Patents

Literature

34results about How to "Excellent tempering performance" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Sludge aerobic composting method

InactiveCN103613418ALower requirementLarge amount of processingBio-organic fraction processingOrganic fertiliser preparationMass ratioSludge

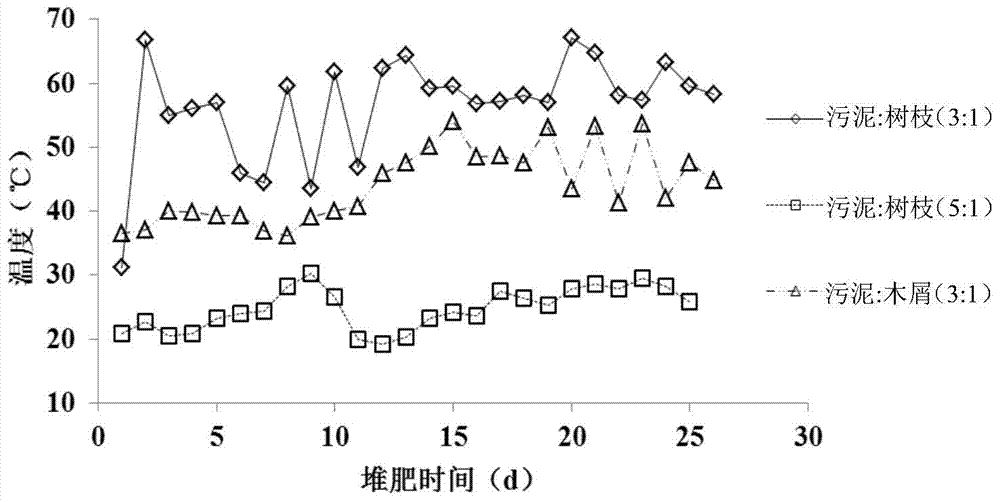

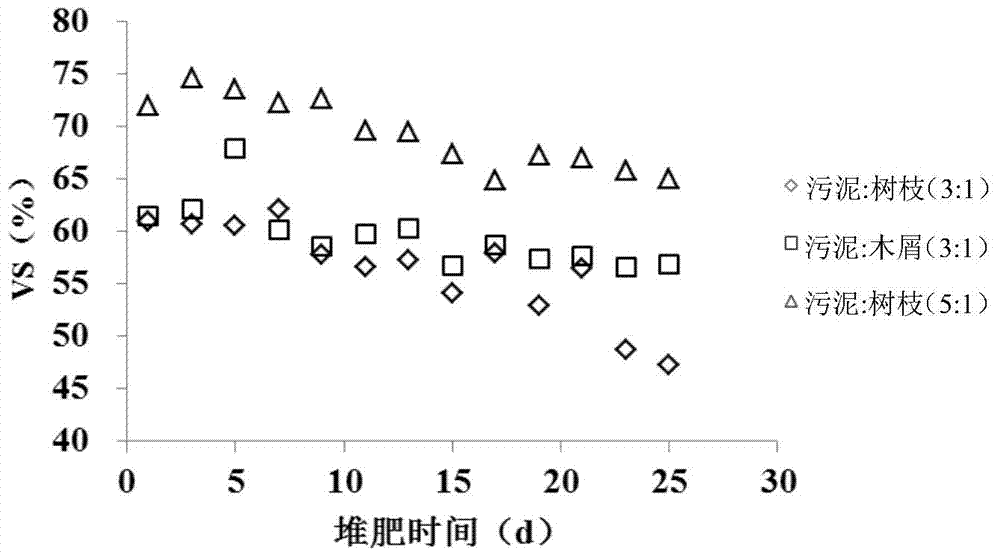

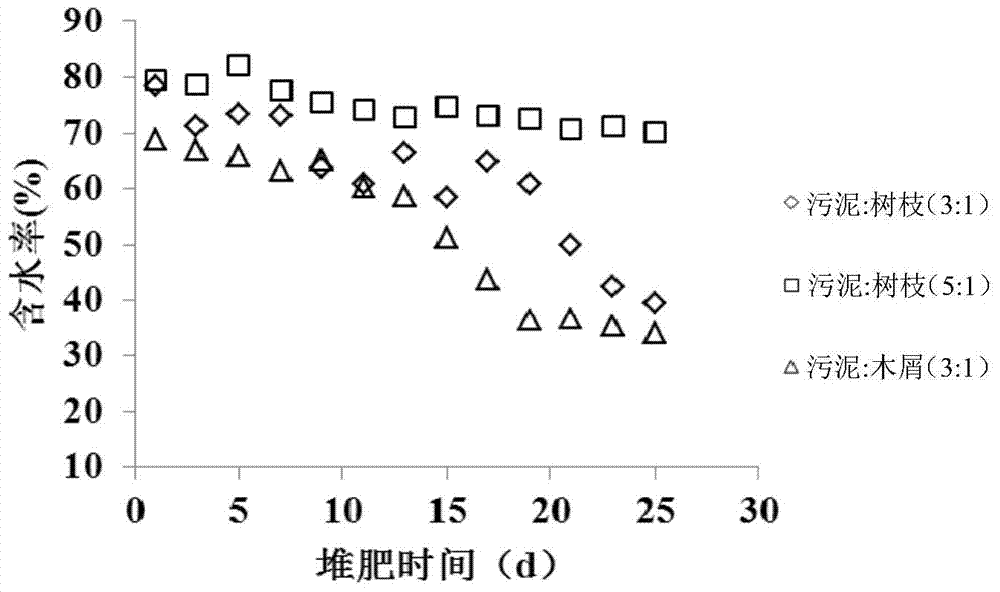

The invention discloses a sludge aerobic composting method. The method disclosed by the invention is a method for carrying out sludge aerobic composting by taking afforest wastes (such as branch sections) as a conditioner, and comprises the following steps: (1) mixing sludge and the afforest wastes according to a mass ratio of (2-4):1, specially 3:1, so as to obtain a mixture; and (2) composting the mixture obtained in the step (1) and monitoring the temperature of a pile body in the composting process; in the composting process, turning for one time when the temperature of the pile body is more than 60 DEG C; finishing the composting after a plurality of times of turning and when the temperature of the pile body is reduced to be lower than 30 DEG C and is not raised. According to the sludge aerobic composting method, the high-temperature aerobic composting of organic wastes is used as the basis and the afforest wastes are used as the conditioner to treat the municipal sludge so as to consume a large amount of the afforest wastes while the harmlessness and the reclamation of the sludge are realized, so that the two aims can be realized by one action. Visibly, the sludge aerobic composting method has a wide application prospect.

Owner:TSINGHUA UNIV

Sludge dewatering conditioning agent and deep dewatering method thereof

ActiveCN103613268ALess quantityHarm reductionSludge treatment by de-watering/drying/thickeningEngineeringSewage

The invention belongs to the technical field of urban sewage and sludge treatment and relates to a sludge dewatering conditioning agent and a deep dewatering method thereof. The invention discloses the novel sludge conditioning agent. The sludge conditioning agent comprises polyacrylamide and a coal pyrolysis product, namely semicoke; the invention also discloses the method for treating the sludge by using the conditioning agent; the method comprises the following steps: firstly, concentrating and dewatering the sludge by using the conditioning agent, wherein the BOD (Biochemical Oxygen Demand), COD (Chemical Oxygen Demand) and SS (Suspended Solids) of supernatant liquor after concentrating and dewatering can meet secondary sewage drain standard, and the water content of the treated sludge is less than 80%; then, directly filter-pressing and dewatering the concentrated and dewatered sludge, wherein the water content of the treated sludge is less than 50%. The used sludge conditioning agent is extremely strong in adsorption capacity, low in cost and excellent in performance; the sludge treatment process is simple, the dewatering time is short and the water content of the sludge is low; the dewatered sludge can be directly recycled without drying and dewatering, so that the sludge dewatering conditioning agent has good application prospect.

Owner:ヂュハイクェァチュアンエンバイロメントリソースィズカンパニーリミテッド

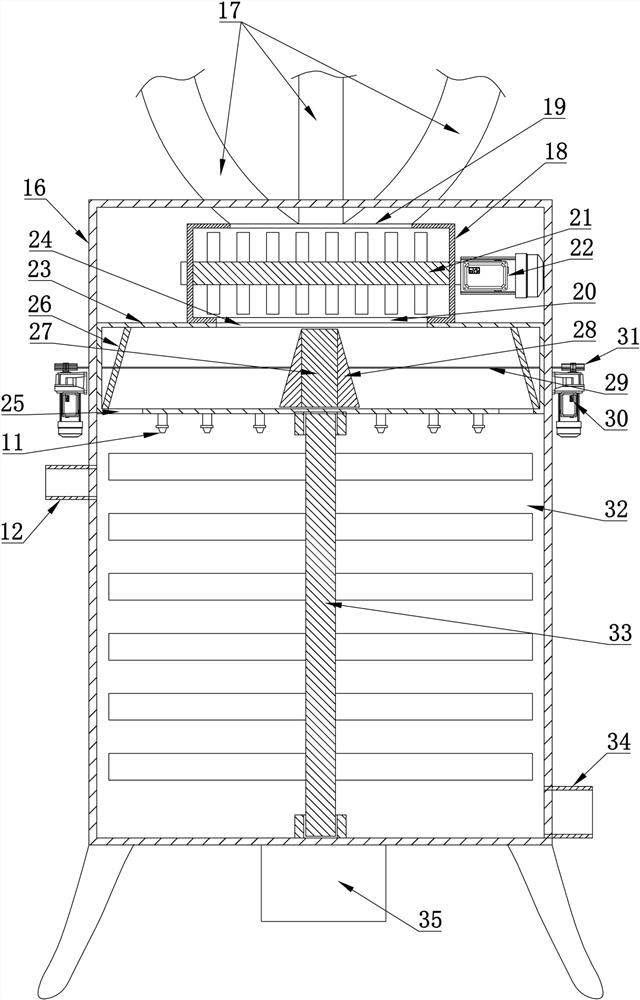

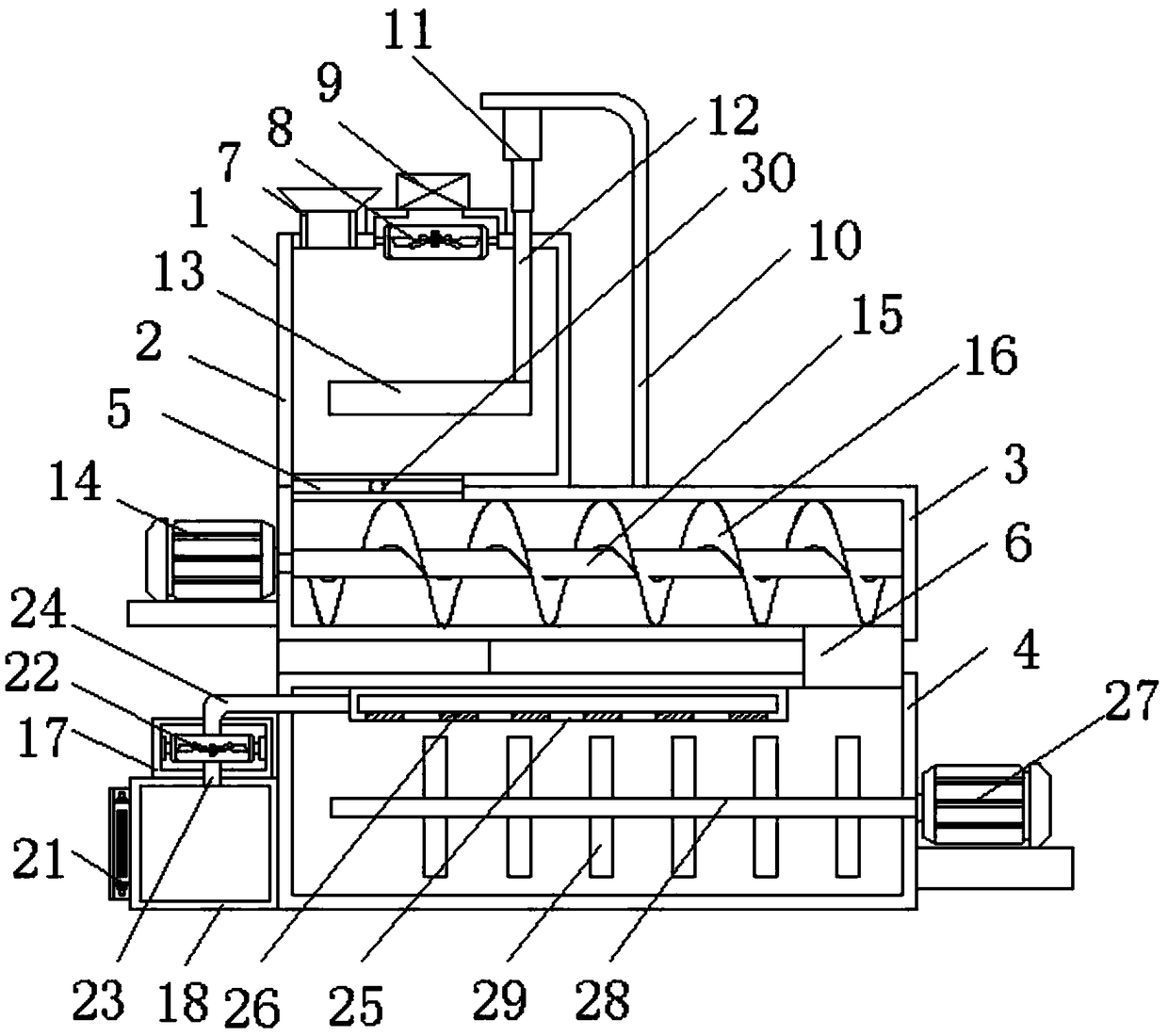

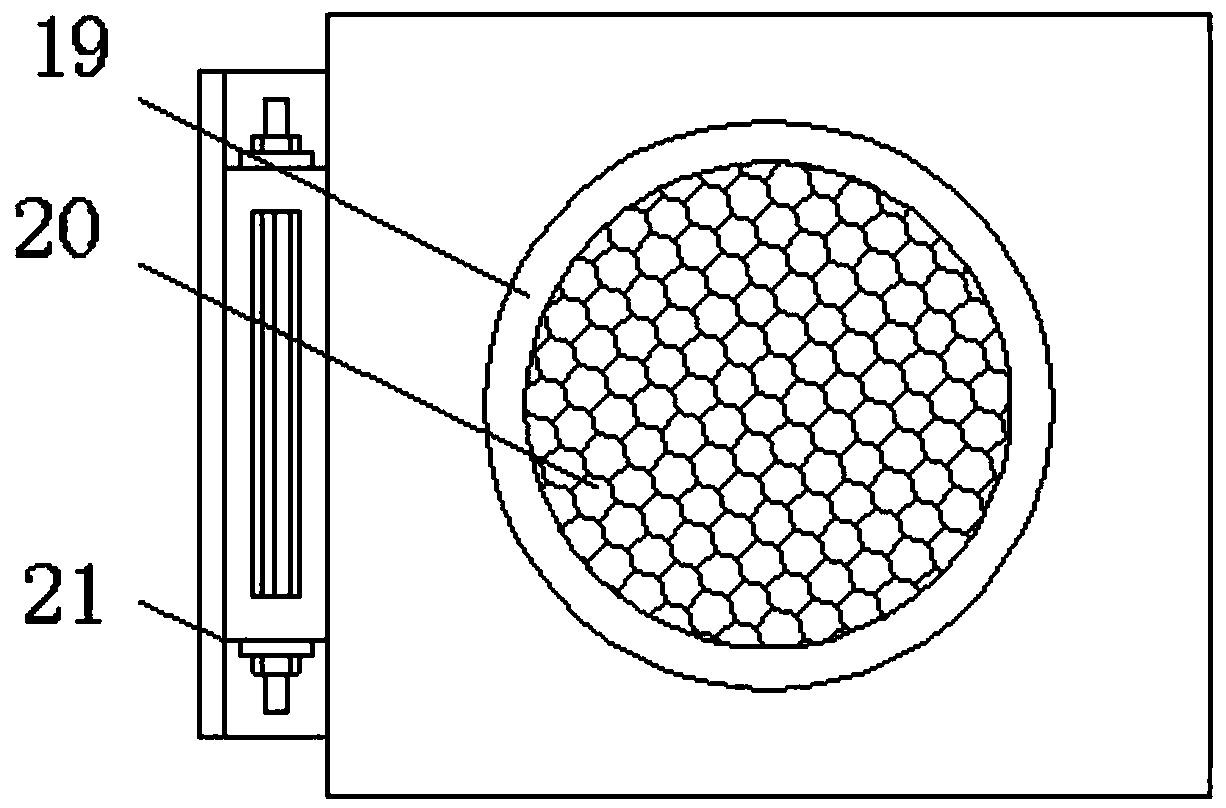

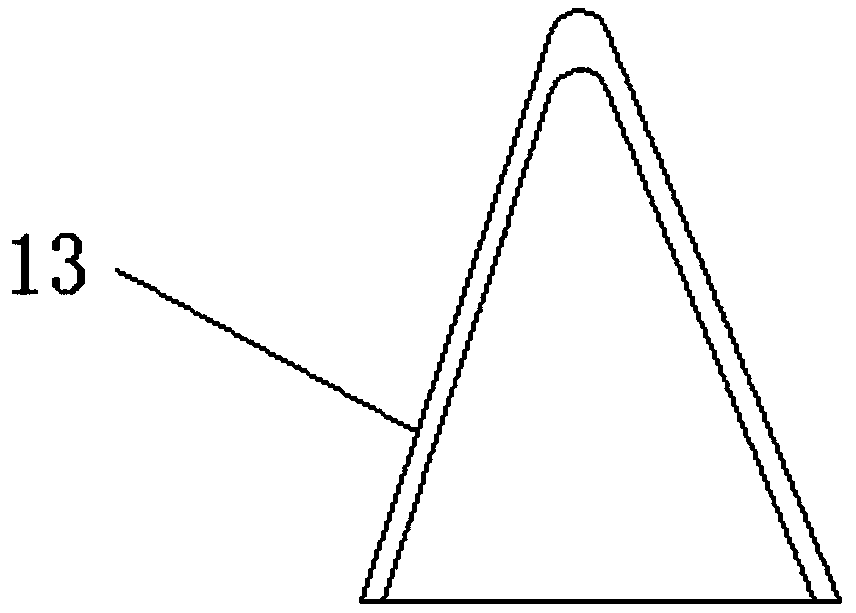

Granulating and screening machine for feed production

InactiveCN107581643AMalleableImprove granulation qualityFeeding-stuffAgricultural engineeringWater pipe

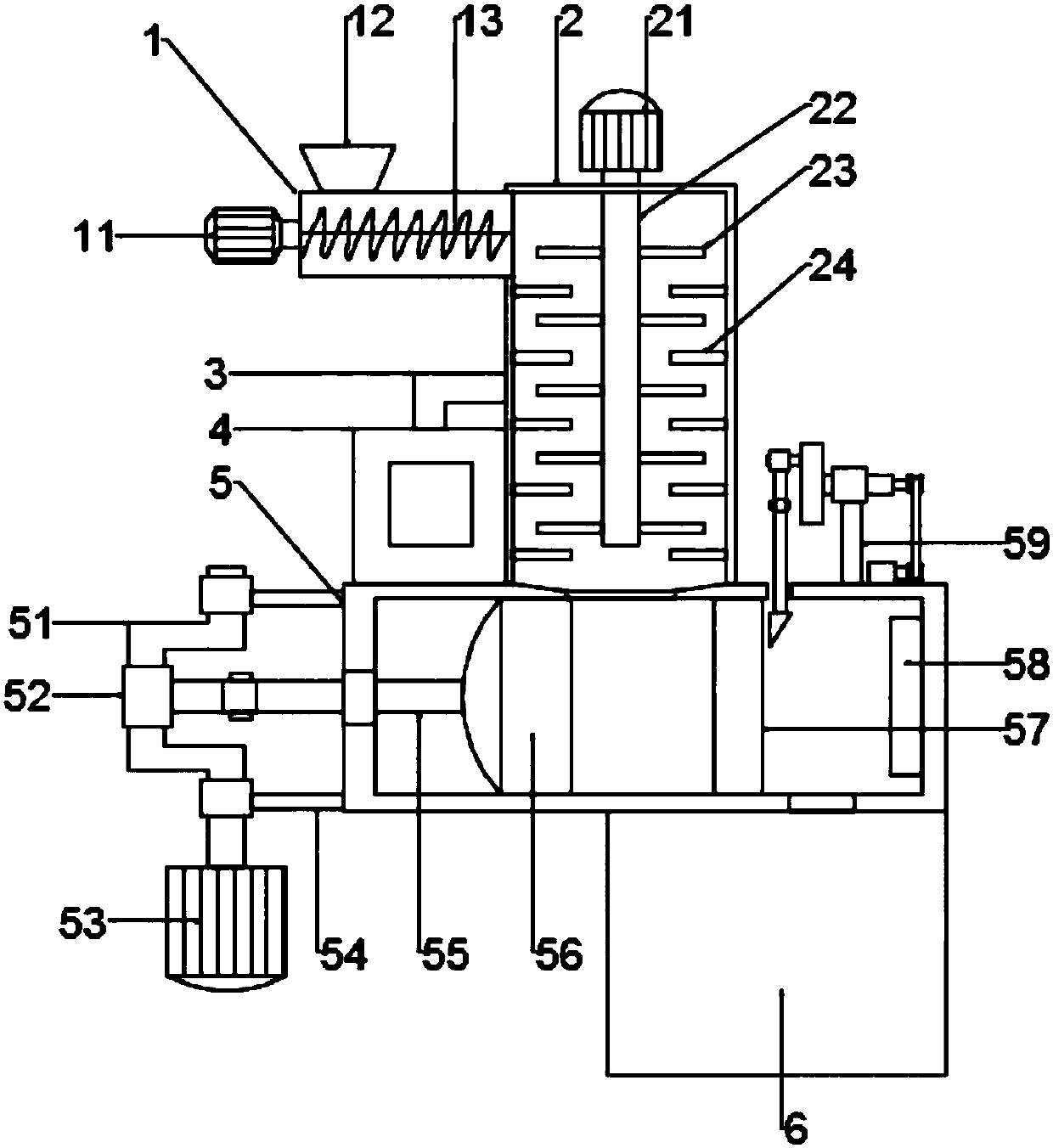

The invention discloses a granulating and screening machine for feed production. The granulating and screening machine comprises a charging device, a conditioning mechanism, a granulating box and a screening box, wherein a charging opening is formed in the upper end of the charging device, a first rotating shaft is arranged in the conditioning mechanism, stirring paddles distributed in arrays arearranged on the first rotating shaft, water filling pipes distributed in arrays are arranged on the conditioning mechanism on the left and right sides of the stirring paddles, a squeezing plate is arranged in the granulating box, a granulating plate is arranged in the granulating box on the right side of the squeezing plate, a cutting device is arranged on the granulating box on the right side ofthe granulating plate, a charging pipe is arranged on the upper end of the screening box, a screening plate is arranged in the screening box on the lower side of the charging pipe, and a discharging pipe is arranged on the screening box on the right side of the screening plate. According to the granulating and screening machine for feed production disclosed by the invention, the contact area between water and feed is large, the conditioning effect is good, the conditioning mechanism is provided with vertical conditioning for solving the problems of insufficient stirring and water addition anddifficulty in discharging of a transverse conditioning mechanism, the granulating efficiency is high, and the feed granulating quality is high.

