Patents

Literature

118results about How to "Improve the tempering effect" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

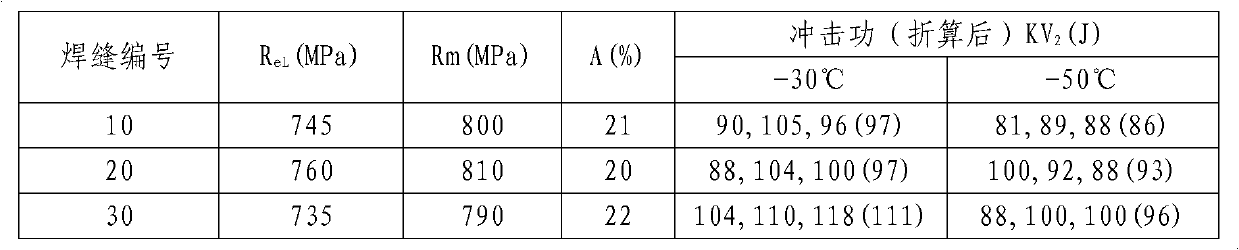

Gas-protection welding wire with low alloy and high strength

InactiveCN101905390AImprove toughnessImprove the tempering effectWelding/cutting media/materialsSoldering mediaGas protectionWeld bead

The invention provides a gas-protection welding wire with low alloy and high strength, comprising the following chemical components in percentage by weight: 0.06%-0.12% of C, 0.30%-0.60% of Si, 1.40%-2.00% of Mn, not more than 0.025% of P, not more than 0.015% of S, 0.30%-0.70% of Cr, 1.0%-1.6% of Ni, 0.28%-0.5% of W, 0.25%-0.50% of Cu, 0.05%-0.15% of Re and the balance of Fe and inevitable impurities. The welding wire has the advantages of favorable welding state of the obtained welding line and thermal-treated toughness, lower cost than that of the traditional welding wire in the same strength level, higher cost performance and strong practicality.

Owner:WUHAN IRON & STEEL (GROUP) CORP

Manufacturing method of toughened glass

InactiveCN101348327AHigh strengthUniform stress distributionGlass tempering apparatusHigh resistanceHigh rate

The invention provides a method for manufacturing toughened glass. Firstly, a glass product to be toughened are put in a stainless steel frame; the frame accommodating the glass product is placed in a muffle furnace and subjected to high-temperature treatment and then is quickly immersed in methyl silicone oil; the glass productand the frame are taken out and put in an oven and naturally cooled down to the room temperature along with the oven; the glass product is taken out, subjected to washing with carbon tetrachloride and washing with fresh water, and mopped up to obtain the toughened glass. In the invention, the methyl silicone oil is used as a cooling fluid, no additive is required to be added, and the manufacture process is simple; the toughened glass produced by the method of the invention has the advantages of high strength, low cost and high rate of finished products, etc.; moreover, the equipment is simple and the investment is low; the invention can be applied to the toughening of plate glass as well as the toughening of special products, such as glass lamp shades and wide mouth glass bottles, etc. The toughened glass made by the method of the invention has advantages of uniform stress distribution, high resistance to impact and good toughening effect.

Owner:SHAANXI TOPRAY SOLAR

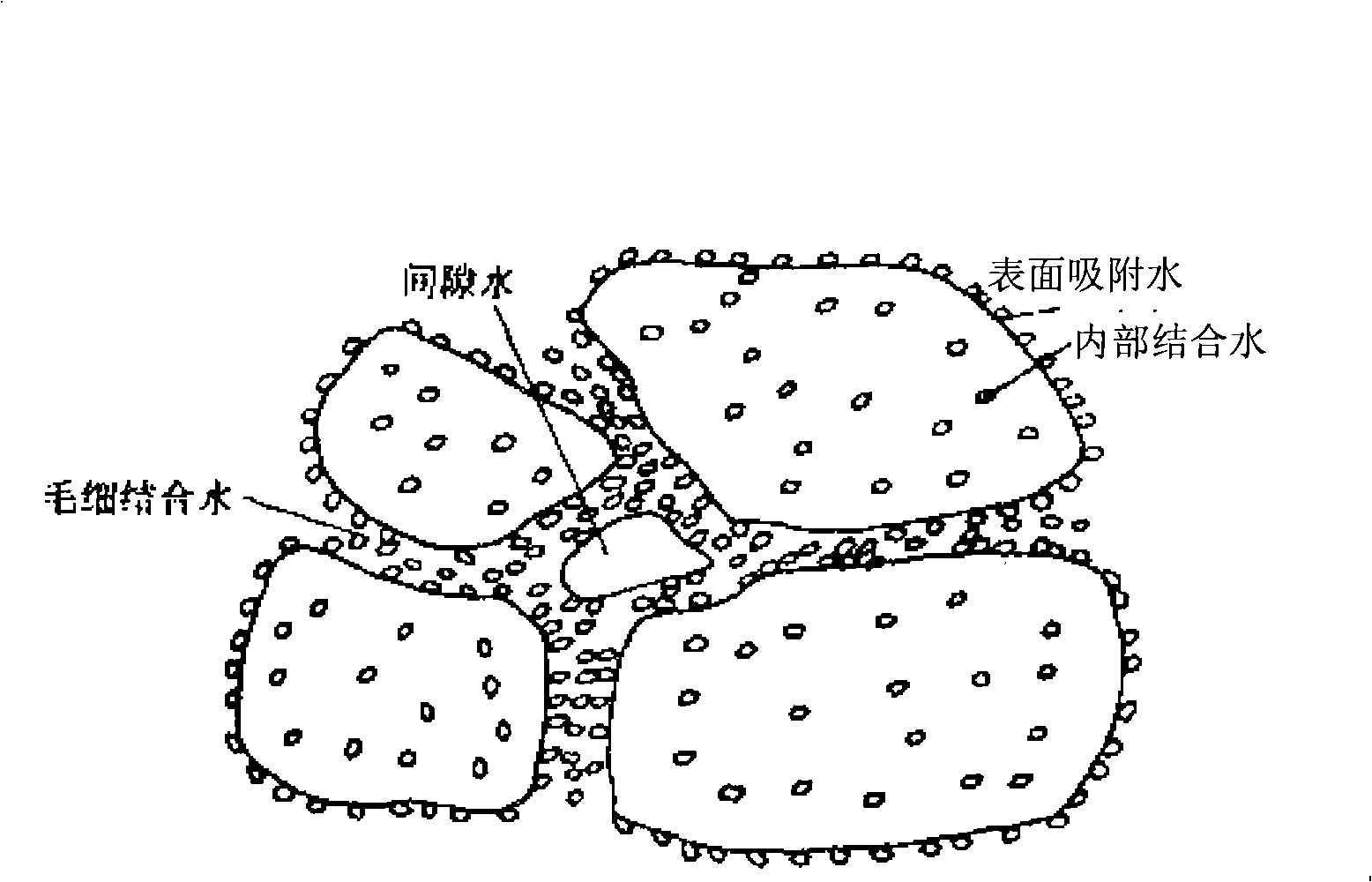

Nano highly effective amendment for sludge dehydration

InactiveCN1621370AHigh floc strengthLow floc strengthSludge treatment by de-watering/drying/thickeningWater/sewage treatment by flocculation/precipitationSulfateSludge

The present invention discloses one kind of Z's nanometer efficient sewage dewatering amendment. The Z's nanometer efficient sewage dewatering amendment consists of polymerized ferric sulfate 85-98 weight portions, polyacrylamide 0.5-6 weight portions, hydroxymethyl cellulose sodium 0.5-6 weight portions and nanometer material 0.5-3 weight portions. The present invention has powerful neutralizing capacity, bridging capacity and permeating capacity and thus has high sewage dewatering effect.

Owner:曾智勇 +1

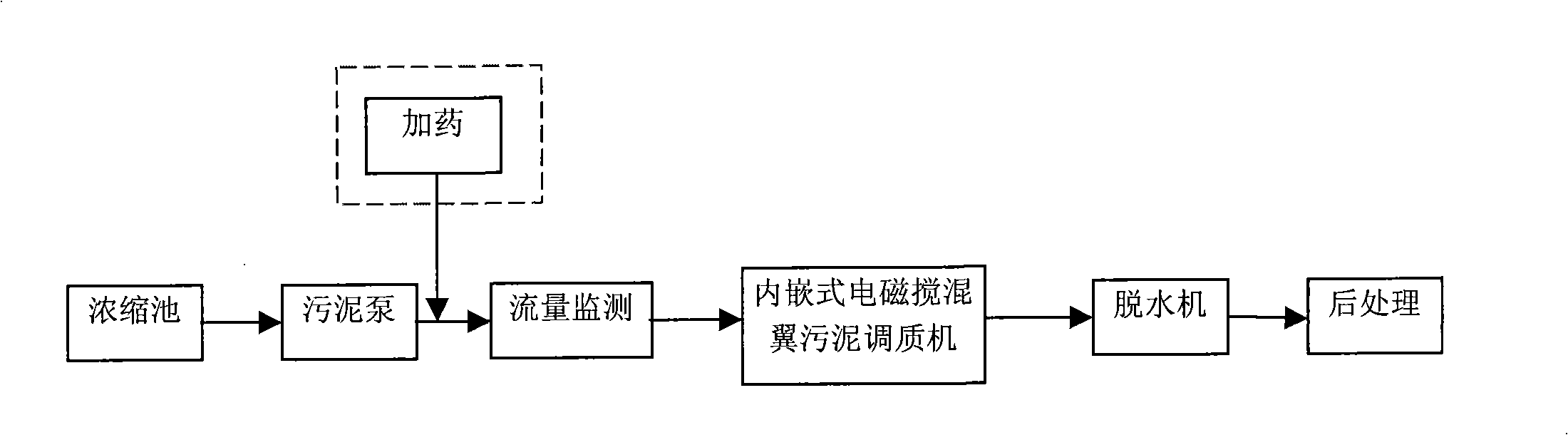

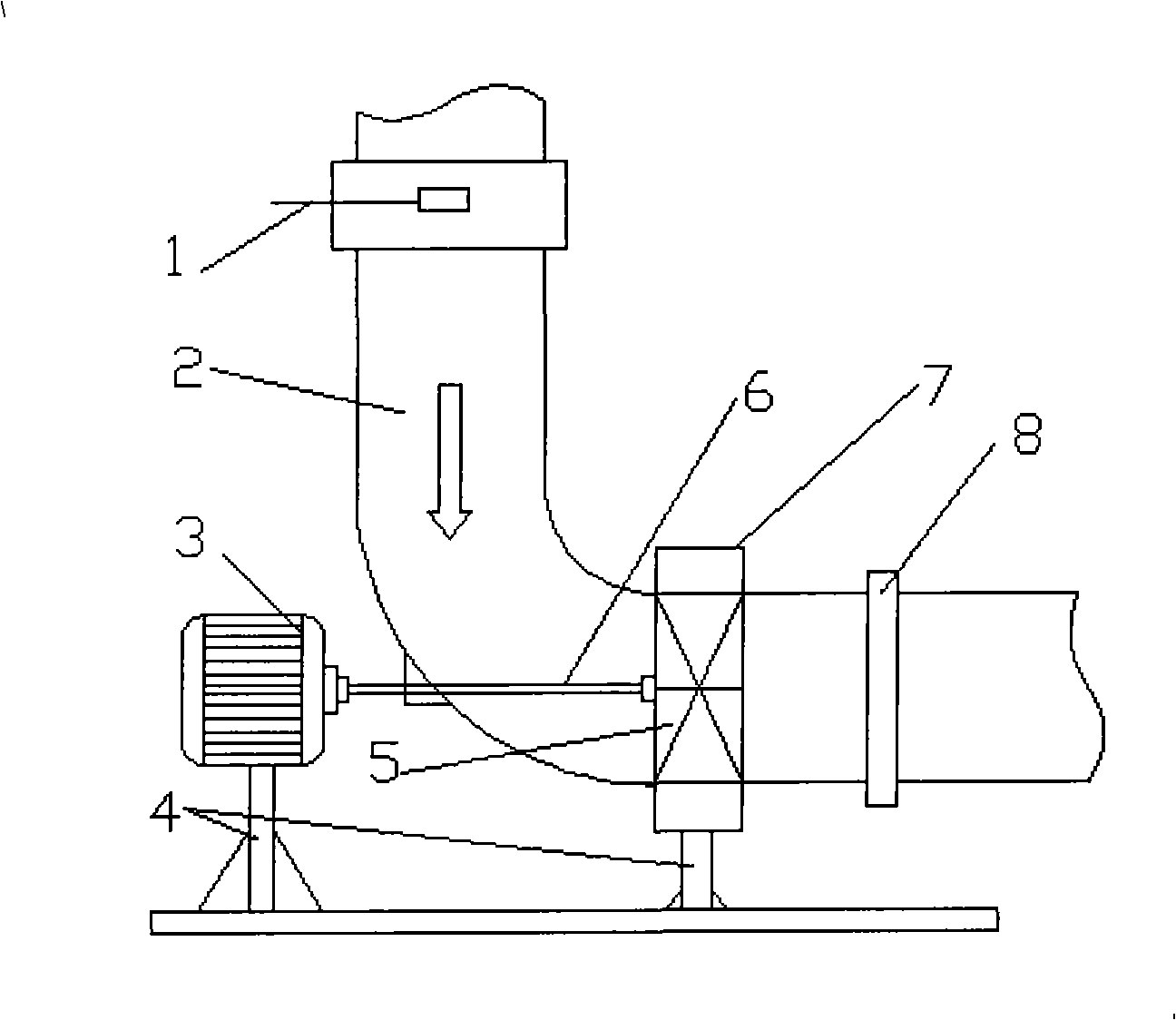

Method and apparatus for improving sludge dehydration

InactiveCN101328002APrecise temperingLower specific resistanceSludge treatment by de-watering/drying/thickeningEnergy expenditureDewatered sludge

The invention discloses a method for improving the dehydrating property of the sludge and equipment thereof. The method is to adopt an inner embedded type electromagnetic swirling wing sludge conditioner arranged in the sludge pipe or an external magnet-rotary sludge conditioner arranged on the sludge pipe to quench and temper the sludge, so as to achieve the purpose of sludge specific resistance reduction and sludge dehydrating property improvement. After the method and the equipment are implemented, the water content of the final dewatered sludge (mud cake) can reach 70-80% which reduces by 2-15% comparing to the technology without conditioner treatment. The work efficiency of the dewaterer is greatly improved, the energy consumption of the dewaterer is reduced by 5-40% and the reagent dosing is reduced by 5-100%. The method and equipment of the invention are not only suitable for the transformation of the old equipment in the prior sludge treatment, but also suitable for the establishment of the new equipment.

Owner:上海滨浦水处理设备有限公司

Blast furnace hot slag microcrystalline glass and preparation method thereof

The invention discloses a blast furnace hot slag microcrystalline glass and a preparation method thereof. The blast furnace hot slag microcrystalline glass comprises the following raw materials by mass percentage: 50-70% of liquid blast furnace slag, 10-30% of fly ash, 2-7% of lithium carbonate, 3-8% of sodium carbonate, 3-5% of sodium fluosilicate, 1-5% of zirconium oxide, 3-6% of titanium dioxide, 0.01-1% of arsenic trioxide, 0.01-1% of antimony oxide, 0.01-3% of phosphorus pentoxide, 0.01-1% of cesium oxide, and 0-2% of a colorant. The preparation method mainly includes: putting the raw materials except liquid blast furnace slag into an auxiliary material melting tank to conduct heating and melting, letting the treated raw materials and the liquid blast furnace slag enter a mixing tank of the slagging furnace together, then making a high-temperature melt enter a melting tank, and then letting the high-temperature melt enter a material channel, subjecting the melt flowing out of the material channel to calendaring molding to obtain a semi-finished glass sheet; and then carrying out annealing and crystallization treatment, thus obtaining the microcrystalline glass.

Owner:宝钢矿棉科技(宁波)有限公司

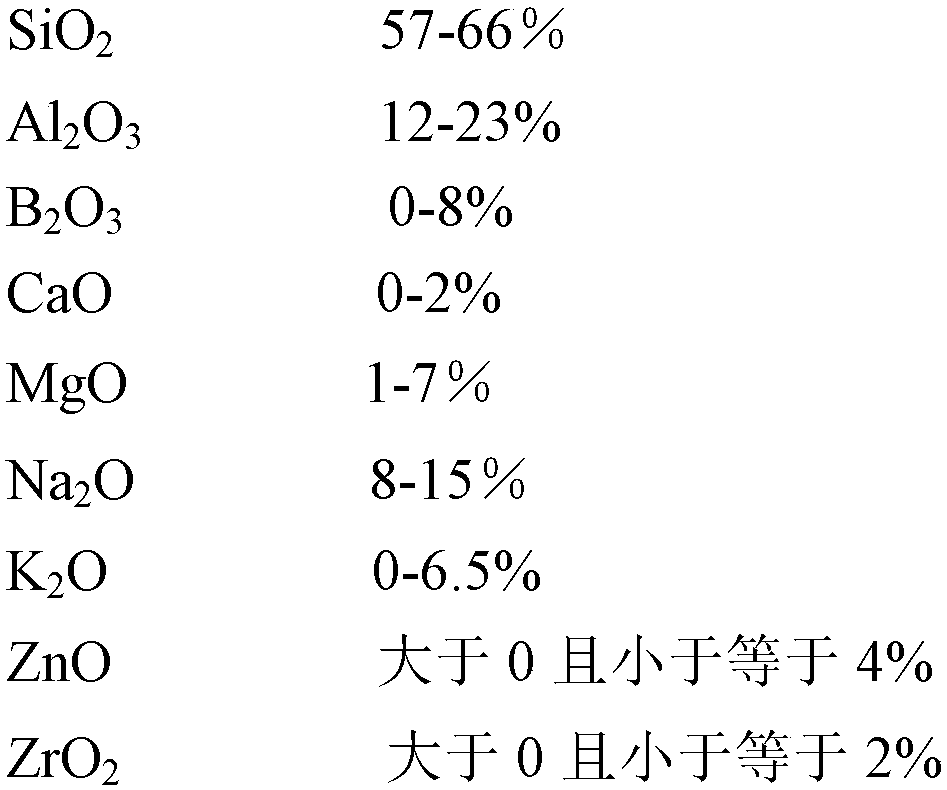

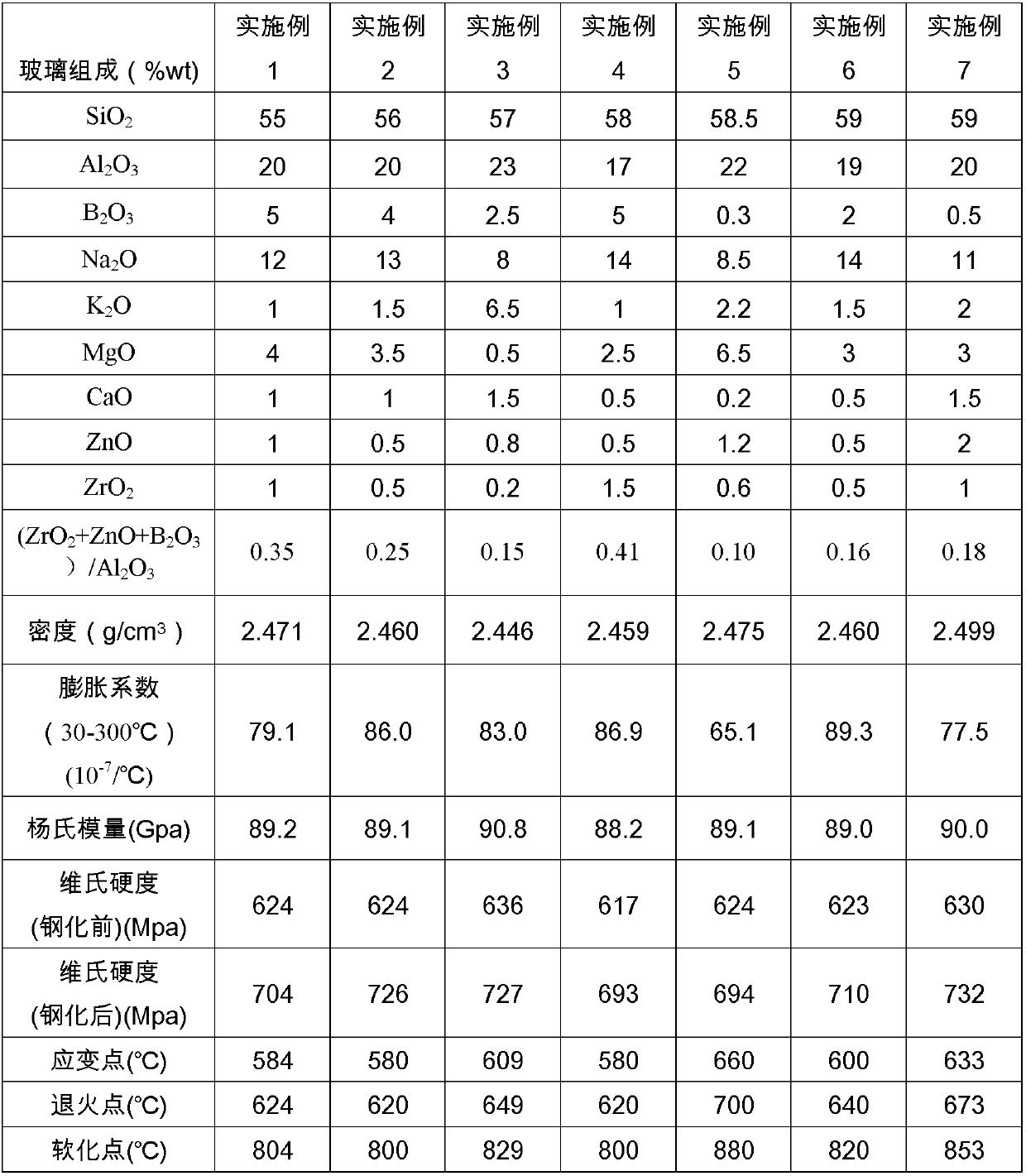

Aluminosilicate glass and preparation method thereof, and touch screen glass cover plate

InactiveCN108046588AIncrease the surface compressive stressImprove thermal stabilityGlass coverIon exchange

The invention discloses an aluminosilicate glass and a preparation method thereof, and a touch screen glass cover plate, wherein the aluminosilicate glass contains, by mass (calculated as the oxide),57-66% of SiO2, 12-23% of Al2O3, 1-7% of MgO, 8-15% of Na2O, more than 0 and less than or equal to 4% of ZnO, and more than 0 and less than or equal to 2% of ZrO2. According to the present invention,the components of the glass contain ZnO and ZrO2, such that the elastic modulus, the hardness and other mechanical performances of the cover plate glass can be improved, the ion exchange effect can beimproved, and the production cost can be reduced.

