Patents

Literature

80results about How to "Guaranteed accuracy and stability" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

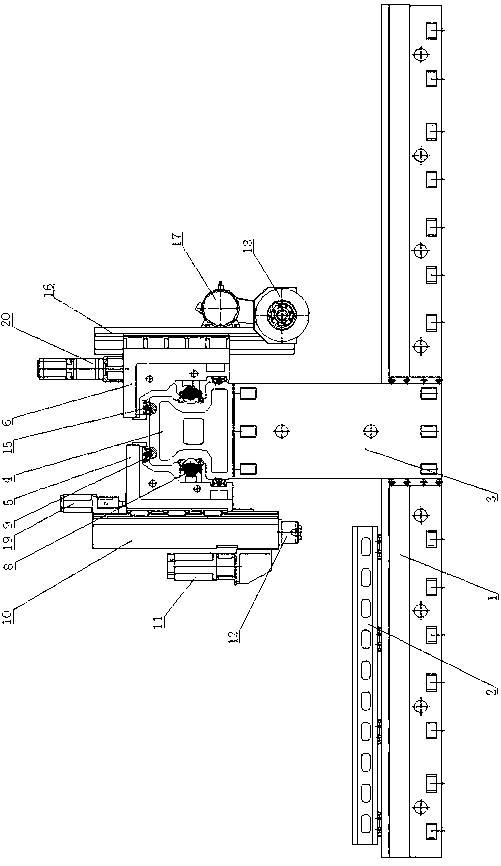

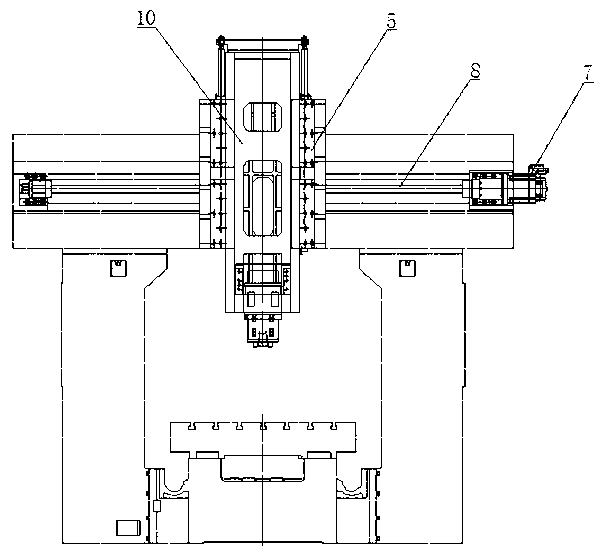

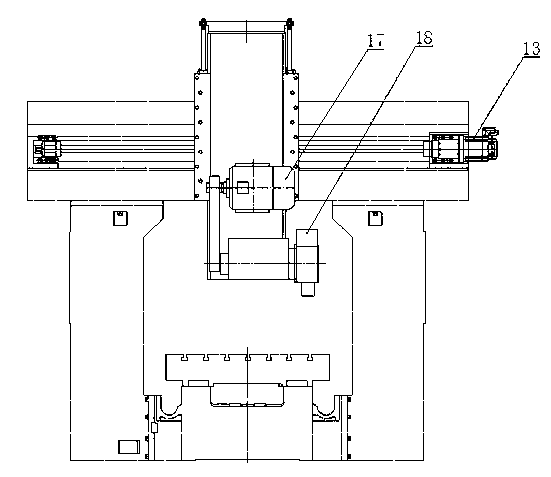

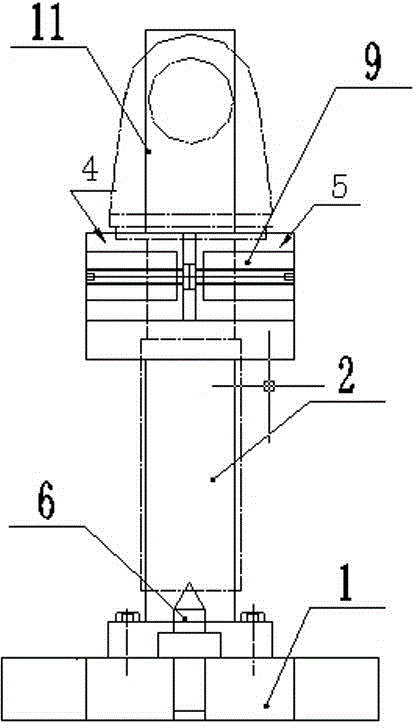

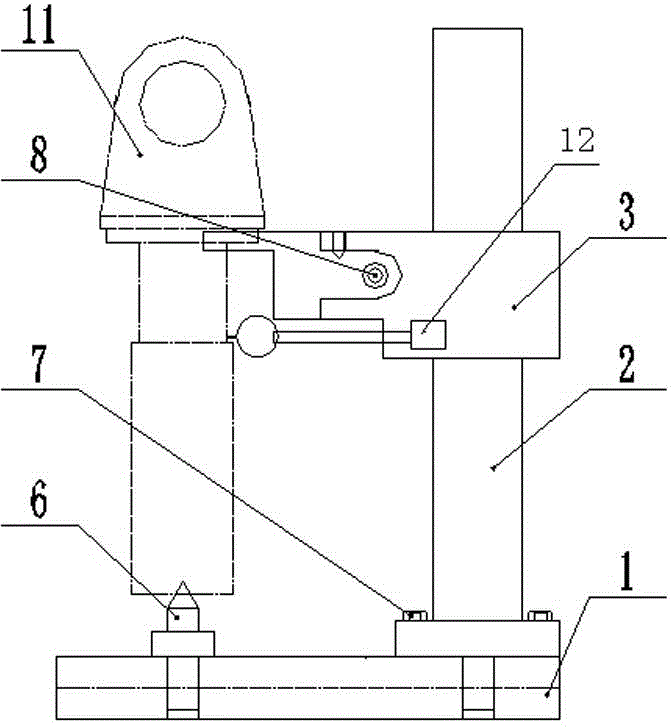

Numerical control gantry milling machine of fixed beam

InactiveCN102699685AImprove machining efficiency and precisionReduce work intensityOther manufacturing equipments/toolsLarge fixed membersEngineeringBall screw

The invention relates to a numerical control gantry milling machine of a fixed beam, comprising a machine body, wherein a work table which can extend along the direction of the machine body is arranged on the machine body, vertical columns are respectively arranged at the two sides of the machine body, and the top ends of the vertical columns are connected with a cross beam. The innovation of the numerical control gantry milling machine is that the front side and the rear side of the cross beam are respectively provided with a milling sliding seat and a grinding sliding seat, and the milling sliding seat and the grinding sliding seat are provided with corresponding components and can be used for milling and grinding the workpieces on the work table after being installed and clamped for one time, so that the time for assembling, detaching and positioning the workpieces can be reduced, the process efficiency and the process precision can be improved, and the utilization rate of the equipment can be improved. The cross beam has a roller guide rail structure which is distributed in a stepped shape, so that the roller guide rail has enough flexural stiffness and torsional stiffness, and long enough precision retaining ability. The weights of a ram and a main gear box are balanced through a hydraulic balance oil box, so that the no-load twisting moment of a bead screw shaft can be reduced, the attrition of the bead screw shaft can be reduced, and the precision stability of the bead screw shaft can be kept.

Owner:南通京鼎机械科技有限公司

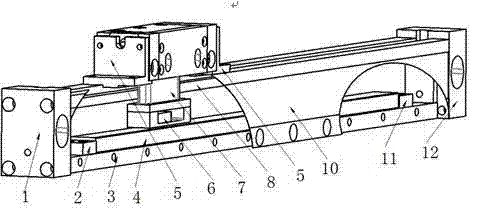

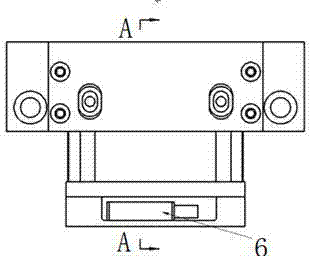

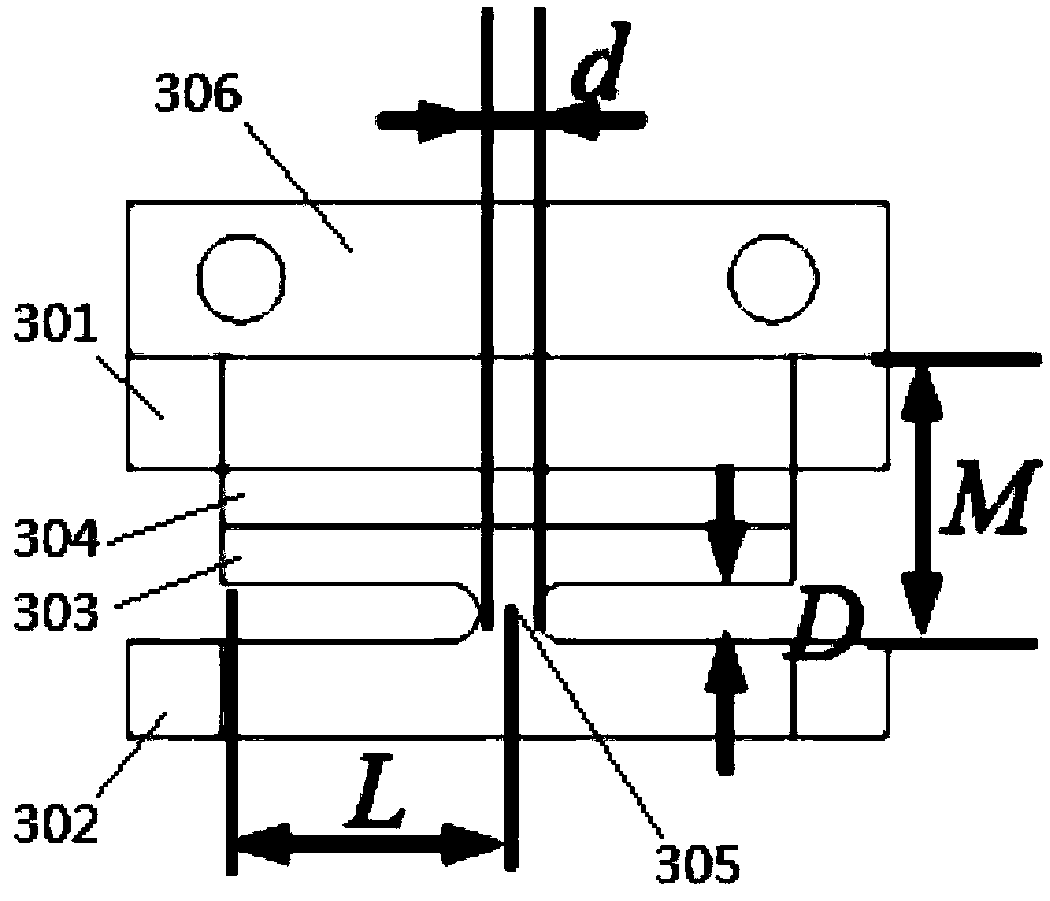

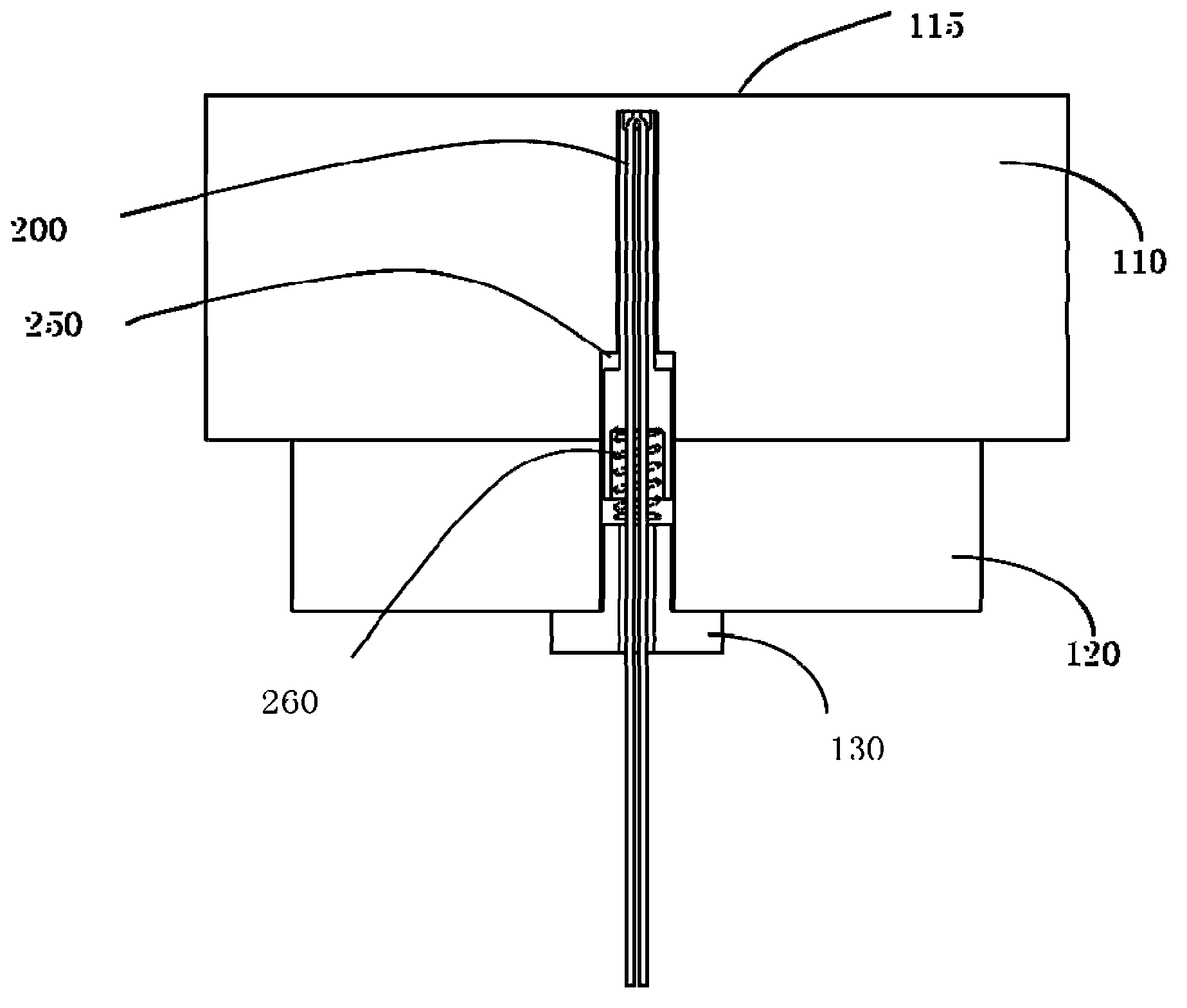

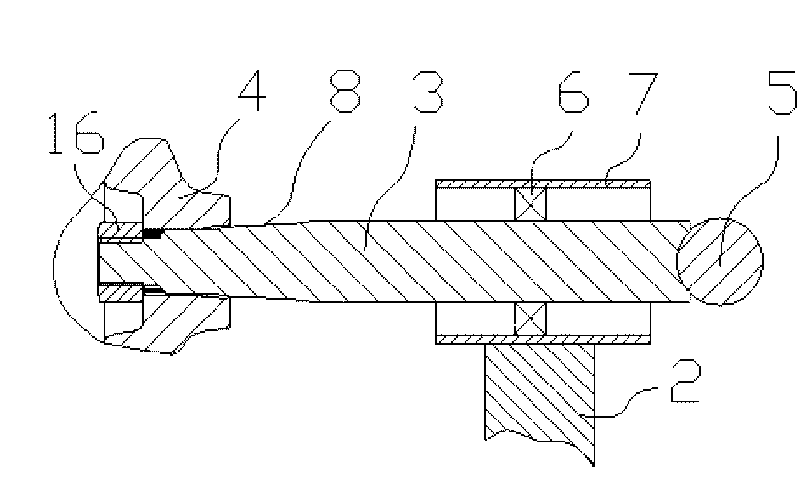

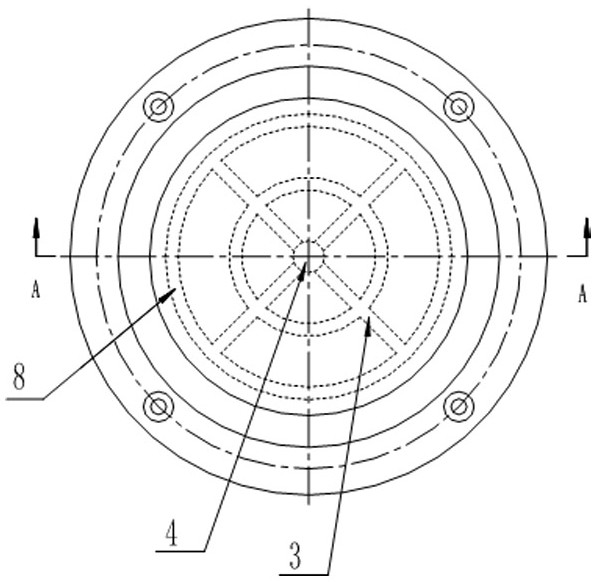

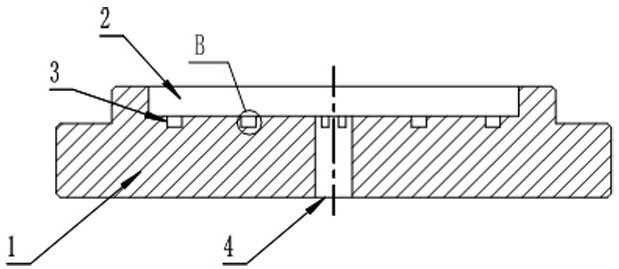

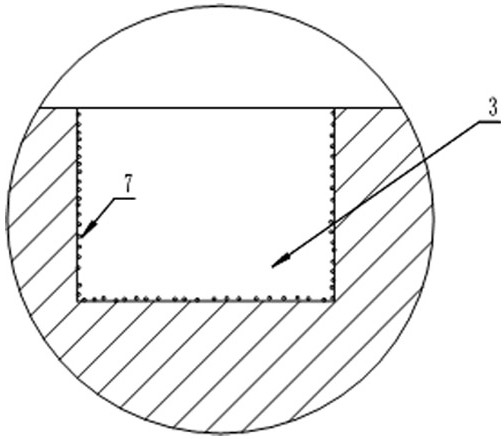

Closed type optical grating linear displacement sensor structure for ultra-precise machine tool

InactiveCN104713484AHigh precisionGuaranteed accuracy and stabilityUsing optical meansPhysicsLinear displacement

The invention discloses a closed type optical grating linear displacement sensor structure for an ultra-precise machine tool. The closed type optical grating linear displacement sensor comprises a metal optical grating ruler, a first stop block, a second stop block, a fundamental plane shell, a non-fundamental-plane shell, a reading head and a reading head support. The metal optical grating ruler is integrally fixed to the fundamental plane shell through an elastic adhesion agent. The first stop block and the second stop block are fixed to the two ends of the metal grating ruler. The non-fundamental-plane shell is fixed to the fundamental plane shell through screws. Sealing strips are fixed to the inner side of the upper edge of the fundamental plane shell. The two ends of the fundamental plane shell seal a ruler base of the metal optical grating ruler through fixing and adjusting blocks in the shell. The reading head is inlaid in the reading head support. A gap exists between the reading head and the metal optical grating ruler. After the optical grating linear displacement sensor is debugged, the position and the precision of the reading head are locked through a reading head fixing frame. According to the closed type optical grating linear displacement sensor structure for the ultra-precise machine tool, the precision of the optical grating linear displacement sensor is improved, the metal optical grating ruler and the shells are made of stainless steel materials, and the expansion coefficients of the stainless steel materials are identical with that of an ultra-precise machine tool body.

Owner:BEIJING AOTEPUSEN PRECISION MACHINERY

Precision mirror frame based on a flexible hinge

PendingCN108562992ASimple and efficient operationGuaranteed accuracy and stabilityMountingsFrame basedHinge angle

The present invention relates to a precision mirror frame based on a flexible hinge, and belongs to the technical field of optical components. The mirror frame includes a mirror group for mounting a mirror, a base for supporting the mirror group, and an adjusting unit for adjusting the angle of the mirror group. The base includes a fixing plate and a connecting plate disposed between the fixing plate and the mirror group, and the fixing plate and the connecting plate are hinged by the first hinge. The connecting plate and the mirror group are hinged by a second hinge, and the first hinge and the second hinge define a different rotation direction. The fixing plate is provided with an adjusting unit, and the adjusting unit is an adjusting bolt. The mirror set includes an adjustment plate, amirror holder, and a mirror press ring. The mirror frame has the advantages of simple structure, convenient installation, and the functions of the mirror adjusting unit and the fixed frame of the existing fine screw with the spring, which ensures the precision and stability of the mirror adjustment, and reduces the adjustment difficulty of the mirror frame, with wide application space.

Owner:NAT UNIV OF DEFENSE TECH

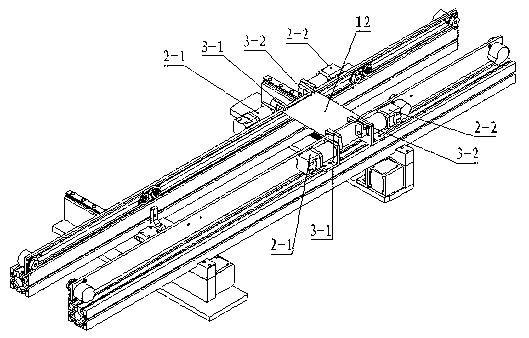

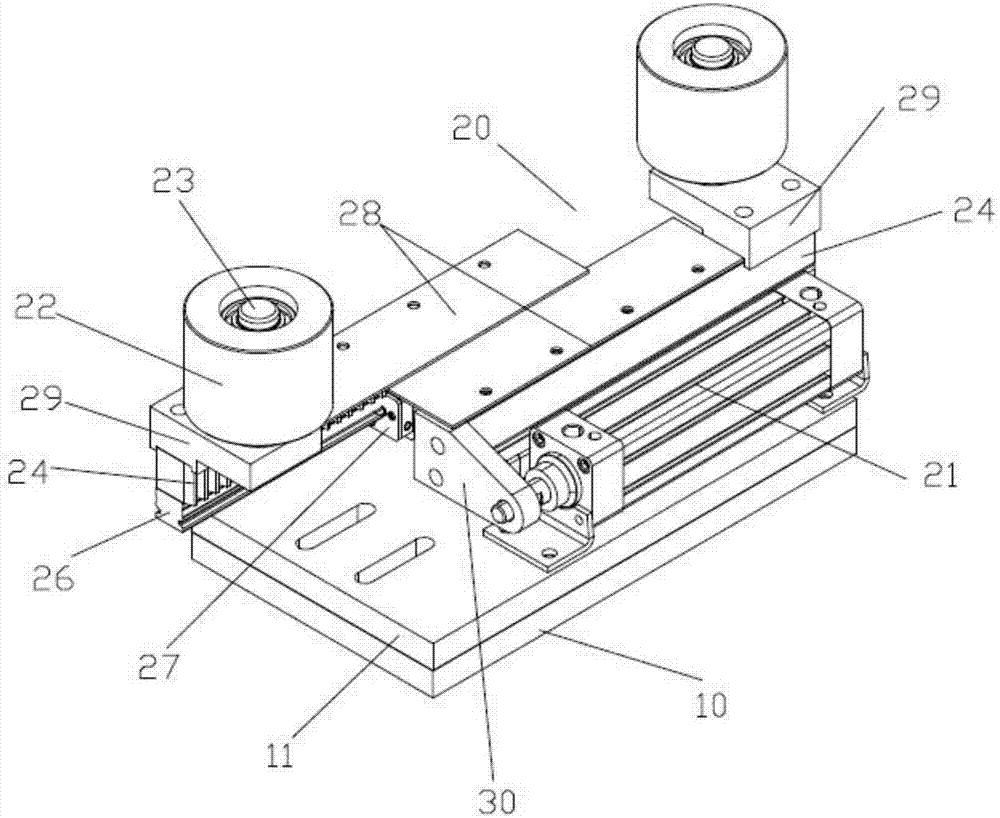

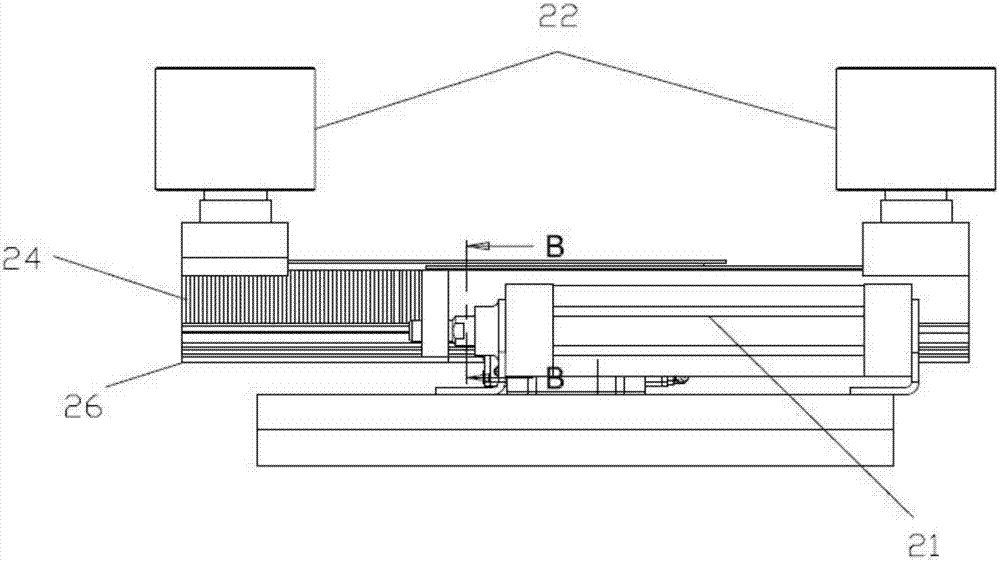

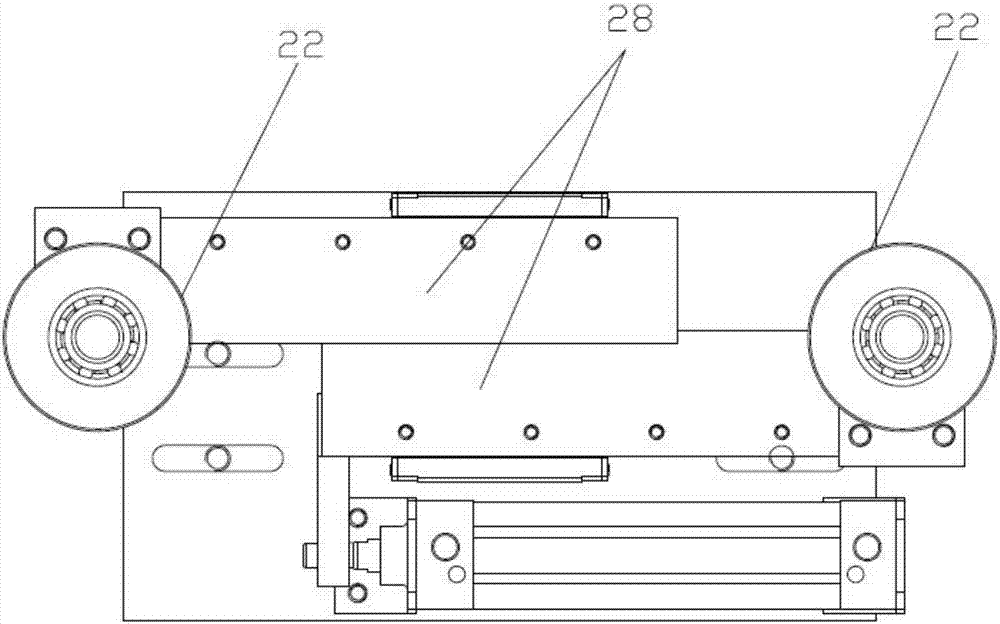

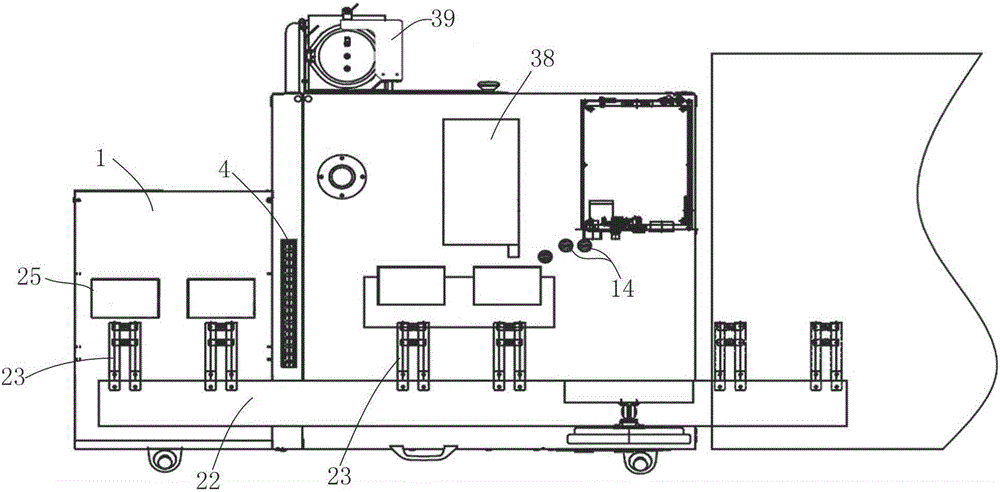

Circuit board conveying fixed rail with automatically-adjusted width

InactiveCN103171914AGuaranteed accuracy and stabilityIncrease the level of automationArticle feedersElectric machineryEngineering

The invention discloses a circuit board conveying fixed rail with automatically-adjusted width. The circuit board conveying fixed rail comprises a fixed edge forming board conveying rail, a linear guide rail, a movable edge rail installation seat, a movable edge forming board conveying rail, a back pressing board speed-reducing stepping motor, a front pressing board speed-reducing stepping motor, a board conveying belt stepping motor and a width adjusting stepping motor. The inner side of the fixed edge forming board conveying rail and the inner side of the movable edge forming board conveying rail are respectively and sequentially provided with a board conveying driving pulley, a board conveying driven pulley, a board conveying driven pulley and a board conveying driving pulley. The circuit board conveying fixed rail with the automatically-adjusted width can achieve the functions of circuit board conveying, clamping and positioning and automatic width adjusting of circuit boards with different specifications, and therefore automation level can be greatly improved. The stepping motors are used for all executive components, and therefore synchronism can be improved, and precise positioning can be guaranteed; and in addition, the whole device is simple in structure, high in reliability and capable of completely replacing an existing board conveying device with pneumatic motors and speed reducing motors as main executive components.

