Sweet potato dumpling flour and preparation method thereof

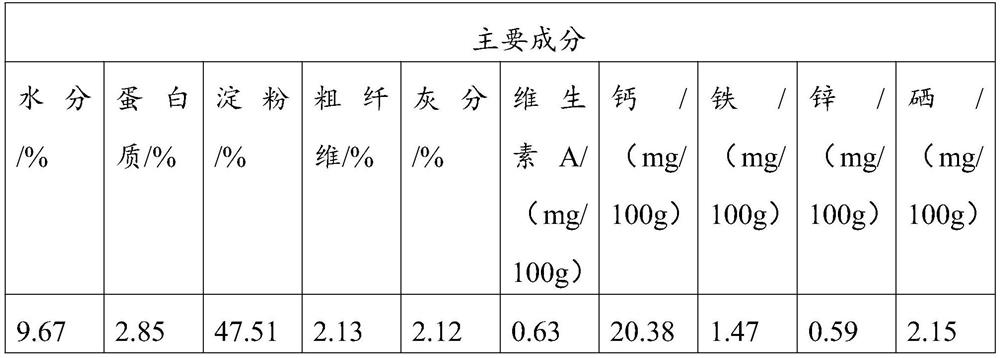

A technology for dumpling powder and sweet potato, which is applied in the field of food processing and can solve the problems of insufficient fineness and whiteness of the whole sweet potato powder.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

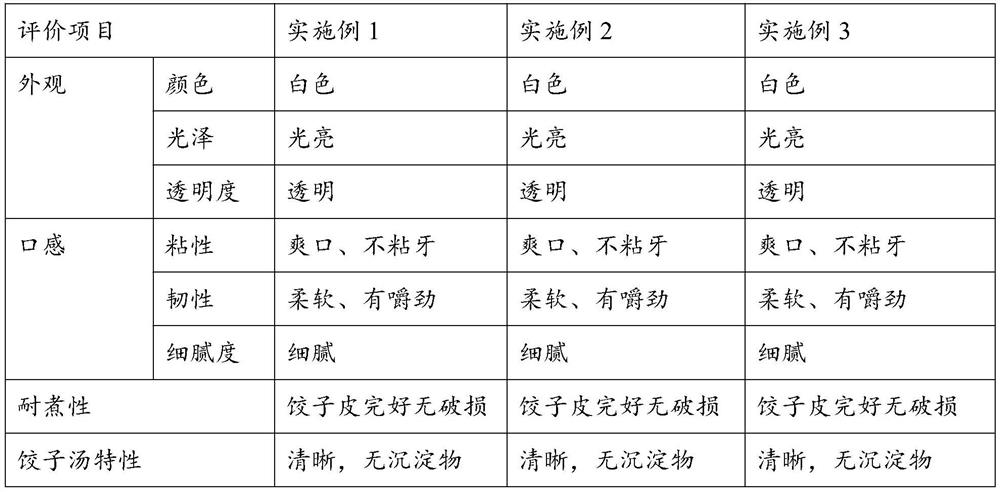

Examples

Embodiment 1

[0024] (1) Clean the selected sweet potatoes that have been manually selected and separated from deterioration and mold spots to remove surface soil and gravel. After cleaning, put the sweet potatoes into the squirrel-cage washing machine for two-way cleaning to separate the potato skins;

[0025] (2) Put the sweet potatoes cleaned in step (1) into a sweet potato crusher, and crush them to a particle size<5mm;

[0026] (3) Using centrifugation to separate the gravel and metal objects from the crushed whey in step (2), and then finely grinding to a particle size of more than 300 mesh to obtain whole milk powder;

[0027] (4) Homogenize the whole powdered milk after step (3) at 40°C to inactivate enzymes, improve transparency and reduce enzyme activity;

[0028] (5) The whole powder emulsion after homogenizing and deactivating the enzyme in step (4) is transported to a spray drying tower, where it is dried and dehydrated at 80° C. until the water content is less than 13%.

Embodiment 2

[0030] (1) Clean the selected sweet potatoes that have been manually selected and separated from deterioration and mold spots to remove surface soil and gravel. After cleaning, put the sweet potatoes into the squirrel-cage washing machine for two-way cleaning to separate the potato skins;

[0031] (2) Put the sweet potatoes cleaned in step (1) into a sweet potato crusher, and crush them to a particle size<5mm;

[0032] (3) Using centrifugation to separate the gravel and metal objects from the crushed whey in step (2), and then finely grinding to a particle size of more than 300 mesh to obtain whole milk powder;

[0033] (4) Homogenize and sterilize the finely ground whole milk powder in step (3) at 45° C. to improve transparency and reduce enzyme activity;

[0034] (5) The whole powder emulsion after homogenizing and deactivating the enzyme in step (4) is transported to a spray drying tower, where it is dried and dehydrated at 90°C until the water content is less than 11%.

Embodiment 3

[0036] (1) Clean the selected sweet potatoes that have been manually selected and separated from deterioration and mold spots to remove surface soil and gravel. After cleaning, put the sweet potatoes into the squirrel-cage washing machine for two-way cleaning to separate the potato skins;

[0037] (2) Put the sweet potatoes cleaned in step (1) into a sweet potato crusher, and crush them to a particle size<5mm;

[0038] (3) Using centrifugation to separate the gravel and metal objects from the crushed whey in step (2), and then finely grinding to a particle size of more than 300 mesh to obtain whole milk powder;

[0039] (4) Homogenize the whole milk powder after step (3) at 50°C to inactivate enzymes, improve transparency and reduce enzyme activity;

[0040] (5) The whole powder emulsion after homogenizing and dehydrating the enzyme in step (4) is transported to a spray drying tower, where it is dried and dehydrated at 100° C. until the water content is less than 10%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com