Owner:CSG HOLDING +1

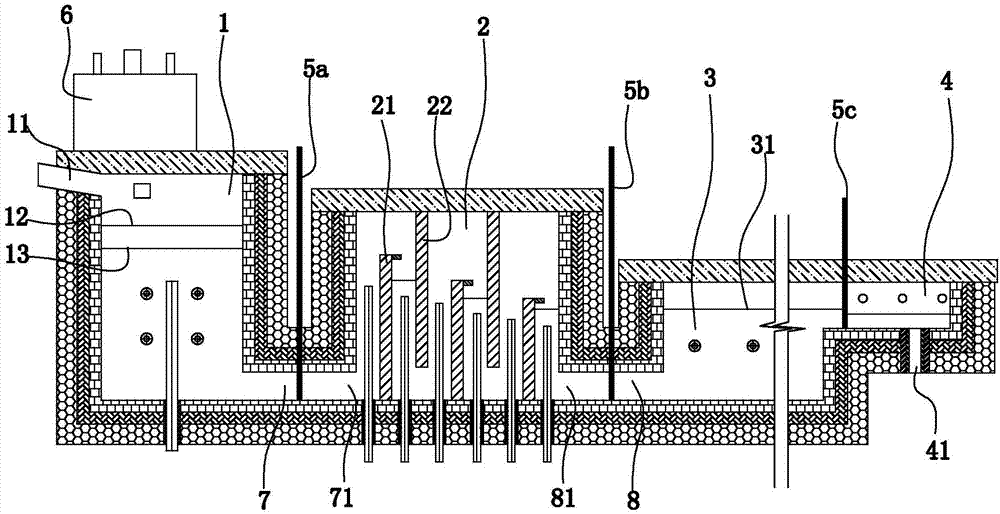

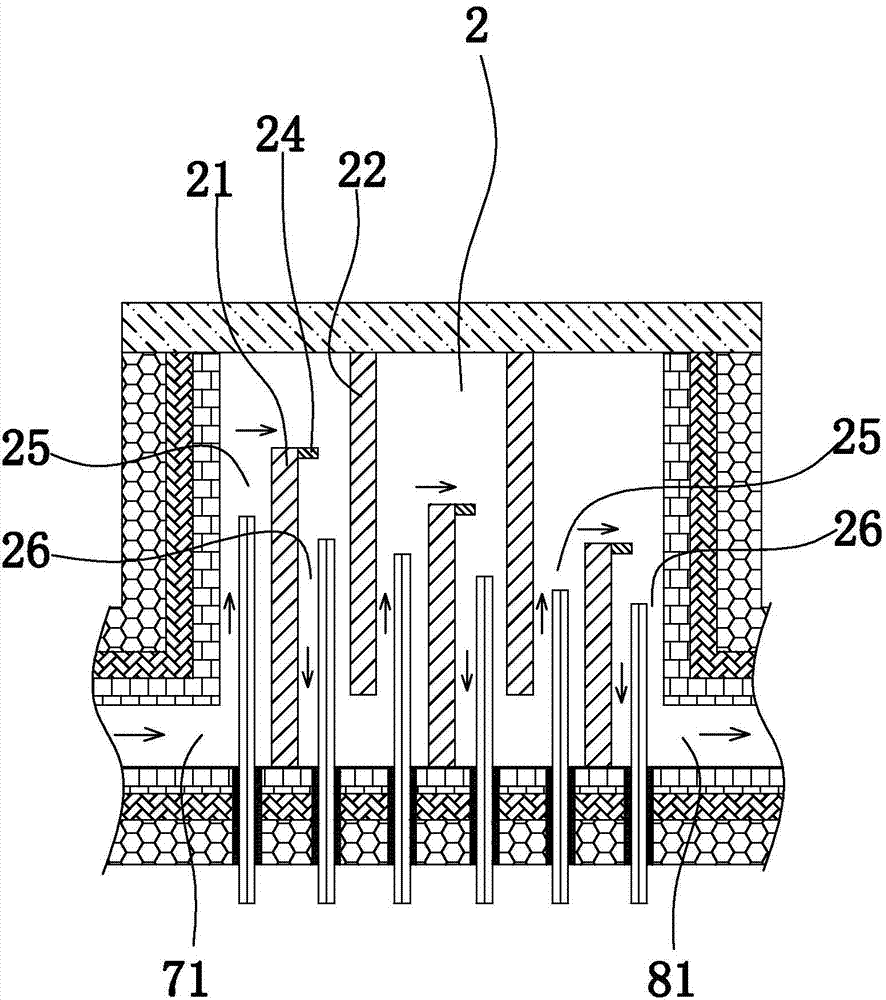

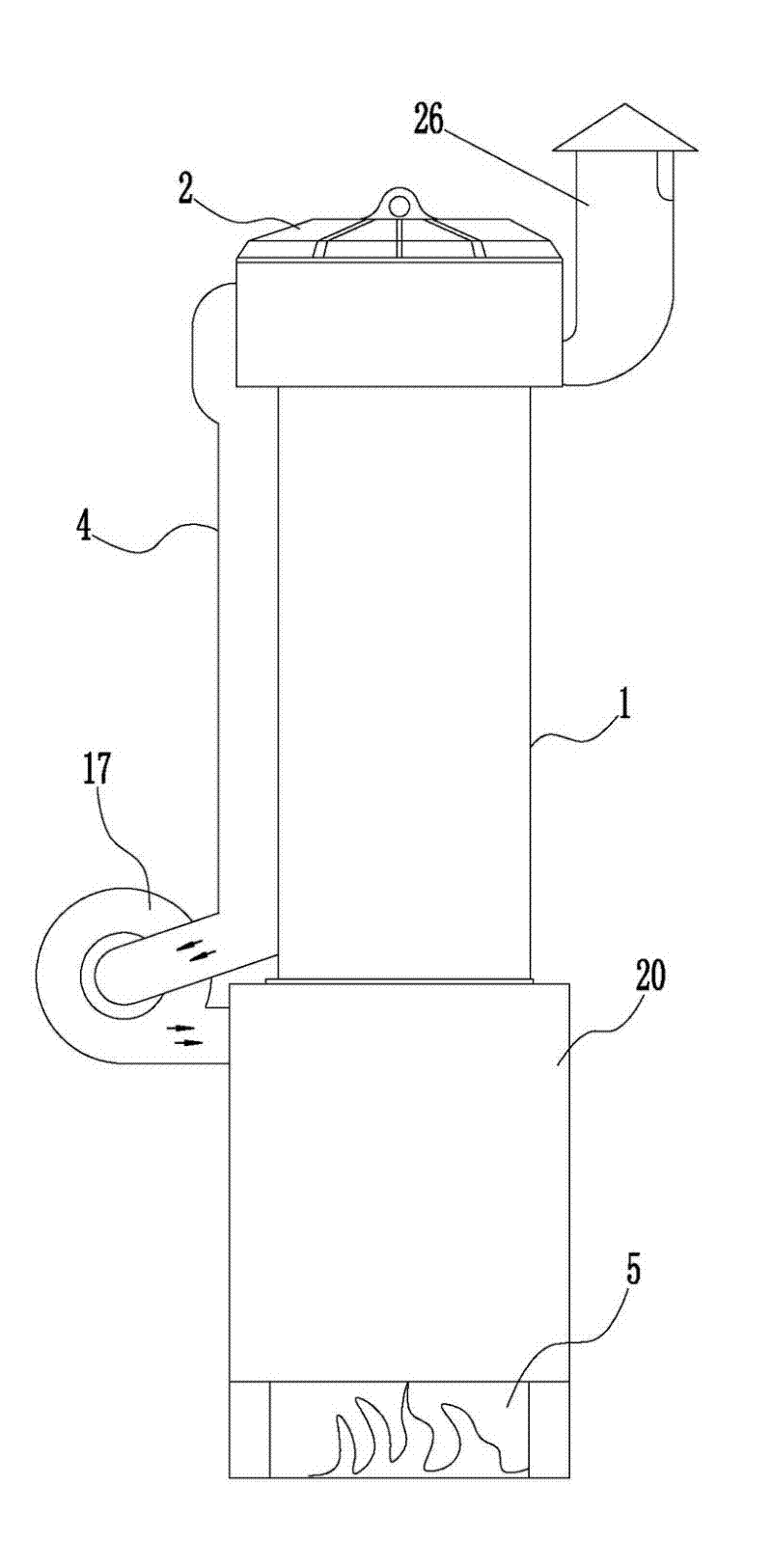

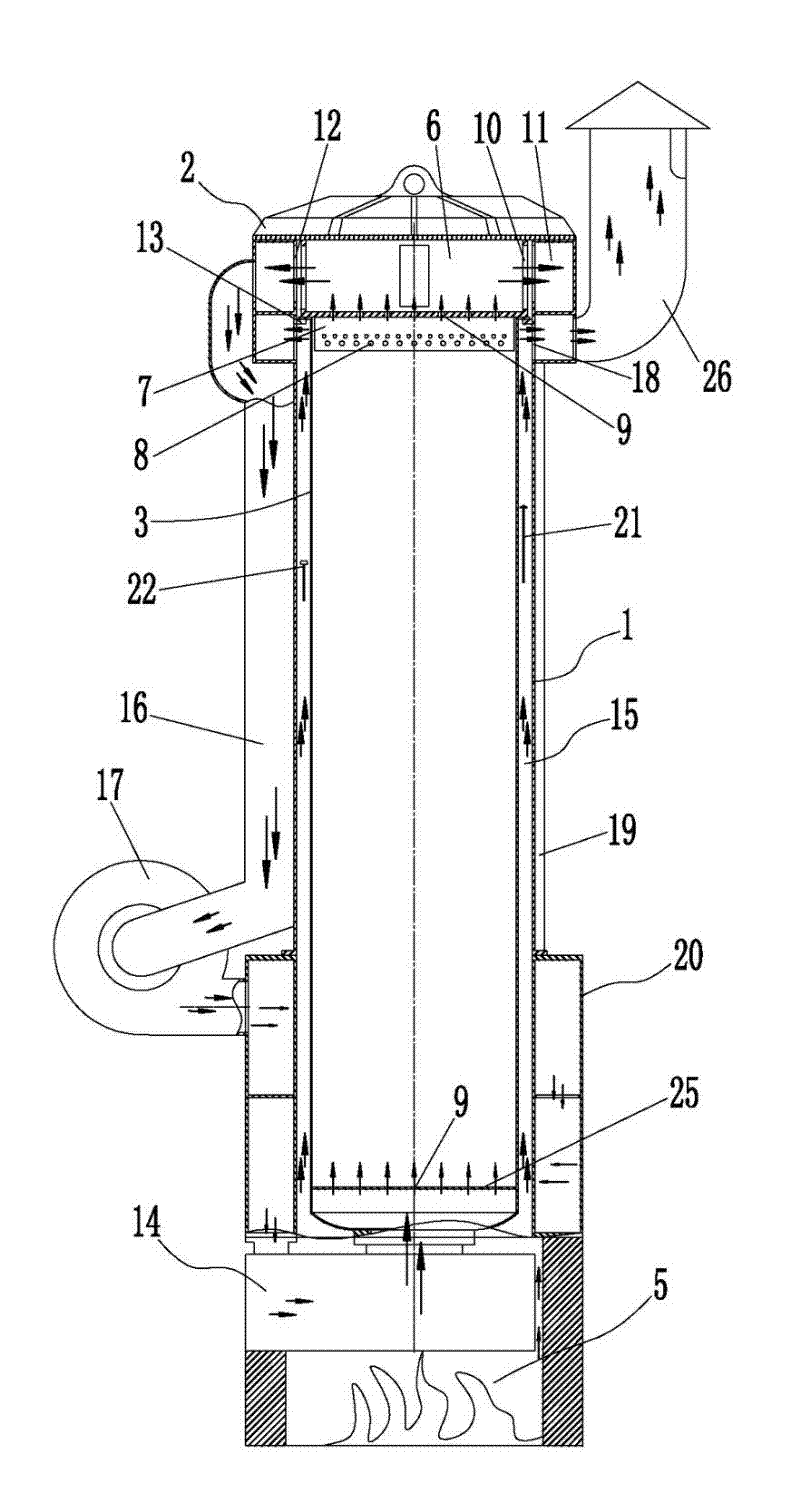

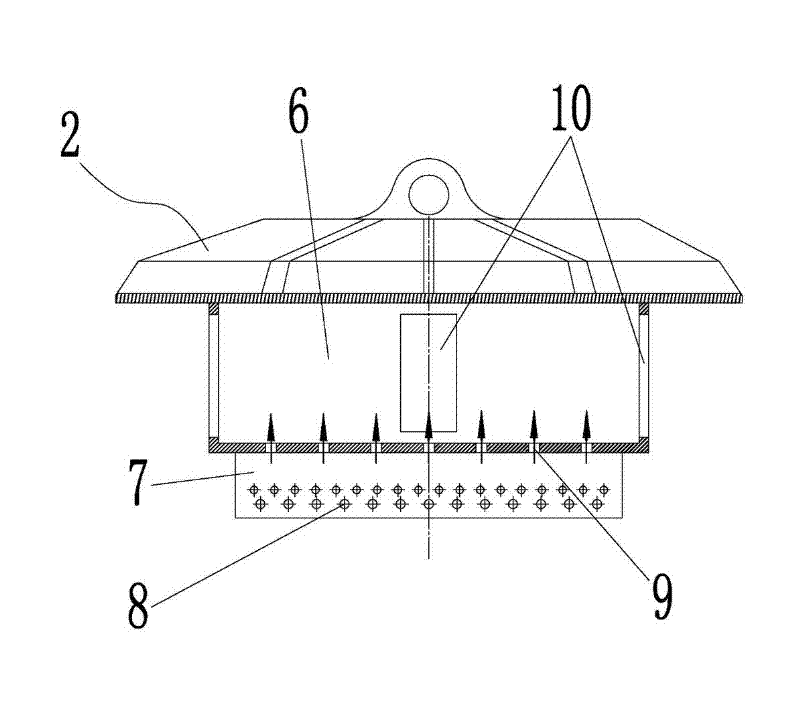

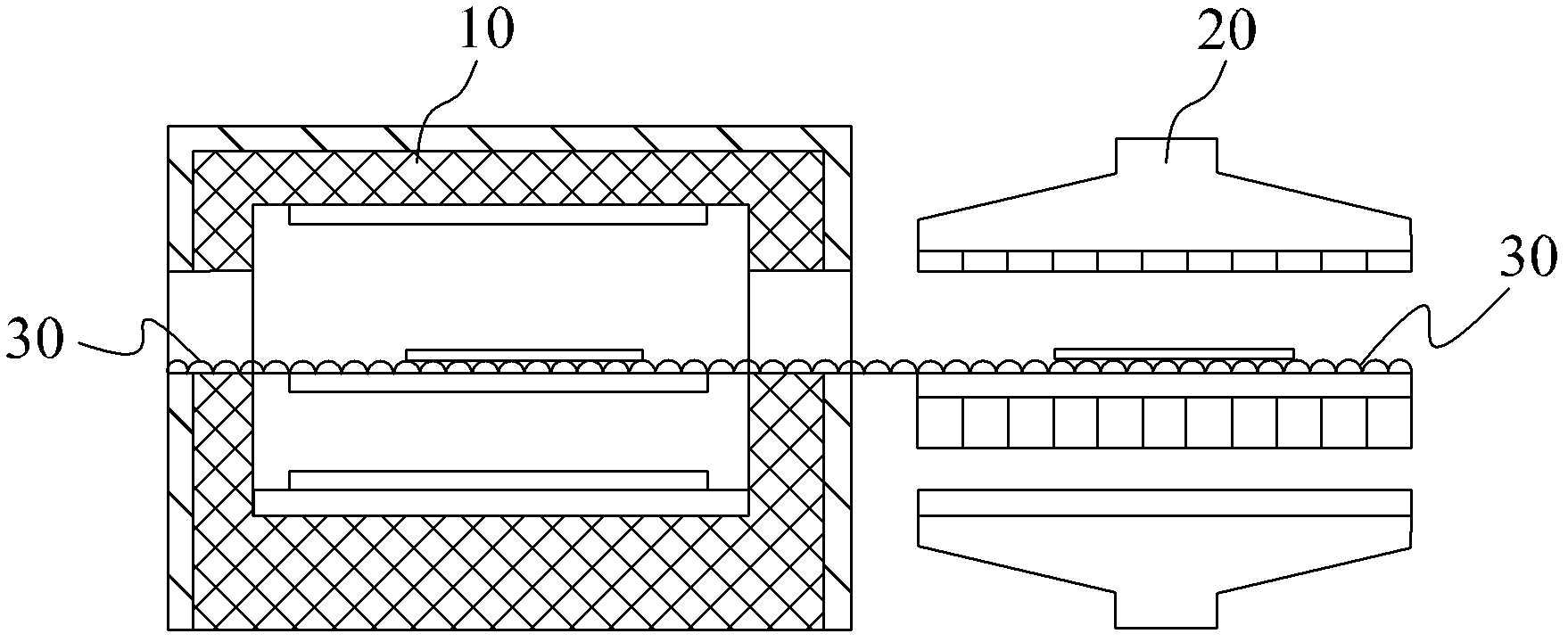

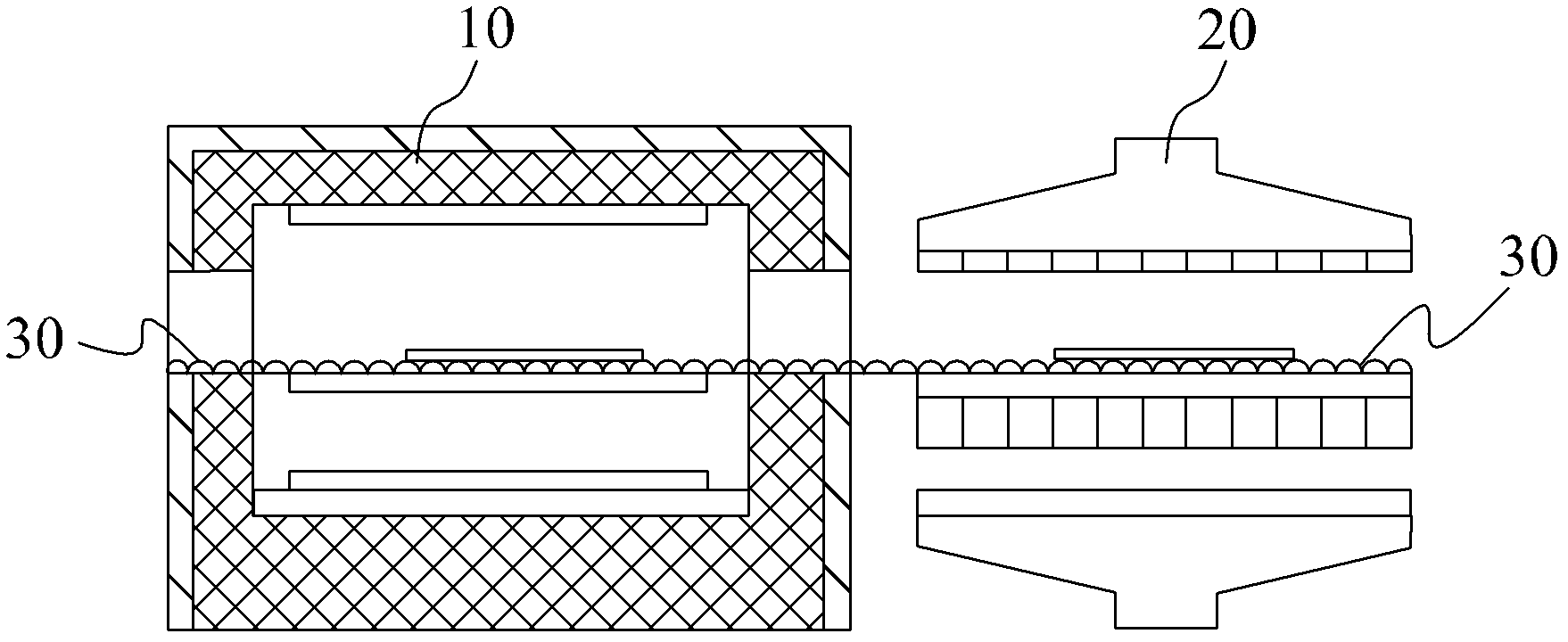

Tempering Furnace

ActiveCN102213544AEasy to control temperatureImprove tempering qualityVertical furnacesHearthEnergy conservation

The invention relates to a tempering furnace. The furnace comprises a furnace body, the top of which is provided with a furnace cover, an inner container is arranged in the furnace body, an air circulating and heating device is arranged on the furnace body, and a hearth is arranged at the bottom end of the furnace body. By properly arranging the furnace cover, the inner container, the air circulating and heating device and the like, the tempering furnace provided by the invention achieves omidirectional tempering of a workpiece which is suspended below the furnace cover by the process of uniformly heating, cycling and preheating the gas in the furnace, thus avoiding tempering blind spot in the furnace, obviously decreasing the temperature deviation in the furnace, and effectively improving the tempering quality of the workpiece in the furnace. Moreover, the tempering furnace maximally utilizes the heat created by burning the fuel, and further improves the furnace tempering effect. The tempering furnace of the invention has the advantages of reasonable and simple structure, low production cost, simplicity of operation, convenience of maintenance, high efficiency and energy conservation, and is suitable for popularization.

Owner:LISHUI HUAYI AUTOMATION TECH

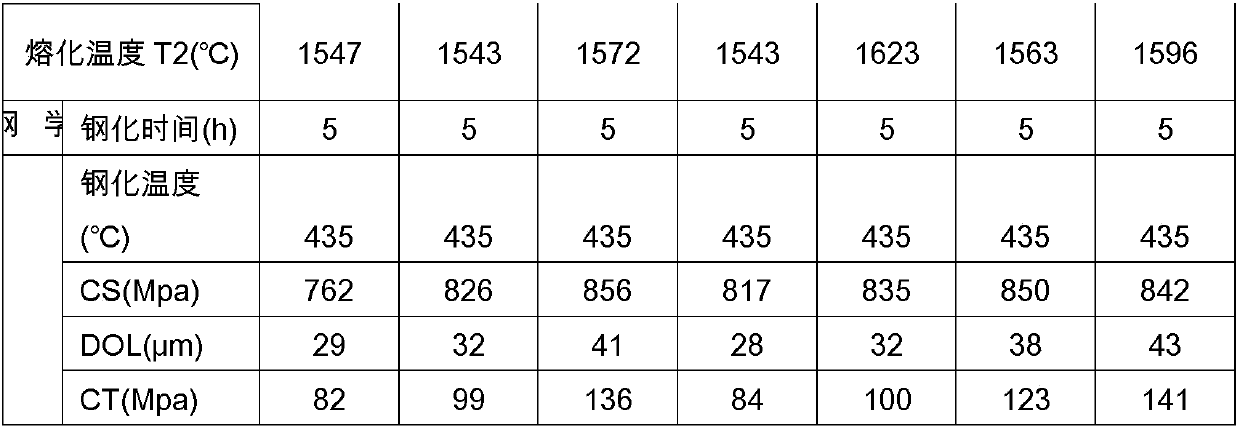

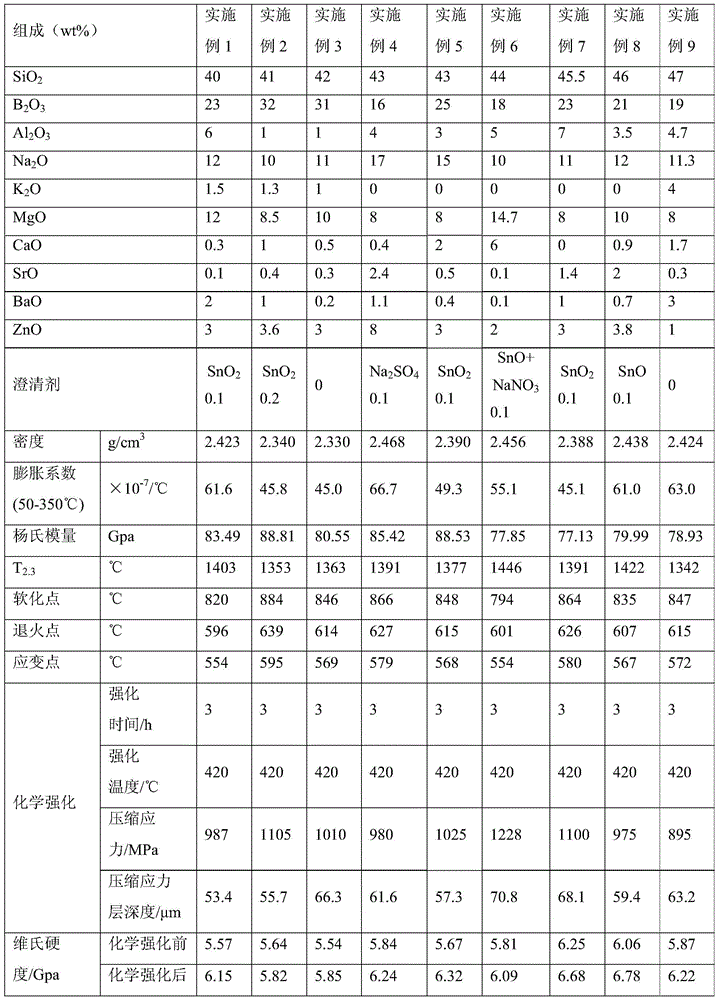

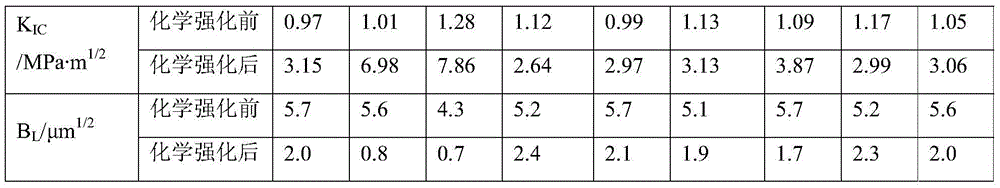

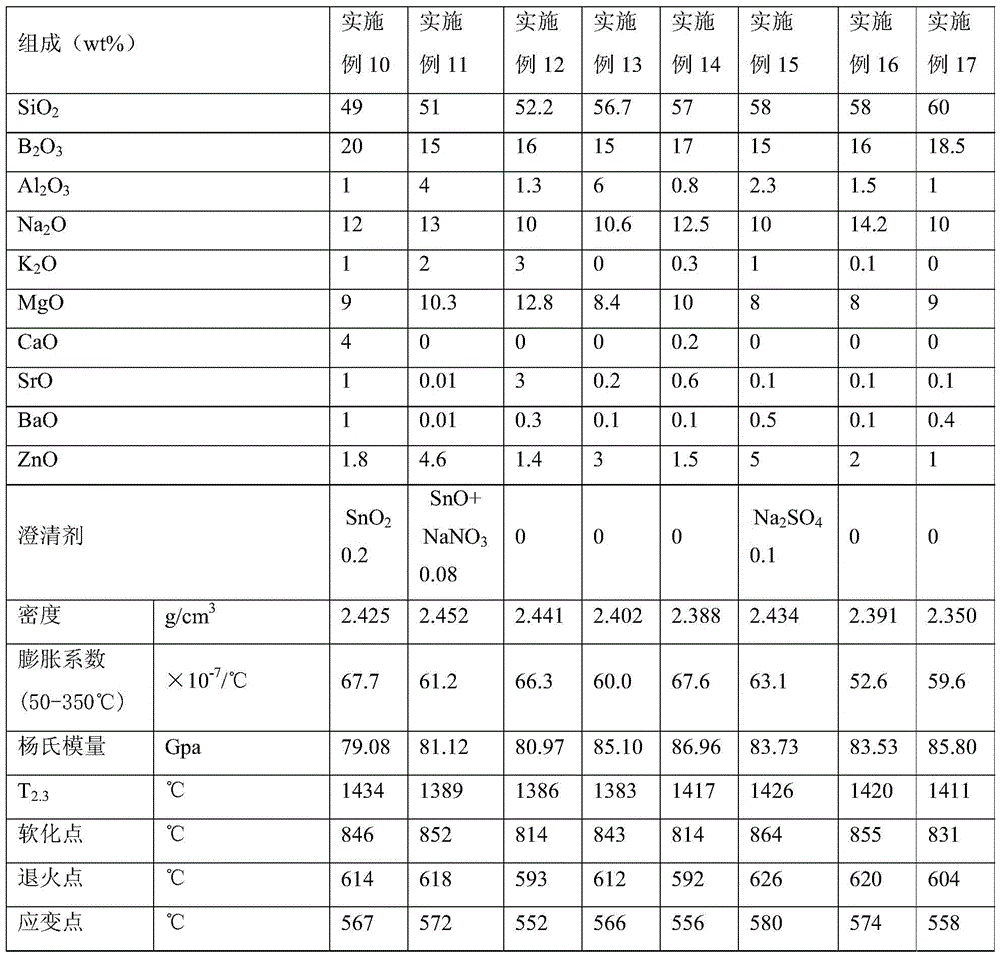

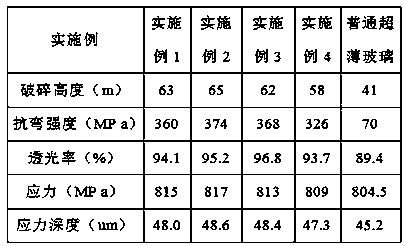

Composition for glass, chemically strengthened glass with low brittleness, and preparation method and application of chemically strengthened glass with low brittleness

The invention relates to the glass field, and discloses a composition for glass, chemically strengthened glass with low brittleness, a preparation method of the chemically strengthened glass with low brittleness and application of the chemically strengthened glass with low brittleness. The composition is prepared from the following components in percent by weight: 40 weight percent to 60 weight percent of SiO2, 15 weight percent to 35 weight percent of B2O3, 1 weight percent to 7 weight percent of Al2O3, 10 weight percent to 17 weight percent of Na2O, 0 to 4 weight percent of K2O, 8 weight percent to 15 weight percent of MgO, 0 to 6 weight percent of CaO, 0.01 weight percent to 3 weight percent of SrO, 0.01 weight percent to 3 weight percent of BaO and 1 weight percent to 8 weight percent of ZnO. The glass prepared according to the preparation method disclosed by the invention has the advantages of good toughening effect, higher strain point, higher modulus of elasticity, lower melting temperature, higher coefficient of thermal expansion, lower brittleness, excellent strength, excellent toughness, suitability for large-scale industrial production, compatibility for PDP (Plasma Display Panel) substrate production and capability of solving the PDP glass waste recycling problem.

Owner:WUHU DONGXU OPTOELECTRONICS EQUIP TECH +2

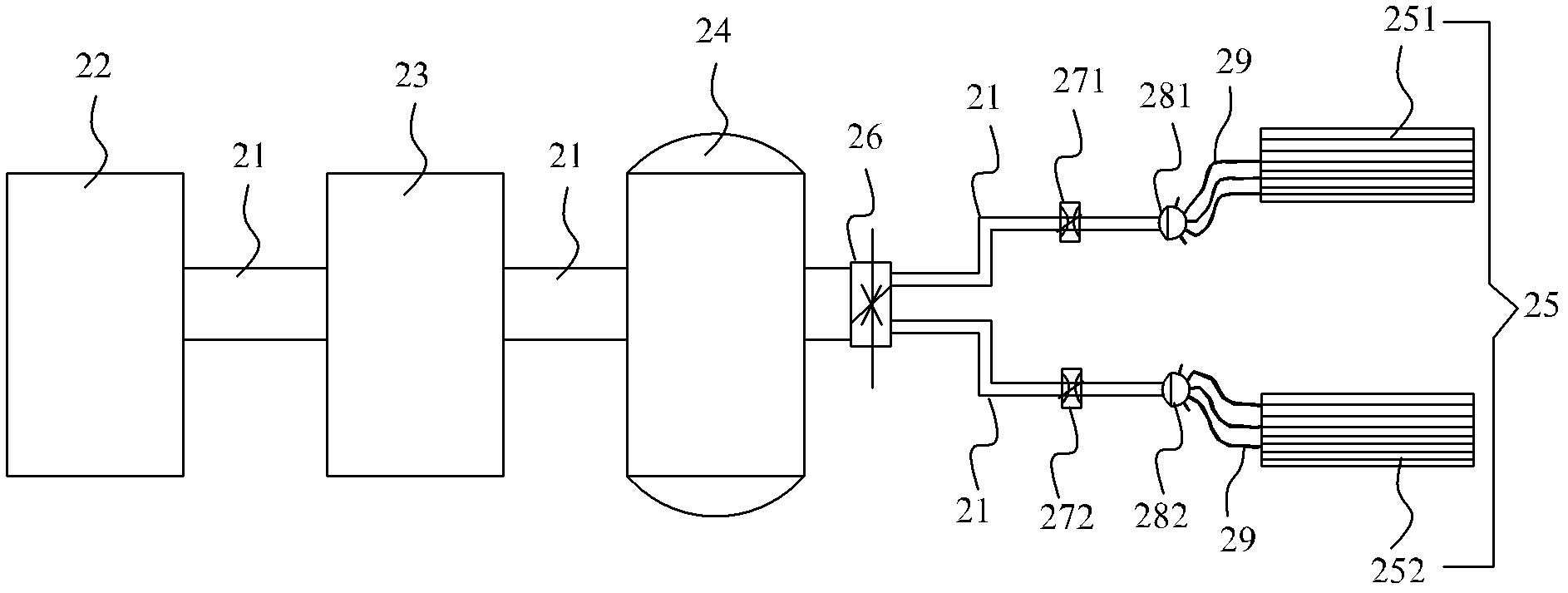

Device and method for producing toughened glass

ActiveCN102603175AImprove efficiencyReduce power consumptionGlass tempering apparatusCold airLow noise

The invention discloses a device for producing toughened glass, comprising a heating device, a toughening device and a roller way device connected between the heating device and the toughening device. The toughening device comprises a screw air compressor, an air filter, an air tank and a quenching cold air grid sequentially connected by an air supply pipeline. The invention also discloses a method for producing toughened glass by utilizing the device above. the device and the method can be used for completely toughening ultra-thin glass with the thickness of 2mm and have the advantages of low energy consumption, low noise, and the like.

Owner:GUANGDONG SHUNDE TIMBERY TECH GLASS

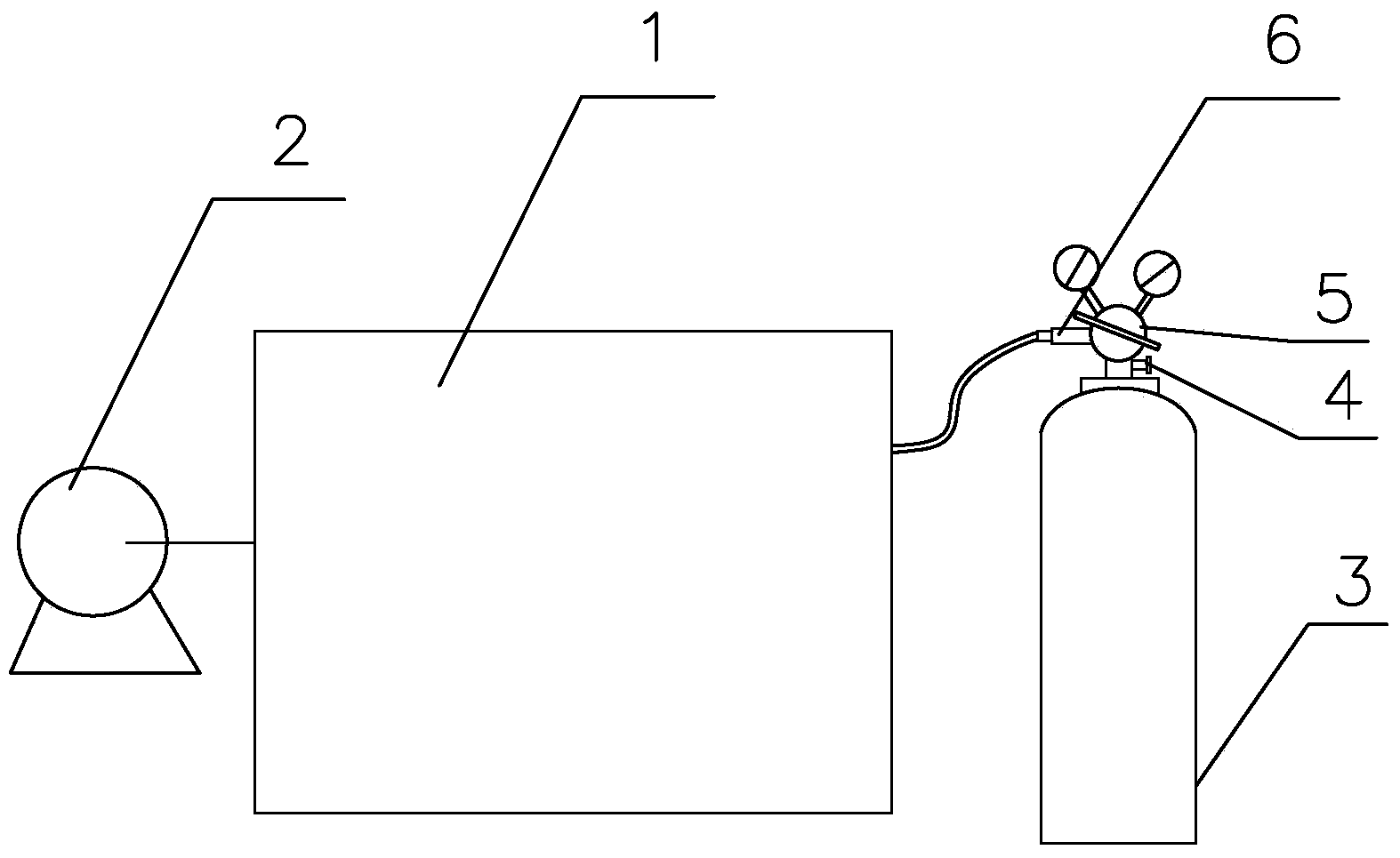

Modified tempering furnace and tempering method

InactiveCN104313257AWon't breakPrevent oxidationFurnace typesHeat treatment furnacesVacuum extractorOxygen

The invention discloses a tempering method. The tempering method comprises the following steps: additionally mounting a vacuum extractor and an inert gas charging device on a common tempering furnace, and tempering and cooling a workpiece under a protective atmosphere, so as to prevent that the workpiece is oxidized by the oxygen in the air at high temperature, further obviously prolong the service life of the workpiece, and lower the production cost.