Owner:深圳市硕安迪科技开发有限公司

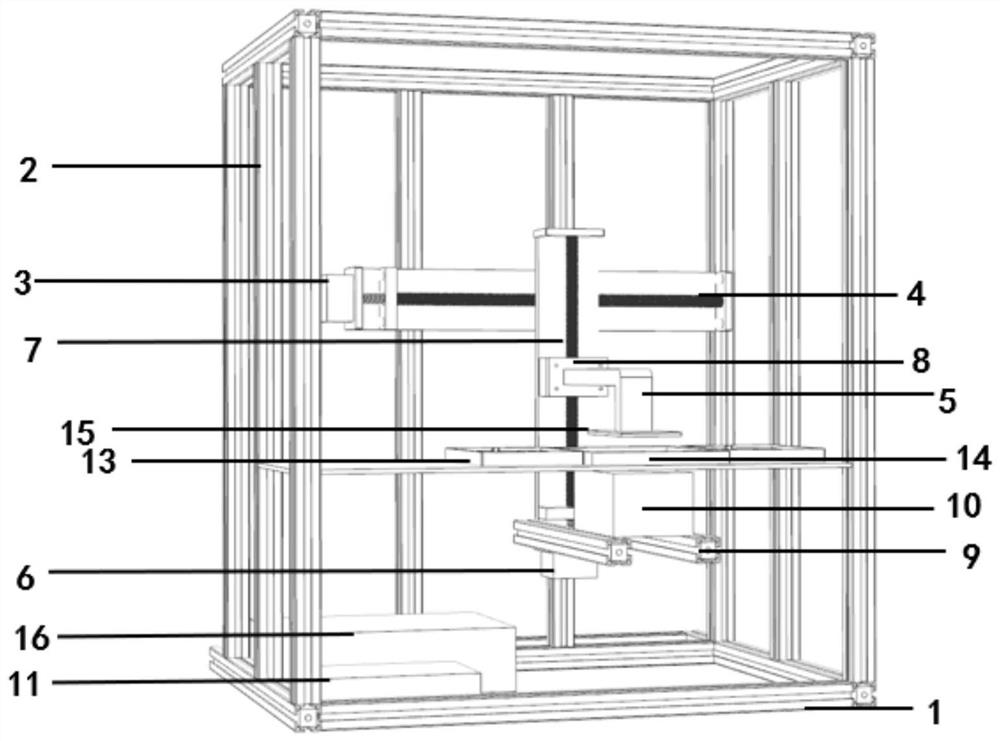

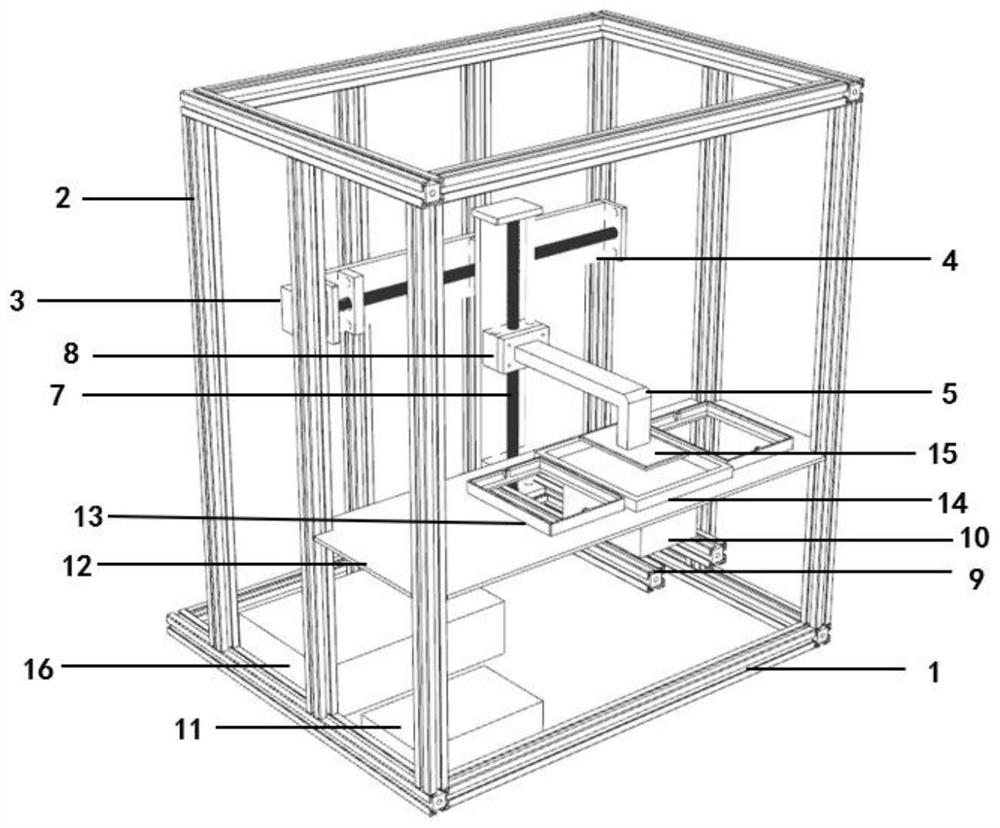

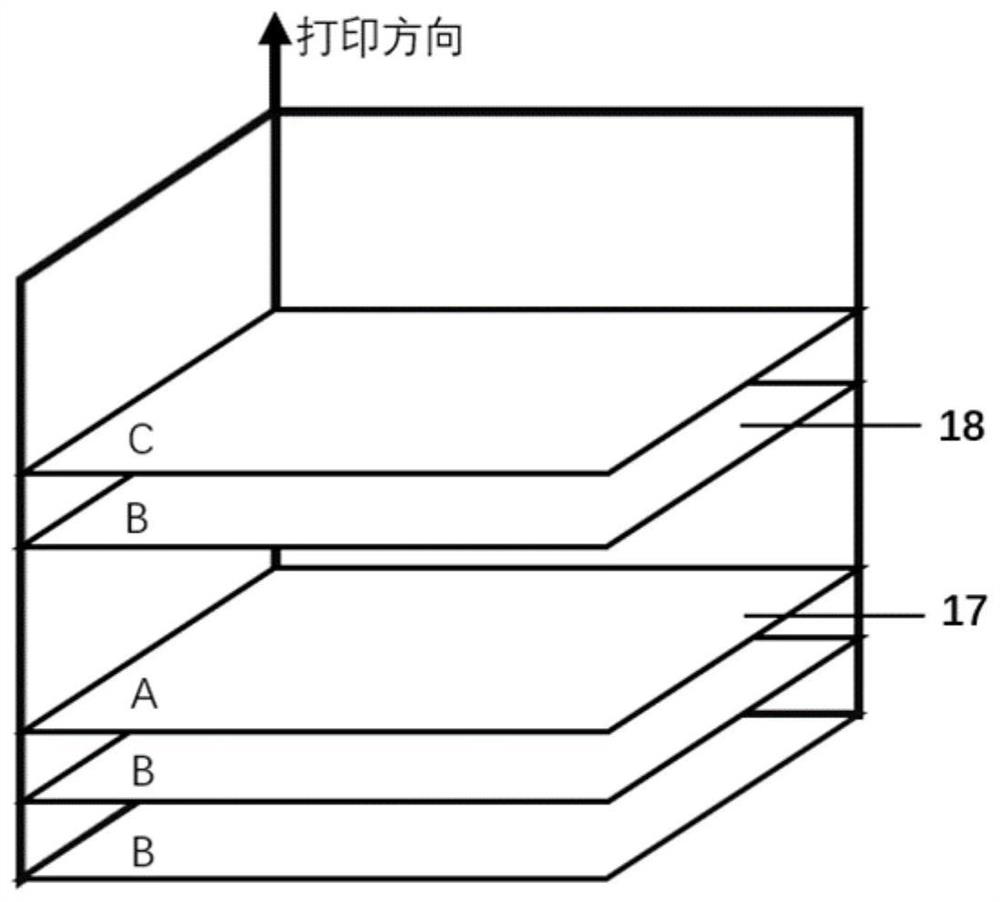

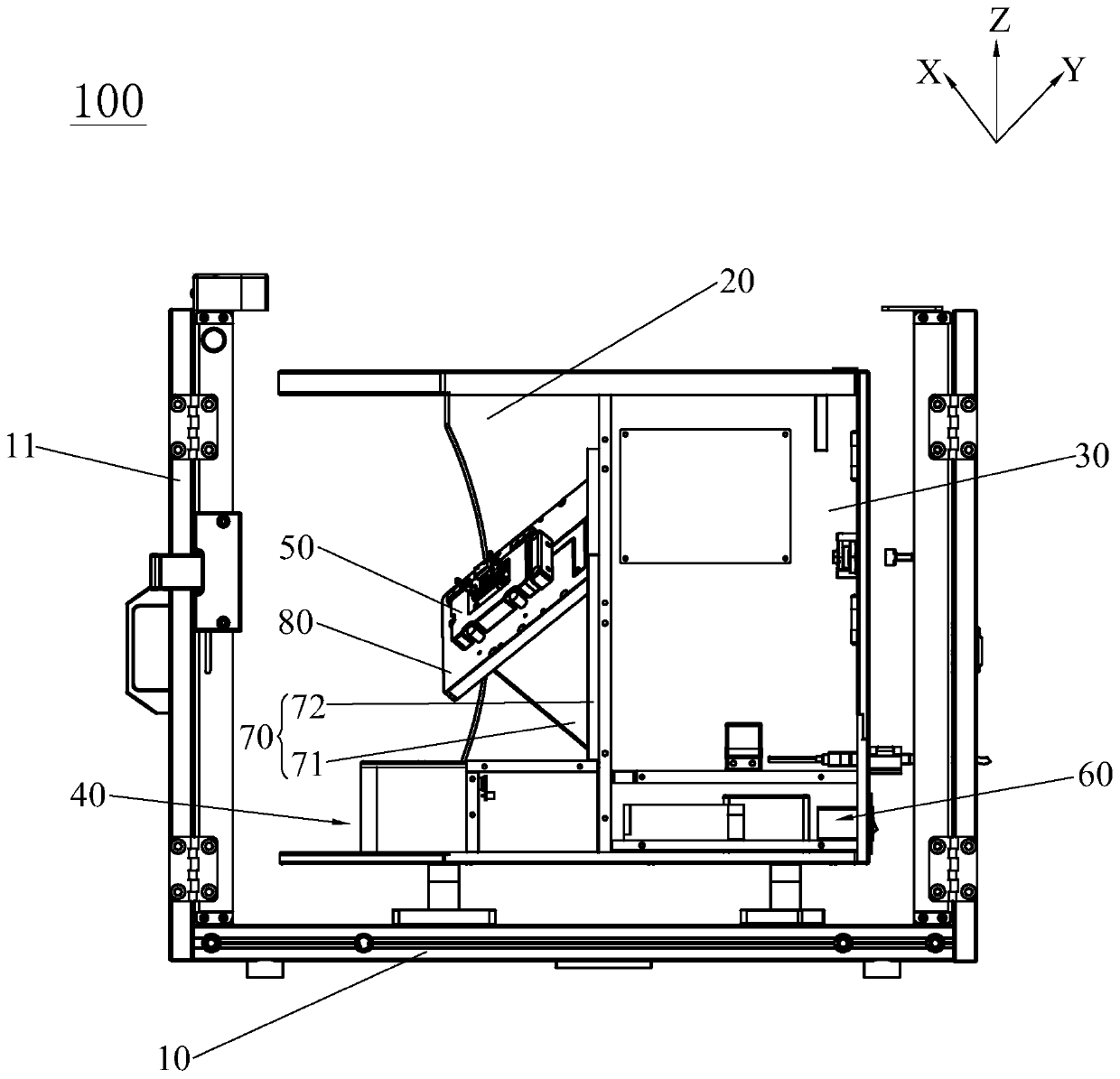

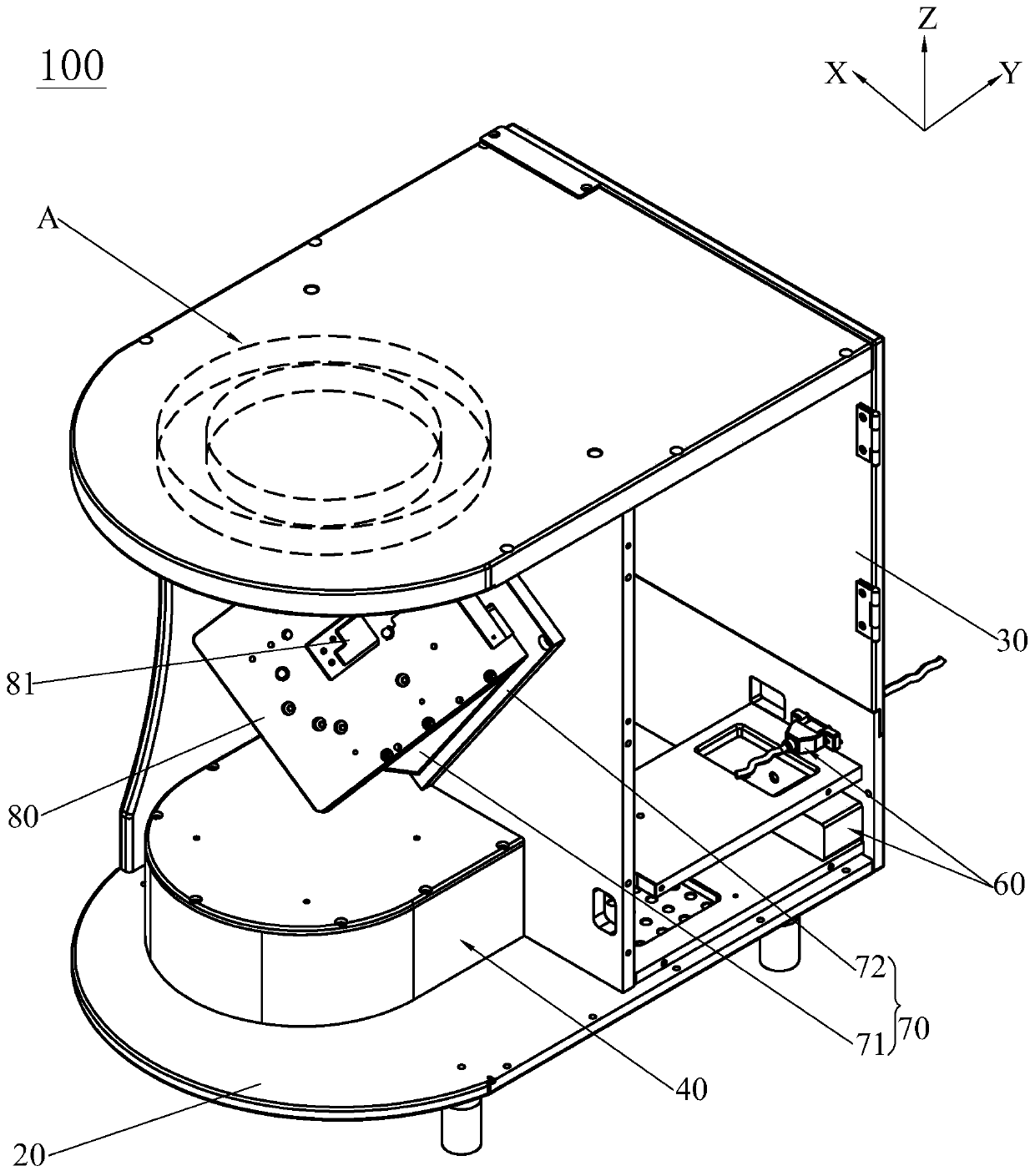

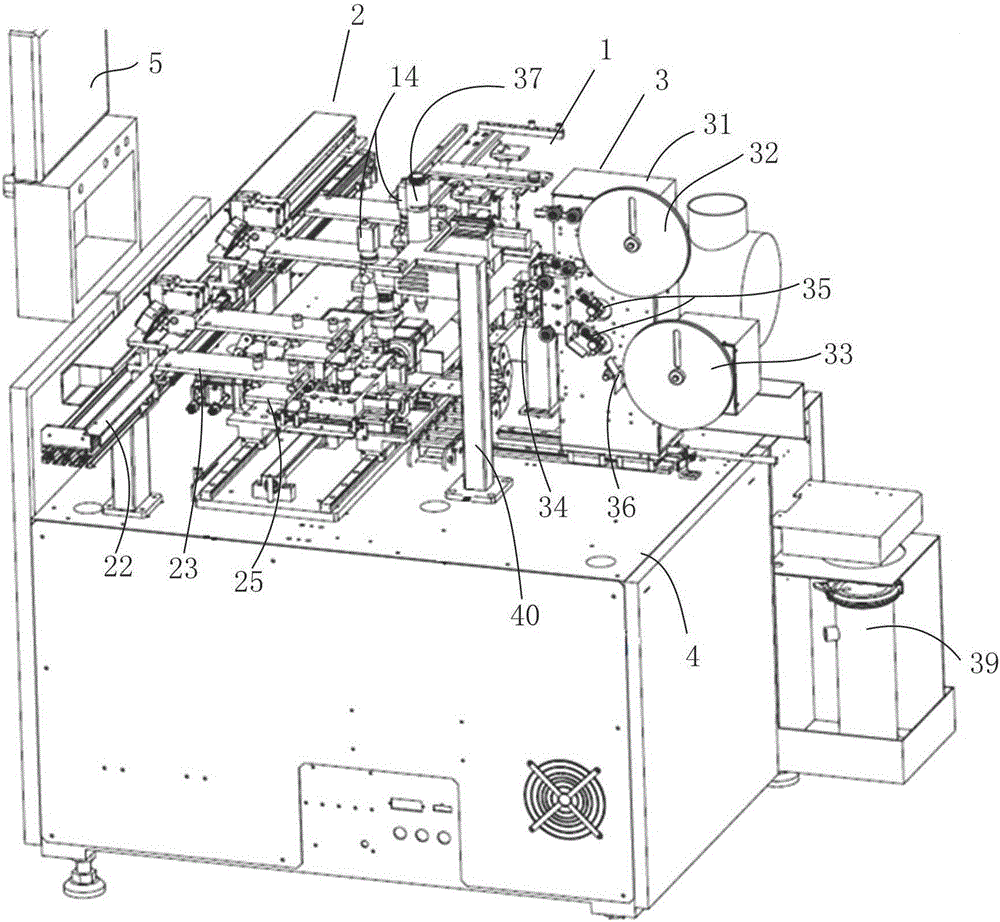

Multi-material photo-curing 3D printer

InactiveCN111674037AGuaranteed accuracy and stabilityImprove printing efficiency and throughputAdditive manufacturing apparatus3D object support structuresManufacturing engineering3D printing

The invention discloses a multi-material photo-curing 3D printer which comprises a machine frame. An X-axis straight moving mechanism and a Z-axis straight moving mechanism are fixed to the machine frame. A printing platform is disposed at the upper portion of the Z-axis straight moving mechanism. An installing platform is disposed below the printing platform. The installing platform is provided with a plurality of resin grooves and a cleaning groove. A graphical exposure system is arranged below the installing platform and is fixed to the lower portion of the Z-axis straight moving mechanism.By adding the plurality of resin grooves, the multi-color, multi-material and multi-performance-structure high-precision photo-curing 3D printing is realized; by arranging the cleaning groove, residual resin on printed structures can be cleaned up during multi-material printing, and precision and stability of printed products are ensured; only by means of one graphical exposure system, integratedmanufacturing of multi-material products can be realized, the printing efficiency and yield are increased, the equipment structure is simplified, equipment cost is reduced, and therefore the requirements of users for high-performance and full-functional customized products are met.

Owner:SOUTHEAST UNIV

Temperature measuring device capable of realizing stable temperature measurement and semiconductor device comprising temperature measuring device

ActiveCN104296887AGuaranteed accuracy and stabilityAvoid breakingSemiconductor/solid-state device testing/measurementThermometers using electric/magnetic elementsPhysicsTemperature measurement

The invention discloses a temperature measuring device capable of realizing stable temperature measurement and a semiconductor device comprising the temperature measuring device. According to the temperature measuring device, a thermal electrode fixing device is arranged in an insulating tube; two thermal electrodes are fixed relative to the insulating tube, so that a measuring end can well contact with the surface of an object to be subjected to temperature measurement, and therefore, influence on measurement results which is caused by a situation in which the thermal electrodes slide relative to the insulating tube due to dragging in a maintenance process when daily equipment maintenance is performed can be avoided, and the stability and accuracy of the measurement results can be ensured; and a spring is arranged below the insulating tube, and therefore, the measuring end can well contact with the object to be subjected to temperature measurement through the elastic force of the spring, and at the same time, the fracture of the object to be subjected to temperature measurement which is caused by rigid contact of the temperature measuring device and the object to be subjected to temperature measurement can be avoided.