Owner:遂昌县宏创技术开发有限公司

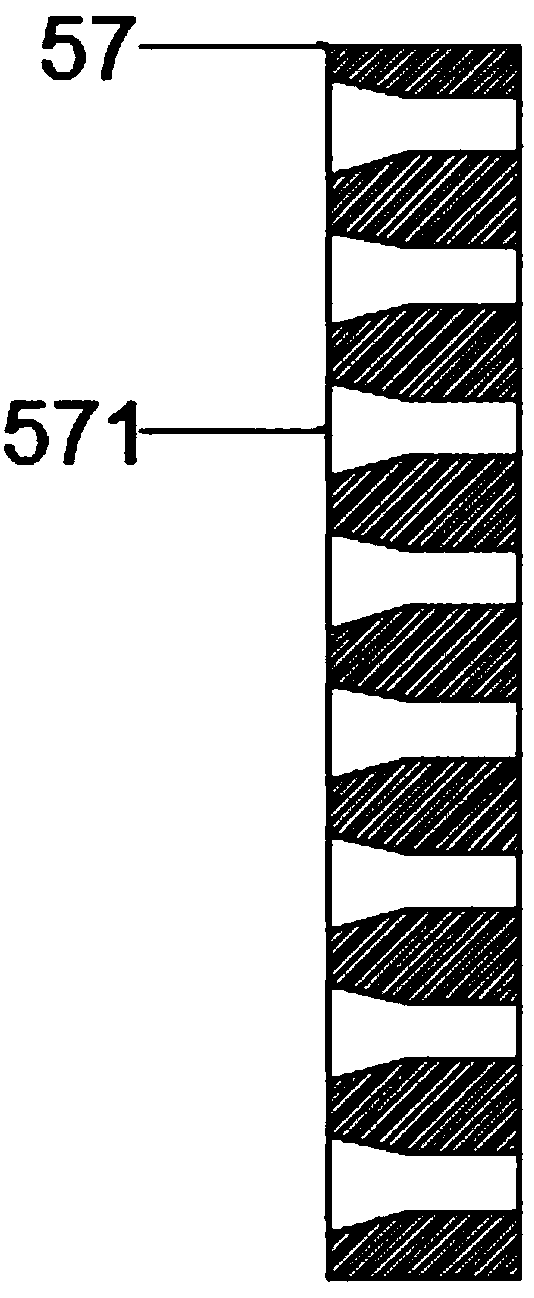

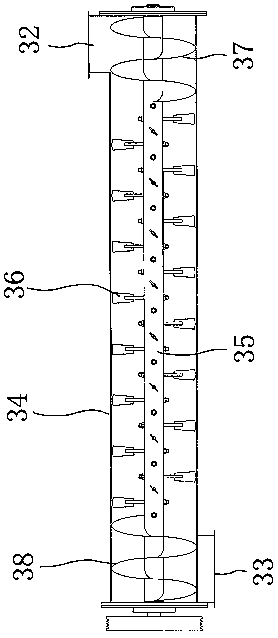

Dynamic sludge tempering and mixing device

InactiveCN106237894AWell mixedQuick mixSludge treatment by de-watering/drying/thickeningRotary stirring mixersWater dischargeSludge

The invention relates to a dynamic sludge tempering and mixing device. The dynamic sludge tempering and mixing device comprises a mixing kettle; one side of the bottom of the mixing kettle is connected with a muddy water feeding pipe, and a muddy water discharging pipe is arranged at the upper part of the other side of the mixing kettle; a flocculating agent guide pipe is arranged on the muddy water feeding pipe; the mixing kettle is internally provided with a stirring device; the stirring device comprises a stirring shaft which is axially arranged in the mixing kettle; the upper end of the stirring shaft is connected with a motor and stirring blades are arranged on a side wall at the lower end of the stirring shaft; the stirring shaft is of a hollow structure and a radial through hole is formed in the side wall at the lower end of the stirring shaft; the radial through hole is located between the upper and lower adjacent stirring blades; the upper end of the stirring shaft is connected with a flocculating agent feeding pipe and is connected with the motor through a driven gear and a driving gear, which are engaged. By adopting a secondary mixing manner, sufficient and rapid mixing of a flocculating agent and muddy water is realized; the tempering effect is good and the efficiency is high.

Owner:WUXI LIANGHUI ENVIRONMENTAL PROTECTION MACHINERY CO LTD

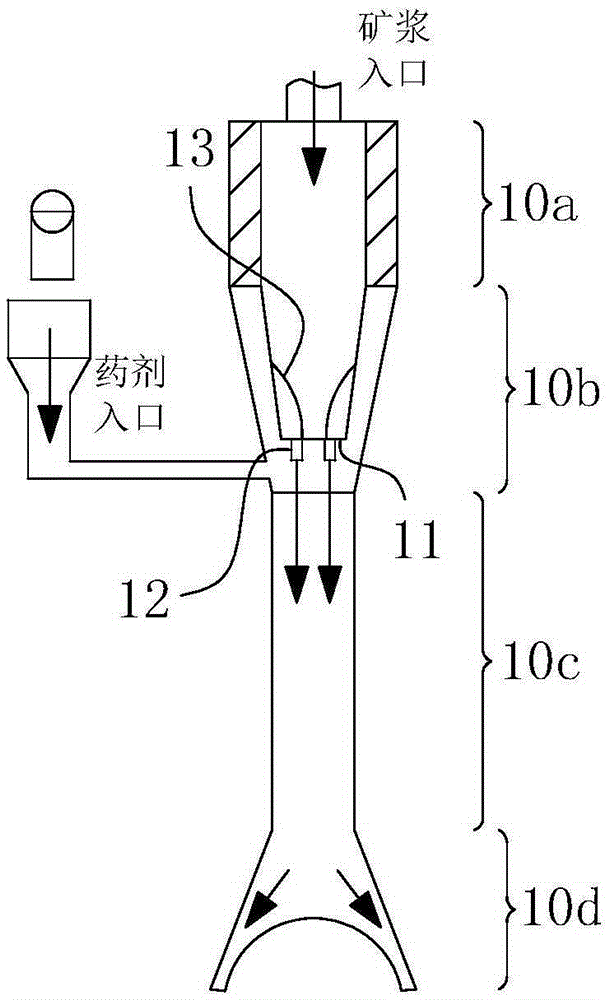

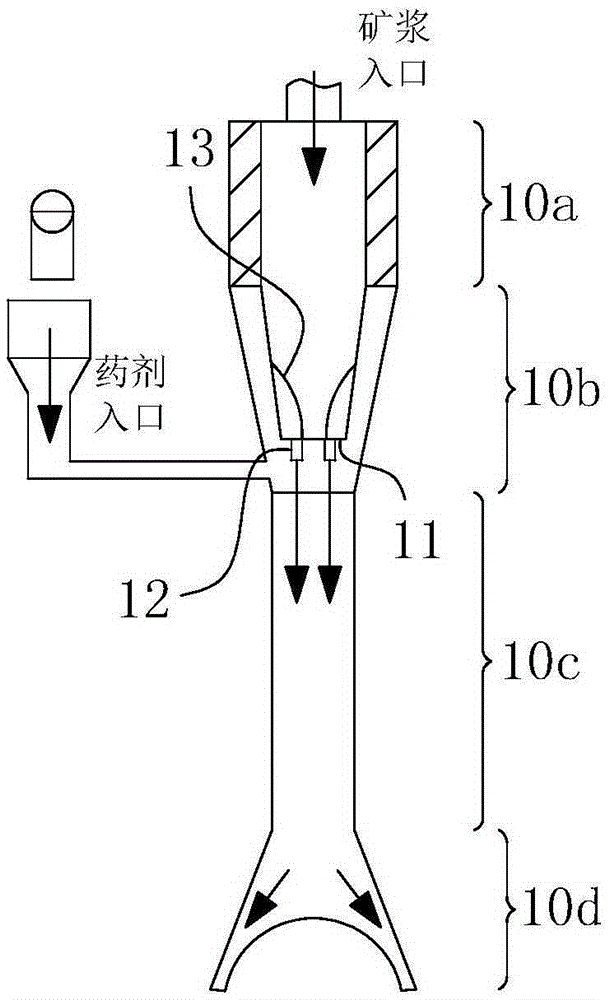

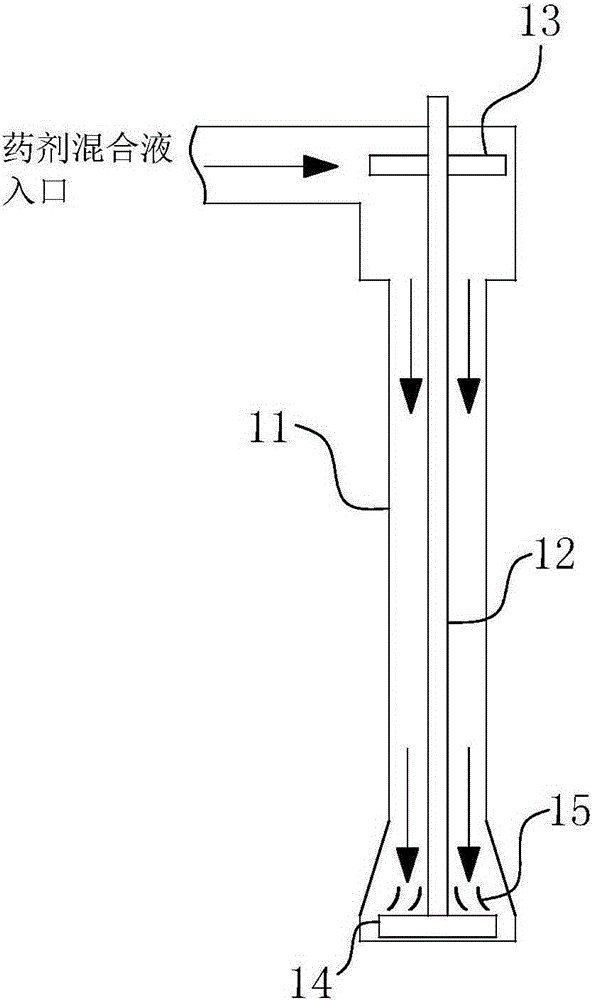

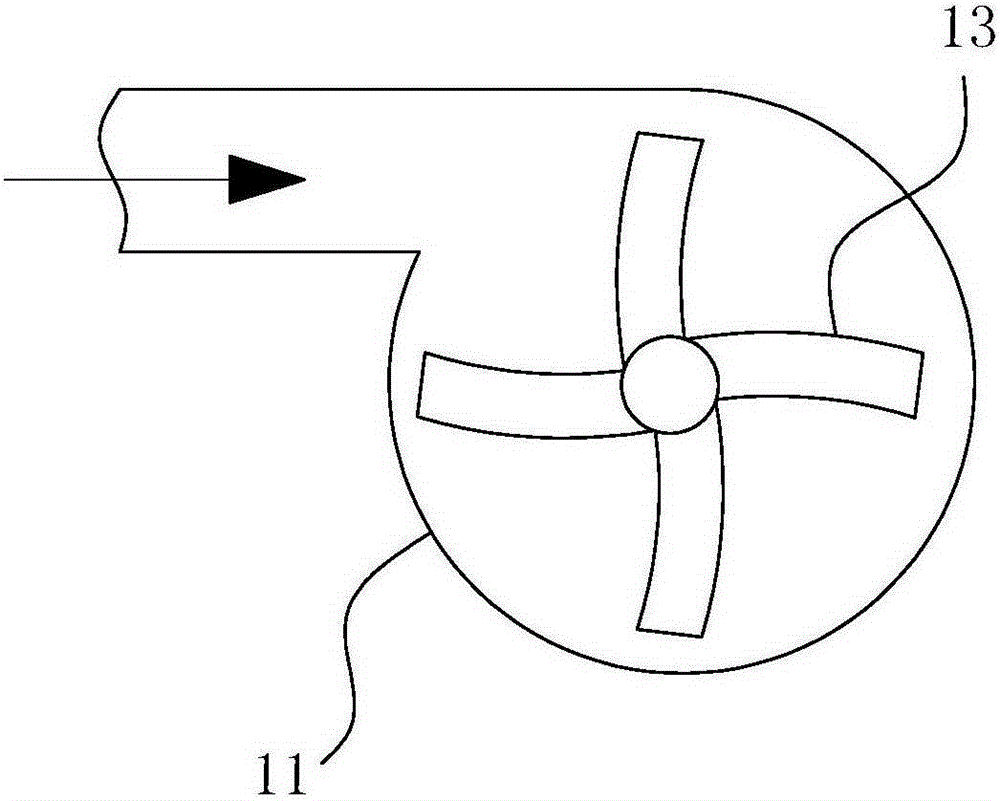

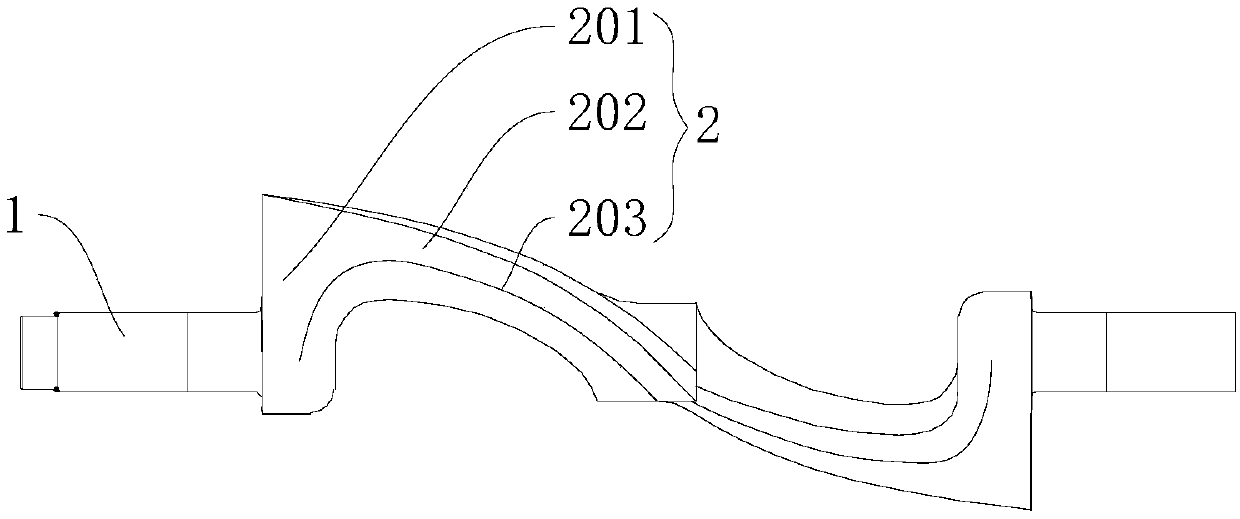

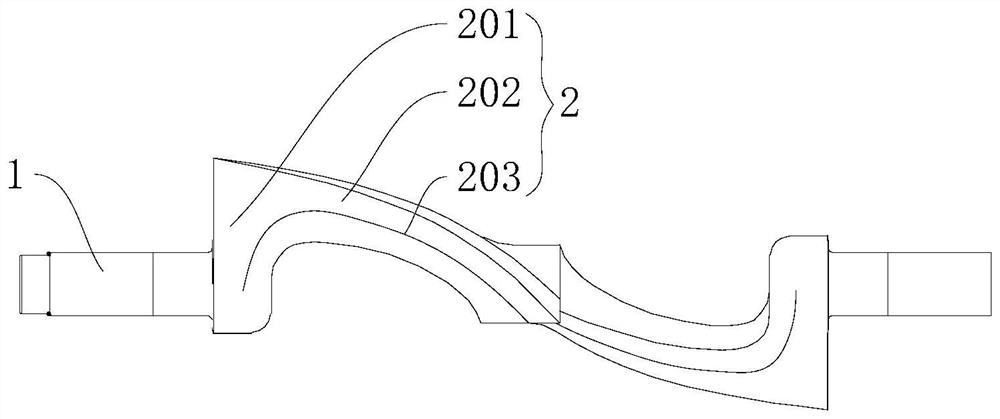

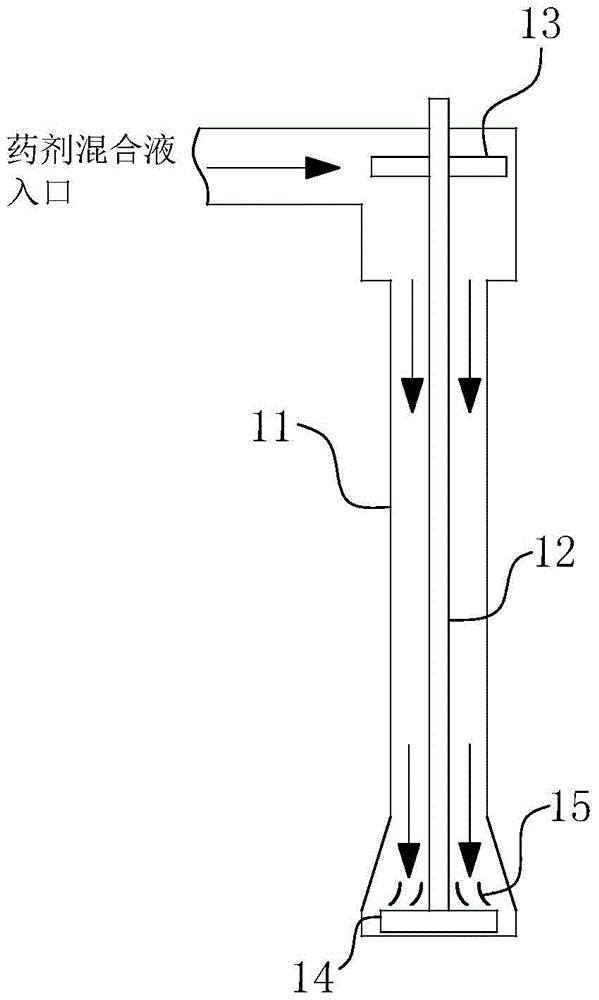

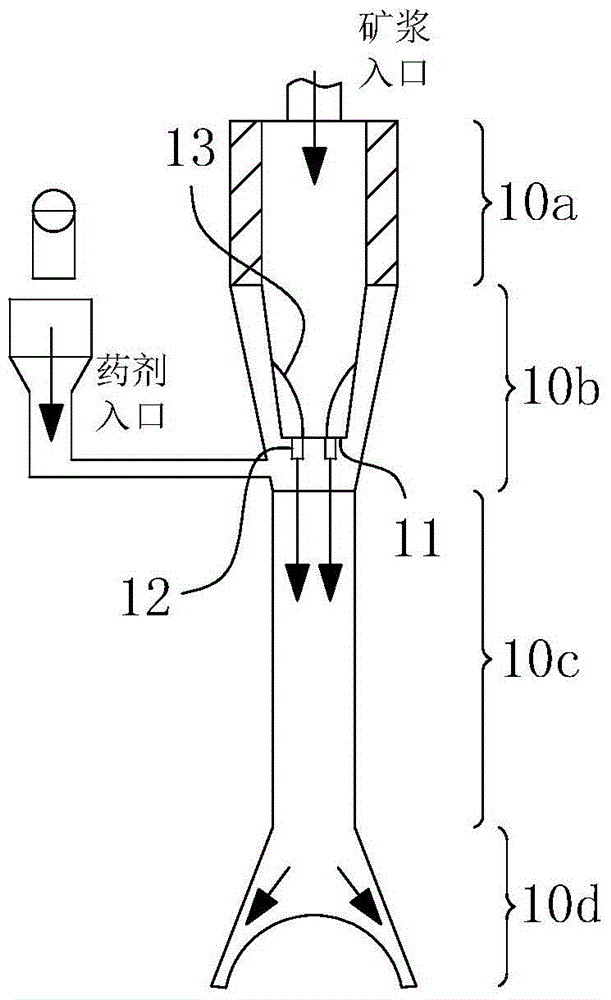

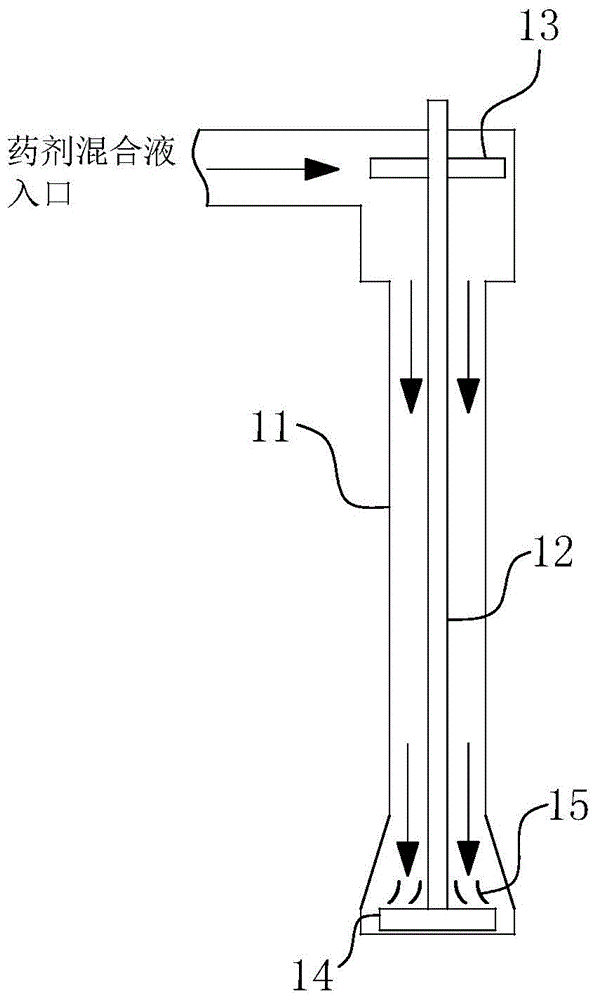

Jet medicament disperse system and fine coal particle pulp mixing modification equipment applying same

ActiveCN105289346AHomogeneous Mix Feed RequirementsPromote rapid formationFlow mixersMixer accessoriesHybrid systemEngineering

The invention relates to the field of coal slurry pre-treatment, and in particular relates to a jet medicament disperse system and fine coal particle pulp mixing modification equipment applying the same. The jet medicament disperse system comprises a pipe body, wherein the tail end of an inlet section of the hollow pipe chamber of the pipe body is provided with a nozzle baffle plate, and nozzles are arranged on the nozzle baffle plate; guide vanes are arranged at a side board surface of the nozzle baffle plate located at the chamber where the inlet section is located; all the nozzles are arranged at the side positions, close to the axis of the pipe body, of the corresponding guide vanes in one-to-one correspondence; an expansion section is of a forked type pipe body structure distributed along the circumferential direction of the axis of the pipe body. The system can effectively realize the uniform mixing feeding requirements of a medicament, ore pulp, and even clean water in a controllable manner. The fine coal particle pulp mixing modification equipment comprises a mixing box and a graded mixing system arranged in the mixing box, the top of the mixing box is provided with a medicament atomization dispersing system and the bottom is provided with the jet medicament disperse system; the equipment is especially suitable for the pulp mixing modification requirement of fine-particle coal difficult to float, the working efficiency of the equipment is high and the pre-treatment process is quick and convenient.