Owner:KUNSHAN YOUTEWEI HEAT TREATMENT

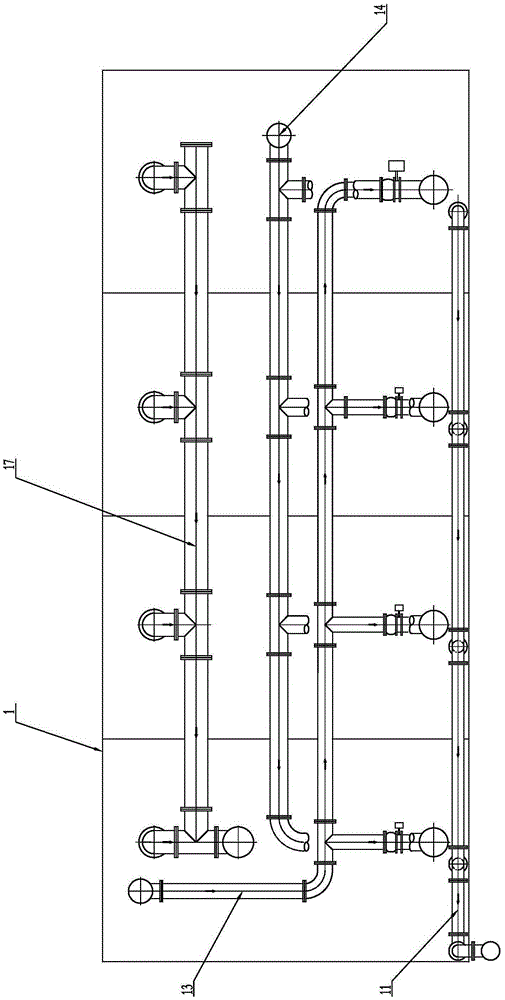

Ultra-thin glass chemical tempering equipment and tempering method

PendingCN110436764AGuaranteed to be fully temperedImprove performanceGlass tempering apparatusGlass productionMolten saltGlass-ceramic

The invention provides ultra-thin glass chemical tempering equipment and a tempering method. According to the tempering equipment, the height of the bottom end of a set glass-ceramic part is lower than the height of the top end of a slot frame, in the actual production process, the bottom end of the glass-ceramic part is immersed in a molten salt solution, an ultra-thin glass part capable of beingcompletely immersed into the molten salt solution, thus complete tempering of the ultra-thin glass part is guaranteed, chemical toughening is even, and the toughening performance and yield of an ultra-thin glass product are improved; moreover, the set slot frame uses materials of stainless steel products, the surface of the slot frame is sprayed and treated with Al2O3 to prevent the slot frame from being oxidized by tempered molten salt, the quality of the molten salt solution is guaranteed, in the process of tempering, the surface of a glass is prevented from being polluted by stain ion of astainless steel support, and thus the effect of tempering is improved; in addition, the equipment is compact in the structure and reasonable in design, the production of high quality tempered ultra-thin glass products can be ensured, and the equipment is suitable for promotion and use in the field of ultra-thin glasses.

Owner:QINHUANGDAO GLASS IND RES & DESIGN INST

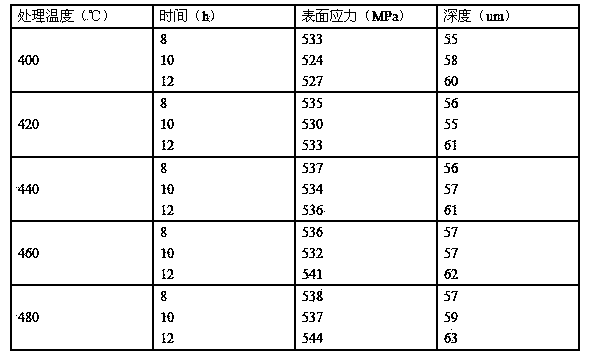

Ultra-thin electronic touch screen glass and processing technology thereof

The invention discloses ultra-thin electronic touch screen glass and a processing technology thereof. The ultra-thin electronic touch screen glass is prepared from the following components: silicon dioxide, aluminum oxide, a first additive, a fused salt treating agent and the like, wherein the first additive is used for improving the properties and ingredients of a glass substrate, the structure of the glass substrate is also optimized while the thermal property and chemical stability are improved, and the ion exchange effect is improved; and the fused salt treating agent is selected from a multiple-component fused salt blending system, the thermal decomposition temperature is increased, and the influence of nitrite ions is lowered. According to the ultra-thin electronic touch screen glassand the processing technology thereof, component proportion is reasonable in design, a preparation technology is optimized, the touch screen glass is prepared, the surface pressure stress value of the glass substrate is increased, anti-folding strength of the glass substrate is improved, meanwhile, the time required by chemical tempering is shortened, the production efficiency is improved, the cost is lowered, and the high practicality is achieved.

Owner:管伟

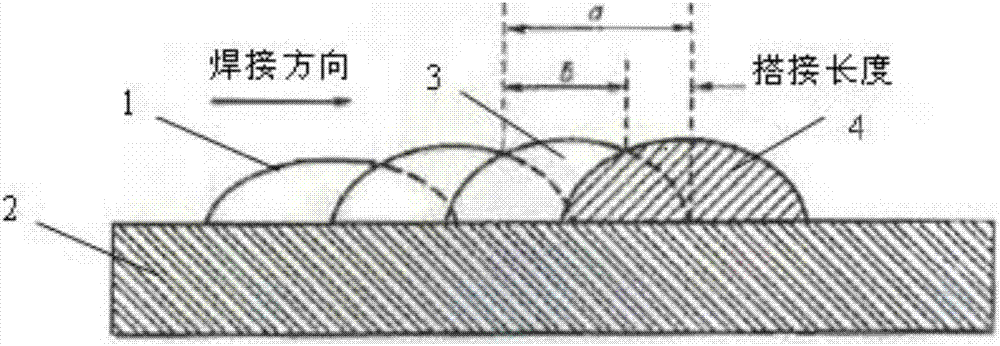

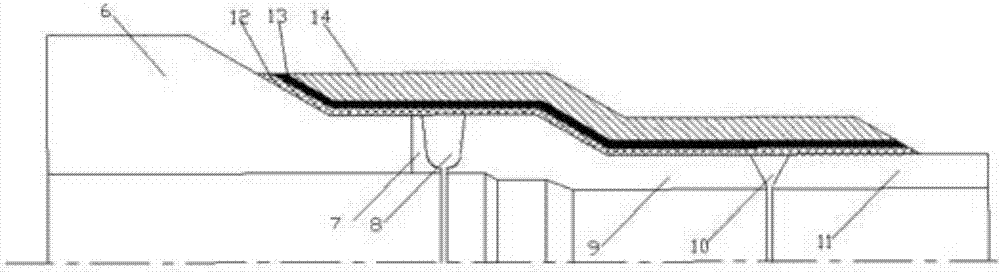

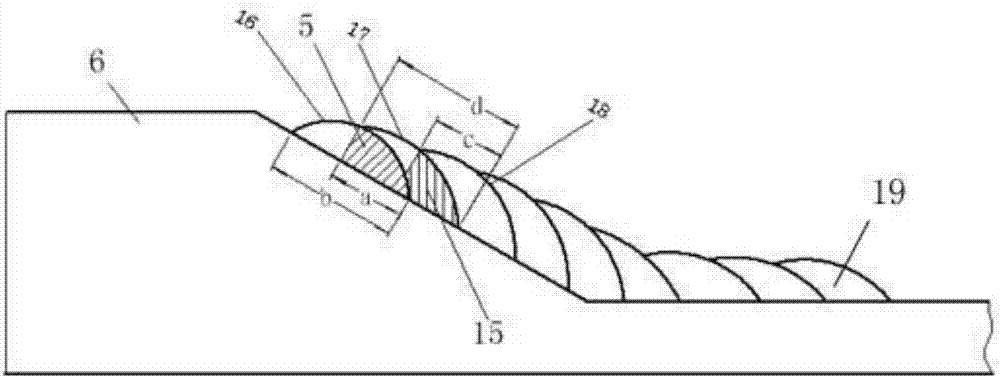

Automatic tempering surfacing welding method for pipeline maintenance

ActiveCN107186317AImprove organizationImprove performanceArc welding apparatusTubular articlesHeat-affected zoneNuclear power

The invention discloses an automatic tempering surfacing welding method for pipeline maintenance. The method comprises the steps of 1, tempering surfacing welding layer welding, wherein a tempering surfacing welding layer is welded to the ring surface of a to-be-maintained pipeline of a dissimilar metal joint, and in the tempering surfacing welding layer welding process, welding is conducted in a layer welding manner, and then a bead overlapping manner is adopted for welding; 2, transition surfacing welding layer welding, wherein a transition surfacing welding layer is welded to the tempering surfacing welding layer in a surfacing welding manner; 3, reinforcing tempering welding bead welding, wherein tempering welding is conducted on the two ends of the tempering surfacing welding layer and the two ends of the transition surfacing welding layer; and 4, polishing, wherein after welding is completed, reinforcing welding seams are polished to required sizes. On the one hand, structure and performance of a heat-affected zone on the low alloy steel side of the dissimilar metal joint of a nuclear power device can be effectively improved, and postweld heat treatment is not conducted after surfacing welding maintenance is conducted; on the other hand, according to the designed reinforcing welding seam structure form, not only can the tempering effect of the two ends of a workpiece be improved, but also the polishing working load of completed welding seams is effectively reduced.

Owner:NUCLEAR POWER INSTITUTE OF CHINA

Conditioning material for preparation of mineral wool from thermal blast furnace slag and preparation method thereof

The invention discloses a conditioning material for preparation of mineral wool from thermal blast furnace slag and a preparation method thereof. The conditioning material for preparation of mineral wool from thermal blast furnace slag is composed of the following raw materials by mass: 30-80% of nepheline, 5-40% of fly ash, 2-10% of Cr2O3, and 5-20% of NaNO3. The preparation method of the conditioning material for preparation of mineral wool from thermal blast furnace slag sequentially includes the steps of: (1) weighing nepheline and fly ash according to mass percentage, and fully mixing them to obtain a mixture A; then weighing Cr2O3 and NaNO3 according to mass percentage, and fully mixing them to obtain a mixture B; and (2) weighing the mixture A and mixture B according to mass percentage, and fully mixing them to obtain the conditioning material for preparation of mineral wool from thermal blast furnace slag. The conditioning material provided by the invention has the advantages of low cost, easily available raw materials and easy processing, and significant conditioning effect. The prepared granulated wool has the characteristics of good high temperature melt glassy state, high fiber forming rate, good quality of formed fiber, and adjustable acidity coefficient.

Owner:宝钢矿棉科技(宁波)有限公司

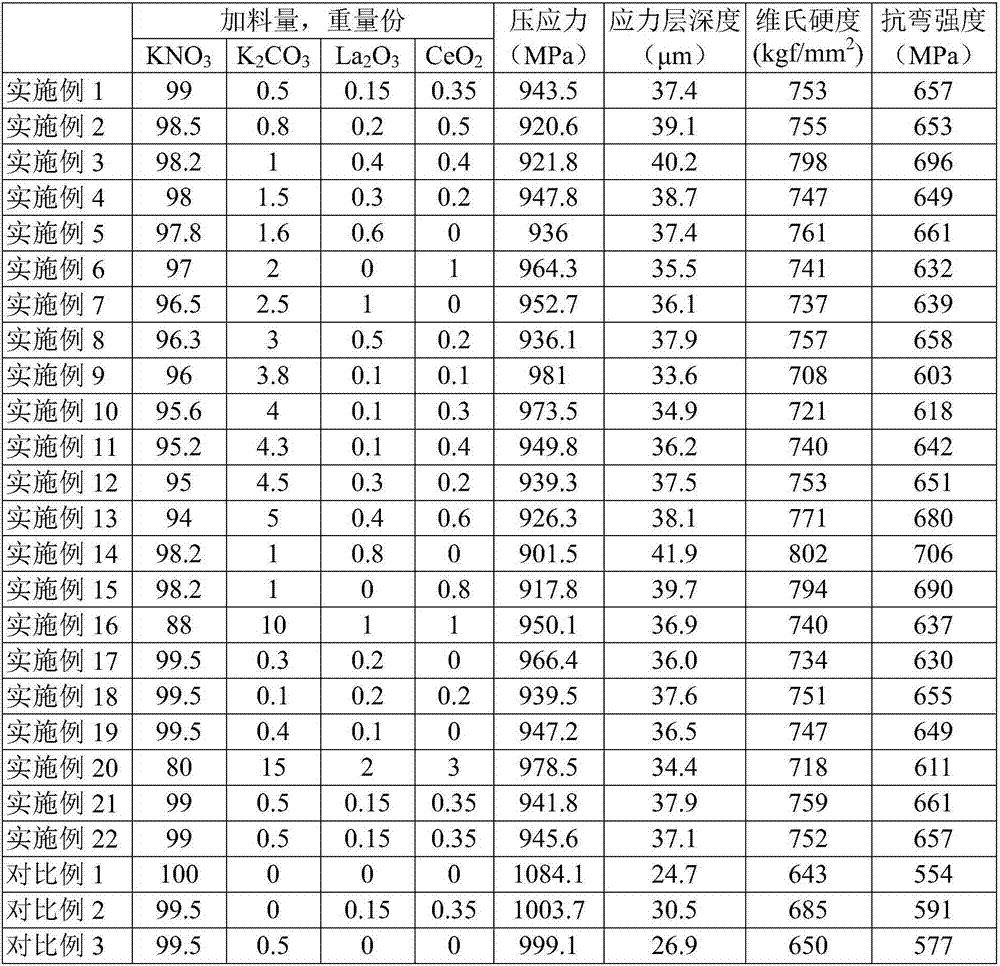

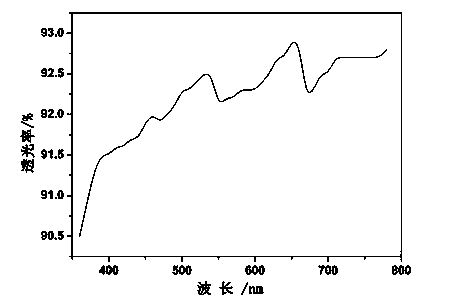

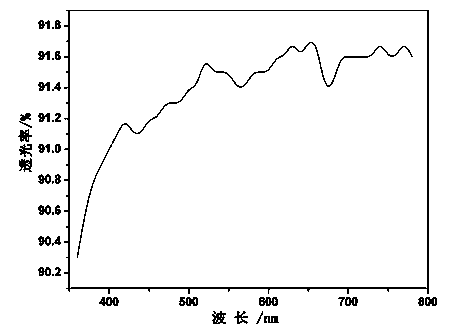

Ion exchange molten salt composition, and tempered cover plate glass and tempering method thereof

ActiveCN107365064AHigh hardnessImprove flexural strengthGlass tempering apparatusRare earthIon exchange

The present invention relates to the technical field of cover plate glass strengthening treatment, and discloses an ion exchange molten salt composition, and a tempered cover plate glass and a tempering method thereof. The ion exchange molten salt composition contains, by weight, 80-99.5% of KNO3, 0.1-15% of K2CO3, and 0.1-5% of a rare earth oxide. The tempering method comprises: heating the ion exchange molten salt composition to melt so as to obtain a molten liquid, and carrying out ion exchange on a cover plate glass to be tempered in the obtained molten liquid. With the method of the present invention, the tempering effect can be significantly improved, and the tempered cover plate glass with advantages of high hardness and high bending strength can be obtained.

Owner:DONGXU OPTOELECTRONICS TECH CO LTD

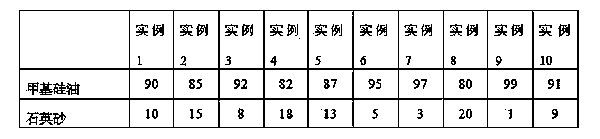

Method for toughening alkali-free aluminoborosilicate ultrathin substrate glass

ActiveCN104211291AUniform stress distributionHigh impact strengthGlass tempering apparatusGlass productionMethyl siliconeToughened glass

The invention discloses a method for toughening alkali-free aluminoborosilicate ultrathin substrate glass. The method is used to toughen the substrate glass after the annealing technology, and is characterized by comprising the following steps: step A, cutting the annealed substrate glass according to the design requirements, polishing the edges of the cut substrate glass, washing, drying, and placing the substrate glass on a sample rack for later use; step B, pushing the substrate glass on the sample rack into an electric oven with a temperature of 700 to 750 DEG C, and maintaining the temperature for 3 to 30 minutes; step C, soaking the substrate glass into a methyl silicone oil toughening liquid with a temperature of 50 to 350 DEG C, and taking out the substrate glass when the temperature of the toughening liquid falls to 50 DEG C or less; step D, washing the substrate glass surface, and finally drying so as to obtain the toughened glass. Methyl silicone oil is taken as the toughening liquid and the cooling liquid, no other additive is added, the preparation technology is simple, and the toughened glass prepared by the provided toughening method has the advantages of high strength, low cost, and high qualified rate.

Owner:北京远大信达科技有限公司

Method and additive capable of accelerating clarification and impurity removal of molten potassium nitrate solution

ActiveCN104909392AImprove adsorption capacityGood clarificationAlkali metal nitrate purificationFlexural strengthAntimony trioxide

The invention provides a method capable of accelerating clarification and impurity removal of a molten potassium nitrate solution. The method comprises the following steps: 1) selecting potassium nitrate, potassium carbonate, alpha-phase silica, beta-phase alumina and antimonous oxide; 2) heating potassium nitrate to a temperature above melting temperature so as to melt potassium nitrate; 3) adding potassium carbonate and antimonous oxide into the fused potassium nitrate molten salt and carrying out stirring; 4) adding alpha-phase silica and beta-phase alumina into the molten salt prepared in the step 3) and carrying out stirring; and 5) subjecting the molten salt to heat preservation and standing for more than 10 hours, wherein tempering can be carried out upon clarification of the solution. The additive provided by the invention can rapidly remove harmful impurities in sylvite, effectively shortens clarification time of the potassium nitrate molten salt, reduces the ion concentrations of harmful impurities in the potassium nitrate molten salt, improves surface stress, stress layer depth and bending strength of chemically-toughened glass and lowers production cost.