Owner:ADVANCED MICRO FAB EQUIP INC CHINA

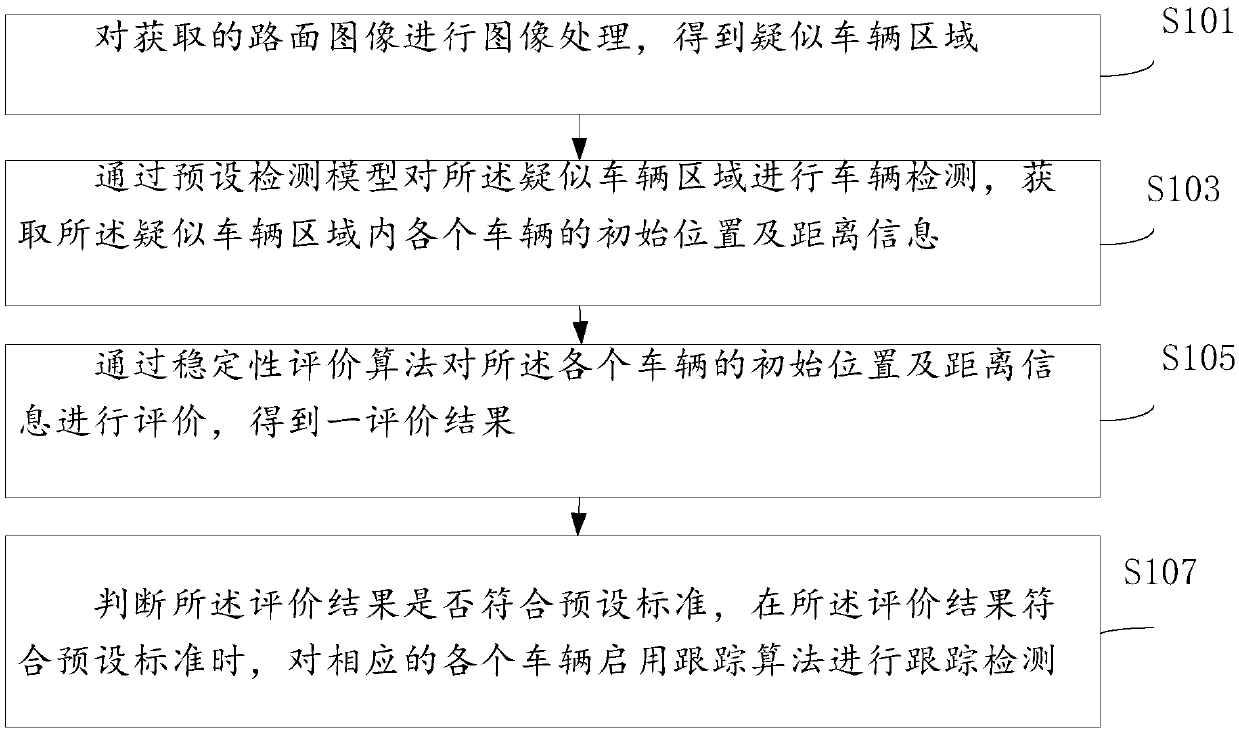

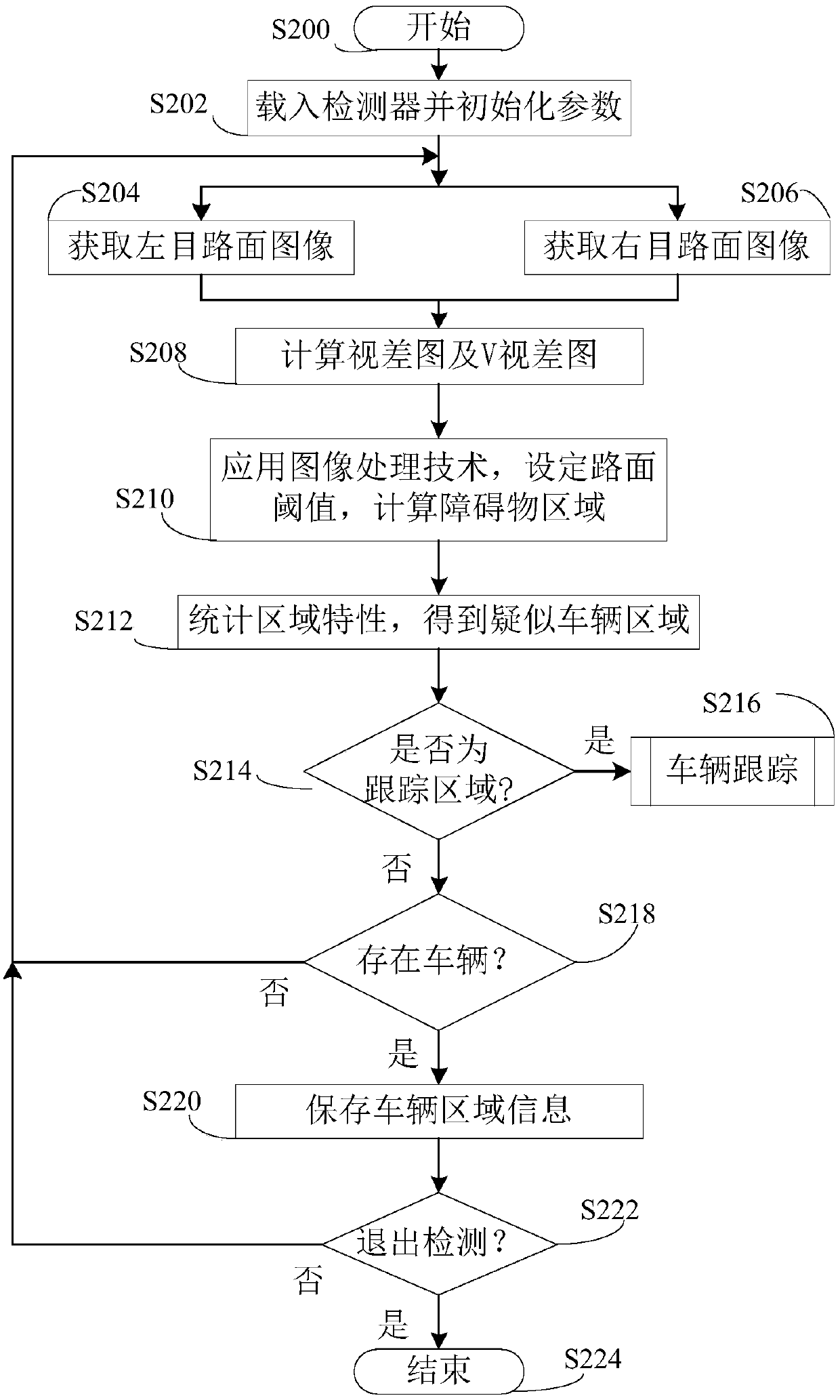

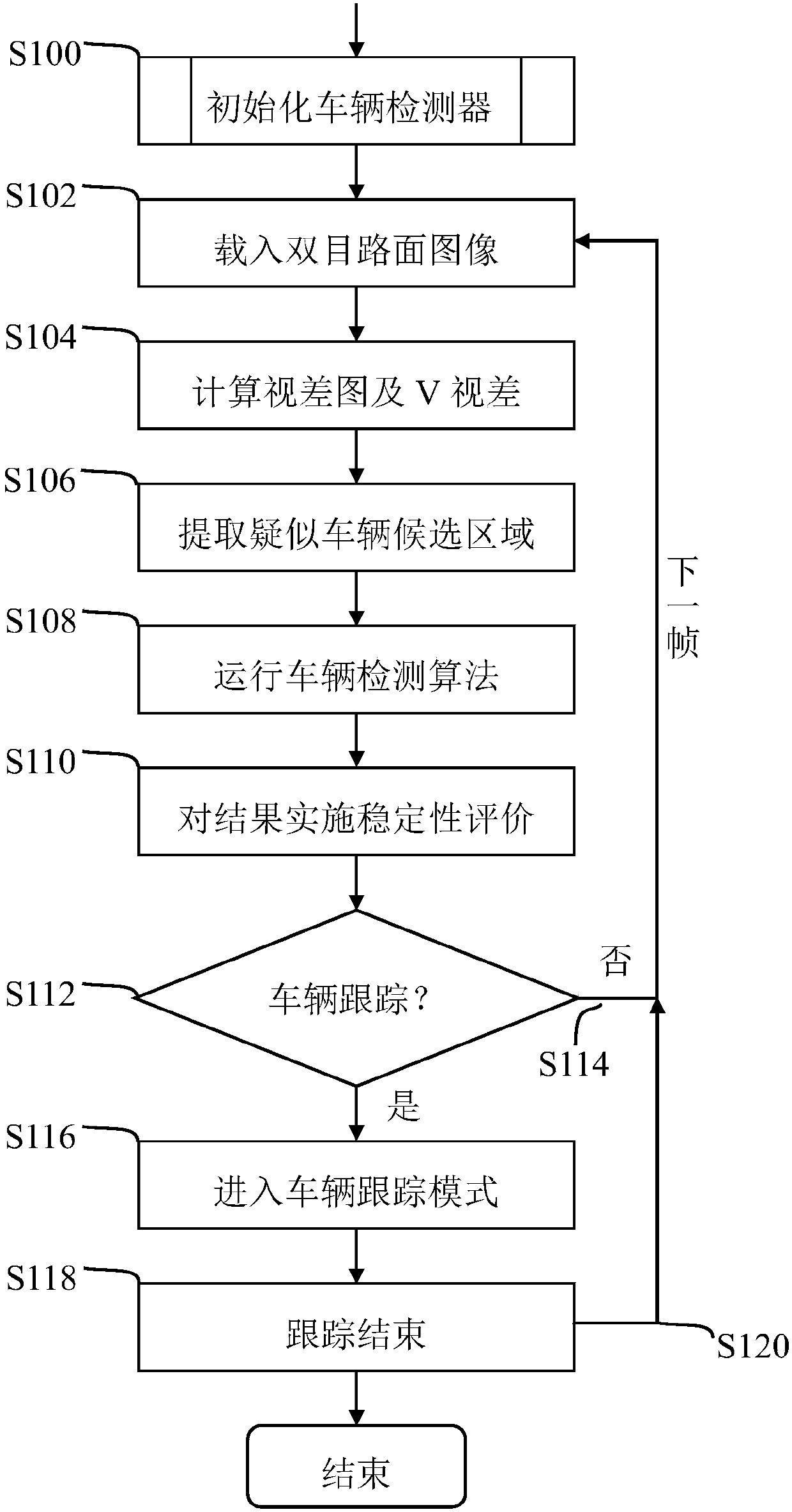

Disparity-map-based real-time vehicle tracking and detection method and device

ActiveCN107909012AShorten the timeGuaranteed accuracy and stabilityImage analysisCharacter and pattern recognitionEvaluation algorithmReal time tracking

The invention discloses a disparity-map-based real-time vehicle tracking and detection method and device. The real-time vehicle tracking and detection method comprises: carrying out image processing on an obtained pavement image to obtain a suspected vehicle area; carrying out vehicle detection on the suspected vehicle area by a preset detection model to obtain initial position and distance information of each vehicle in the suspected vehicle area; evaluating the initial position and distance information of each vehicle based on a stability evaluation algorithm to obtain an evaluation result;determining whether the evaluation result meets a preset standard; and if so, carrying out tracking and detection on all corresponding vehicles by starting a tracking algorithm. According to the invention, on the basis of a disparity map, real-time tracking and detection of a vehicle is realized under the circumstance that the computing resources are limited; and thus the real-time performance andstability of positioning are improved on the premise that the vehicle detection precision is ensured.

Owner:BEIJING SMARTER EYE TECH CO LTD

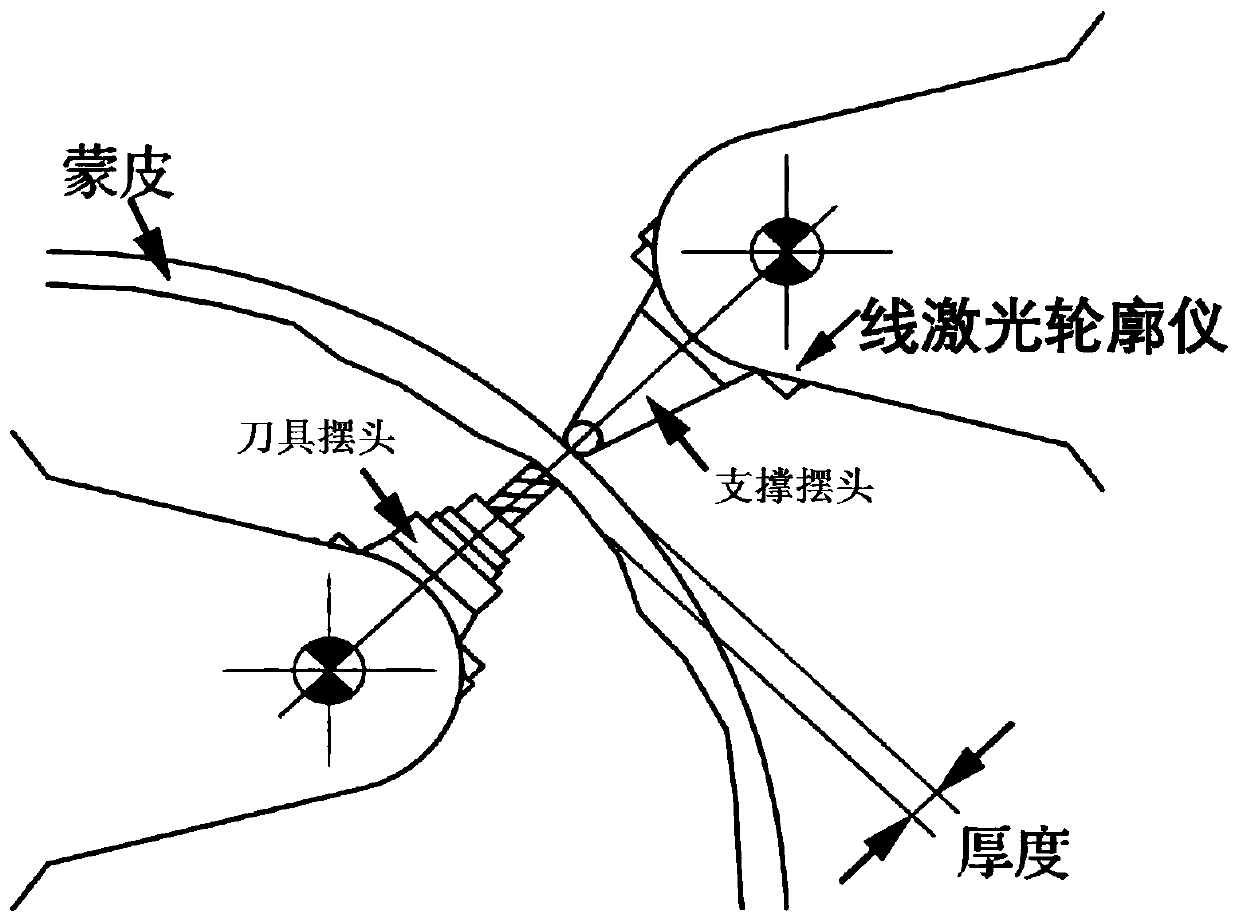

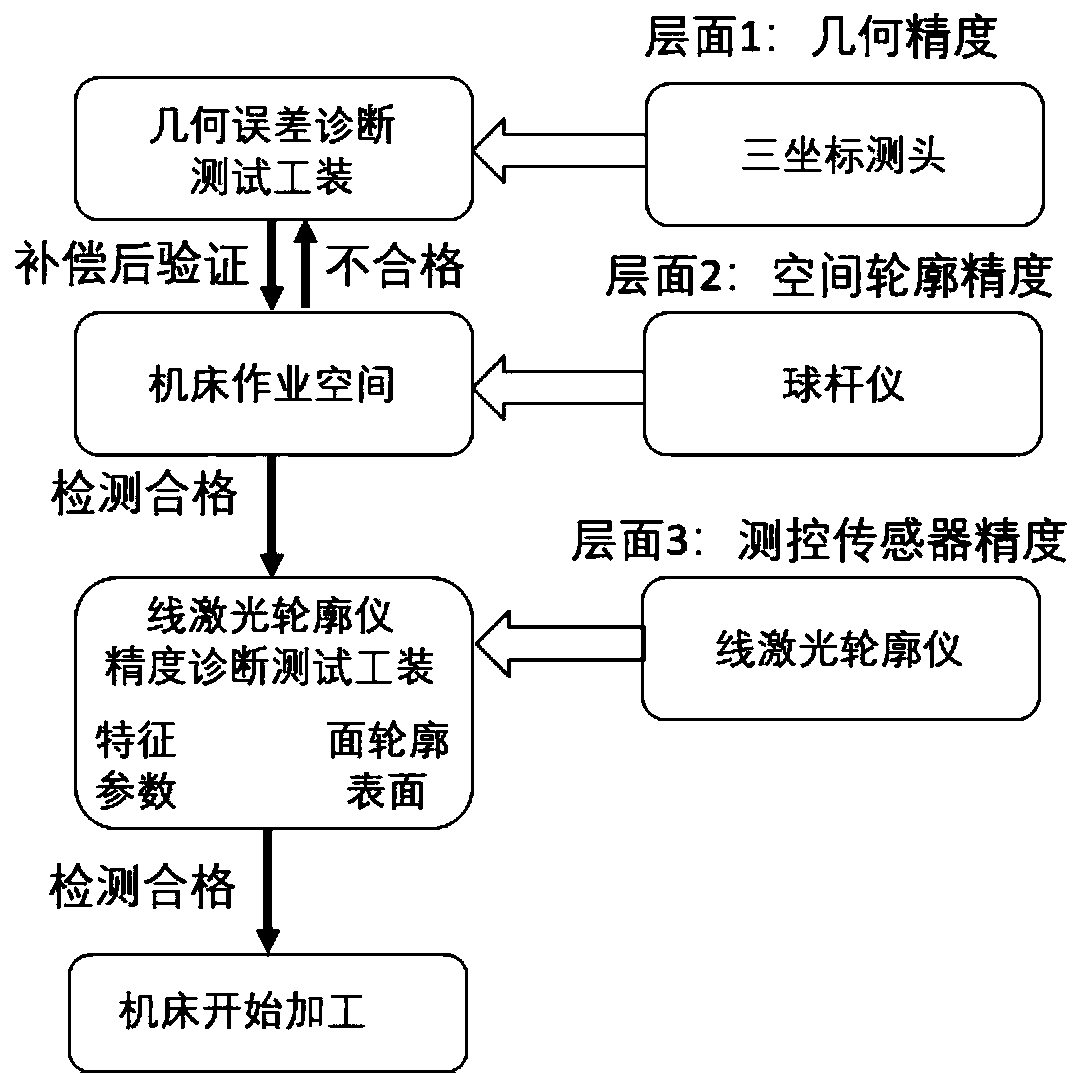

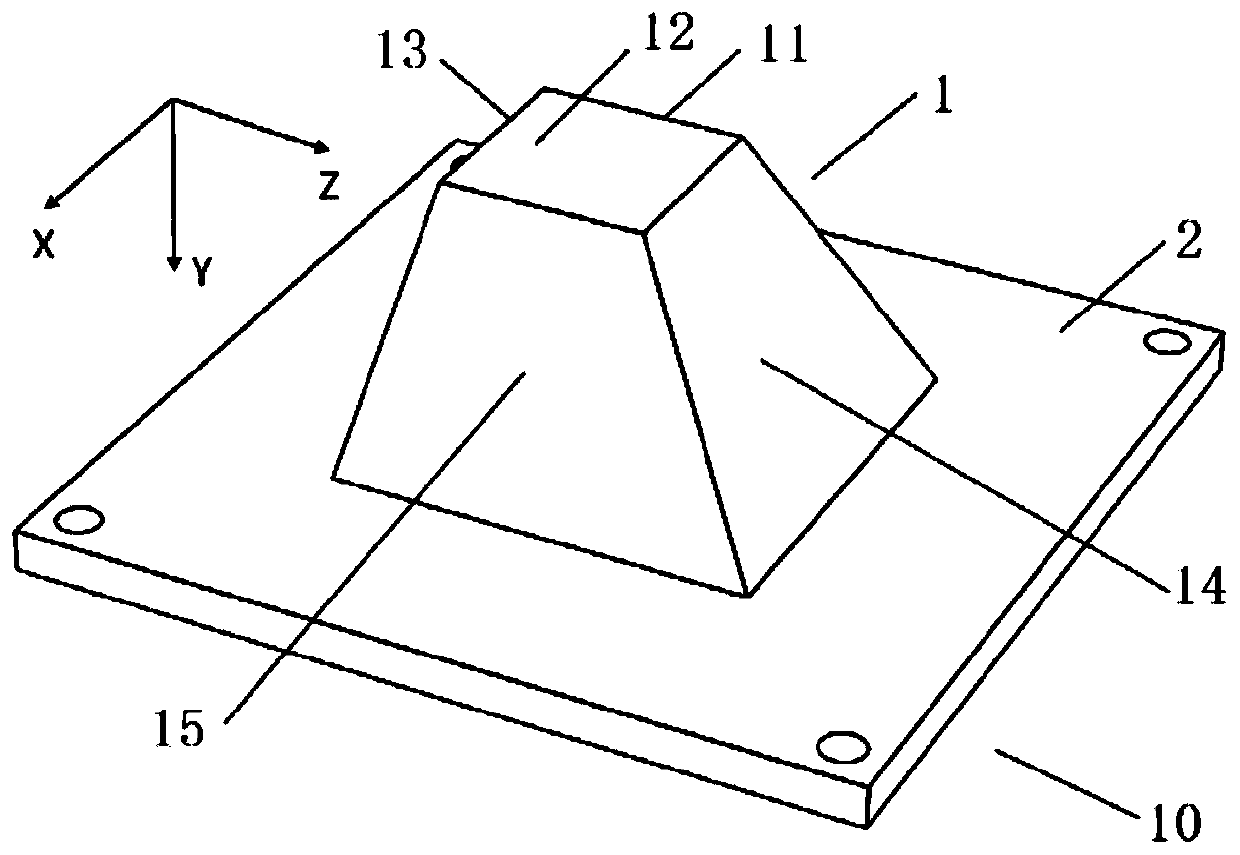

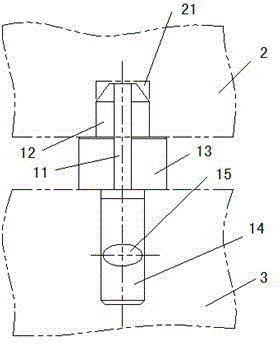

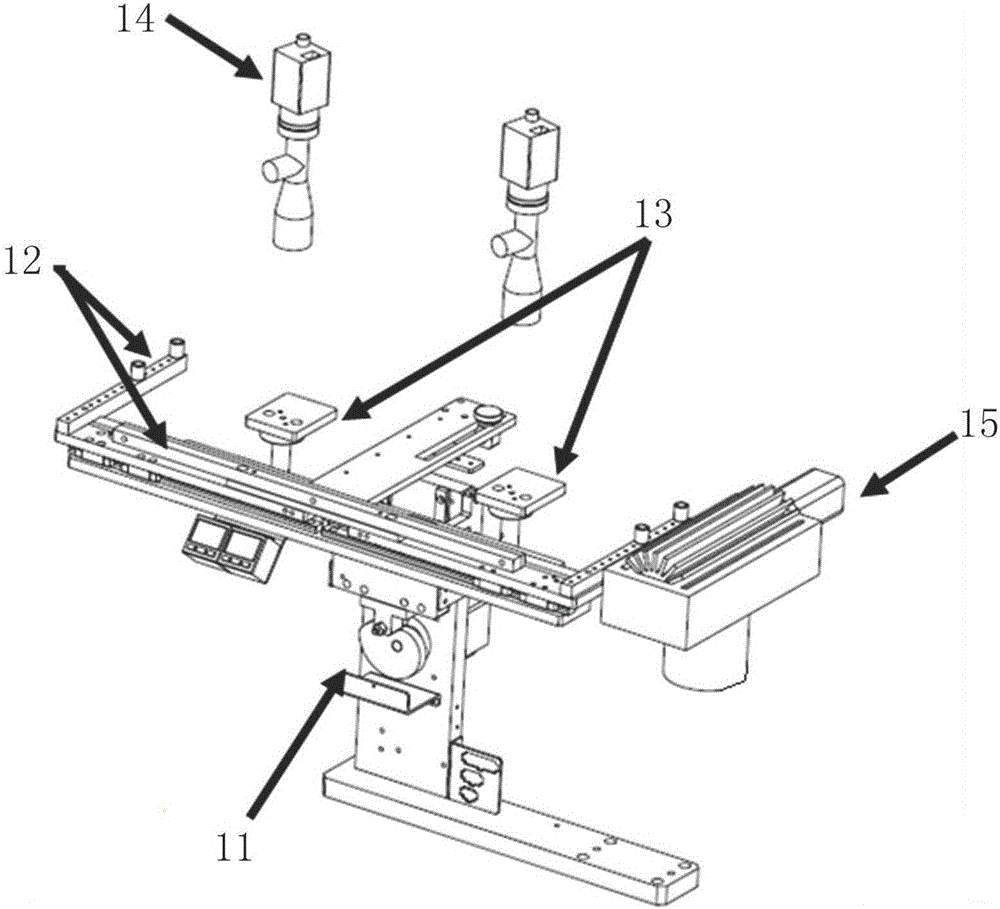

Precision self-diagnosis method of double-five-axis mirror milling machine tool

ActiveCN110539020AImplement diagnosticsRealize all-round precision detectionAutomatic control devicesMeasurement/indication equipmentsContour errorMachine tool

The invention discloses a precision self-diagnosis method of a double-five-axis mirror milling machine tool. The precision self-diagnosis method comprises the steps that automatic zero point detectionbased on a three-coordinate measuring head and a self-diagnosis testing tool is adopted to carry out position detection on the tool to calculate zero return deviation so that the geometric precisionof the machine tool can be diagnosed; a ball-bar is used for obtaining the machine tool movement contour error so as to diagnose the machine tool spatial contour precision; and the precision of a sensor is evaluated according to the testing result of the tool process position tested by a line laser contour instrument, and the measurement and control sensor precision of the mirror milling machine tool is diagnosed. According to the method, the state characteristics of the double-five-axis mirror milling machine tool are extracted according to production requirements, and the machine tool precision is diagnosed from three aspects of machine tool geometric precision, spatial contour precision and measurement and control sensor precision, so that the diagnosis efficiency is improved on the premise of guaranteeing the evaluation precision, and the self-evaluation of the periodic operation health state of the machine tool is completed.

Owner:TSINGHUA UNIV

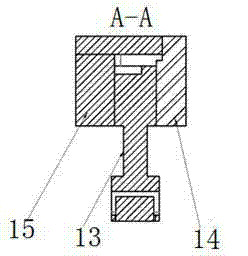

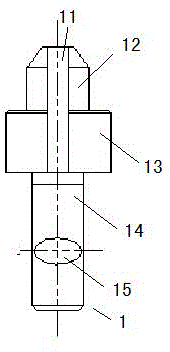

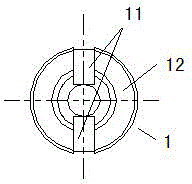

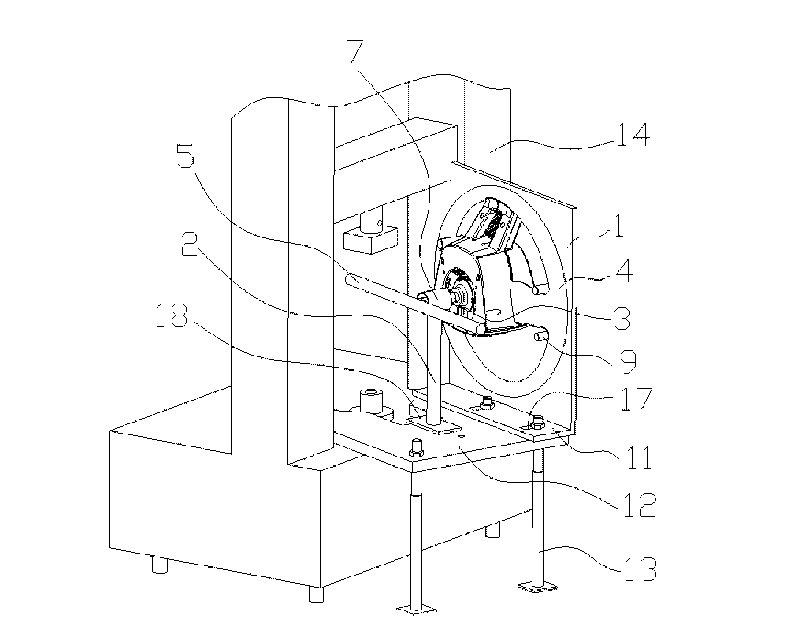

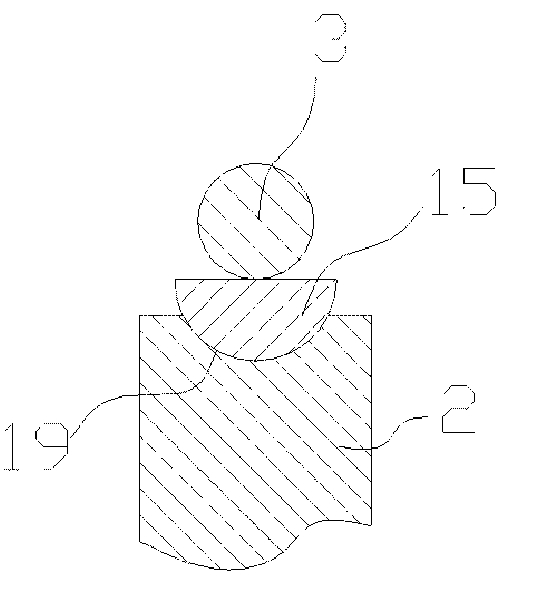

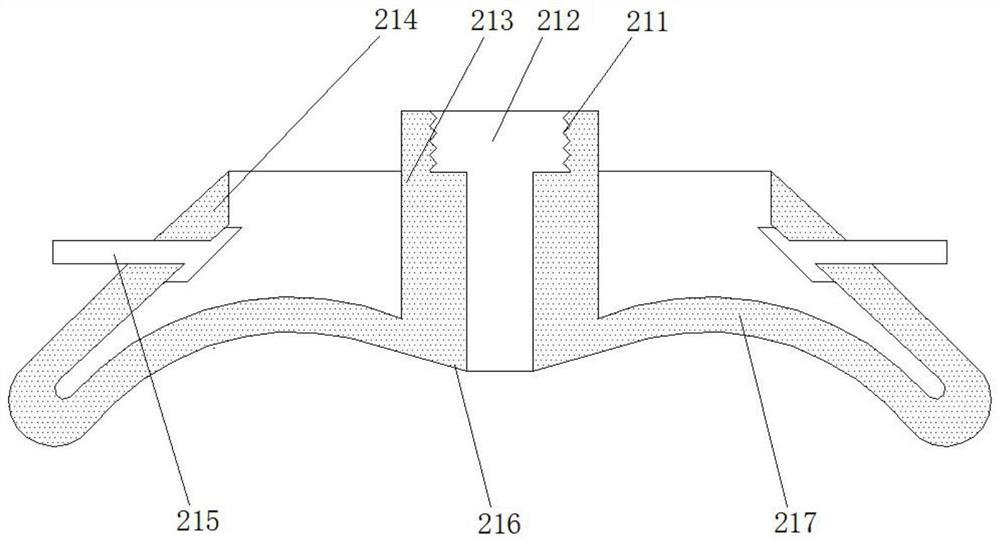

Positioning pin facilitating workpiece cleaning

ActiveCN104826849AGuaranteed accuracy and stabilitySimple structureBoltsCleaning processes and apparatusEngineeringScrew thread

The invention relates to a positioning pin facilitating workpiece cleaning. The positioning pin comprises a pin body, a positioning column inserted into a workpiece pin hole is arranged at one end of the pin body, a connection column in threaded connection with a fixture is arranged at the other end of the pin body, the surface of the connection column is provided with external threads, a supporting table is disposed between the positioning column and the connection column, and multiple channels penetrate out of the surface of the supporting table from the bottom end of the positioning column and along the side face of the positioning column. By means of the technical scheme, the problem that a workpiece pin hole is not cleaned thoroughly when an existing cleaning machine positioning pin is used can be solved.