Owner:ANHUI UNIV OF SCI & TECH

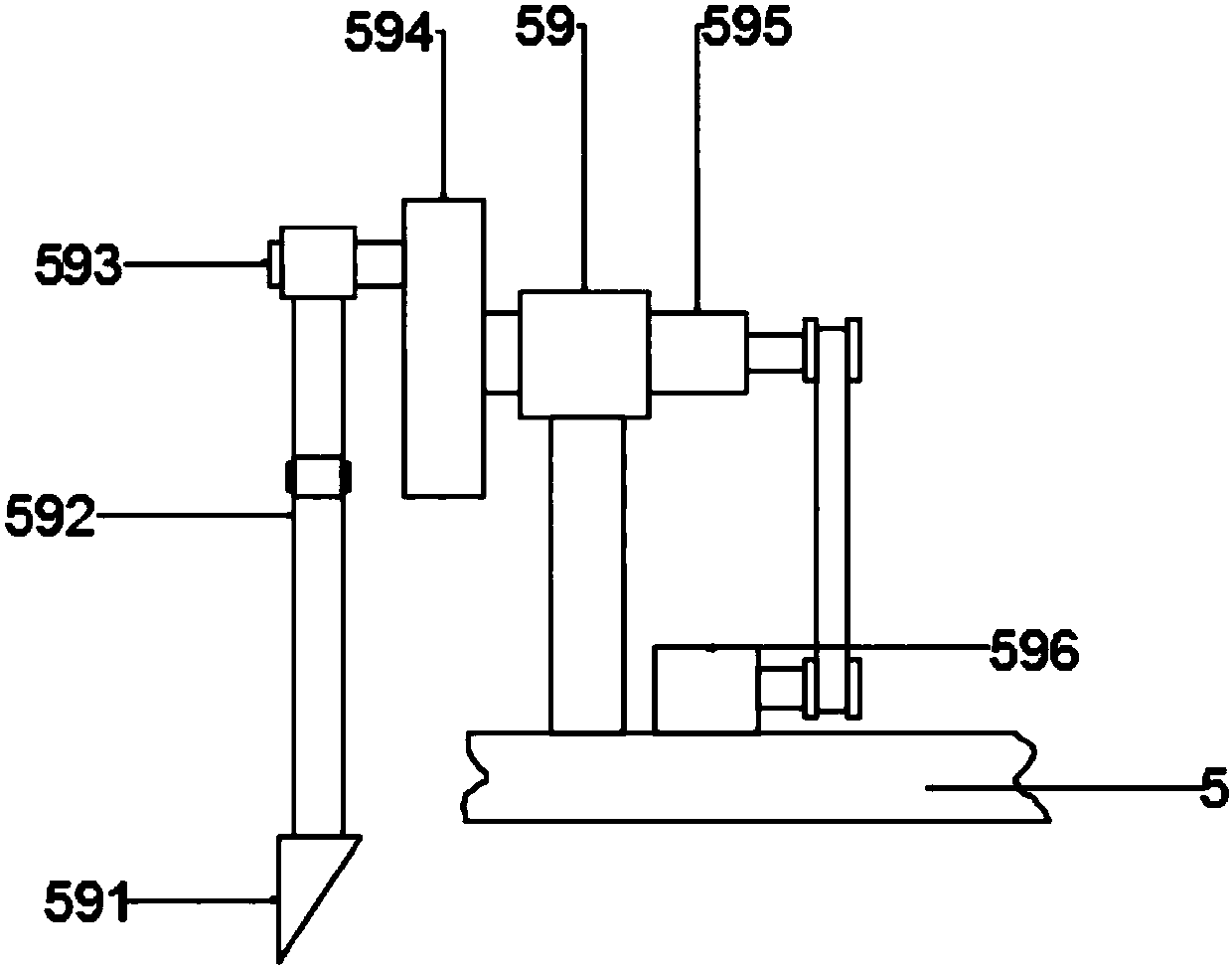

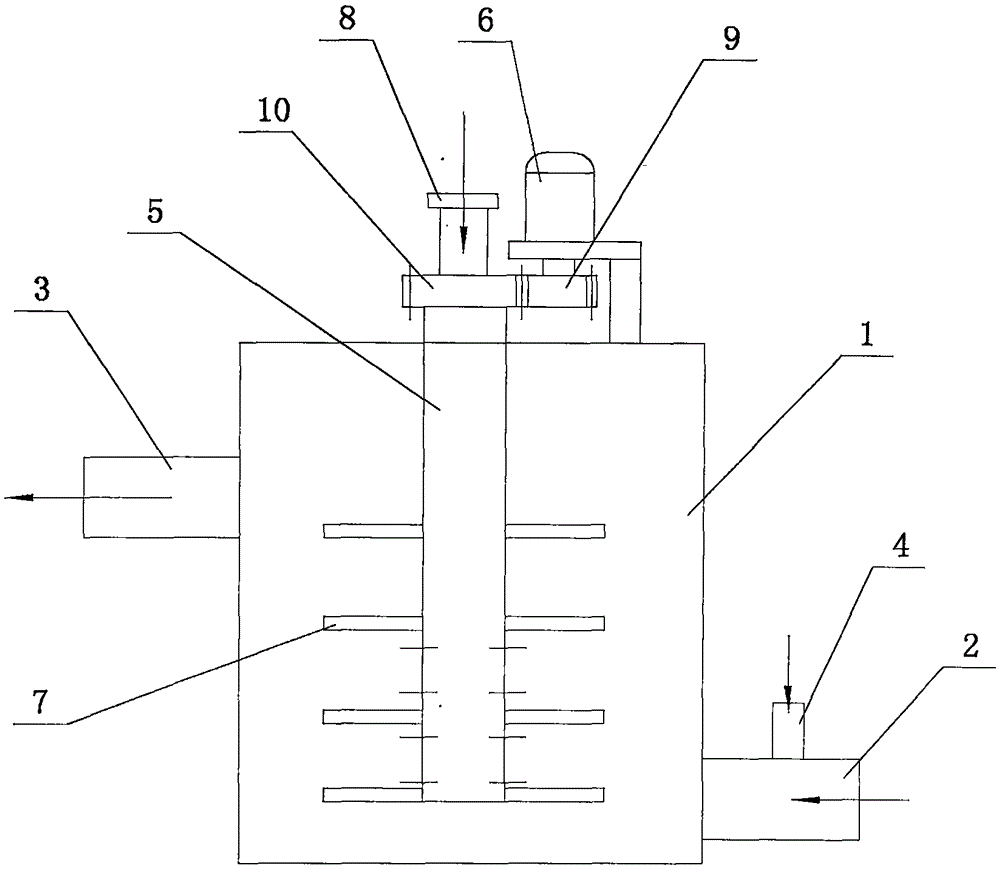

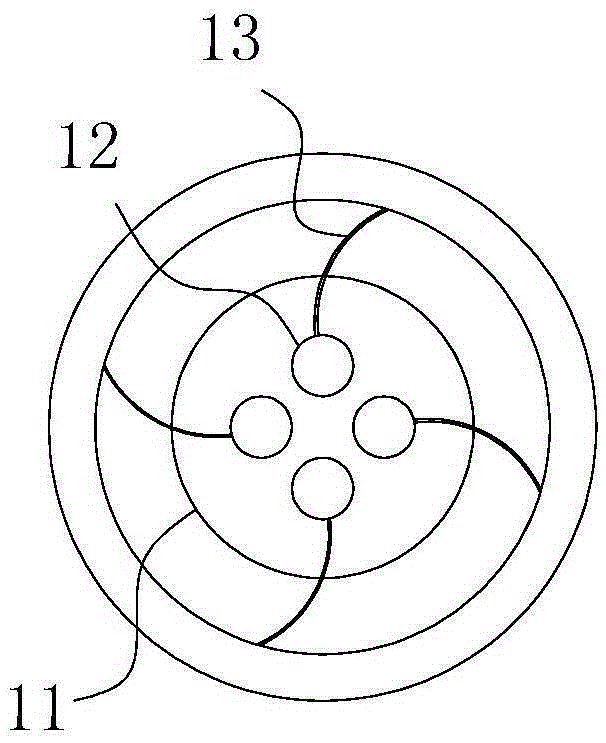

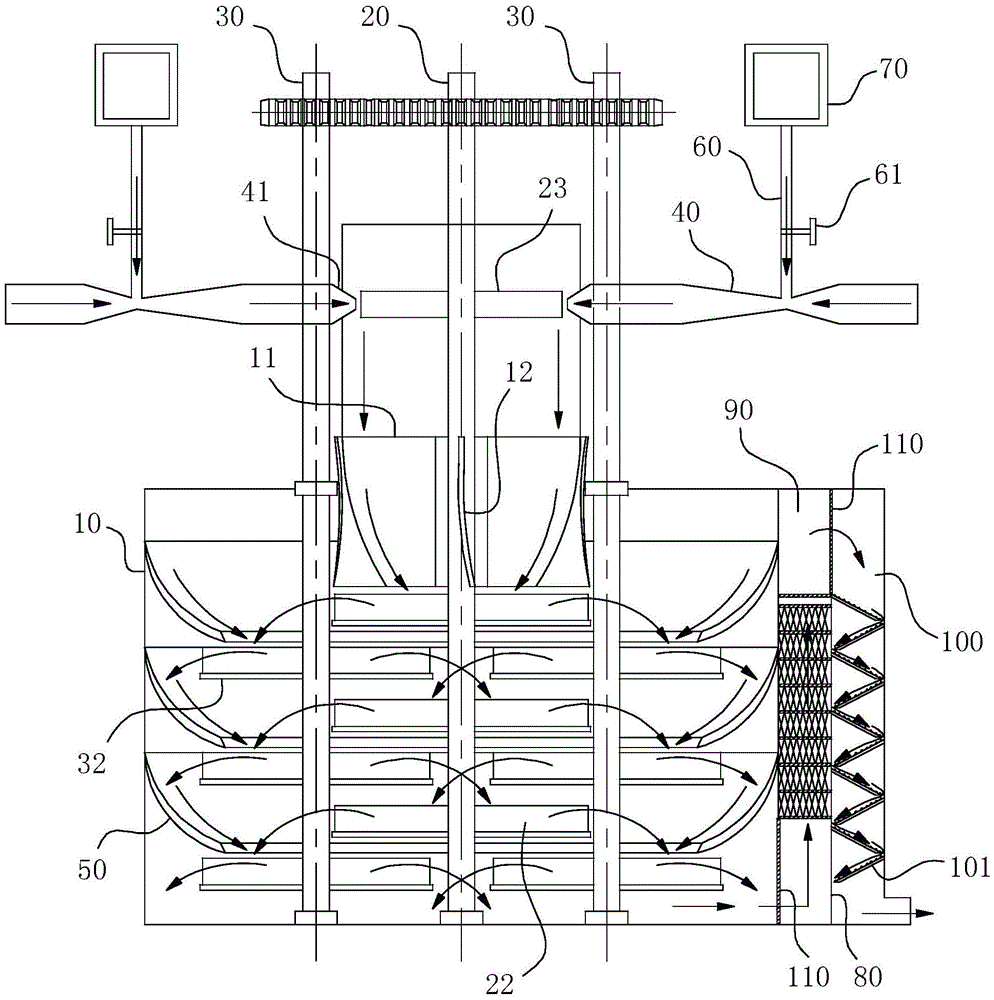

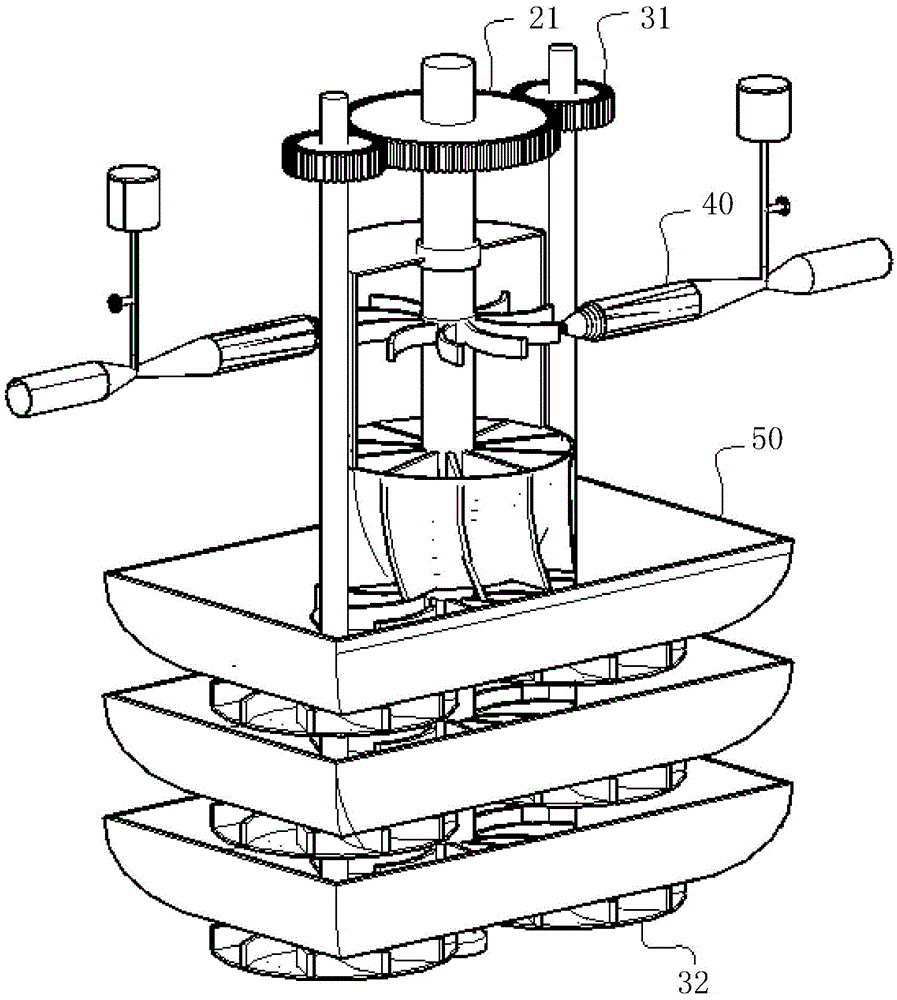

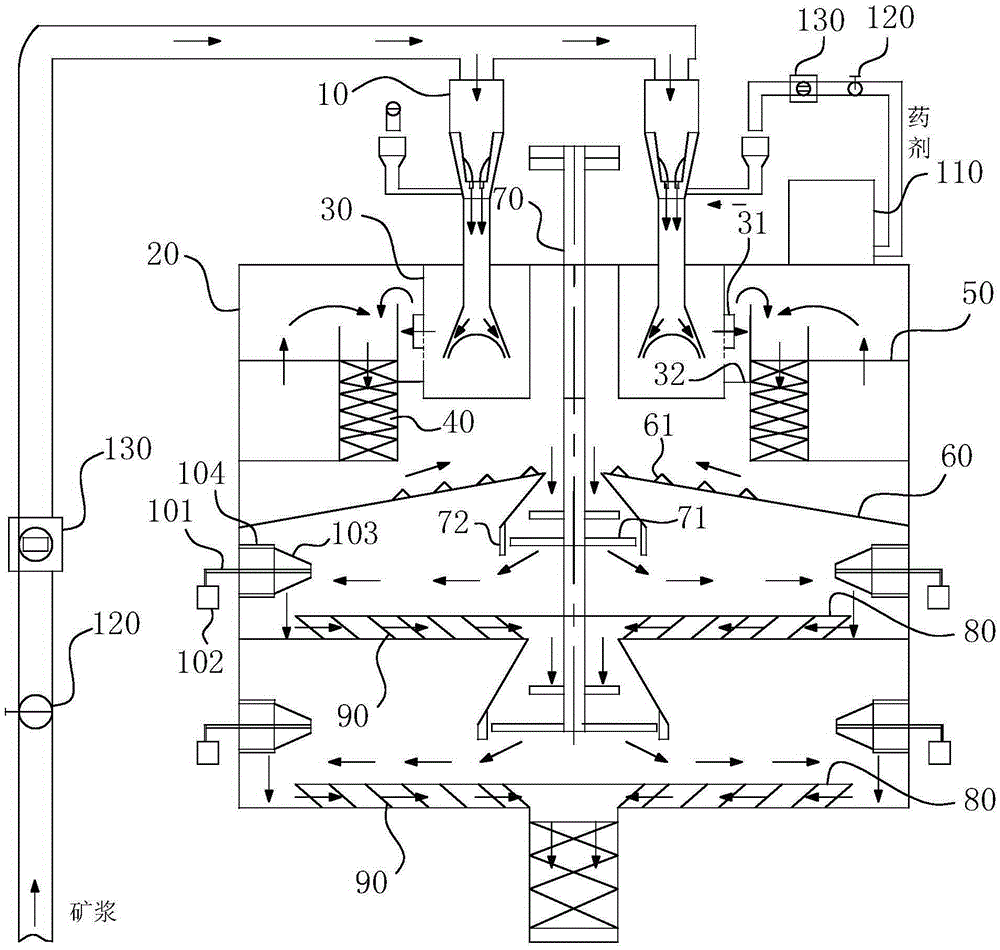

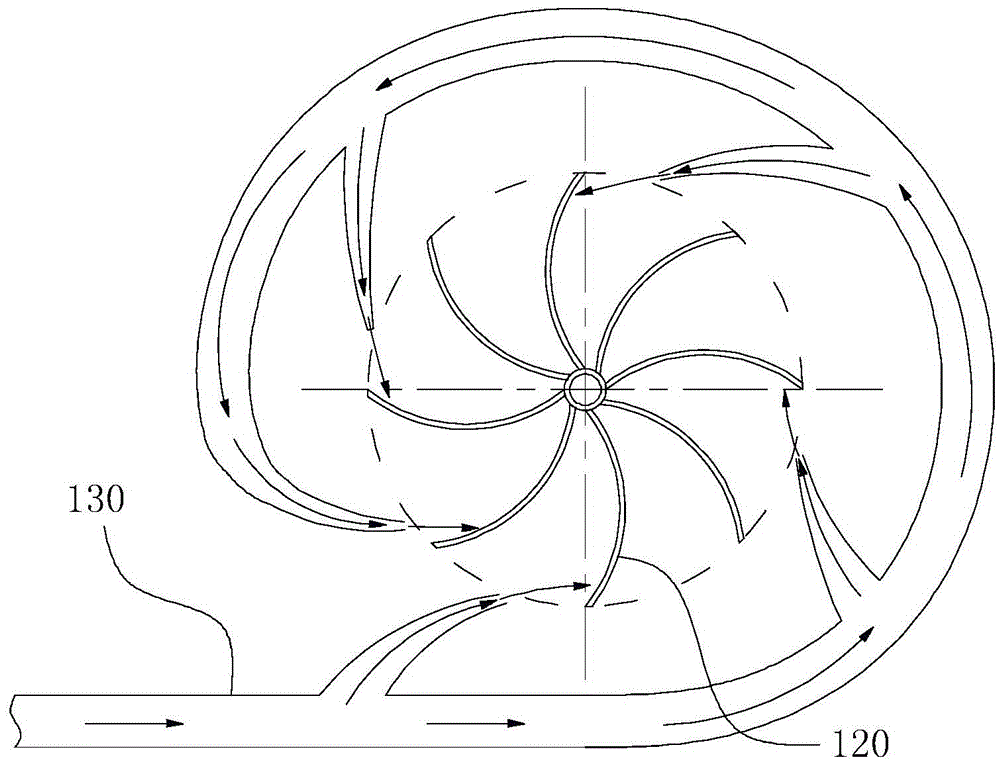

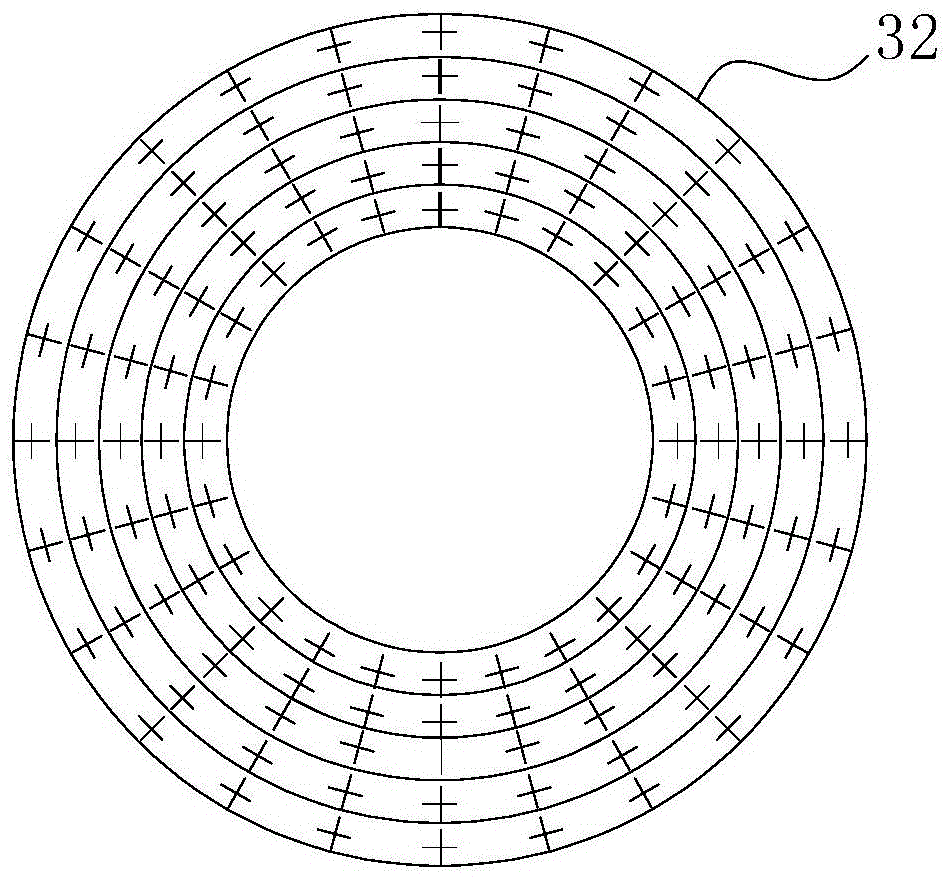

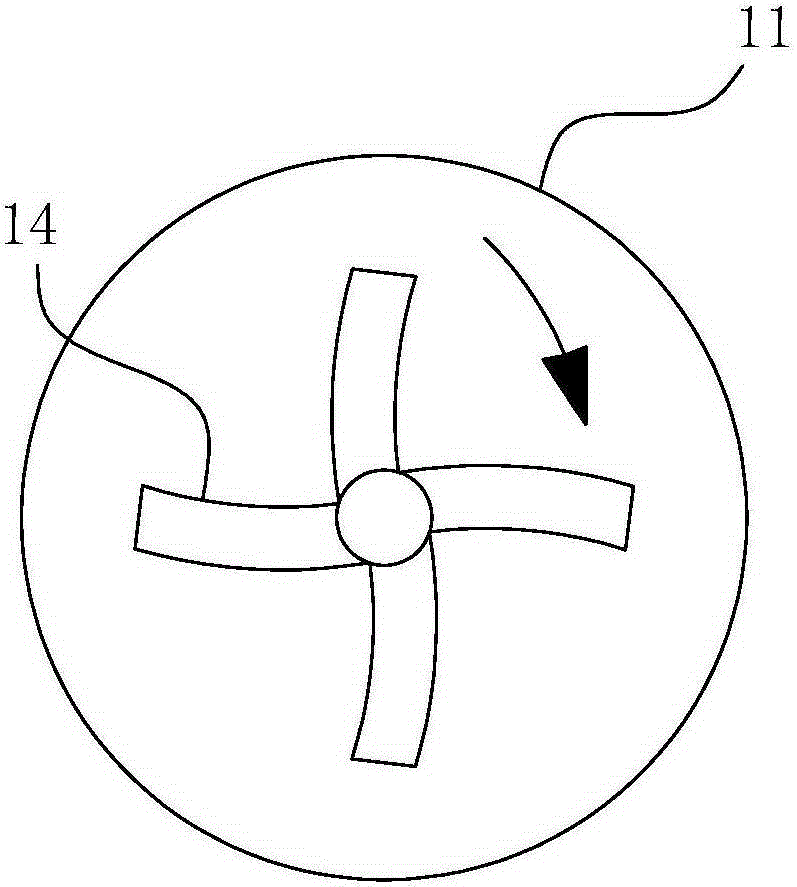

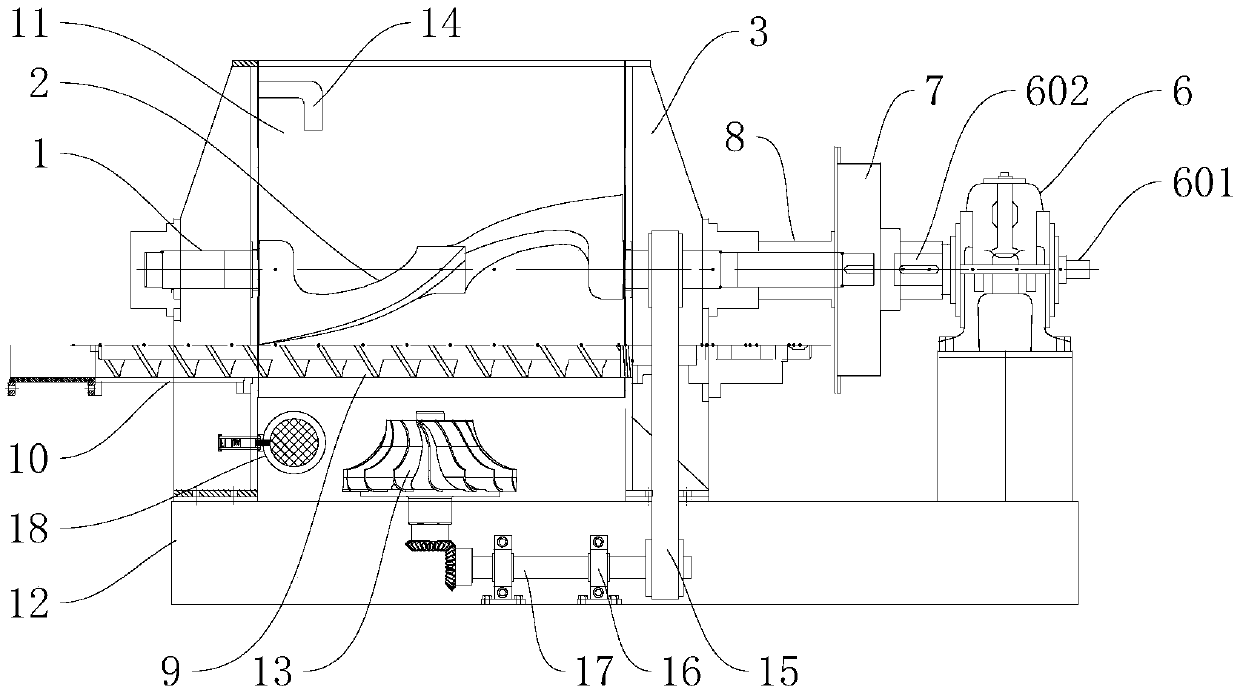

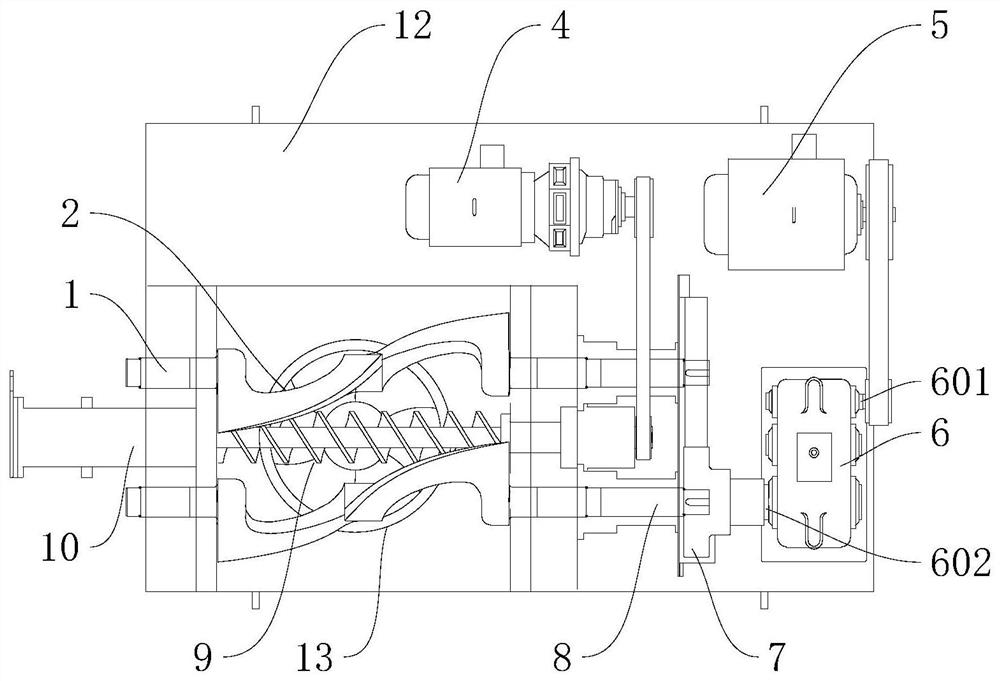

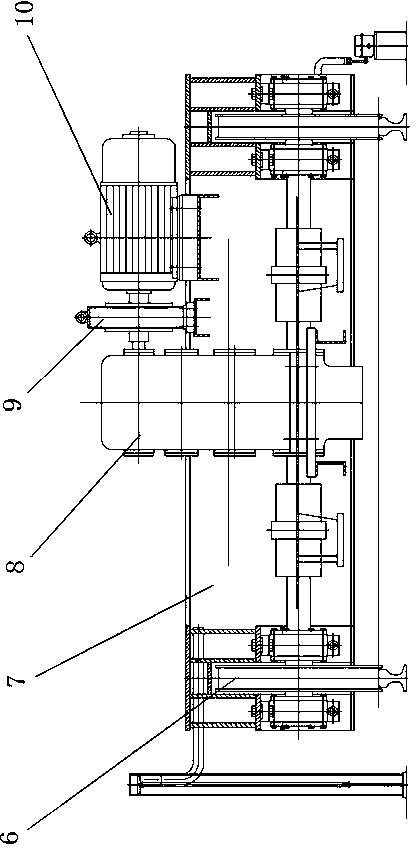

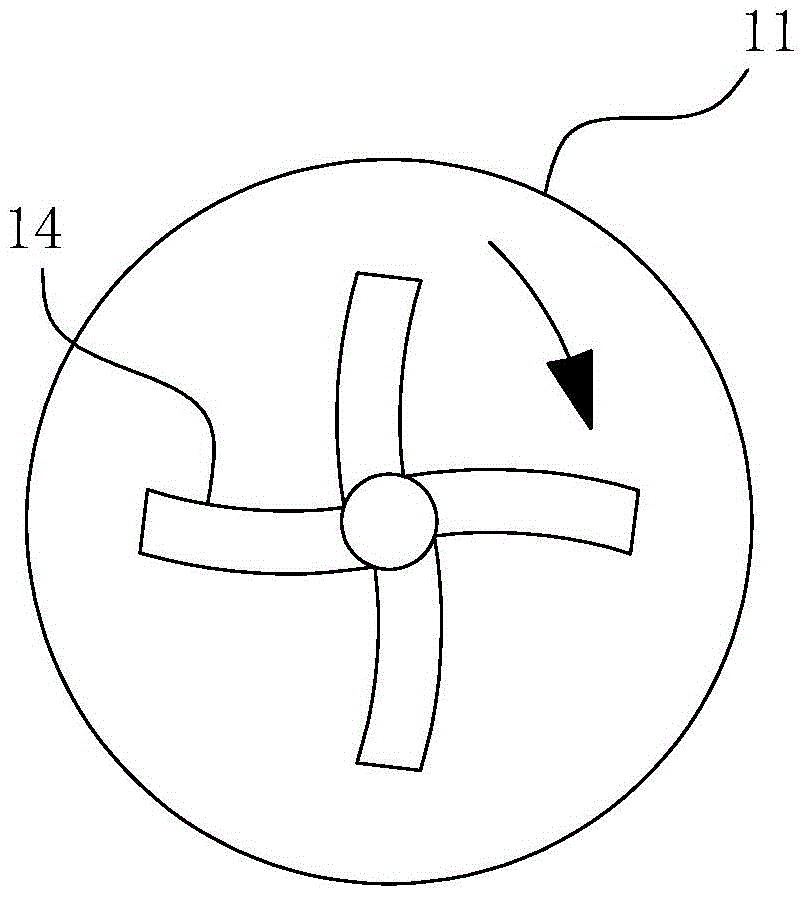

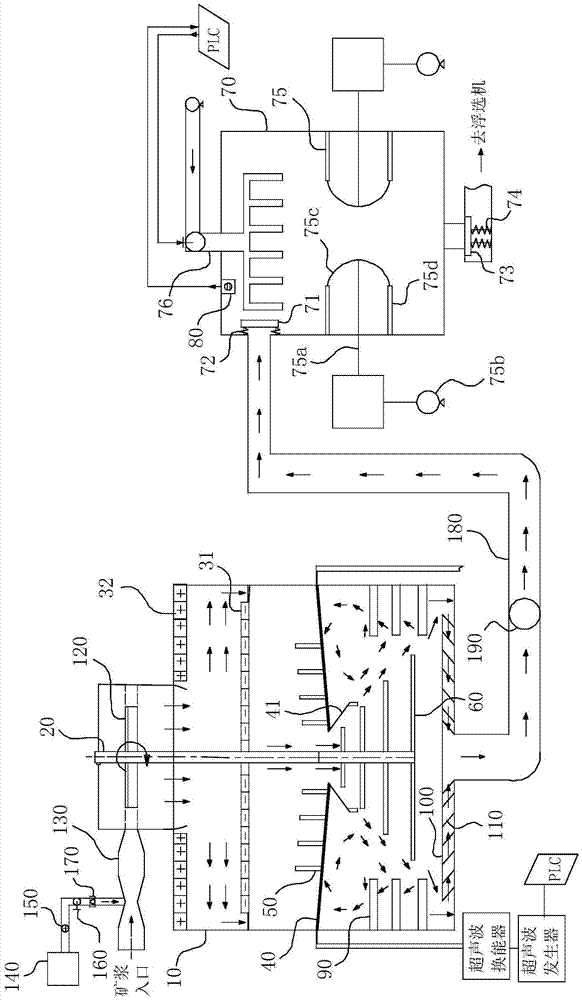

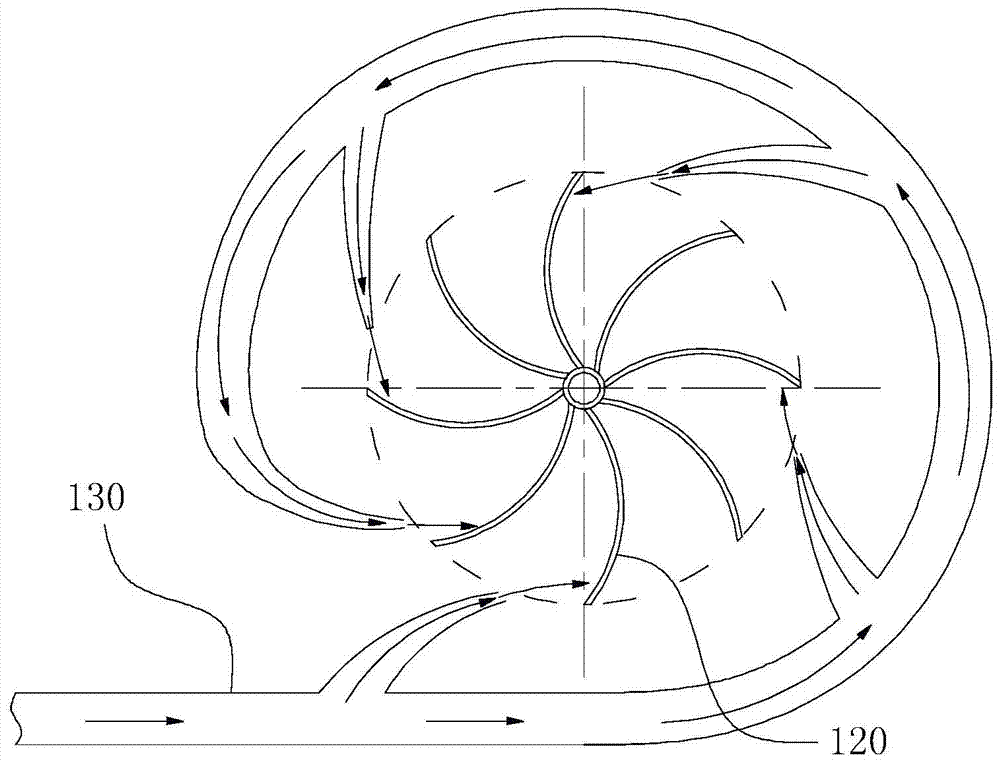

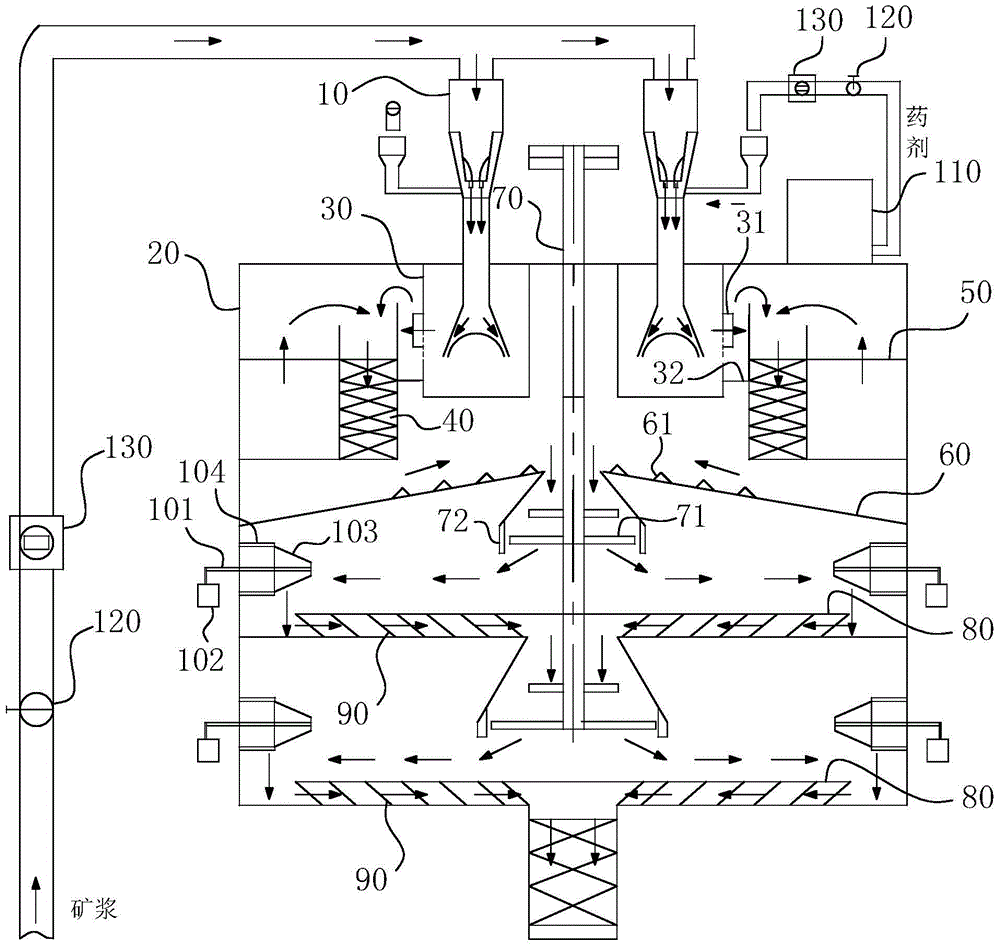

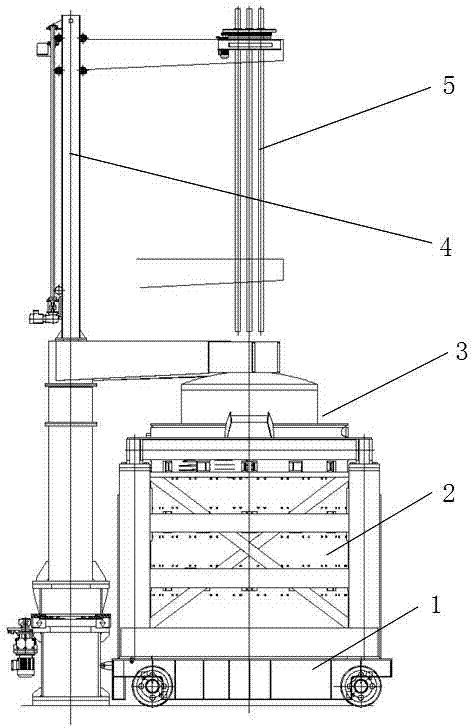

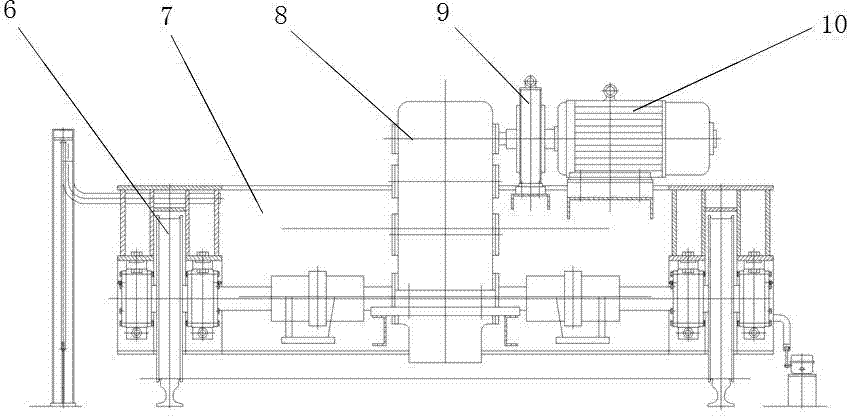

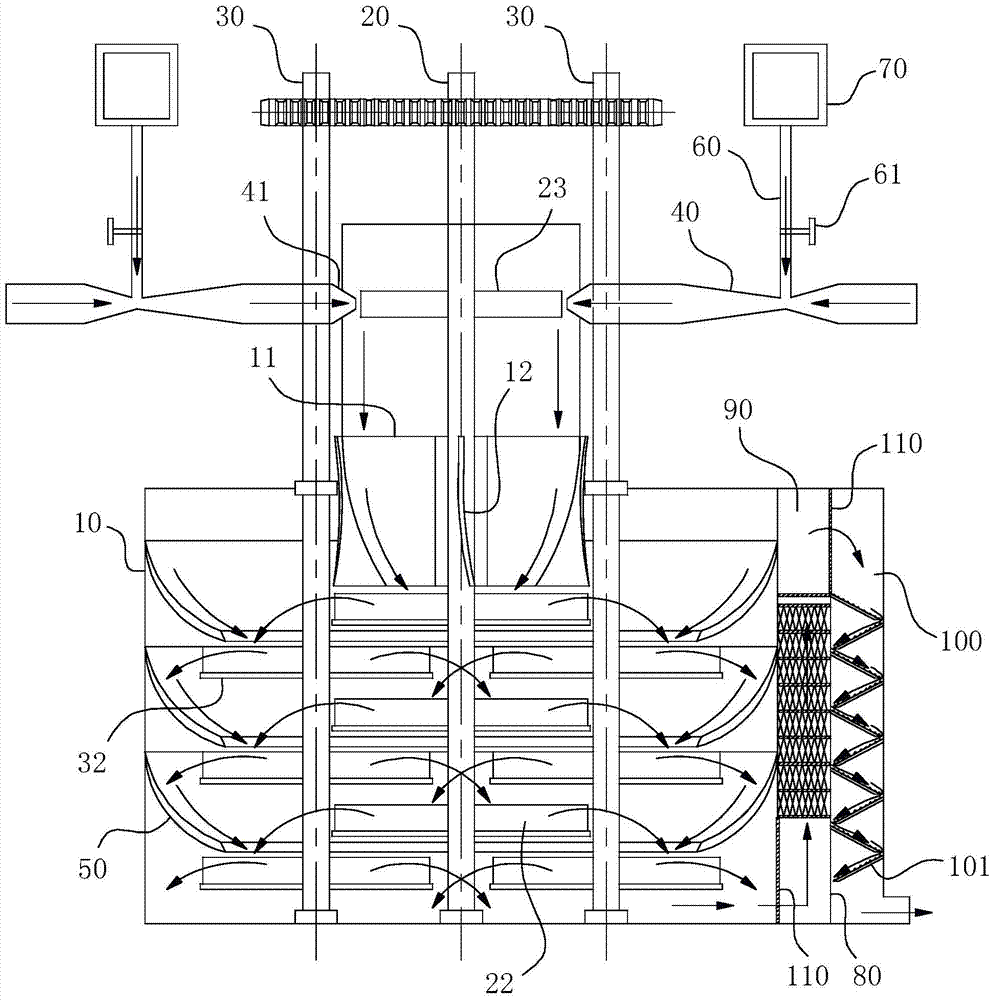

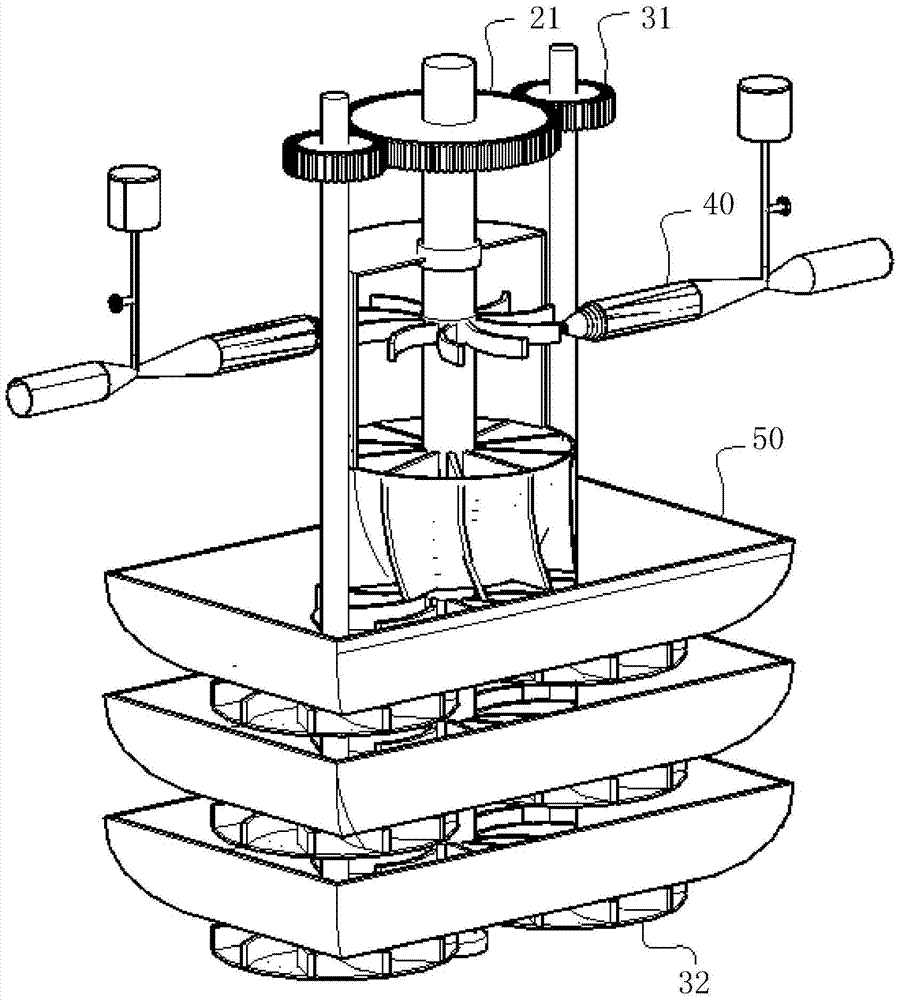

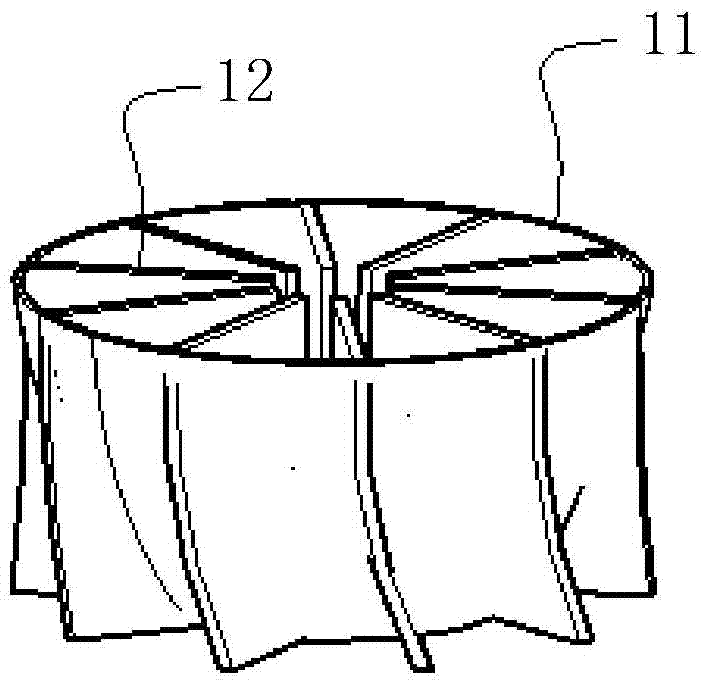

Multi-impeller mixed flow field ore pulp preprocessor based on ore pulp pipeline pressure drive

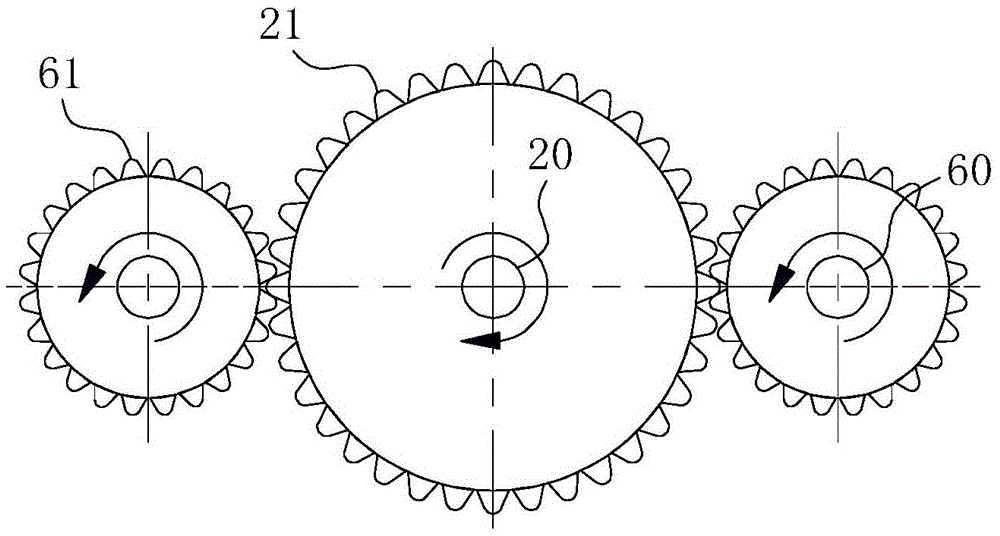

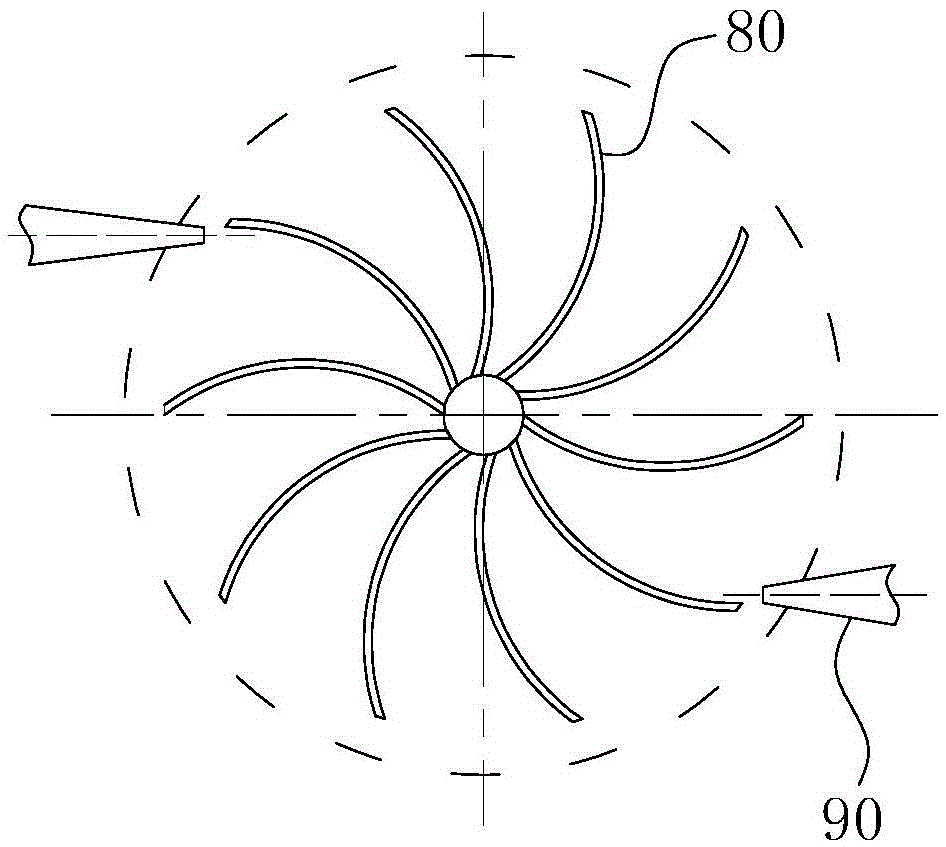

ActiveCN105536610AReduce consumption costImprove the mixing effectRotary stirring mixersTransportation and packagingImpellerMixed flow

The invention relates to the field of coal slurry pretreatment, in particular to a multi-impeller mixed flow field ore pulp preprocessor based on ore pulp pipeline pressure drive. The multi-impeller mixed flow field ore pulp preprocessor comprises a mixing box, a driving rotary shaft and a driven rotary shaft. A driving gear is coaxially arranged on the driving rotary shaft, and a driven gear is arranged on the driven rotary shaft to form the meshing relation. A driving turbine is further coaxially arranged on the driving rotary shaft. A group of stirring impellers is fixed to the driving rotary shaft, and a group of stirring wheels is fixed to the driven rotary shaft respectively in a coaxial and mutual equal-height mode. In the vertical direction, the stirring impellers and projections of the stirring impellers produce intersections. A guide sleeve is arranged under the driving turbine. Guide blades are arranged inside the guide sleeve in a circinate mode, and the rotating direction of the mixed liquid guided by the guide blades is mutually identical to the rotating direction of the stirring impellers under the guide blades. The multi-impeller mixed flow field ore pulp preprocessor can play a very good hardening and tempering effect on floated coal slime, is especially suitable for slurry-mixing and quality-improving demands of fine coal difficult to float and is high in working efficiency, and the preprocessing process is quick and convenient.

