue is 1.05 ~ 1.08g / ml;

[0054] S5. drying;

[0055] S6. Firing:

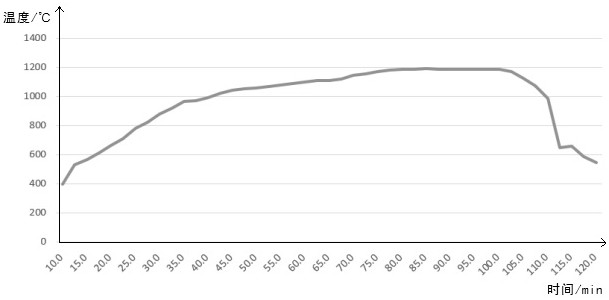

[0056] S61. The first heating stage: from normal temperature to 500~580℃, the heating time i...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com