Owner:CHONGQING CHANGAN AUTOMOBILE CO LTD

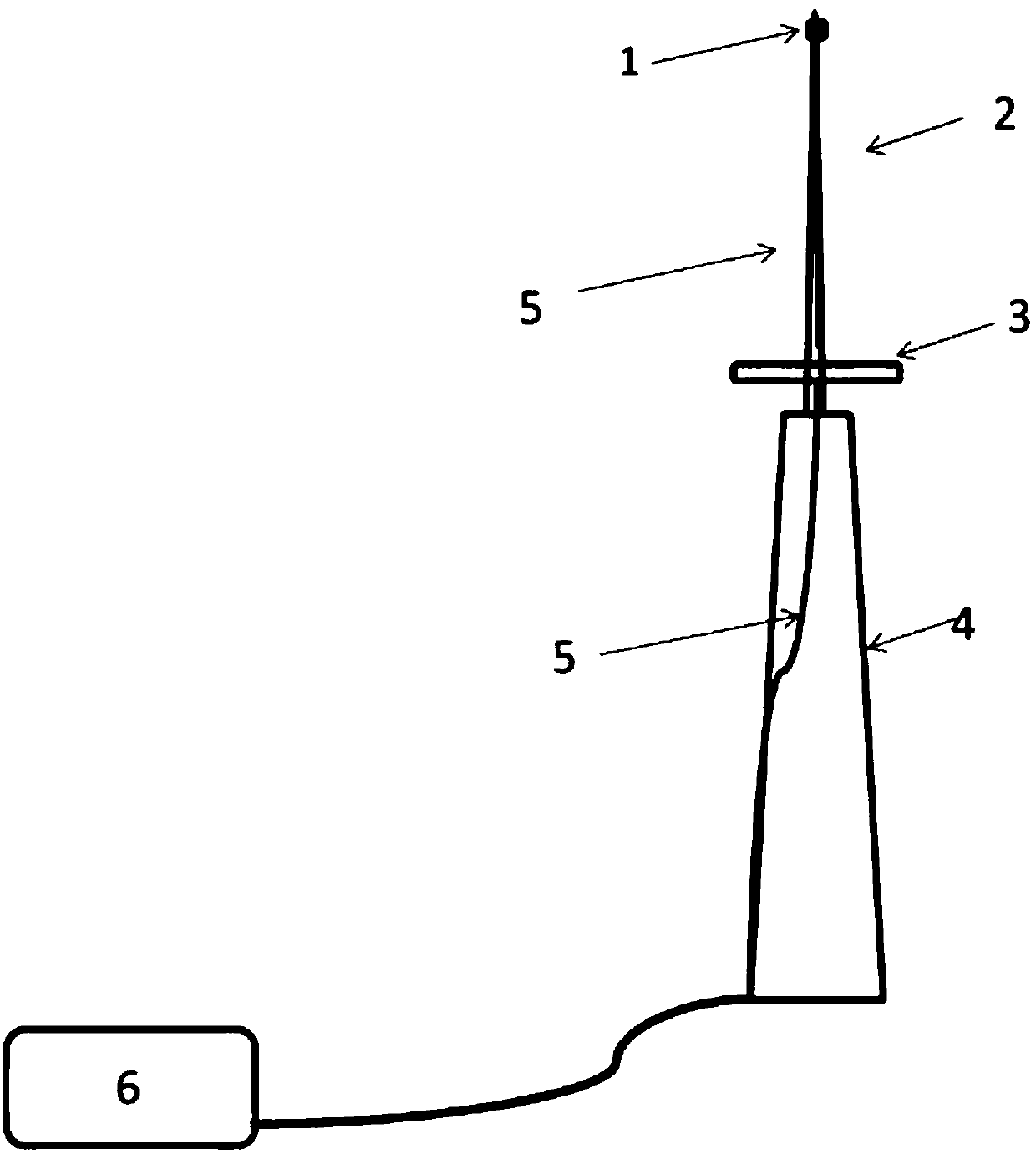

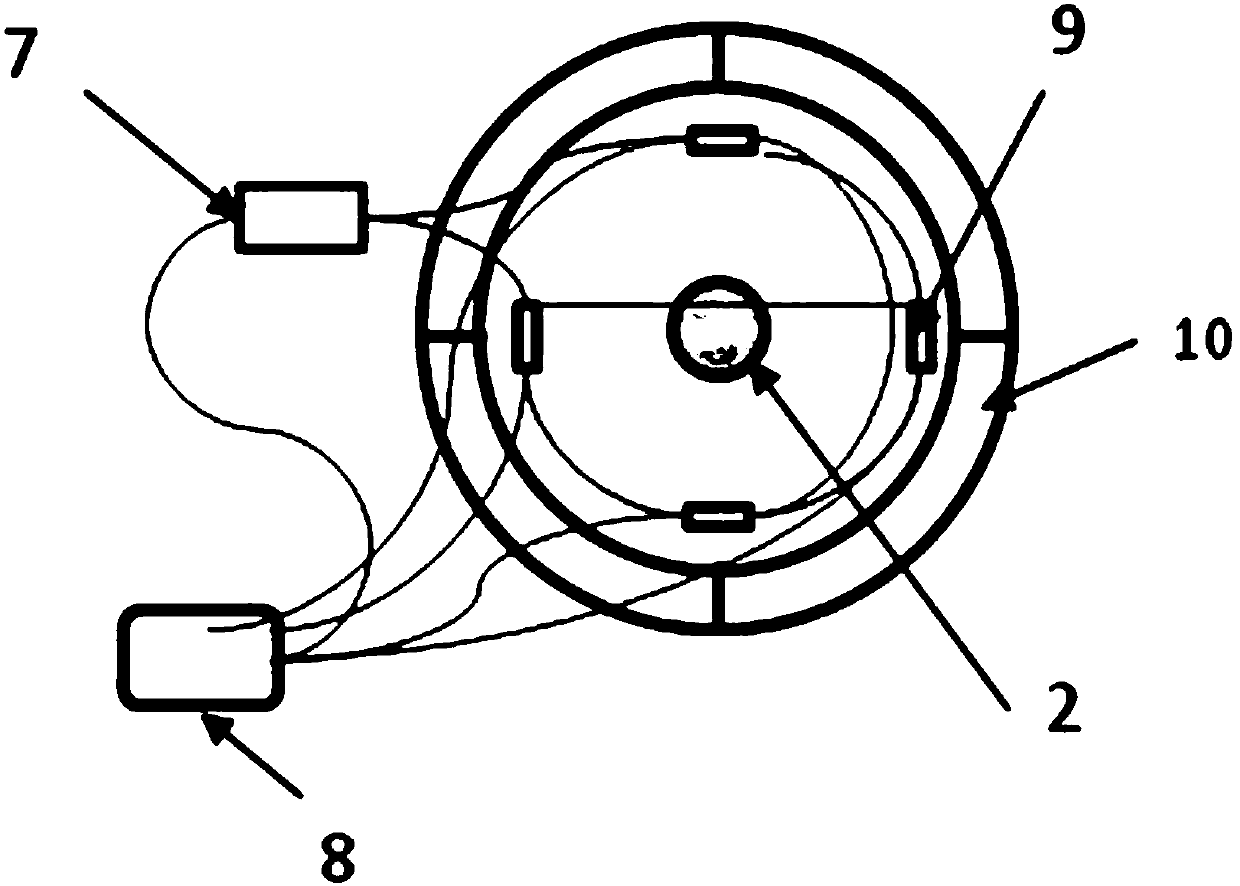

Crystal magneto-optical valve system used for DC large current monitoring

InactiveCN107765060AStrong ability to resist external magnetic field interferenceHigh measurement accuracyCurrent measurements onlyVoltage/current isolationFiberEngineering

The invention discloses a crystal magneto-optical valve system for direct current high current monitoring, comprising: a trigger, a fiber optic current transformer and a demodulator, the trigger and the fiber optic current transformer are respectively connected with the demodulator by optical cables; The optical fiber current transformer includes a plurality of magneto-optical crystal sensor heads, optical fiber branchers, optical scales and homogeneous magnetic rings, and a plurality of magneto-optical crystal sensor heads are connected in series on the optical scale and are grouped and connected in parallel on the optical fiber brancher. The splitter is connected with the optical scale, and the other end of the optical fiber splitter is connected with the demodulator by an optical cable; the magneto-optical crystal sensor head is a sensor head made of a crystal light valve; the demodulator Including information storage module and current calculation module. It has the characteristics of strong resistance to external magnetic field interference, high measurement accuracy, strong accuracy and high reliability.