Owner:WUHAN UNIV OF TECH

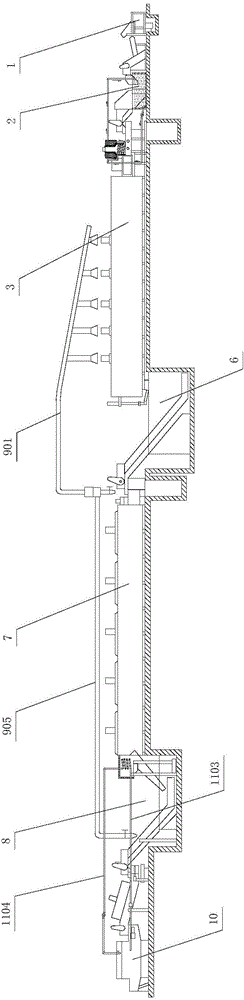

Heat circulation trolley furnace

PendingCN107619910AImprove sealingHeating evenlyMaintainance of heating chambersFurnace typesElectricityInverted u

The invention relates to the technical field of heat treatment equipment, in particular to a heat circulation trolley furnace. The heat circulation trolley furnace includes a trolley, a furnace shell,a liner, a plurality of heating pipes, a hot air circulation device, an electric sealing device, a furnace door and a lifting mechanism. A diversion cover is an inverted-U-shaped diversion cover arranged in the opening direction of an annealing furnace. A return wind channel is formed between the diversion cover and the liner. A return wind opening is formed between the lower side of the diversion cover and a heat insulating bottom liner. A wind inlet matched with a drainage cover is formed in the top of the diversion cover. The wind inlet is in sealed connection with a wind outlet of the drainage cover. A heating pipe is arranged in the vertical direction and arranged in the return wind channel. The electric sealing device seals the junction between the liner and the heat insulating bottom liner. The heat circulation trolley furnace uses the electric sealing device to seal the junction between the liner and the heat insulating bottom liner, the sealing effect is good, sealing is durable, and heating of the heat circulation trolley furnace is made to be more even.

