Granulating and screening machine for feed production

A screening machine and feed technology, applied in the fields of feed, application, food science, etc., can solve the problems affecting the quality of feed pelleting, poor mixing and conditioning effect, and unqualified feed products, so as to improve the quality of feed pelleting and pelletizing. High efficiency and good conditioning effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The technical solutions of the present invention will be further described in detail below in conjunction with specific embodiments.

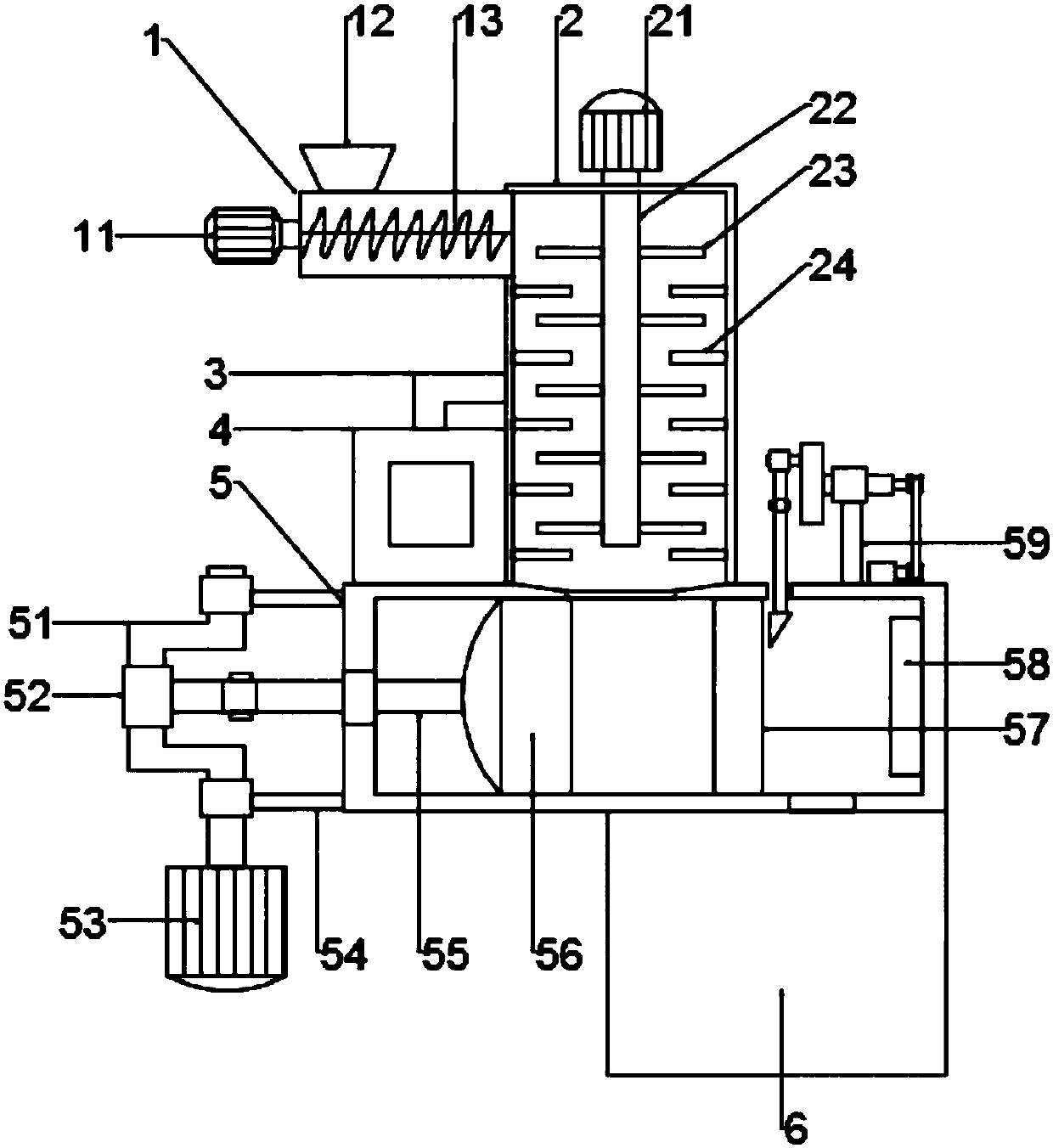

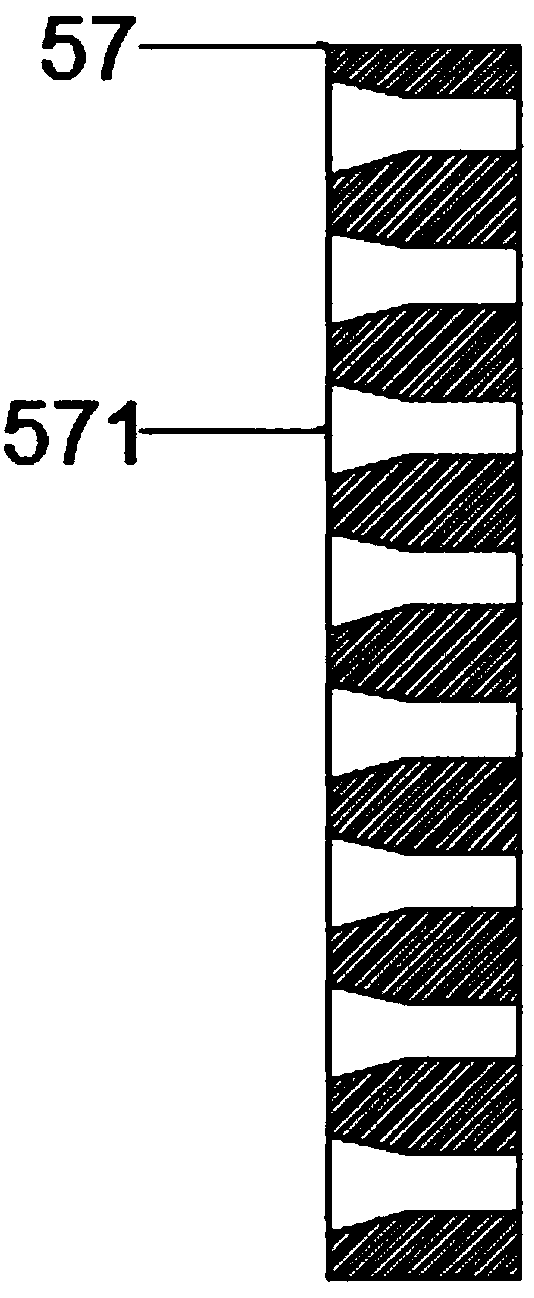

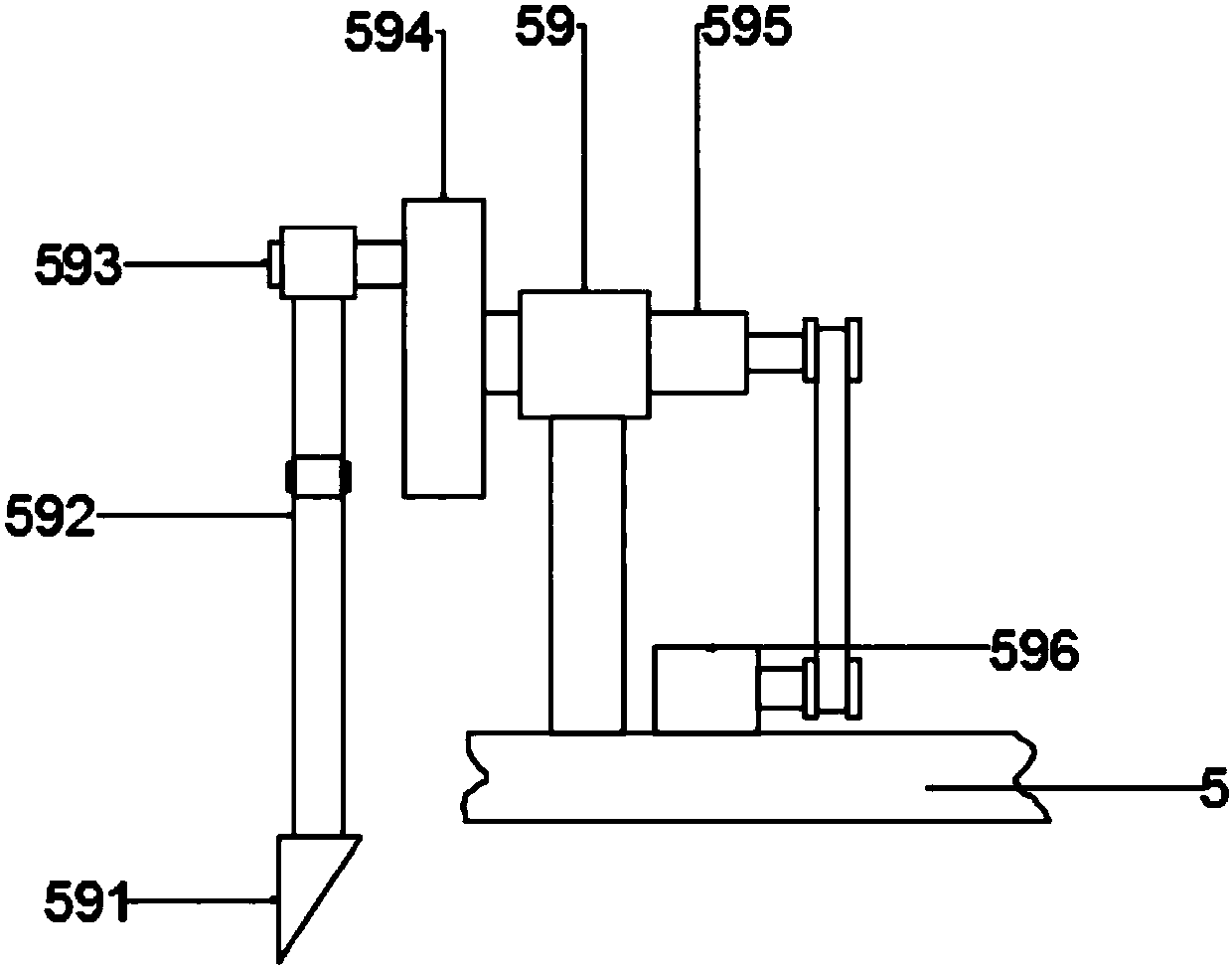

[0022] see Figure 1-4 , a pelletizing and screening machine for feed production, comprising a feeding device 1, a tempering mechanism 2, a pelletizing box 5 and a screening box 6, the upper end of the feeding device 1 is provided with a feeding port 12, and the lower end of the feeding port 12 is provided with There is Jiaolong 13, the left end of Jiaolong 13 is connected to the output shaft of the first motor 11, the left end of the quenching and tempering structure 2 is connected to the feeding device 1, the interior of the quenching and tempering mechanism 2 is provided with a first rotating shaft 22, and the upper end of the first rotating shaft 22 is connected to On the output shaft of the second motor 21, the first rotating shaft 22 is provided with agitating paddles 23 distributed in an array, and the tempering mechanism 2 on the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com