Combined process for treatment of PTA (pure terephthalic acid) refined waste water

A technology for terephthalic acid and refined wastewater, applied in natural water treatment, water/sewage multi-stage treatment, water/sludge/sewage treatment, etc., can solve the problem of increasing treatment difficulty, affecting hydrogenation reaction, and affecting product purity and other issues to achieve the effect of reducing overall emissions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

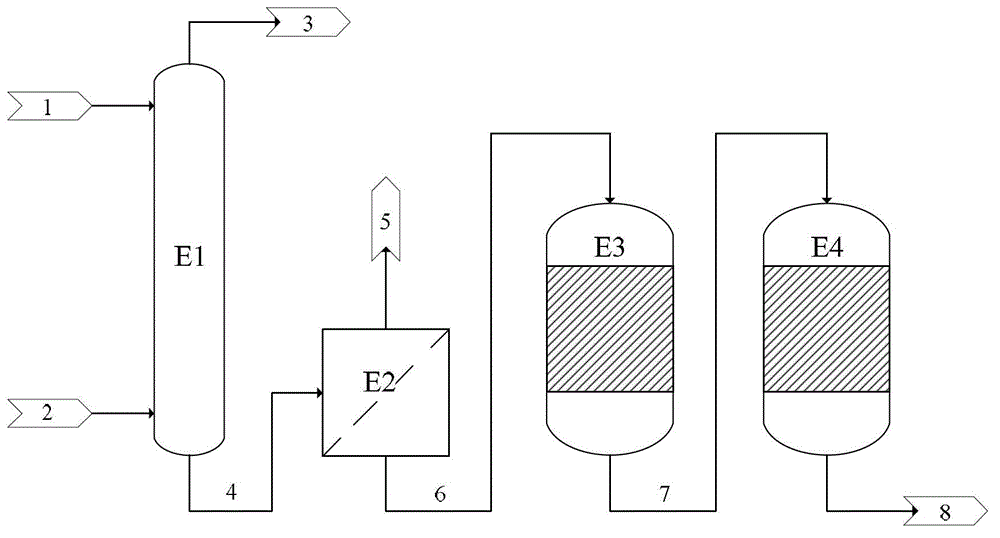

[0019] The method adopted in this embodiment is as figure 1 shown.

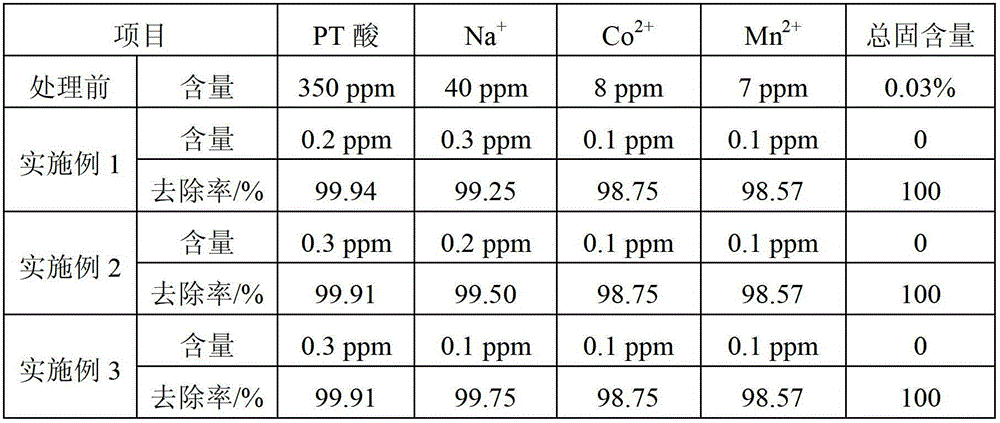

[0020] PTA refined wastewater enters the sieve plate extraction tower from the top of the tower, PX enters from the bottom of the tower, the volume ratio of PX to wastewater is 1:4, the extraction temperature is 30°C, the two phases are in countercurrent contact in the extraction tower, and the waste water in the extraction tower The residence time is 8min. The extract phase is cut out from the top of the tower and sent to the PTA oxidation system as the reaction raw material. The raffinate phase enters the microfiltration membrane separation device through the circulation pump. The membrane material is porous alumina ceramic membrane with a membrane pore size of 0.05 μm and an operating pressure of 0.2 MPa. The resin adsorption device is equipped with styrene-based macroporous adsorption resin (model LS105), and the residence time of the permeate in the resin bed is about 0.5h. The ion exchange device is e...

Embodiment 2

[0022] PTA refined wastewater enters the rotary extraction tower from the top of the tower, PX enters from the bottom of the tower, the volume ratio of PX to wastewater is 1:8, the extraction temperature is 40°C, the two phases are in countercurrent contact in the extraction tower, and the wastewater stays in the extraction tower The time is 6 minutes. The extract phase is cut out from the top of the tower and sent to the PTA oxidation system as the reaction raw material. The raffinate phase enters the microfiltration membrane separation device through the circulation pump. The membrane material is a sintered stainless steel powder membrane with a pore size of 0.1 μm and an operating pressure of 0.1 MPa. The resin adsorption device is equipped with styrene-based macroporous adsorption resin (model LS100), and the residence time of the permeate in the resin bed is about 0.75h. The ion exchange device is equipped with styrene-based strong acid cation exchange resin (model Amberj...

Embodiment 3

[0024] PTA refined wastewater enters the rotary extraction tower from the top of the tower, PX enters from the bottom of the tower, the volume ratio of PX to wastewater is 1:12, the extraction temperature is 50°C, the two phases are in countercurrent contact in the extraction tower, and the wastewater stays in the extraction tower The time is 4 minutes. The extract phase is cut out from the top of the tower and sent to the PTA oxidation system as the reaction raw material. The raffinate phase enters the microfiltration membrane separation device through the circulating pump. The membrane material is polyethylene hollow fiber membrane with a membrane pore size of 0.1 μm and an operating pressure of 0.4 MPa. The resin adsorption device is equipped with styrene-based anion exchange resin (model D301), and the residence time of the permeate in the resin bed is about 1 hour. The ion exchange device is equipped with styrene-based strongly acidic cation exchange resin (model D001), a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com