Owner:JIANGSU HENGLI FURNACE IND

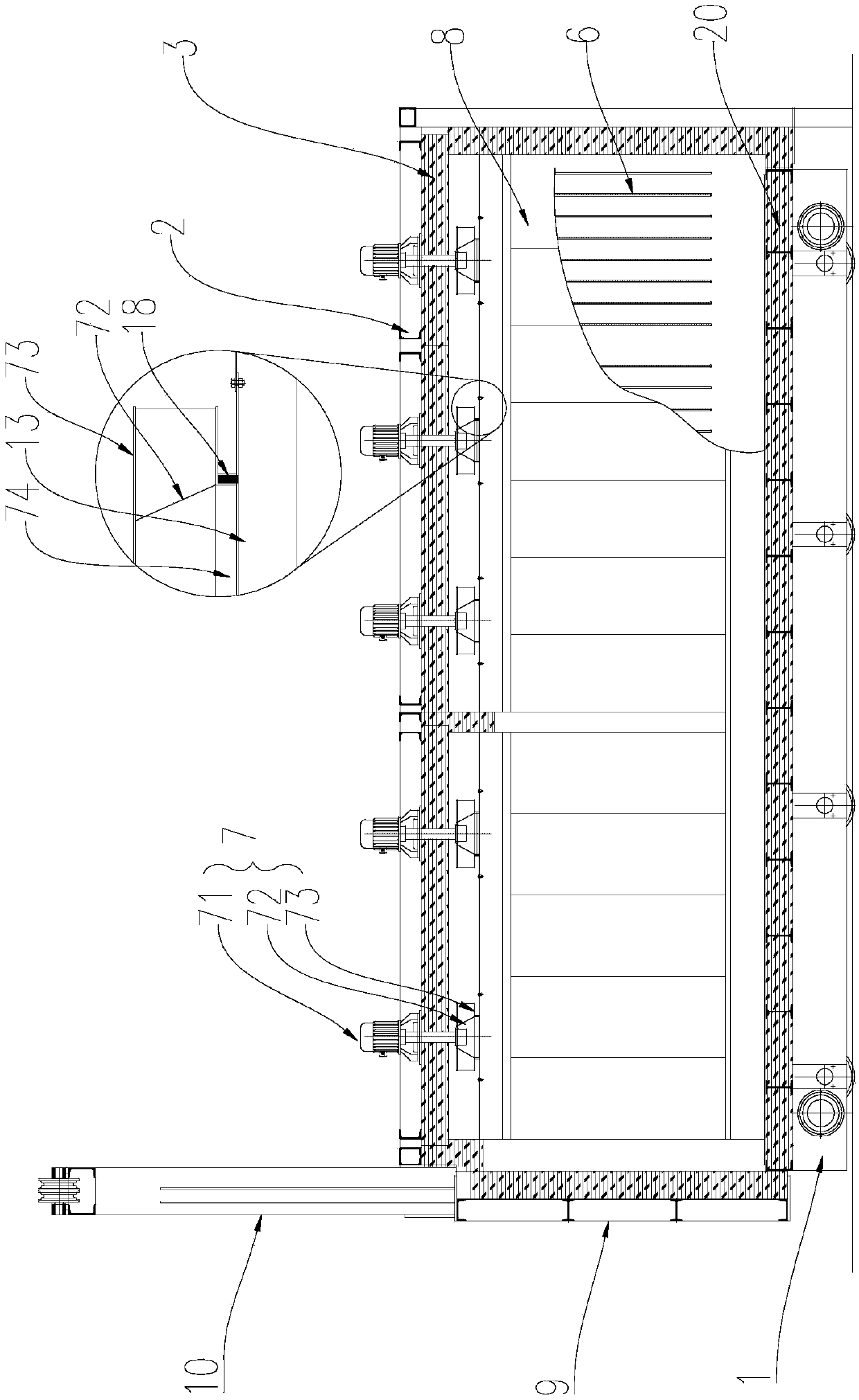

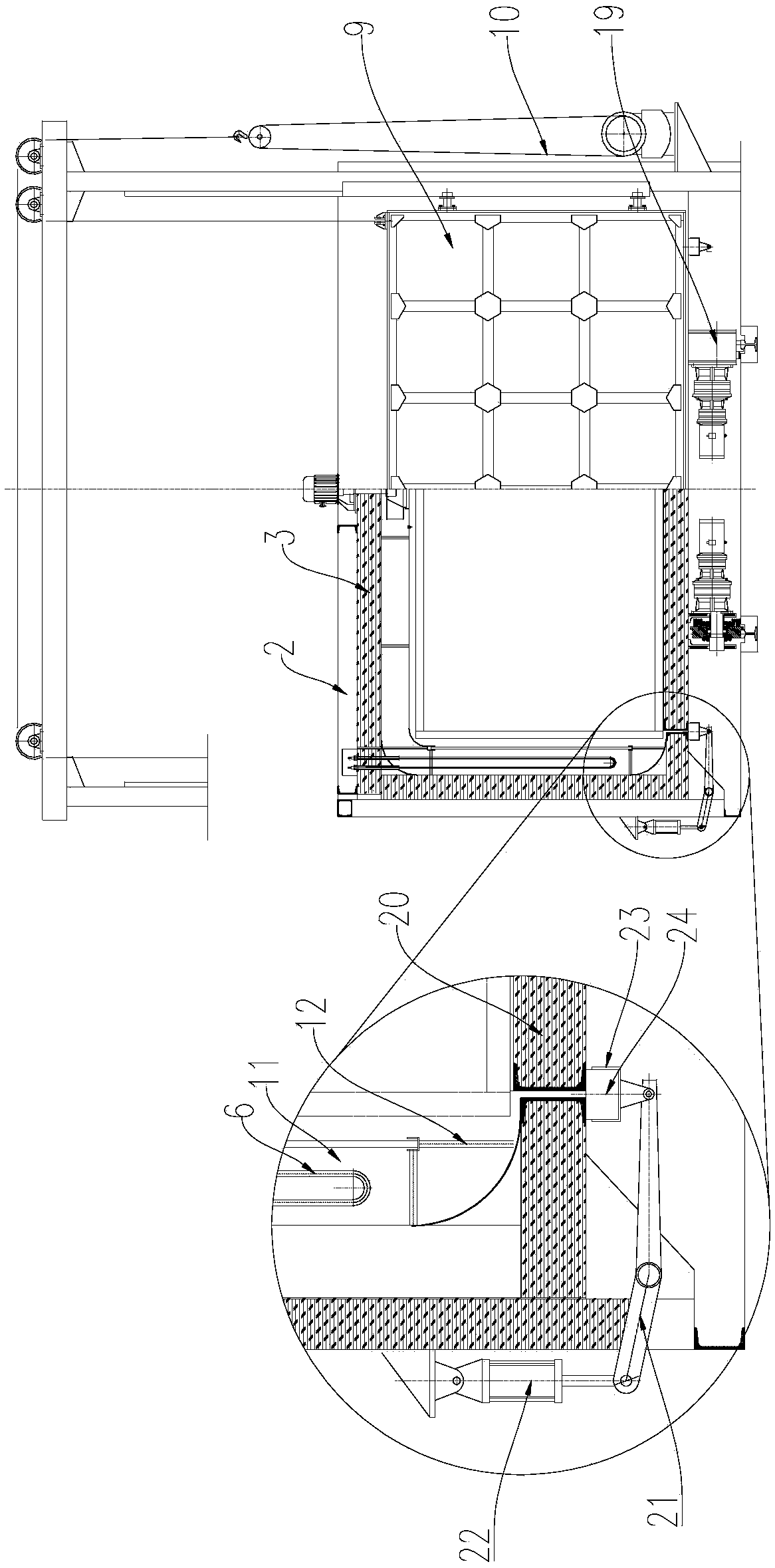

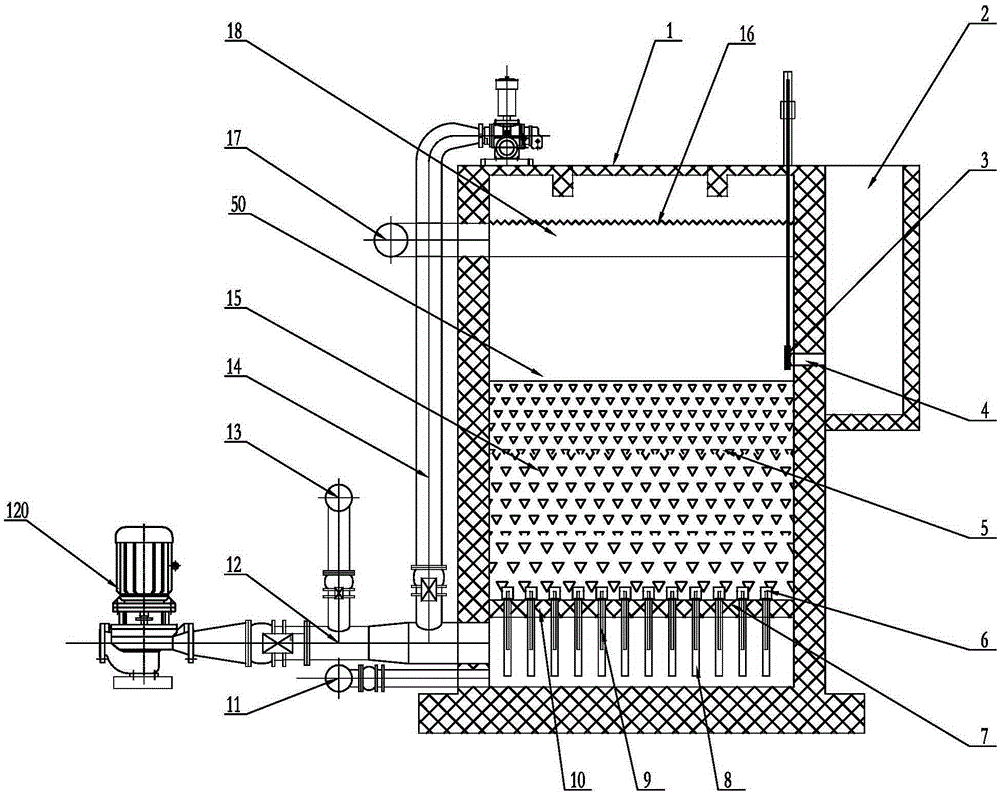

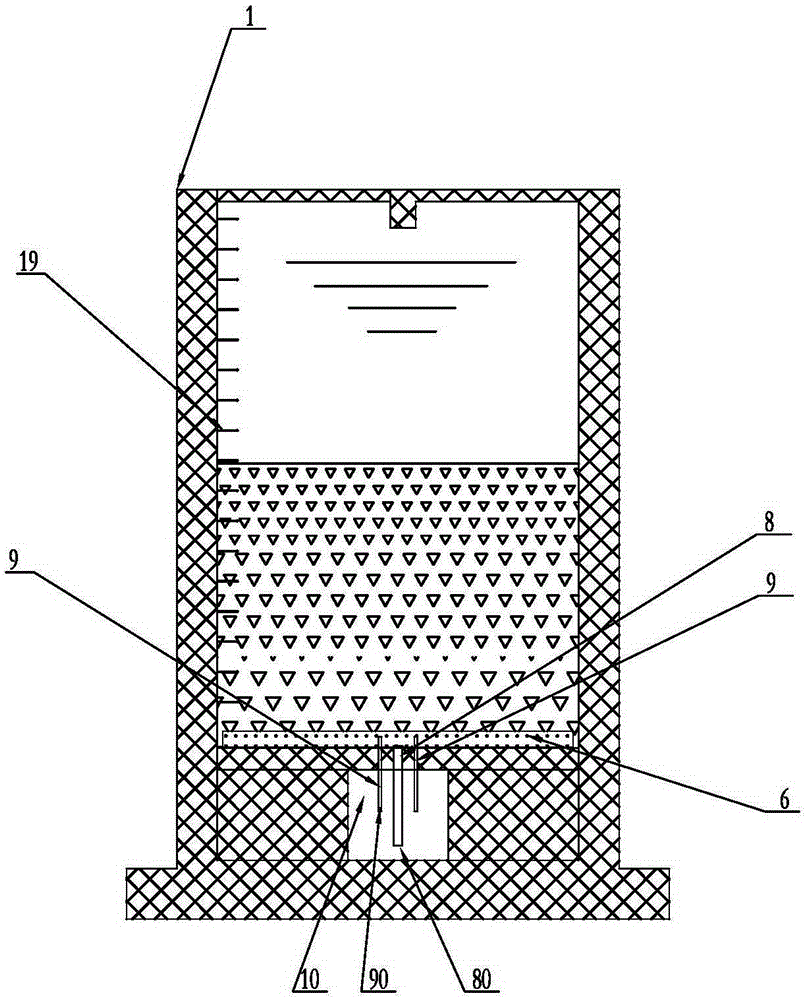

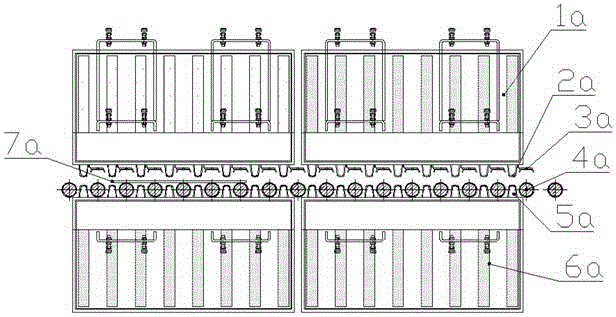

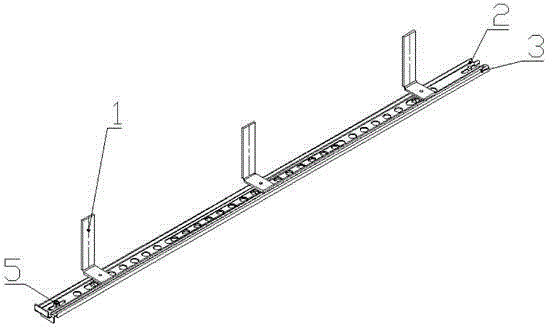

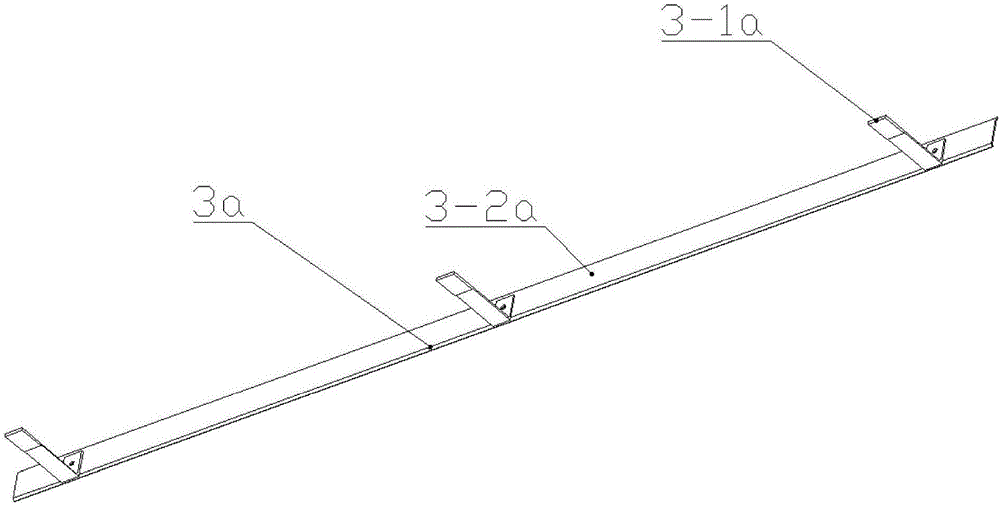

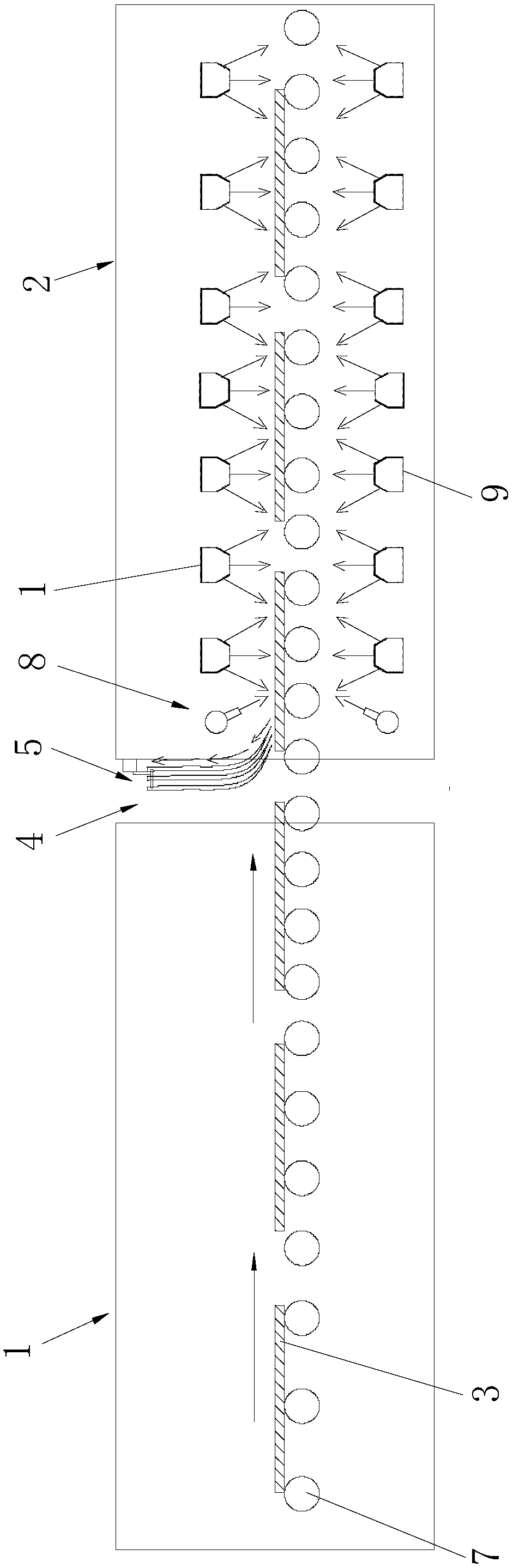

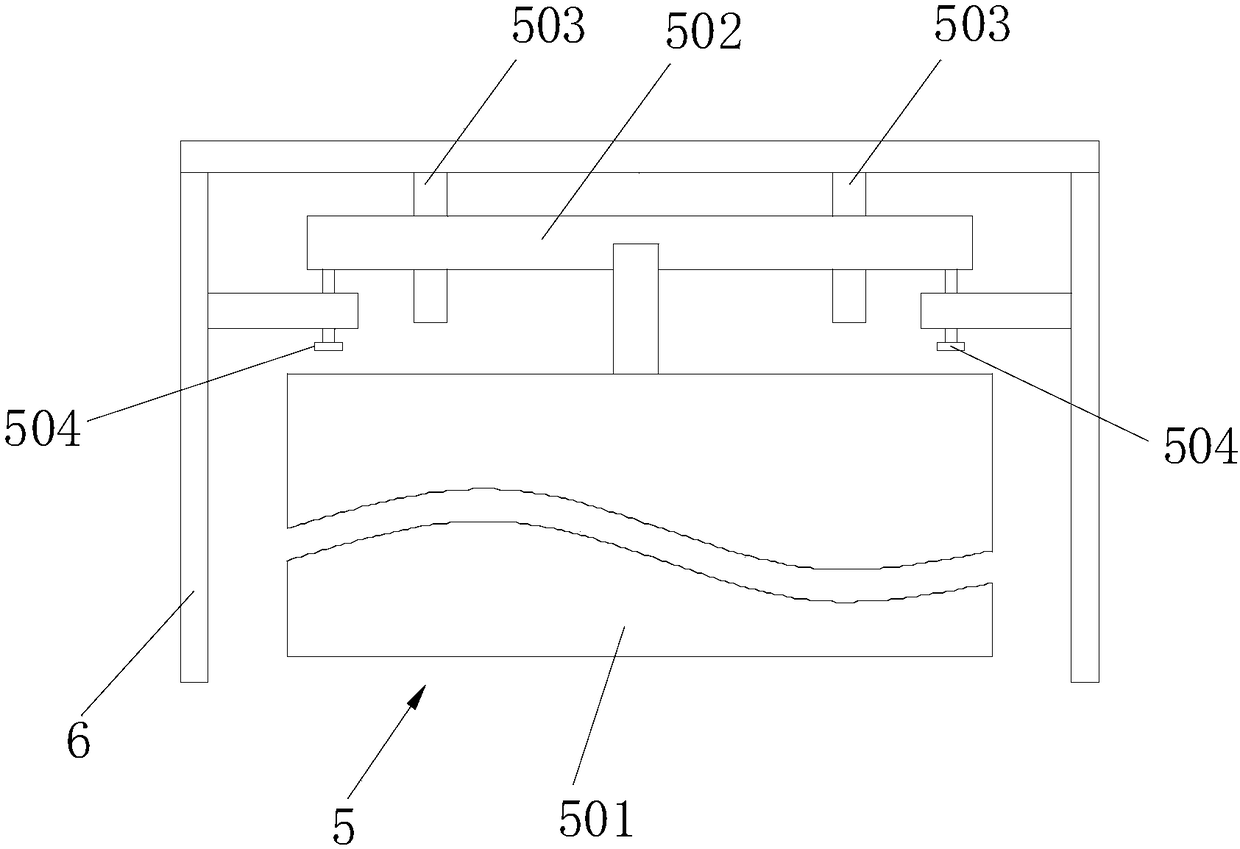

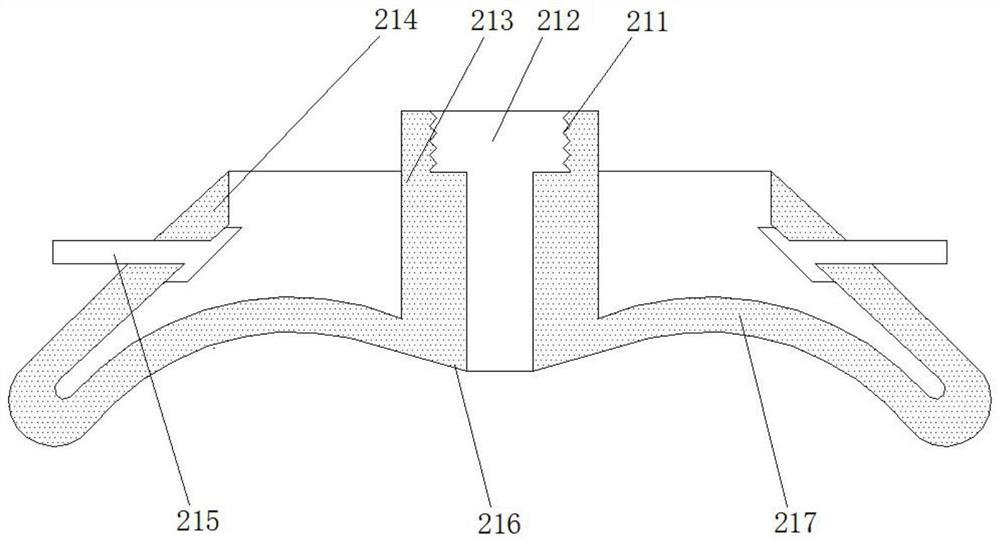

Shell padding hardening and tempering pond used for mineralization after seawater desalination

InactiveCN105293671AImprove reaction efficiencyImprove the tempering effectWater/sewage treatment by substance additionSocial benefitsInlet channel

The invention provides a shell padding hardening and tempering pond used for mineralization after seawater desalination. The pond comprises a shell padding hardening and tempering pond body, a flushing water outlet area, a shell padding hardening and tempering pond water outlet area, a water and gas inflow channel and a shell flushing water and gas inflow system. A water outlet of the shell padding hardening and tempering pond water outlet area is formed in the side, opposite to the flushing water outlet area, of the shell padding hardening and tempering pond body. A natural fragmentation shell padding bed is arranged in a shell padding hardening and tempering pond reaction area and arranged on a hardening and tempering pond bottom plate. A plurality of transverse water and gas distribution pipes are evenly arranged on the hardening and tempering pond bottom plate and are connected with vertical water distribution pipes and vertical gas distribution pipes to be communicated with a shell padding hardening and tempering pond water and gas inlet channel. According to the hardening and tempering pond, pollution-free natural fragmentation shells serve as padding, the hardening and tempering pond is obvious in economic performance, and hygienic safety is better than that of calcium ore. Shell waste is subjected to resource utilization, and the hardening and tempering pond has the economic benefits and social benefits of energy conservation and emission reduction.

Owner:POWERCHINA HUADONG ENG COPORATION LTD

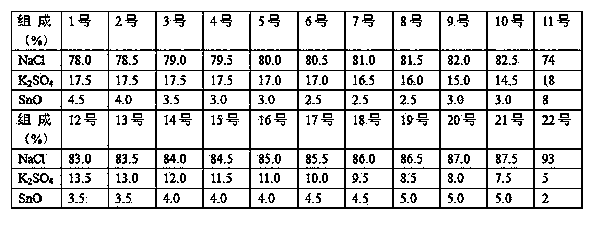

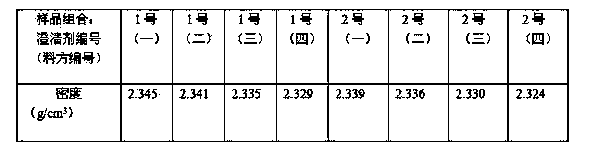

Composite clarifying used in production technology of contact screen cover plate glass

The invention discloses a composite clarifying agent, which is used in the production technology of a contact screen cover plate glass to eliminate the bubbles in molten glass. The clarifying agent is composed of a main material (NaCl) and two auxiliary materials (SnO and K2SO4), wherein the NaCl accounts for 74 to 93% of the total weight of the clarifying agent, SnO accounts for 2 to 8% of the total weight of the clarifying agent, and K2SO4 accounts for 5 to 18% of the total weight of the clarifying agent. The composite clarifying agent can guarantee the clarifying effect, and at the same time has the advantages of light weight and easiness for chemical toughening.

Owner:TUNGHSU GRP

Method for preparing high-borosilicate anti-explosion glass cover

ActiveCN110117156AImprove tempering effectMeet safety requirementsGlass furnace apparatusElectric furnaceBorosilicate glassRaw material

The invention discloses a method for preparing a high-borosilicate anti-explosion glass cover. The high-borosilicate anti-explosion glass cover is prepared from, by mass, 69.5%-73.5% of SiO2, 12.5%-17.5% of B2O3, 5.5%-9.5% of Na2O, 1.5%-4.5% of Al2O3, 0.01%-0.05% of Li2O, 0.1%-0.6% of K2O, 0.1%-0.6% of BaO, 0.1%-0.5% of ZnO and 0%-0.03% of Fe2O3 in cooperation with high-borosilicate glass raw materials. An electric melting furnace with the highest use temperature of 1800 DEG C is used as founding equipment of the high-borosilicate anti-explosion glass cover, the glass raw materials are converted into glass clear liquid, and the founding process of glass is completed through the processes of silicate forming, clarification, homogenizing and cooling; the finished glass is formed through a forming process and toughening treatment in combination with planeness treatment. The method has the advantages of being capable of meeting the quality requirement and safety requirement of explosion-proof glass and has wide development and application prospects.

Owner:绥中明晖工业技术有限公司

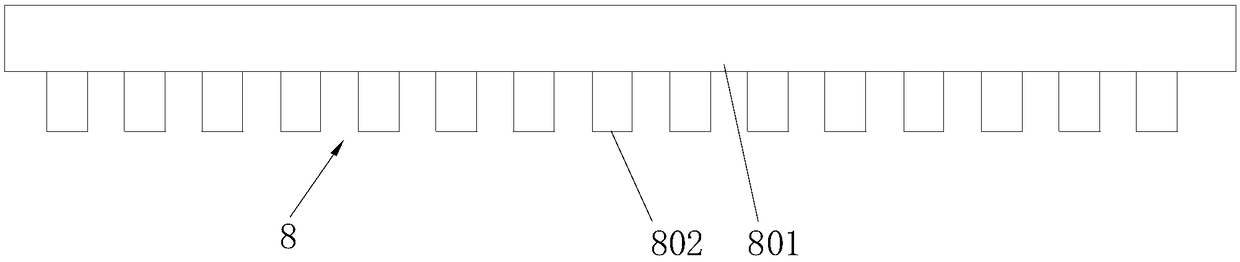

Adjustable air compressing device for quenching cold air grate of glass toughening furnace

The invention discloses an adjustable air compressing device for a quenching cold air grate of a glass toughening furnace. The adjustable air compressing device comprises a mounting plate and an air compressing mechanism, wherein the air compressing mechanism is connected with the mounting plate; the mounting plate is connected with an air grate; the air compressing mechanism comprises an air compressing plate and a first adjusting plate which are overlapped with each other; the air compressing plate and the first adjusting plate are connected through an adjustable connecting structure; the tightness of the adjustable connecting structure can be adjusted; the adjustable connecting structure can drive the air compressing plate and the first adjusting plate to relatively move along a length direction; a plurality of first air vents are arrayed on the air compressing plate along the length direction; a first long ventilating hole is formed in the middle of the first adjusting plate; first adjusting holes are formed at the two ends of the first adjusting plate; the arraying distance of the first adjusting holes is consistent to the arraying distance of the first air vents on the air compressing plate. Under the effect of the adjustable air compressing device disclosed by the invention, the upper surface of the processed glass can be uniformly cooled and the glass deformation is prevented, so that the glass quality is increased.