Owner:ANHUI UNIV OF SCI & TECH

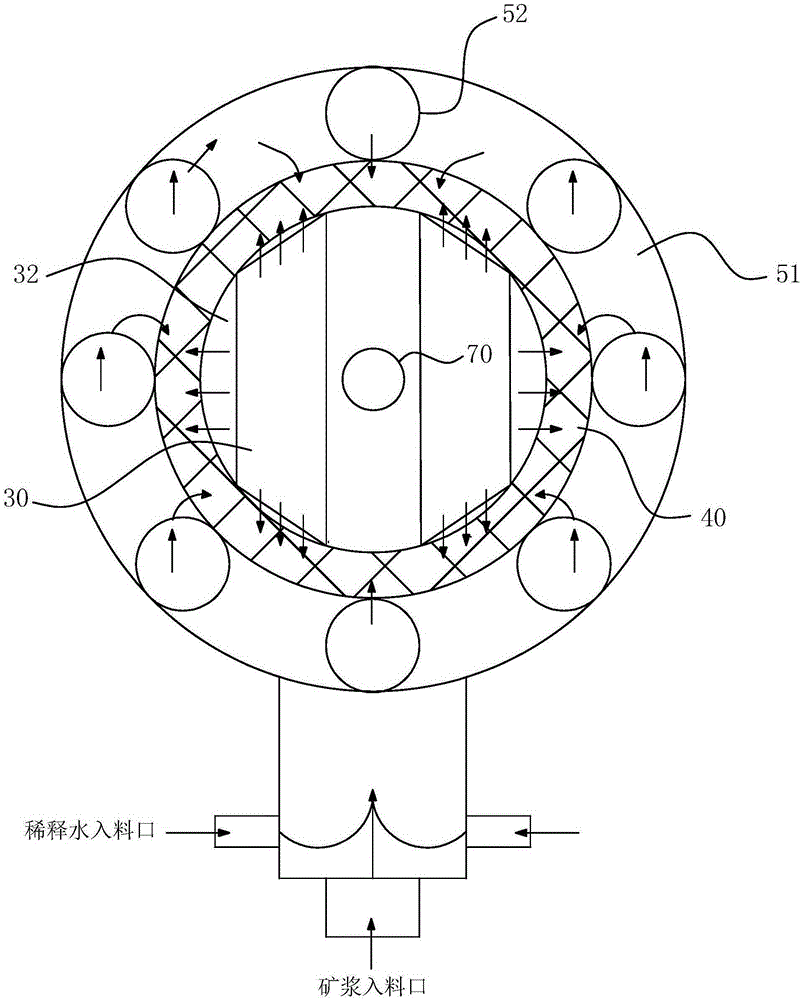

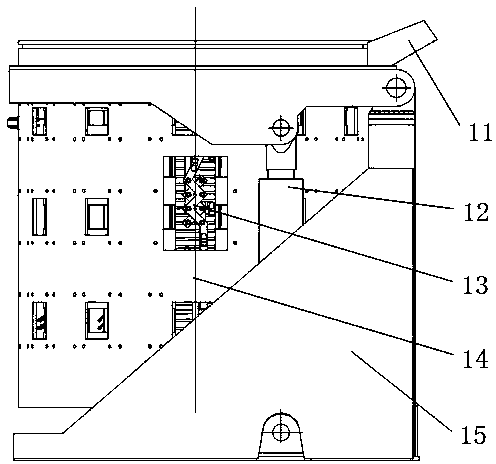

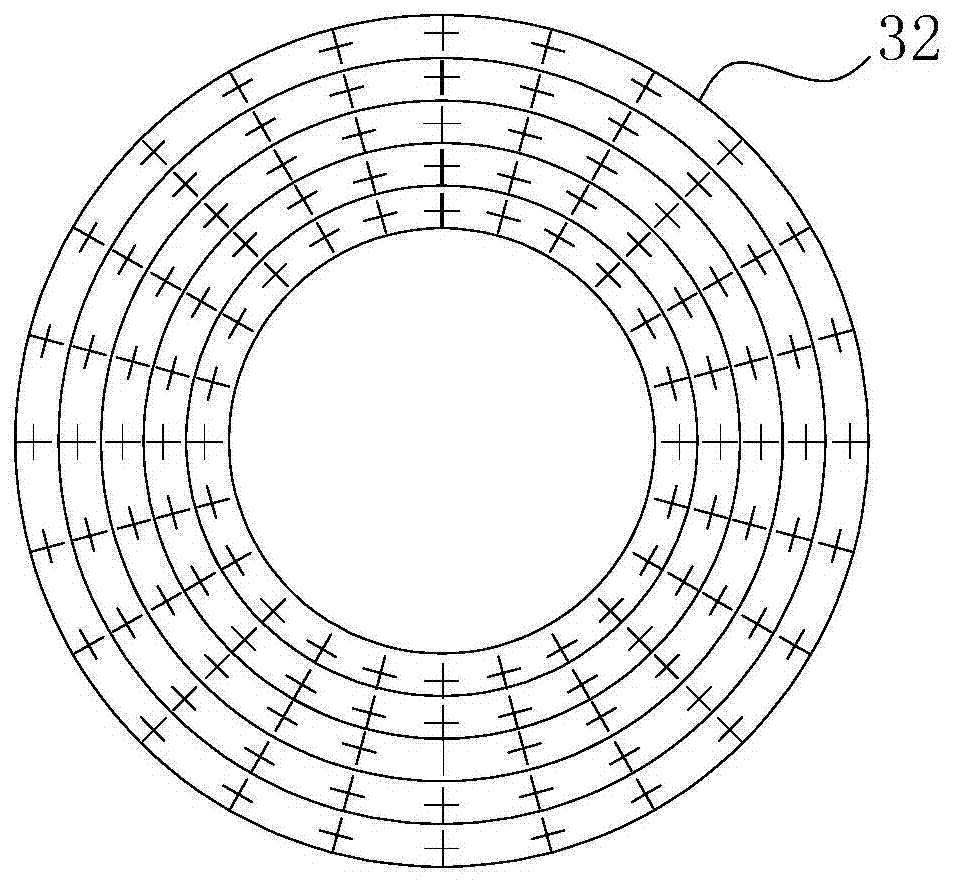

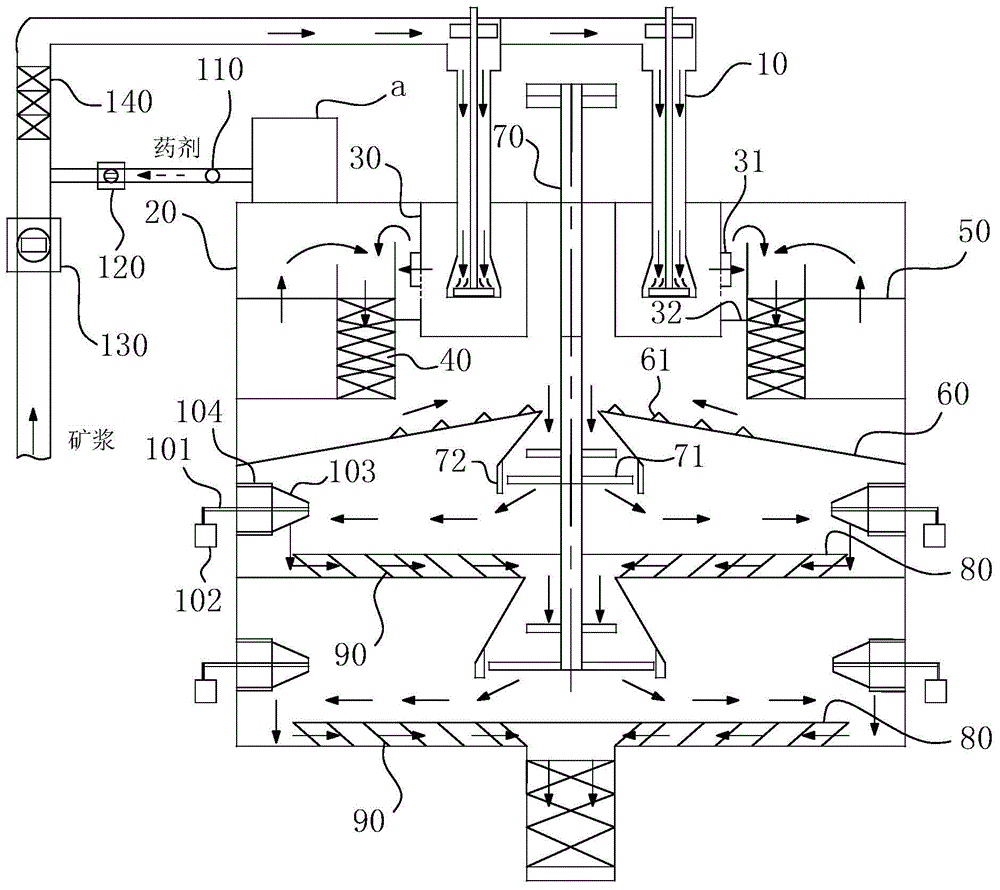

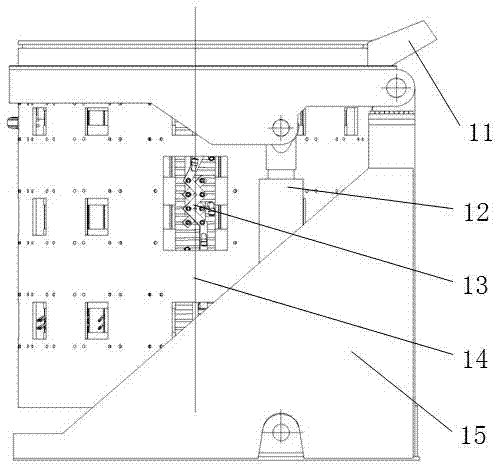

Equipment of deeply slurry mixing and modifying for coal slime

ActiveCN105289389AIncrease flow rateEfficient and deep pulping and modifying functionRotary stirring mixersMixer accessoriesImpellerEngineering

The invention relates to the field of coal slurry pretreatment, in particular to equipment of deeply slurry mixing and modifying of coal slime for slurry mixing and modifying of high-ash fine coal slime difficult to float. The equipment comprises a mixing box; agentia dispersion tanks are arranged at the top of a chamber of the mixing box, and an annular dispersion unit and an annular ore pulp feed chutes are arranged at the outside of the agentia dispersion tanks in sequence; a fallplate with a dip angle is arranged below a discharge port of the annular dispersion unit; vane wheels are arranged below the fallplate with the dip angle, and stator walls encircle the vane wheels; a liquid outlet of the mixing box is formed in bottom end surface of the mixing box; double row side-by-side nozzles with dispersed jet flows for providing agentia mixed liquor to the agentia dispersion tanks are arranged at the top end surface of the mixing box; two agentia dispersion tanks are arranged in parallel along the tank direction; diffusers of each nozzle with the dispersed jet flow extents into chambers of corresponding agentia dispersion tank. The equipment can play a very good role in modifying of floated coal slime and is particularly suitable for the demand of slurry mixing and modifying of fine coal difficult to float, the work efficiency of the equipment is high and a treatment process is rapid and convenient.

Owner:ANHUI UNIV OF SCI & TECH

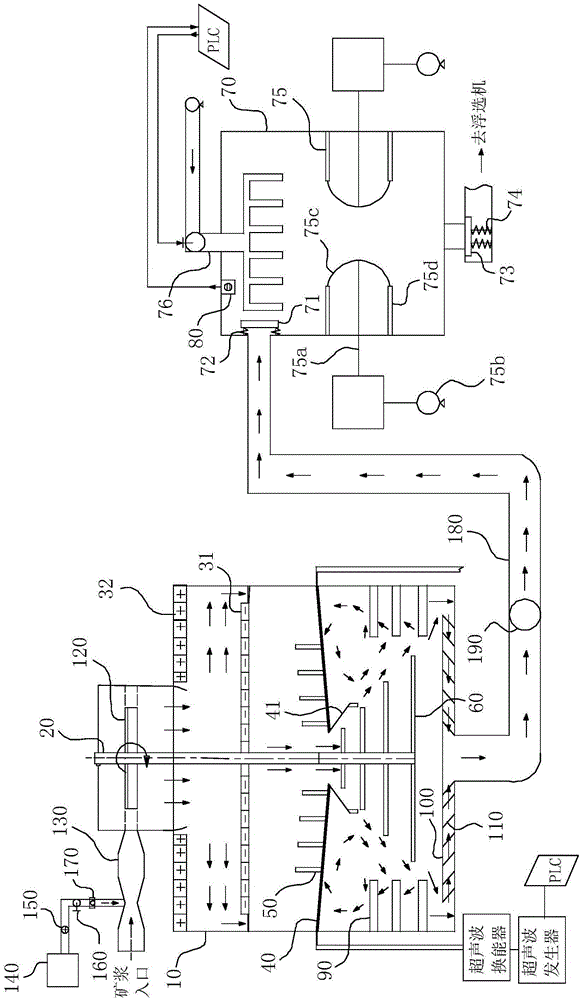

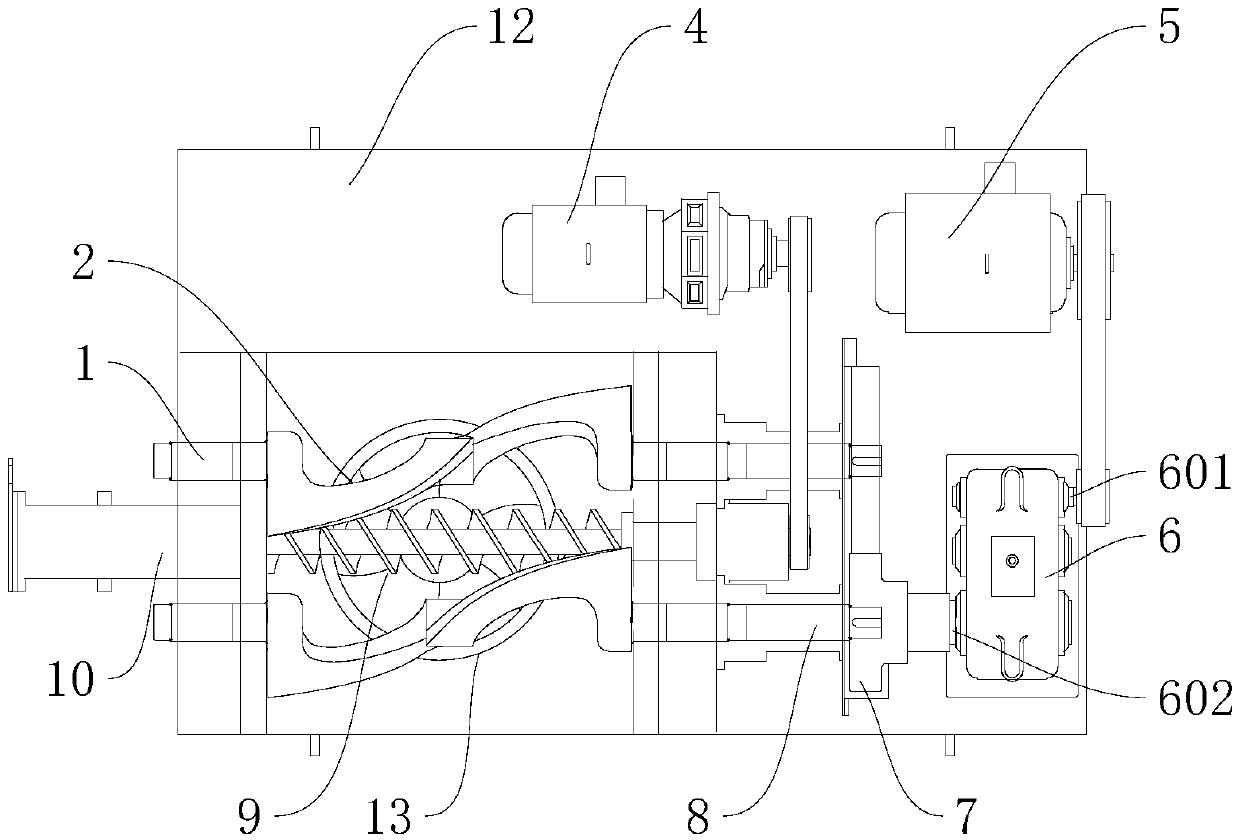

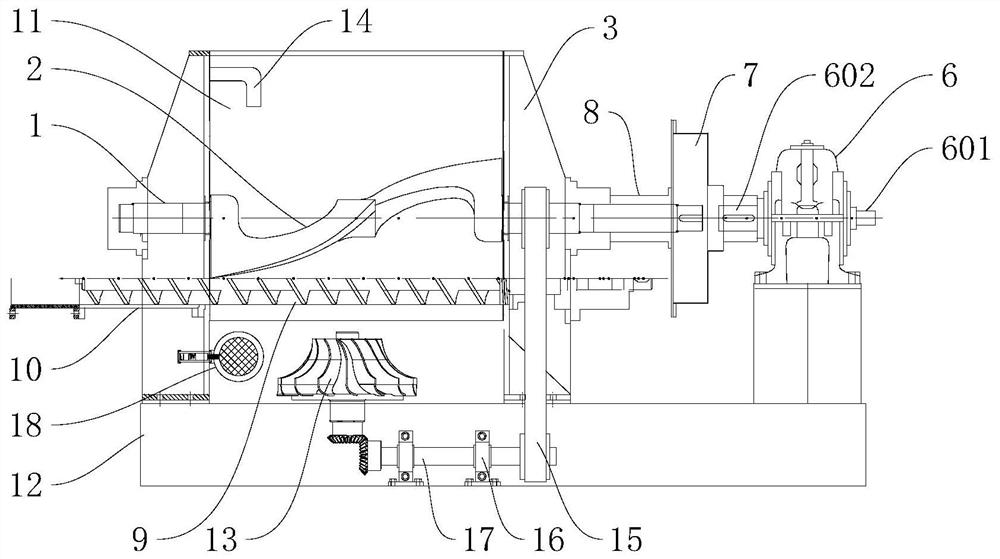

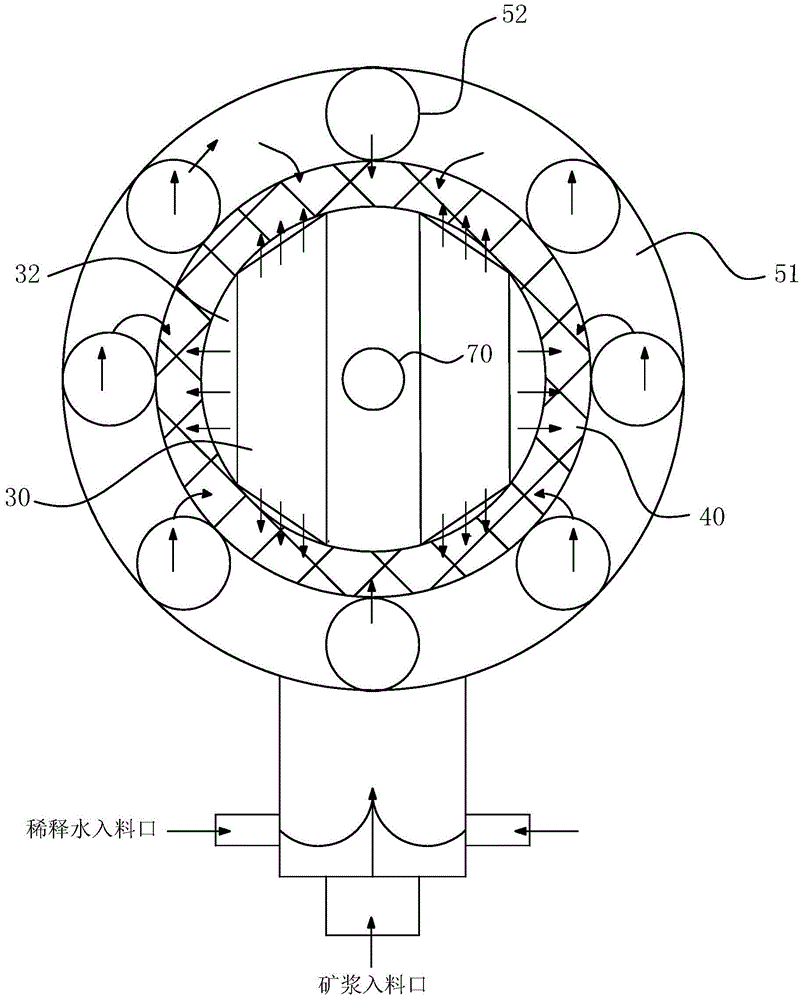

Combined slurry mixing equipment for fine coal difficult to float

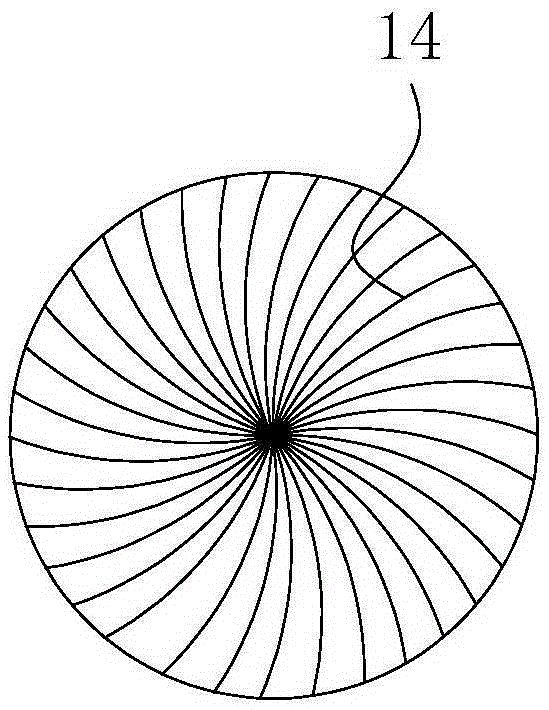

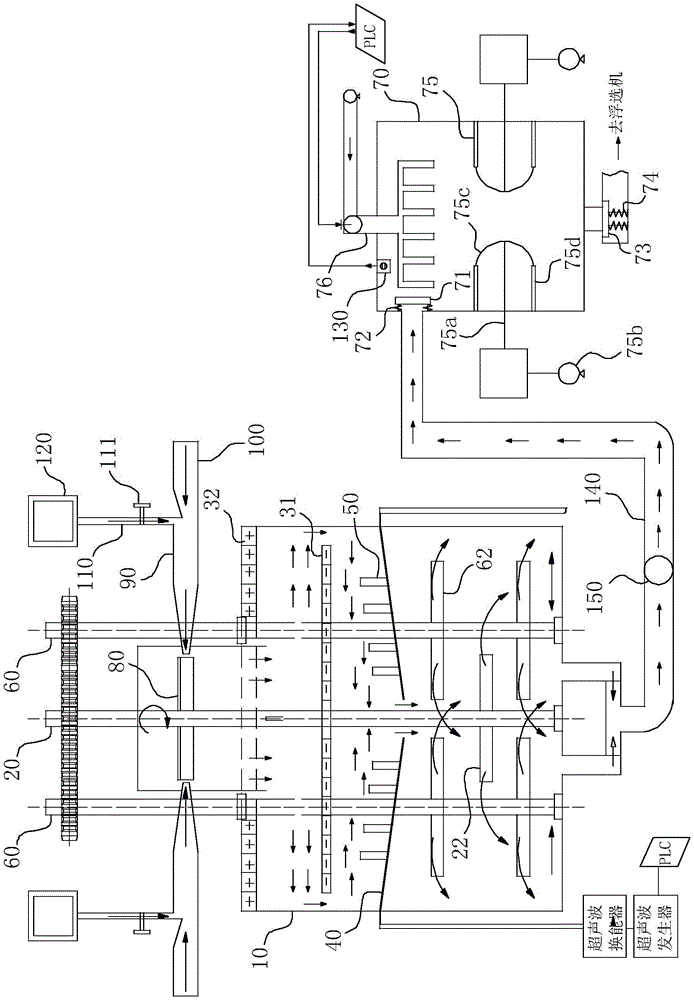

ActiveCN105521727ARealize deep slurry modificationExcellent tempering performanceRotary stirring mixersTransportation and packagingImpellerEngineering

