Method for toughening alkali-free aluminoborosilicate ultrathin substrate glass

An aluminoborosilicate and substrate technology, which is applied in glass tempering, glass production, glass manufacturing equipment, etc., can solve the problems of no reports on the glass strengthening of aluminoborosilicate ultra-thin substrates, and achieve a good surface condition of the glass, High impact strength and uniform stress distribution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

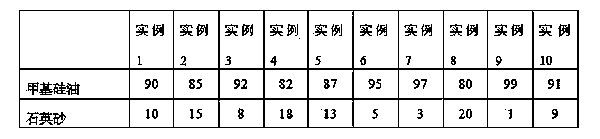

Embodiment 1

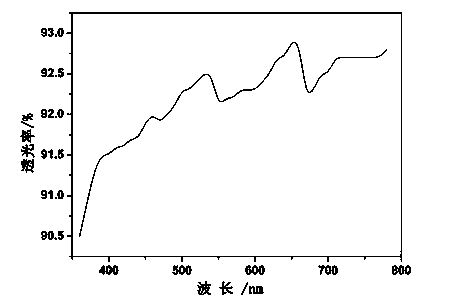

[0033]Example 1: First, the annealed substrate glass is cut and edged, cleaned and dried according to the requirements, and then placed on the sample holder for use; then, the cleaned and dried substrate glass sample holder is pushed into the heated Put it in an electric furnace at 700°C and keep it warm for 10 minutes; then, quickly drop the substrate glass into the strengthening liquid at 150°C (prepared according to the formula ratio of Example 1 in Table 1), and take it out when the strengthening liquid cools below 50°C. Substrate glass; finally, thoroughly wash away impurities such as silicone oil on the surface of the substrate glass, and dry to obtain strengthened glass. The impact resistance of the sample was measured by the GB9963-88 impact resistance test. The weight of the falling ball was 5.6 grams. The impact resistance of the sample was measured to be 0.8 m, and it was not broken after three impacts. The light transmittance curve of the sample tested by a spectro...

Embodiment 2

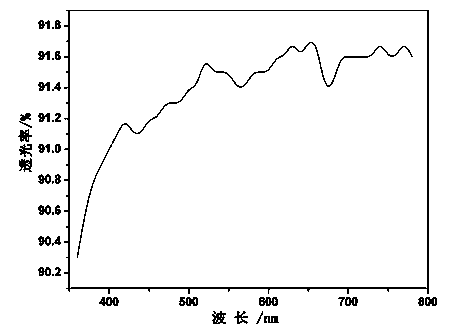

[0035] Example 2: First, cut, grind, clean and dry the annealed substrate glass according to the requirements, and put it on the sample holder for use; then, push the cleaned and dried substrate glass sample holder into the The temperature has been raised to 730°C in an electric furnace, and the temperature is kept for 15 minutes; then, the substrate glass is quickly dropped into the 160°C strengthening liquid (prepared according to the formula ratio of Example 2 in Table 1), and when the strengthening liquid is cooled to below 50°C , take out the substrate glass; finally, thoroughly wash off impurities such as silicone oil on the surface of the substrate glass, and dry to obtain strengthened glass. The impact resistance of the sample was measured by the GB9963-88 impact resistance test. The weight of the falling ball was 5.6 grams, and the impact resistance of the sample was measured to be 0.82 m, and it was not broken after three impacts. The light transmittance curve of the...

Embodiment 3

[0037] Embodiment 3, at first, according to the requirements, the substrate glass after annealing is cut, edging, cleaned and dried, and put into the sample holder for use; then, the substrate glass sample holder that has been cleaned and dried is pushed into the Raise the temperature to an electric furnace at 740°C and keep it warm for 30 minutes; then, quickly drop the substrate glass into the strengthening liquid at 350°C (prepared according to the formula ratio of Example 3 in Table 1), and when the strengthening liquid cools below 50°C, Take out the substrate glass; finally, thoroughly wash away impurities such as silicone oil on the surface of the substrate glass, and dry to obtain strengthened glass. The impact resistance of the sample was measured by the GB9963-88 impact resistance test. The weight of the falling ball was 5.6 grams. The impact resistance of the sample was measured to be 0.9 m, and it was not broken after three impacts.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Impact resistance | aaaaa | aaaaa |

| Impact resistance | aaaaa | aaaaa |

| Impact resistance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com