Owner:SOOS (GUANGDONG) GLASS TECH CO LTD

Tempering method of 2-mm glass

ActiveCN108483885AAvoid deformationImprove the tempering effectGlass tempering apparatusRoom temperatureHigh pressure

The invention relates to the technical field of glass production, in particular to a tempering method of 2-mm glass. The tempering method comprises the following steps: (1) sequentially increasing thetemperature of glass at a uniform speed through multiple heating intervals in a heating zone, wherein a temperature increasing curve of the glass is shown as follows: S1, the room temperature is increased to 300 DEG C within 0-30 s; S2, the temperature is continuously increased to 350-360 DEG C within 30-55 s; S3, the temperature is continuously increased to 400-420 DEG C within 55-75 s; S4, thetemperature is continuously increased to 550 DEG C within 75-90 s; S5, the temperature is continuously increased to 630 DEG C within 90-100 s; S6, the temperature is maintained to 630 DEG C within 100-105 s; (2) accelerating to pass through a vacancy zone between the heating zone and an air-cooling zone within 105-108 s and then entering the air-cooling zone; (3) performing high-pressure quenchingon all the glass and reducing the temperature from 630 DEG C to 150 DEG C within 1.5 s; (4) performing low-pressure cooling on the glass and continuously reducing the temperature to 90 DEG C within 10 s. By the adoption of the tempering method provided by the invention, a tempering effect is good, and the deformation of the 2-mm glass produced in the tempering process can be effectively avoided.

Owner:WUJIANG CSG GLASS CO LTD

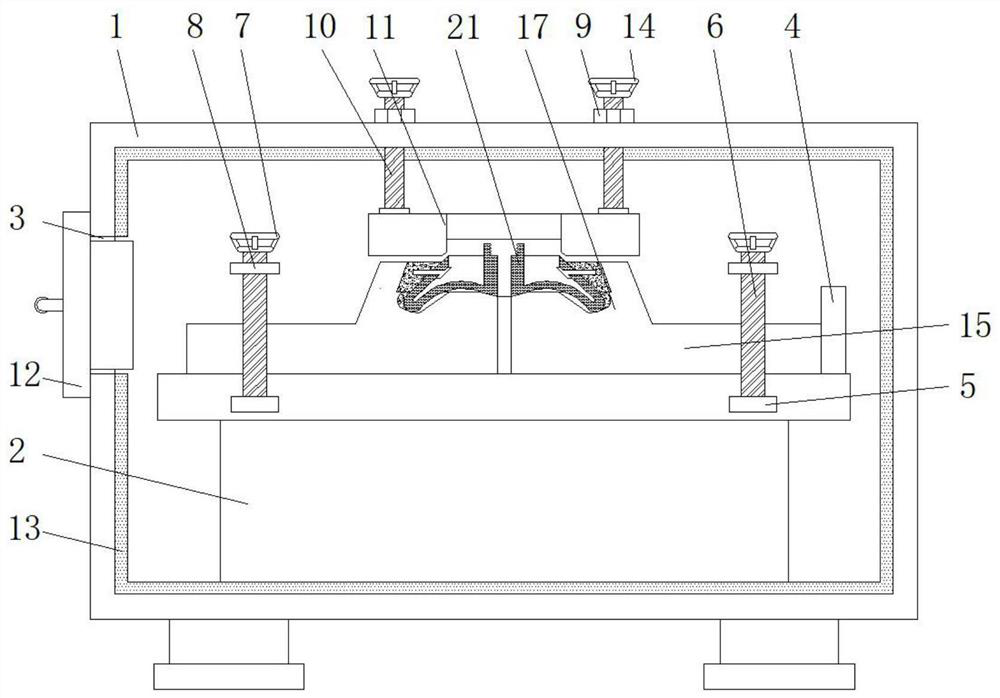

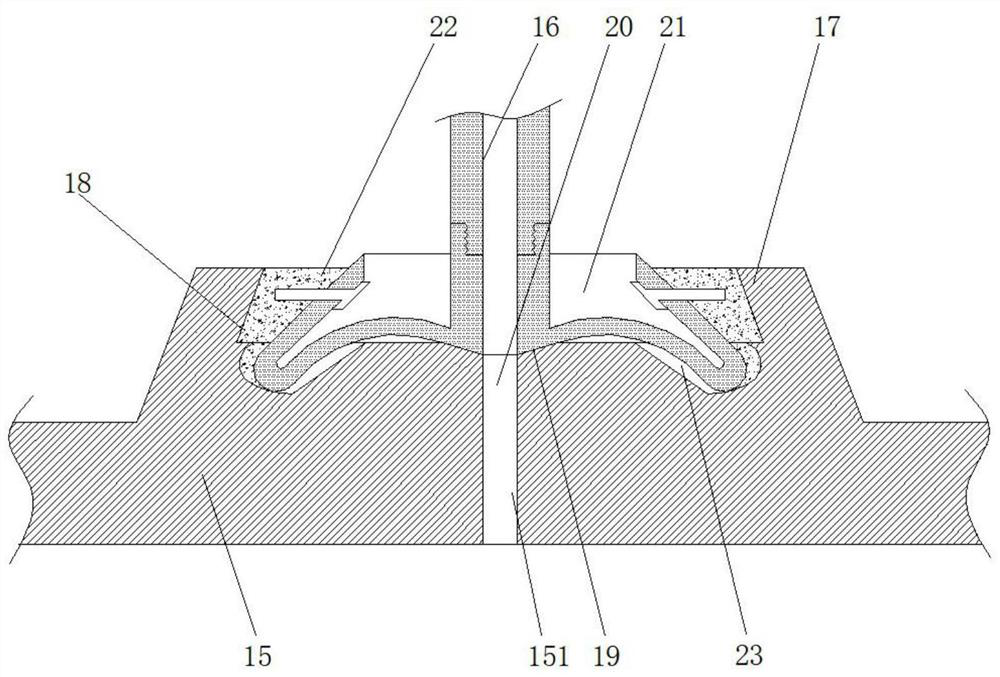

Welding device for ceramic plate and metal cylinder component

ActiveCN111922470AGuaranteed accuracyGuaranteed accuracy and stabilityHeating appliancesWelding/soldering/cutting articlesMetal cylinderWorkbench

The invention discloses a welding device for a ceramic plate and a metal cylinder component, and belongs to the field of welding equipment. The welding device comprises a heating furnace, a workbenchis fixedly connected to the bottom of the inner wall of the heating furnace, a limiting plate is fixedly connected to the right side of the top of the workbench, and mounting blocks are fixedly connected to two sides of the front surface of the workbench. The tops of the mounting blocks are rotationally connected with clamping lead screws, the top ends of the clamping lead screws are fixedly connected with adjusting hand wheels, and the clamping lead screws are in threaded connection with clamping plates. According to the welding device, the mounting blocks are fixedly connected to the two sides of the front face of the workbench, the clamping lead screws are rotationally connected to the tops of the mounting blocks, the adjusting hand wheels are fixedly connected to the top ends of the clamping lead screws, the clamping plates are in threaded connection with the clamping lead screws so that the ceramic plate can be fixed after the ceramic plate is placed in the heating furnace, the ceramic plate is prevented from being dislocated in the welding process, the welding accuracy is guaranteed, and an extrusion disc can prevent welding flux from overflowing from the filling position.

Owner:ANHUI UNIVERSITY OF TECHNOLOGY AND SCIENCE

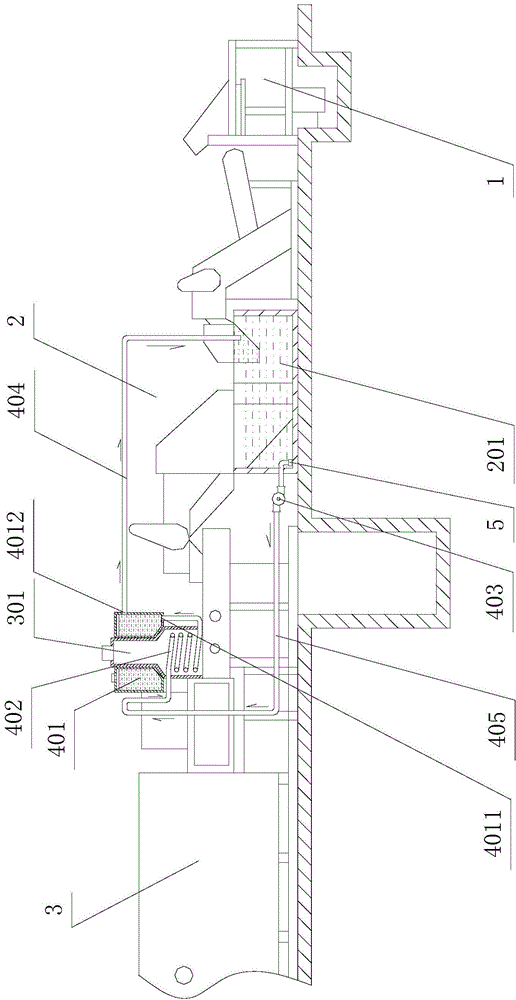

Quenching furnace smoke outlet heat energy recovery system of mesh heating furnace production line

InactiveCN104404217AEasy to transformImprove tempering effectFurnace typesHeat treatment furnacesQuenchingThermal energy

The invention provides a quenching furnace smoke outlet heat energy recovery system of a mesh heating furnace production line. The system comprises a quenching furnace, a quenching tank, a tempering furnace and a blackening tank which are sequentially connected, the quenching furnace is provided with a gas discharge tube, the gas discharge tube is provided with a second-stage heat energy recovery device, the second-stage heat energy recovery device comprises a heat collecting tube, a fan and a wind regulating valve, the heat collecting tube is provided with a heat connecting branch tube connected with the gas discharge tube of the quenching furnace in a branch manner, the fan is arranged on the heat collecting tube, the wind regulating valve is arranged at the outlet end of the fan, the outlet end of the wind regulating valve is divided into a first branch and a second branch, the outlet end of the first branch faces the inlet of the tempering furnace, the outlet end of the second branch faces the outlet end of the blackening tank, and a heat insulation layer is arranged outside each of the heat collecting tube, the heat collecting branch tube, the first branch and the second branch. The quenching furnace smoke outlet heat energy recovery system of the mesh heating furnace production line has the advantages of heat energy discharge reduction, reduction of the heat pollution to surrounding environment, energy saving, environmental protection, and substantial reduction of the production cost.

