A device for improving the uniformity and dispersion of grain products and its method for producing grain products

A production method and uniformity technology, applied in food forming, application, food science, etc., can solve the problems of large dust pollution, poor mixing uniformity and dispersion, time-consuming and labor-consuming, etc., and achieve high-efficiency tempering, dispersion and conditioning qualitative effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

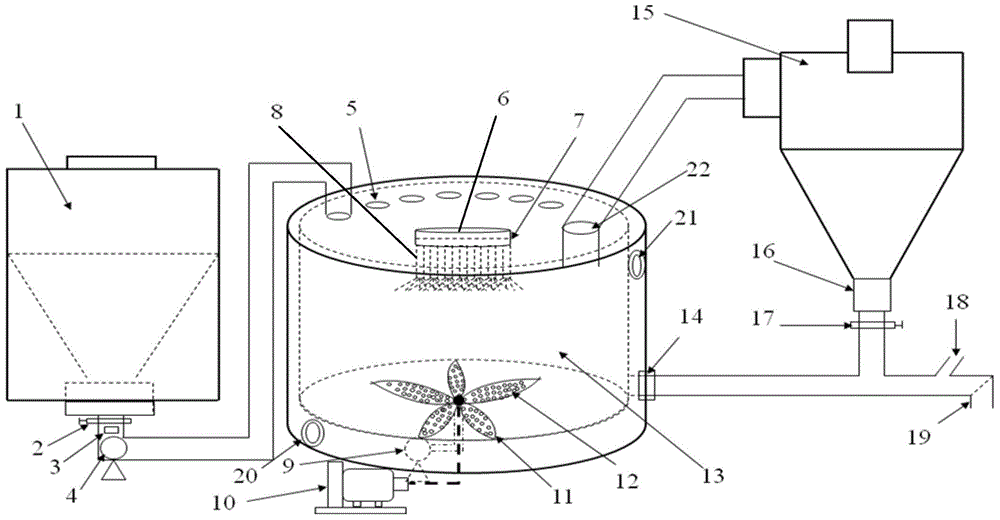

[0053] Through the equipment to improve the uniformity and dispersibility of grain products, the production of whole rough nutrition recombined rice is carried out.

[0054] Whole brown nutritional recombined rice uses broken rice and extruded stabilized rice bran as raw materials. The production formula is designed based on the effective nutrients in brown rice. Rice: The ratio of stabilized rice bran is 7:1, and the extruder is used as the production equipment for recombined rice. The die hole of the discharge mold is extruded, cut into rice grains by a cutter, and finally the whole rough nutrition recombined rice is prepared.

[0055] The specific operation of the pretreatment process is as follows: firstly, in the computer operation interface, select the crushing function crushing module, pass through a 80-100 mesh sieve, set the output ratio of the two crushing modules to 7:1, and the output rate is 105kg / h respectively and 15kg / h, set the water intake to be 18% of the m...

Embodiment 2

[0059] The production of whole brown nutritional rice paste is carried out through the equipment for improving the uniformity and dispersibility of grain products.

[0060] Whole brown nutritional rice paste uses broken rice and extruded and stabilized rice bran as raw materials. The production formula is designed based on the effective nutrients in brown rice. Rice: The stabilized rice bran ratio is 7:1, and the extruder is used as the production equipment for nutritional rice paste. The material is extruded from the die hole of the discharge mold, cut into short strips by a cutter, dried by microwave, and then pulverized, and finally the whole brown nutritional rice paste is prepared.

[0061] The specific operation of the pretreatment process is as follows: firstly, in the computer operation interface, select the crushing module with ultra-fine crushing function, pass through a 200-250 mesh sieve, set the output ratio of the two crushing modules to 7:1, and the output volum...

Embodiment 3

[0064] Feed preparation is carried out by equipment that improves the uniformity and dispersion of grain products.

[0065] The feed is prepared by extruding corn flour, soybean meal and wheat bran as raw materials. The percentage weight ratio of each raw material is: corn flour 50, soybean meal 25 and wheat bran 25, that is, corn flour: soybean meal: wheat bran is 2:1:1, and the mixed material is expanded by microwave irradiation expansion method, and the parameters are set It is: the temperature is 130°C, the microwave irradiation time is 10min, and the power is 65KW, and finally the feed product is prepared. In the conditioning process, the mixed material is pre-gelatinized first, and then the quality of the feed product is better after microwave irradiation. Therefore, pre-gelatinization can be performed by steam injection in the conditioning process.

[0066] The specific operation of the pretreatment process is as follows: first, in the computer operation interface, sel...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com