Owner:广州申畅沃光电科技有限公司

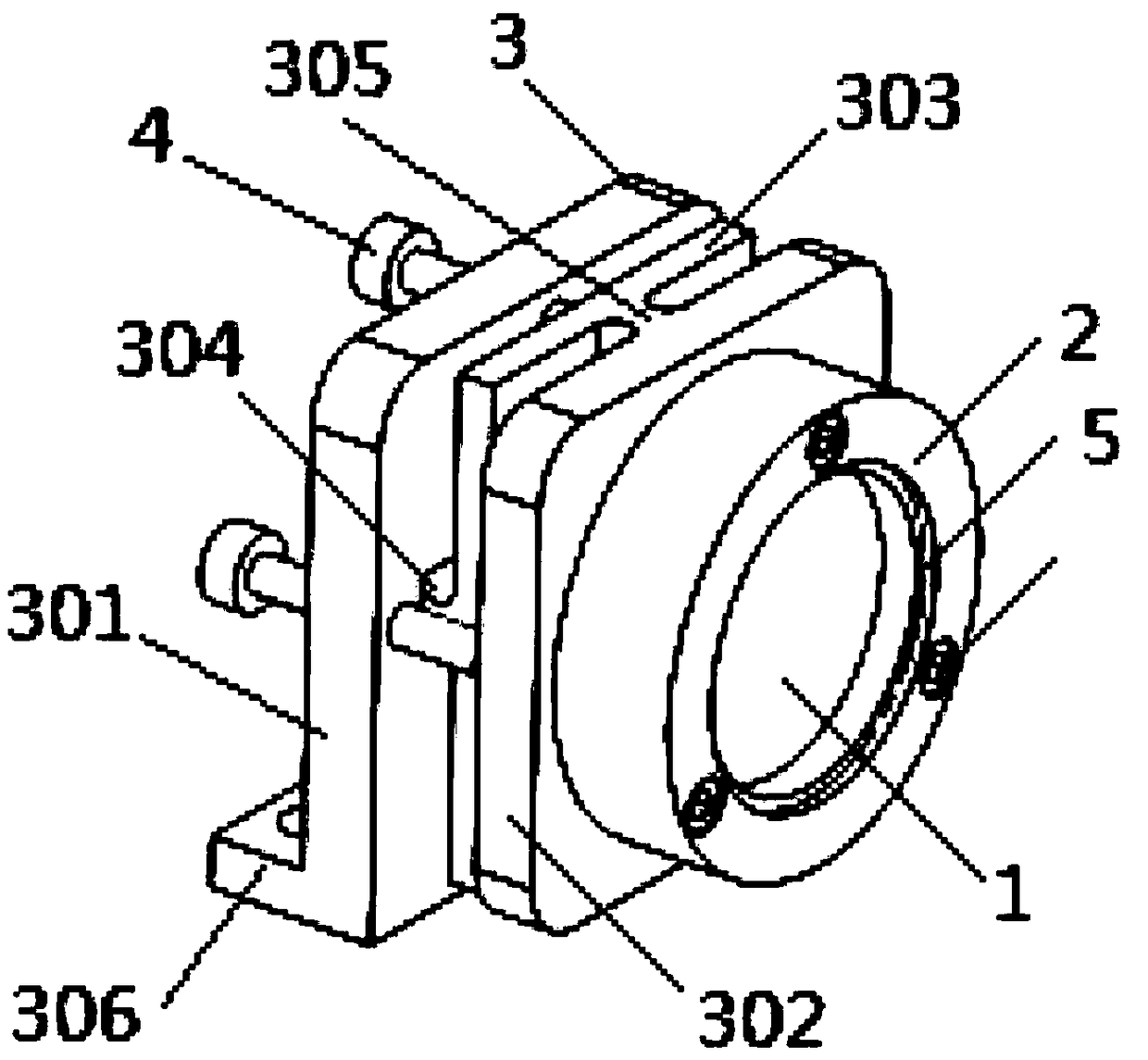

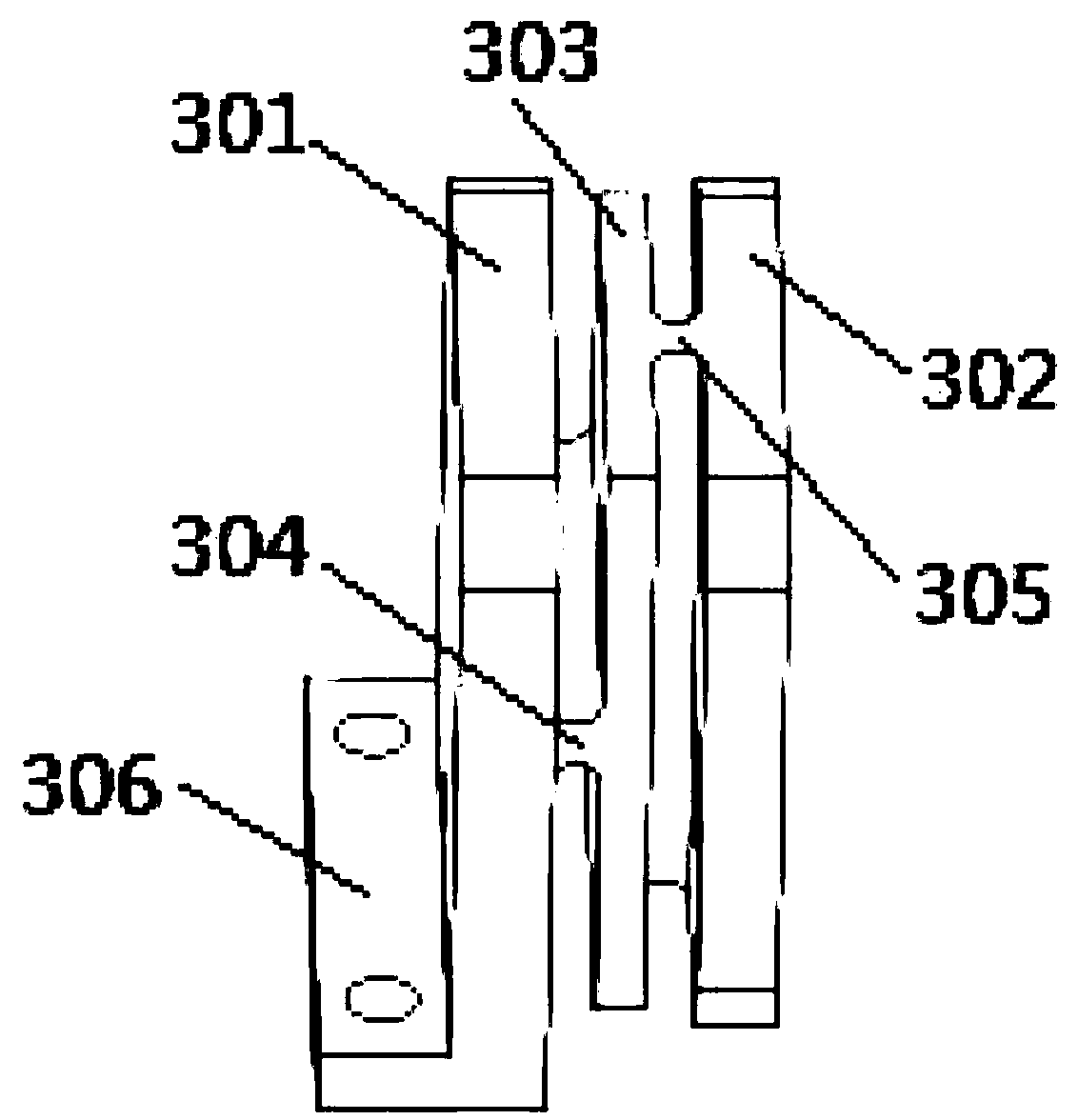

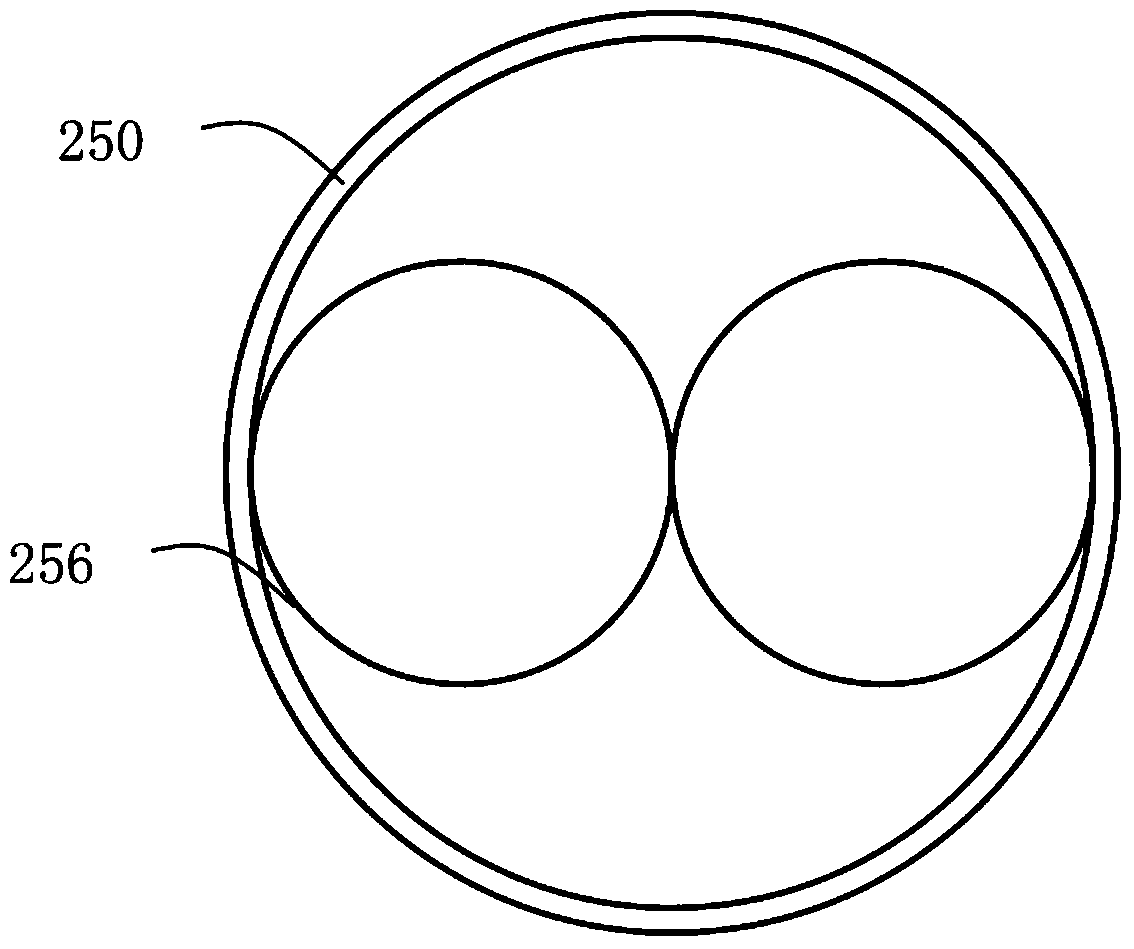

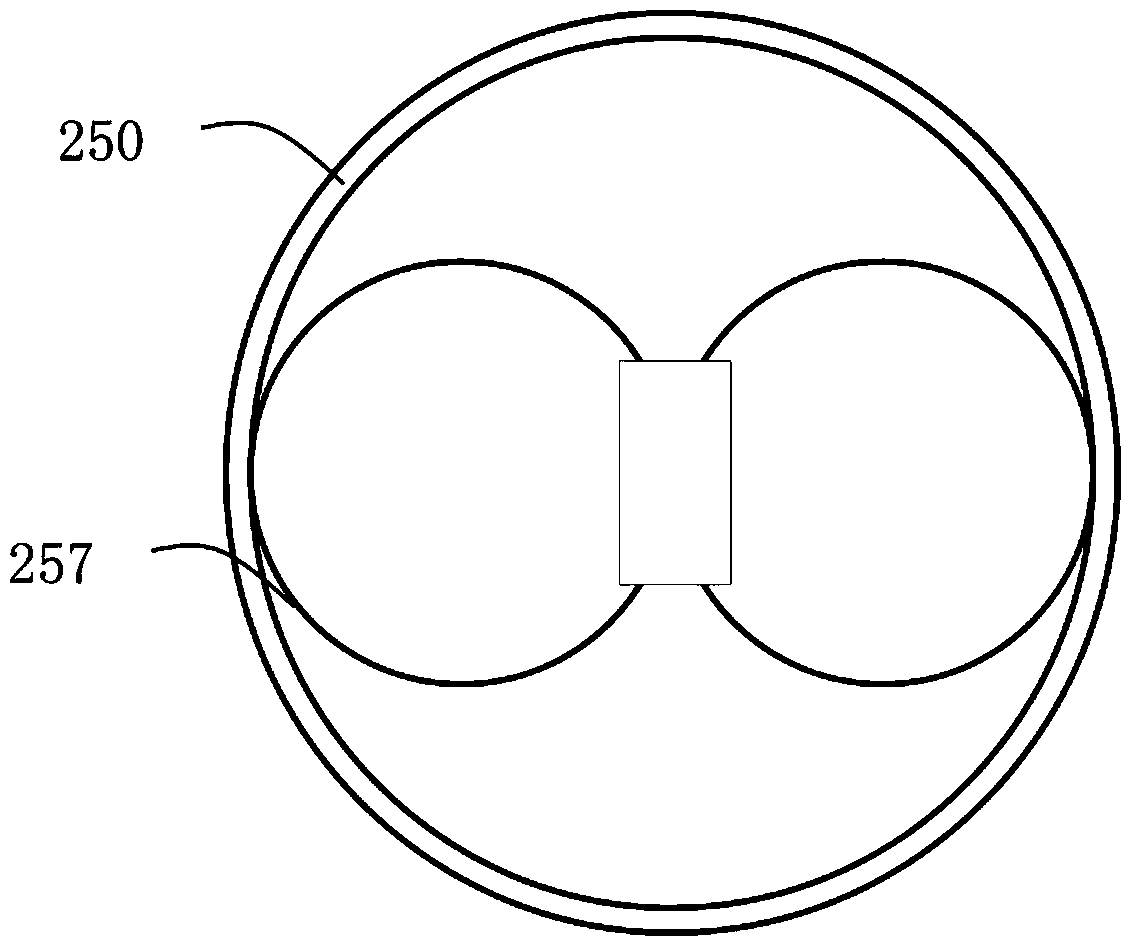

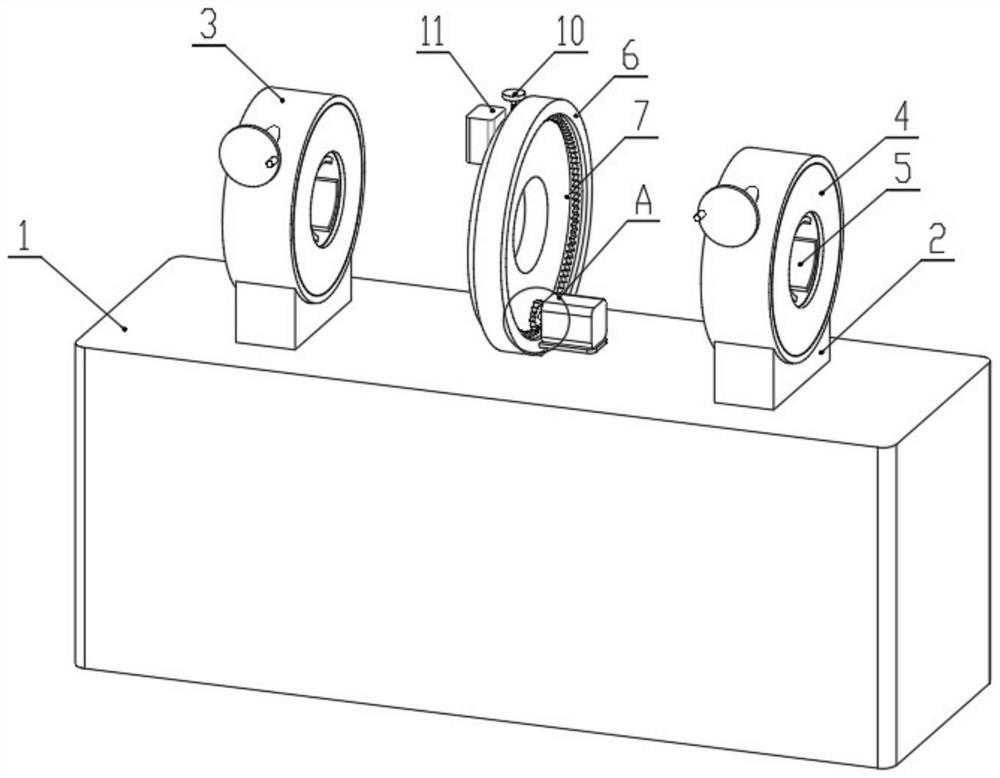

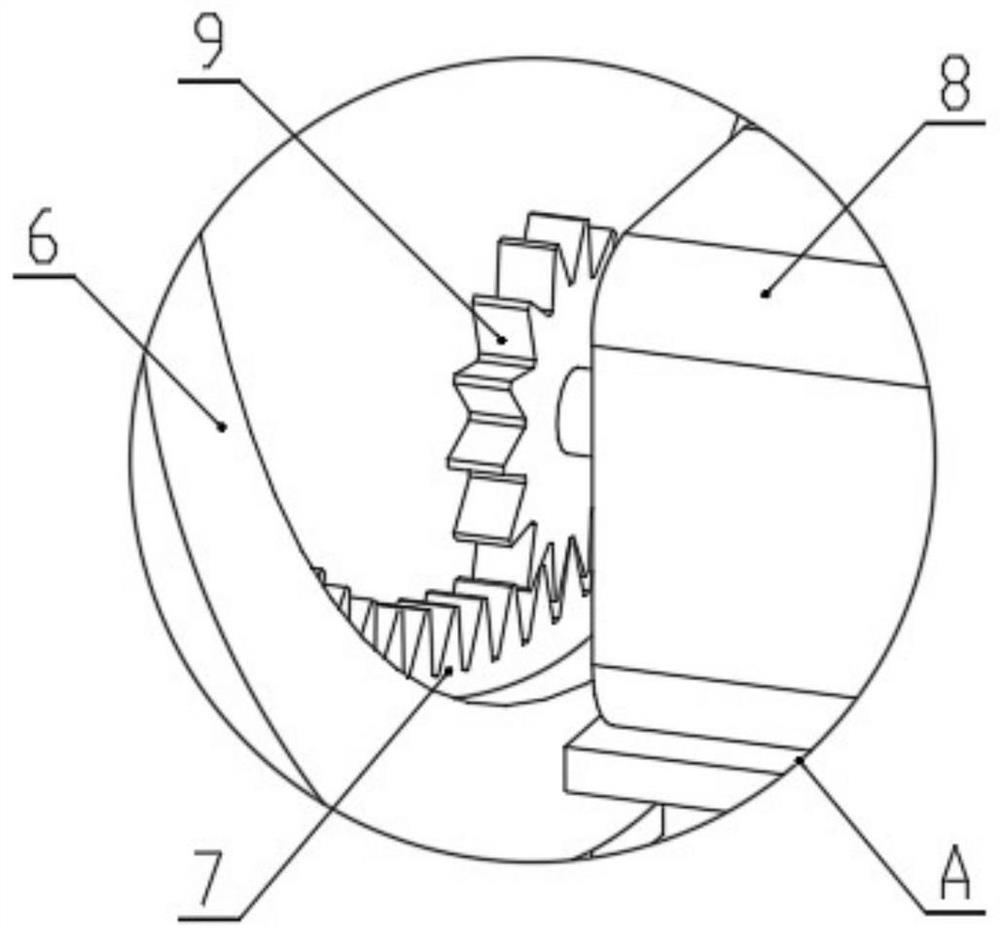

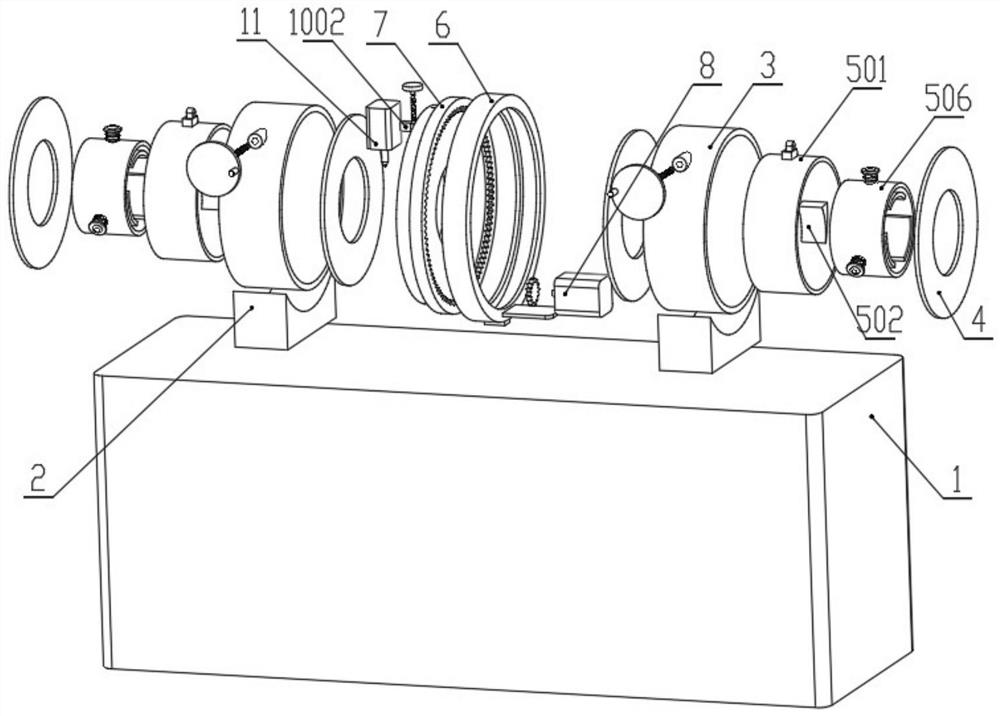

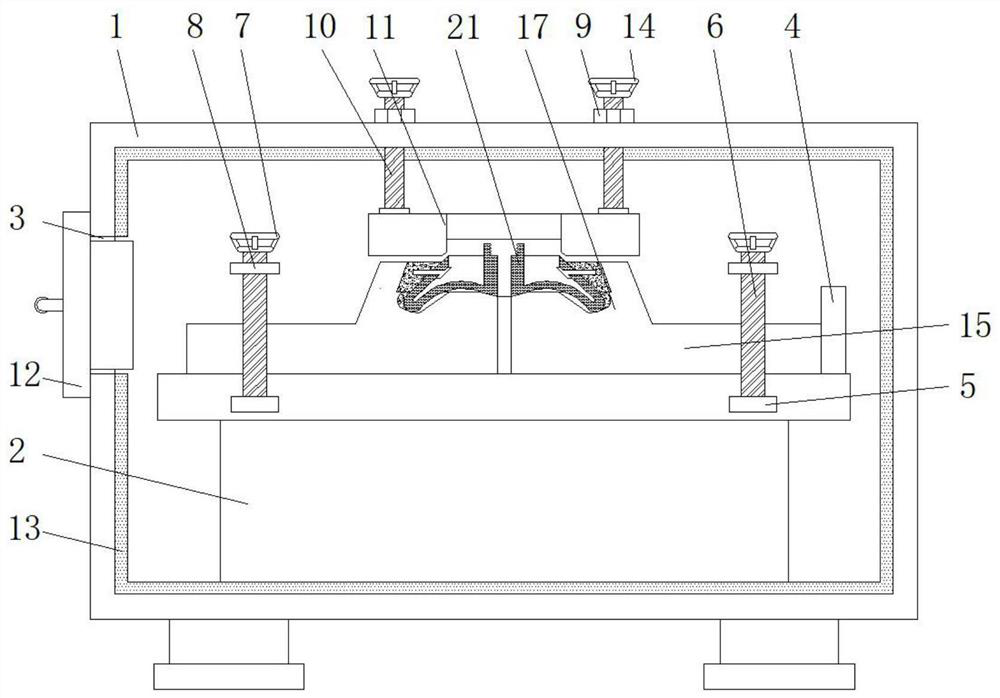

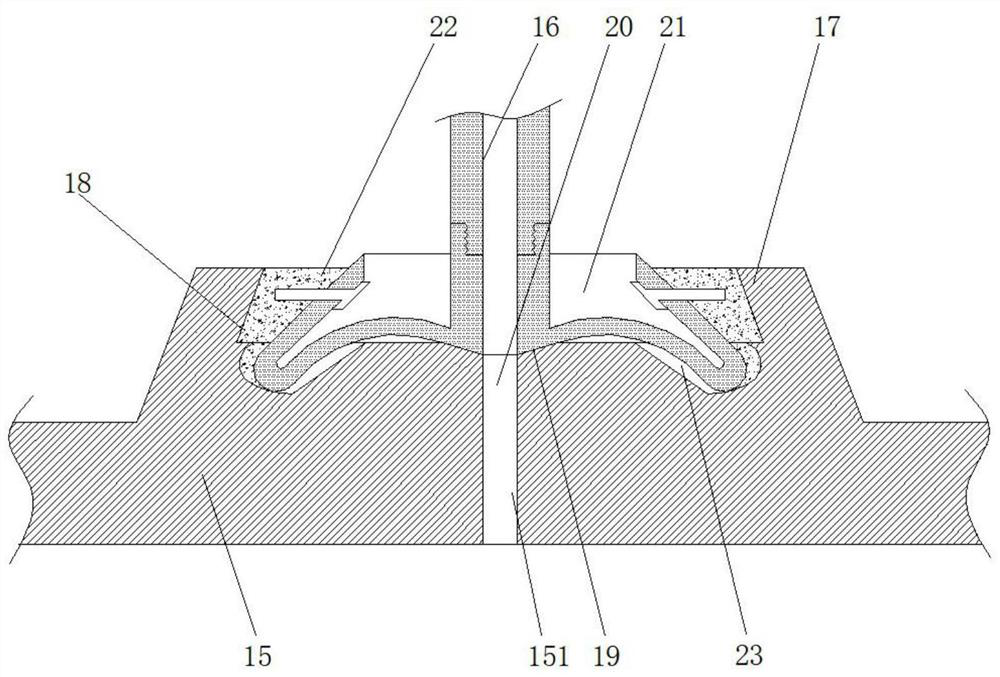

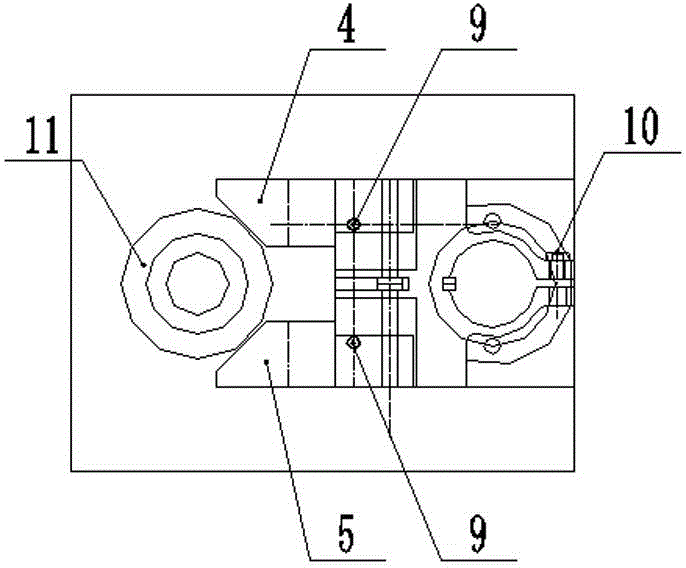

Automatic welding device and method for pipeline butt-joint machining

InactiveCN114029693AGuaranteed accuracy and stabilityQuality improvementWelding/cutting auxillary devicesAuxillary welding devicesSteel tubeManufacturing engineering

The invention discloses an automatic welding device and method for pipeline butt-joint machining. The automatic welding device comprises a workbench, fixing seats, clamping frame bodies, side cover plates and clamping adjusting mechanisms, wherein the fixing seats are connected to the left side and the right side of the upper end face of the workbench; the clamping frame body is fixedly connected to the position of the upper side of the fixing seat; the side cover plates are connected to the left side and the right side of the clamping frame body; and the clamping adjusting mechanism is arranged in the clamping frame body. According to the automatic welding device for pipeline butt-joint machining, steel pipes can be conveniently, rapidly and stably clamped and fixed, so that the butt-joint precision and stability of the steel pipes can be effectively guaranteed, the welding quality of the steel pipes is improved, the steel pipes can be conveniently, automatically and uniformly welded, the welding machining efficiency of the steel pipes is improved, the steel pipes with different diameters can be conveniently welded through adjustment of a distance adjusting mechanism, and the applicability of the welding device is improved.

Owner:NANJING NIEBO INTERNET OF THINGS TECH CO LTD

Novel orthodontics correction method

InactiveCN110236709AAchieve tight fitGuaranteed accuracy and stabilityAdditive manufacturing apparatusOthrodonticsThree dimensional modelCorrection method

The invention discloses a novel orthodontics correction method. The novel orthodontics correction method comprises the steps of (1) obtaining the data of the oral cavity of a patient; (2) determining the parameter of an oral cavity three-dimensional model; (3) constructing a three-dimensional model of an invisible correction machine; (4) making the invisible correction machine; and (5) performing treatment. According to the orthodontics correction method, the problem that a conventional treatment scheme which is set is greatly different from actual desired results for invisible correction is solved, the correction machine device can be used for designing treatment re-set targets according to the specific situation of different patients from designing the treatment method to making the invisible correction machine, so as to realize tight cooperation of the design target with the wearing precision of the correction machine by a patient to be corrected, which is favorable for correction for the patient.

Owner:苏州博思美医疗科技有限公司

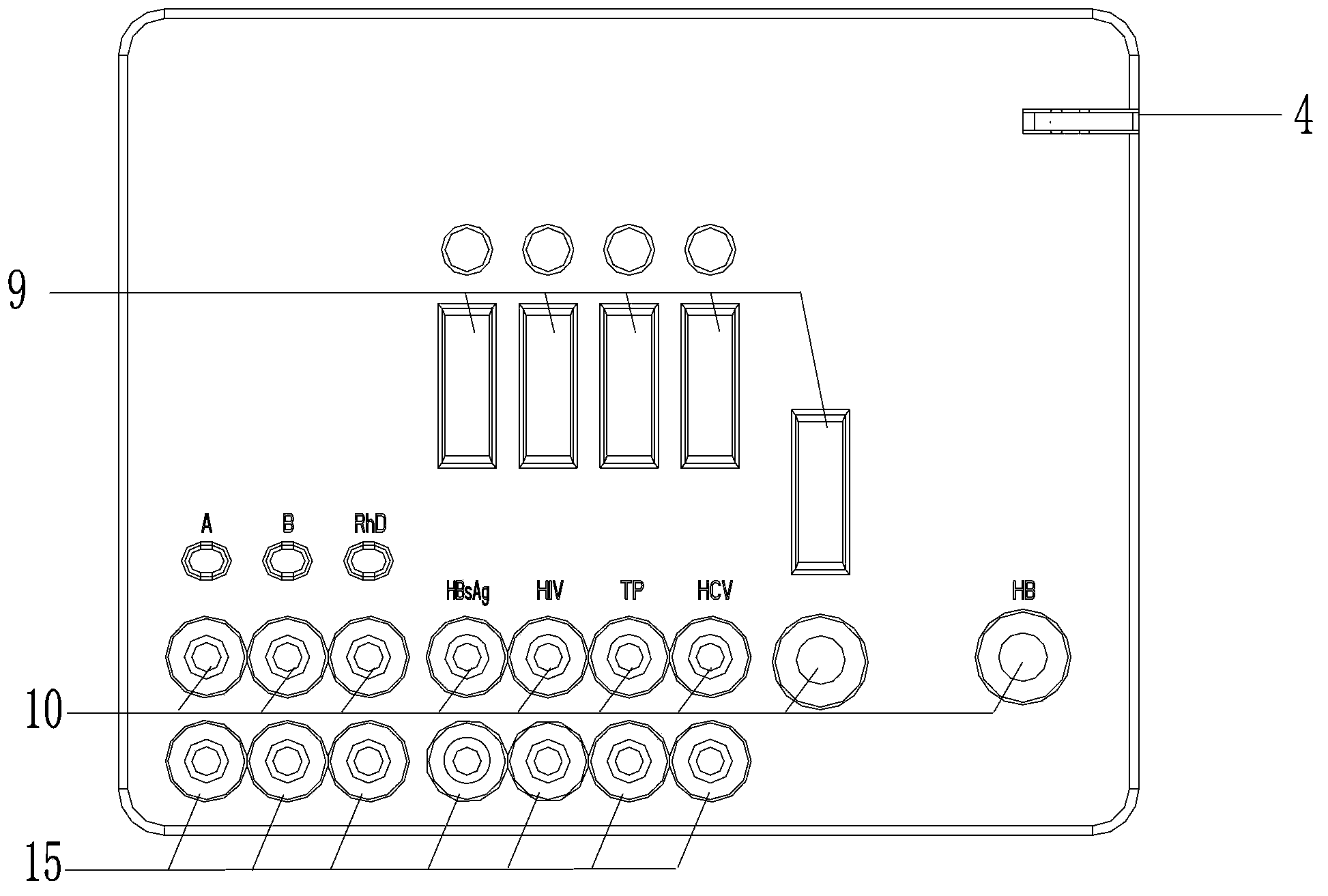

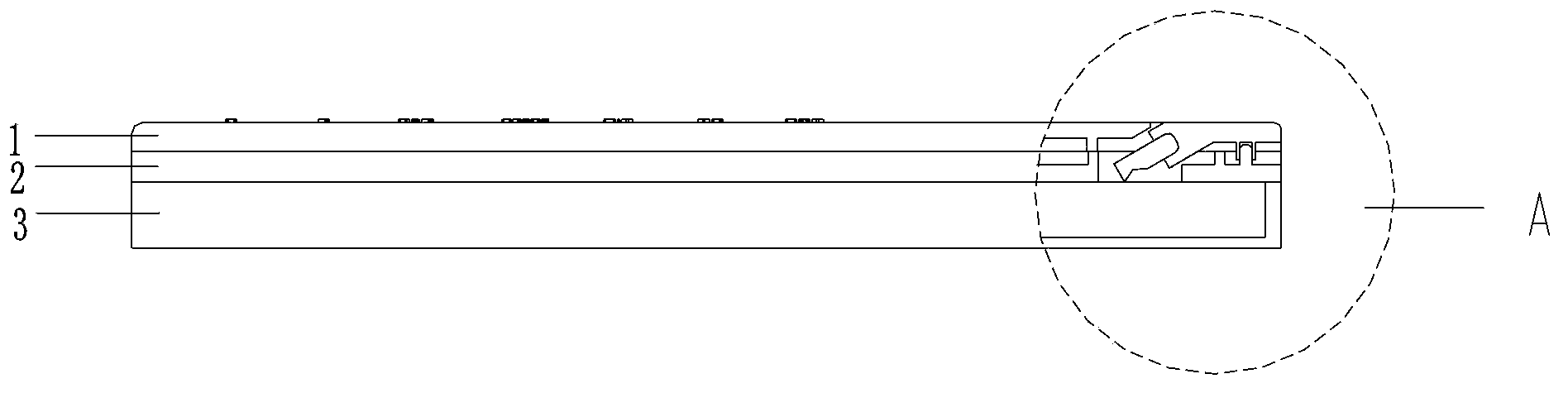

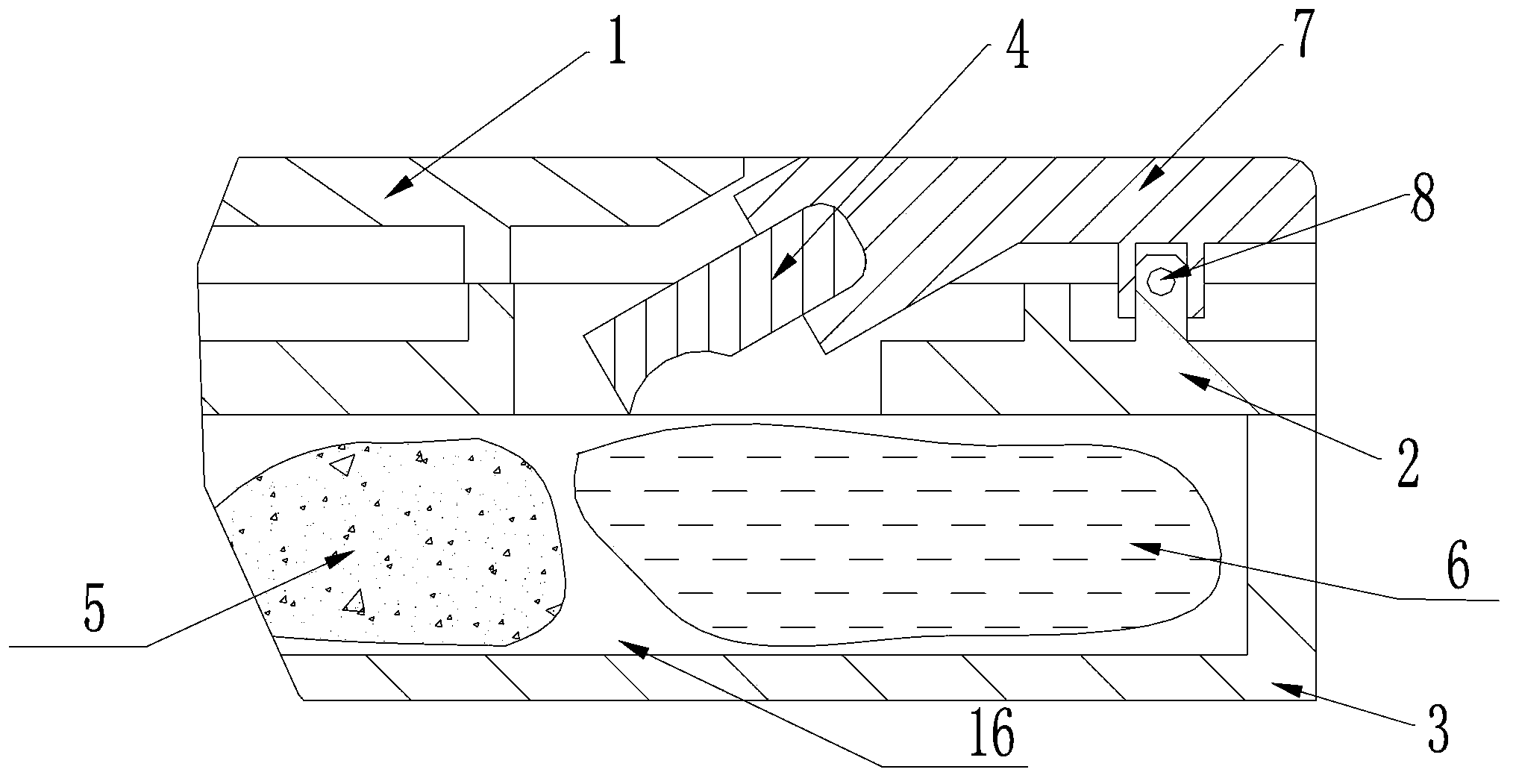

Field emergency blood safety screening test card

ActiveCN103439479AGuaranteed accuracy and stabilityEasy to operateBiological testingBlood ScreeningReagent strip

The invention discloses a field emergency blood safety screening test card. The test card comprises a card seat (3), a reagent strip layer (2) and a card cover (1) buckling on the card seat (3). The card seat (3) is provided with a card slot (16); a water bag (6) and a quick lime bag (5) are arranged in the card slot (16); the water bag (6) is tightly against the quick lime bag (5); and a movable buckle knife (4) is disposed above the water bag (6). The field emergency blood safety screening test card is suitable for a plurality of comprehensive tests with one card in a low temperature environment. Test results can be read only by naked eyes. Operations are simple; test is fast; results are accurate; and the test card is particularly suitable for blood screening before field emergency transfusion.

Owner:NANJING GENERAL HOSPITAL NANJING MILLITARY COMMAND P L A +1

Static twist positioning and clamping device of steering wheel

InactiveCN101713704AGuaranteed accuracy and stabilityReduce frictionVehicle testingWork measurementEngineeringSteering wheel

The invention discloses a static twist positioning and clamping device of a steering wheel, which has simple structure, high test precision, convenient operation and use, high efficiency and low cost. The device comprises a supporting platform and is characterized in that the supporting platform is in an L shape, and the transverse surface of the L-shaped supporting platform is provided with a strut bar on the same side of the longitudinal surface thereof; the top end of the strut bar is provided with a locating bar which rotates vertically to the axis of the strut bar; one end of the locating bar is coaxially connected with the steering wheel inserted and hung on the longitudinal surface of the L-shaped supporting platform; and the other end is connected with a force applying bar.

Owner:ZHEJIANG GEELY AUTOMOBILE RES INST CO LTD +1

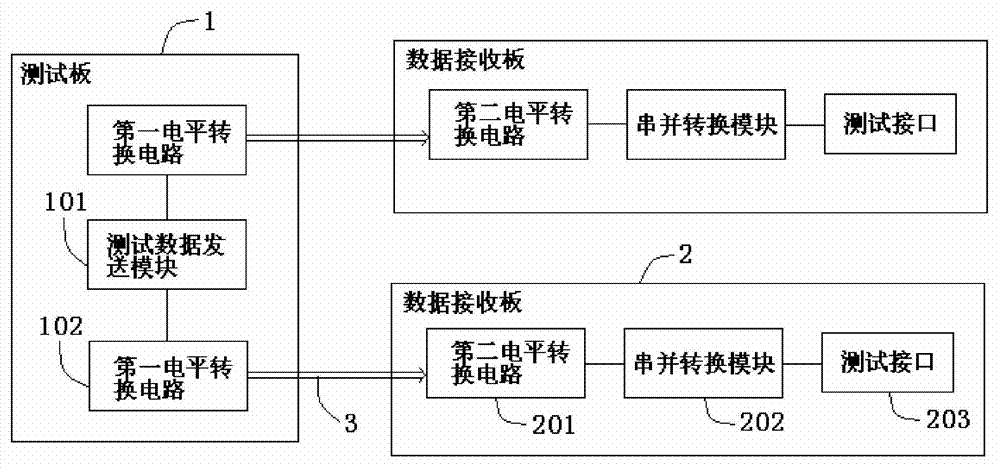

Power-up aging test device for liquid crystal display module

InactiveCN104297954AImprove convenienceGuaranteed accuracy and stabilityNon-linear opticsContinuous operationLiquid-crystal display

The invention discloses a power-up aging test device for a liquid crystal display module. The power-up aging test device comprises a test board arranged outside an aging test chamber, and a data receiving board arranged in the aging test chamber. The test board and the data receiving board are connected through a serial port extension cord. The test board comprises a test data transmitting module and a first level switch module. The data receiving board comprises a second level switch module, a series-to-parallel module and a plurality of test interfaces used for being connected with the liquid crystal display module. According to the power-up aging test device for the liquid crystal display module, as the test board is arranged outside the aging test chamber, continuous operation of the test board is ensured, and the purpose of the power-up aging test is achieved; meanwhile, as the test board and the data receiving board are connected through the serial port extension cord, the distance between the test board and the data receiving board can be up to more than 15 meters, and the convenience of the aging test is greatly improved.

Owner:冀雅(廊坊)电子股份有限公司

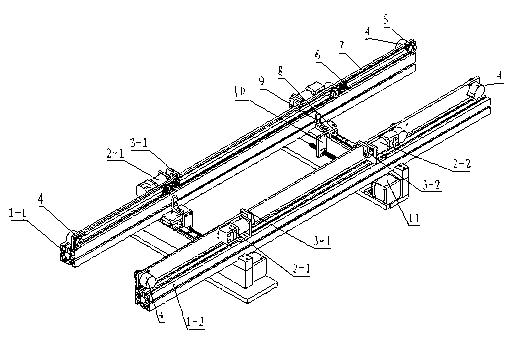

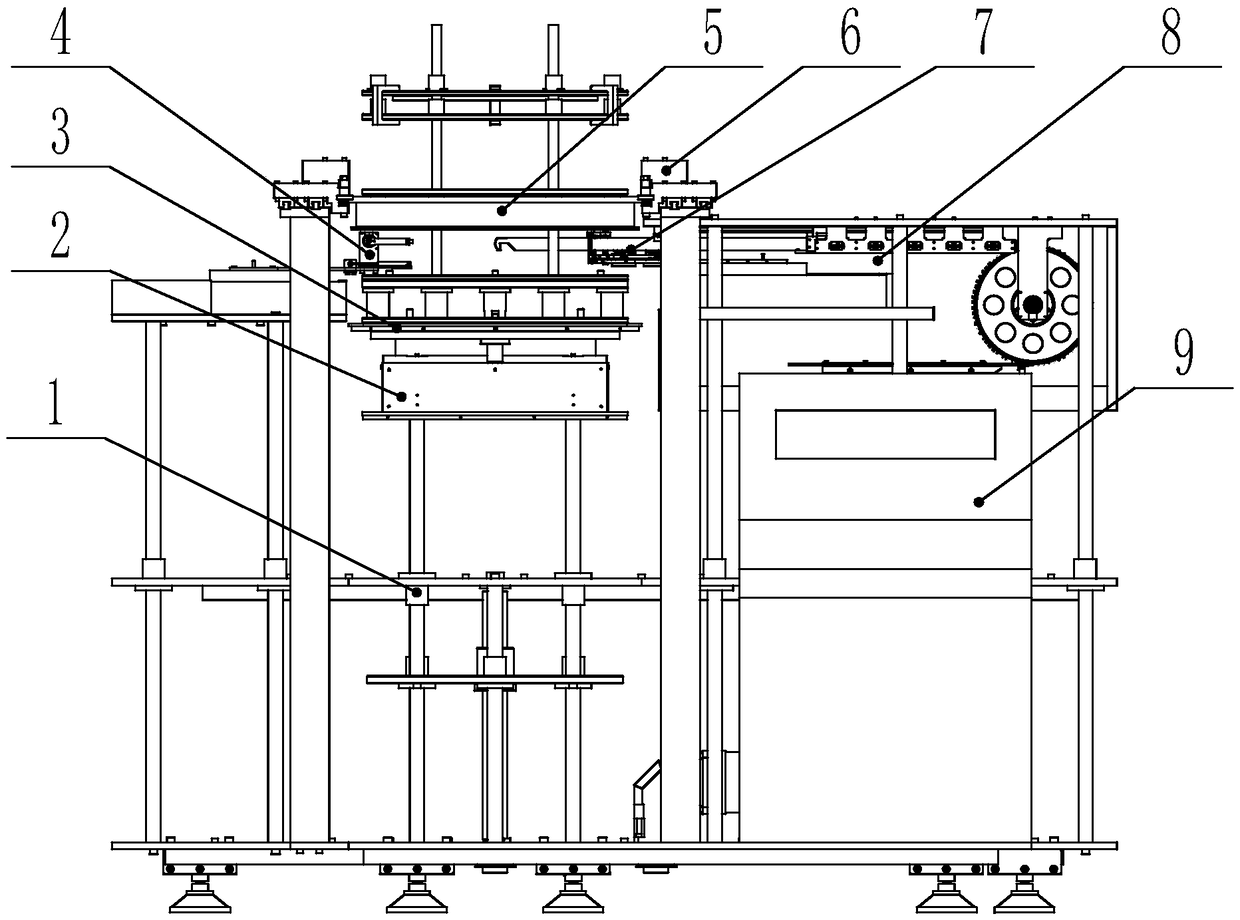

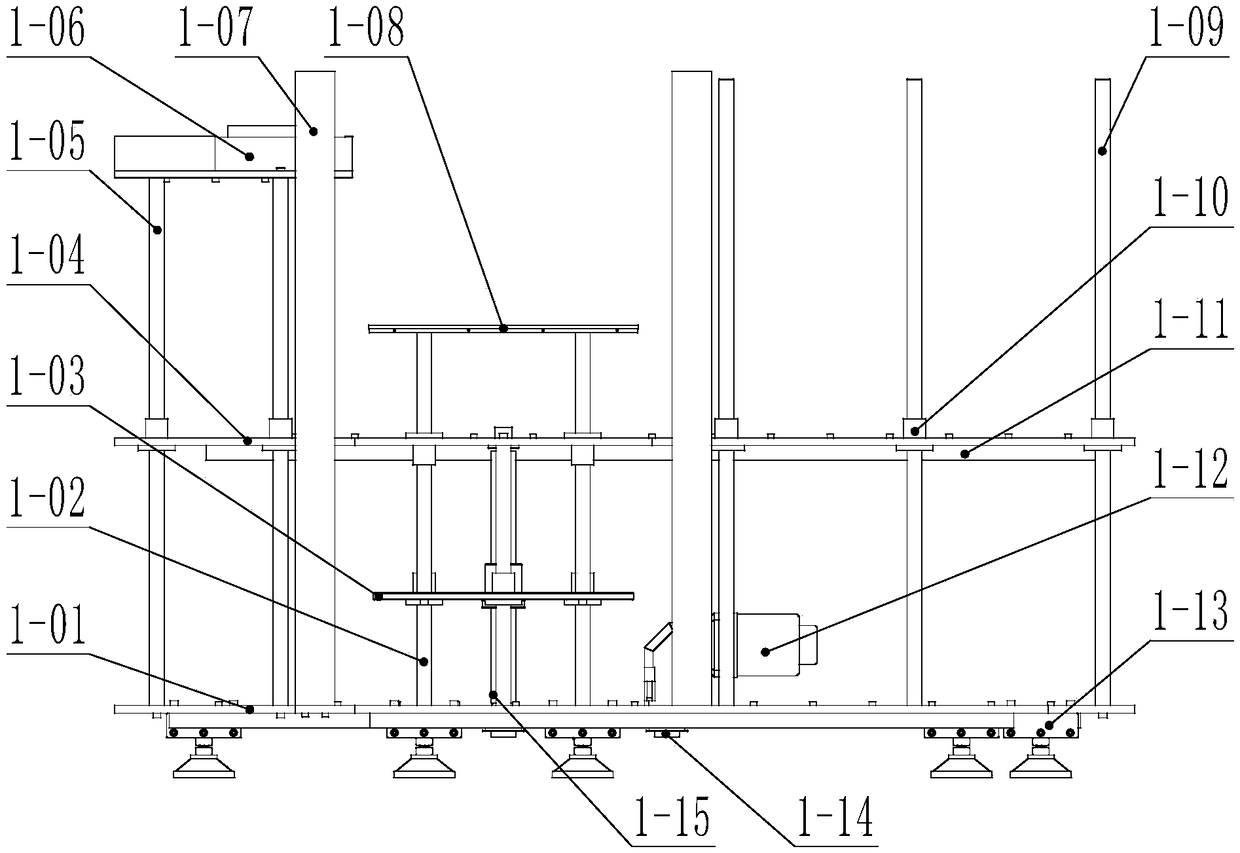

Carbon fiber three-dimensional fabric automatic weaving machine

PendingCN109023668AGuaranteed accuracy and stabilityIncrease success rateLoomsElectrical controlEngineering

The invention discloses a carbon fiber three-dimensional fabric automatic weaving machine. The machine includes a lifting worktable, a horizontal moving worktable, a rotating worktable, a weft conveying mechanism, a tool, a horizontal moving sliding table, a weft guiding mechanism, a weft guiding worktable and an electrical control cabinet. The weft conveying mechanism is positioned and installedon a linear weft conveying module on one side of the lifting worktable, the horizontal moving sliding table is positioned and installed on a column of the lifting worktable, and the horizontal movingworktable is positioned and installed on an upper moving board; the rotating worktable is positioned and installed on a horizontal moving worktable moving board, the tool is positioned and installed on a rotating worktable turntable, the weft guiding worktable is positioned and installed at the upper end of a third optical shaft of the lifting worktable, the weft guiding mechanism is positioned and installed on the linear weft guiding module, and the electrical control cabinet is positioned and installed on the outer side of the third optical shaft. The machine is compact in structure, novel and reasonable in design and free of manual interference during weaving, automated weaving is achieved through coordinated cooperation and movement among the mechanisms above, the labor intensity is greatly reduced, the production efficiency is improved, the practicability is high, and convenience is provided for application and popularization.