Owner:NINGBO ZHENHAI ZHONGBIN MACHINERY MFG

Low-manganese cast grinding ball

ActiveCN104109796AImprove performanceReduce adverse effectsFurnace typesHeat treatment furnacesRoom temperatureManganese

The invention discloses a low-manganese cast grinding ball which is composed of the following components in percentage by mass: 2.1-2.8% of C, 0.3-0.8% of Si, 0.08-0.6% of Mn, 10-23% of Cr, 0-0.05% of P, 0-0.05% of S, 0.03-0.06% of Al and the balance of Fe. The grinding ball is prepared by the following steps: S1: weighing the raw materials according to percentage by mass, smelting, and carrying out casting molding to obtain a cast grinding ball semi-finished product; and S2: putting the grinding ball semi-finished product obtained in the step S1 into the furnace, heating to 510-530 DEG C, keeping the temperature for 140-160 minutes, heating to 740-760 DEG C, keeping the temperature for 140-160 minutes, heating to 880-960 DEG C, keeping the temperature for 140-160 minutes, heating to 970-1040 DEG C, keeping the temperature for 140-160 minutes, carrying out oil quenching in quenching oil with the temperature of 75-120 DEG C for 3-14 minutes, putting in a holding furnace, heating from room temperature to 300-380 DEG C at the heating rate of 20-100 DEG C / hour, keeping the temperature for 470-490 minutes, and slowly cooling to room temperature within 450-470 minutes to obtain the cast grinding ball. The cast grinding ball has favorable comprehensive properties.

Owner:宁国东方碾磨材料股份有限公司

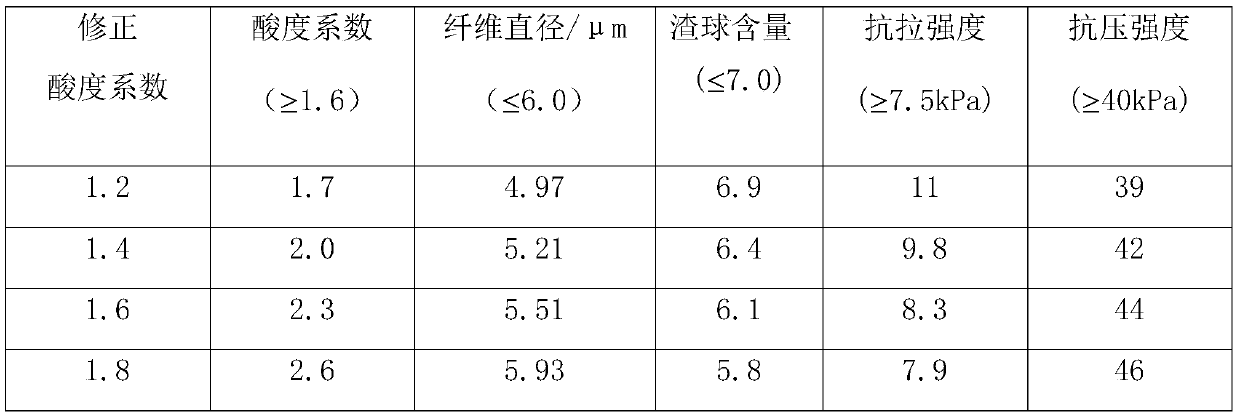

Rock wool product and method for preparing mineral wool by tempering silica sand and albite

PendingCN111072286AGood tempering effectImprove the tempering effectGlass making apparatusMining engineeringFiber diameter

The invention provides a rock wool product and a method for preparing mineral wool by tempering silica sand and albite. The rock wool product is prepared from the following components in parts by mass: 35-50 parts of SiO2, 10-17 parts of Al2O3, 18-27 parts of CaO, 1-5 parts of MgO, 4-14 parts of MnO, 1-2 parts of TFe, 1-3 parts of K2O and 0-2 parts of Na2O. According to the method for preparing the mineral wool by tempering the silica sand and the albite, in the slag melting process, the added tempering agent is the silica sand and the albite which are uniformly mixed in advance; silica sand and albite are adopted as tempering materials, the tempering effect on the product is obvious, the rock and mineral wool board is prepared through adoption of a sensible heat new one-step method, and the slag ball content, the fiber diameter, the tensile strength, the mine pressure strength and the acidity coefficient all meet the technical requirements of a rock / mineral wool product GB / T25975-2010rock wool board for building outer wall heat preservation.

Owner:NINGXIA JIYUAN METALLURGICAL GRP CO LTD +1

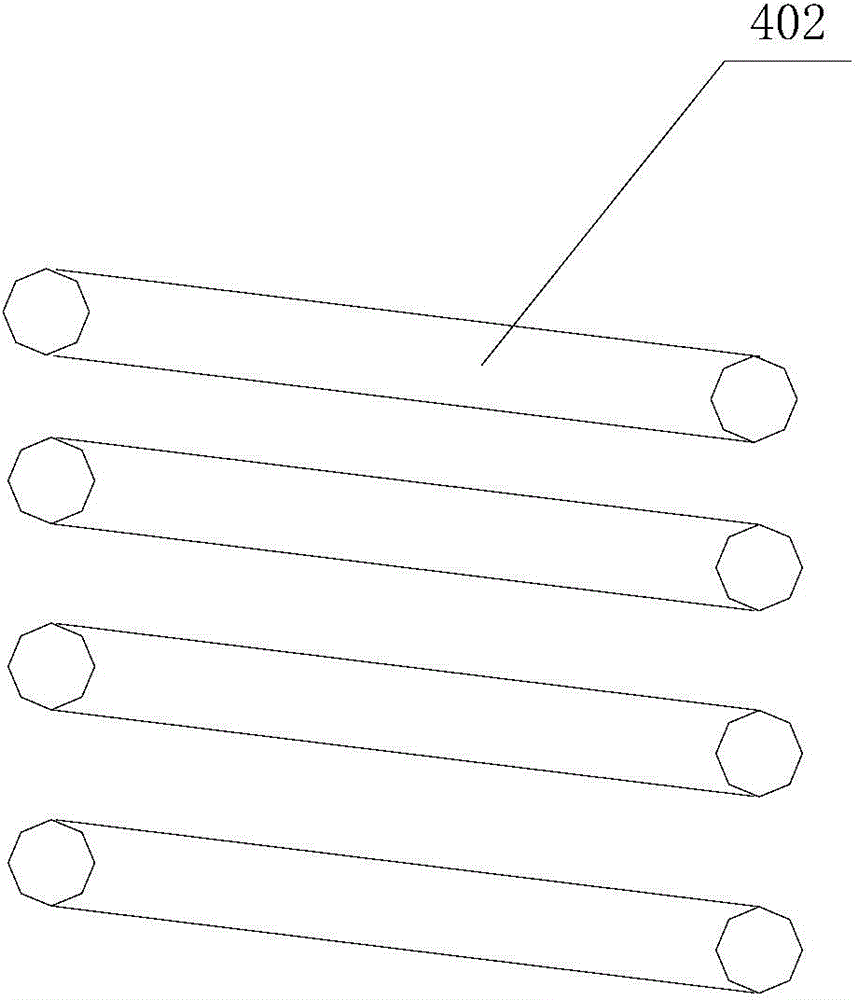

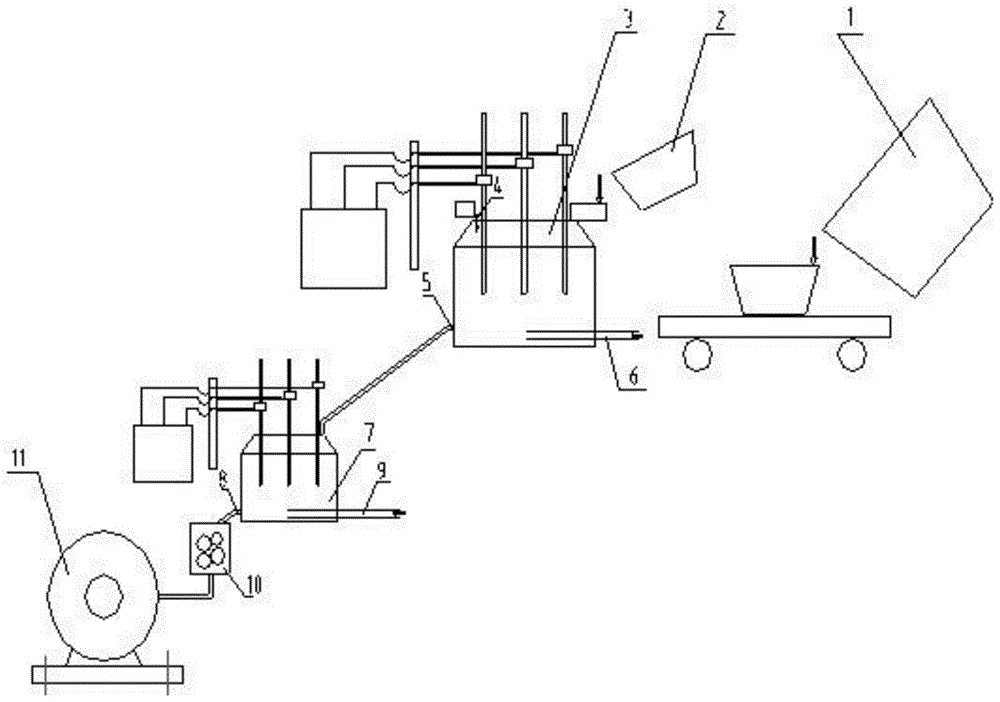

Method and device for producing mineral wool with molten blast furnace slag and mine tailings

ActiveCN104370455BEfficient use ofReduce production energy consumptionGlass making apparatusMolten stateSlag

The invention relates to a method for producing mineral wool by matching molten-state blast furnace slag with mine tailings. Molten-state blast furnace slag is taken as a raw material, the mine tailings are taken as a quenching and tempering agent, two stages of electric furnaces are adopted for heating, a nitrogen spraying and blowing system is arranged at the bottom of each furnace, magma after refinement, homogenization, quenching and tempering is thrown into mineral wool filaments of 3-5 microns by a centrifuge, and a mineral wool product is obtained after being collected by a wool collecting machine. A device for implementing the method comprises the electric furnace I, the electric furnace II, the centrifuge and the wool collecting machine which are sequentially connected. Compared with the prior art, the method and the device provided by the invention have the following beneficial effects that 1) the potential heat energy of the molten-state blast furnace slag is effectively utilized; 2) the shortcomings of high energy consumption and high pollution of a cupola furnace are avoided; 3) the mine tailings are selected as the quenching and tempering agent, so that the operation cost is reduced, the waste of resources is avoided, and the difficult problem of treatment of the mine tailings is effectively solved; 4) the quenching and tempering effect is strengthened and the quenching and tempering of a melt is more uniform; and 5) the acidic system after quenching and tempering is 1.0-2.2, and external heat preservation mineral wool products for exterior walls for buildings can be produced.