The invention relates to the field of pretreatment of coal slurry, in particular to combined slurry mixing equipment for fine coal difficult to float. The equipment comprises a mixing box and a main rotary shaft, wherein an electric field activation layer, an ultrasonic oscillation layer and a turbulent mixing and stirring layer are sequentially arranged in an inner cavity of the mixing box from top to bottom; at least one pair of driven rotary shafts is symmetric to the axis of the main rotary shaft; a driven gear is coaxially arranged at the shaft end of the top of each driven rotary shaft; stirring wheels are arranged at shaft ends of the driven rotary shafts, and a stirring impeller is arranged at the shaft end of the main rotary shaft. The equipment further comprises a pressurizing air-dissolving box, an air inlet pipe is arranged in a box body of the pressurizing air-dissolving box, and a feeding partition board is arranged at the inlet end of the box body and seals the inlet end through an extension spring; a discharge partition board is arranged at an outlet end of the box body and seals the outlet end through a compression spring. The equipment can perform a very good tempering function on floated coal slime and especially meets the slurry mixing and quality improving requirement of fine coal difficult to float, the work efficiency is high, and the pre-treatment process is quick and convenient.

Owner:ANHUI UNIV OF SCI & TECH

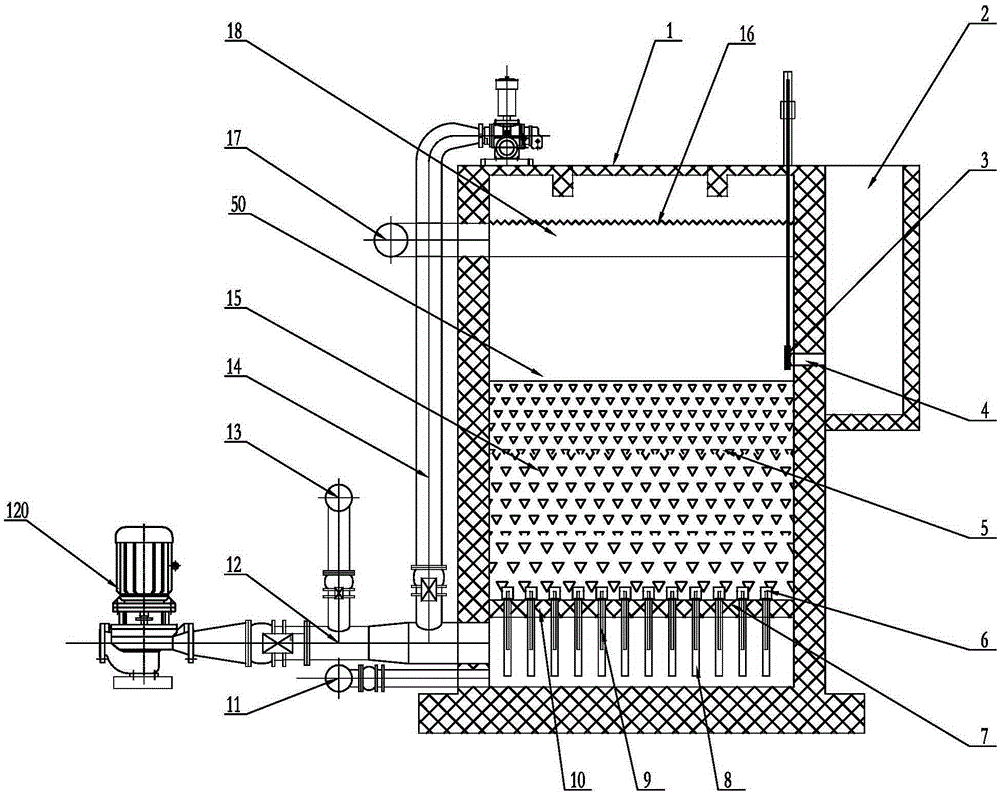

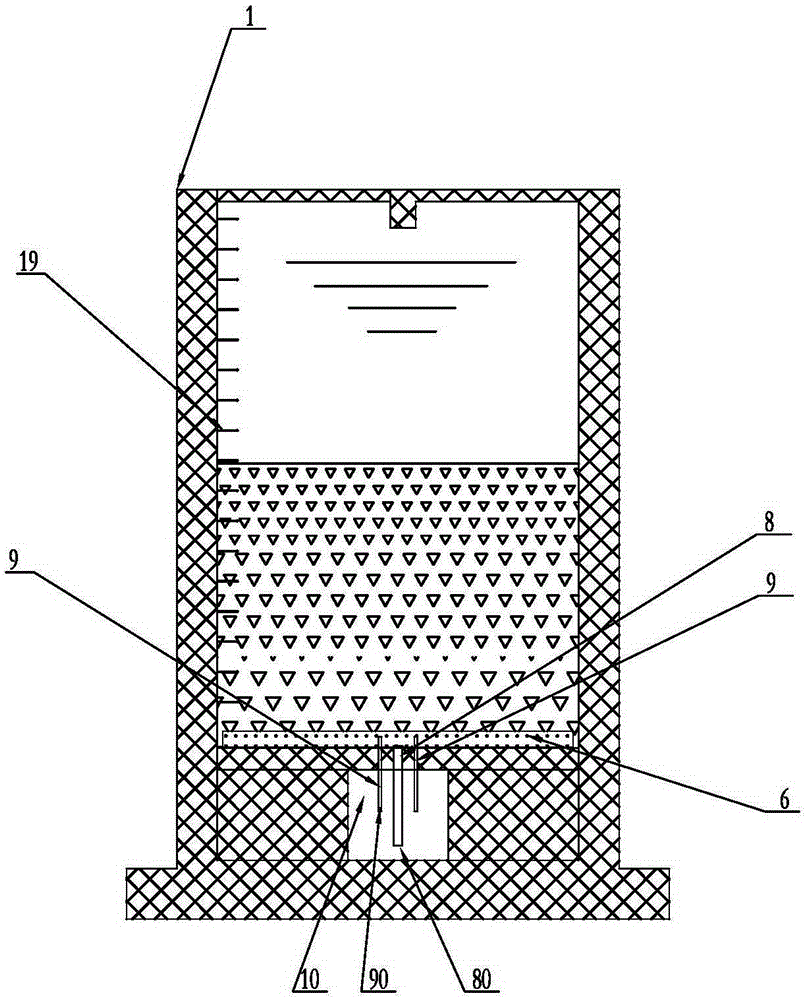

Shell padding hardening and tempering pond used for mineralization after seawater desalination

InactiveCN105293671AImprove reaction efficiencyImprove the tempering effectWater/sewage treatment by substance additionSocial benefitsInlet channel

The invention provides a shell padding hardening and tempering pond used for mineralization after seawater desalination. The pond comprises a shell padding hardening and tempering pond body, a flushing water outlet area, a shell padding hardening and tempering pond water outlet area, a water and gas inflow channel and a shell flushing water and gas inflow system. A water outlet of the shell padding hardening and tempering pond water outlet area is formed in the side, opposite to the flushing water outlet area, of the shell padding hardening and tempering pond body. A natural fragmentation shell padding bed is arranged in a shell padding hardening and tempering pond reaction area and arranged on a hardening and tempering pond bottom plate. A plurality of transverse water and gas distribution pipes are evenly arranged on the hardening and tempering pond bottom plate and are connected with vertical water distribution pipes and vertical gas distribution pipes to be communicated with a shell padding hardening and tempering pond water and gas inlet channel. According to the hardening and tempering pond, pollution-free natural fragmentation shells serve as padding, the hardening and tempering pond is obvious in economic performance, and hygienic safety is better than that of calcium ore. Shell waste is subjected to resource utilization, and the hardening and tempering pond has the economic benefits and social benefits of energy conservation and emission reduction.

Owner:POWERCHINA HUADONG ENG COPORATION LTD

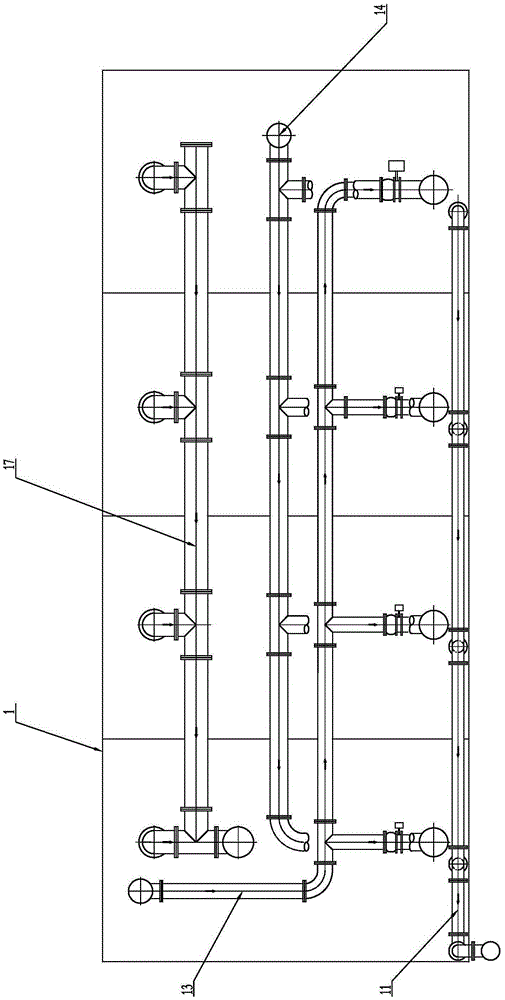

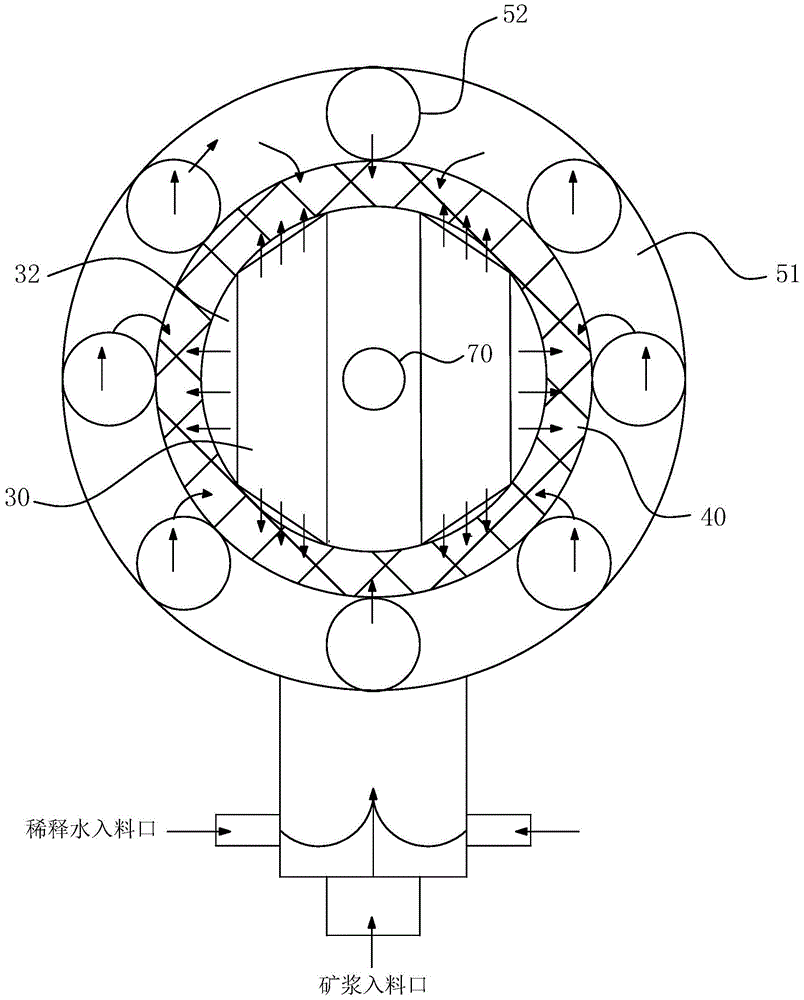

Integrated slurry mixing equipment for difficult-to-float fine coal

ActiveCN105521738ARealize deep slurry modificationExcellent tempering performanceTransportation and packagingMixersDrive shaftHigh pressure

The invention relates to the field of coal slurry pretreatment, in particular to integrated slurry mixing equipment for difficult-to-float fine coal. The equipment comprises a mixing box, wherein a drive shaft is vertically arranged in an inner cavity of the mixing box, and an electric field activation layer, an ultrasonic wave shocking layer and a forced stirring layer are sequentially arranged in the inner cavity of the mixing box from top to bottom in the length direction of the drive shaft. The equipment further comprises a pressurized gas dissolving box, an air inlet pipe used for introducing high-pressure air is arranged in a box body of the pressurized gas dissolving box, and a feeding partition board used for realizing opening and closing of an inlet end is arranged at an inlet end, used for being communicated with a discharge port of the mixing box, of the box body and is fastened through an extension spring and butted against the inlet end to close the inlet end; an outlet end of the box body is connected with a floatation machine, and a discharging partition board used for realizing opening and closing of the position is arranged at the outlet end, is tensioned through a compression spring and closes the outlet end. The equipment has a good conditioning function on floated coal mud, particularly meets the slurry mixing and conditioning demands of the difficult-to-float fine coal, has high working efficiency and rapidly and conveniently performs pretreatment.

Owner:ANHUI UNIV OF SCI & TECH

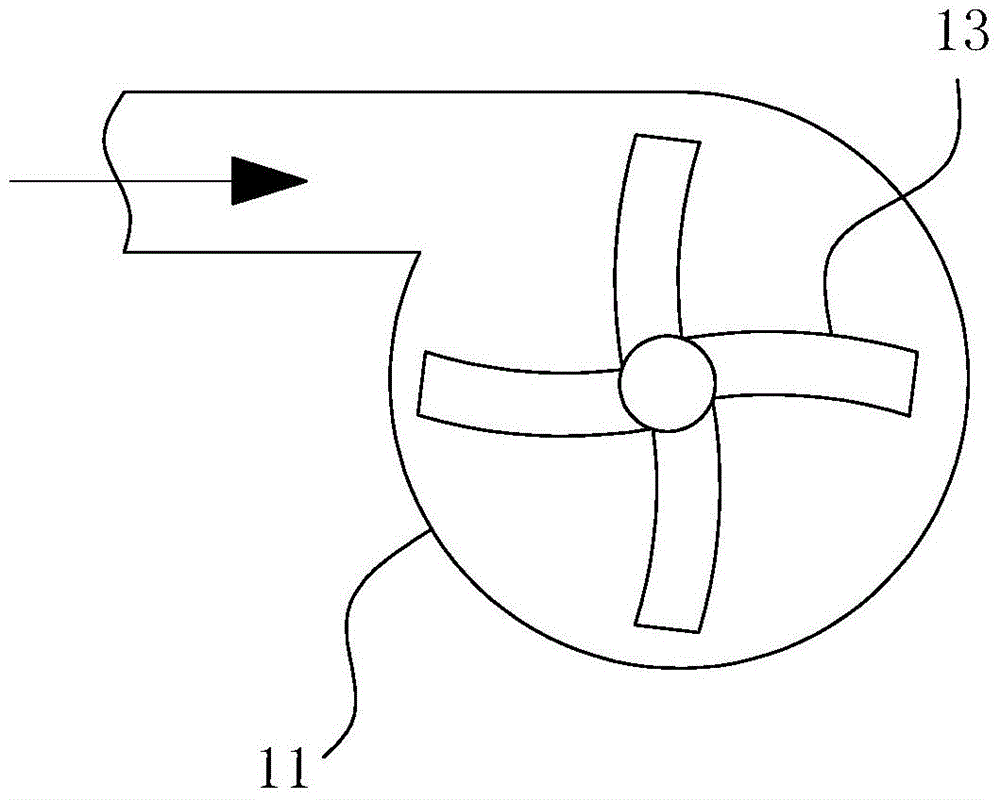

Jet-driven medicament disperse system and pulp mixing modification equipment applying same

ActiveCN105289390AHomogeneous Mix Feed RequirementsImprove impact performanceMixer accessoriesImpellerHybrid system

The invention relates to the field of coal slurry pre-treatment, and in particular relates to a jet-driven medicament disperse system and pulp mixing modification equipment applying the same. The jet-driven medicament disperse system comprises a jet spray nozzle and a liquid flow pipe, wherein the jet spray nozzle comprises an outer pipe body, the outer pipe body is internally and coaxially provided with a rotating shaft in a sleeving manner, and a driving impeller and a driven impeller are coaxially arranged on the rotating shaft; the liquid discharging direction of a pass pipeline, connected with the outer pipe body, of the liquid flow pipe is located in the tangential direction of the driving impeller, and a pipe chamber of the pass pipeline is provided with a pipeline mixer for preliminarily mixing ore pulp and a medicament. The system can effectively realize the uniform mixing feeding requirements of the medicament and the ore pulp in a controllable manner. The pulp mixing modification equipment comprises a mixing box and a graded mixing system, the top of the mixing box is provided with a medicament atomization dispersing system and the bottom is provided with the jet spray nozzle, a liquid outlet of the mixing box is arranged in a way different from the mounting position of the outer pipe body. The equipment is especially suitable for the pulp mixing modification requirement of fine-particle coal difficult to float, the working efficiency of the equipment is high and the pre-treatment process is quick and convenient.

