Self-cleaning detection device and method for porous vacuum suction disc

A vacuum suction cup and detection device technology, which is applied in measuring devices, suspension and porous material analysis, instruments, etc., can solve the problems of inconspicuous effect, easy blockage and contamination, and high hardness of porous ceramic adsorption plates.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

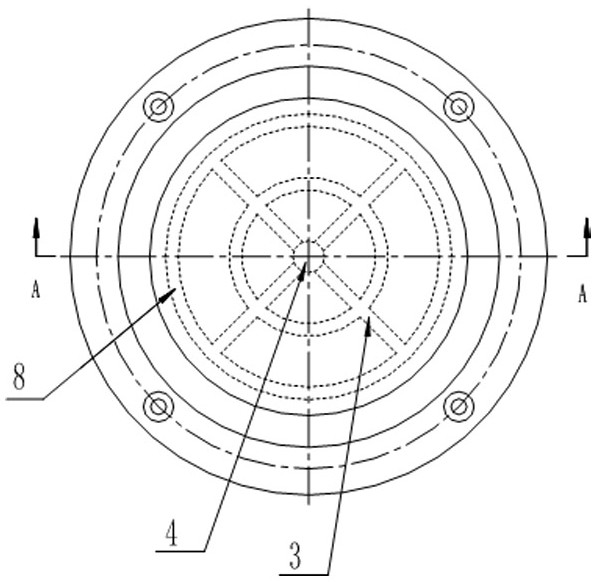

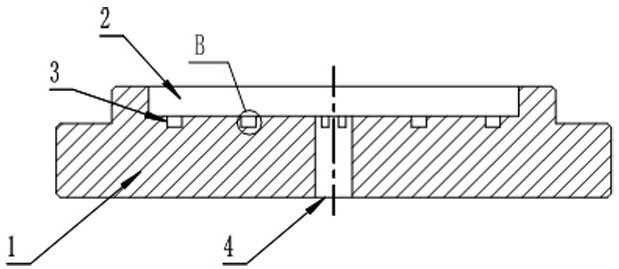

[0039] Such as Figure 1-3 As shown, the self-cleaning porous vacuum chuck of the present invention includes a base 1 and a porous metal adsorption plate 2 arranged on the base 1. In the sunken platform; the middle part of the sunken platform of the base 1 is provided with an air extraction hole 4 passing through the base 1, and the upper surface of the sunken platform is provided with a cross groove 3 and two concentric annular grooves 8 extending vertically downward, The cross groove 3 runs through the annular groove 8 and the air extraction hole 4 , and the two annular grooves 8 are arranged concentrically with the air extraction hole 4 .

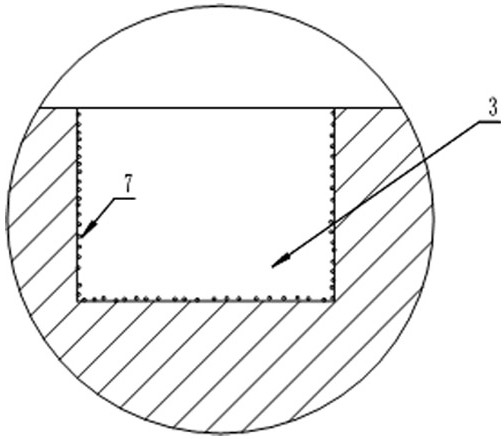

[0040]The inner walls of the annular groove 8 , the cross groove 3 and the suction hole 4 are all provided with a composite coating 7 , and the thickness of the composite coating 7 is 3-5 μm. The part of the base 1 that is in contact with the porous metal adsorption plate 2 is coated with an adhesion aid layer.

[0041] The preparation...

Embodiment 2

[0069] The difference between this embodiment and embodiment 1 is that the thickness of the composite coating is 8-10um.

[0070] The preparation method of the self-cleaning porous vacuum chuck of this embodiment comprises the following steps:

[0071] (1) Preparation of porous metal adsorption plate

[0072] ① Weigh the materials required for the porous metal adsorption plate: spherical 321 stainless steel powder with a particle size of 30um, Cu-Al alloy powder with a particle size of 20um (Cu:Al=1:1) and PMMA with a particle size of 10um, stainless steel powder, alloy powder and PMMA The mass ratio is 1:0.1:0.2, and then the three materials are put into a V-type mixer and dry mixed for 24 hours to obtain mixed powder A;

[0073] ②Add 10% of the total volume of the mixed powder A to the mixed powder A in step ①, wetting agent water, manually stir clockwise for 10 minutes, then put it into a V-type mixer for wet mixing for 2 hours, and pass through a 400-mesh stainless steel ...

Embodiment 3

[0083] The difference between this embodiment and embodiment 1 is that the thickness of the composite coating is 5-7um.

[0084] The preparation method of the self-cleaning porous vacuum chuck of this embodiment comprises the following steps:

[0085] (1) Preparation of porous metal adsorption plate

[0086] ①Weigh the materials required for the porous metal adsorption plate: spherical 321 stainless steel powder with a particle size of 30um, Fe-Cu alloy powder with a particle size of 20um (Fe:Cu=3:1) and starch with a particle size of 10um, stainless steel powder, alloy powder and The mass ratio of starch is 1:0.4:0.3, and then the three materials are put into a V-type mixer and dry mixed for 24 hours to obtain mixed powder A;

[0087] ②Add 7.5% wetting agent propylene glycol in the total volume of mixed powder A to the mixed powder A in step ①, manually stir clockwise for 30 minutes, then put it into a V-type mixer for wet mixing for 6 hours, and pass through a 400-mesh stai...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Granularity | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com