Owner:鞍钢绿色资源科技有限公司

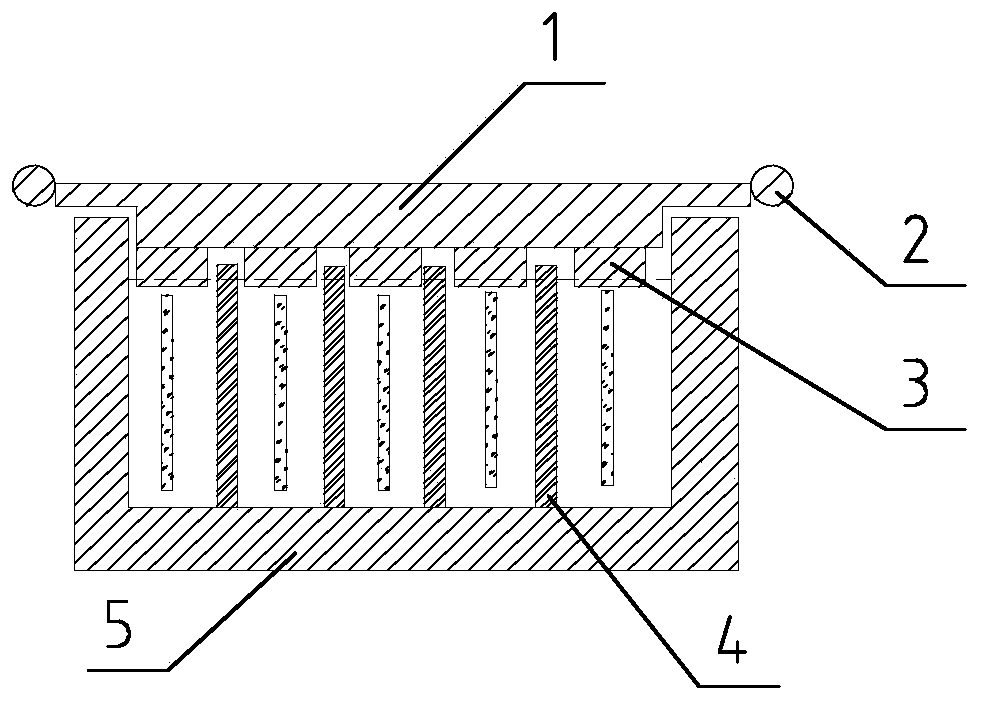

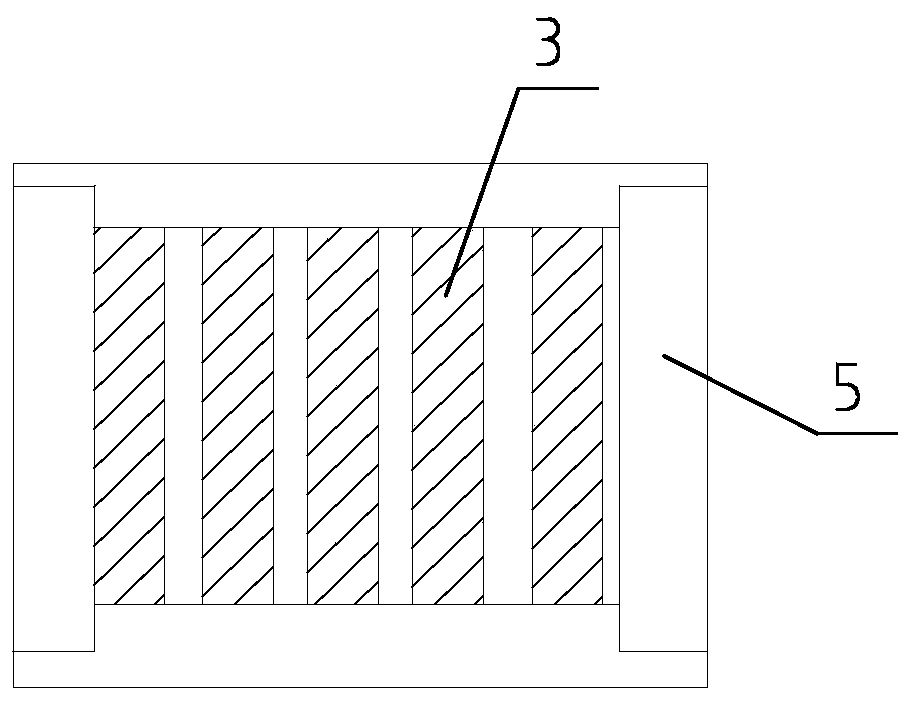

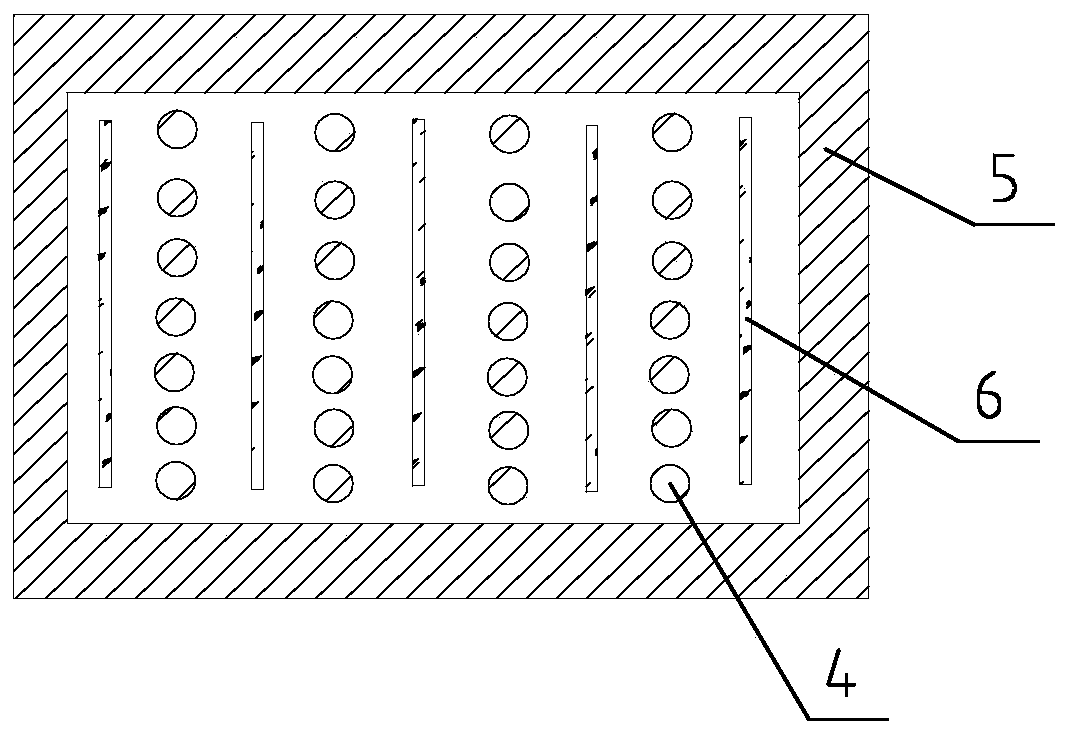

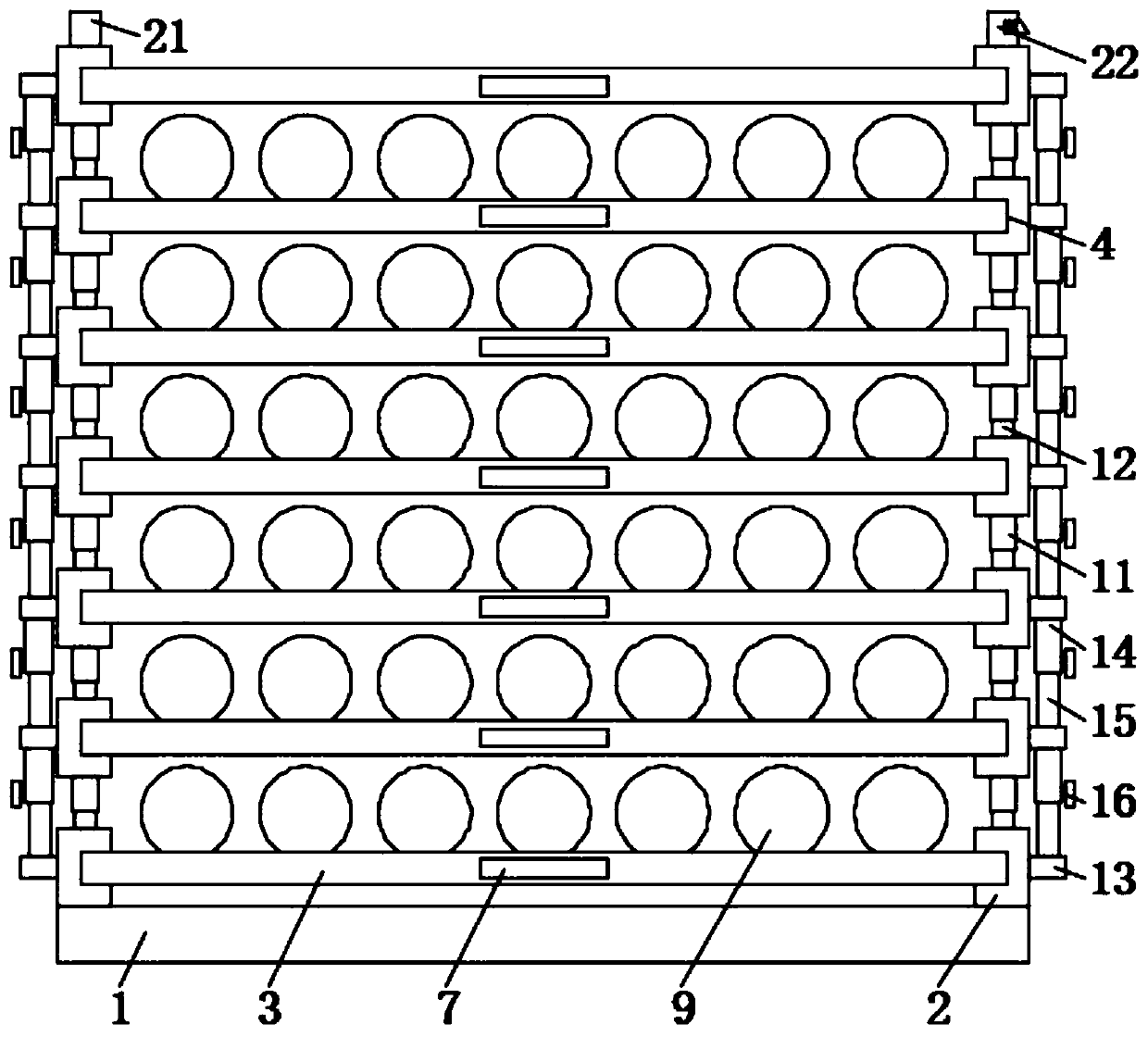

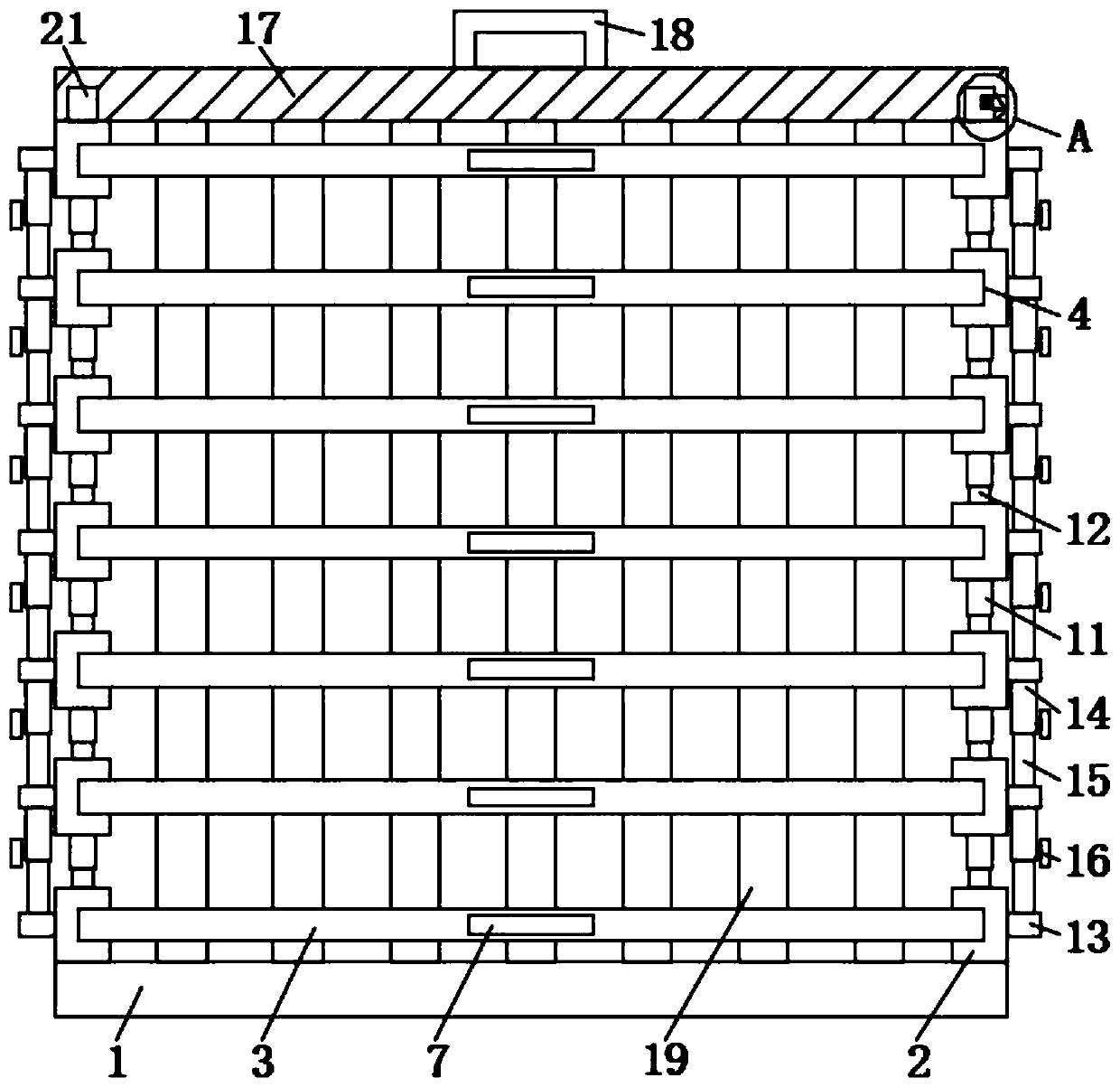

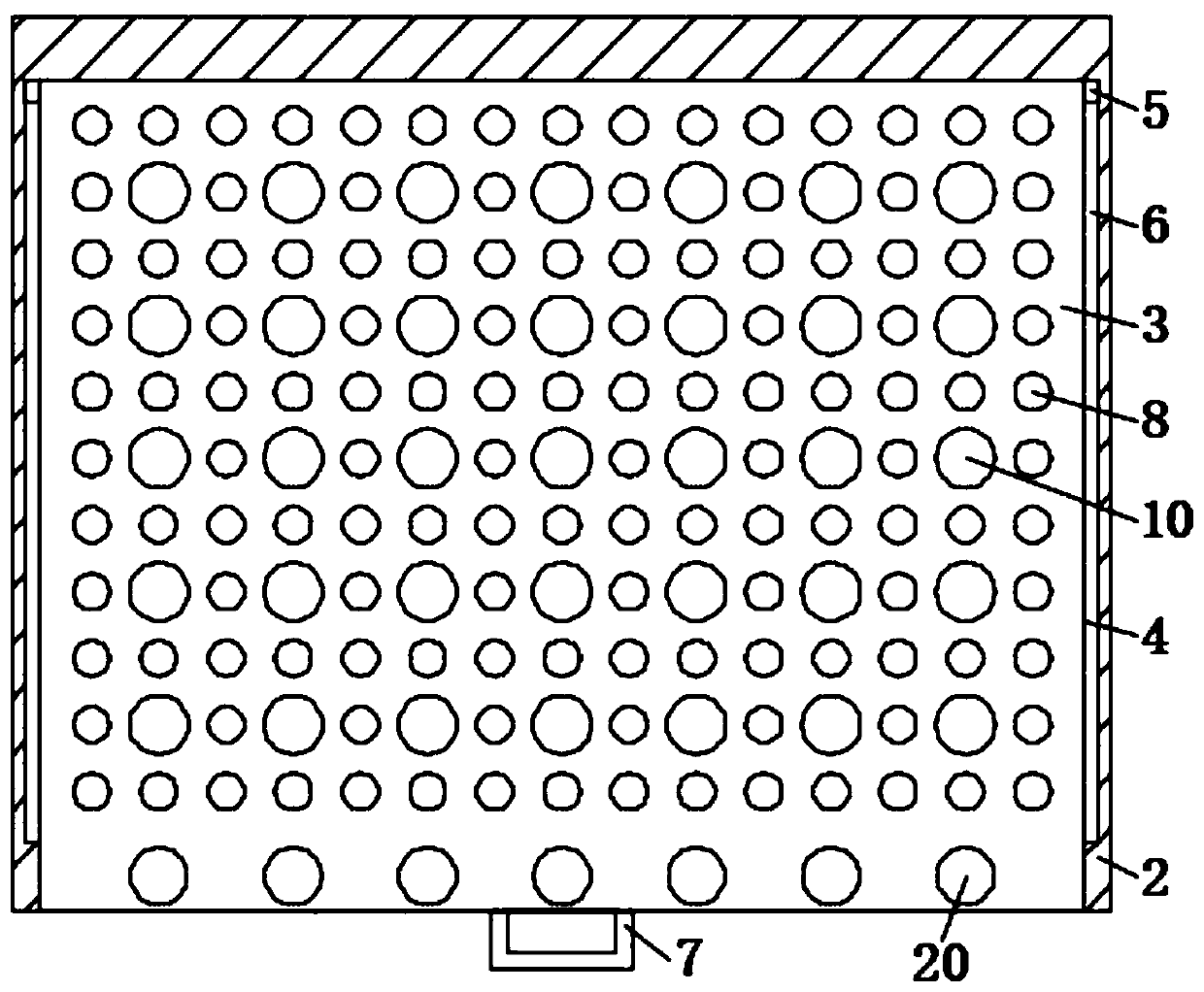

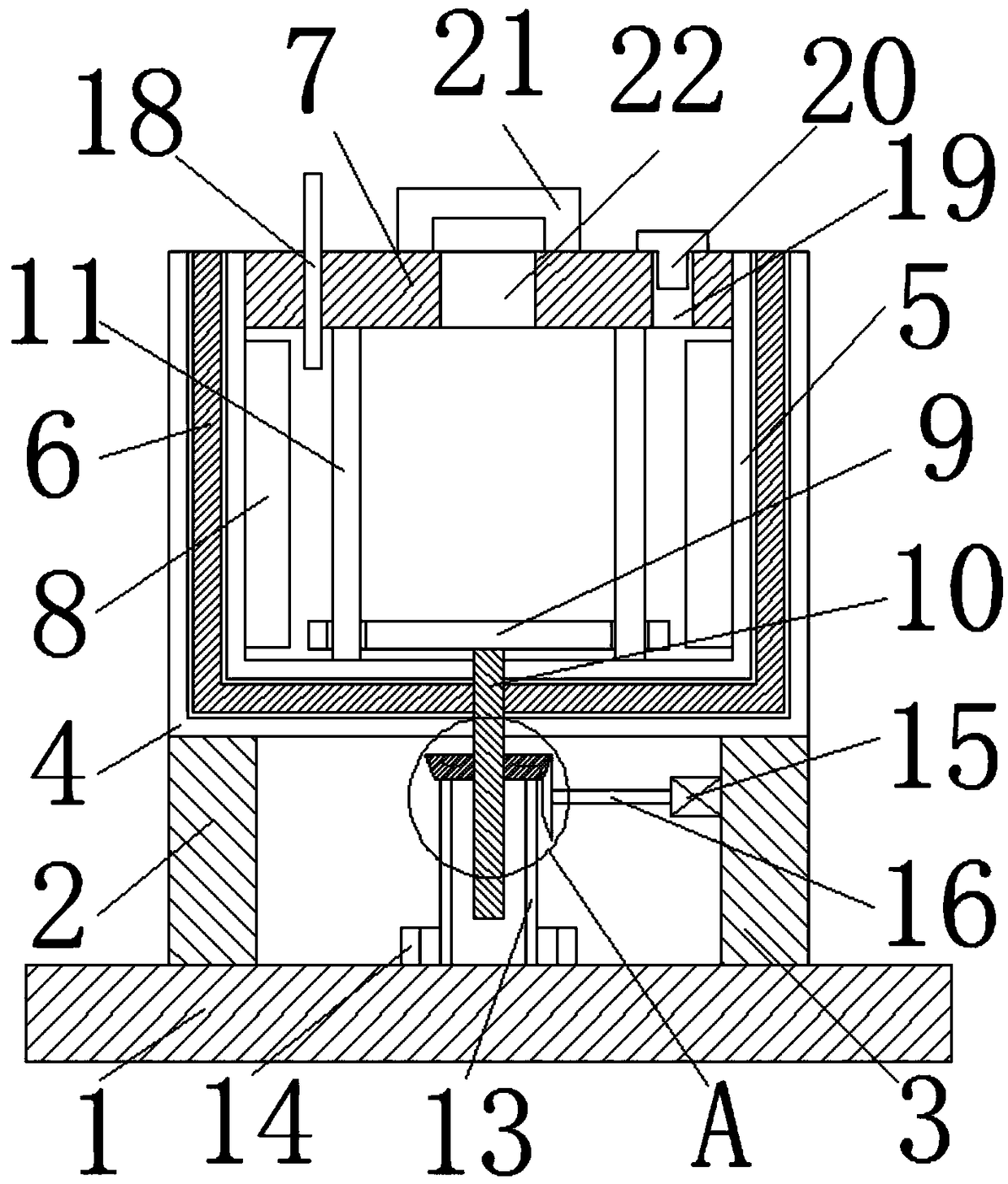

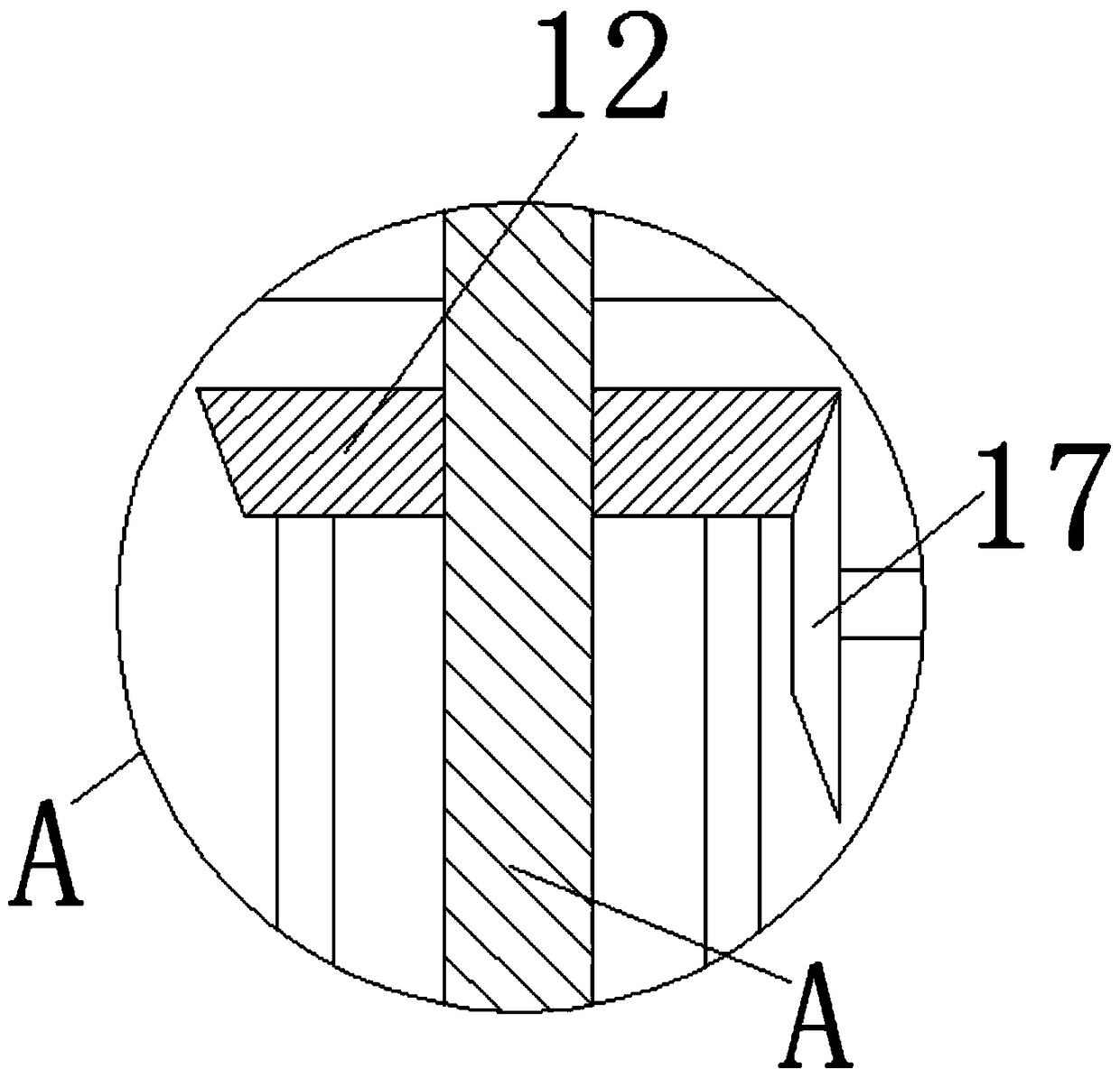

Wear-resisting steel ball tempering container with partition plates

ActiveCN110273058AImprove breathabilityImprove the tempering effectFurnace typesHeat treatment furnacesSteel ballEngineering

The invention discloses a wear-resisting steel ball tempering container with partition plates. The wear-resisting steel ball tempering container comprises a bottom frame. Multiple installing frames are uniformly installed at the top end of the bottom frame. An opening is formed in one end of each installing frame. One partition plate can be movably inserted to the outer side wall of one end, close to the opening, of each installing frame. Multiple air holes are formed in each partition plate at equal distance. Steel balls are arranged on each partition plate at equal distance. Multiple handrails matched with the steel balls are installed between the two adjacent installing frames at equal intervals. Each handrail comprises a telescopic rod mother rod and a telescopic rod son rod which are mutually connected. According to the container, a container body is composed of a bottom frame and multiple installing frames uniformly installed at the top end of the bottom frame, the adjacent installing frames are connected mutually through the handrails, air permeability of the container body is improved, thus the steel balls in the container body can be fully exposed in the air, the tempering effect of the steel balls in the container body is improved, and design is reasonable.

Owner:徐州兰岳企业管理服务有限公司

Valve base heat treatment device

InactiveCN109182668ASave energyEasy to placeFurnace typesHeat treatment furnacesMechanical engineeringHeat treated

The invention discloses a valve base heat treatment device which comprises a base. A first supporting plate and a second supporting plate are connected to the upper surface of the base symmetrically and fixedly. The ends, away from the base, of the first supporting plate and the second supporting plate are connected with a heating box with an opening formed in the upper end together. The heating box comprises an outer shell and an inner shell. A heat preserving layer is fixedly installed between the inner shell and the outer shell. A box cover is hinged to one end, away from the box bottom, ofthe inner wall of the inner shell. A heating device is installed on the vertical inner wall of the inner shell symmetrically and fixedly. The heating device is located below the box cover. The valvebase heat treatment device reduces consumption of resources effectively, moreover, the situation that the temperature of the device is lowered too fast can be prevented effectively, heat can be preserved effectively, and the tempering effect of a valve base is better.

Owner:盐城市景盛石化机械有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com