Owner:ANHUI UNIV OF SCI & TECH

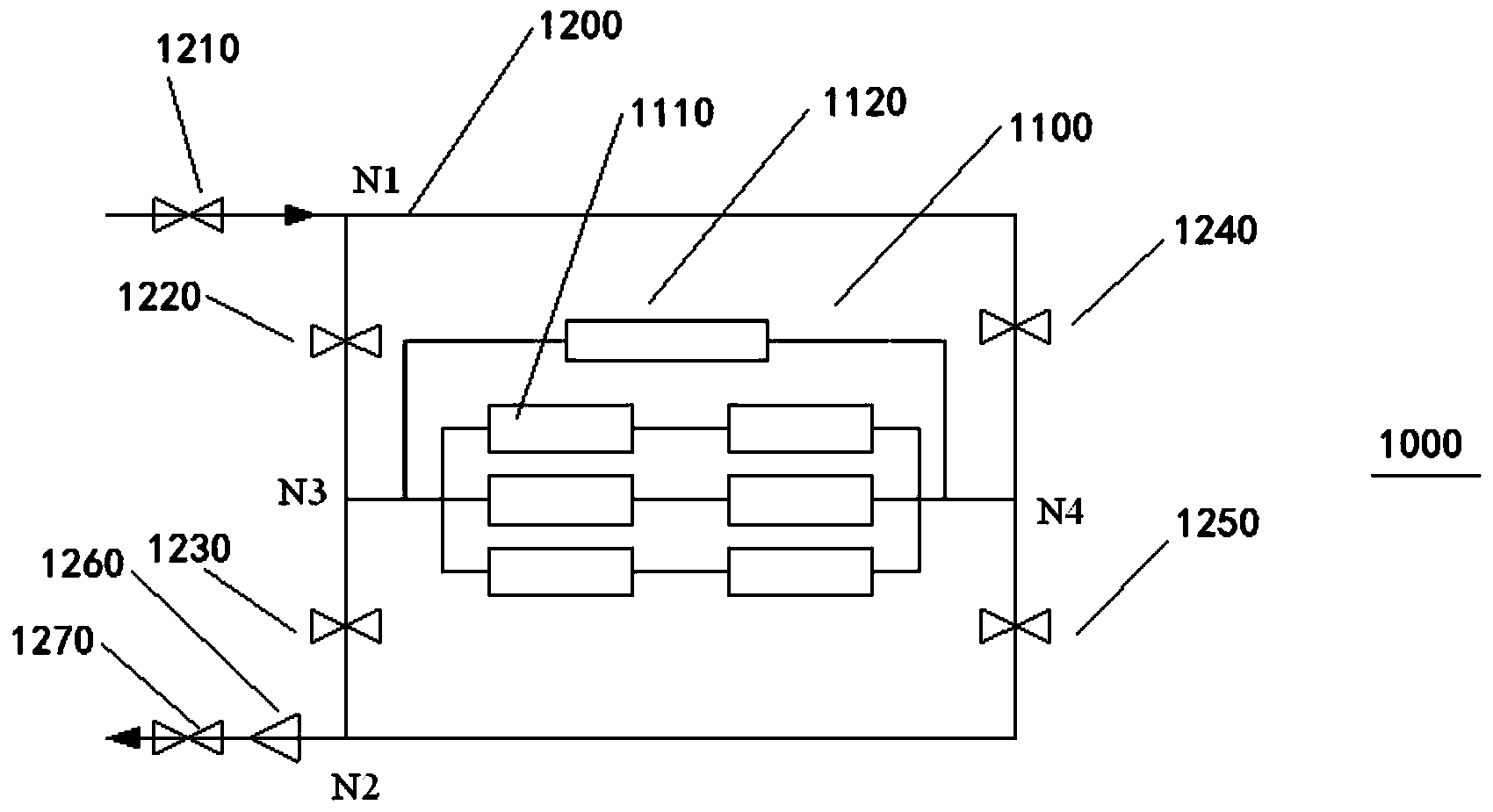

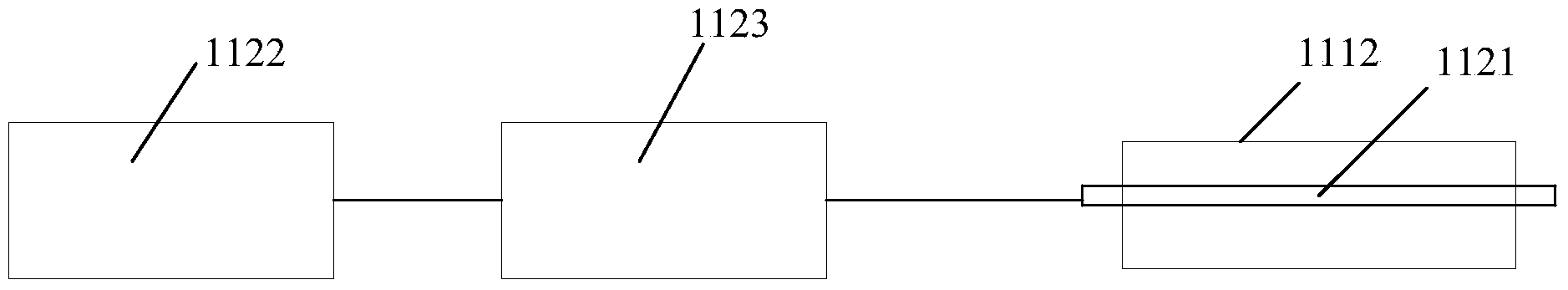

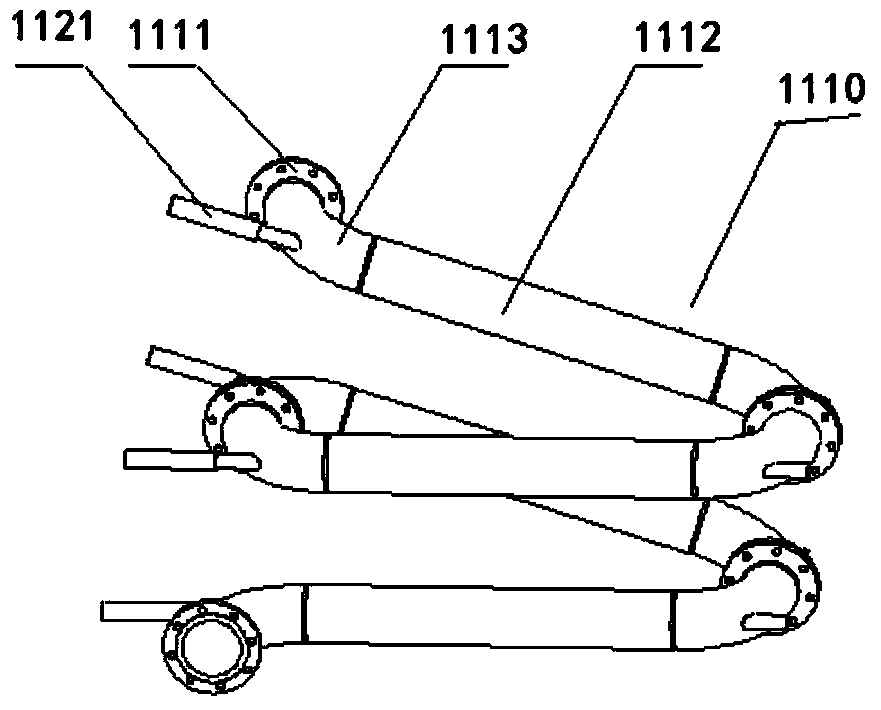

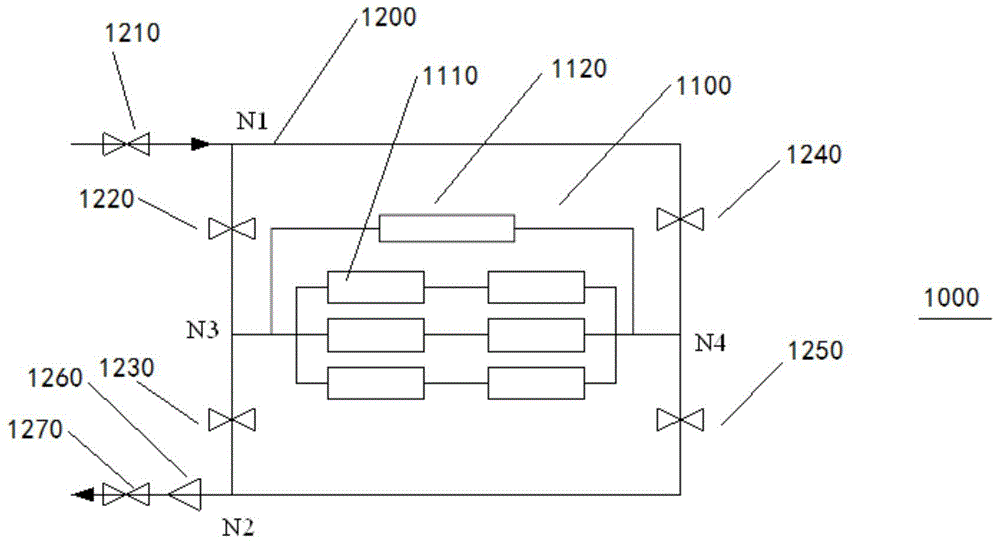

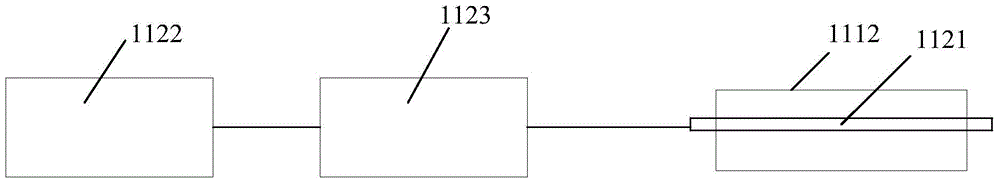

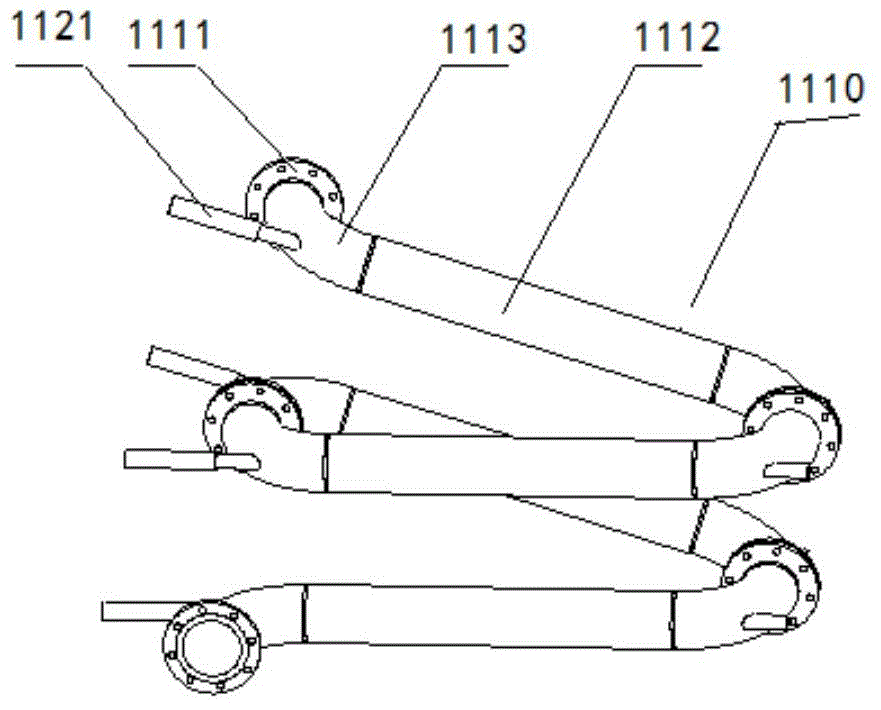

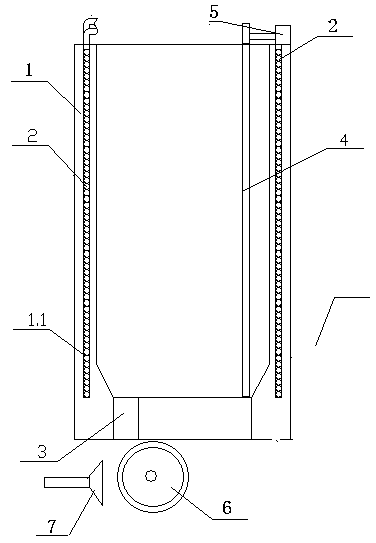

Sludge conditioning system and sludge conditioning method

ActiveCN103588366AExcellent tempering performanceImprove broken rateSludge treatmentSludgeEngineering

The invention discloses a sludge conditioning system. The sludge conditioning system comprises a preprocessing pipeline which comprises one or more preprocessing pipeline units and a high-voltage electric field generating device, wherein the high-voltage electric field generating device comprises electrode bars coaxial with the preprocessing pipeline units, high-voltage generating modules for forming high-voltage variable electric fields in the preprocessing pipeline units, and voltage control modules, the first ends of the voltage control modules are connected with the high-voltage generating modules, the second ends of the voltage control modules are connected with the electrode bars and the voltage control modules are used for controlling the frequency and the amplitude of high voltage generated by the high-voltage generating modules; the sludge conditioning system further comprises blockage preventing pipelines; the blockage preventing pipelines and the preprocessing pipelines form bridge pipelines together, so that the preprocessing pipelines can flow in the positive direction and the negative position to effectively reduce the sludge blockage. The invention further discloses a sludge conditioning method using the sludge conditioning system. The sludge conditioning system disclosed by the invention is used for sludge conditioning, so that the pipelines are difficult to block, and the wall-broken rate is high.

Owner:TIANJIN CARING TECH DEV

Feed conditioning granulator

PendingCN111387535AAvoid accumulationAvoid getting lostFeeding-stuffRotary stirring mixersProcess engineeringMechanical engineering

The invention belongs to the technical field of feed production devices, and discloses a feed conditioning granulator. The feed conditioning granulator is mainly technically characterized by comprising a frame body, a feeding mechanism, a conditioner and a granulating mechanism, wherein the conditioner comprises a power mechanism, a shell with a feed port and a discharge port, a stirring shaft andstirring fins located on the stirring shaft; and spiral fin plates are arranged, opposite to the feed port and the discharge port, on the stirring shaft. After materials enter from the feed port, thefirst spiral fin plate on the stirring shaft located at the feed port pushes the materials forwards rapidly, feeding is more uniform, the materials and steam are fully mixed under the action of the stirring fins on the stirring shaft, and due to the fact that the first spiral fin plate and the second spiral fin plate are arranged at the two ends of the stirring shaft, the steam is sealed in the conditioner, the steam cost is saved, and the heat loss is avoided, so that the temperature is higher in the conditioning process, and the conditioning and sterilizing effects are greatly improved.

Owner:河北鸿岳机械设备制造有限公司

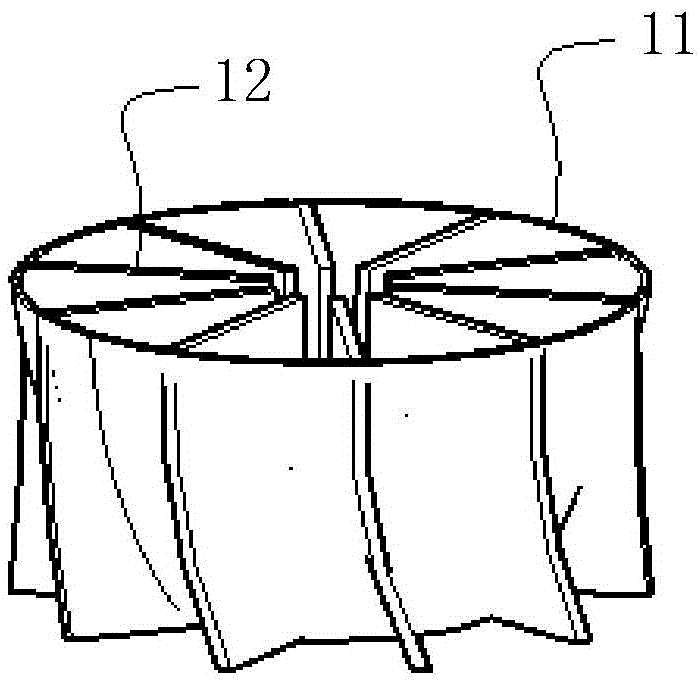

Quenching and tempering system for oil-containing sludge

ActiveCN109650687AAchieving deep reductionFully temperedSludge treatmentRotary stirring mixersOil sludgeQuenching

The invention relates to the technical field of oil-containing sludge treatment, in particular to a quenching and tempering system for oil-containing sludge. The system comprises a body, the body is provided with a quenching and tempering chamber and a quenching and tempering device. The quenching and tempering device comprises two quenching and tempering blades which are located in the quenchingand tempering chamber of the body with opposite rotation directions, the quenching and tempering blades comprise two quenching and tempering parts which are symmetrically arranged, the quenching and tempering parts comprise rotary members and stirring members which are mutually connected, and the stirring parts of the two quenching and tempering parts are mutually connected and coaxial with the rotary members; the quenching and tempering chamber is internally provided with a viscosity level detecting device, the body is provided with a water inlet device, and the starting and stopping of the water inlet device are controlled by the viscosity level detecting device. According to the quenching and tempering system, a quenching and tempering agent is added to the quenching and tempering chamber when quenching and tempering are conducted, oil-containing sludge is fully quenched and tempered by the rotation of the two quenching and tempering blades; by arranging multiple quenching and tempering blades which achieve quenching and tempering by rotating in different directions, the quenching and tempering is thorougher, the quenching and tempering effect is better, deep reduction of oil-containing sludge quenching and tempering is achieved; the refining and using of resources can be achieved by quenched and tempered oil-containing sludge more easily.

Owner:北京净界新宇环保科技有限公司

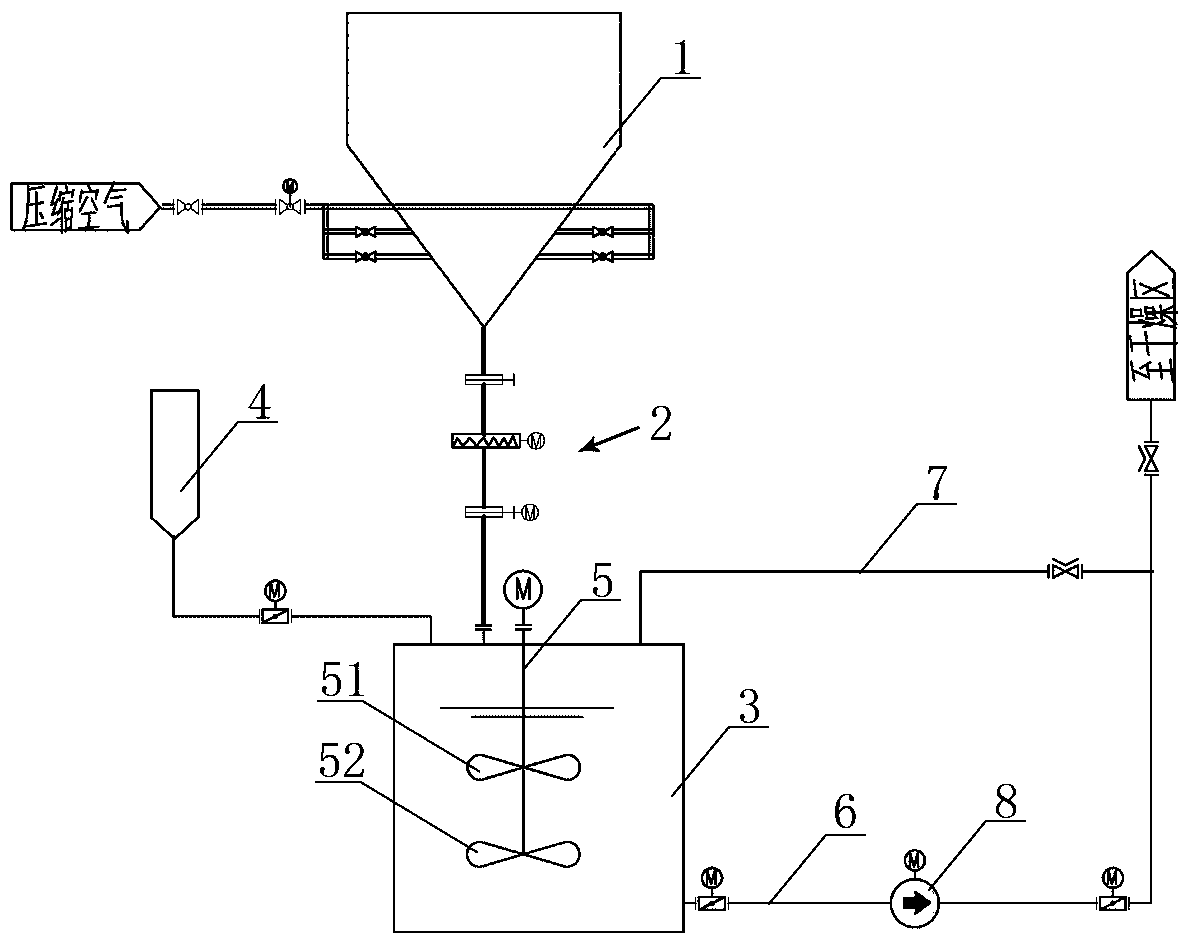

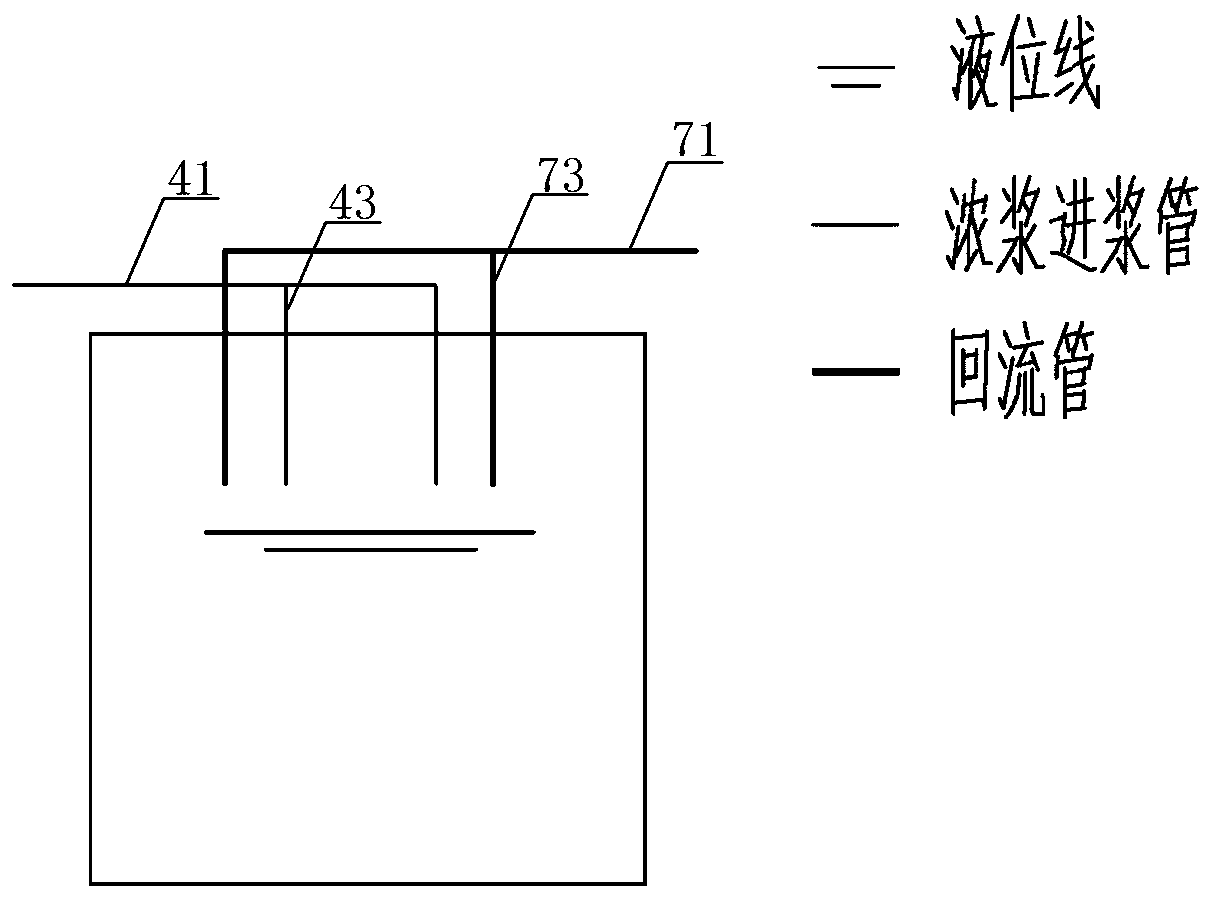

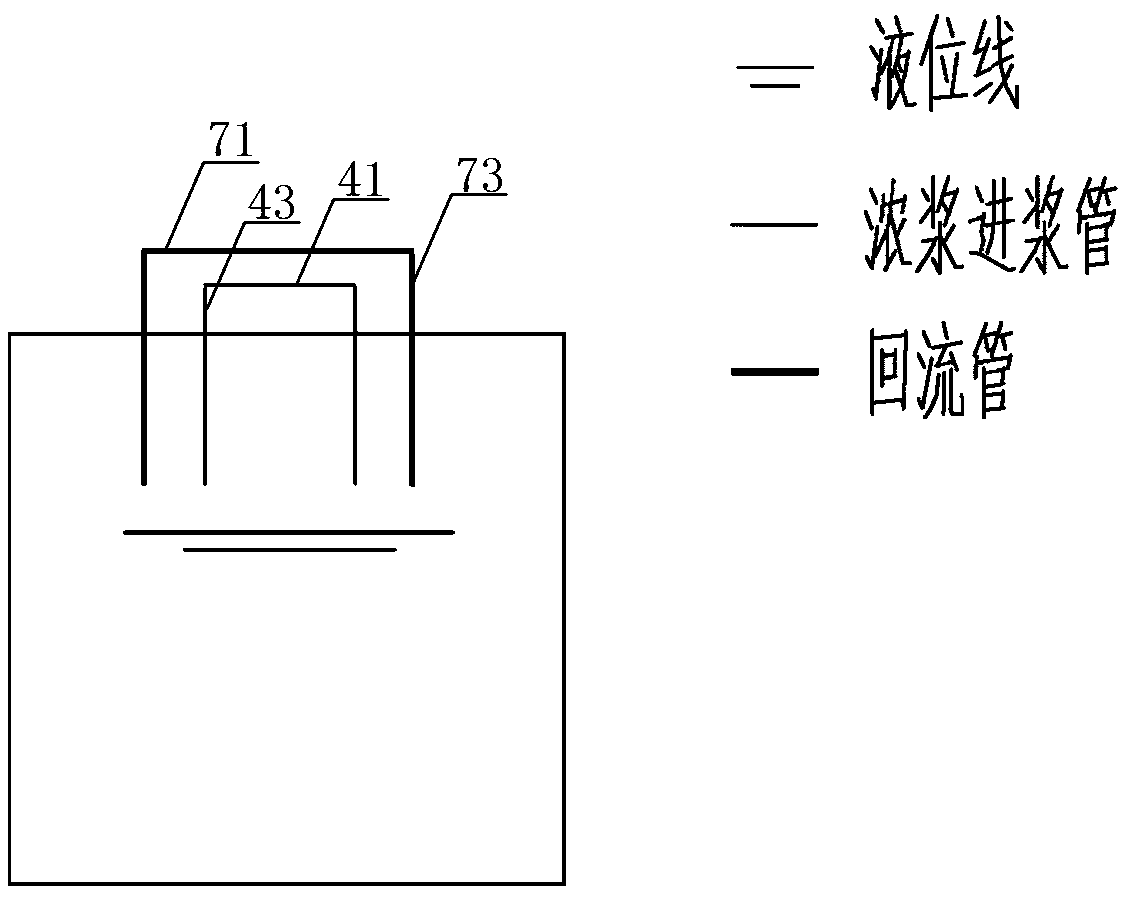

Slurry conditioning system of zero-wastewater-discharge device and operation method thereof

PendingCN109200871APrevent floatingDestroy surface tensionRotary stirring mixersTransportation and packagingWastewaterSystem stability

The invention discloses a slurry conditioning system of a zero-wastewater-discharge device and an operation method thereof. The slurry conditioning system comprises a slaked lime powder bin, a feedingsystem and a conditioning box sequentially communicating with each other from top to bottom, wherein the conditioning box communicates with a thick slurry feeding pipeline, a conditioned slurry outlet pipeline and a return pipeline; an agitator is arranged in the conditioning box; and a mixing pump is arranged on the conditioned slurry outlet pipeline. The invention provides an improved scheme for the slurry conditioning system of a device used for zero discharging of the wastewater of a thermal power generating unit; the improved slurry conditioning system can improve the sufficient dissolving of slaked lime in concentrated slurry and promote conditioning effect, and avoids vicious circulation caused by floating of the slaked lime on the surface of the concentrated slurry due to delayeddissolution of the slaked lime; at the same time, the slurry conditioning system also avoids influence on the operation stability of the system caused by deposition of the slaked lime on the bottom ofthe conditioning box due to excessive supply of slaked lime powder when the slaked lime powder is not sufficiently dissolved or not dissolved in time; and the slurry conditioning system greatly improves the sufficiency and timeliness of a conditioning reaction, is enhanced in system stability, reduces the consumption of the slaked lime powder, and can be extensively applied to thick slurry conditioning units in devices for zero discharging of the wastewater of thermal power generating units.