Owner:TIANJIN POLYTECHNIC UNIV +1

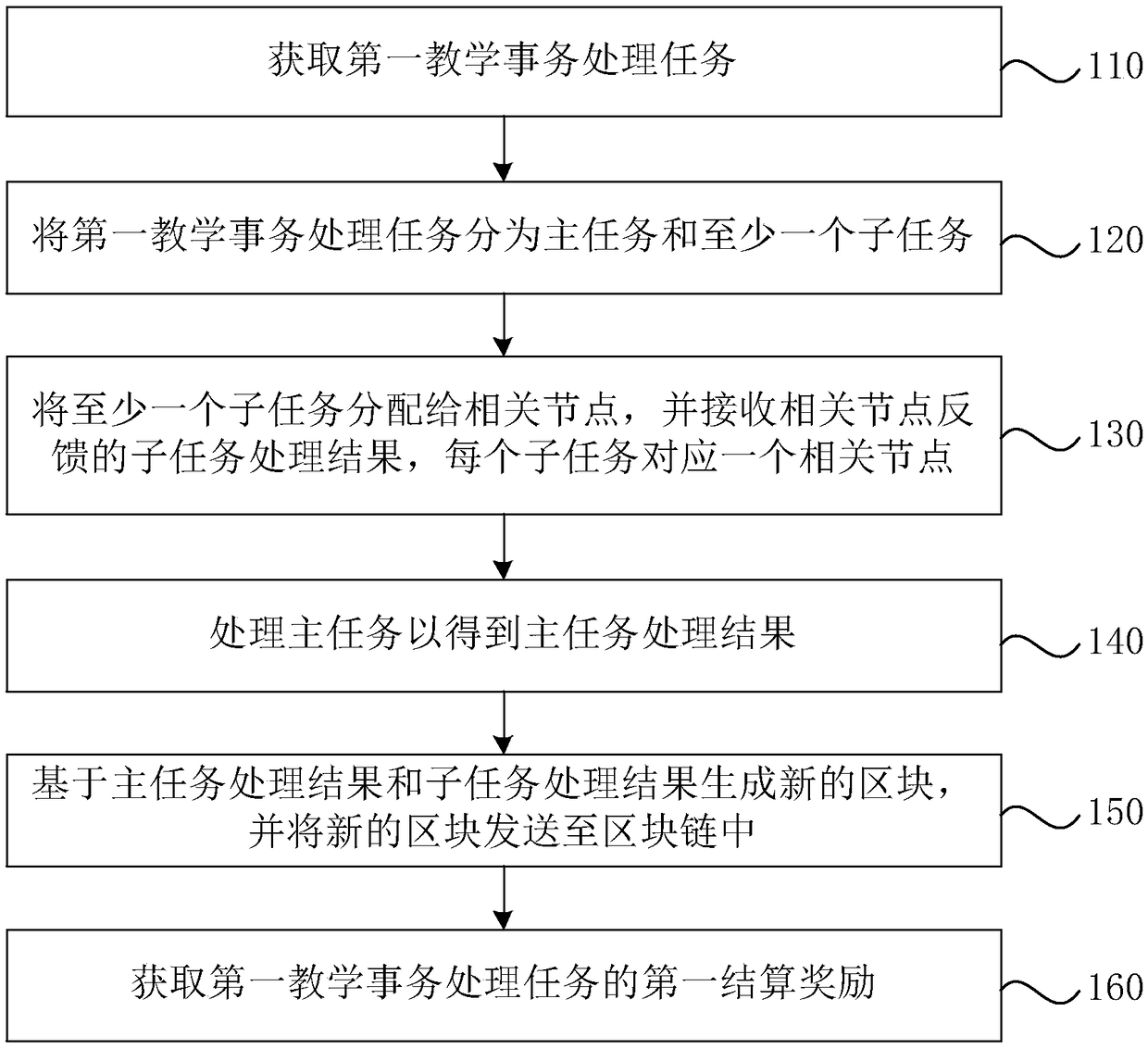

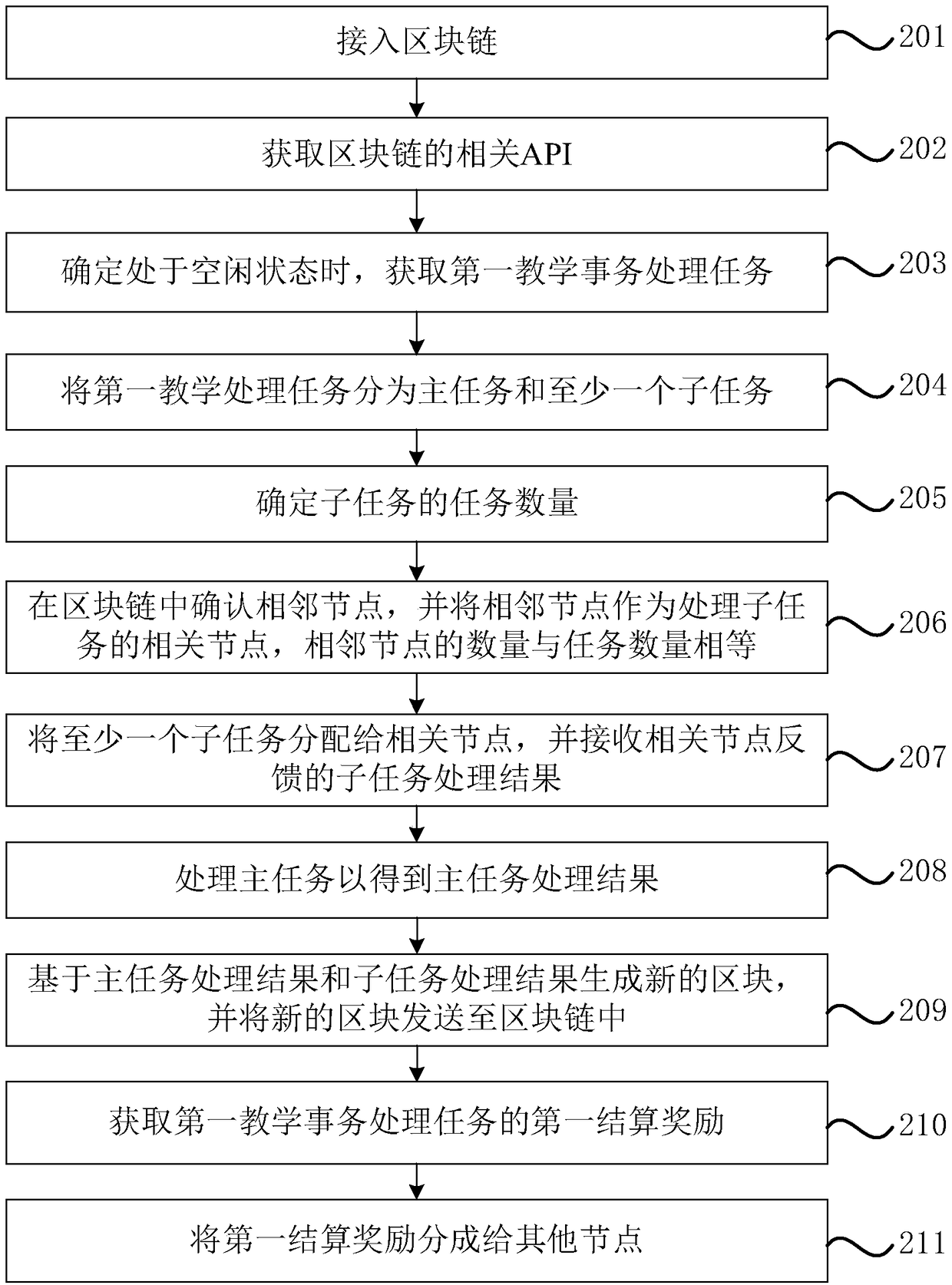

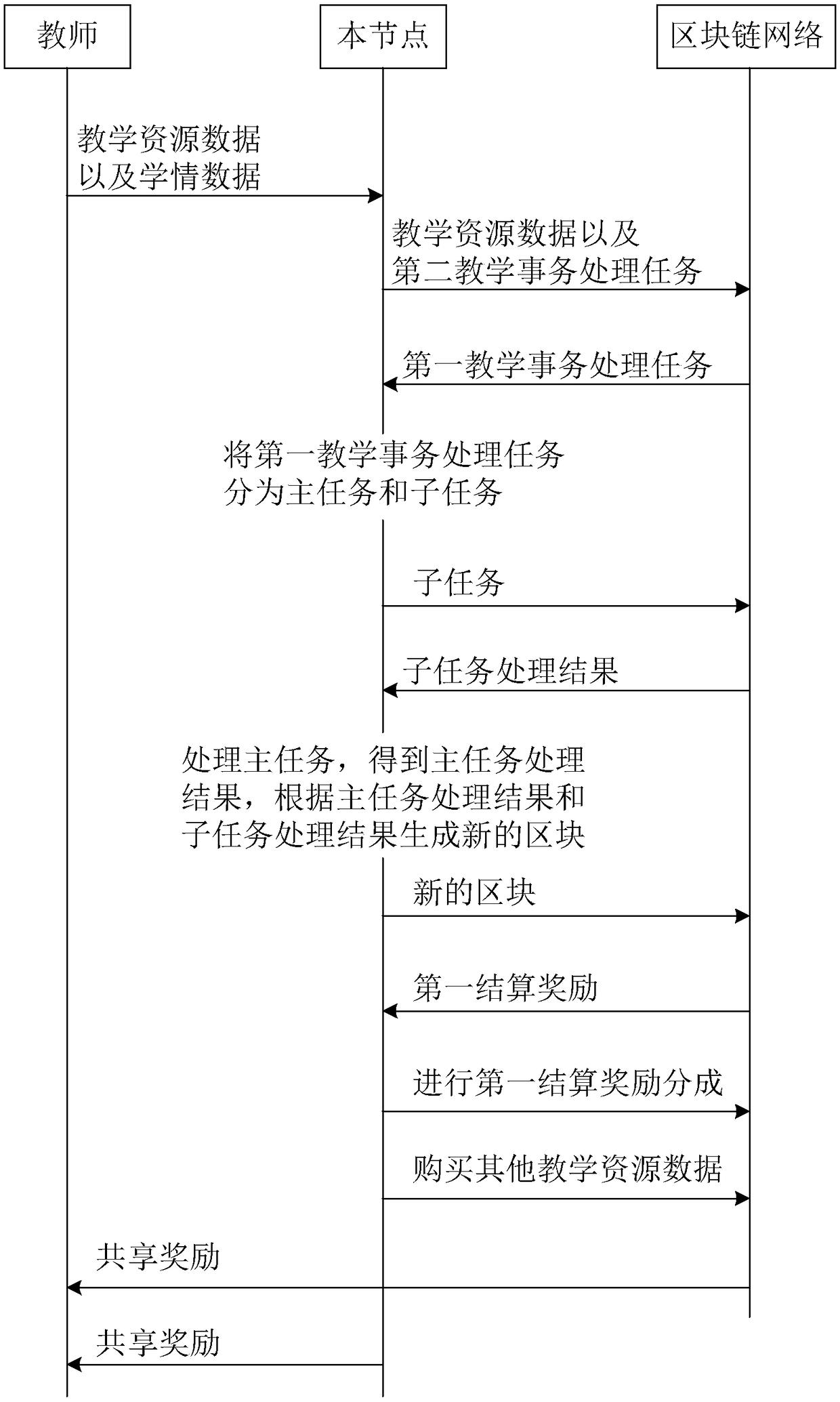

Teaching transaction processing method, apparatus and device based on a block chain and storage medium

InactiveCN108984311AGuaranteed accuracy and stabilityPrevent excessive useless workloadData processing applicationsResource allocationBlockchainTransaction processing system

The invention discloses a teaching transaction processing method, apparatus and device based on a block chain and a storage medium, which relate to the technical field of the block chain. The method comprises the following steps: obtaining a first teaching transaction processing task; obtaining the first teaching transaction processing task; obtaining the first teaching transaction processing task; assigning at least one of the sub-tasks to a relevant node and receiving a sub-task processing result fed back by the relevant node, each sub-task corresponding to a relevant node; processing the master task to obtain a master task processing result; generating a new block based on the main task processing result and the sub-task processing result, and sending the new block to a block chain; obtaining a first settlement award for the first teaching transaction task. The method can solve the technical problem that the processing burden of the server in the prior art is large, and when the server makes an error, the intelligent device cannot obtain the data in the server.

Owner:GUANGZHOU SHIYUAN ELECTRONICS CO LTD +1

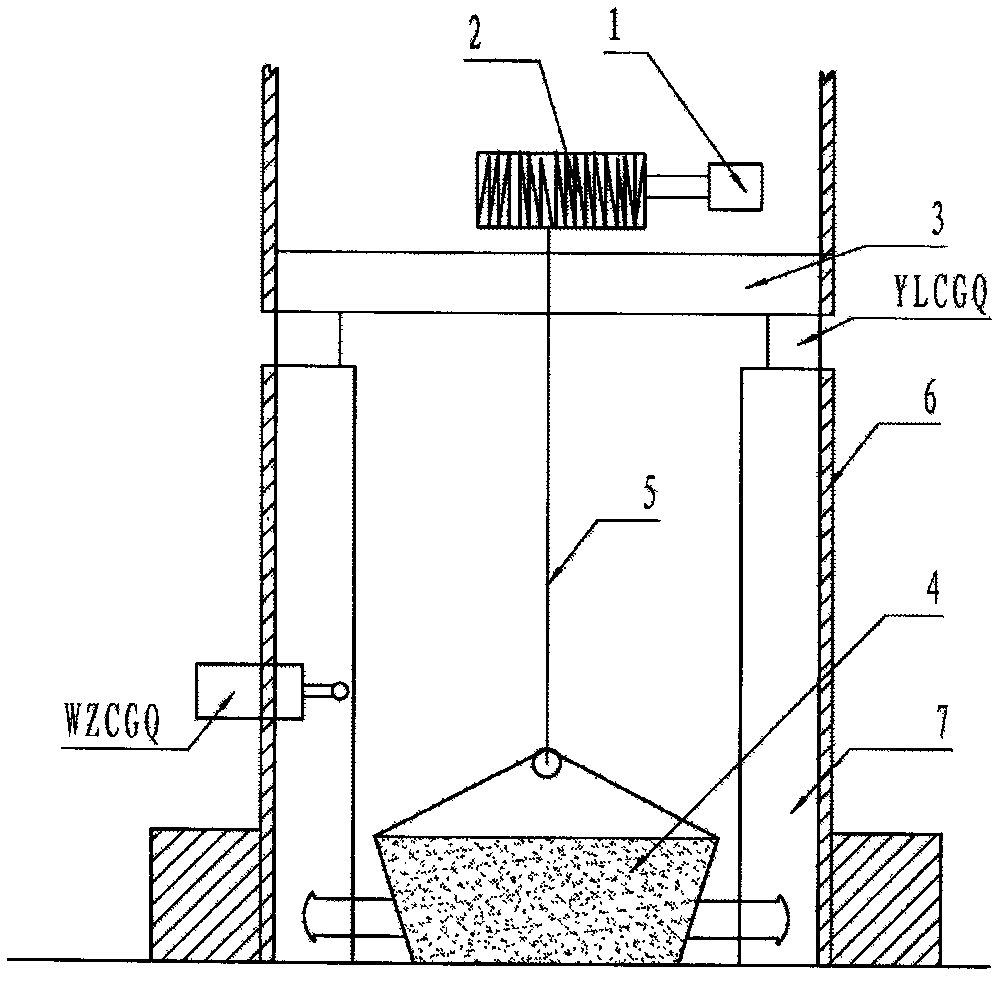

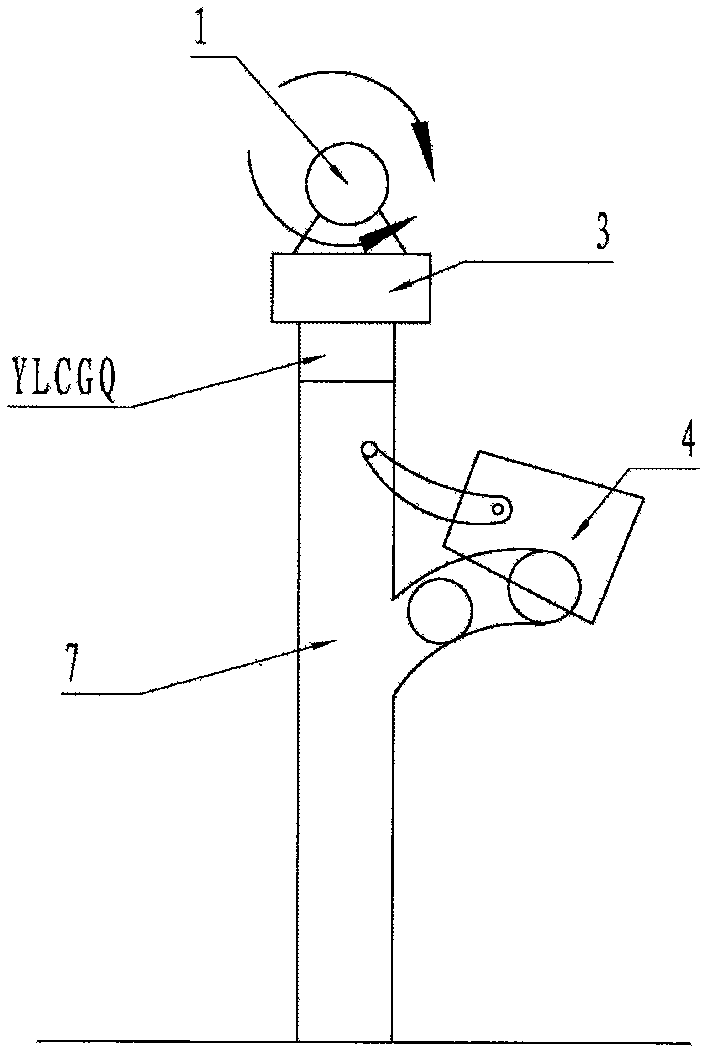

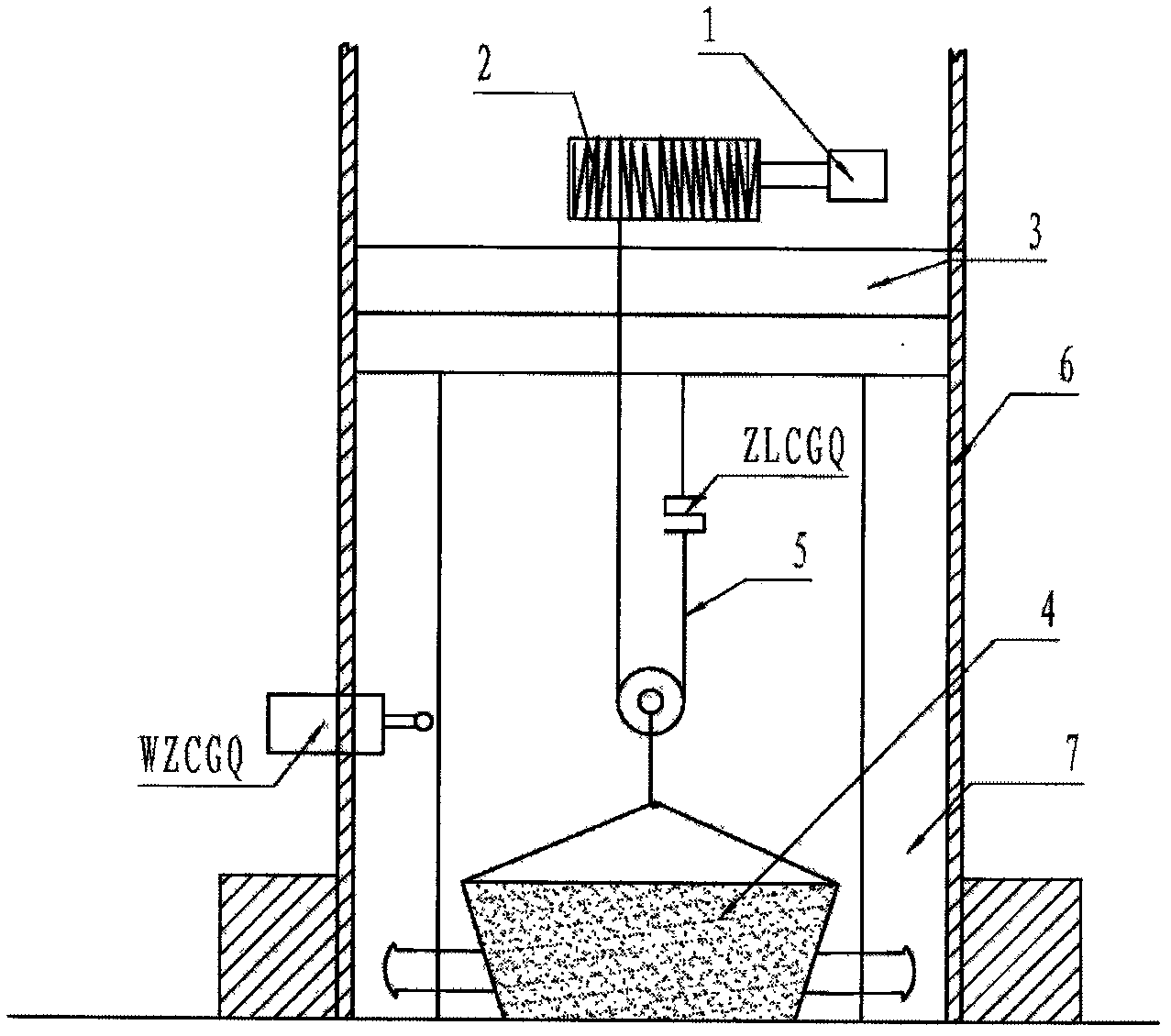

Metering method and device for fuel coal of boiler

InactiveCN103017879AAvoid entanglementGuaranteed accuracy and stabilityFuel supply regulationSpecial purpose weighing apparatusCoalProcess engineering

The invention relates to a metering method and device for fuel coal of a boiler. The device comprises an overturning coal hopper, a chute-type support, a coal hopper lifting device, a weighing sensor, a coal metering controller, a coal hopper lifting sensor and a position sensor, wherein the chute-type support and the coal hopper lifting device are matched with the overturning coal hopper; the outputs of the weighing sensor and the lifting sensor are connected with the input end of the coal metering controller; the position sensor is arranged on a chute of the chute-type support; and the output of the position sensor is connected with the input end of the coal metering controller. By virtue of acquisition of multiple groups of signals and a real-time and sequential control method, the accurate calculation in the metering of the fuel coal can be automatically accomplished, and all external factors which influence the accurate metering of the fuel coal can be removed. The metering method and device can realize the automatic accurate metering of the fuel coil, and are high in practicability.

Owner:BAODING RUNLI ENERGY SAVING & ENVIRONMENTAL PROTECTION

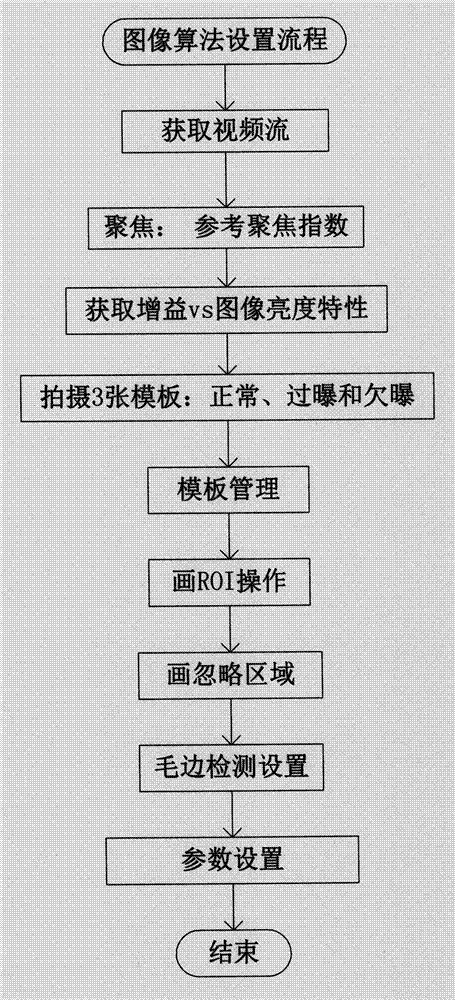

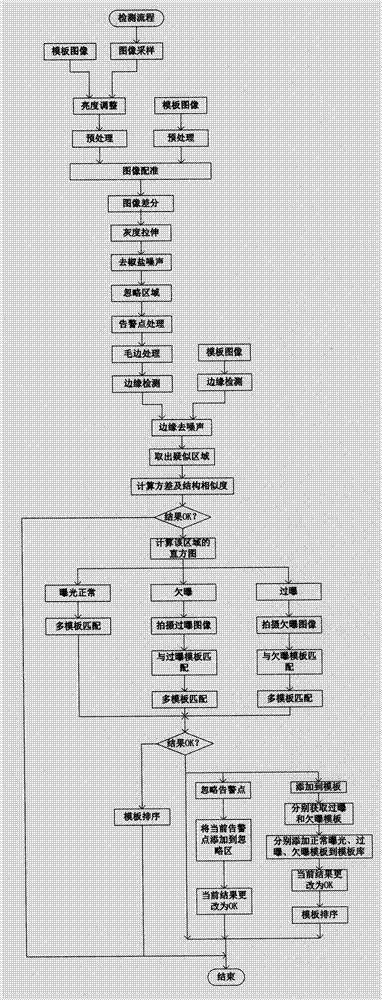

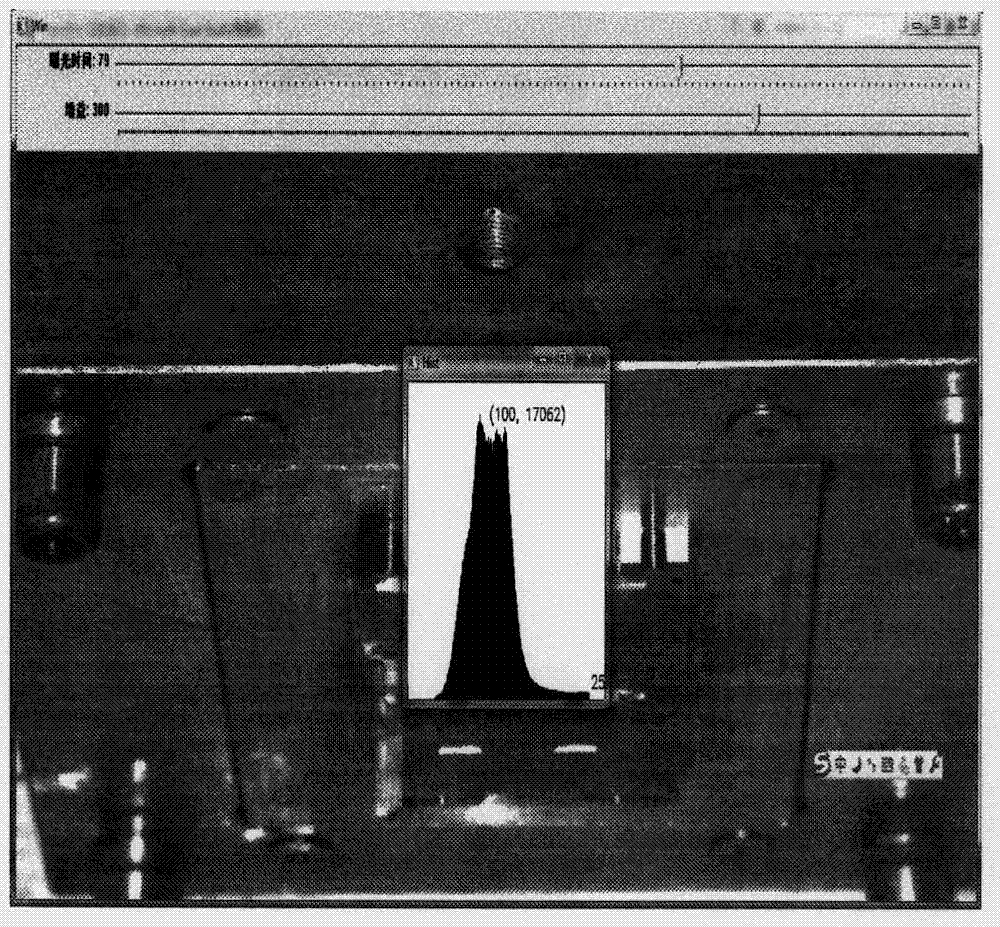

Image processing software algorithm for realizing mold monitor

ActiveCN106934786AGuaranteed accuracy and stabilityImprove environmental adaptabilityImage enhancementImage analysisTemplate matchingSoftware

The invention discloses an image processing software algorithm for realizing a mold monitor. A plastic piece and a mold cavity can be detected at the same time, through adding comparison with over exposure and under exposure templates, image error detection by the previous mold protector caused by image pixel value saturation (reaching areas near 255 and 0) is solved, or manual intervention is needed for adding an easy error detection area to a neglect area, manual intervention is thus reduced, and besides, the brightness change problem can be solved through judgment on structure similarities, the original contour of a surplus template and the contour of a differential image are compared, the error detection possibility is further reduced, and the manual intervention times are greatly reduced. The image processing speed is quickened through variance ratio comparison, multi-template matching is only carried out on a detected suspected NG area, the detection speed is quickened, and influences on a production period are shortened.

