Self-cleaning porous vacuum chuck and preparation method thereof

A vacuum suction cup and self-cleaning technology, applied in metal processing equipment, semiconductor/solid-state device manufacturing, liquid chemical plating, etc., can solve problems such as easy clogging and contamination, ineffective effect, and high hardness of porous ceramic adsorption plates , to achieve the effect of solving non-anti-static, excessive temperature sensitivity, and ensuring high-precision stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

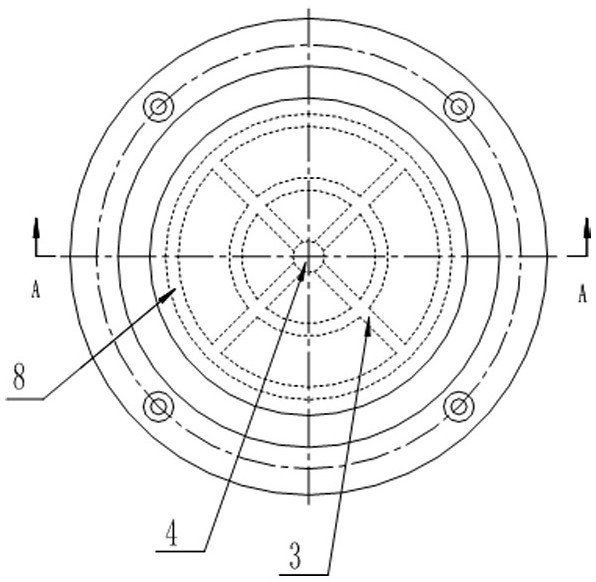

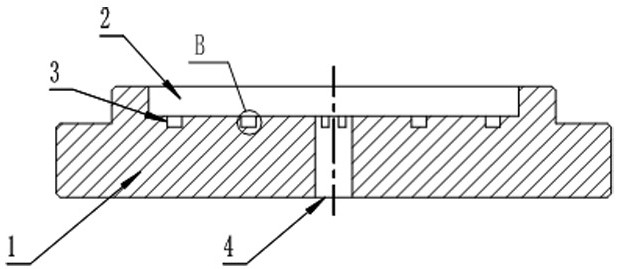

[0055] Such as Figure 1-3 As shown, the self-cleaning porous vacuum chuck of the present invention includes a base 1 and a porous metal adsorption plate 2 arranged on the base 1. In the sunken platform; the middle part of the sunken platform of the base 1 is provided with an air extraction hole 4 passing through the base 1, and the upper surface of the sunken platform is provided with a cross groove 3 and two concentric annular grooves 8 extending vertically downward, The cross groove 3 runs through the annular groove 8 and the air extraction hole 4 , and the two annular grooves 8 are arranged concentrically with the air extraction hole 4 .

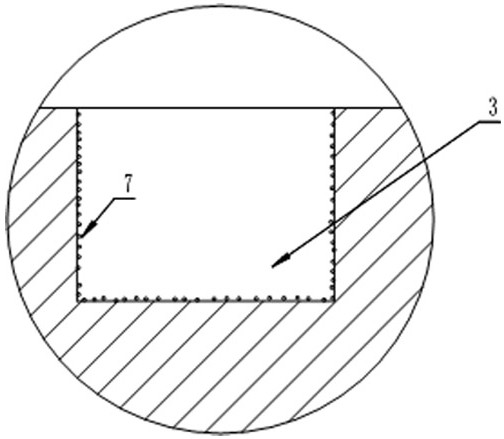

[0056] The inner walls of the annular groove 8 , the cross groove 3 and the suction hole 4 are all provided with a composite coating 7 , and the thickness of the composite coating 7 is 3-5 μm. The part of the base 1 that is in contact with the porous metal adsorption plate 2 is coated with an adhesion aid layer.

[0057] The preparatio...

Embodiment 2

[0085] The difference between this embodiment and embodiment 1 is that the thickness of the composite coating is 8-10um.

[0086] The preparation method of the self-cleaning porous vacuum chuck of this embodiment comprises the following steps:

[0087] (1) Preparation of porous metal adsorption plate

[0088] ① Weigh the materials required for the porous metal adsorption plate: spherical 321 stainless steel powder with a particle size of 30um, Cu-Al alloy powder with a particle size of 20um (Cu:Al=1:1) and PMMA with a particle size of 10um, stainless steel powder, alloy powder and PMMA The mass ratio is 1:0.1:0.2, and then the three materials are put into a V-type mixer and dry mixed for 24 hours to obtain mixed powder A;

[0089] ②Add 10% of the total volume of the mixed powder A to the mixed powder A in step ①, wetting agent water, manually stir clockwise for 10 minutes, then put it into a V-type mixer for wet mixing for 2 hours, and pass through a 400-mesh stainless steel ...

Embodiment 3

[0099] The difference between this embodiment and embodiment 1 is that the thickness of the composite coating is 5-7um.

[0100] The preparation method of the self-cleaning porous vacuum chuck of this embodiment comprises the following steps:

[0101] (1) Preparation of porous metal adsorption plate

[0102] ①Weigh the materials required for the porous metal adsorption plate: spherical 321 stainless steel powder with a particle size of 30um, Fe-Cu alloy powder with a particle size of 20um (Fe:Cu=3:1) and starch with a particle size of 10um, stainless steel powder, alloy powder and The mass ratio of starch is 1:0.4:0.3, and then the three materials are put into a V-type mixer and dry mixed for 24 hours to obtain mixed powder A;

[0103] ②Add 7.5% wetting agent propylene glycol in the total volume of mixed powder A to the mixed powder A in step ①, manually stir clockwise for 30 minutes, then put it into a V-type mixer for wet mixing for 6 hours, and pass through a 400-mesh stai...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com