Ceramic product with metallic copper wear-resistant glaze and preparation method thereof

A technology for ceramic products and metal copper, which is applied in the field of ceramic products with metal copper color wear-resistant glaze and its preparation, can solve the problems of poor wear resistance of metal copper color glaze, and achieves improved hardness, reduced wear, and reduced fluidity. small effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

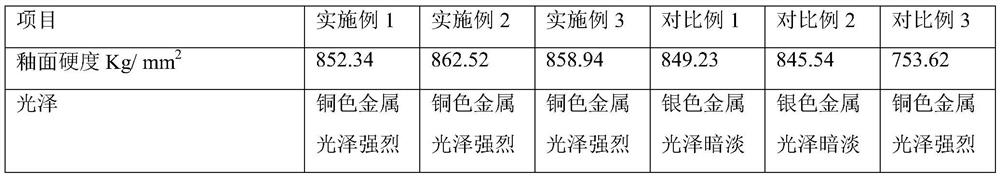

Examples

Embodiment 1

[0021] A method for preparing a ceramic product with metallic copper color wear-resistant glaze, comprising the following steps:

[0022] S1 Ingredients: Weigh 24 parts of kaolin, 18 parts of limestone, 10 parts of quartz, 12 parts of clay, 2 parts of glass powder, 16 parts of calcium carbonate, 12 parts of calcium silicate, and 8 parts of barium sulfate according to parts by weight. Mix in the medium, add 50% water of the total weight of the billet, obtain the billet slurry after ball milling for 8 hours, pass through a 100-mesh sieve, and the sieve residue is 0.03%, for subsequent use; take 2 parts by weight of talc, 18 parts of iron phosphate, 105 parts of albite, 5 parts of alumina, 8 parts of clay, 6 parts of mullite fiber, 4 parts of potassium oxide, 12 parts of lithium oxide, 4 parts of barium sulfate, 25 parts of silicon dioxide, 2 parts of copper oxide, 4 parts of manganese and 2 parts of lead oxide, pulverized and mixed in a ball mill, adding 55% water of the total w...

Embodiment 2

[0028] Further, the glaze includes the following materials in parts by weight: 3 parts of talc, 21 parts of iron phosphate, 12 parts of albite, 6 parts of alumina, 9 parts of clay, 11 parts of mullite fiber, 6 parts of potassium oxide, Lithium oxide 14 parts, barium sulfate 6 parts, silicon dioxide 30 parts, copper oxide 6 parts, manganese dioxide 8 parts, lead oxide 3 parts.

[0029] A method for preparing a ceramic product with metallic copper color wear-resistant glaze, comprising the following steps:

[0030] S1 Ingredients: Weigh 32 parts of kaolin, 21 parts of limestone, 12 parts of quartz, 15 parts of clay, 3 parts of glass powder, 20 parts of calcium carbonate, 13 parts of calcium silicate, and 11 parts of barium sulfate according to parts by weight. Mix in the medium, add 55% water of the total weight part of the billet, obtain the billet slurry after ball milling for 9 hours, pass through a 100 mesh sieve, and the sieve residue is 0.04%, for subsequent use; take 3 pa...

Embodiment 3

[0036] A method for preparing a ceramic product with metallic copper color wear-resistant glaze, comprising the following steps:

[0037]S1 Ingredients: Weigh 38 parts of kaolin, 24 parts of limestone, 13 parts of quartz, 17 parts of clay, 4 parts of glass powder, 22 parts of calcium carbonate, 14 parts of calcium silicate, and 14 parts of barium sulfate according to parts by weight. Mix in the medium, add 60% water of the total weight of the billet, obtain the billet slurry after ball milling for 10 hours, pass through a 100-mesh sieve, and the sieve residue is 0.05%, for subsequent use; take 4 parts by weight of talc, 22 parts of iron phosphate, 15 parts of albite, 8 parts of alumina, 10 parts of clay, 11 parts of mullite fiber, 7 parts of potassium oxide, 16 parts of lithium oxide, 9 parts of barium sulfate, 34 parts of silicon dioxide, 6 parts of copper oxide, 10 parts, 4 parts of lead oxide, pulverized and mixed in a ball mill, adding 65% water of the total weight of the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com