Owner:BEIJING GUODIAN LONGYUAN ENVIRONMENTAL ENG

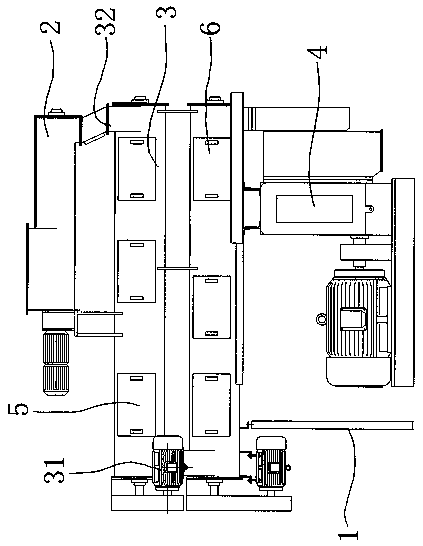

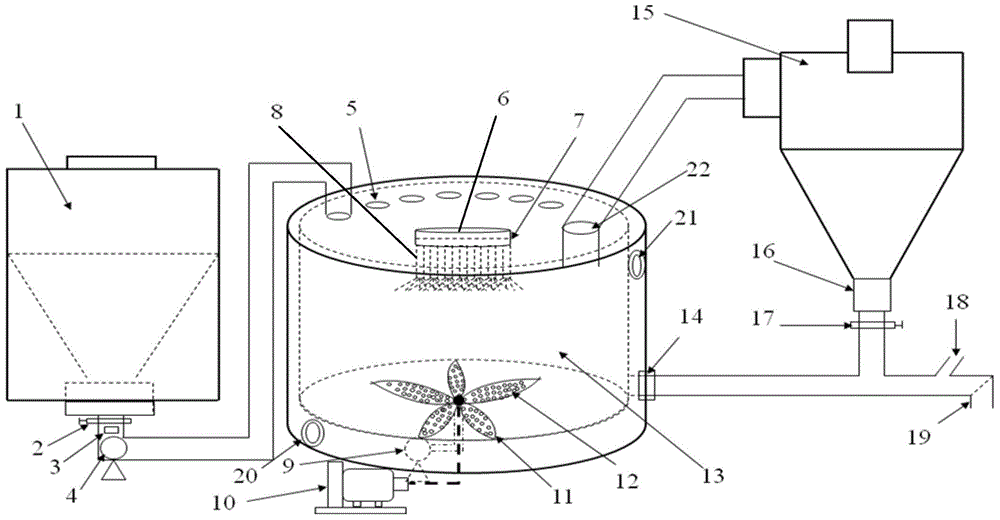

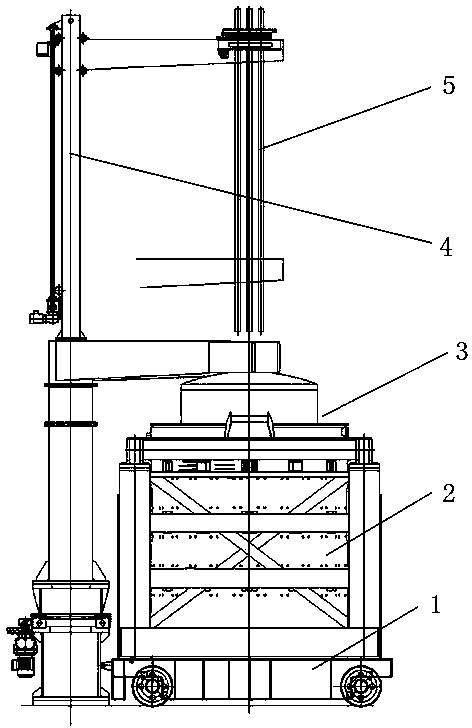

A device for improving the uniformity and dispersion of grain products and its method for producing grain products

ActiveCN104223338BSave time for batch crushingHigh degree of automationFeeding-stuffFood shapingImpellerProcess engineering

A device for improving the uniformity and dispersibility of grain products and a method for producing grain products thereof mainly solve the problems of cumbersome procedures, poor mixing uniformity and dispersibility, and the like. The plant consists of two modules, crushing and tempering, within a frame, and an external separation unit. The crushing module is connected to the inlet corresponding to the top of the quenching and tempering module, and there are electronic control valves and flow meters on the pipeline. The bottom of the conditioning module is impeller blade with air inlet, the top has steam and / or water inlet, atomizer and distributor, and the external separation device is connected to the top of the conditioning module. The production method is to crush the material first and then classify it, and then feed the material to the conditioning module, start the wave wheel, blow in air, and inject steam or water mist to form an up-and-down cycle of high-efficiency conditioning. The equipment and method effectively improve the uniformity and dispersion of grain products in the pretreatment process.

Owner:SHENYANG NORMAL UNIV

A conditioning system for oily sludge

ActiveCN109650687BAchieving deep reductionFully temperedSludge treatmentRotary stirring mixersProcess engineeringOil sludge

Owner:北京净界新宇环保科技有限公司

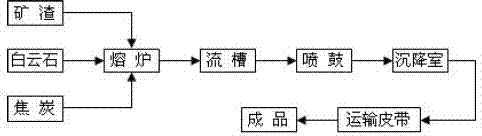

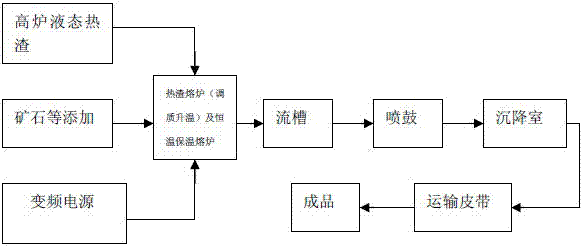

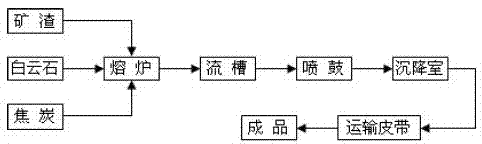

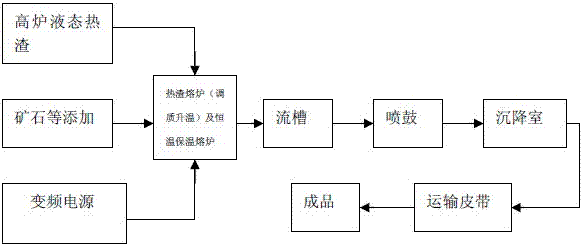

Method used for meeting requirement on mineral wool production with short process

ActiveCN102826747BEasy to adjustLarge loading capacityGlass making apparatusGlass productionSlagElectromagnetic induction

The invention relates to a production method used for meeting the requirement on mineral wool production with a short process. The production method comprises the following steps of: (1) directly loading blast furnace hot slag into an electromagnetic induction smelting furnace or transferring the blast furnace hot slag into a hot slag ladle trolley and then loading into the electromagnetic induction smelting furnace, wherein the temperature of the hot slag is 1,400-1,500 DEG C and can be reduced to 1,100-1,200 DEG C after the hot slag is loaded into the smelting tempered hot slag smelting furnace; (2) rising the temperature of electromagnetic induction passing through the electromagnetic induction smelting furnace to 1,450-1,550 DEG C; and (3) adding quartz stones which are 10-20 percent of the weight of the blast furnace hot slag to 80-90 percent of the blast furnace hot slag to temper and rise the temperature to 1,450-1,550 DEG C so as to convert blast furnace slag wool into high-quality mineral wool, wherein the electromagnetic induction smelting furnace comprises a furnace nozzle, a tilting oil cylinder, an induction coil, a furnace shell and a furnace frame. The production method has the advantages that the problem of difficult hot blast furnace hot slag temperature rising and tempering is solved, and the heat efficiency of the smelt furnace and the flexibility of short process production are improved; the consumption is reduced by more than 40 percent, and the cost is reduced by 15 percent; and the electromagnetic induction smelting furnace has the characteristics of energy saving, cost reduction, short process, high quality, high efficiency and the like.

Owner:朱兴发

Jet-driven chemical dispersion system and pulping and upgrading equipment using the system

ActiveCN105289390BHomogeneous Mix Feed RequirementsImprove impact performanceMixer accessoriesImpellerSpray nozzle

Owner:ANHUI UNIV OF SCI & TECH

Sludge conditioning system and sludge conditioning method

ActiveCN103588366BExcellent tempering performanceImprove broken rateSludge treatmentSludgeHigh pressure

Owner:TIANJIN CARING TECH DEV

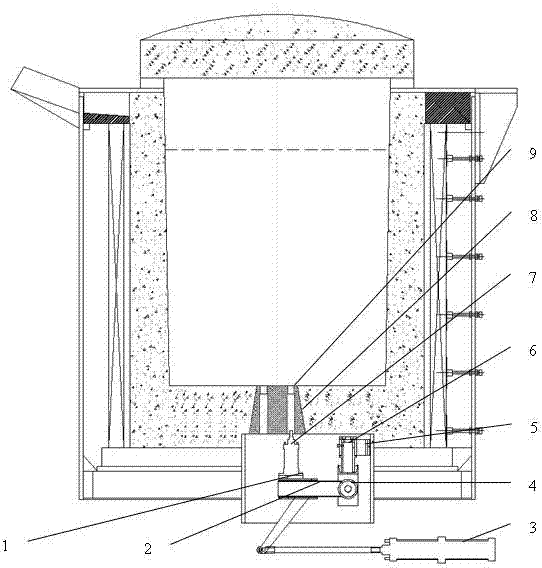

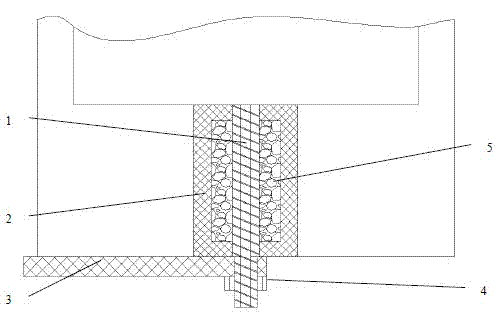

Left wheel popup box type porous pull-down plug graphite water gap device of electromagnetic slag smelter

ActiveCN103353232BMeet the technical requirements of the production processMeet the technical requirements of the processCharge manipulationFiberEngineering

The invention provides a left wheel popup box type porous pull-down plug graphite water gap device of an electromagnetic slag smelter. The left wheel popup box type porous pull-down plug graphite water gap device of the electromagnetic slag smelter structurally comprises a moving arm, a plug shifting arm, a plug shifting air cylinder, a pin shaft, a fixed frame, a rotating shaft, a plug pushing air cylinder, a graphite water gap, a graphite plug and a porous cone. The left wheel popup box type porous pull-down plug graphite water gap device of the electromagnetic slag smelter has the advantages of achieving the effects that the blocking of high temperature slag in base flow of an electromagnetic induction slag smelter is relieved when the flow is open, and the flow is controlled at a constant temperature. Besides, the technological requirements of rock wool production are met, and a bottleneck is broken for the production of high quality rock wool. The designed bottom leakage deslagging water gap ensures flow accuracy, can be opened and closed at will, and does not waste melts. The energy consumption is low, thermal efficiency is high, the amount of waste residue is small, the fiber forming rate is high, and the cost advantage is obvious. The electromagnetic slag smelter is not only excellent in temperature rise and regulation performance, heat preservation performance and hardening and tempering performance, but also high in storage capacity, thereby laying a good foundation for scale production. The left wheel popup box type porous pull-down plug graphite water gap device has the advantages of being controllable in high temperature liquid state slag flow, smooth, free of blocking, safe, reliable, convenient to use and efficient.

Owner:朱兴发

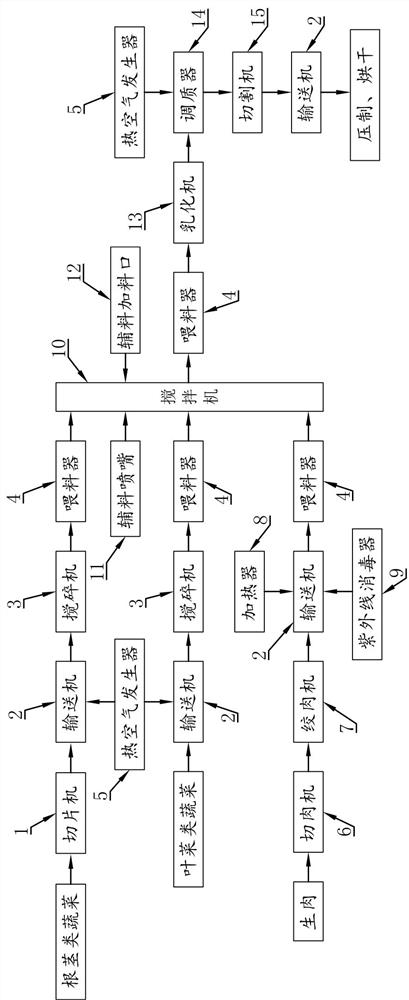

Pet food production system

ActiveCN114209075ASimple processIncrease productivityFodderFeeding-stuffVegetable processingProcess engineering

The invention relates to a pet food production system which comprises a rhizome vegetable processing device, a leaf vegetable processing device, a raw meat processing device, a stirring machine and a mixed material processing device, the rhizome vegetable processing device comprises a slicing machine, a conveyor, a smashing machine and a feeder which are connected in sequence, and the feeder is connected with the stirring machine; the leaf vegetable processing device comprises a conveyor, a crusher and a feeder which are connected in sequence, and the feeder is connected with the stirrer; the raw meat processing device comprises a meat cutter, a meat grinder, a conveyor and a feeder which are connected in sequence, a heater and an ultraviolet sterilizer are arranged in the conveyor, and the feeder is connected with the stirrer; the mixed material processing device comprises a feeder, an emulsifying machine, a conditioner, a cutting machine and a conveyor which are connected in sequence, the conditioner is connected with the hot air generator, and the feeder is connected with the stirrer.

Owner:深州市欧迪宠物食品有限公司

Underflow-type flow-controllable electric-heating graphite nozzle device of electromagnetic induction slag smelter

The invention relates to an underflow-type flow-controllable electric-heating graphite nozzle device used for short-flow rock wool production. The device is structurally characterized in that a graphite sleeve is fixed on a bottom lining, the upper end of a graphite electric-heating spiral tube is connected to the graphite sleeve in a threaded manner, an electric-heating tube graphite conducting plate is fixed to the graphite electric-heating spiral tube through a graphite fixing nut, and refractory filler is arranged on two sides of the graphite electric-heating spiral tube. The device has the advantages that the process using the device saves more than 60% of energy consumption per ton as compared to the cupola rock wool process; no environmental pollution occurs; the slag smelter is high in power factor, low in energy consumption and high in heating speed; the bottom-leak deslagging nozzle ensures accurate flow, and no melt is wasted; the adaptation range is wider, and the furnace burden ingredients are adjustable; a slag bath with the upper temperature limit of 1700 DEG C is satisfactory to melts of various qualities, with no need for coke; magnetic stirring and mechanical stirring guarantee even melt ingredients; energy consumption is low, heat efficiency is high, and waste slag is little; the smelter is superior in terms of temperature rise, temperature adjustment, temperature retention and conditioning and is high in loading capacity.

Owner:朱兴发

An integrated refractory fine coal slurry mixing equipment

ActiveCN105521738BRealize deep slurry modificationExcellent tempering performanceTransportation and packagingMixersBiochemical engineeringDrive shaft

The invention relates to the field of coal slurry pretreatment, in particular to an integrated refractory fine coal slurry adjustment equipment. The equipment includes a mixing box; the drive shaft is arranged vertically in the inner cavity of the mixing box, and the electric field activation layer, ultrasonic vibration layer and forced stirring layer are arranged in the inner cavity of the mixing box from top to bottom along the length direction of the drive shaft; The air box and the pressurized dissolved air box are arranged with an air inlet pipe for feeding high-pressure air, and the inlet end of the box body used to communicate with the outlet of the mixing box is arranged with a feed compartment for realizing the opening and closing of the inlet end. The feed partition is fastened with a tension spring and leans against the inlet end to close the inlet end; the outlet end of the box is connected to the flotation machine, and the outlet end is arranged to realize the opening and closing of the outlet. Partition, the discharge partition is tensioned by a compression spring and closes the outlet end. The invention can play a very good conditioning effect on the floating coal slime, and is especially suitable for the pulping and upgrading requirements of the difficult-to-float fine-grained coal, and has high working efficiency and quick and convenient pretreatment process.

Owner:ANHUI UNIV OF SCI & TECH

Processing technology of metal strip for assembling iron core of electronic transformer

InactiveCN110295323AExcellent tempering performanceAvoid breakingMelt-holding vesselsMagnetic materialsMetal stripsMetallurgy

The invention discloses a processing technology of a metal strip for assembling an iron core of an electronic transformer. The processing technology comprises the steps of preparing materials, smelting the materials, carrying out secondary melting, casting the melting liquid, coiling the metal strip and the like. According to the processing technology of the metal strip, due to the processes of secondary melting, instant cooling to normal temperature and the like, the flexibility of the steel strip can be effectively improved, so that the steel strip is hard and not brittle, and the rejectionrate is reduced to be less than 4% when the steel strip is coiled into the iron core.

Owner:湖南金子山电子科技股份有限公司

Crack preventing brown rice conditioning assembly line

PendingCN108786959AImprove liquidityAvoid sticking to each otherGrain millingSpiral bladeElectric machinery

The invention discloses a crack preventing brown rice conditioning assembly line. The crack preventing brown rice conditioning assembly line comprises an assembly line body. The assembly line body issequentially provided with a conditioning bin, a transmission bin and a drying bin from top to bottom. A draught fan is arranged on the top of the conditioning bin, an atomizer is arranged above the conditioning bin through a supporting frame, and the atomizer is located above the draught fan. One side of the transmission bin is provided with a first motor through an installing plate, the output end of the first motor is provided with a first rotation shaft extending into the transmission bin, and a spiral blade is arranged on the outer side of the first rotation shaft. The atomizer is used for atomizing water, water mist is evenly distributed under the action of the draught fan and is diffused to the top end in the whole conditioning bin, and the conditioning effect is better. An air pressure cylinder drives a flow dividing plate to move up and down in the conditioning bin, mobility of the brown rice is improved, the brown rice is overturned back and forth, it is ensured that the brown rice is evenly misted, and convenience is brought to later processing of the brown rice.

Owner:湖南长乐粮油贸易有限公司

A coal slime deep slurry modification equipment

ActiveCN105289389BIncrease flow rateEfficient and deep pulping and modifying functionRotary stirring mixersMixer accessoriesImpellerEngineering

The invention relates to the field of coal slurry pretreatment, in particular to equipment of deeply slurry mixing and modifying of coal slime for slurry mixing and modifying of high-ash fine coal slime difficult to float. The equipment comprises a mixing box; agentia dispersion tanks are arranged at the top of a chamber of the mixing box, and an annular dispersion unit and an annular ore pulp feed chutes are arranged at the outside of the agentia dispersion tanks in sequence; a fallplate with a dip angle is arranged below a discharge port of the annular dispersion unit; vane wheels are arranged below the fallplate with the dip angle, and stator walls encircle the vane wheels; a liquid outlet of the mixing box is formed in bottom end surface of the mixing box; double row side-by-side nozzles with dispersed jet flows for providing agentia mixed liquor to the agentia dispersion tanks are arranged at the top end surface of the mixing box; two agentia dispersion tanks are arranged in parallel along the tank direction; diffusers of each nozzle with the dispersed jet flow extents into chambers of corresponding agentia dispersion tank. The equipment can play a very good role in modifying of floated coal slime and is particularly suitable for the demand of slurry mixing and modifying of fine coal difficult to float, the work efficiency of the equipment is high and a treatment process is rapid and convenient.

Owner:ANHUI UNIV OF SCI & TECH

Difficult-to-float fine-grained coal deep slurry modification equipment

ActiveCN105327647BEfficient and deep pulping and modifying functionInto the uniformMixersImpellerEngineering

The invention relates to the field of coal slurry pretreatment, in particular to deep slurry mixing and modifying equipment for fine coal hard to float, and the equipment is used for slurry mixing and modifying of high-ash fine coal slime hard to separate. The equipment comprises a mixing box, drug distributing grooves are formed in the top of a cavity of the mixing box, and an annular distributing unit and an annular ore pulp feeding grooves are sequentially arranged outside the drug distributing groove. An inclined falling plate is arranged below a discharging outlet of the annular distributing unit. A stirring impeller is arranged below the inclined falling plate, and a stator wall is arranged around the impeller. A liquid outlet of the mixing box is located at the bottom end face of the mixing box, and jetting sprayers and a liquid pipeline are arranged on the top end face of the mixing box. The two drug distributing grooves are arranged in parallel and correspond to the jetting sprayers in a one-to-one mode. Mixed liquid outlet ends of the two jetting sprayers stretch into cavities of the corresponding drug distributing grooves. The equipment has a good modifying effect on fed floating coal slime and especially meets the slurry mixing and modifying requirements of the fine coal hard to float, the work efficiency of the equipment is high, and the pretreatment process is quick and convenient.

Owner:ANHUI UNIV OF SCI & TECH

Electromagnetic induction slag melting furnace satisfying short-process production of mineral wool and production method thereof

ActiveCN102826748BEasy to adjustLarge loading capacityGlass making apparatusGlass productionSlagElectromagnetic shielding

The invention relates to an electromagnetic induction slag smelting furnace meeting the requirement on mineral wool production with a short process and a production method thereof. The electromagnetic induction slag smelting furnace has the structure that the electromagnetic induction slag smelting furnace is fixed on a trolley by using bolts, and a rotary furnace cover is fixed on an embedded steel plate on a ground foundation; an electrode lifting and rotation mixing device is fixed on the rotary furnace cover by using bolts and can be rotated along with the rotary furnace cover; and an induction heating electrode is fixed on the electrode lifting and rotation mixing device and can be rotated along with the rotary furnace cover. The production method comprises the following steps of: directly loading blast furnace hot slag into an electromagnetic induction smelting furnace or transferring the blast furnace hot slag into a hot slag ladle trolley and then loading into the electromagnetic induction smelting furnace; rising the temperature of electromagnetic induction passing through the electromagnetic induction smelting furnace to 1,450-1,550 DEG C; and adding quartz stones into the blast furnace hot slag to temper and stir to output high-quality mineral wool. The production method have the characteristic that the problem of difficult hot blast furnace hot slag temperature rising and tempering is solved, and the heat efficiency of the smelt furnace and the flexibility of short process production are improved; the consumption is reduced by more than 40 percent, and the cost is reduced by 15 percent; and the electromagnetic induction smelting furnace has the characteristics of energy saving, cost reduction, short process, high quality, high efficiency and the like.

Owner:朱兴发

A multi-impeller mixed flow field slurry preconditioner driven by slurry pipeline pressure

ActiveCN105536610BReduce consumption costImprove the mixing effectTransportation and packagingRotary stirring mixersImpellerMixed flow

The invention relates to the field of coal slurry pretreatment, in particular to a multi-impeller mixed flow field slurry preprocessor driven by the pressure of a slurry pipeline. The equipment includes a mixing box, a main shaft and a driven shaft; the driving gear is coaxially arranged on the main shaft, and the driven gear is arranged on the driven shaft to form a meshing relationship; the driving turbine is coaxially arranged on the main shaft; A group of stirring impellers, the driven rotating shafts are coaxial and fixed with a set of stirring wheels at the same height as each other; in the vertical direction, the projections of the stirring impellers and the stirring wheels intersect; a guide sleeve is set directly below the driving turbine; Guide vanes are arranged in a vortex shape inside the sleeve, and the rotation direction of the mixed liquid guided by the guide vanes is the same as the rotation direction of the stirring impeller directly below. This equipment can play a very good conditioning effect on the floating coal slime, especially suitable for the slurry modification and upgrading of difficult-to-float fine-grained coal. It has high working efficiency and the pretreatment process is fast and convenient.

Owner:ANHUI UNIV OF SCI & TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com