Owner:深圳市宝捷信科技有限公司

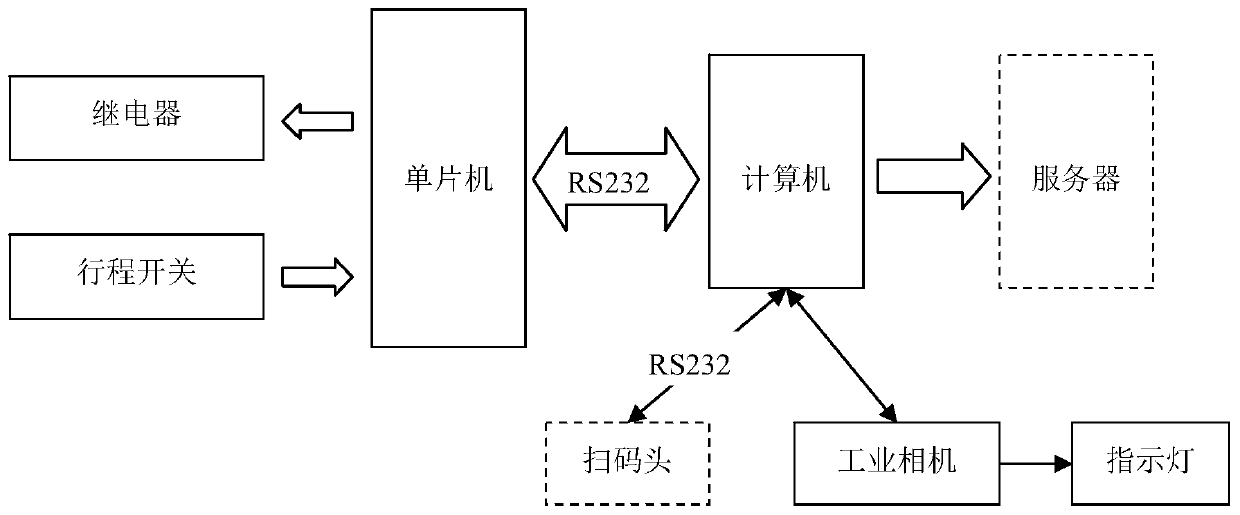

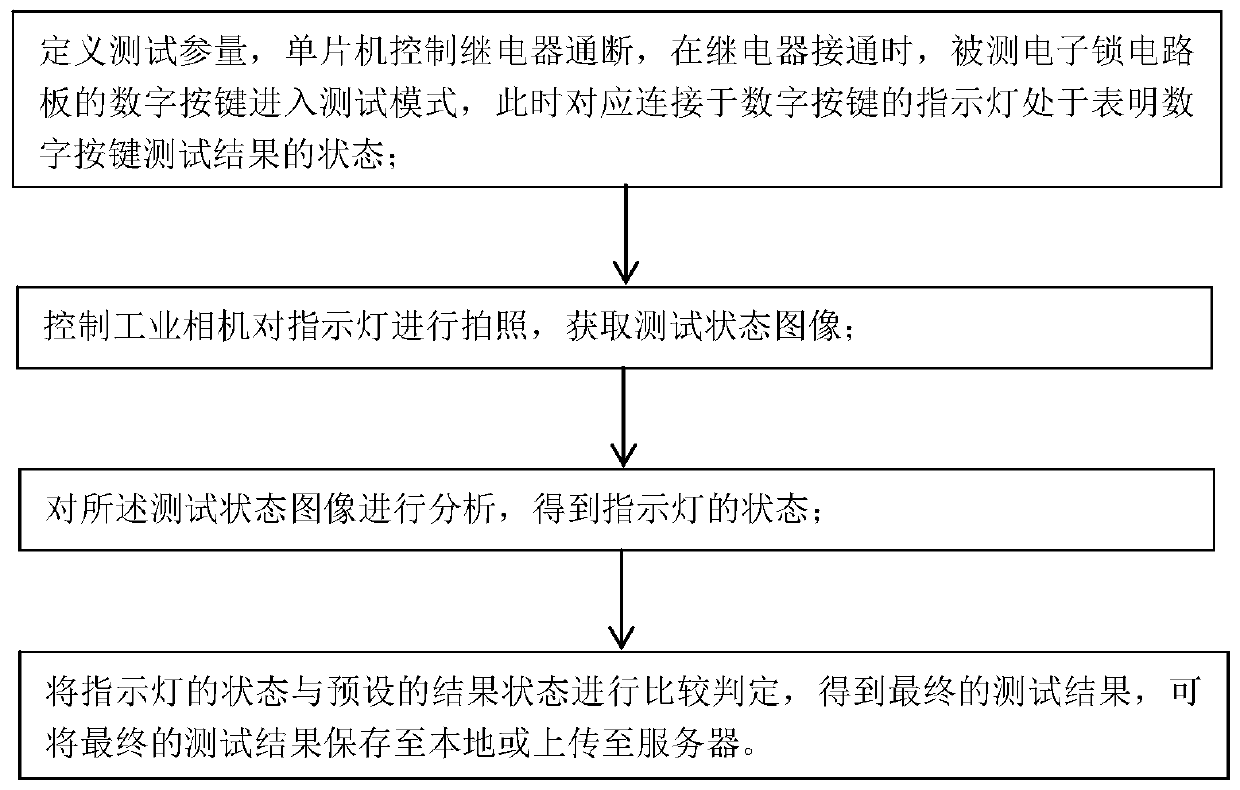

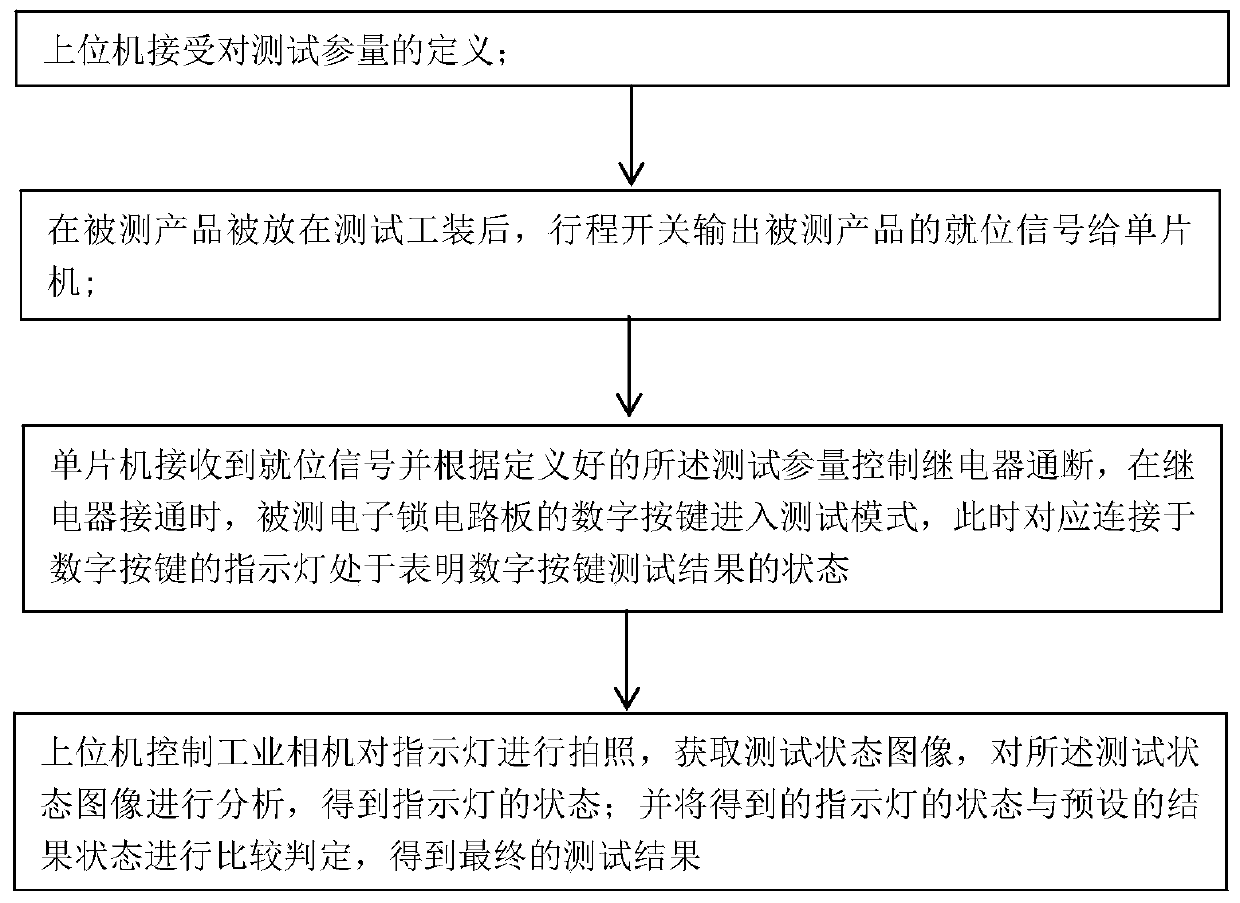

Method, device and system for testing circuit board of electronic lock

PendingCN111239589AImprove test efficiencyGuaranteed accuracy and stabilityElectronic circuit testingManual testingReliability engineering

The invention provides a method, a device and a system for testing a circuit board of an electronic lock. The method comprises the following steps: S1, defining test parameters, and controlling the on-off of a relay through a single-chip microcomputer according to the defined test parameters, wherein when the relay is switched on, digital keys of a tested electronic lock circuit board enter a testmode, and at the moment, indicating lamps correspondingly connected to the digital keys are in a state of indicating test results of the digital keys; S2, controlling an industrial camera to photograph the indicator lamp to obtain a test state image; S3, analyzing the test state image to obtain the state of the indicator lamp; and S4, comparing and judging the state of the indicator lamp with a preset result state to obtain a final test result. The single-chip microcomputer is used for controlling the on-off of the relay to replace a manual operation key, and the image recognition technologyis used for replacing manual subjective judgment, thereby reducing the workload of manual testing, improving the testing efficiency, and improving the testing accuracy and stability, and of the method, the device and the system have great significance to the improvement of the automation degree of testing.

Owner:福建宏泰智能工业互联网有限公司

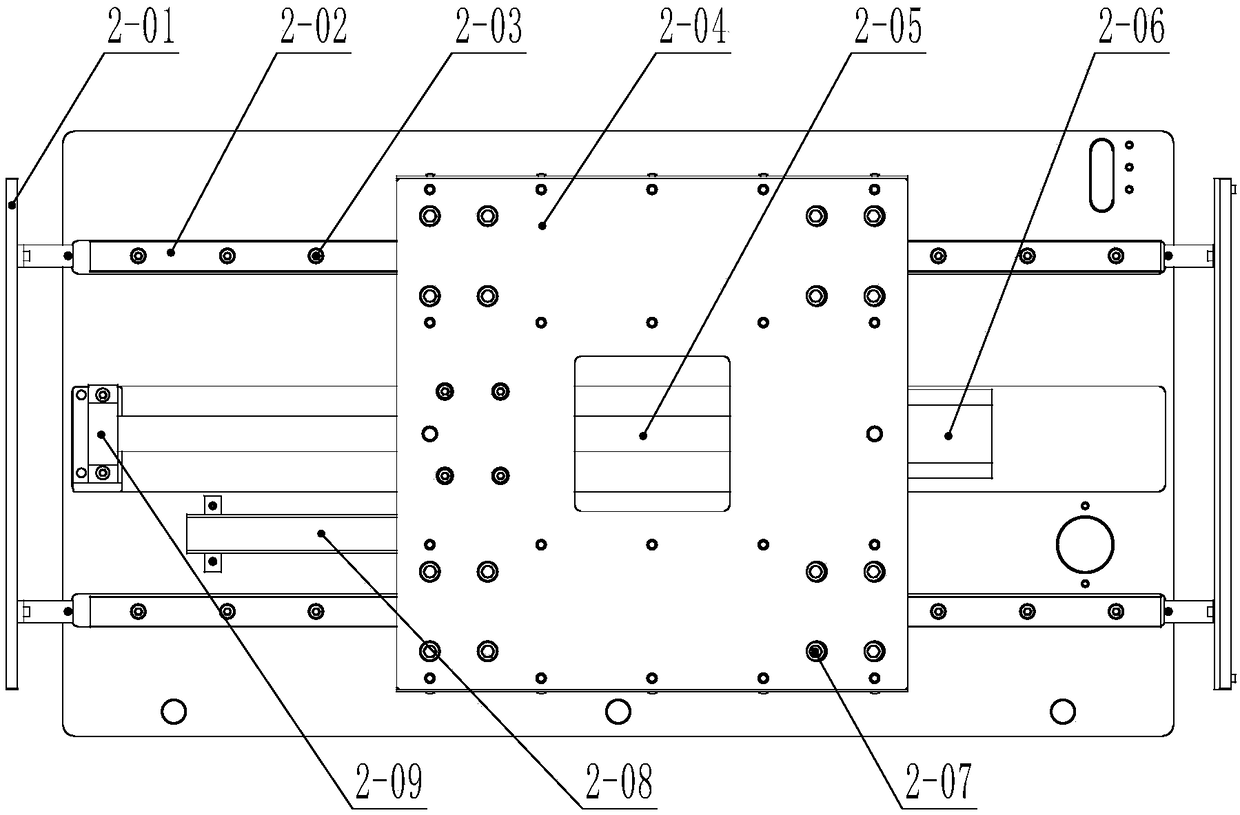

Automatic centering device for elevator guiderail conveyer line

PendingCN106882568AGuaranteed accuracy and stabilityLow costConveyorsPackagingEngineeringMechanical engineering

The invention discloses an automatic centering device for an elevator guiderail conveyer line. The automatic centering device is arranged on the conveyer line; the automatic centering device comprises a bottom plate which is vertical to the conveyer line and two sets of adjustment devices which are arranged on the bottom plate oppositely; the two sets of adjustment devices can synchronously move along a direction vertical to the conveyer line in an approaching manner or a departing manner; an elevator guiderail is located between the two sets of adjustment devices; during centering, the two adjustment devices synchronously move toward the middle part of the conveyer line from two sides of the conveyer line and are in contact with the two sides of the elevator guiderail; deviation correction can be timely performed during an elevator guiderail conveying process; deviation loopholes of the elevator guiderail are avoided; conveying efficiency is improved; and conveying safety is ensured. The two sets of adjustment devices are simultaneously driven by adopting one set of driving mechanism, so that synchronous movement of the adjustment devices on the two sides of the elevator guiderail is ensured; accuracy and stability of centering are ensured; and meanwhile, cost is reduced.

Owner:苏州塞维拉上吴电梯轨道系统有限公司

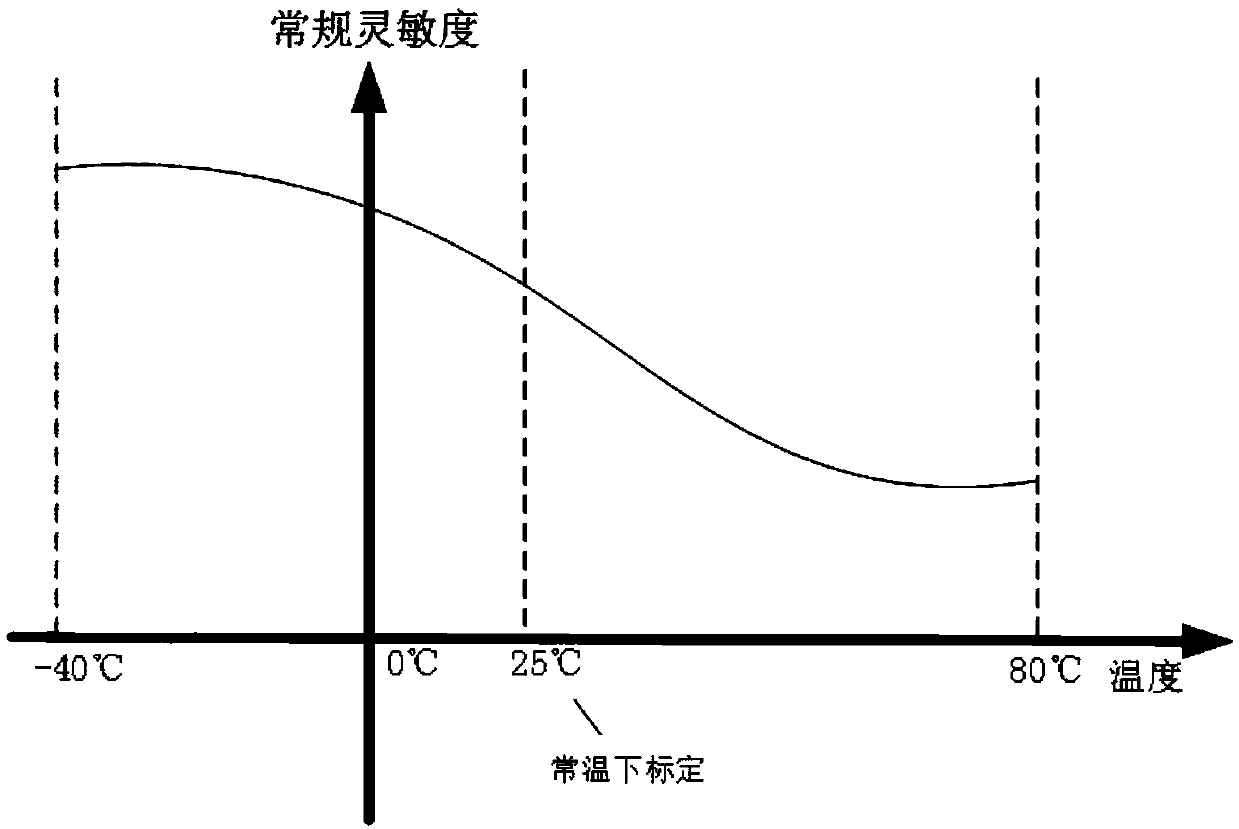

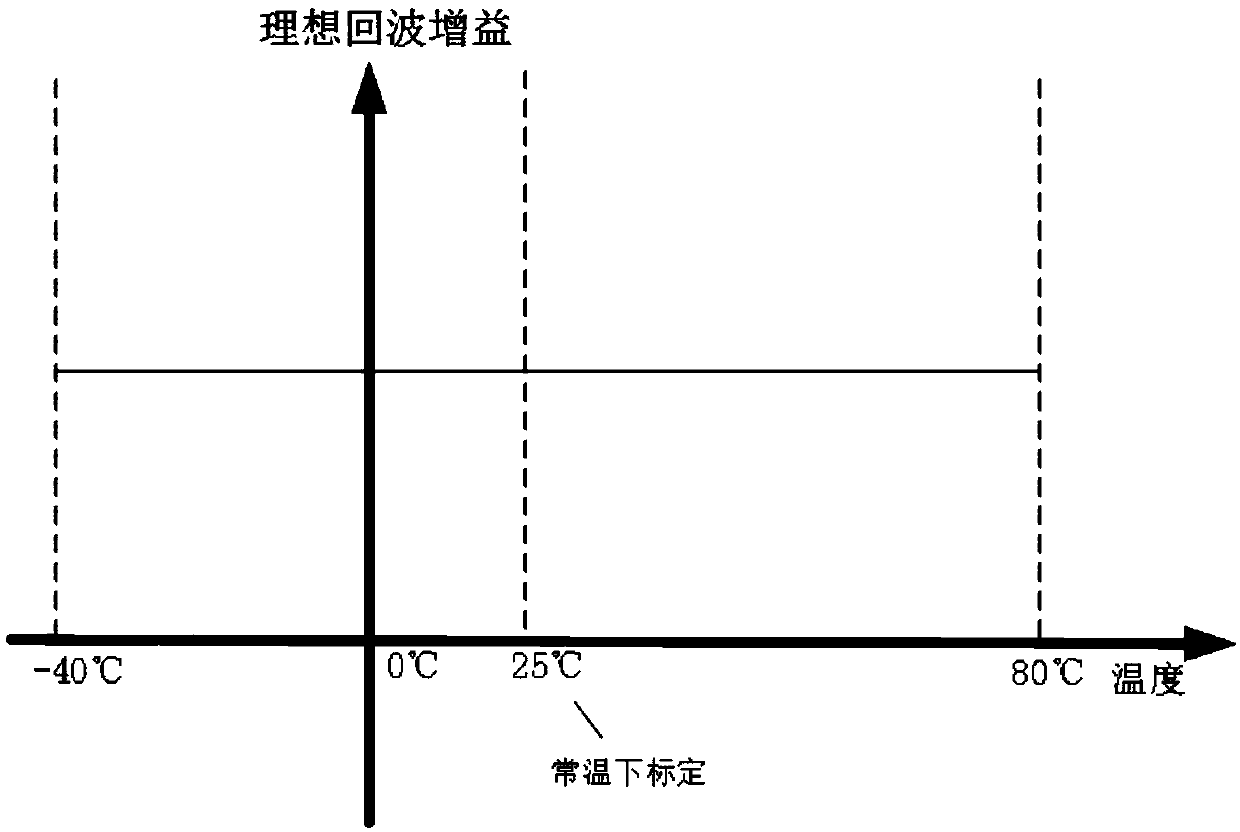

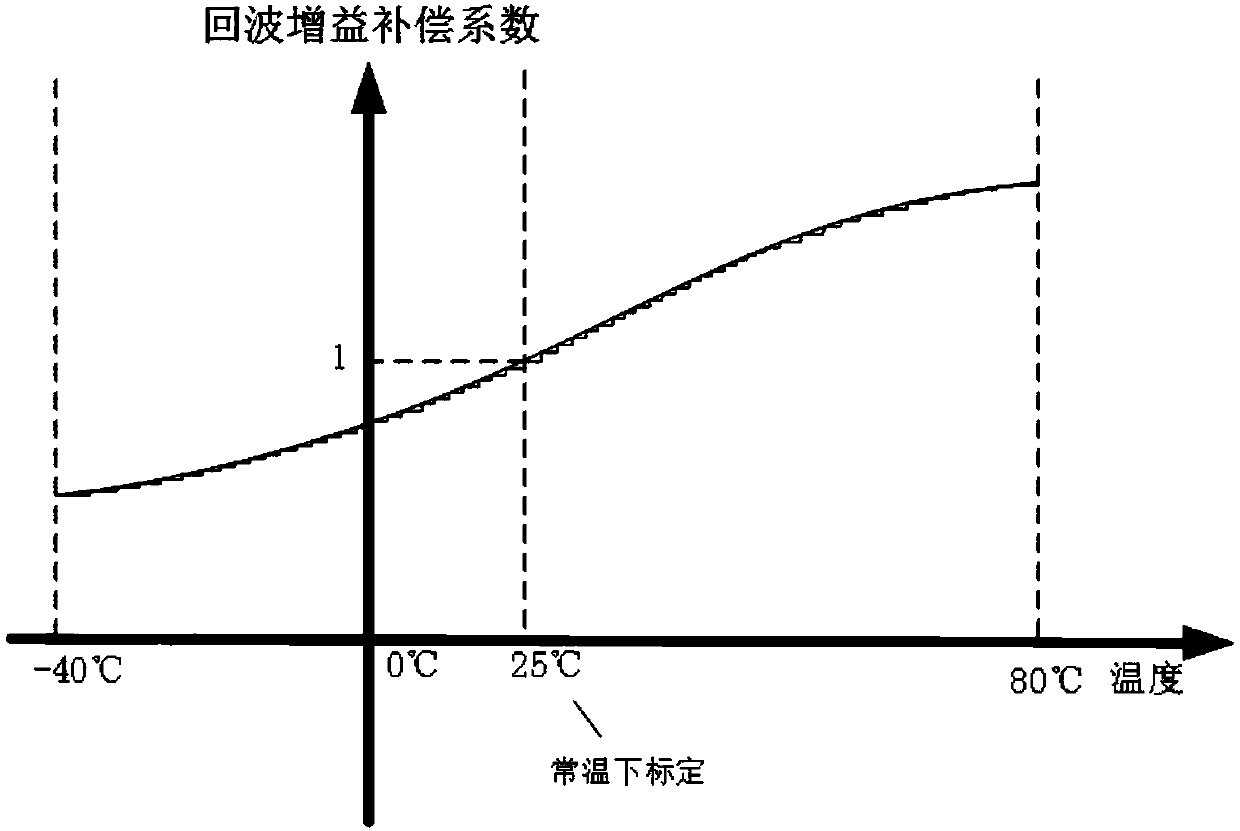

Sensitivity compensation method of parking auxiliary system

The invention discloses a sensitivity compensation method of parking auxiliary system, which includes the following steps: A. pre-collecting sensitivity data of an ultrasonic sensor changing with temperature and getting an ordinary sensitivity-temperature curve; B. if in ideal echo gain remains unchanged while the ultrasonic sensor changing with the temperature, getting an ideal echo gain-temperature curve; C. analyzing and comparing the ordinary sensitivity-temperature curve and the ideal echo gain-temperature curve, calculating echo gain compensation coefficients in different environment temperatures, and getting an echo gain compensation coefficients-temperatures curve; D. in the actual application, a real-time collection of operating temperatures of the ultrasonic sensor is made and sent by a temperature sensor to a control unit, current echo gain compensation coefficients are obtained by the control unit according to the echo gain compensation coefficients-temperatures curve, thecurrent ordinary sensitivity is obtained by the control unit according to the ordinary sensitivity-temperature curve, and then multiplying the echo gain compensation coefficients to the current ordinary sensitivity to obtain the compensated operating sensitivity.

Owner:HEFEI SOFTEC AUTO ELECTRONICS

Purchase order determination method and device, server and readable storage medium

PendingCN110363468AImprove accuracyGuaranteed accuracy and stabilityFinanceBuying/selling/leasing transactionsOrder documentMultiple dimension

The embodiment of the invention discloses a purchase order determination method. The method comprises the steps of obtaining a to-be-implemented commodity purchase order of a target commodity category; inputting the to-be-implemented commodity purchase order into a commodity purchasing model corresponding to the target commodity category to obtain purchasing evaluation data of the to-be-implemented commodity purchase order; if the purchase evaluation data does not meet the purchase evaluation condition, adjusting the to-be-implemented commodity purchase order to obtain a final implemented commodity purchase order. Thus, the final commodity purchasing order is constrained in multiple dimensions through the constraint condition. The accuracy and the stability of the obtained final commoditypurchase order can be effectively ensured. The final commodity purchase order is obtained by processing the purchasing evaluation data, and on the basis of high accuracy of the purchasing evaluation data, the accuracy of the obtained final commodity purchase order can be promoted to be improved accordingly.

Owner:ADVANCED NEW TECH CO LTD

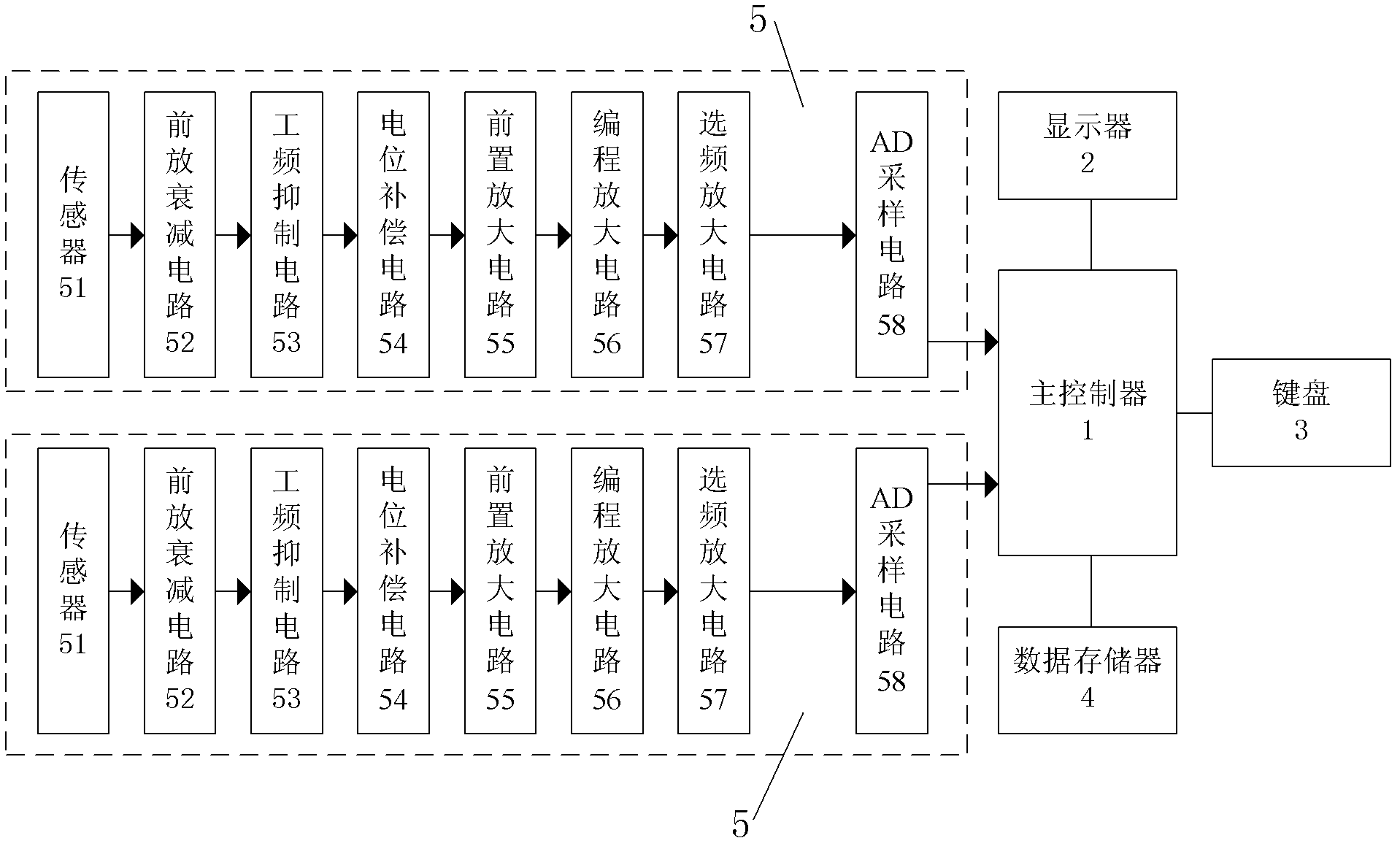

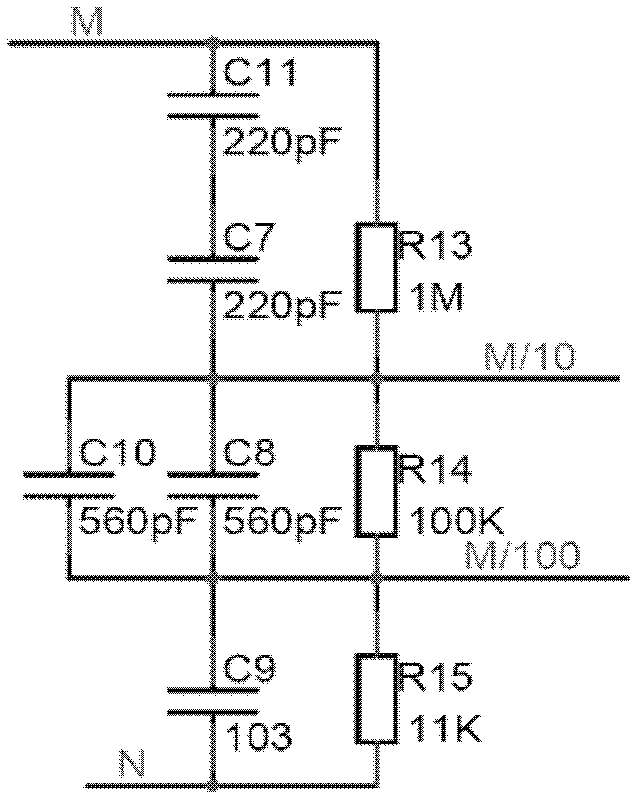

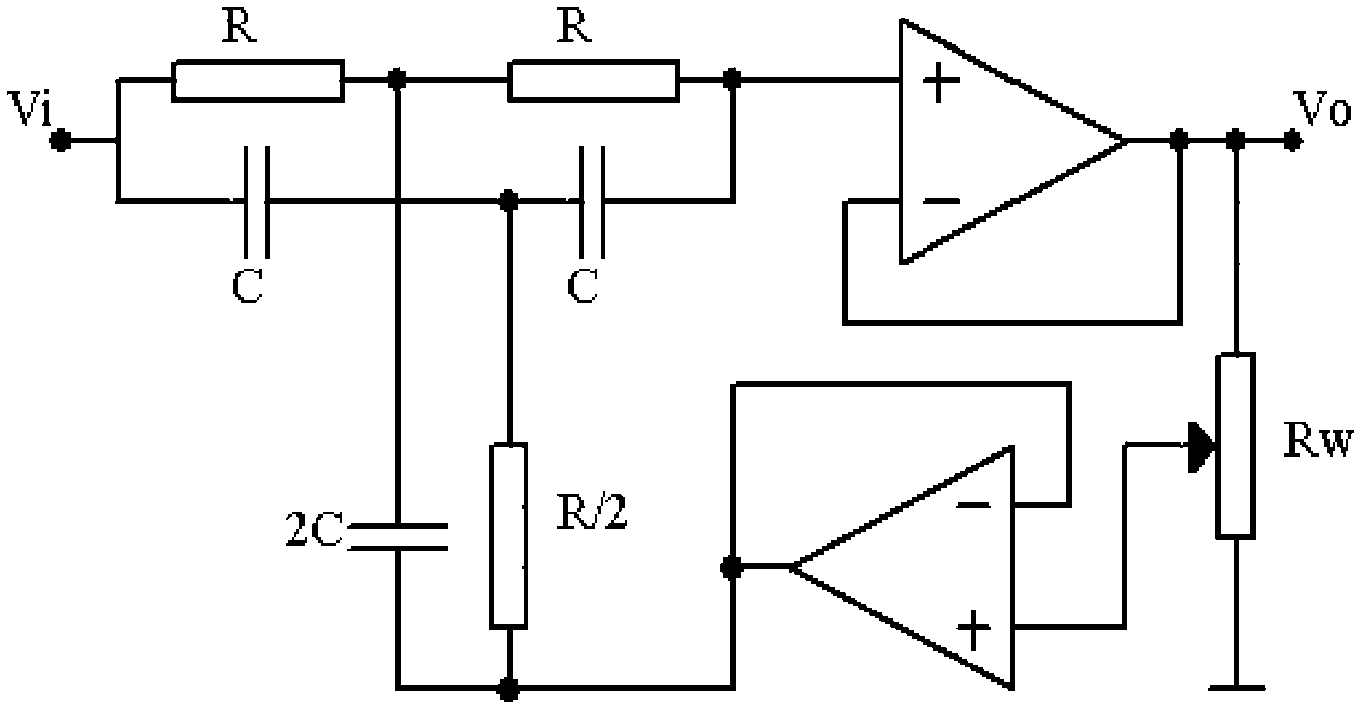

Earth audio electrical instrument

InactiveCN102621580AWide range of useGuaranteed accuracy and stabilitySeismologyData memoryElectricity

The invention relates to an earth audio electrical instrument. The earth audio electrical instrument comprises a master controller, a display, a keyboard, a data memory and two same signal input modules, wherein the two signal input modules are connected with the master controller; and the master controller is respectively connected with the display, the keyboard and the data memory. Compared with the prior art, the earth audio electrical instrument has the advantages of high measurement precision, convenience for use, high speed, high efficiency and the like.

Owner:上海柏艾环保科技有限公司

Self-cleaning detection device and method for porous vacuum suction disc

PendingCN112509963ATest self-cleaningFull evaluationSemiconductor/solid-state device manufacturingPermeability/surface area analysisPhysicsEngineering

The invention belongs to the technical field of vacuum suction discs, and particularly relates to a self-cleaning detection device and method for a porous vacuum suction disc. The self-cleaning detection device of the porous vacuum suction disc comprises a vacuum generator, which is provided with three interfaces which are connected with a first connecting pipe, a second connecting pipe and a third connecting pipe respectively, wherein the tail end of the first connecting pipe is connected with a compressed air filtering and pressure reducing valve, the tail end of the second connecting pipe is communicated with the atmosphere, the tail end of the third connecting pipe is connected with the exhaust hole of a porous vacuum suction disc, the third connecting pipe is connected with an electronic pressure gauge, and the compressed air filtering and reducing valve is connected with an air compressor through a fourth connecting pipe. By adopting the detection device and the detection methodprovided by the invention, the self-cleaning performance of the porous vacuum suction disc can be well and accurately detected.

Owner:ZHENGZHOU RES INST FOR ABRASIVES & GRINDING CO LTD

Welding device for ceramic plate and metal cylinder component

ActiveCN111922470AGuaranteed accuracyGuaranteed accuracy and stabilityHeating appliancesWelding/soldering/cutting articlesMetal cylinderWorkbench

The invention discloses a welding device for a ceramic plate and a metal cylinder component, and belongs to the field of welding equipment. The welding device comprises a heating furnace, a workbenchis fixedly connected to the bottom of the inner wall of the heating furnace, a limiting plate is fixedly connected to the right side of the top of the workbench, and mounting blocks are fixedly connected to two sides of the front surface of the workbench. The tops of the mounting blocks are rotationally connected with clamping lead screws, the top ends of the clamping lead screws are fixedly connected with adjusting hand wheels, and the clamping lead screws are in threaded connection with clamping plates. According to the welding device, the mounting blocks are fixedly connected to the two sides of the front face of the workbench, the clamping lead screws are rotationally connected to the tops of the mounting blocks, the adjusting hand wheels are fixedly connected to the top ends of the clamping lead screws, the clamping plates are in threaded connection with the clamping lead screws so that the ceramic plate can be fixed after the ceramic plate is placed in the heating furnace, the ceramic plate is prevented from being dislocated in the welding process, the welding accuracy is guaranteed, and an extrusion disc can prevent welding flux from overflowing from the filling position.

Owner:ANHUI UNIVERSITY OF TECHNOLOGY AND SCIENCE

Shaft fork detecting device for transmission shaft

InactiveCN105091721AGuaranteed accuracy and stabilityShow flexibilityAngles/taper measurementsUsing optical meansBackplaneDrive shaft

The invention provides a shaft fork detecting device for a transmission shaft. A tip is arranged perpendicularly upward the middle part of a bottom board. A stand post is arranged perpendicularly upward on a side edge of the bottom board and an adjustment slide table is arranged on the stand post. The adjustment slide table is provided with a V-shaped groove pointing to the bottom board. The bottom board, the stand post and the V-shaped groove form a semi-frame structure. The center of the V-shaped groove is aligned to the center of the tip. The adjustment slide table is provided with a detection instrument. According to the invention, by enabling a central hole of the tail part of a spline shaft of a shaft fork to be perpendicular and coaxial to a line of the center of the tip and to fit with the center of the V-shaped groove, the central line of the spline shaft of the shaft fork, the central line of a stiffening part of the shaft fork and the central line of a lug hole of the shaft fork are all enabled to perpendicular to a detection platform. Besides, the stability of the shaft fork is ensured and inclination is prevented. An effect similar to that the spline shaft of the shaft fork is mounted in a transmission shaft assembly is achieved, high-degree simulation is realized and the spline shaft is enabled to be coaxial with a shaft tube of the transmission shaft, a universal joint fork, a flange yoke and the like.

Owner:十堰瑞程传动轴有限公司

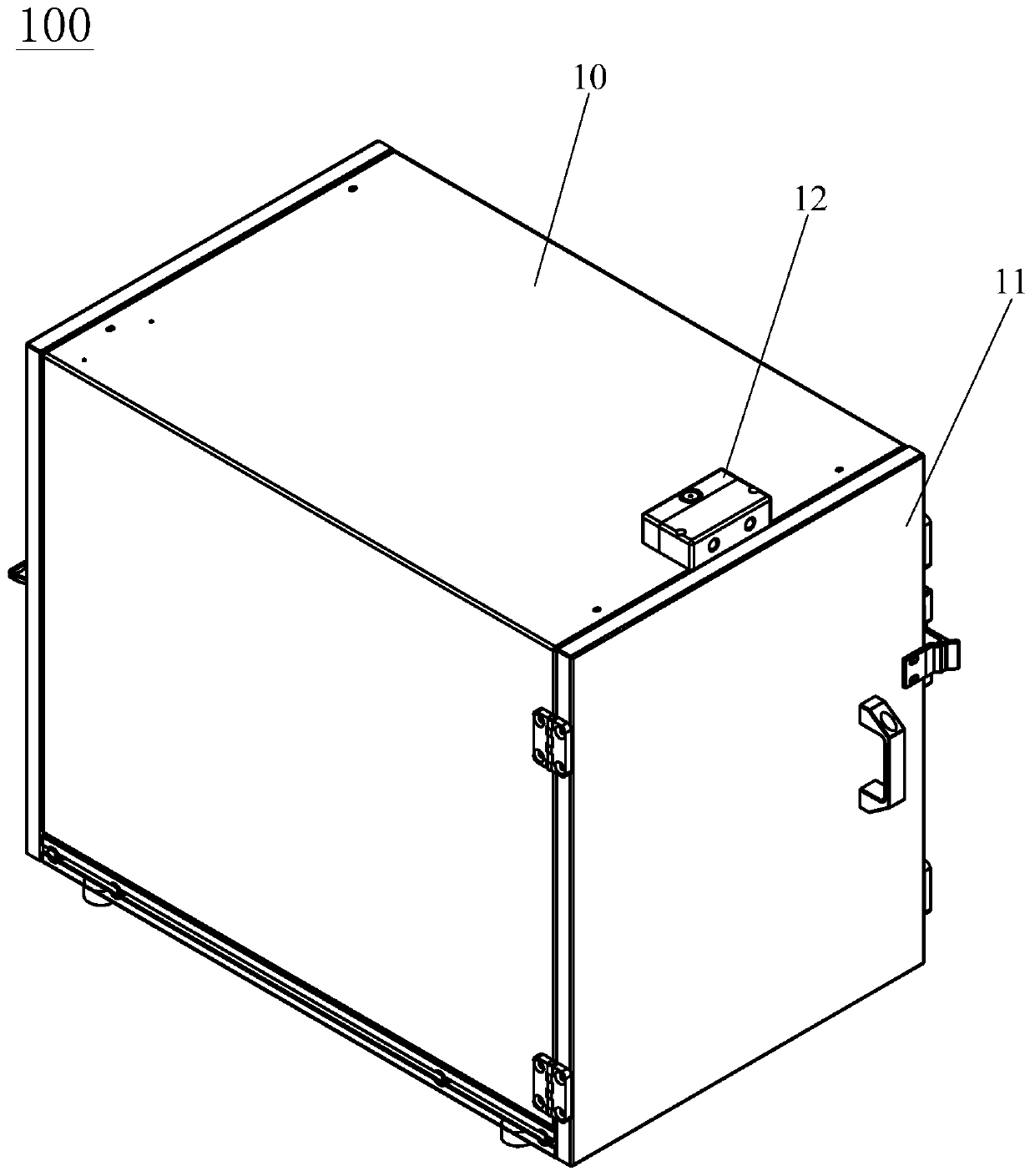

Smartwatch compass function test equipment

PendingCN110763218AGuaranteed accuracy and stabilityReduce distractionsRegulating apparatusCompassesMagnetic orientationEngineering

The invention discloses smartwatch compass function test equipment. The equipment comprises a shielding box, a test box, an electric control box, an upper coil, a lower coil, a carrier and an electriccontrol device, wherein the test box and the electric control box are enclosed in the shielding box; the upper coil, the lower coil and the carrier are arranged in the test box; the electric controldevice is arranged in the electric control box; the electric control device is electrically connected with the upper coil, the lower coil and the carrier; after electrification, a simulation magneticfield can be formed between the upper coil and the lower coil; the carrier is obliquely arranged in the test box to ensure that the induction center of an electronic compass clamped in the carrier islocated at the central position of the simulation magnetic field; and the magnetic field direction of the simulation magnetic field is changed along with the change of the current directions in the upper coil and the lower coil, so as to realize the test of an indication function, in a south and north pole magnetic field simulated by the simulation magnetic field, of the electronic compass. The equipment is simple in structure and convenient to use, and is capable of effectively improving the test correctness.

Owner:DONGGUAN WORLD PRECISION MACHINERY

Automatic high-speed terminal cleaning machine of flexible OLED

InactiveCN106025749AGuaranteed accuracy and stabilityWide range of applicationsLine connector maintainanceTerminal cleaningEngineering

The invention relates to an automatic high-speed terminal cleaning machine of a flexible OLED. The automatic high-speed terminal cleaning machine comprises a transporting unit and a cleaning unit, wherein the transporting unit comprises a transporting shaft and a transporting arm arranged on the transporting shaft; the transporting arm is provided with a micropore adsorption platform for adsorbing a flexible product; the micropore adsorption platform comprises a vacuum plate and a micropore platform; the micropore platform can be embedded into the vacuum plate; and the cleaning unit is arranged in fit with the micropore adsorption platform and is used for cleaning and adsorbing the flexible product. The flexible product adsorption device designed by the invention is different from a traditional suction rod and suction cup structure; the flexible product can be stably adsorbed by the micropore adsorption platform; implementation of subsequent transporting, cleaning and plasma surface treatment is facilitated; the precision and the stability of the flexible product are ensured; and the automatic high-speed terminal cleaning machine is suitable for cleaning of the flexible product, is also suitable for cleaning of a traditional rigid product, and is wide in application range and beneficial to promotion and application.

Owner:SUZHOU PROTECH PRECISION IND CO LTD

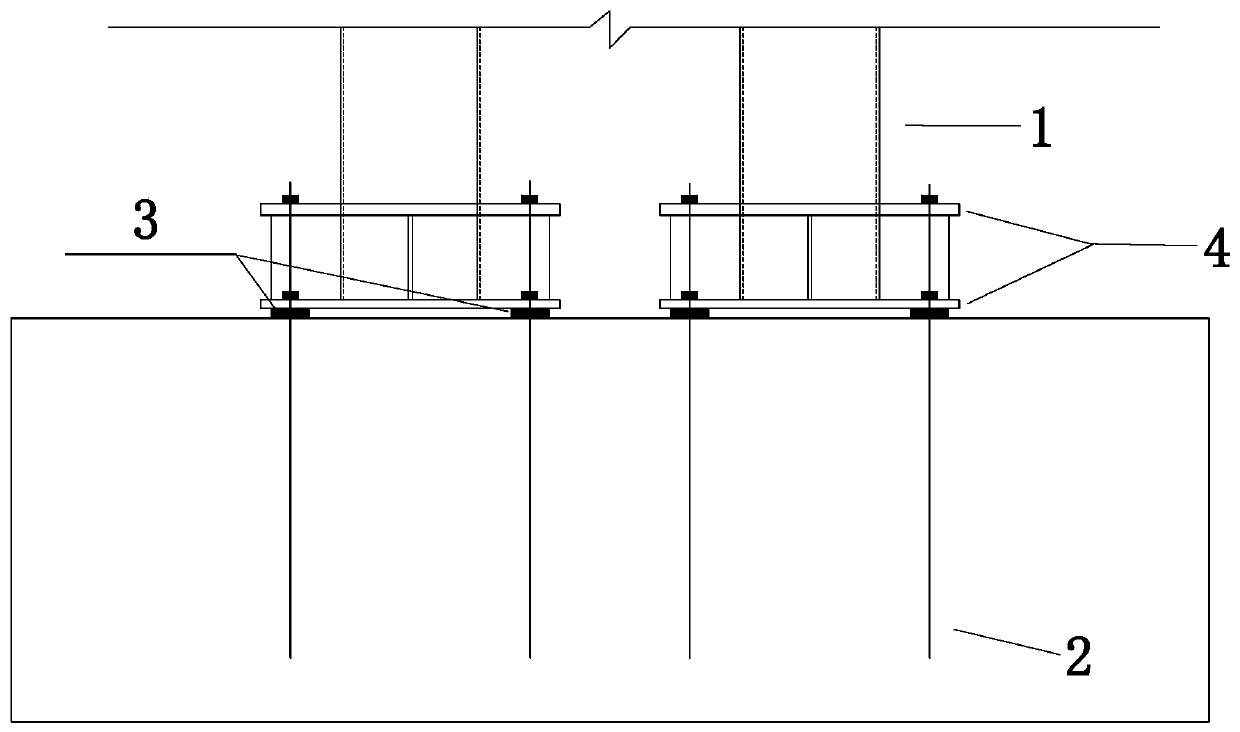

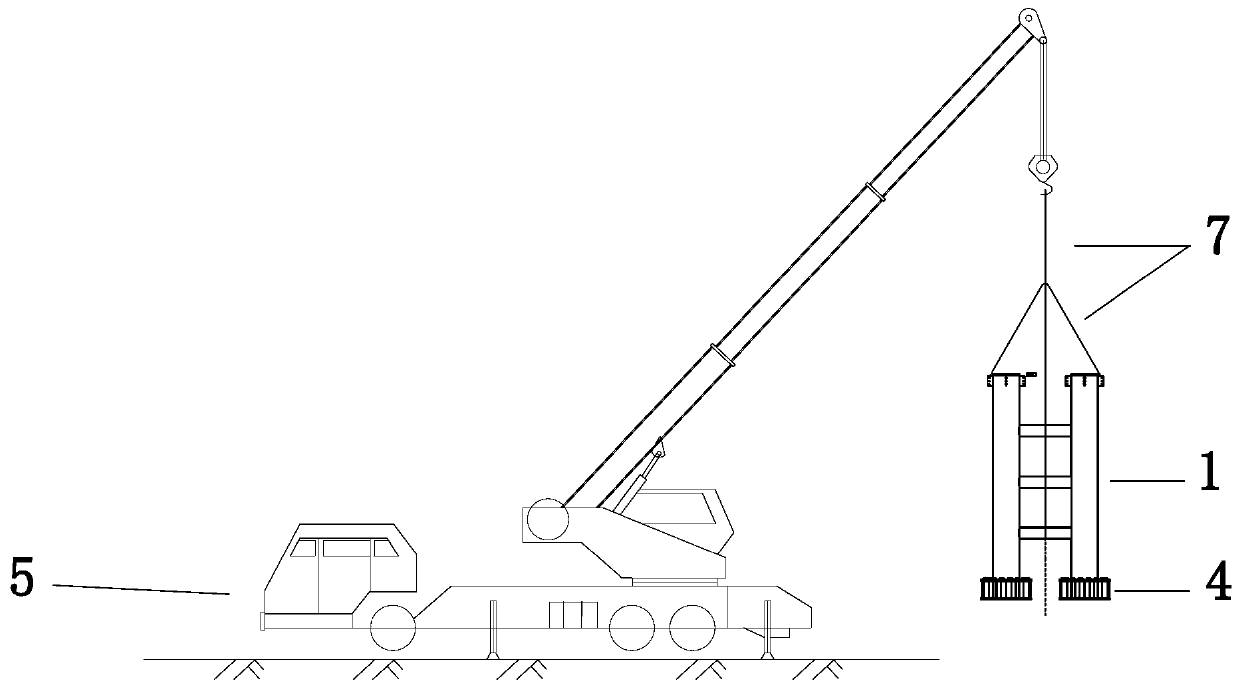

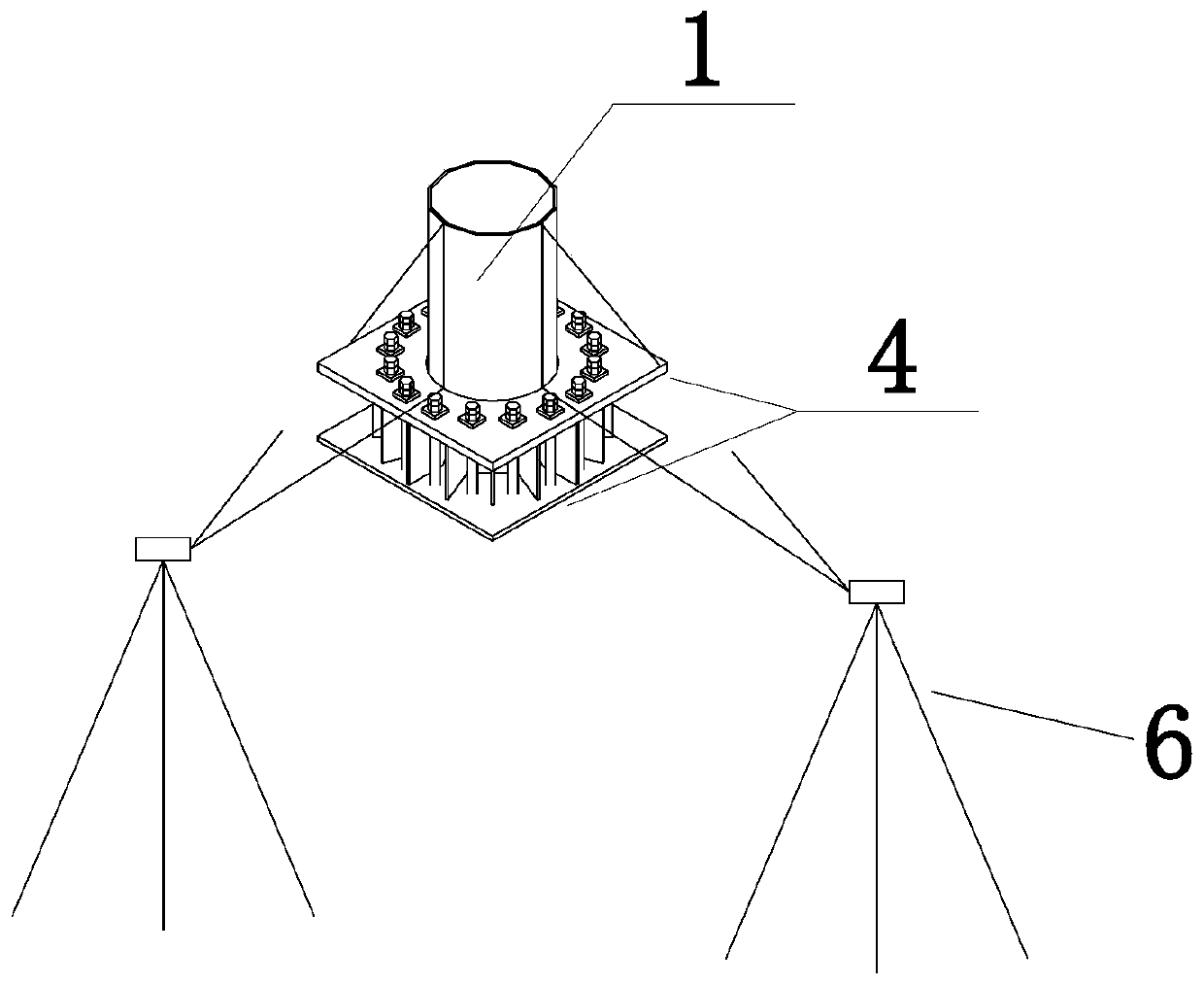

Construction method for hoisting platform steel upright post

InactiveCN111502120ASimple equipmentGuaranteed accuracy and stabilityStrutsBuilding material handlingSteel platesGrout

Owner:CHINA RAILWAY SIXTH GROUP +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com